Influence of Mixing Conditions on the Strength and Microstructure of Cement Paste

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Cementitious Paste

2.3. Compressive Strength Test

2.4. Microstructure Characterization

- XRD

- 2.

- SEM

- 3.

- LF-NMR

3. Results and Discussion

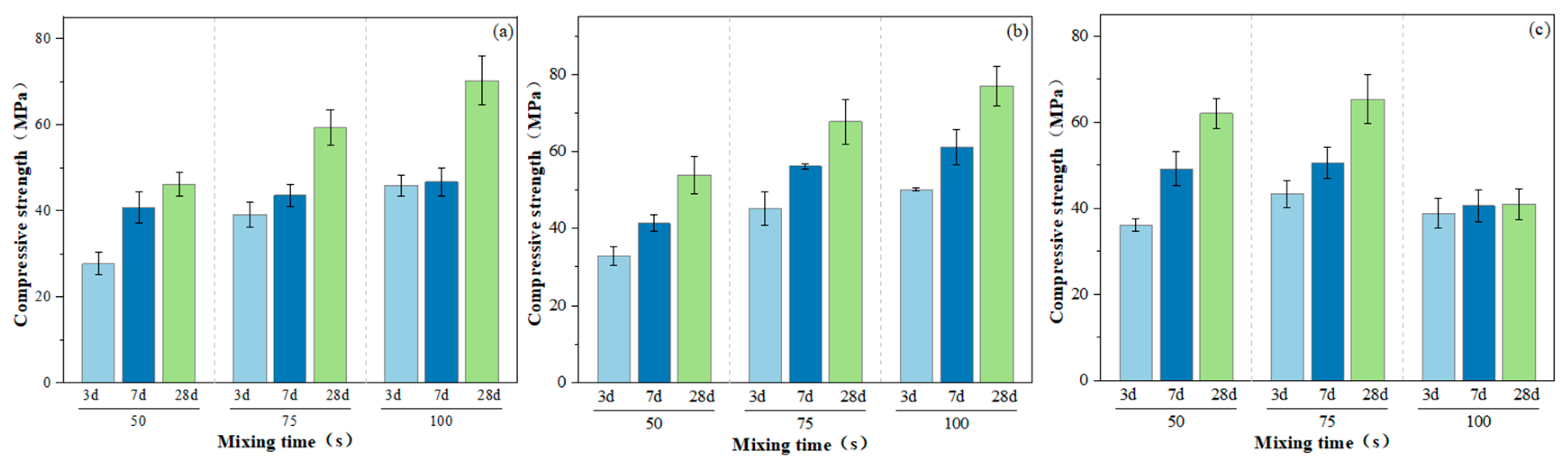

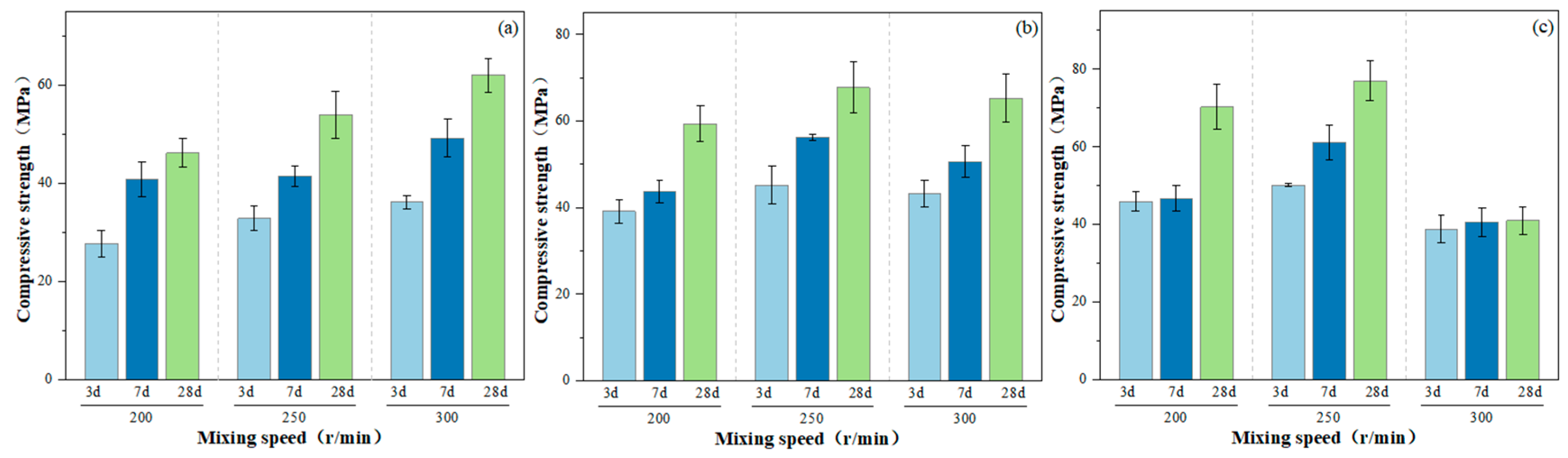

3.1. Compressive Strength

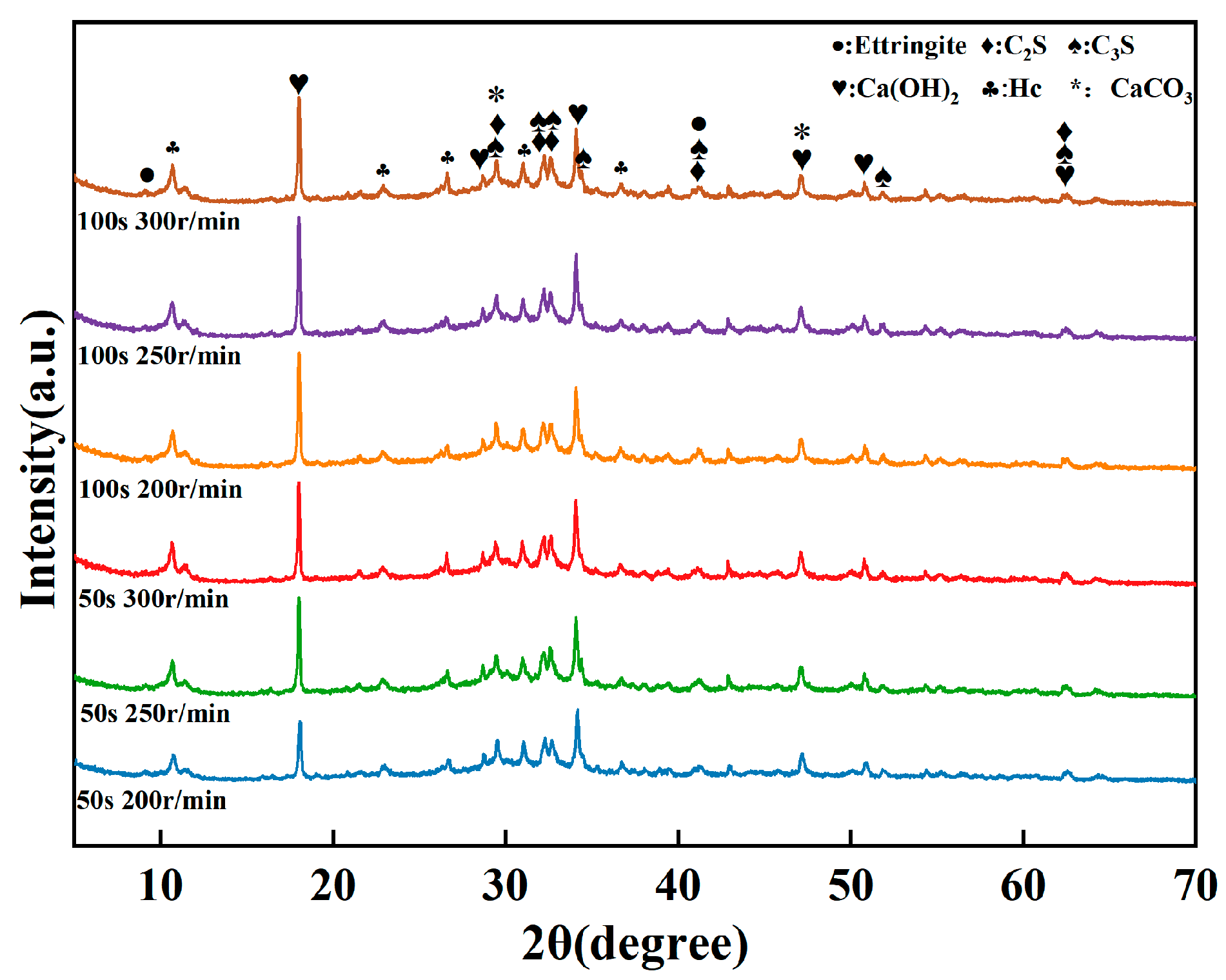

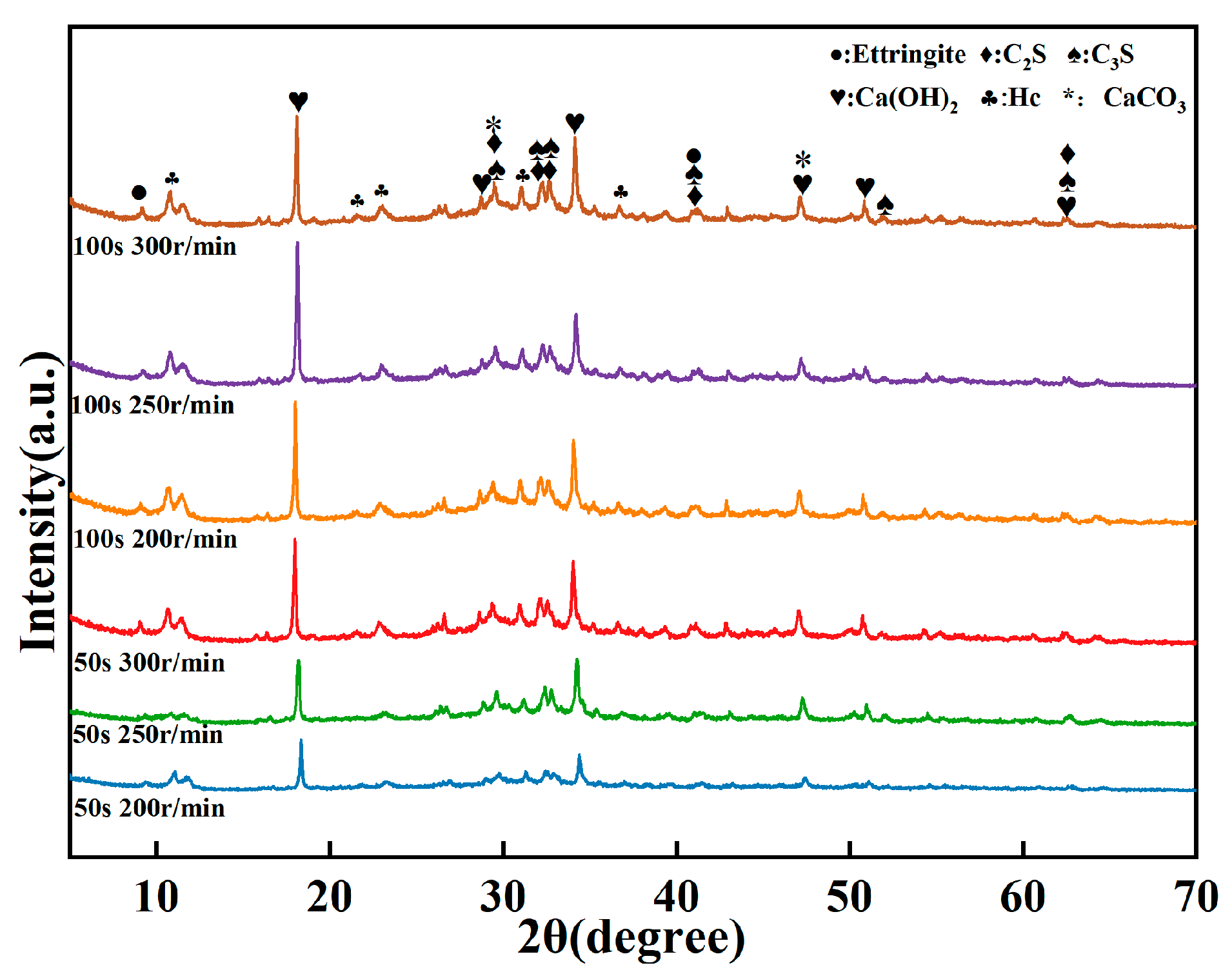

3.2. Phase Composition

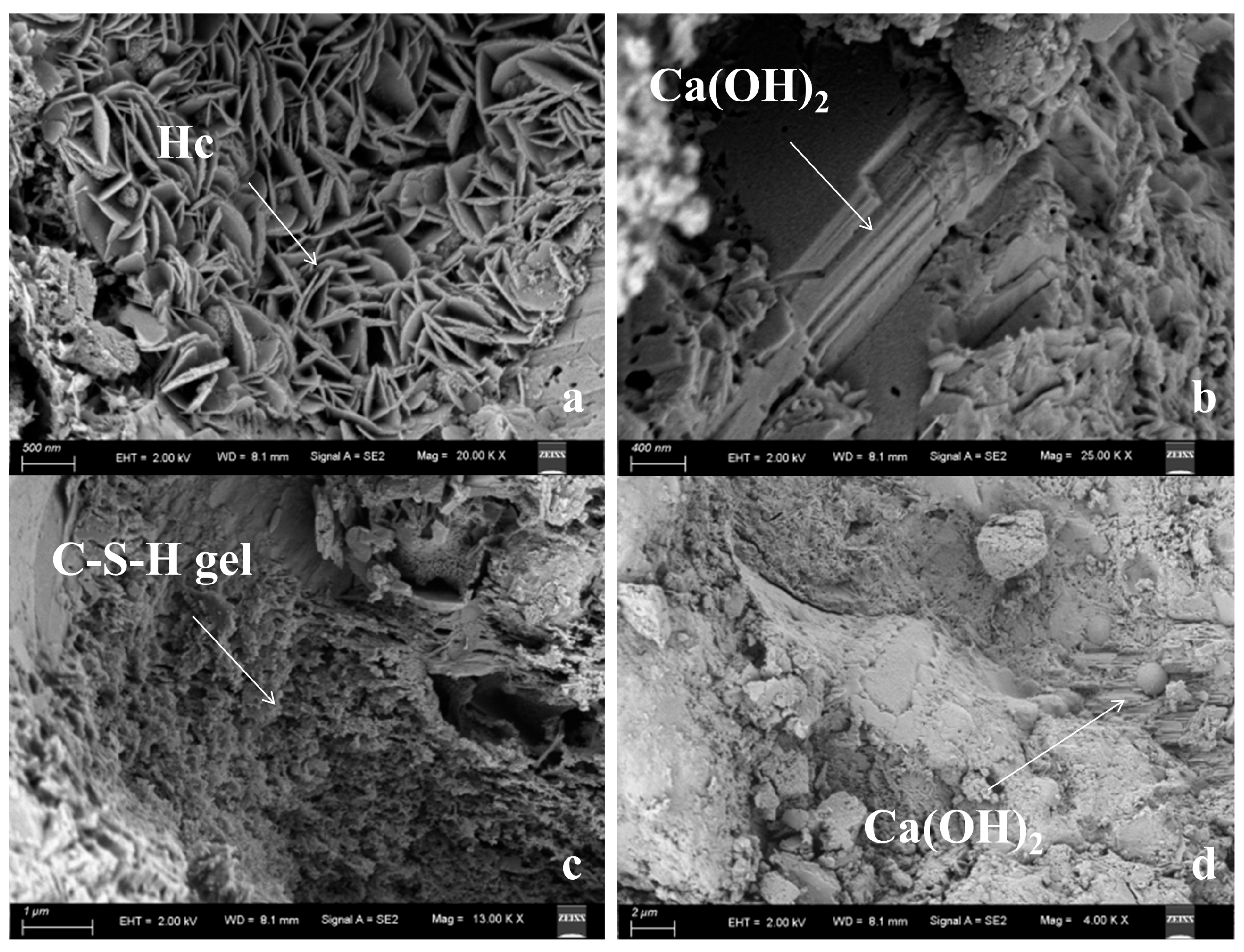

3.3. Microstructure

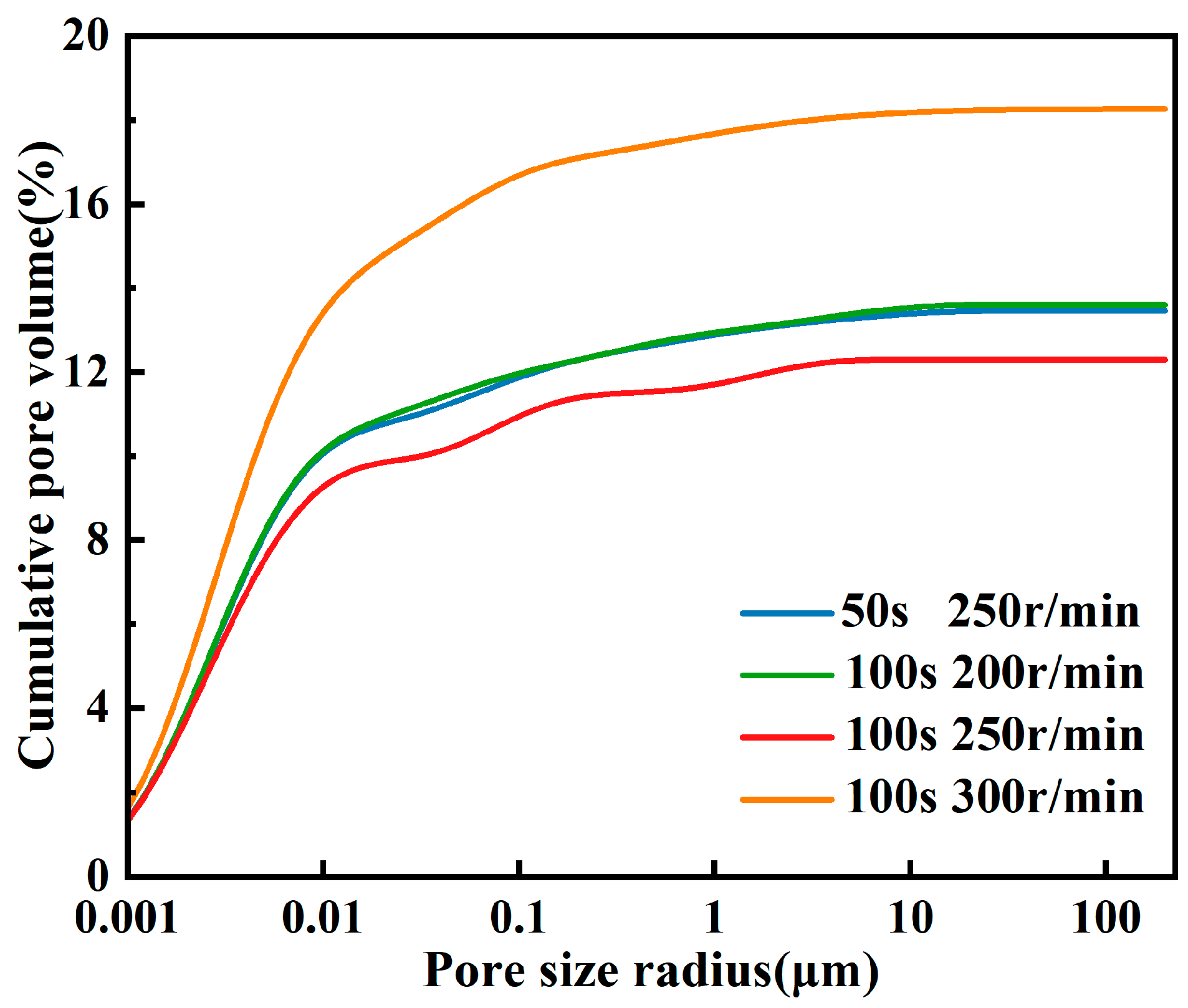

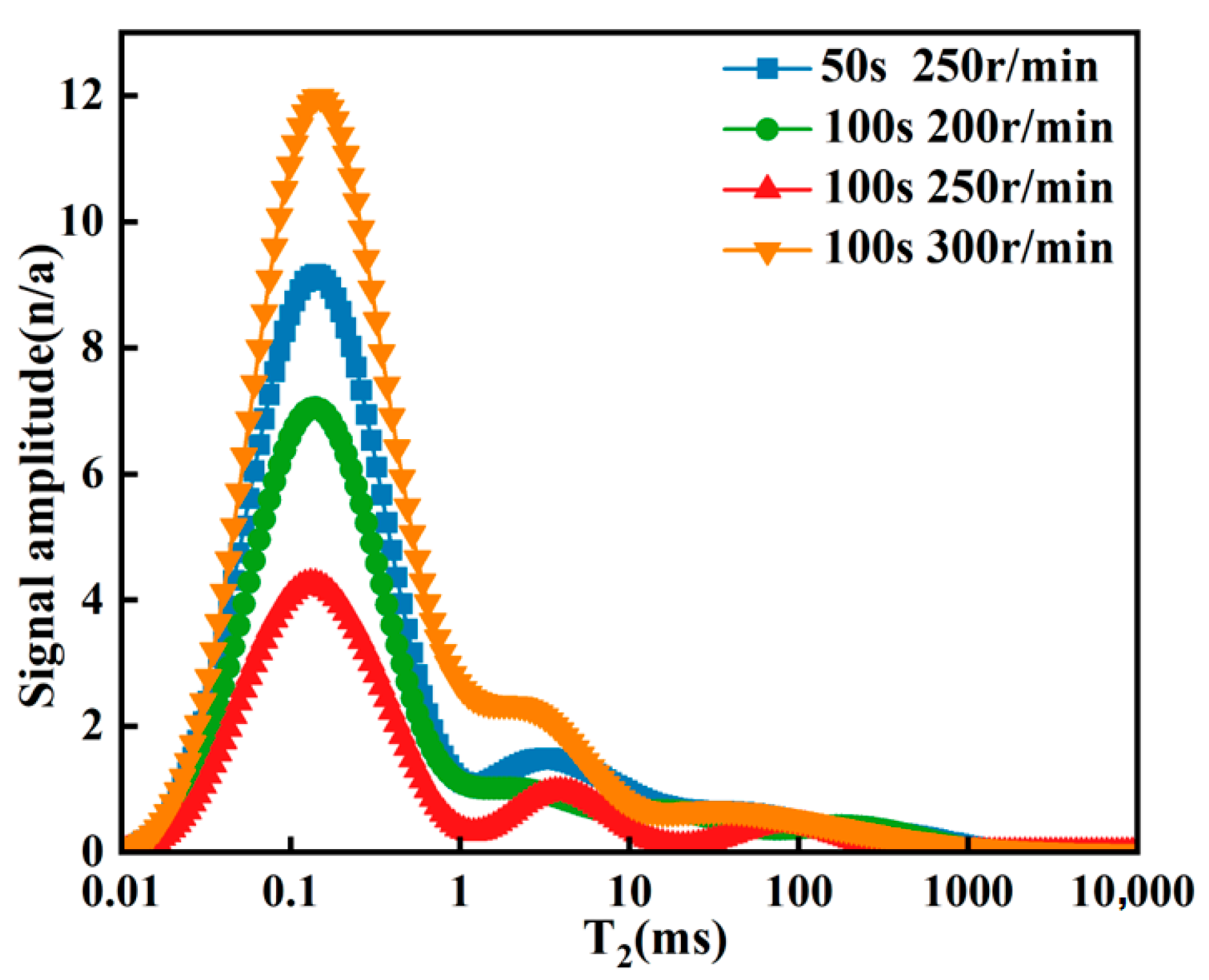

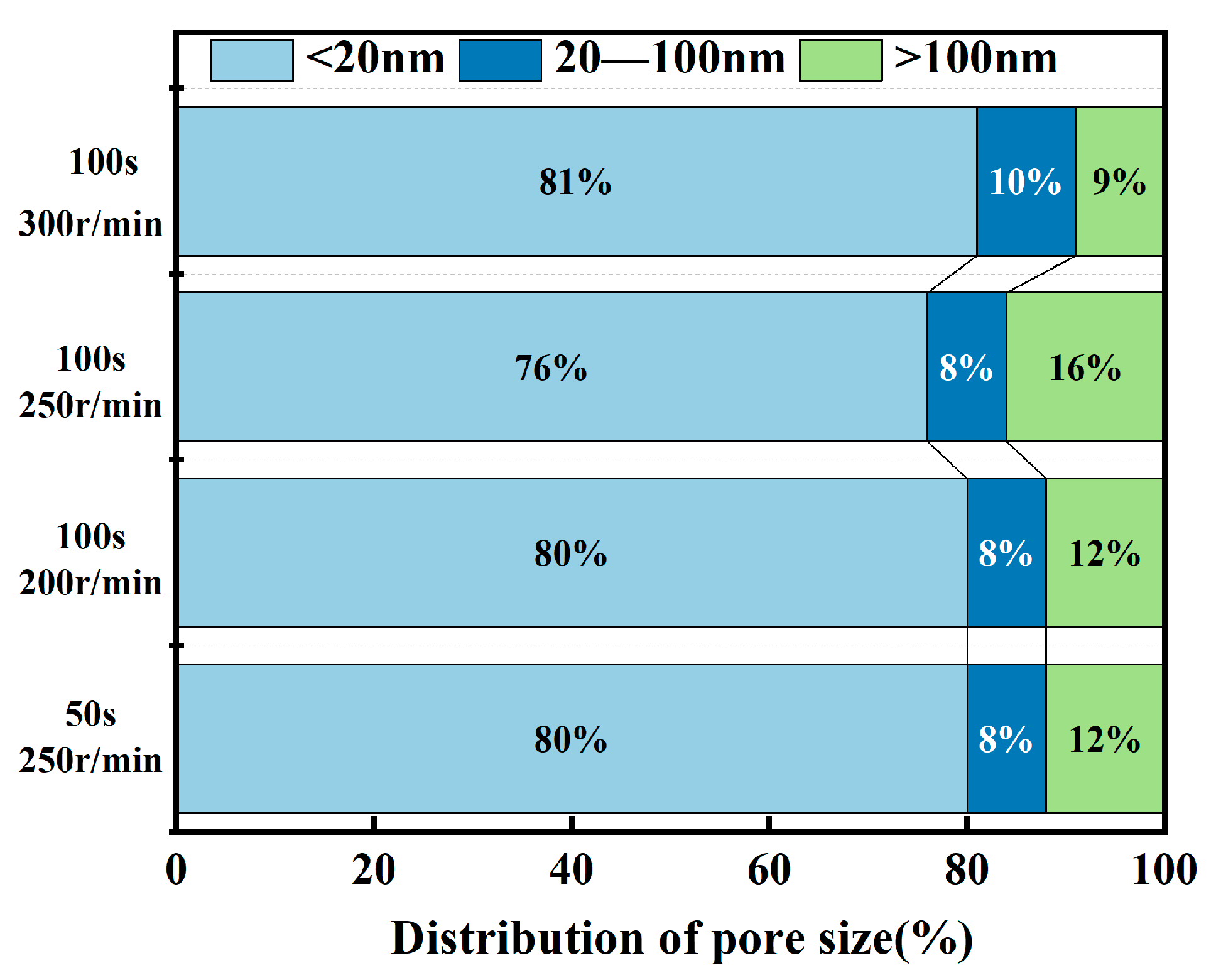

3.4. Pore Structure

4. Conclusions

- (1)

- At rotational speeds of 200 and 250 r/min, extended mixing duration enhances compressive strength, whereas at 300 r/min, excessive mixing duration adversely affects strength development. When mixing durations below 75 s, compressive strength shows a positive correlation with rotational speed, while beyond this threshold, higher speeds result in strength reduction. The optimal compressive strength was observed at 100 s mixing duration and 250 r/min, with 3 d, 7 d, and 28 d strengths reaching 50.1 MPa, 61.1 MPa, and 77.0 MPa, respectively.

- (2)

- Variations in rotational speed and time exerted a minor influence on the phase composition and morphology of hydration products in the cementitious paste. An extended mixing duration facilitated cement hydration and improved the compactness of the hardened cementitious paste. Moderately increasing the rotational speed enhanced the content of hydration products, but excessive speeds adversely affected cement hydration.

- (3)

- Both excessively high and low rotational speeds lead to an increase in the total porosity of hardened cementitious paste. The lowest porosity was achieved when mixing at 250 r/min for 100 s, correlating with the optimal compressive strength performance. Under these conditions, over 75% of the pores in the sample were classified as harmless, with diameters below 20 nm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pachman, J.; Chapman, D.; Foglar, M.; Künzel, M.; Proud, W. Shock response of concrete, fibre concrete and ultrahigh performance concrete. Int. J. Impact Eng. 2024, 183, 104787. [Google Scholar] [CrossRef]

- Wang, X.; Dong, S.; Ashour, A.; Zhang, W.; Han, B. Effect and mechanisms of nanomaterials on interface between aggregates and cement mortars. Constr. Build. Mater. 2020, 240, 117942. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, X.; Zhang, Z.; Wei, C.; Xu, C. Synergistic utilization of blast furnace slag with other industrial solid wastes in cement and concrete industry: Synergistic mechanisms, applications, and challenges. Green Energy Resour. 2023, 1, 100012. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, X.; Feng, Z. Research on double-speed mixing technique of concrete. Concrete 2006, 10, 78–80. [Google Scholar]

- Zhao, L. Researeh on Mixing in Effieient Zone and Its Eliminating Methods. Ph.D. Thesis, Chang’an University, Xi’an, China, 2005. [Google Scholar]

- Liu, S.; Xiao, T.; Zhuang, Z.; Zhang, Z.; Lu, G. Discussion on multi-step mixing process of concrete. China South. Agric. Mach. 2019, 50, 236–237. [Google Scholar]

- Fu, X. The influence by the method of aggregate enveloped with cement of multi-step mixing to durability of high performance concrete. Appl. Mech. Mater. 2013, 438–439, 153–156. [Google Scholar] [CrossRef]

- Ryu, J. Improvement on strength and impermeability of recycled concrete made from crushed concrete coarse aggregate. J. Mater. Sci. Lett. 2002, 21, 1565–1567. [Google Scholar] [CrossRef]

- Şanin, R.; Demirboga, R.; Uysal, H.; Gül, R. The effects of different cement dosages, slumps and pumice aggregate ratios on the compressive strength and densities of concrete. Cem. Concr. Res. 2003, 33, 1245–1249. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Liu, C.; Wang, L.; Chen, M.; Yue, G. Study of mix design and performance of alkali-activated concrete with recycled concrete aggregate. Constr. Build. Mater. 2023, 400, 132882. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, H.; Liu, J.; Wu, R.; Cheng, H.; Huang, S.; Wang, J.; Huang, Q. Evaluation of a hybrid-polymer pervious mortar and optimization of its mix design. J. Build. Eng. 2024, 84, 108510. [Google Scholar] [CrossRef]

- Ji, G.; Peng, X.; Wang, S.; Hu, C.; Ran, P.; Sun, K.; Zeng, L. Influence of magnesium slag as a mineral admixture on the performance of concrete. Constr. Build. Mater. 2021, 295, 123619. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Mi, G. Effect of blended steel slag-GBFS mineral admixture on hydration and strength of cement. Constr. Build. Mater. 2012, 35, 8–14. [Google Scholar] [CrossRef]

- Long, W.; Xu, P.; Yu, Y.; Xing, F.; He, C. Scalable preparation of high-dispersion g-C3N4 via GQDs-assisted ultrasonic exfoliation for accelerating cement hydration. Cem. Concr. Compos. 2022, 134, 104782. [Google Scholar] [CrossRef]

- He, H.; Shuang, E.; Lu, D.; Hu, Y.; Yan, C.; Shan, H.; He, C. Deciphering size-induced influence of carbon dots on mechanical performance of cement composites. Constr. Build. Mater. 2024, 425, 136030. [Google Scholar] [CrossRef]

- Shan, H.; Shuang, E.; Zhao, R.; Miao, Y.; Wang, Z.; He, H.; He, C. Effect of carbon dots with different sizes on chloride binding of cement. Constr. Build. Mater. 2024, 425, 136031. [Google Scholar] [CrossRef]

- Meng, S.; Shi, Z.; Ouyang, X. Comparison of the effects of carbon-based and inorganic nanomaterials on early cement hydration. Constr. Build. Mater. 2024, 421, 135705. [Google Scholar] [CrossRef]

- He, C.; Sun, T.; Wang, X.; He, H.; Shuang, E. Development of high-dispersion CLDH/carbon dot composites to boost chloride binding of cement. Cem. Concr. Compos. 2024, 152, 105669. [Google Scholar] [CrossRef]

- He, W.; Li, S.; Jiao, Z.; Wang, N.; Xu, J.; Zhou, J.; Zhao, Q. Effect of regenerated nano-FeB on mechanical properties of cement paste. Constr. Build. Mater. 2023, 366, 130172. [Google Scholar] [CrossRef]

- Long, W.; Zhong, A.; Zheng, S.; He, C. Effects of a novel carbon nanomaterial on hydration, mechanics, and chloride binding of cement composites. Carbon 2024, 221, 118933. [Google Scholar] [CrossRef]

- Zhang, Y.; Gan, D.; Xue, Z.; Lu, H. Influence of mass concentration, cement-to-tailings ratio, and stirring duration on the strength of CPB considering pore characteristics. Int. J. Environ. Sci. Technol. 2022, 20, 4373–4382. [Google Scholar] [CrossRef]

- Xu, T.; Garrecht, H. Effects of mixing techniques and material compositions on the compressive strength and thermal conductivity of ultra-lightweight foam concrete. Materials 2024, 17, 2640. [Google Scholar] [CrossRef]

- Zheng, D.; Hou, Y.; Si, B. Effect of mixing time on workability and strength of high flowing concrete. J. Beijing Univ. Civ. Eng. Archit. 2017, 33, 18–21+32. [Google Scholar]

- Ren, C. The influence of mixer stirring time on concrete uniformity. Sichuan Cem. 2015, 6, 299. [Google Scholar]

- Yan, Q.; Wang, E.; Shen, Z.; Zheng, Q.; Wang, C.; Hao, W.; Chen, S. Experimental study on mechanical properties of vibration mixing recycled aggregate concrete. New Build. Mater. 2023, 50, 88–90+102. [Google Scholar]

- Gao, H.; Tian, B.; Hao, G.; Hou, Z. Evaluation method of uniformity of new cement concrete mixture. J. Highw. Transp. Res. Dev. 2014, 31, 25–30. [Google Scholar]

- Lu, Z.; Peng, X.; Liu, Z.; Sun, Z.; Stephan, D. Influence of mixing speed on the hydration and setting performance of cement paste in the presence of triethanolamine. Constr. Build. Mater. 2023, 385, 131490. [Google Scholar] [CrossRef]

- Han, D.; Ferron, R. Influence of high mixing intensity on rheology, hydration, and microstructure of fresh state cement paste. Cem. Concr. Res. 2016, 84, 95–106. [Google Scholar] [CrossRef]

- Juilland, P.; Kumar, A.; Gallucci, E.; Robert, J.; Karen, L. Effect of mixing on the early hydration of alite and OPC systems. Cem. Concr. Res. 2012, 42, 1175–1188. [Google Scholar] [CrossRef]

- Hiremath, P.; Yaragal, S. Influence of mixing method, speed and duration on the fresh and hardened properties of reactive powder concrete. Constr. Build. Mater. 2017, 141, 271–288. [Google Scholar] [CrossRef]

- GB/T 17671–2021; Test Method of Cement Mortar Strength (ISO Method). State Administration for Market Regulation, Standardization Administration of China: Beijing, China, 2021.

- Duff, A. Effect of time of mixing on the strength and wear of concrete. J. Proc. 1918, 14, 15787. [Google Scholar]

- Yao, Y.; Liu, H.; Ren, F.; Zhang, L.; Kong, X.; Li, G.; Liu, Q.; Zhang, M. Experimental study on vibration mixing of high-performance concrete. Bull. Chin. Ceram. Soc. 2020, 39, 730–733. [Google Scholar]

- Xu, J.; Zhao, Z.; Chen, M.; Lu, L. Effect of stone powder on rheological and mechanical properties of 3D-printed white cement-based materials. China Build. Mater. Sci. Technol. 2021, 30, 93–97. [Google Scholar]

- Lyu, H.; Yu, J.; Jeon, D.; Oh, J. CaCO3 dissolution-driven enhancement of strength and microstructure in clinker-free CaCO3-blended GGBFS binder via hydrated Al2(SO4)3. Constr. Build. Mater. 2025, 458, 139762. [Google Scholar] [CrossRef]

- Xi, H.; Zhang, Z.; Zhuo, F.; Hou, L.; Zhang, H.; Zhang, W.; Ji, X.; Liu, K.; Shen, Y.; Lao, J. High-strength high-ductility Engineered/Strain-Hardening Geopolymer Composites (EGC/SHGC) incorporating dredged river sand. Case Stud. Constr. Mater. 2025, 22, e04796. [Google Scholar] [CrossRef]

- Han, X.; Wang, B.; Feng, J. Relationship between fractal feature and compressive strength of concrete based on MIP. Constr. Build. Mater. 2022, 332, 126504. [Google Scholar] [CrossRef]

- Lin, R.; Liao, Y.; Fu, C.; Pan, T.; Guo, R.; Wang, X. Mechanism analysis of microwave-carbonation solidification for carbide slag-based low-carbon materials. Cem. Concr. Compos. 2025, 157, 105938. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, H.; He, X.; Zhao, R.; Yang, J.; Su, Y. Nano particles prepared from hardened cement paste by wet grinding and its utilization as an accelerator in Portland cement. J. Clean. Prod. 2021, 283, 124632. [Google Scholar] [CrossRef]

- Hossein, K.; Jordan, W.; Sunav, D.; Tony, J.; Nishant, G. Automated estimation of cementitious sorptivity via computer vision. Nat. Commun. 2024, 15, 9935. [Google Scholar] [CrossRef]

- Song, Z.; Zou, S.; Zhou, W.; Huang, Y.; Shao, L.; Yuan, J.; Gou, X.; Jin, W.; Wang, Z.; Chen, X.; et al. Clinically applicable histopathological diagnosis system for gastric cancer detection using deep learning. Nat. Commun. 2020, 11, 4294. [Google Scholar] [CrossRef]

| Materials | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Others |

|---|---|---|---|---|---|---|---|

| Cement | 59.4 | 21.6 | 7.2 | 3.5 | 2.9 | 2.5 | 2.9 |

| Fly ash | 3.0 | 38.9 | 30.5 | 3.2 | 1.2 | 0.4 | 22.8 |

| GGBS | 36.0 | 30.9 | 13.6 | 0.3 | 2.2 | 8.3 | 8.7 |

| Standard Consistency Water Consumption (%) | Initial Setting Time (min) | Final Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|---|---|

| 29 | 170 | 330 | 7 d | 28 d | 7 d | 28 d |

| 30.7 | 49.4 | 5.3 | 7.9 | |||

| Maturity | Cement | Fly Ash | GGBS | Water | Superplasticizer |

|---|---|---|---|---|---|

| C50 | 65 | 15 | 20 | 27 | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Y.; Cao, H.; Zhang, G.; Lu, X.; Gao, Y.; Niu, J.; He, C.; Lu, X. Influence of Mixing Conditions on the Strength and Microstructure of Cement Paste. Buildings 2025, 15, 3277. https://doi.org/10.3390/buildings15183277

Wan Y, Cao H, Zhang G, Lu X, Gao Y, Niu J, He C, Lu X. Influence of Mixing Conditions on the Strength and Microstructure of Cement Paste. Buildings. 2025; 15(18):3277. https://doi.org/10.3390/buildings15183277

Chicago/Turabian StyleWan, Yufan, Hongbo Cao, Guangqiao Zhang, Xue Lu, Yanru Gao, Jintao Niu, Chuang He, and Xiaolei Lu. 2025. "Influence of Mixing Conditions on the Strength and Microstructure of Cement Paste" Buildings 15, no. 18: 3277. https://doi.org/10.3390/buildings15183277

APA StyleWan, Y., Cao, H., Zhang, G., Lu, X., Gao, Y., Niu, J., He, C., & Lu, X. (2025). Influence of Mixing Conditions on the Strength and Microstructure of Cement Paste. Buildings, 15(18), 3277. https://doi.org/10.3390/buildings15183277