1. Introduction

Ordinary Portland cement (OPC) concrete remains one of the most widely used construction materials globally. However, its production is associated with high energy consumption and significant carbon dioxide (CO

2) emissions. The cement industry alone accounts for approximately 8% of global annual CO

2 emissions [

1,

2], primarily due to the calcination of limestone during clinker production, which contributes nearly 60% of the sector’s total emissions [

3,

4,

5]. These emissions are widely recognized as a major contributor to anthropogenic climate change. Therefore, reducing clinker consumption and implementing CO

2 capture during production are essential measures for advancing carbon neutrality and meeting the 1.5 °C climate target set by the Paris Agreement.

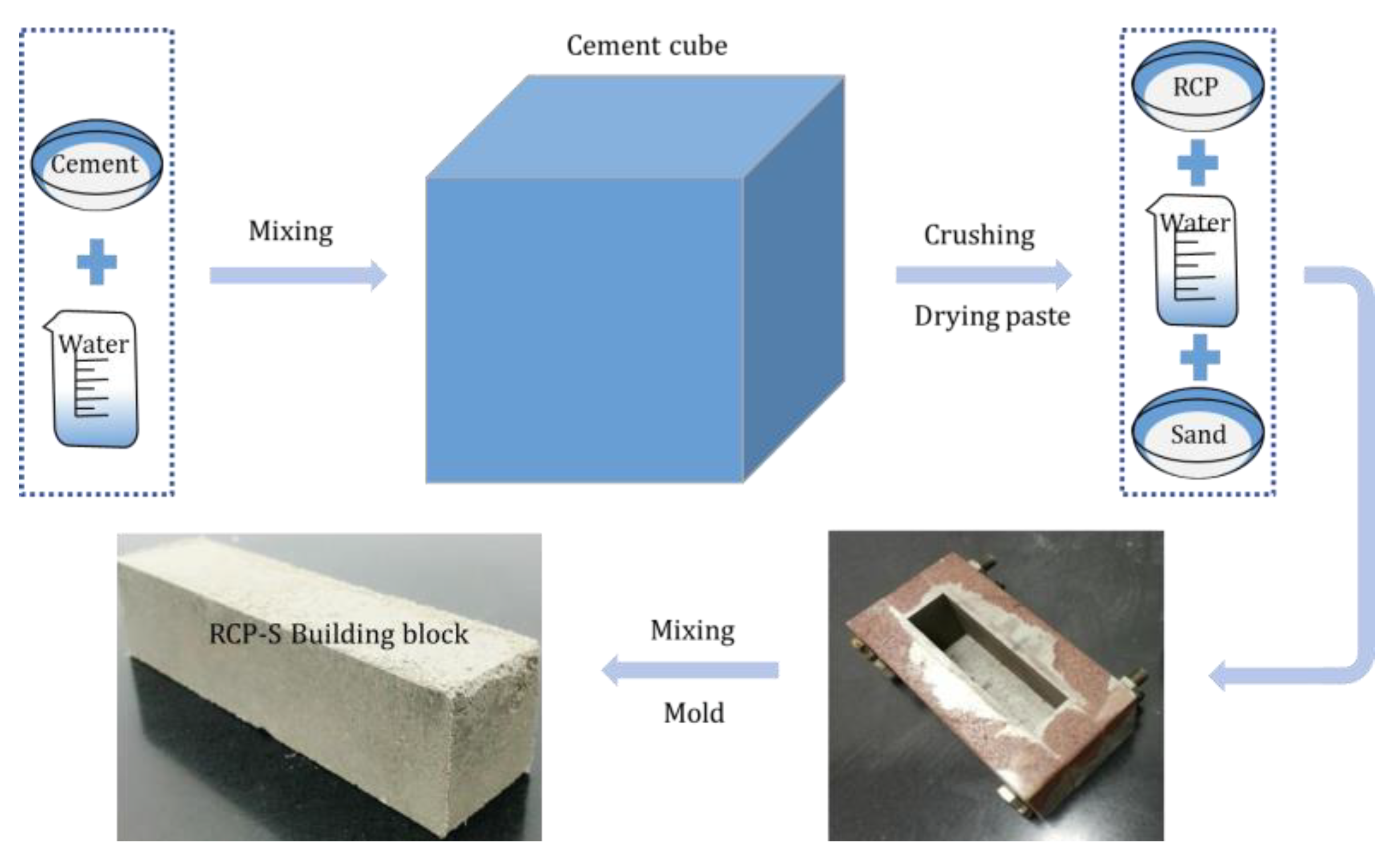

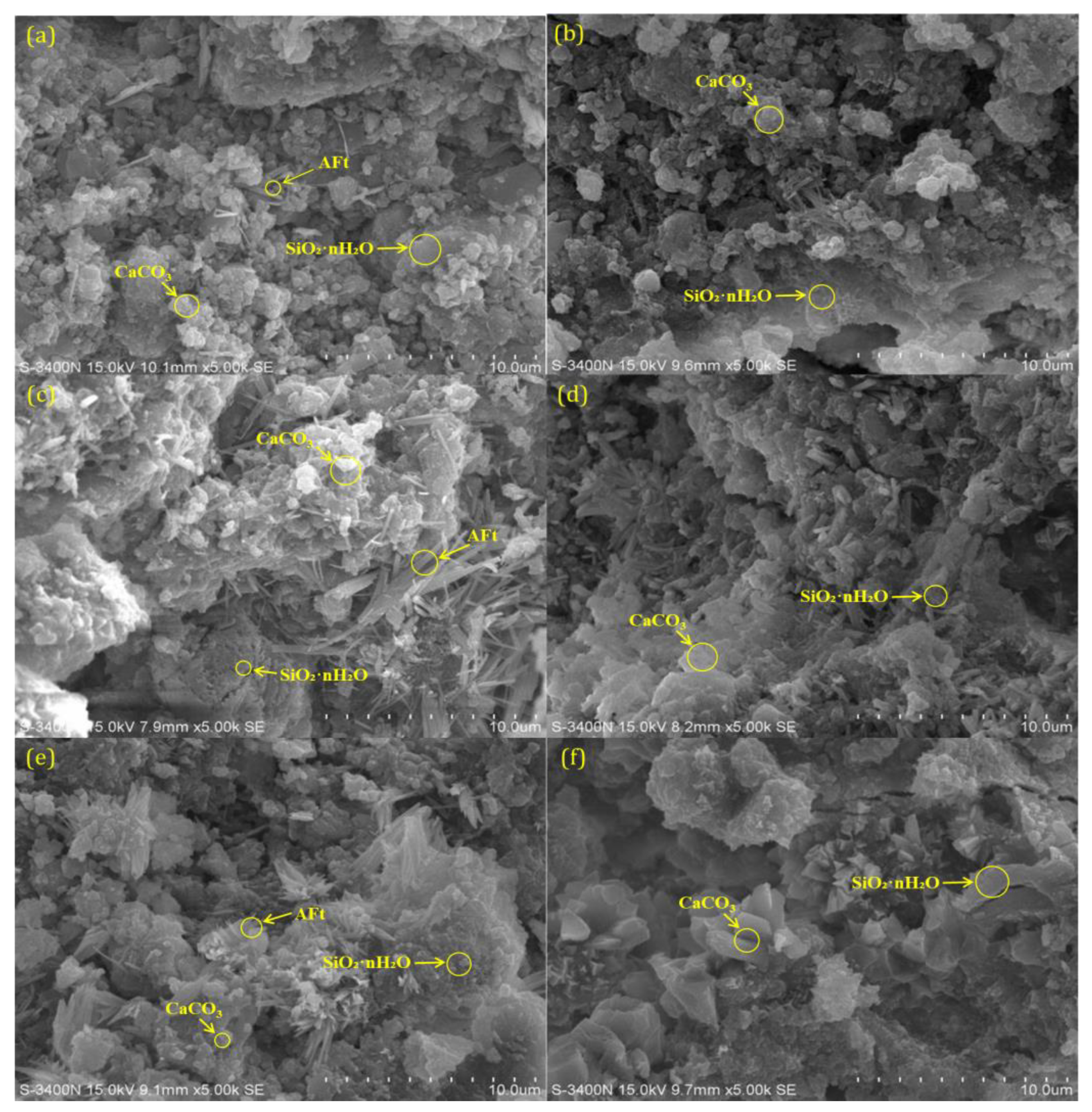

Construction activities such as building demolition, road rehabilitation, and concrete production inevitably generate large volumes of waste concrete. This material is often processed into recycled aggregates, from which recycled cement paste (RCP) can be recovered. Recycled cement paste typically contains residual hydrated and unhydrated phases, including calcium hydroxide (Ca(OH)

2, CH), calcium silicate hydrate (C–S–H, Ca

5Si

6O

16(OH)·4H

2O), ettringite, and unreacted cement clinker. To improve its mechanical properties for engineering applications, sand is commonly added to form recycled cement paste with sand (RCP-S), a composite material with enhanced applicability. Under carbonation conditions, the active components in RCP-S react with CO

2 to form calcium carbonate (CaCO

3, predominantly as calcite) and amorphous silica gel (SiO

2·nH

2O). These carbonation products effectively occupy internal pore spaces, refine the microstructure, and contribute to long-term CO

2 sequestration [

6,

7]. Additionally, the SiO

2·nH

2O generated exhibits pozzolanic reactivity, enabling further reaction with CH to form secondary C–S–H gel during continued curing, thereby enhancing microstructural connectivity [

8,

9]. The precipitation of CaCO

3 also provides nucleation sites for the formation of additional hydration products, further improving mechanical strength [

10]. These mechanisms collectively suggest that carbonated RCP-S can partially restore the binding capacity of recycled cementitious systems and offer promise as a sustainable substitute for conventional binders in construction applications [

11].

The use of recycled sand in the form of RCP-S mortar provides a dual environmental benefit. First, it reduces the need for natural sand extraction, thereby conserving natural resources and minimizing energy-intensive aggregate mining processes. Second, by utilizing recycled fine materials instead of cement or clinker-based binders, it contributes to a direct reduction in CO

2 emissions associated with cement manufacturing. These benefits are particularly significant given that cement production accounts for nearly 8% of global CO

2 emissions. Therefore, RCP-S mortar offers a sustainable approach to both waste valorization and embodied carbon reduction in concrete construction. Recycled cement paste with sand (RCP-S) mortar, primarily derived from waste concrete and construction debris, has garnered increasing attention in recent years due to its environmental benefits and potential contributions to sustainable construction practices. Previous studies have demonstrated that RCP-S can serve as a partial substitute for cement in concrete mixtures, effectively reducing CO

2 emissions and decreasing the reliance on virgin raw materials for cement production [

6,

7]. Research has also focused on the physicochemical properties of RCP-S mortar produced under various processing and treatment regimes. Findings suggest that optimizing particle size distribution and enhancing the surface reactivity of the recycled micro-powders can substantially improve both the mechanical strength and durability of the resulting composites. Among the key factors affecting the performance of RCP-S mortar, the sand-to-powder ratio plays a particularly critical role in governing its pore structure. An appropriate increase in this ratio has been shown to promote matrix densification, reduce the prevalence of large capillary pores, and consequently enhance compressive strength and durability characteristics [

12]. Given its widespread availability, low cost, and favorable environmental profile, RCP-S mortar represents a promising strategy for valorizing construction waste while mitigating the ecological footprint of conventional concrete production [

13]. Furthermore, recent advances have explored various modification techniques—such as alkali activation and thermal treatment—to improve the reactivity and cementitious behavior of RCP-S mortar. These approaches have demonstrated potential to further expand the material’s applicability and support the development of sustainable alternatives to traditional cement-based materials [

14].

Although carbonation has been shown to promote microstructural densification in cement-based materials [

15], recycled cement paste (RCP) often retains residual sand particles. This retention arises from physicochemical adhesion, particle size heterogeneity, and electrostatic interactions, all of which may negatively impact the material’s mechanical performance. As a result, achieving sufficient strength in RCP-based composites for structural applications remains a critical challenge. Addressing this issue requires a more comprehensive understanding of the interrelationship between micropore characteristics and the mechanical behavior of RCP composites.

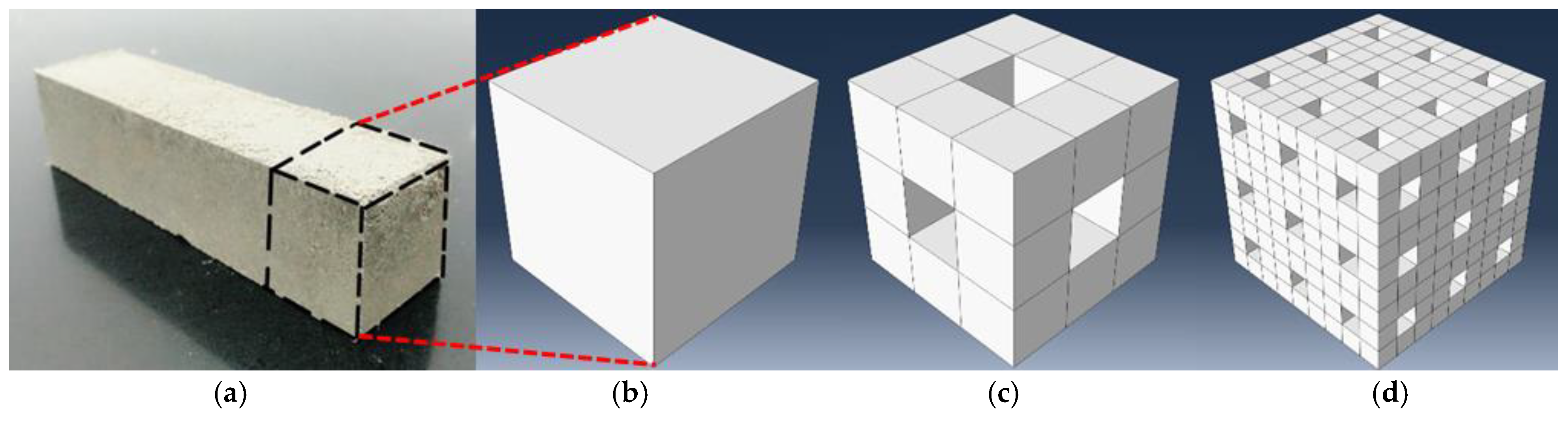

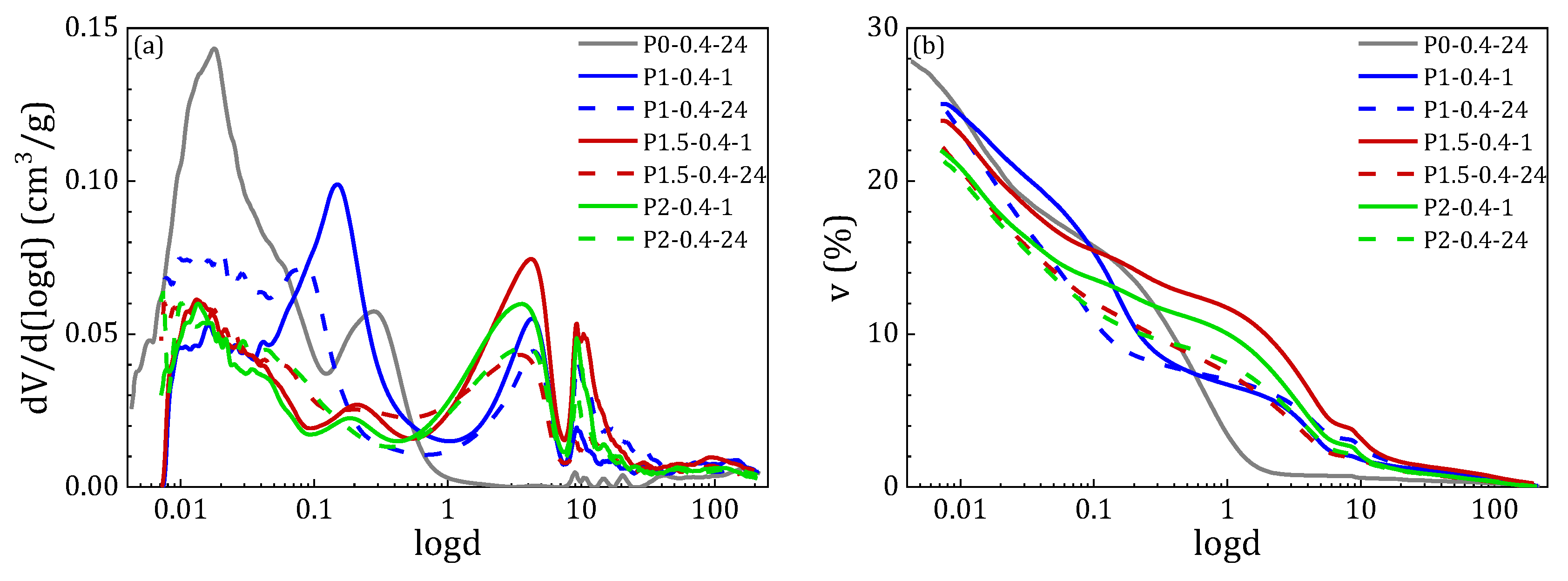

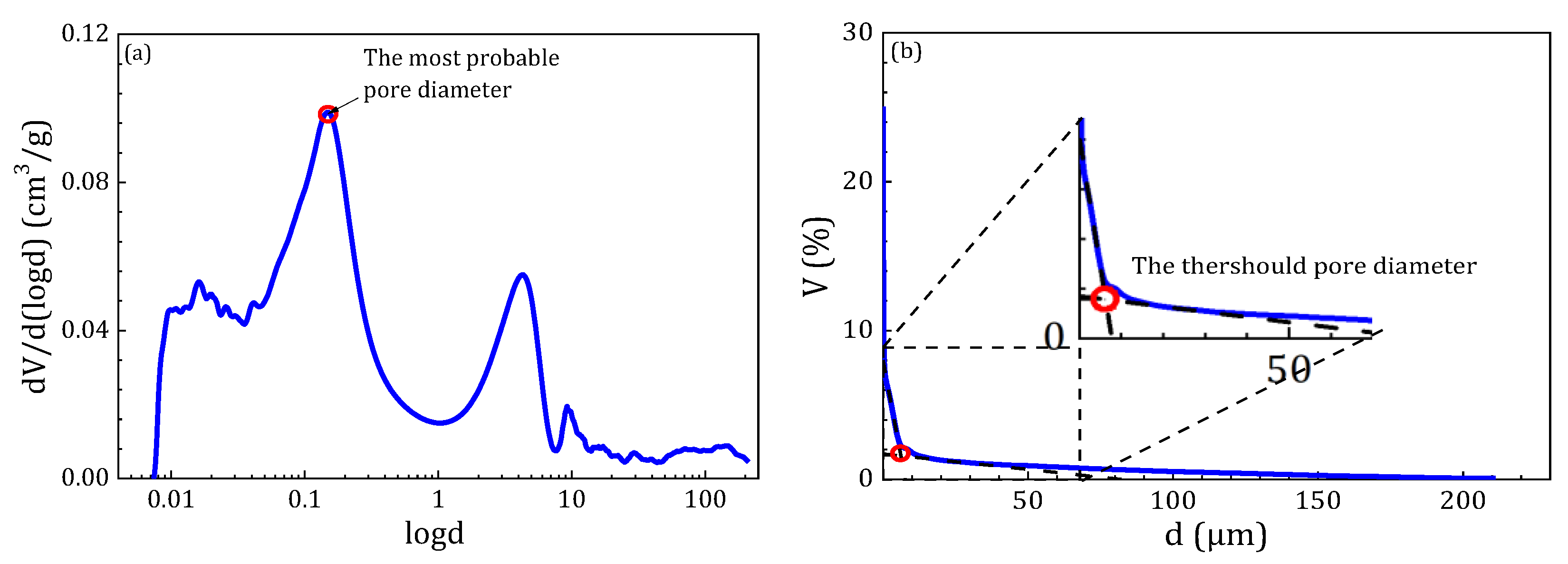

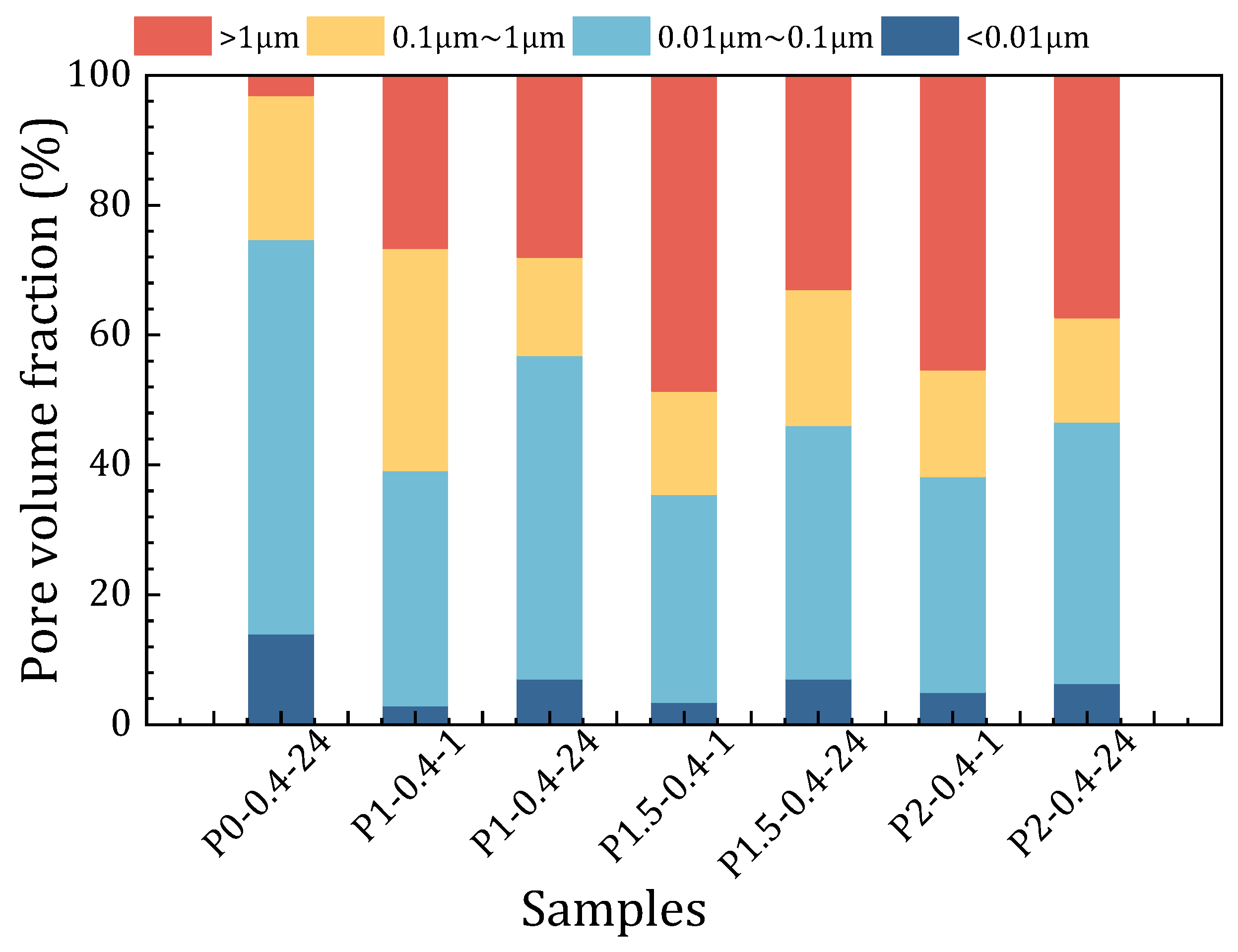

The strength characteristics of RCP-S composites are intrinsically linked to their pore structure, as deformation, damage, and failure may occur across multiple length scales, including macro-, meso-, micro-, and nanoscales. Pores are typically classified into gel pores (<10 nm), fine capillary pores (10–50 nm), medium capillary pores (50–100 nm), large capillary pores (100 nm–10 μm), and macropores (>10 μm). Each category of pore plays a distinct role in determining the strength, density, and permeability of the material, all of which are crucial to its overall performance. Accurate characterization of these pore structures is essential for elucidating the material’s behavior. Several techniques are available for pore structure analysis, including scanning electron microscopy (SEM), nuclear magnetic resonance (NMR), nitrogen adsorption/desorption (NAD), small-angle X-ray scattering (SAXS), and mercury intrusion porosimetry (MIP) [

16,

17,

18,

19]. Scanning electron microscopy is effective for identifying the geometry and distribution of pores larger than 10 μm, while NMR and NAD are more suitable for analyzing pores smaller than 0.1 μm. Small-angle X-ray scattering (SAXS) is particularly valuable for studying pores smaller than 30 nm. Among these, MIP offers a broad pore size characterization range, from 0.005 μm to 750 μm, enabling a comprehensive analysis of the pore structure. Despite its wide applicability, MIP has recognized limitations. First, the high pressure involved in the intrusion process may damage the pore structure, leading to inaccurate results. Second, ink-bottle-shaped pores can cause measurement artifacts and misrepresentation of true pore connectivity [

20,

21]. To address these issues, solvent-exchange pretreatment has been proposed and shown to be effective in minimizing pore collapse and improving measurement accuracy during MIP testing [

22,

23]. This approach has been particularly beneficial for the characterization of RCP-S mortar. With the incorporation of solvent-exchange pretreatment, MIP has been shown to reduce measurement artifacts and remains a practical method for characterizing the pore structure of RCP-S mortar across a wide pore size range [

24].

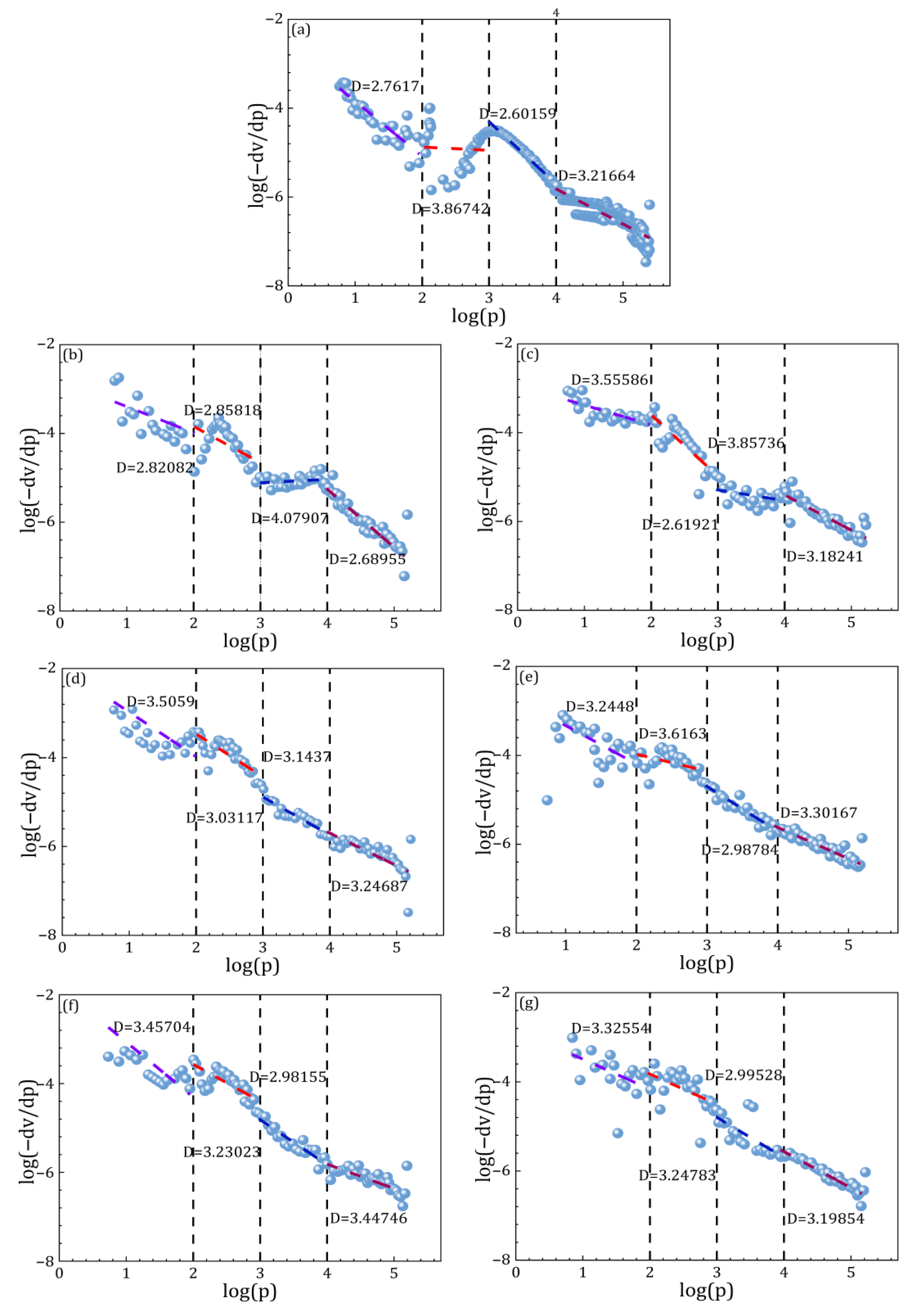

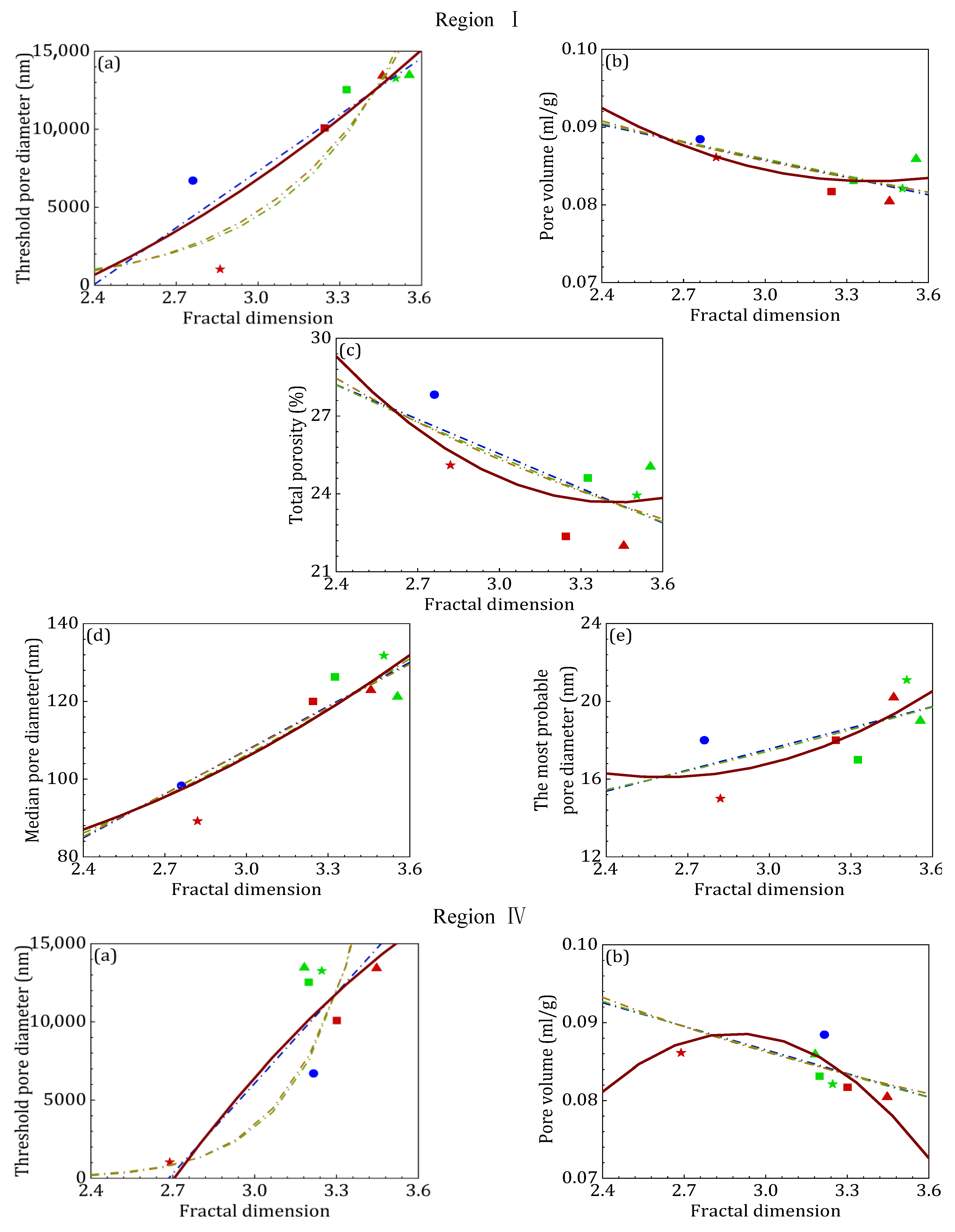

Previous research has demonstrated that recycled cement paste with sand (RCP-S) mortar exhibits a wide range of irregular pore diameters and morphologies, resulting in highly complex pore structures. In conventional Euclidean geometry, pore dimensions are defined using integer-based measures, which limits the accurate characterization of such irregular features. To overcome this, fractal theory, initially proposed by Mandelbrot, has been increasingly applied to describe the pore structures of cement-based composites with greater precision. The use of fractal dimensions enables the quantification of pore geometry complexity through mathematical approaches, thereby addressing the limitations inherent in traditional geometric descriptors. Fractal dimensions have been shown to align well with the heterogeneous and multiscale characteristics of real material systems. Recent studies [

25] have confirmed that pore area, volume, and shape exhibit pronounced fractal behavior and are closely associated with the macroscopic performance of cementitious materials.

The pore network within an RCP-S composite is inherently disordered, making it difficult to fully characterize using conventional parameters such as total porosity, cumulative pore volume, or pore size distribution. To address this challenge, fractal analysis offers an effective framework for quantifying and comparing the structural complexity of composite pore networks. It has been reported that cementitious composites contain numerous pores and microcracks spanning multiple scales, which collectively form sponge-like porous structures. The Menger sponge model, a mathematical construct developed to represent fractal porous materials, has proven especially relevant for simulating adsorption, diffusion, and transport processes in such systems [

26,

27,

28]. Due to the similarity between the fractal characteristics of the Menger sponge and the measurement principles underlying MIP, this model provides a useful analytical tool for simulating and interpreting the pore structures of RCP-S mortar composites.

In earlier research, Khelafi et al. [

29] investigated the hydration behavior and interfacial characteristics of reclaimed cement slurry and mortar using various microscopic characterization techniques. Their findings provided valuable theoretical insights for optimizing mix proportions and pretreatment methods. Sui et al. [

30] reported that waste concrete powder subjected to thermal treatment at 700 °C exhibited optimized particle size distribution and enhanced hydration activity. This treatment yielded the highest activity index among the tested samples, suggesting its potential as an efficient mineral admixture for mortar.

Although relatively few studies have focused specifically on RCP-S, a number of investigations on RCP offer important references for understanding RCP-S behavior. For example, Zhao et al. [

31] employed a machine learning model to analyze MIP data from 204 RCP composite specimens and successfully predicted their compressive strengths. Kong et al. [

32] examined the microstructure, hydration process, and mechanical performance of composites containing recycled micro-powders. Similarly, Hoang [

33] applied a hybrid machine learning model to predict the compressive strength of roller-compacted concrete incorporating recycled aggregates, demonstrating that the gradient boosting algorithm could achieve strength predictions with less than 8% error. Several additional studies have explored the effects of recycled aggregates on concrete performance. Li et al. [

34] investigated how recycled aggregates influence strength, durability, and workability, while Khan et al. [

35] compared the effects of different types of recycled aggregates on mechanical performance, long-term durability, and economic viability. Hossain et al. [

36] analyzed the sustainability of recycled aggregate concrete by evaluating aggregate properties, mix design, and curing conditions, as well as assessing its environmental impact. Wang et al. [

37] studied the influence of recycled fine aggregates on strength, crack resistance, and durability, and Kumar et al. [

38] reviewed how recycled concrete aggregates affect the microstructure and mechanical properties of concrete. In addition, Clark et al. [

39] evaluated the applicability of fractal models for describing the pore structure of recycled concrete and discussed their relationship with material performance, although fractal theory was not explicitly applied in their modeling.

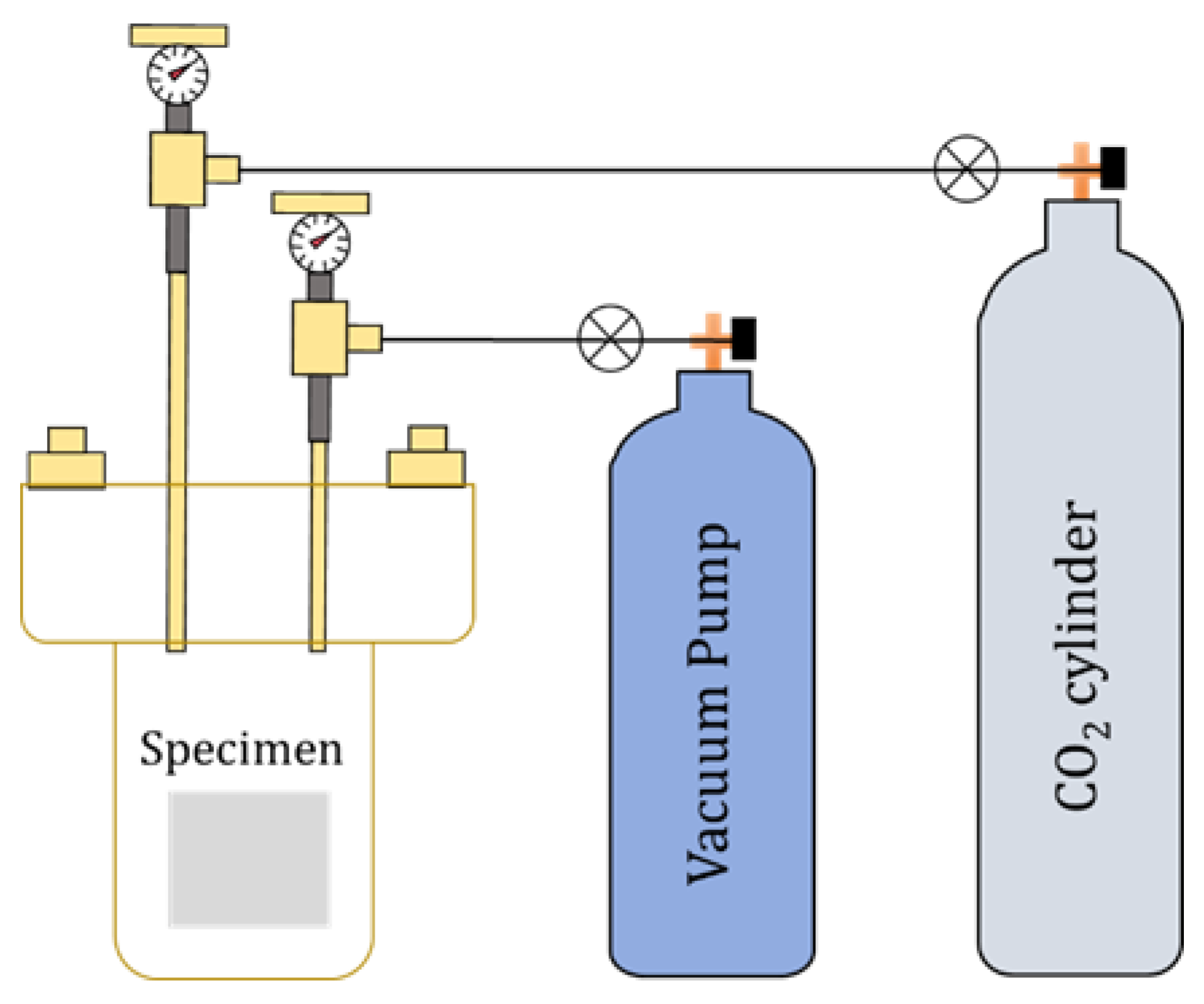

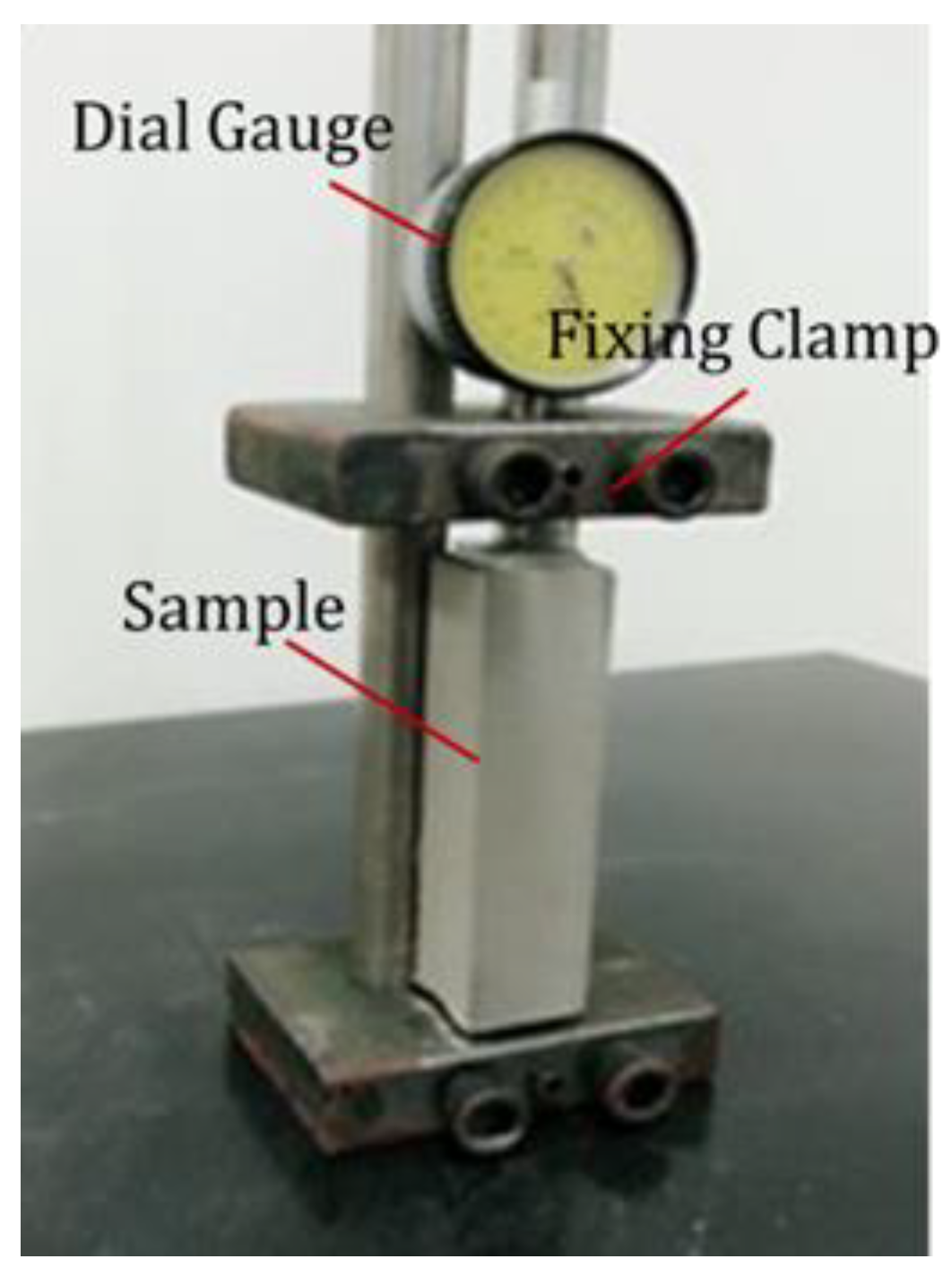

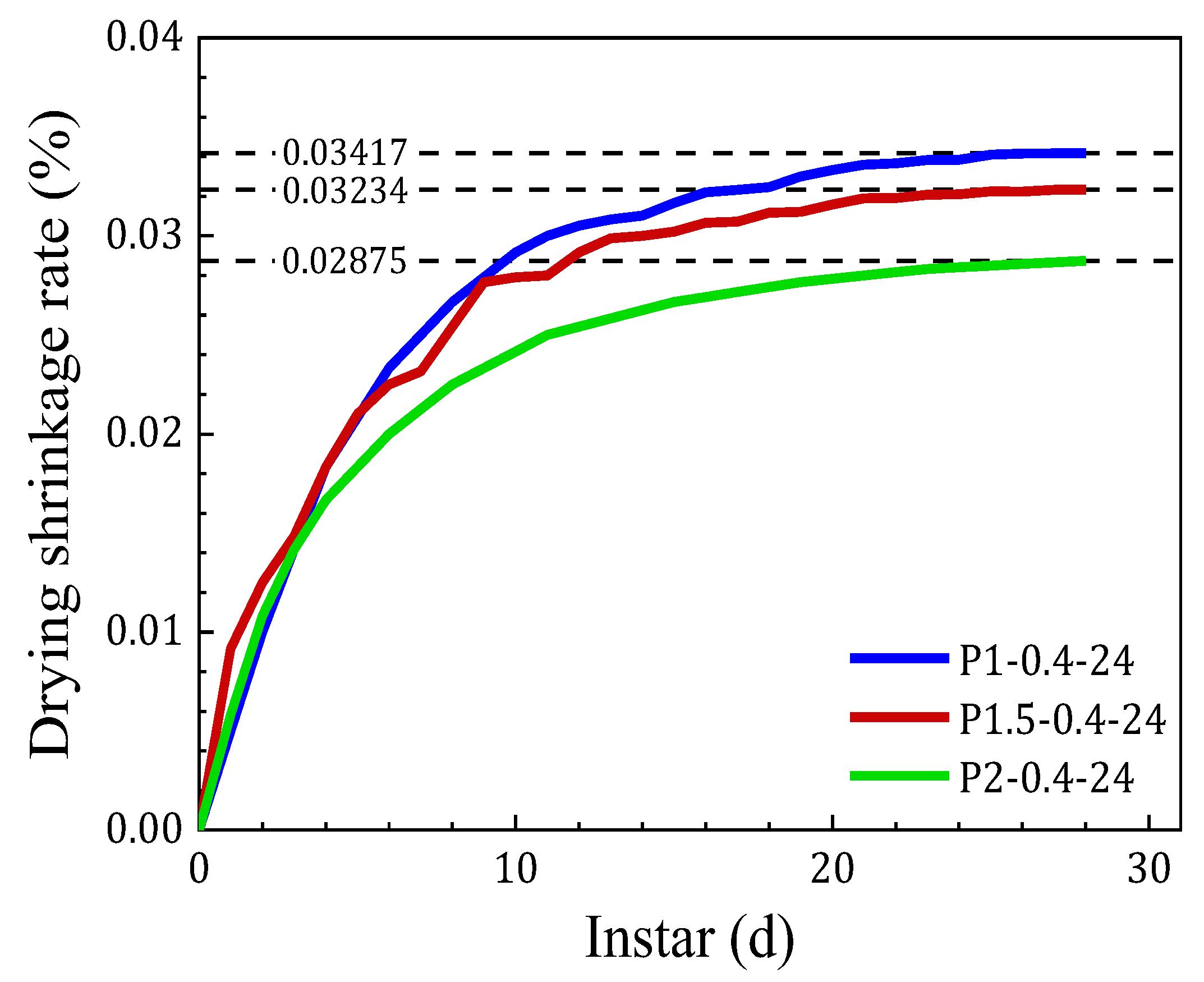

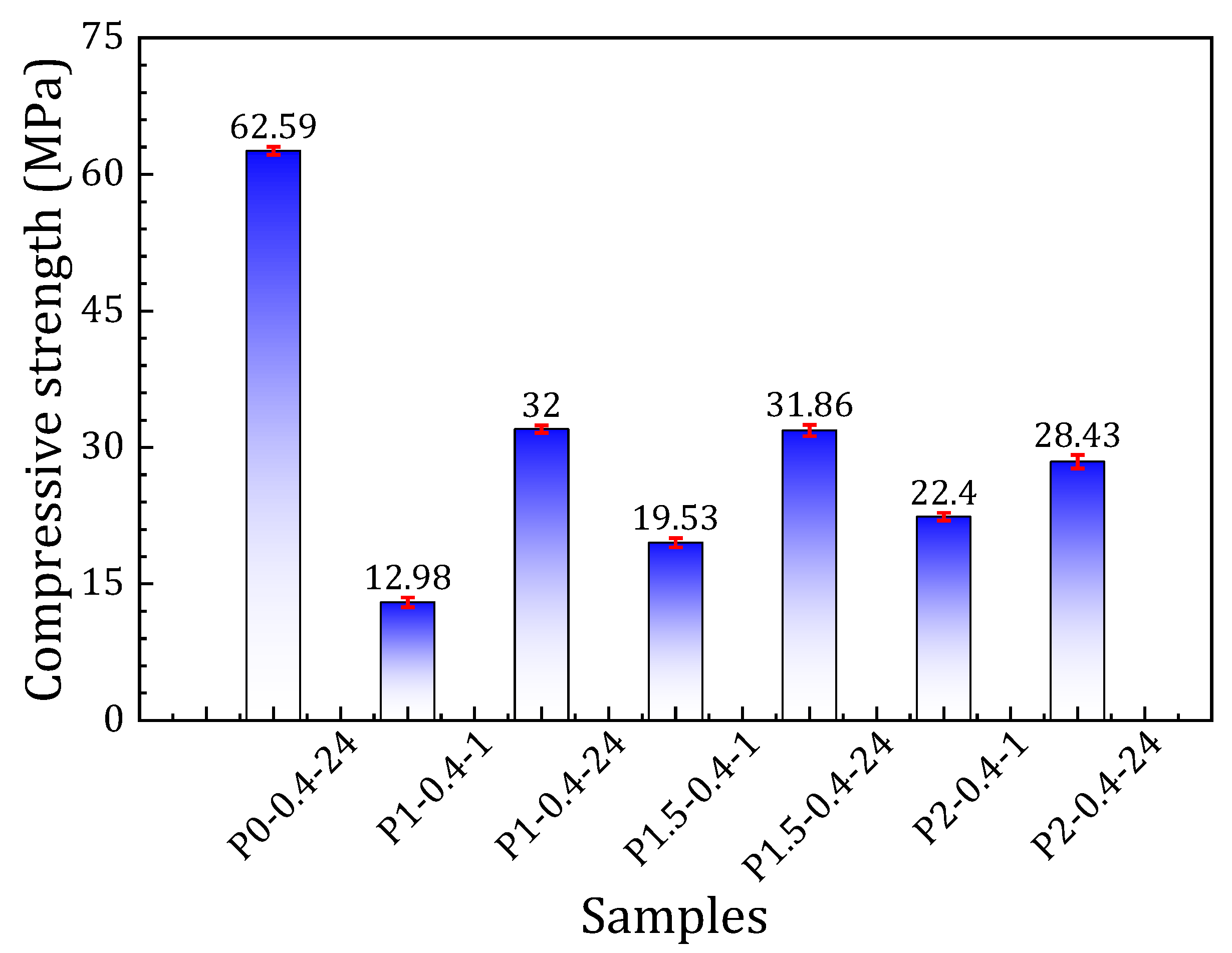

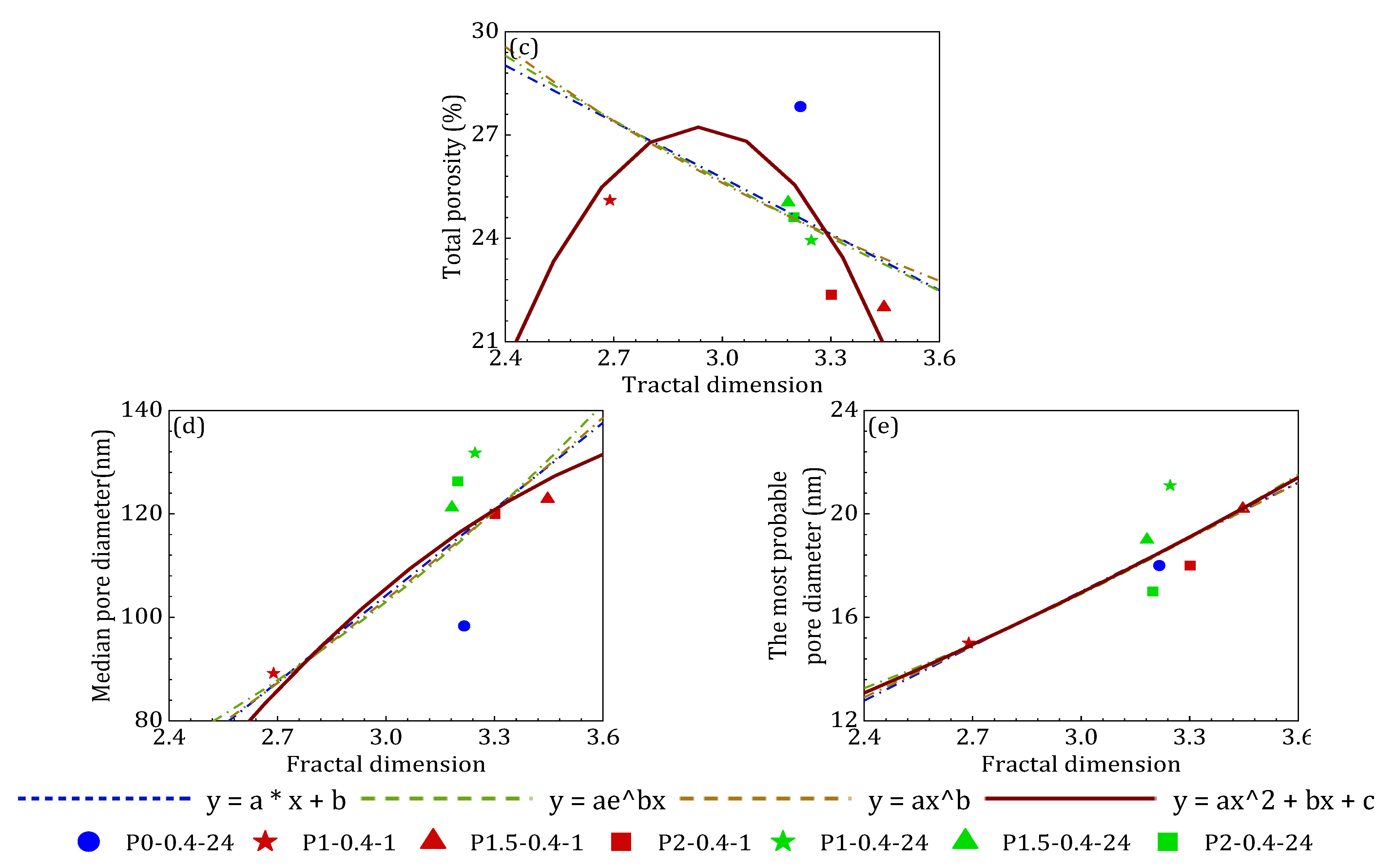

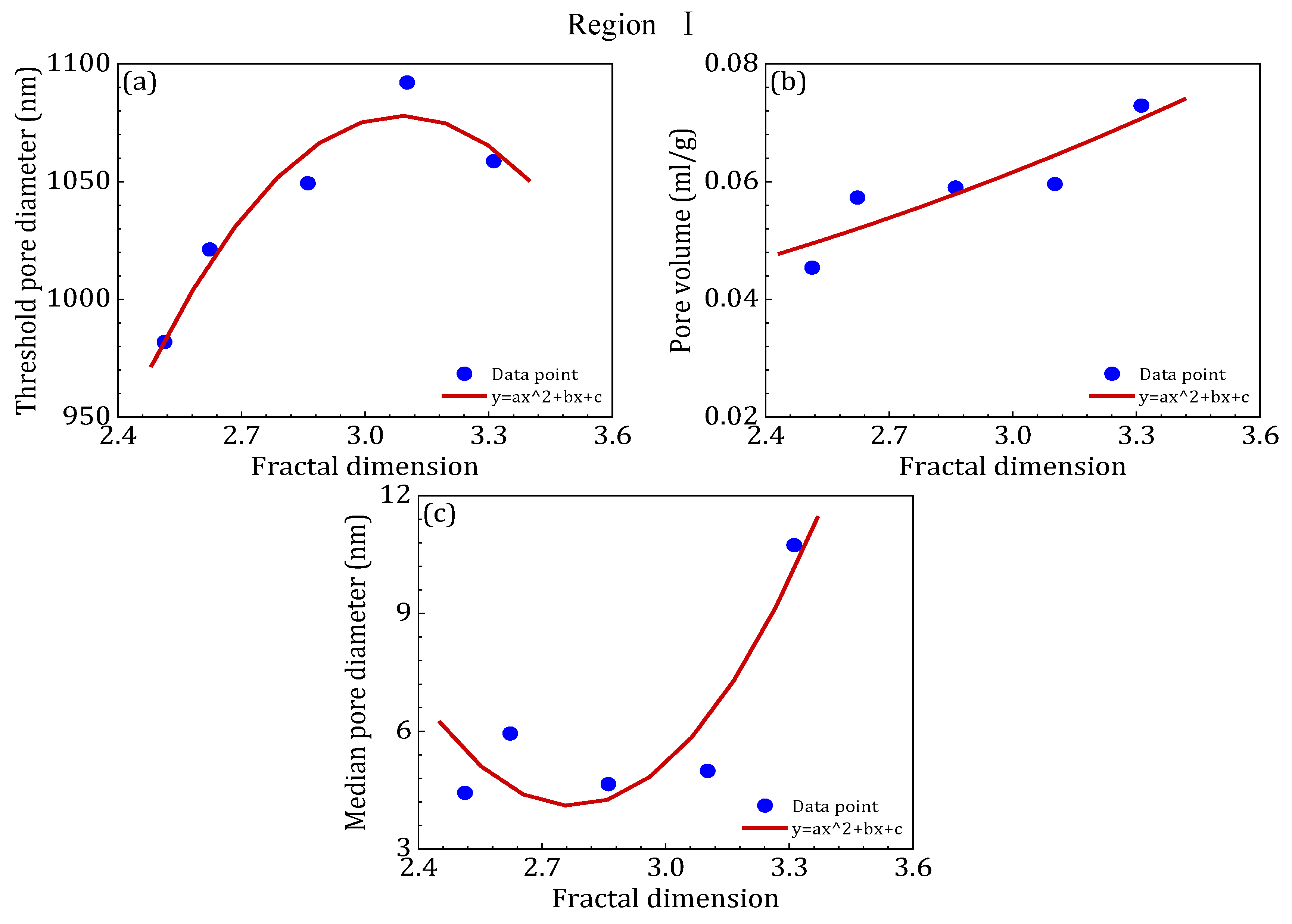

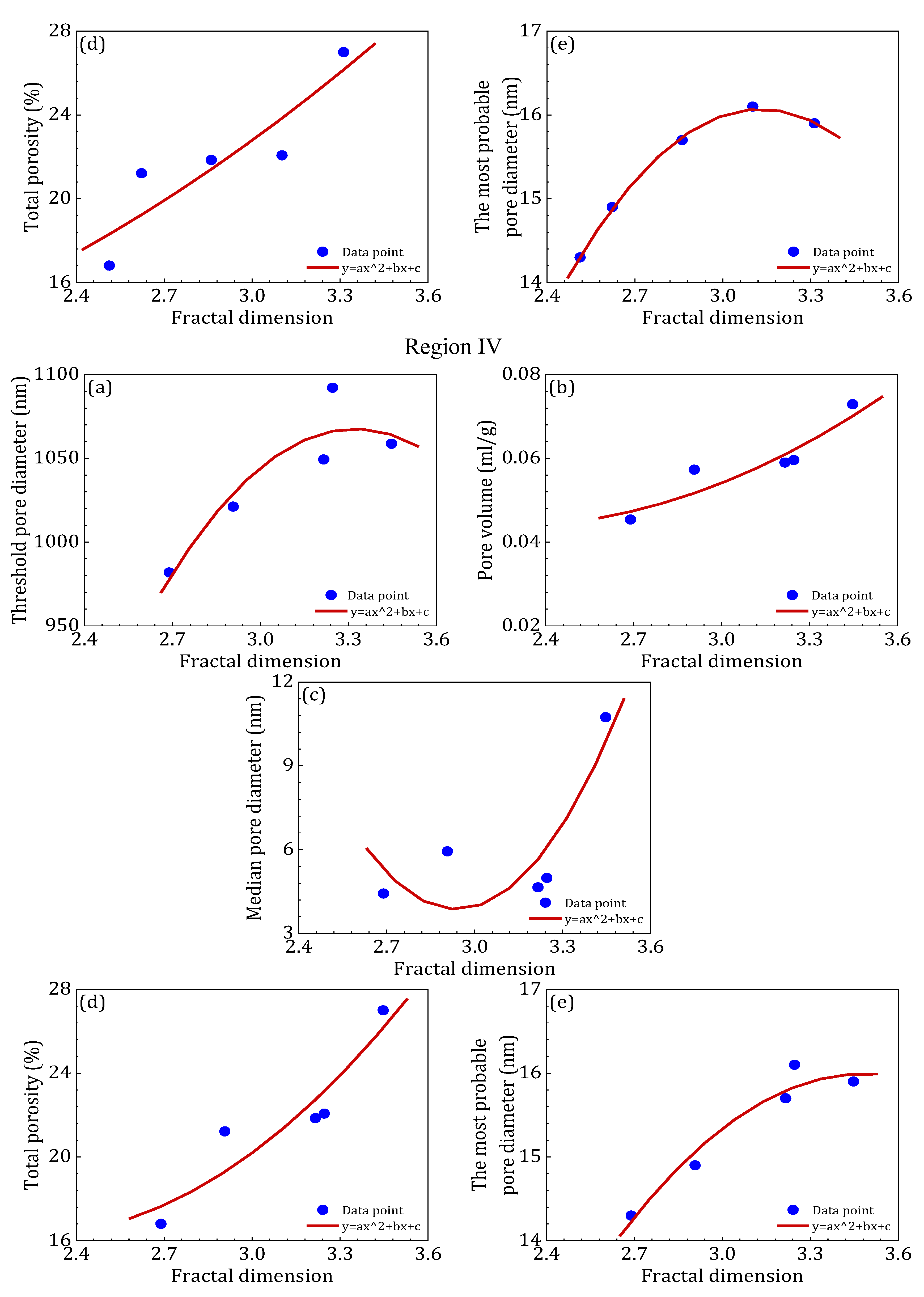

However, existing research has predominantly focused on concrete-based systems, whereas the evolution mechanisms of pore fractal characteristics in RCP-S mortar—particularly under high sand-to-powder ratios—remain insufficiently understood. To address this knowledge gap, the present study investigates the mechanical properties and pore structures of RCP-S mortar subjected to varying carbonation durations and sand-to-powder ratios. Compressive strength testing and mercury intrusion porosimetry (MIP) were conducted to assess porosity, pore volume, pore diameter, and fractal characteristics in both RCP-S mortar and RCP micro-powder specimens. To calculate fractal dimensions, the Menger sponge model was applied, and appropriate curve segments were selected for dimensional analysis. Regression analyses were performed to quantify the relationships between fractal dimensions and pore structure parameters, followed by multiple function fitting to evaluate the observed correlations. A mathematical model was subsequently developed to link pore structural characteristics with compressive strength, and its statistical significance was verified using t-tests and F-tests.

Compared with existing studies on recycled cementitious materials, the innovations of this work lie in two aspects. First, it introduces a coupled parameter system involving both carbonation time and sand-to-powder ratio, allowing systematic control of microstructural densification in RCP-S mortar. This contrasts with prior studies that typically vary only one factor. Second, this study employs a fractal modeling approach based on the Menger sponge to quantify pore structure complexity, enabling a deeper understanding of how carbonation-induced densification mechanisms influence strength development. These advantages provide new insight into designing low-carbon, high-performance recycled cement mortar through process parameter optimization.