Hospital Ventilation Optimization: Balancing Thermal Comfort and Energy Efficiency in Nonlinear Building Dynamics

Abstract

1. Introduction

2. Background

- Insufficient validation: Few studies validate these integrated systems in real-world hospital settings, limiting their practical applicability [42].

3. Materials and Methods

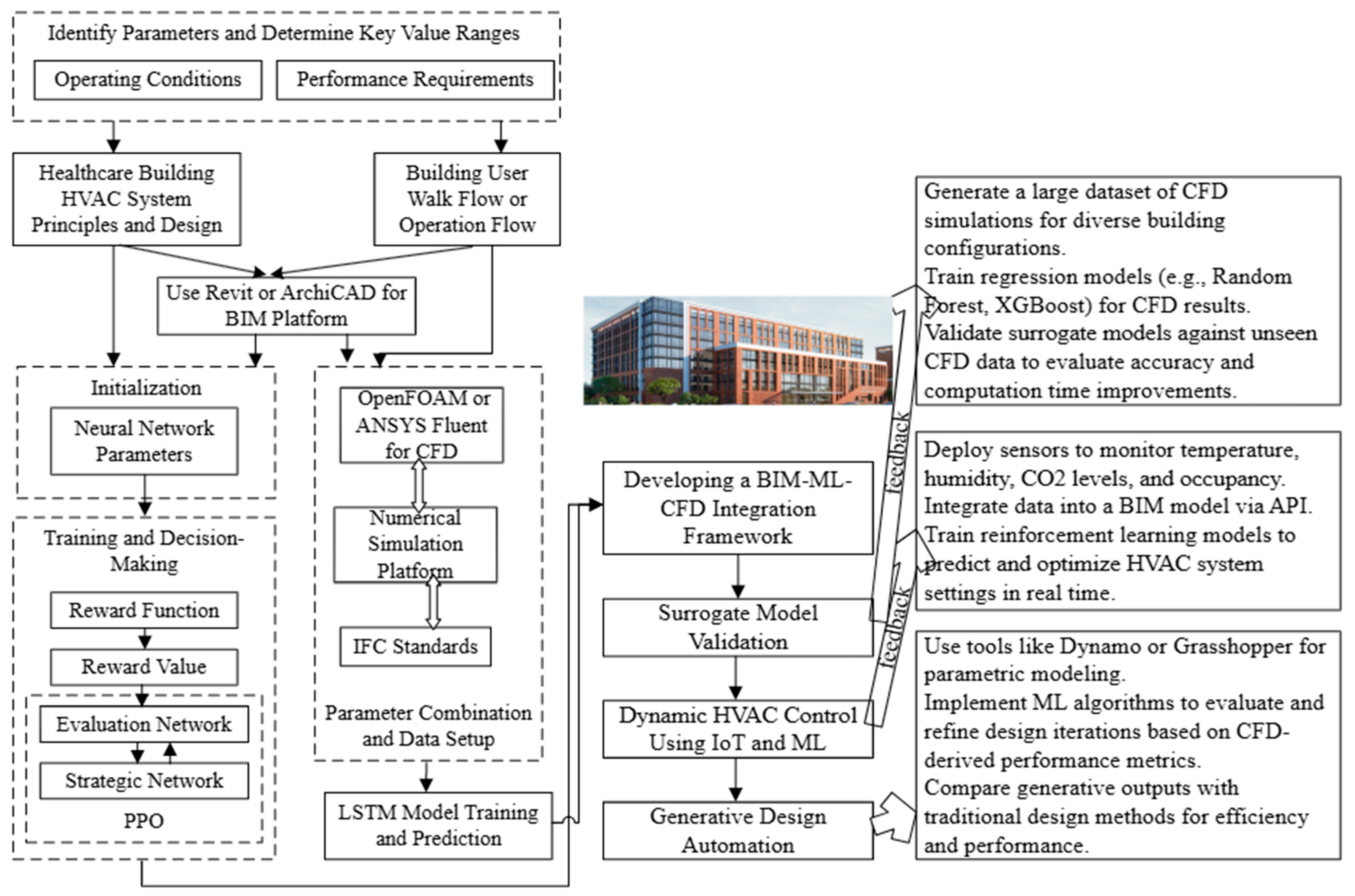

3.1. Framework Development

3.2. Energy Calculation

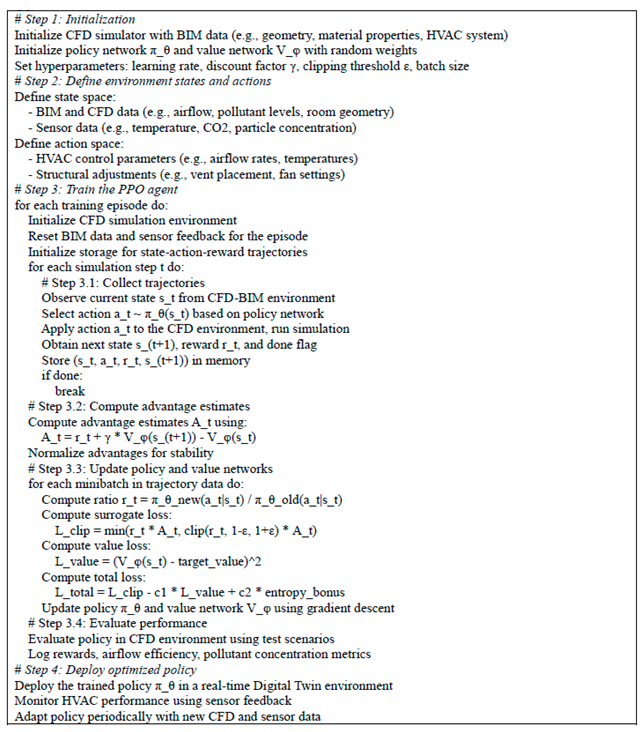

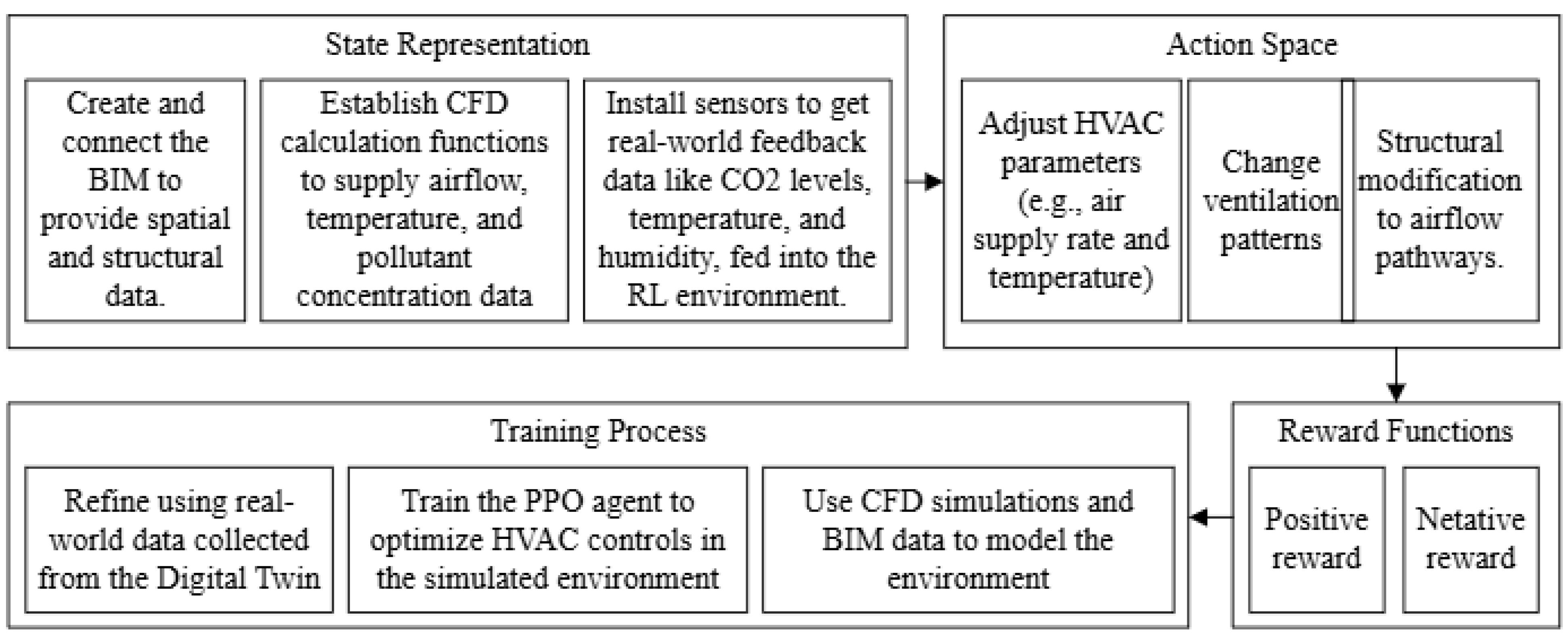

3.3. Reinforcement Learning

3.4. CFD Simulation Setup

3.5. Hypothesis and Scenario Selection

- Floor layout optimization is performed using LSTM-based patient flow prediction, which leverages historical check-in and appointment data to anticipate congestion and inform spatial arrangement decisions.

- AI-driven spatial analysis and optimization integrate BIM geometry with reinforcement learning to evaluate airflow patterns, thermal comfort, and contaminant dispersion, ensuring that design choices align with both clinical and environmental performance goals.

- Real-time adaptive HVAC system modeling simulates dynamic responses to occupancy and contaminant levels, enabling the system to adjust ventilation rates and pressure zones based on predicted usage patterns.

- Multi-objective optimization balances competing priorities—such as energy efficiency, infection control, and patient comfort—using a weighted scoring system informed by ASHRAE and WHO indoor air quality guidelines.

4. Results

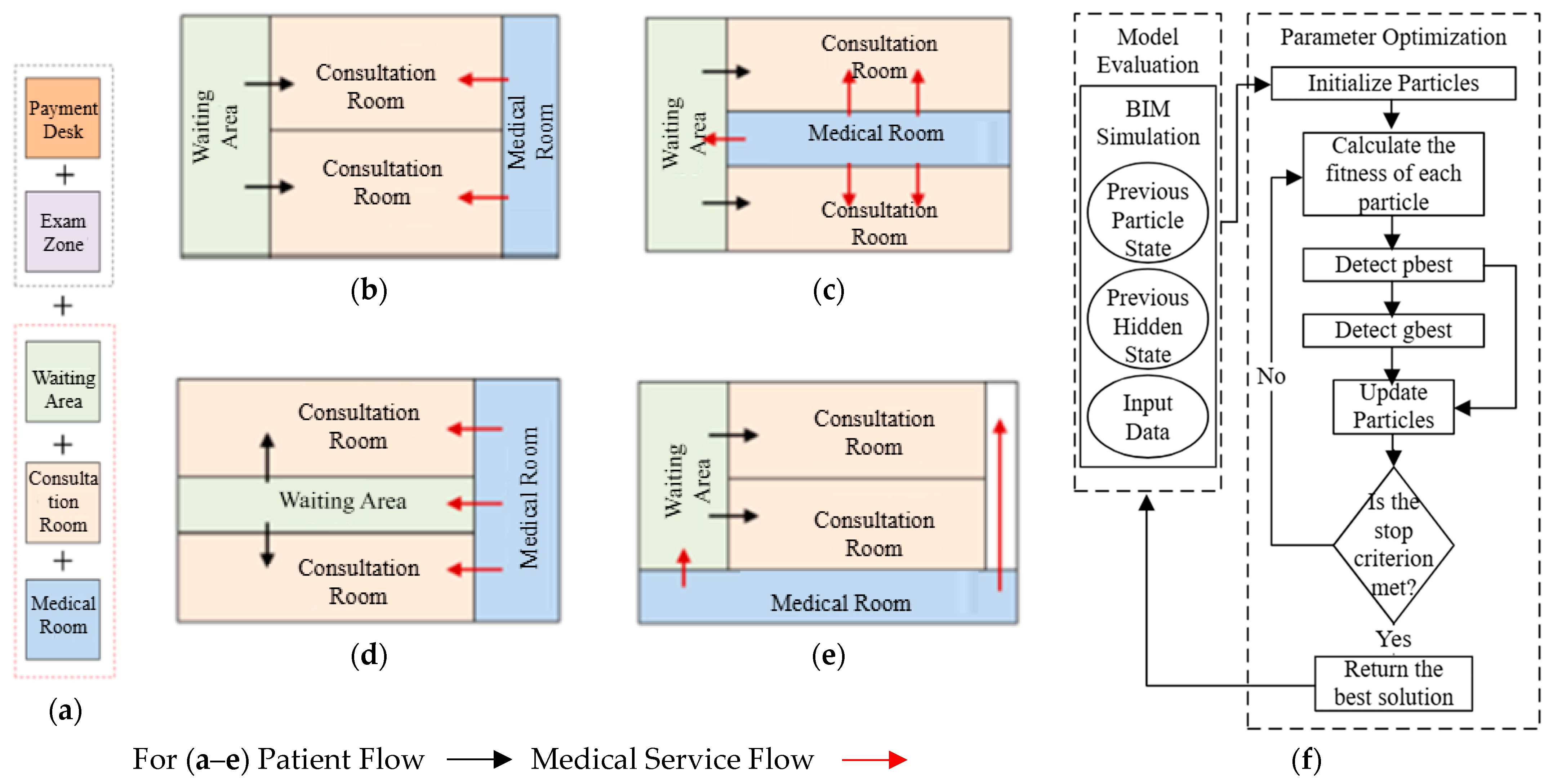

4.1. Case Study 1: Floor Layout Optimization Using LSTM-Based Patient Flow Predictions

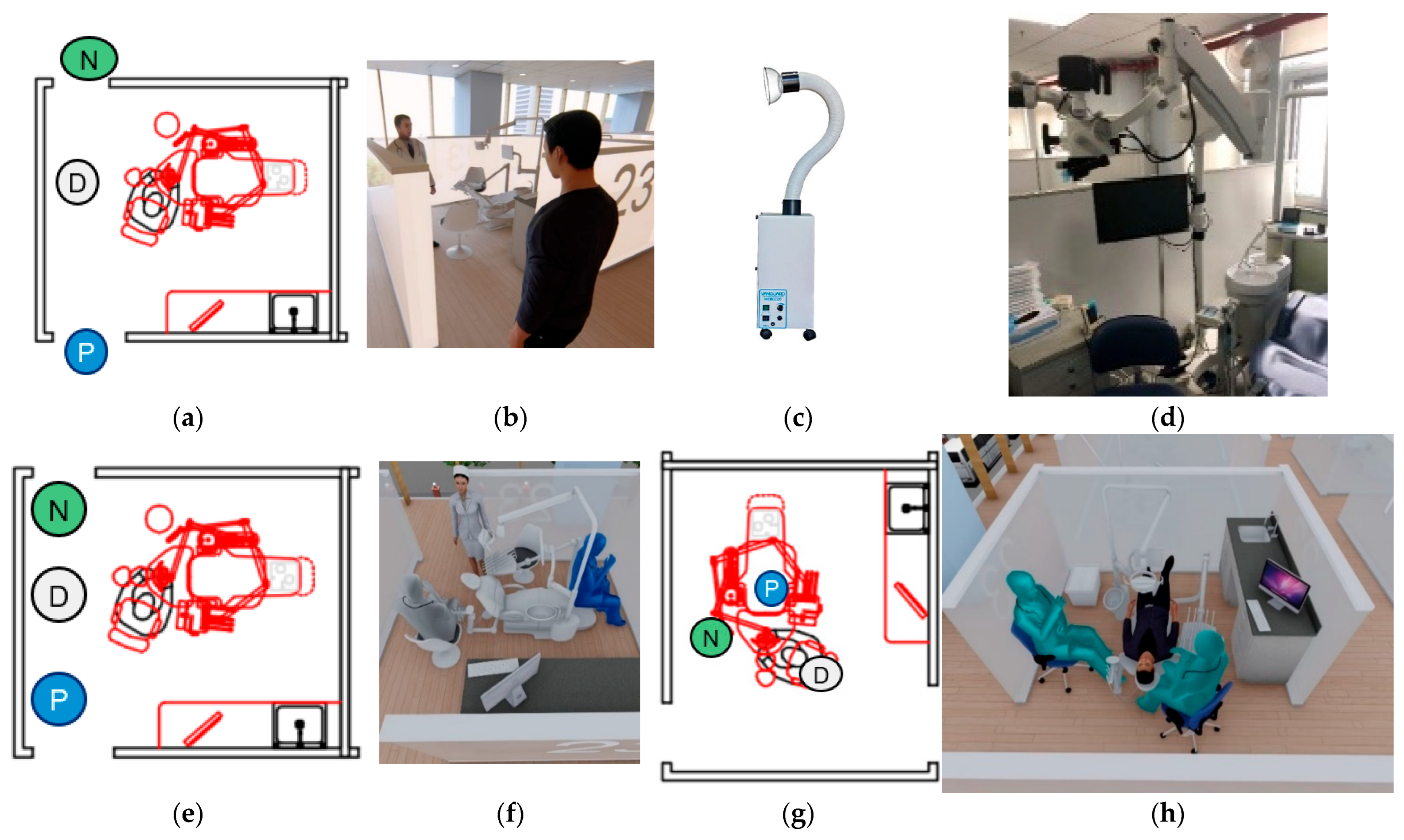

- Designs that maintain clear separation between doctor-patient flow lines and short circulation paths (e.g., Figure 3b) are shown to improve operational efficiency and reduce cross-contamination risks.

- Impact of Room Proximity: Layouts where medical rooms are placed close to waiting areas (Figure 3c,e) result in suboptimal working environments, potentially increasing exposure to airborne pathogens and reducing staff comfort.

- Design Selection Justification: Among the evaluated layouts, Figure 3b was selected for implementation due to its parallel arrangement, which optimizes spatial flow, minimizes congestion, and supports better ventilation control.

- Human-Centric Spatial Planning: The analysis highlights how architectural layout directly influences HVAC performance, patient experience, and staff workflow, reinforcing the need for integrated design strategies in healthcare infrastructure.

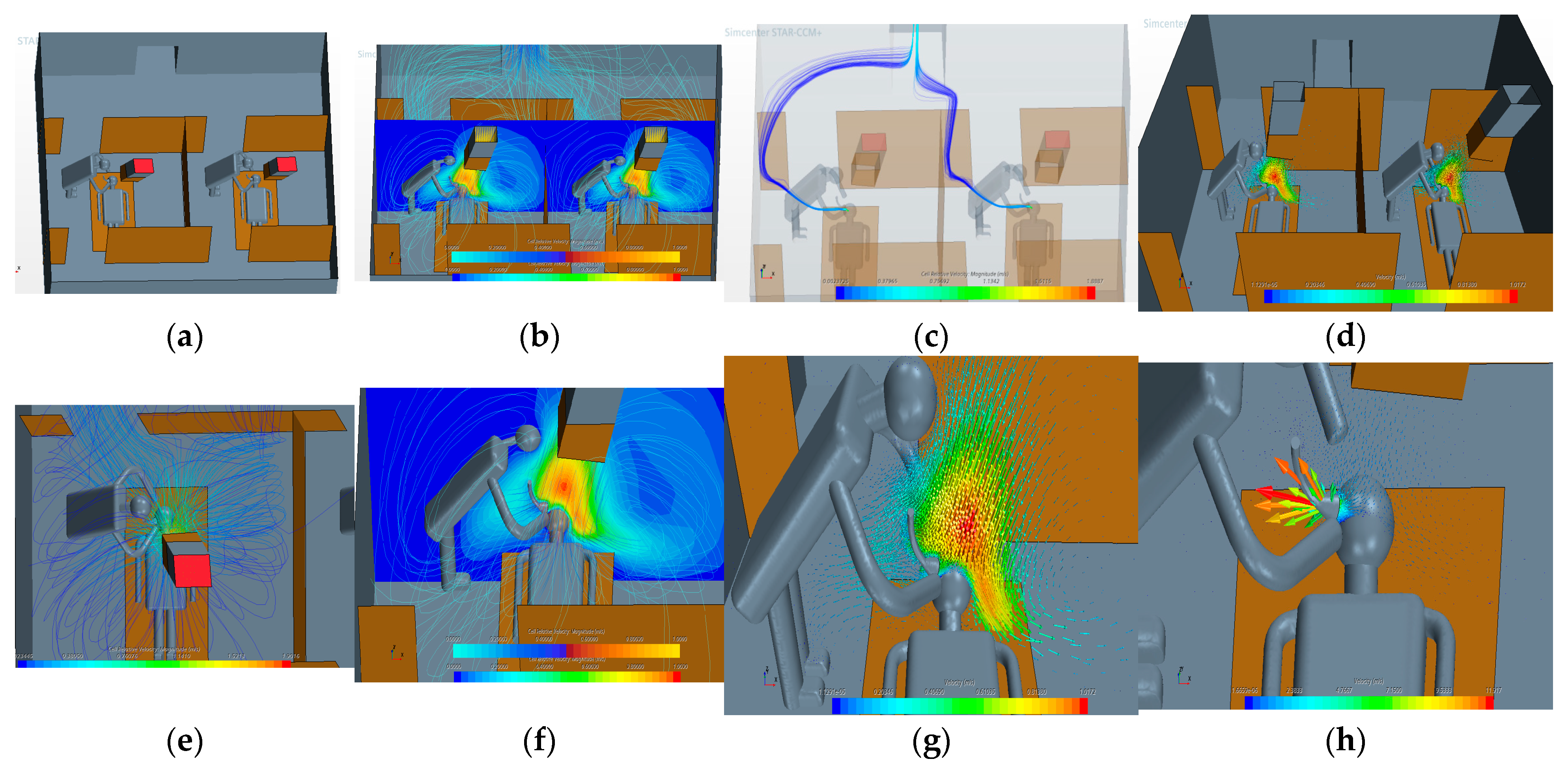

4.2. Case Study 2: AI-Driven Spatial Analysis and Optimization

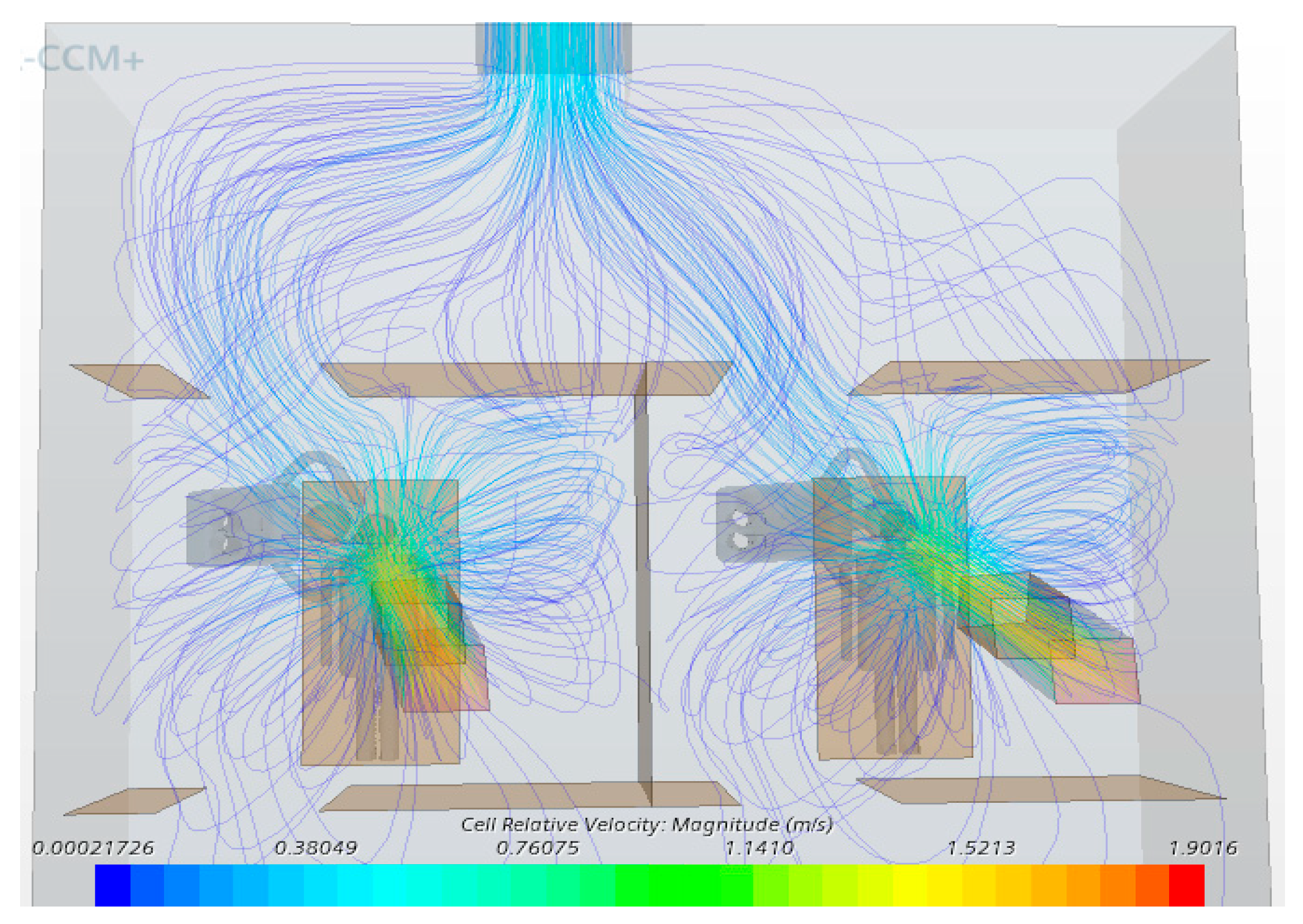

4.3. Case Study 3: Real-Time Adaptive HVAC System

4.4. Case Study 4: Multi-Objective Optimization

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers |

| CFD | Computational Fluid Dynamics |

| HVAC | Heating, Ventilation, and Air Conditioning |

| LSTM | Long Short-Term Memory |

| PPO | Proximal Policy Optimization |

| WHO | World Health Organization |

Appendix A

References

- Dion, H.; Evans, M.; Farrell, P. Hospitals Management Transformative Initiatives; Towards Energy Efficiency and Environmental Sustainability in Healthcare Facilities. J. Eng. Des. Technol. 2023, 21, 552–584. [Google Scholar] [CrossRef]

- Rahman, N.M.A.; Haw, L.C.; Fazlizan, A. A Literature Review of Naturally Ventilated Public Hospital Wards in Tropical Climate Countries for Thermal Comfort and Energy Saving Improvements. Energies 2021, 14, 435. [Google Scholar] [CrossRef]

- Karimi, H.; Adibhesami, M.A.; Bazazzadeh, H.; Movafagh, S. Green Buildings: Human-Centered and Energy Efficiency Optimization Strategies. Energies 2023, 16, 3681. [Google Scholar] [CrossRef]

- Del Regno, N.; Gigante, A.; Ruggiero, S.; Tariello, F.; Vanoli, G.P. Energy efficiency in hospitals: Comparative analysis of different HVAC configurations. Adv. Build. Energy Res. 2023, 17, 554–577. [Google Scholar] [CrossRef]

- Kek, H.Y.; Mohd Saupi, S.B.; Tan, H.; Dzarfan Othman, M.H.; Nyakuma, B.B.; Goh, P.S.; Altowayti, W.A.H.; Qaid, A.; Wahab, N.H.A.; Lee, C.H.; et al. Ventilation Strategies for Mitigating Airborne Infection in Healthcare Facilities: A Review and Bibliometric Analysis (1993–2022). Energy Build. 2023, 295, 113323. [Google Scholar] [CrossRef]

- Tsang, T.W.; Wong, L.T.; Mui, K.W.; Satheesan, M.K.; Yuen, J.W.M. Preparing for the Next Pandemic: Minimizing Airborne Transmission in General Inpatient Wards through Management Practices. Energy Build. 2023, 294, 113214. [Google Scholar] [CrossRef]

- Bulot, F.M.J.; Russell, H.S.; Rezaei, M.; Johnson, M.S.; Ossont, S.J.J.; Morris, A.K.R.; Basford, P.J.; Easton, N.H.C.; Foster, G.L.; Loxham, M.; et al. Laboratory Comparison of Low-Cost Particulate Matter Sensors to Measure Transient Events of Pollution. Sensors 2020, 20, 2219. [Google Scholar] [CrossRef]

- Han, K.; Zhang, J. Energy-Saving Building System Integration with a Smart and Low-Cost Sensing/Control Network for Sustainable and Healthy Living Environments: Demonstration Case Study. Energy Build. 2020, 214, 109861. [Google Scholar] [CrossRef]

- Ismail, N.D.; Tan, H.; Othman, M.H.D.; Kek, H.Y.; Nyakuma, B.B.; Woon, K.S.; Tan, L.K.; Chiong, M.C.; Ong, P.Y.; Wong, K.Y. Energy-Efficient Ventilation Strategies at Hospital Front Desks for Minimizing Infectious Particle Dispersion: Considering Patient Postures and Airflow Optimization. Energy 2024, 307, 132822. [Google Scholar] [CrossRef]

- Palmisani, J.; Di Gilio, A.; Viana, M.; de Gennaro, G.; Ferro, A. Indoor Air Quality Evaluation in Oncology Units at Two European Hospitals: Low-Cost Sensors for TVOCs, PM2.5 and CO2 Real-Time Monitoring. Build. Environ. 2021, 205, 108237. [Google Scholar] [CrossRef]

- Tan, H.; Wong, K.Y.; Nyakuma, B.B.; Kamar, H.M.; Chong, W.T.; Wong, S.L.; Kang, H.S. Systematic Study on the Relationship between Particulate Matter and Microbial Counts in Hospital Operating Rooms. Environ. Sci. Pollut. Res. 2022, 29, 6710–6721. [Google Scholar] [CrossRef]

- Um-e-Habiba; Ahmed, I.; Asif, M.; Alhelou, H.H.; Khalid, M. A Review on Enhancing Energy Efficiency and Adaptability through System Integration for Smart Buildings. J. Build. Eng. 2024, 85, 109354. [Google Scholar] [CrossRef]

- Dadi, N.C.T.; Radochová, B.; Vargová, J.; Bujdáková, H. Impact of Healthcare-Associated Infections Connected to Medical Devices—An Update. Microorganisms 2021, 9, 2332. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.; Aggarwal, A.; Khan, F. Medical Device-Associated Infections Caused by Biofilm-Forming Microbial Pathogens and Controlling Strategies. Antibiotics 2024, 13, 623. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, A.T.; Pham, D.H.; Oo, B.L.; Santamouris, M.; Ahn, Y.; Lim, B.T. Modelling building HVAC control strategies using a deep reinforcement learning approach. Energy Build. 2024, 310, 114065. [Google Scholar] [CrossRef]

- Liu, L.; Huang, Y. HVAC Design Optimization for Pharmaceutical Facilities with BIM and CFD. Buildings 2024, 14, 1627. [Google Scholar] [CrossRef]

- Satheesan, M.K.; Tsang, T.W.; Mui, K.W.; Wong, L.T. Optimal ventilation strategy for multi-bed hospital inpatient wards: CFD simulations using a genetic algorithm. Indoor Built Environ. 2024, 33, 658–674. [Google Scholar] [CrossRef]

- Kadamala, K.; Chambers, D.; Barrett, E. Enhancing HVAC control systems through transfer learning with deep reinforcement learning agents. Smart Energy 2024, 13, 100131. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Zeng, Y.; Cheng, G.; Hu, H.; Hu, J.; Huang, X. Automated Building Layout Generation Using Deep Learning and Graph Algorithms. Autom. Constr. 2023, 154, 105036. [Google Scholar] [CrossRef]

- Andersen, A.H.; Jradi, M. Multi-Objective Optimization of Building Ventilation Systems Using Model Predictive Control: Integrating Air Quality, Energy Cost, and Environmental Impact. Appl. Sci. 2025, 15, 451. [Google Scholar] [CrossRef]

- Lu, R.; Li, X.; Chen, R.; Lei, A.; Ma, X. An Alternative Reinforcement Learning (ARL) control strategy for data center air-cooled HVAC systems. Energy 2024, 308, 132977. [Google Scholar] [CrossRef]

- Kim, I.; Jeon, Y.; Chae, J.; You, D. Deep reinforcement learning for fluid mechanics: Control, optimization, and automation. Fluids 2024, 9, 216. [Google Scholar] [CrossRef]

- Quang, T.V.; Doan, D.T.; Phuong, N.L.; Yun, G.Y. Data-Driven Prediction of Indoor Airflow Distribution in Naturally Ventilated Residential Buildings Using Combined CFD Simulation and Machine Learning (ML) Approach. J. Build. Phys. 2024, 47, 439–471. [Google Scholar] [CrossRef]

- Ascione, F.; De Masi, R.F.; Mastellone, M.; Vanoli, G.P. The Design of Safe Classrooms of Educational Buildings for Facing Contagions and Transmission of Diseases: A Novel Approach Combining Audits, Calibrated Energy Models, Building Performance (BPS) and Computational Fluid Dynamics (CFD) Simulations. Energy Build. 2021, 230, 110533. [Google Scholar] [CrossRef]

- Roumi, S.; Zhang, F.; Stewart, R.A.; Santamouris, M. Commercial Building Indoor Environmental Quality Models: A Critical Review. Energy Build. 2022, 263, 112033. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Li, C. Airflow Modeling Based on the Zonal Method for a Naturally Ventilated Double Skin Façade with Venetian Blinds. Energy Build. 2019, 191, 211–223. [Google Scholar] [CrossRef]

- Panchigar, D.; Kar, K.; Shukla, S.; Mathew, R.M.; Chadha, U.; Selvaraj, S.K. Machine Learning-Based CFD Simulations: A Review, Models, Open Threats, and Future Tactics. Neural Comput. Appl. 2022, 34, 21677–21700. [Google Scholar] [CrossRef]

- Sousa, P.; Rodrigues, C.V.; Afonso, A. Enhancing CFD Solver with Machine Learning Techniques. Comput. Methods Appl. Mech. Eng. 2024, 429, 117133. [Google Scholar] [CrossRef]

- Lee, H.; Rim, D. Assessment of airborne transmitted infection risk in classrooms using computational fluid dynamics and machine learning-based surrogate modeling. J. Build. Eng. 2024, 97, 110760. [Google Scholar] [CrossRef]

- Owoyele, O.; Pal, P.; Vidal Torreira, A.; Probst, D.; Shaxted, M.; Wilde, M.; Senecal, P.K. Application of an Automated Machine Learning-Genetic Algorithm (AutoML-GA) Coupled with Computational Fluid Dynamics Simulations for Rapid Engine Design Optimization. Int. J. Eng. Res. 2022, 23, 1586–1601. [Google Scholar] [CrossRef]

- Hou, F.; Cheng, J.C.; Ma, J.; Kwok, H.H.; Huang, C.; Wu, Z. Occupancy-driven HVAC control optimization via LSTM and deep reinforcement learning for enhanced indoor air quality, thermal comfort and energy efficiency. Build. Environ. 2025, 284, 113501. [Google Scholar] [CrossRef]

- Abida, A.; Richter, P. HVAC control in buildings using neural network. J. Build. Eng. 2023, 65, 105558. [Google Scholar] [CrossRef]

- Tariq, S.; Ali, U.; Kim, S.; Yoo, C. Multi-agent distributed reinforcement learning for energy-efficient thermal comfort control in multi-zone buildings with diverse occupancy patterns. Energy 2025, 332, 137082. [Google Scholar] [CrossRef]

- Wang, Y.Z.; He, X.J.; Hua, Y.; Chen, Z.H.; Wu, W.T.; Zhou, Z.F. Closed-loop forced heat convection control using deep reinforcement learning. Int. J. Heat Mass Transf. 2023, 202, 123655. [Google Scholar] [CrossRef]

- Zong, J.; Ai, Z.; Ma, G. Accurate Evaluation of Inhalation Exposure Based on CFD Predicted Concentration in the Breathing Zone towards Personalized and Smart Control. J. Build. Eng. 2023, 71, 106404. [Google Scholar] [CrossRef]

- Caron, C.; Lauret, P.; Bastide, A. Machine Learning to speed up Computational Fluid Dynamics engineering simulations for built environments: A review. Build. Environ. 2025, 267, 112229. [Google Scholar] [CrossRef]

- Gan, V.J.L.; Luo, H.; Tan, Y.; Deng, M.; Kwok, H.L. BIM and Data-Driven Predictive Analysis of Optimum Thermal Comfort for Indoor Environment. Sensors 2021, 21, 4401. [Google Scholar] [CrossRef]

- Iqbal, F.; Mirzabeigi, S. Digital Twin-Enabled Building Information Modeling–Internet of Things (BIM-IoT) Framework for Optimizing Indoor Thermal Comfort Using Machine Learning. Buildings 2025, 15, 1584. [Google Scholar] [CrossRef]

- Elsarraj, M.; Yasser, M.; Amir, K. Linking Airflow Dynamics to Infection Risk Reduction and Predictive Strategies. J. Build. Eng. 2025, 110, 113027. [Google Scholar] [CrossRef]

- Hu, Y.; Peng, Y.; Gao, Z.; Xu, F. Application of CFD plug-ins integrated into urban and building design platforms for performance simulations: A literature review. Front. Archit. Res. 2023, 12, 148–174. [Google Scholar] [CrossRef]

- Tsikas, P.; Chassiakos, A.; Papadimitropoulos, V.; Papamanolis, A. BIM-Based Machine Learning Application for Parametric Assessment of Building Energy Performance. Energies 2025, 18, 201. [Google Scholar] [CrossRef]

- Sheikhnejad, Y.; Aghamolaei, R.; Fallahpour, M.; Motamedi, H.; Moshfeghi, M.; Mirzaei, P.A.; Bordbar, H. Airborne and Aerosol Pathogen Transmission Modeling of Respiratory Events in Buildings: An Overview of Computational Fluid Dynamics. Sustain. Cities Soc. 2022, 79, 103704. [Google Scholar] [CrossRef]

- Tsang, T.W.; Mui, K.W.; Wong, L.T. Computational Fluid Dynamics (CFD) Studies on Airborne Transmission in Hospitals: A Review on the Research Approaches and the Challenges. J. Build. Eng. 2023, 63, 105533. [Google Scholar] [CrossRef]

- Calzolari, G.; Wei, L. Deep learning to replace, improve, or aid CFD analysis in built environment applications: A review. Build. Environ. 2021, 206, 108315. [Google Scholar] [CrossRef]

- Burqan, A.; El-Ajou, A.; Saadeh, R.; Al-Smadi, M. A New Efficient Technique Using Laplace Transforms and Smooth Expansions to Construct a Series Solution to the Time-Fractional Navier-Stokes Equations. Alex. Eng. J. 2022, 61, 1069–1077. [Google Scholar] [CrossRef]

- Zheng, L.; Lu, W.; Wu, L.; Zhou, Q. A Review of Integration between BIM and CFD for Building Outdoor Environment Simulation. Build. Environ. 2023, 228, 109862. [Google Scholar] [CrossRef]

- Kang, K.Y.; Wang, X.; Wang, J.; Xu, S.; Shou, W.; Sun, Y. Utility of BIM-CFD Integration in the Design and Performance Analysis for Buildings and Infrastructures of Architecture, Engineering and Construction Industry. Buildings 2022, 12, 651. [Google Scholar] [CrossRef]

- Hauer, M.; Hammes, S.; Zech, P.; Geisler-Moroder, D.; Plörer, D.; Miller, J.; Pfluger, R. Integrating Digital Twins with BIM for Enhanced Building Control Strategies: A Systematic Literature Review Focusing on Daylight and Artificial Lighting Systems. Buildings 2024, 14, 805. [Google Scholar] [CrossRef]

- Kaggle Healthcare Datasets. Hospital Admissions Data. Available online: https://www.kaggle.com/datasets/ashishsahani/hospital-admissions-data (accessed on 7 July 2025).

- Miao, Y.; Chau, K.W.; Lau, S.S.Y.; Ye, T. A novel thermal comfort model modified by time scale and habitual trajectory. Renew. Sustain. Energy Rev. 2025, 207, 114903. [Google Scholar] [CrossRef]

- Ramadan, M.N.; Ali, M.A.; Alkhedher, M. Federated Learning-Enabled IoT Framework for Indoor Air Quality and HVAC Optimization in Healthcare Buildings. J. Build. Eng. 2025, 107, 112758. [Google Scholar] [CrossRef]

- Faezi, S.; Shirmarz, A. A comprehensive survey on machine learning using in software defined networks (SDN). Hum.-Centric Intell. Syst. 2023, 3, 312–343. [Google Scholar] [CrossRef]

| Ref | Keywords | Relevancy | Features and Advantages | Limitations |

|---|---|---|---|---|

| [37] | BIM, Airflow Simulation, Machine Learning | High (Dynamic HVAC control) | -Real-time BIM-CFD integration Focus: Healthcare | High computational load compromises adaptability |

| [38] | Nonlinear Optimization, BIM, Pattern Identification | High (Energy efficiency) | -ML-driven adaptive airflow control Method: Genetic Algorithms | Requires extensive sensor data; Not for hospitals. |

| [39] | Pattern Identification, ML, Airflow Simulation | High (Pathogen mitigation) | -BIM + IoT for occupancy patterns Dataset: An office room | Complex calibration; Not for hospitals. |

| [40] | BIM, Airflow Simulation, ML | Medium (Urban scale) | -Urban-scale BIM-CFD coupling Application: Smart cities | Limited to pre-trained scenarios; Not for hospitals |

| [41] | Nonlinear Optimization, BIM, ML | Medium (District energy) | -ML for wind flow prediction Focus: Renewable integration | Needs high-resolution CFD data; For apartments, not for hospitals |

| [42] | Pattern Identification, ML, Airflow Simulation | High (Post pandemic design) | -RL for energy grids Tool: Python (3.13.7)-based ML | Generalizes micro-scale details; Not spatial optimization (BIM) |

| [43] | Nonlinear Optimization, BIM, Airflow Simulation | High (Healthcare HVAC) | -Hybrid GA-CFD approach Validation: ASHRAE standards | Scalability challenges |

| [15,18,21] | Nonlinear Optimization, ML, Pattern Identification | High (Predictive control) | -BIM for spatial constraints Method: Phasic Policy Gradient | Limited to static layouts |

| [44] | BIM, Pattern Identification, ML | Medium (Automation) | -MPC + ML for ventilation DL Model: CNN-LSTM | Slow convergence of GA; Fast predictions come at a cost of degraded accuracy |

| Pressure at the Return Vent (Bar) | Speed at Supply Diffuser (m/s) | Aerosol Existence Time (s) |

|---|---|---|

| 0 | 1 | 351 |

| −0.5 | 1 | 159 |

| −1 | 1 | 67 |

| −2 | 1 | 36 |

| 0 | 2 | 418 |

| −0.5 | 2 | 182 |

| −1 | 2 | 105 |

| −2 | 2 | 81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, F.; Xie, H.; Shi, Q.; Gai, H. Hospital Ventilation Optimization: Balancing Thermal Comfort and Energy Efficiency in Nonlinear Building Dynamics. Buildings 2025, 15, 3267. https://doi.org/10.3390/buildings15183267

Jiang F, Xie H, Shi Q, Gai H. Hospital Ventilation Optimization: Balancing Thermal Comfort and Energy Efficiency in Nonlinear Building Dynamics. Buildings. 2025; 15(18):3267. https://doi.org/10.3390/buildings15183267

Chicago/Turabian StyleJiang, Fengchang, Haiyan Xie, Quanbin Shi, and Houzhuo Gai. 2025. "Hospital Ventilation Optimization: Balancing Thermal Comfort and Energy Efficiency in Nonlinear Building Dynamics" Buildings 15, no. 18: 3267. https://doi.org/10.3390/buildings15183267

APA StyleJiang, F., Xie, H., Shi, Q., & Gai, H. (2025). Hospital Ventilation Optimization: Balancing Thermal Comfort and Energy Efficiency in Nonlinear Building Dynamics. Buildings, 15(18), 3267. https://doi.org/10.3390/buildings15183267