Evaluation of the Use of Waste Almond Shell Ash in Concrete: Mechanical and Environmental Properties

Abstract

1. Introduction

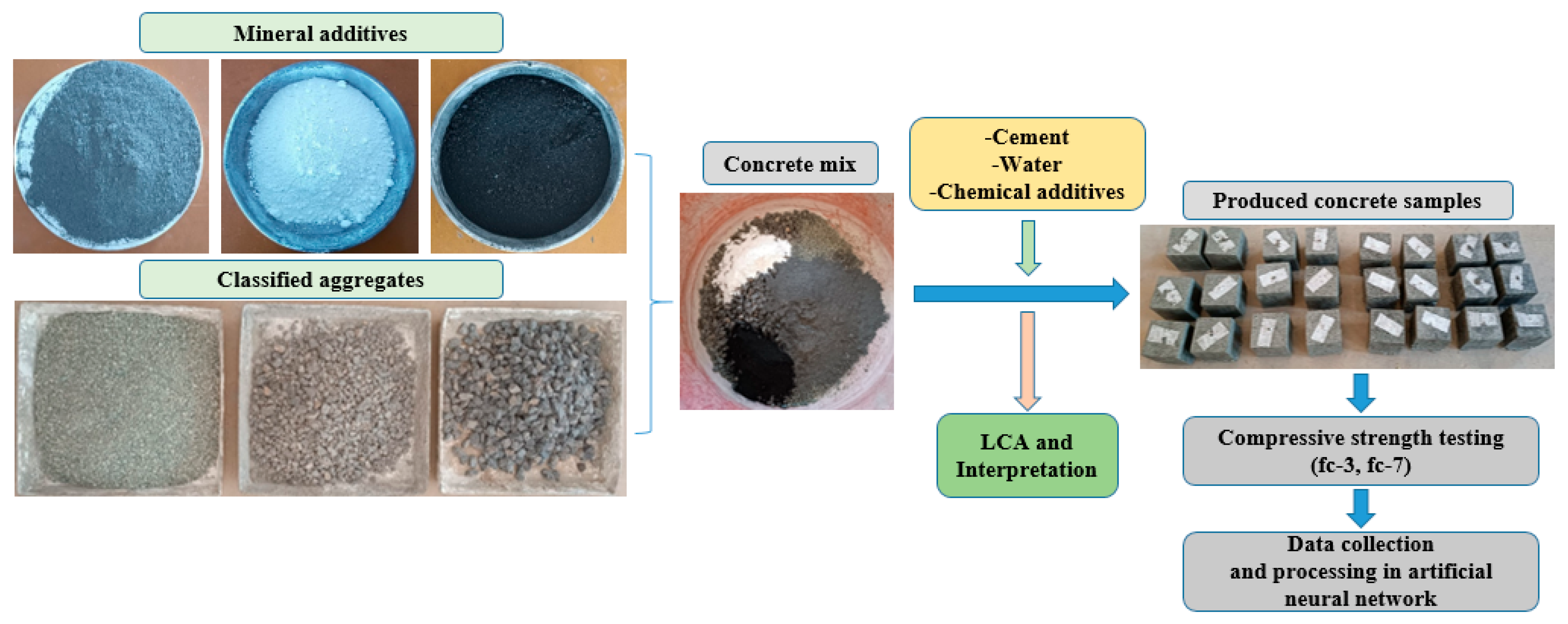

2. Methodology

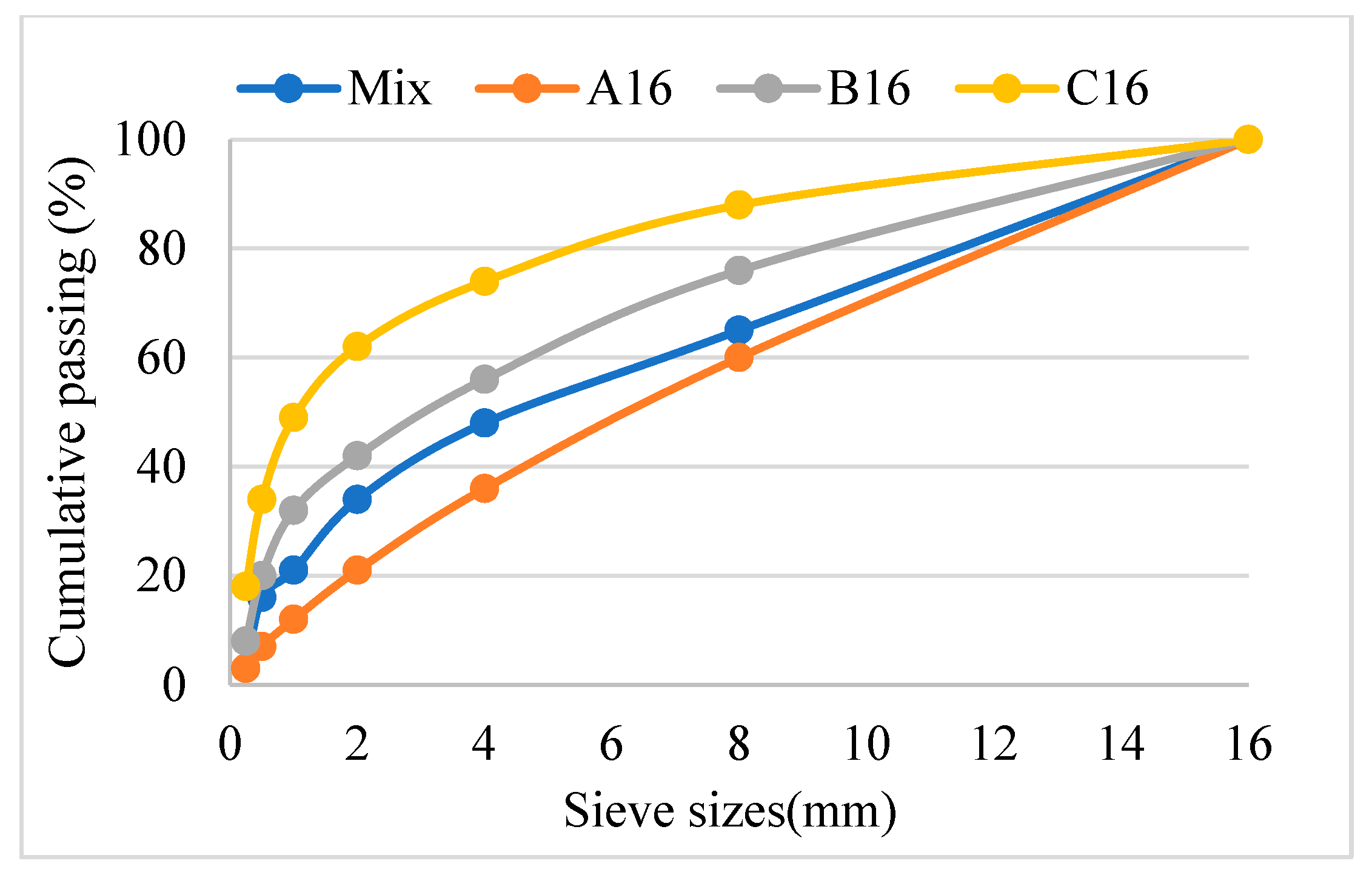

2.1. Materials and Properties

2.2. Biochar Production and Properties

2.3. Mix Proportions and Preparation

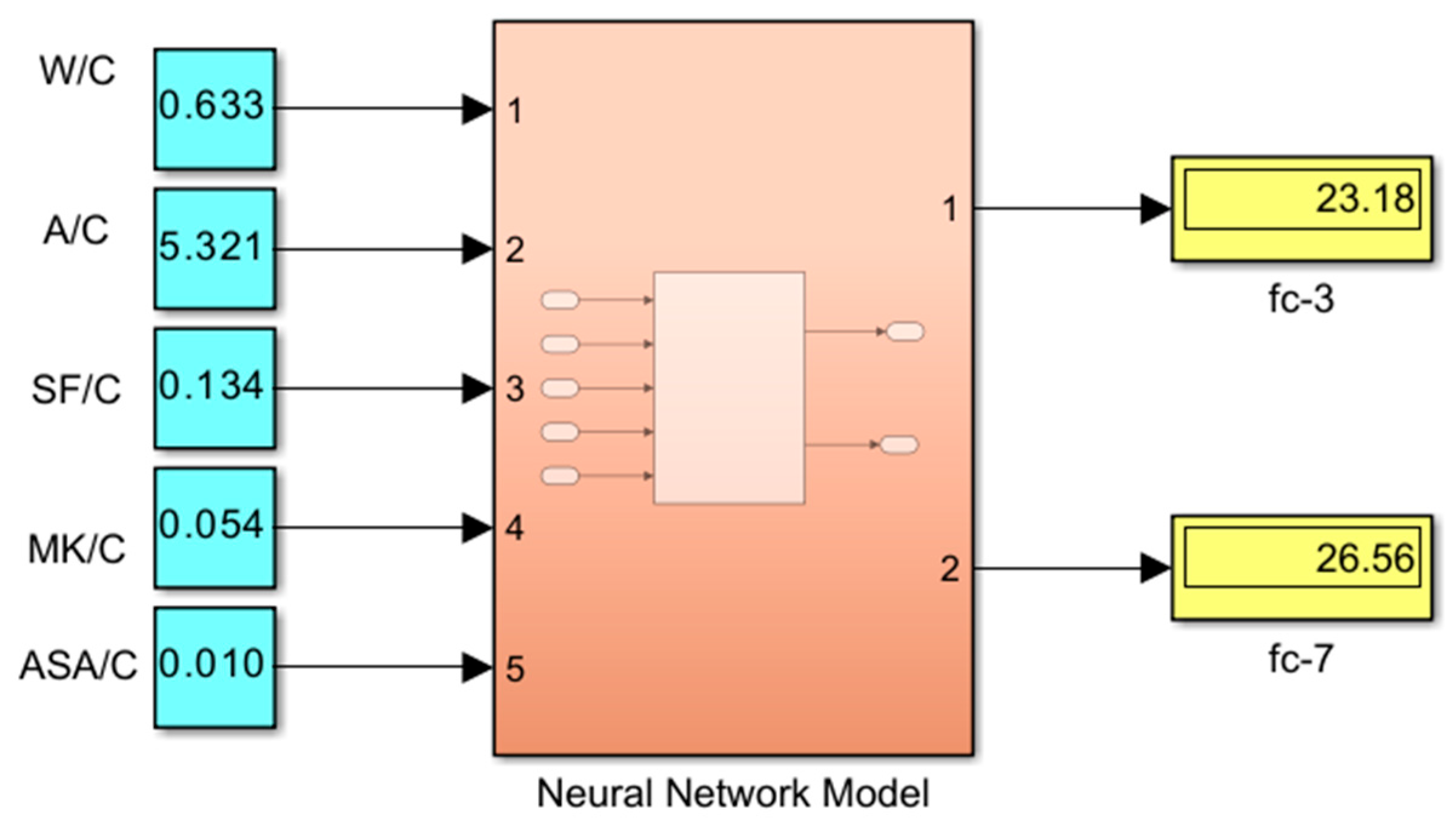

2.4. Artificial Neural Network (ANN)

3. Results and Discussion

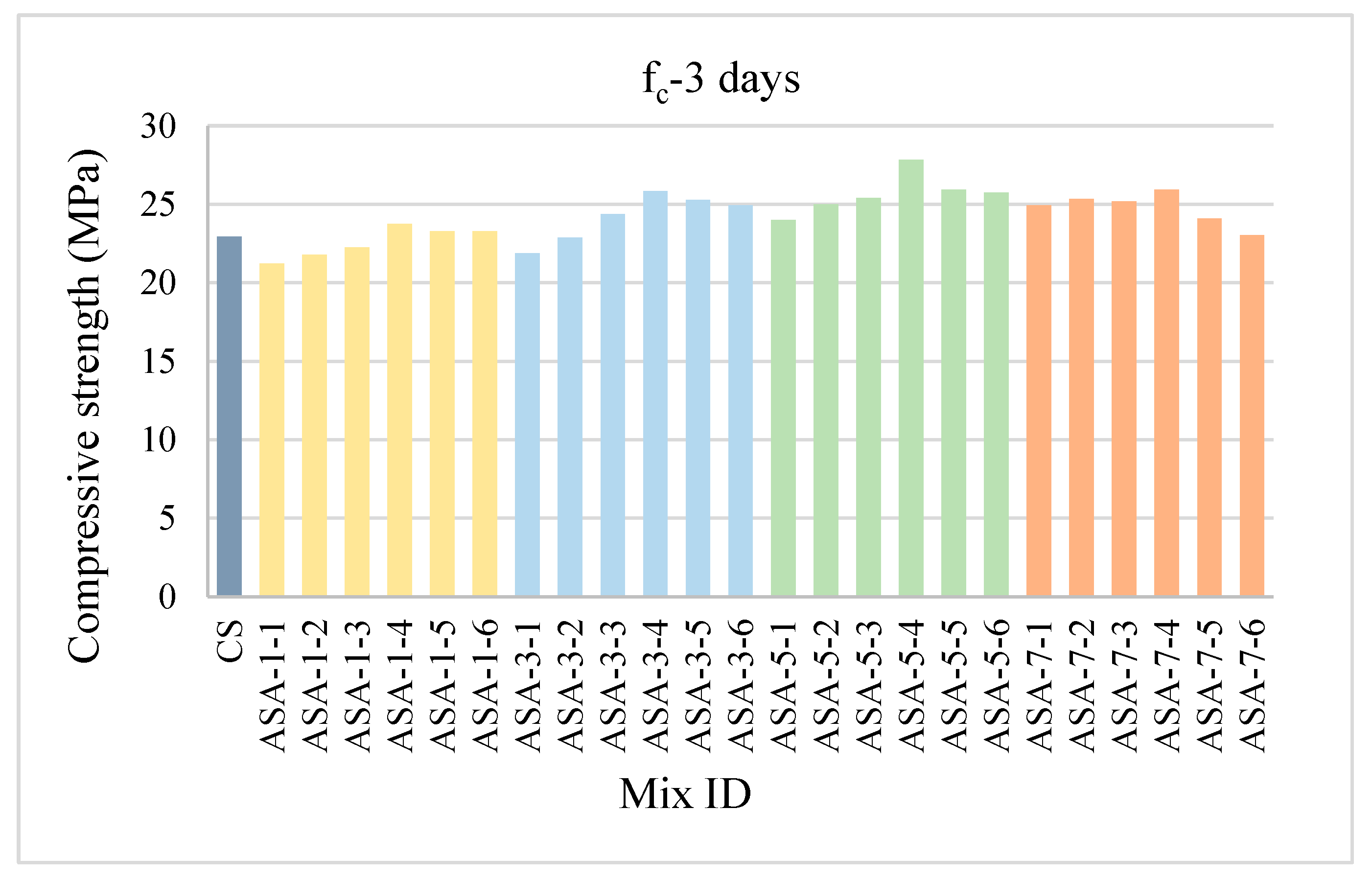

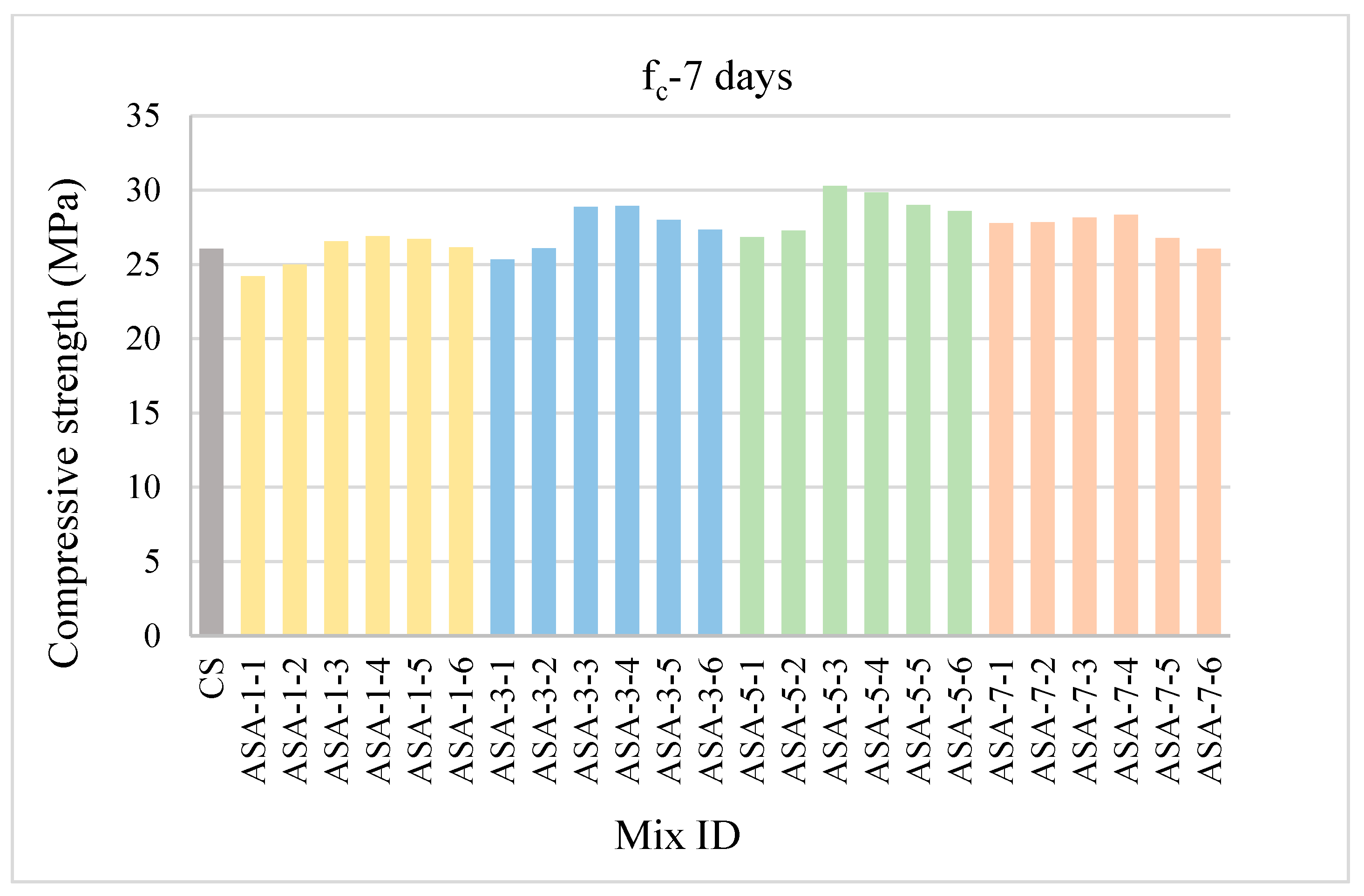

3.1. Compressive Strength

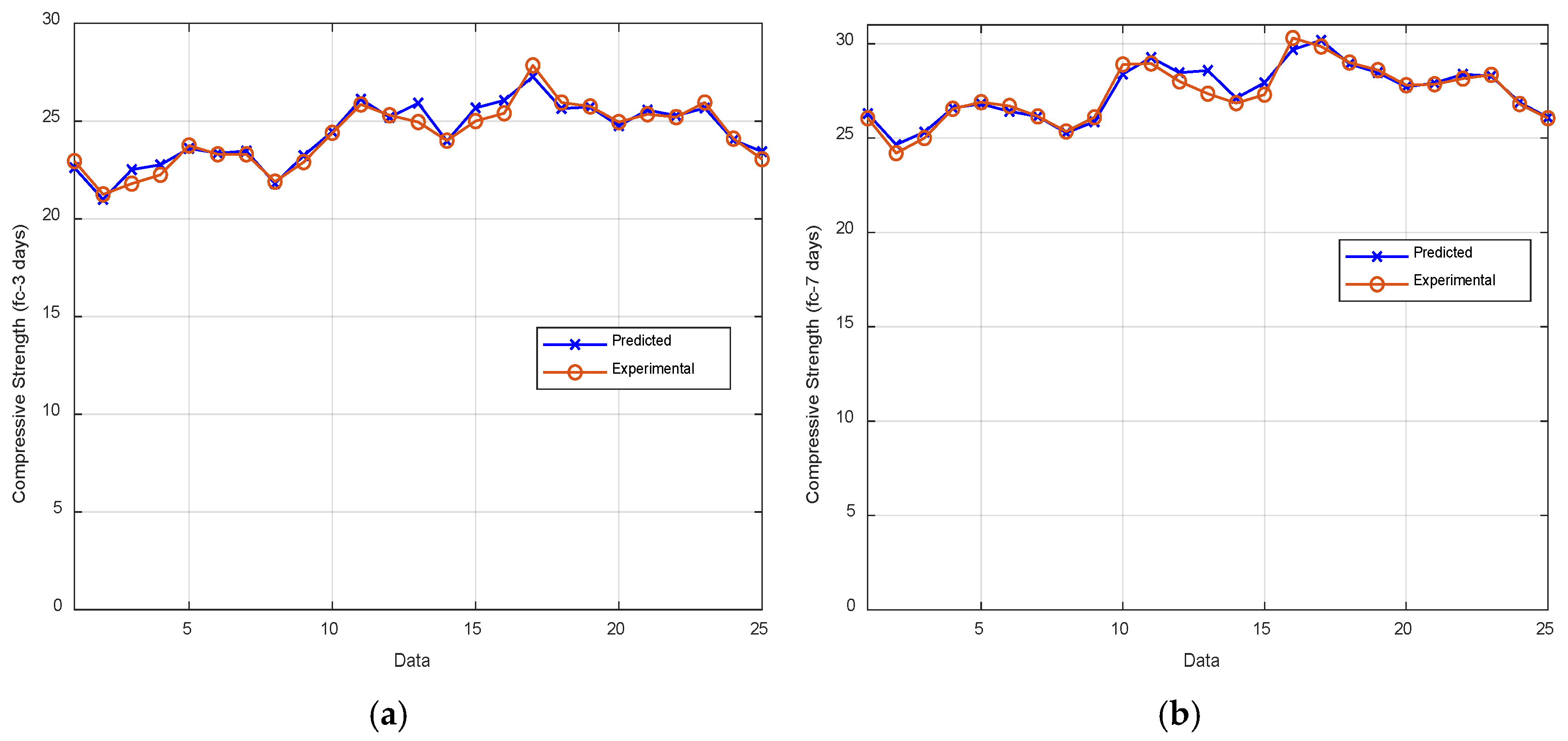

3.2. Artificial Neural Network and Its Evaluation

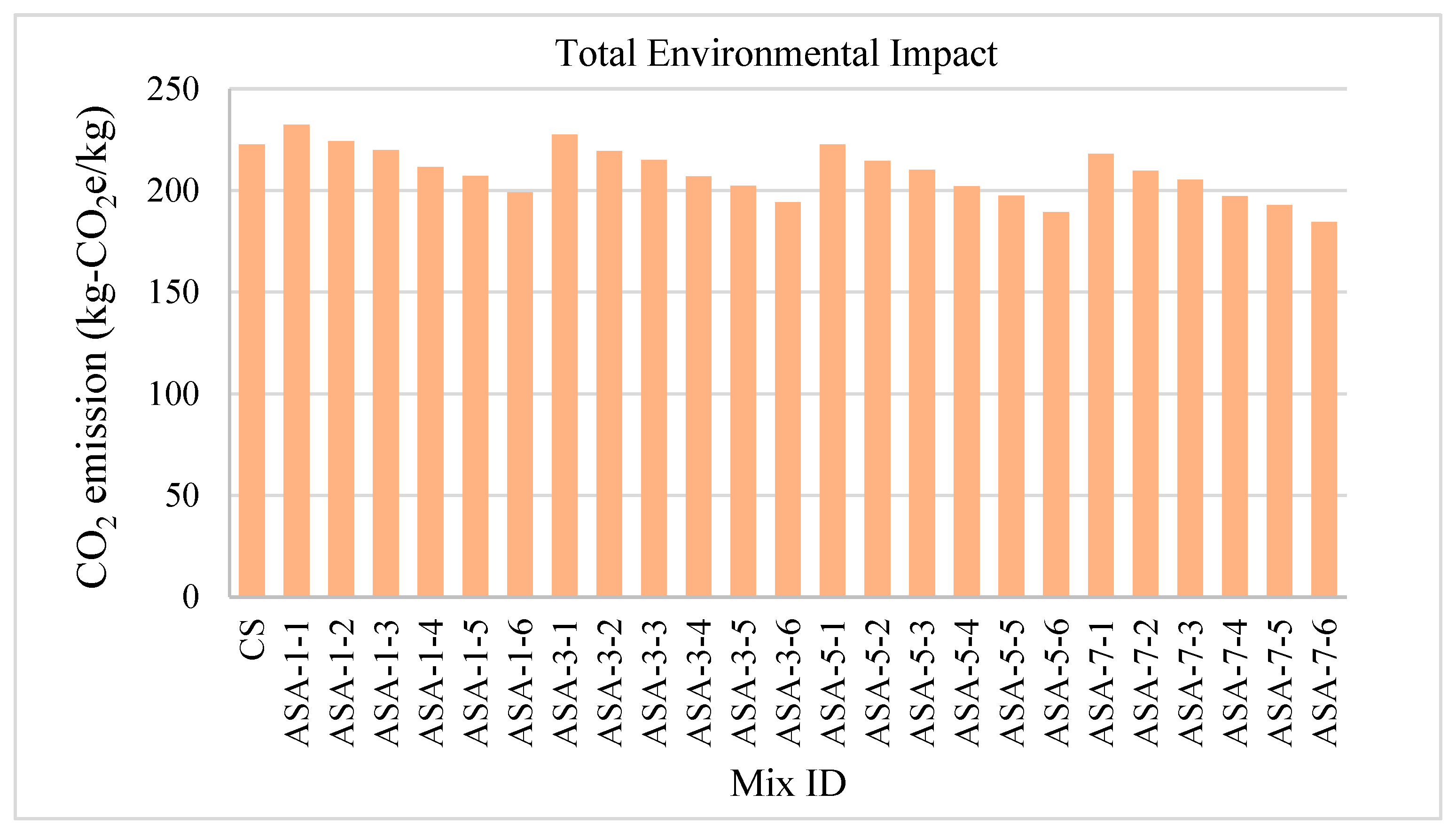

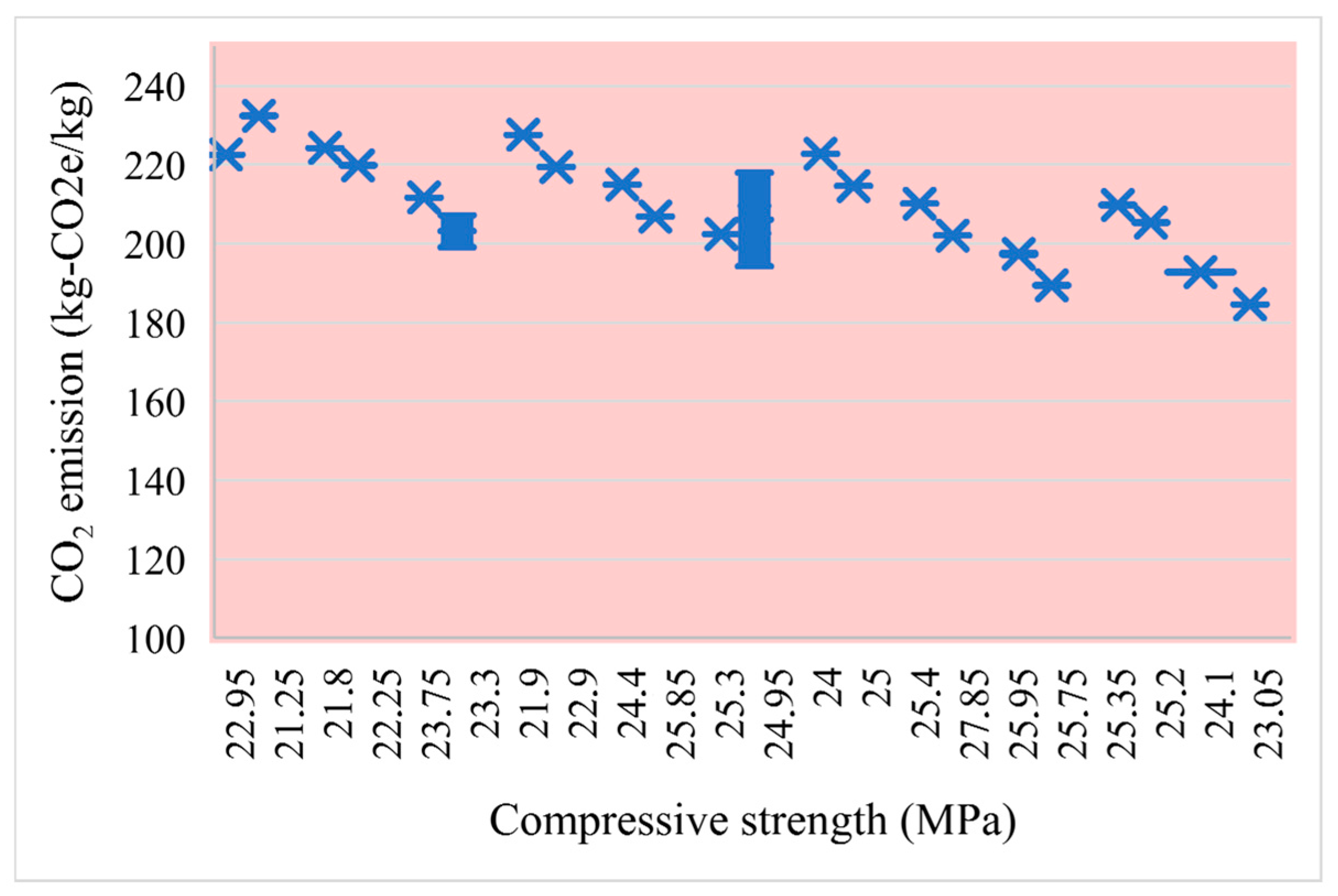

4. Environmental Impact Results

4.1. Goal and Scope

4.2. Global Warming Potential

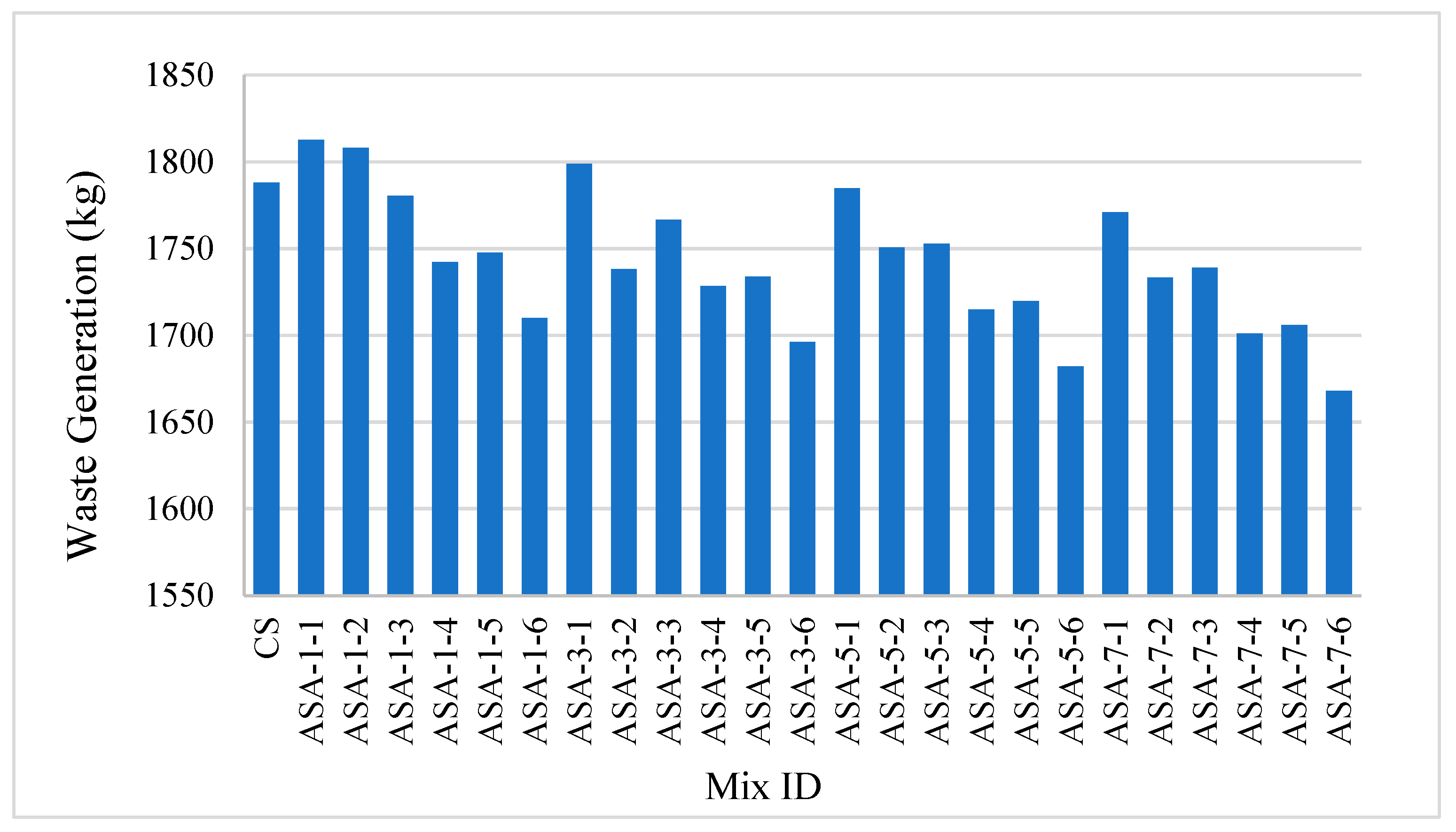

4.3. Waste Generation

5. Conclusions

- (1)

- The use of ASA with cement-based materials in concrete production has improved the concrete performance and significantly reduced the carbon footprint. Using ASA in conjunction with cement-based materials in concrete production has improved concrete performance and significantly reduced its carbon footprint. Furthermore, the optimum ASA usage rate in concrete mixtures was 5%. For silica fume and metakaolin, these rates were 10% and 10%, respectively. Based on these results, it was determined that biochar has potential for use in concrete and can be used as an alternative to aluminum-nano-silica-based materials such as silica fume and metakaolin.

- (2)

- Experiments have shown that using biochar with a higher silica content in concrete mixtures up to a certain level increases compressive strength. However, using AS above the optimum value results in a decrease in strength.

- (3)

- The fact that the strength tends to increase as the ASA usage rate increases up to a certain percentage leads to the conclusion that this material exhibits good hydration and filling effects.

- (4)

- In this study, a time and cost-saving approach was adopted to evaluate the compressive strength of concrete without the need to conduct several experimental tests, and an ANN-based prediction model was developed. The model predicted the performance of concrete with high accuracy, and a strong agreement was obtained between the predicted results and the experimental data. These results emphasize the importance of using alternative materials to cement and show that AI-based approaches are an effective tool for more environmentally sustainable concrete production.

- (5)

- Using five-fold cross-validation to evaluate model reliability, the performance of the proposed ANN model was compared with other artificial intelligence techniques, including SVM, GPR, kernel-based, and ensemble methods. The ANN achieved the best results with an R value of 0.84 and an MSE of 0.30, while the other techniques showed lower accuracies (R = 0.32–0.67, MSE = 0.33–0.68). These results demonstrate that the ANN model provides the most reliable predictions for the given dataset.

- (6)

- Life cycle assessments have shown significant advantages in terms of GWP and WG. This could achieve ecologically neutral emissions.

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, T.; Yue, X.; Qin, M.; Norena-Chavez, D. Towards Paris Climate Agreement goals: The essential role of green finance and green technology. Energy Econ. 2024, 129, 107273. [Google Scholar] [CrossRef]

- Gonnon, P.; Lootens, D. Toward net zero carbon for concrete and mortar: Clinker substitution with ground calcium carbonate. Cem. Concr. Compos. 2023, 142, 105190. [Google Scholar] [CrossRef]

- Wen, W.; Su, Y.; Tang, Y.; Zhang, X.; Hu, Y. Evaluating carbon emissions reduction compliance based on’dual control’policies of energy consumption and carbon emissions in China. J. Environ. Manag. 2024, 367, 121990. [Google Scholar] [CrossRef]

- Gomes, K.C.; Carvalho, M.; Diniz, D.d.P.; Abrantes, R.d.C.C.; Branco, M.A.; Carvalho, P.R.O.d. Carbon emissions associated with two types of foundations: CP-II Portland cement-based composite vs. geopolymer concrete. Matéria 2019, 24, e12525. [Google Scholar] [CrossRef]

- Tang, X.; Liu, S.; Wang, Y.; Wan, Y. Study on carbon emission reduction countermeasures based on carbon emission influencing factors and trends. Environ. Sci. Pollut. Res. 2024, 31, 14003–14022. [Google Scholar] [CrossRef] [PubMed]

- Martínez, A.; Miller, S.A. Life cycle assessment and production cost of geopolymer concrete: A meta-analysis. Resour. Conserv. Recycl. 2025, 215, 108018. [Google Scholar] [CrossRef]

- Zhuge, Y.; Duan, W.; Liu, Y. Utilization of wood waste ash in green concrete production. In Sustainable Concrete Made with Ashes and Dust from Different Sources; Elsevier: Amsterdam, The Netherlands, 2022; pp. 419–450. [Google Scholar]

- Xu, L.; Wang, J.; Hu, X.; Ran, B.; Wu, T.; Zhou, X.; Xiong, Y. Physical performance, durability, and carbon emissions of recycled cement concrete and fully recycled concrete. Constr. Build. Mater. 2024, 447, 138128. [Google Scholar] [CrossRef]

- Galusnyak, S.C.; Petrescu, L.; Cormos, C.C. Environmental impact assessment of post-combustion CO2 capture technologies applied to cement production plants. J. Environ. Manag. 2022, 320, 115908. [Google Scholar] [CrossRef]

- Ahmad, S.; Al-Amoudi, O.S.B.; Khan, S.M.S.; Maslehuddin, M. Effect of silica fume inclusion on the strength, shrinkage and durability characteristics of natural pozzolan-based cement concrete. Case Stud. Constr. Mater. 2022, 17, e01255. [Google Scholar] [CrossRef]

- Demir, T.; Ulucan, M.; Alyamac, K.E. Development of Combined Methods Using Non-Destructive Test Methods to Determine the In-Place Strength of High-Strength Concretes. Processes 2023, 11, 673. [Google Scholar] [CrossRef]

- Derinpinar, A.N.; Karakoç, M.B.; Özcan, A. Performance of glass powder substituted slag based geopolymer concretes under high temperature. Constr. Build. Mater. 2022, 331, 127318. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Mechanical behaviour and microstructural investigation of geopolymer concrete after exposure to elevated temperatures. Arab. J. Sci. Eng. 2020, 45, 3843–3861. [Google Scholar] [CrossRef]

- Abdulkareem, O.M.; Ben Fraj, A.; Bouasker, M.; Khelidj, A. Mixture design and early age investigations of more sustainable UHPC. Constr. Build. Mater. 2018, 163, 235–246. [Google Scholar] [CrossRef]

- Paul, D.; Bindhu, K.R.; Matos, A.M.; Delgado, J. Eco-friendly concrete with waste glass powder: A sustainable and circular solution. Constr. Build. Mater. 2022, 355, 129217. [Google Scholar] [CrossRef]

- Adamu, M.; Alanazi, H.; Ibrahim, Y.E.; Abdellatief, M. Mechanical, microstructural characteristics and sustainability analysis of concrete incorporating date palm ash and eggshell powder as ternary blends cementitious materials. Constr. Build. Mater. 2024, 411, 134753. [Google Scholar] [CrossRef]

- Amin, M.; Attia, M.M.; Agwa, I.S.; Elsakhawy, Y.; El-hassan, K.A.; Abdelsalam, B.A. Effects of sugarcane bagasse ash and nano eggshell powder on high-strength concrete properties. Case Stud. Constr. Mater. 2022, 17, e01528. [Google Scholar] [CrossRef]

- Amna, N.; Faheem, B.; Farhan, A. Enhanced mechanical and axial resilience of recycled plastic aggregate concrete reinforced with silica fume and fibers. Innov. Infrastruct. Solut. 2025, 10, 4. [Google Scholar] [CrossRef]

- Arslan, F.; Benli, A.; Karatas, M. Effect of high temperature on the performance of self-compacting mortars produced with calcined kaolin and metakaolin. Constr. Build. Mater. 2020, 256, 119497. [Google Scholar] [CrossRef]

- Hamalı, Y. Properties of Mortars and Concretes Containing Metakaolin and Silica Fume. Master’s Thesis, Istanbul Technical University, Institute of Science, Istanbul, Turkey, 2007. [Google Scholar]

- Bheel, N.; Chohan, I.M.; Ghoto, A.A.; Abbasi, S.A.; Tag-eldin, E.M.; Almujibah, H.R.; Ahmad, M.; Benjeddou, O.; Gonzalez-Lezcano, R.A. Synergistic Effect of recycling waste coconut shell ash, metakaolin, and calcined clay as supplementary cementitious material on hardened properties and embodied carbon of High strength concrete. Case Stud. Constr. Mater. 2024, 20, e02980. [Google Scholar] [CrossRef]

- Abdellatief, M.; AL-adamu, S.M.; Elemam, W.E.; Alanazi, H.; Elgendy, G.M.; Tahwia, A.M. Development of ultra-high-performance concrete with low environmental impact integrated with metakaolin and industrial wastes. Case Stud. Constr. Mater. 2022, 18, e01724. [Google Scholar] [CrossRef]

- Wang, X.Y.; Lee, H.S. Microstructure modeling of carbonation of metakaolin blended concrete. Adv. Concr. Constr. 2019, 7, 167–174. [Google Scholar]

- Kaplan, A.N.; Tufan, M.Z.; Özel, C. Investigation of some cellulose derivatives effects on concrete properties using response surface methodology. Constr. Build. Mater. 2024, 416, 135115. [Google Scholar] [CrossRef]

- Kandasamy, S. Investigation study data to develop sustainable concrete mix using waste materials as constituents. Data Br. 2024, 52, 109837. [Google Scholar]

- Krishnan, A.; Subramanian, S.S. Effect of green gram pod ash (GGPA) as supplementary cementitious material (SCM) in mechanical and durability properties of concrete. Constr. Build. Mater. 2024, 411, 134663. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q. Preparation of green concrete from bamboo biochar (BB) and concrete slurry waste (CSW): Preparation method and performance evaluation. Constr. Build. Mater. 2025, 462, 139964. [Google Scholar] [CrossRef]

- Zou, S.; Chen, X.; Sham, M.L.; Lu, J.X.; Poon, C.S. Carbon sequestration in aggregate and concrete by encapsulated biochar and carbonation: Experiment and simulation. Cem. Concr. Compos. 2025, 159, 105990. [Google Scholar] [CrossRef]

- Raj, V.R.; Parthasarathy, K.; Kumar, D.P.; Dwivedi, Y.D.; Sathish, T. Evaluation of the mechanical strength of mortars with almond shell ash. Mater. Today Proc. 2023, in press.

- Tan, T.H.; Mo, K.H.; El-Hassan, H. Biochar waste biomass in pervious concrete. In Pervious Concrete Pavements; Elsevier: Amsterdam, The Netherlands, 2025; pp. 113–131. [Google Scholar]

- Chen, L.; Zhang, Y.; Wang, L.; Ruan, S.; Chen, J.; Li, H.; Yang, J.; Mechtcherine, V.; Tsang, D.C.W. Biochar-augmented carbon-negative concrete. Chem. Eng. J. 2022, 431, 133946. [Google Scholar]

- Aman, A.M.N.; Selvarajoo, A.; Lau, T.L.; Chen, W.H. Biochar as cement replacement to enhance concrete composite properties: A review. Energies 2022, 15, 7662. [Google Scholar] [CrossRef]

- Tayyab, S.; Ferdous, W.; Lokuge, W.; Siddique, R.; Manalo, A. Biochar in cementitious composites: A comprehensive review of properties, compatibility, and prospect of use in sustainable geopolymer concrete. Resour. Conserv. Recycl. Adv. 2024, 25, 200242. [Google Scholar] [CrossRef]

- Lin, X.; Li, W.; Guo, Y.; Dong, W.; Castel, A.; Wang, K. Biochar-cement concrete toward decarbonisation and sustainability for construction: Characteristic, performance and perspective. J. Clean. Prod. 2023, 419, 138219. [Google Scholar] [CrossRef]

- Dong, Y. Performance assessment and design of ultra-high performance concrete (UHPC) structures incorporating life-cycle cost and environmental impacts. Constr. Build. Mater. 2018, 167, 414–425. [Google Scholar] [CrossRef]

- Wang, J.; Xu, L.; Li, M.; Wang, Y.; He, H.; Xiang, D.; Li, K.; Hao, T. Investigations on factors influencing physical properties of recycled cement and the related carbon emissions and energy consumptions. J. Clean. Prod. 2023, 414, 137715. [Google Scholar] [CrossRef]

- Salgado-Ramos, M.; Martí-Quijal, F.J.; Huertas-Alonso, A.J.; Sánchez-Verdú, M.P.; Barba, F.J.; Moreno, A. Almond hull biomass: Preliminary characterization and development of two alternative valorization routes by applying innovative and sustainable technologies. Ind. Crops Prod. 2022, 179, 114697. [Google Scholar] [CrossRef]

- TS EN 196-2; Methods of Testing Cement. Turkish Standards Institute: Ankara, Türkiye, 2010.

- Sirico, A.; Bernardi, P.; Sciancalepore, C.; Vecchi, F.; Malcevschi, A.; Belletti, B.; Milanese, D. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 2021, 303, 124500. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Kanavaris, F. Biochar-concrete: A comprehensive review of properties, production and sustainability. Case Stud. Constr. Mater. 2024, 20, e02859. [Google Scholar] [CrossRef]

- Ofori-Boadu, A.N.; Bryant, D.; Bock-Hyeng, C.; Zerihun, A.; Frederick, A.; Samira, M.; Elham, F. Physiochemical characterization of agricultural waste biochars for partial cement replacement. Int. J. Build. Pathol. Adapt. 2022, 40, 569–586. [Google Scholar] [CrossRef]

- El Mashad, H.M.; Edalati, A.; Zhang, R.; Jenkins, B.M. Production and characterization of biochar from almond shells. Clean Technol. 2022, 4, 854–864. [Google Scholar] [CrossRef]

- Senadheera, S.S.; Gupta, S.; Kua, H.W.; Hou, D.K.; Tsang Daniel, C.W.; Ok, Y.S. Application of biochar in concrete—A review. Cem. Concr. Compos. 2023, 143, 105204. [Google Scholar] [CrossRef]

- Murali, G.; Wong, L.S. A comprehensive review of biochar-modified concrete: Mechanical performance and microstructural insights. Constr. Build. Mater. 2024, 425, 135986. [Google Scholar] [CrossRef]

- ISO 589; Hard Coal-Determination of Total Moisture. ISO: Switzerland, Geneva, 2008.

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete. ASTM: West Conshohocken, PA, USA, 2019.

- TS EN 196-5; Cement-Test Methods-Part 5: Test for Pozzolanicity of Pozzolanic Cements. Turkish Standards Institute: Ankara, Türkiye, 2002.

- Açikgenç, M.; Ulaş, M.; Alyamaç, K.E. Using an artificial neural network to predict mix compositions of steel fiber-reinforced concrete. Arab. J. Sci. Eng. 2015, 40, 407–419. [Google Scholar]

- Shafaie, V.; Ghodousian, O.; Ghodousian, A.; Cucuzza, R.; Rad, M.M. Integrating push-out test validation and fuzzy logic for bond strength study of fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2024, 425, 136062. [Google Scholar]

- Coşkun, F.; Gülleroğlu, H.D. Historical development of artificial intelligence and its use in education. Ank. Univ. J. Fac. Educ. Sci. 2021, 54, 947–966. [Google Scholar]

- Duranay, Z.B.; Guldemir, H. Power Prediction in Photovoltaic Systems with Neural Networks: A Multi-Parameter Approach. Appl. Sci. 2025, 15, 3615. [Google Scholar] [CrossRef]

- Güçlüer, K.; Özbeyaz, A.; Göymen, S.; Günaydın, O. A comparative investigation using machine learning methods for concrete compressive strength estimation. Mater. Today Commun. 2021, 27, 102278. [Google Scholar] [CrossRef]

- Demir, T.; Duranay, Z.B.; Demirel, B.; Yildirim, B. Artificial neural network evaluation of concrete performance exposed to elevated temperature with destructive–non-destructive tests. Neural Comput. Appl. 2024, 36, 17079–17093. [Google Scholar] [CrossRef]

- Duranay, Z.B.; Aslan Topçuoğlu, Y.; Gürocak, Z. Estimation of Compressive Strength of Basalt Fiber-Reinforced Kaolin Clay Mixture Using Extreme Learning Machine. Materials 2025, 18, 245. [Google Scholar] [CrossRef]

- ISO 14044: 2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Duranay, Z.B. Extreme learning machine-based power forecasting in photovoltaic systems. IEEE Access 2023, 11, 128923–128931. [Google Scholar] [CrossRef]

- Murad, Y. Compressive strength prediction for concrete modified with nanomaterials. Case Stud. Constr. Mater. 2021, 15, e00660. [Google Scholar] [CrossRef]

- Panchal, J.N.; Challagulla, S.P.; Kishore, I.S. Influence of palm oil fuel ash on strength properties of concrete. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1197, 12082. [Google Scholar] [CrossRef]

- Aslan Topçuoğlu, Y.; Duranay, Z.B.; Gürocak, Z.; Güldemir, H. AI-Driven Analysis of Tuff and Lime Effects on Basalt Fiber-Reinforced Clay Strength. Buildings 2025, 15, 2433. [Google Scholar] [CrossRef]

- Kina, C.; Tanyildizi, H.; Acik, V. Hybrid portland cement-slag-based geopolymer mortar: Strength, microstructural and environmental assessment. Process Saf. Environ. Prot. 2025, 195, 106771. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Alengaram, U.J.; Praveen, B.; Tattukolla, K. Performance evaluation on engineering properties and sustainability analysis of high strength geopolymer concrete. J. Build. Eng. 2022, 60, 105147. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K.; Viegas, R. Material efficiency in the design of UHPC paste from a life cycle point of view. Constr. Build Mater. 2018, 160, 505–513. [Google Scholar] [CrossRef]

- Miyan, N.; Omur, T.; Amed, B.; Özkan, H.; Aydın, R.; Kabay, N. Recycled waste concrete and metakaolin based alkali-activated paste: Characterization, optimization, and life cycle assessment. Constr. Build. Mater. 2024, 416, 135233. [Google Scholar] [CrossRef]

- Bhandari, I.; Kumar, R. Effect of silica fume and PCE-HPMC on LC3 mortar: Microstructure, statistical optimization and life cycle Assessment. Constr. Build Mater. 2023, 403, 133073. [Google Scholar] [CrossRef]

- Fan, J.; Yeo, B.L.; Markandeya, A.; Martínez, A.; Harvey, J.; Miller, S.A.; Nassiri, S. Transforming almond shell waste into high-value activators for low-carbon concrete: Life cycle assessment and technoeconomic analysis. J. Build. Eng. 2025, 105, 112547. [Google Scholar] [CrossRef]

- Lyu, B.C.; Guo, L.P.; Fei, X.P.; Wu, J.D.; Bian, R.S. Preparation and properties of green high ductility geopolymer composites incorporating recycled fine brick aggregate. Cem. Concr. Compos. 2023, 139, 105054. [Google Scholar] [CrossRef]

- Mim, N.J.; Meraz, M.M.; Islam, M.H.; Farsangi, E.N.; Mehedi, M.T.; Arafin, S.A.K.; Shrestha, R.K. Eco-friendly and cost-effective self-compacting concrete using waste banana leaf ash. J. Build. Eng. 2023, 64, 105581. [Google Scholar] [CrossRef]

- Ulucan, M. From waste to sustainable production: Experimental design and optimization of sustainable concrete using response surface methodology and life cycle assessment. Sustain. Chem. Pharm. 2024, 42, 101770. [Google Scholar] [CrossRef]

- Manjunatha, M.; Preethi, S.; Mounika, H.G.; Niveditha, K.N. Life cycle assessment (LCA) of concrete prepared with sustainable cement-based materials. Mater. Today Proc. 2021, 47, 3637–3644. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Saha, A.K.; Sarker, P.K. Reuse of waste glass as a supplementary binder and aggregate for sustainable cement-based construction materials: A review. J. Build. Eng. 2020, 28, 101052. [Google Scholar] [CrossRef]

- Ozcelikci, E.; Hu, M.; van der Meide, M.; Sahmaran, M. Life cycle assessment of SCM substitution in various CDW-based geopolymer concretes and sensitivity analyses on allocation methods. Waste Manag. 2025, 205, 115034. [Google Scholar] [CrossRef] [PubMed]

- González-Quintero, R.; Bolívar-Vergara, D.M.; Chirinda, N.; Arango, J.; Pantevez, H.; Barahona-Rosales, R.; Sánchez-Pinzón, M.S. Environmental impact of primary beef production chain in Colombia: Carbon footprint, non-renewable energy and land use using Life Cycle Assessment. Sci. Total Environ. 2021, 773, 145573. [Google Scholar] [CrossRef] [PubMed]

| Chemical Composition | Cement (C) | Silica Fume (SF) | Metakaolin (MK) |

|---|---|---|---|

| SiO2 | 21.12 | 94.94 | 48 |

| Al2O3 | 5.62 | 0.70 | 47 |

| Fe2O3 | 3.24 | 0.60 | 0.6 |

| CaO | 62.94 | 0.83 | <0.5 |

| MgO | 2.73 | 0.71 | <0.4 |

| SO3 | 2.30 | 0.21 | - |

| Na2O | 0.10 | - | <0.1 |

| K2O | - | - | <2 |

| Physical Composition | |||

| Density (g/cm2) | 3.15 | 2.20 | 2.64 |

| Specific surface (cm2/g) (Blaine) | 3379 | 96.5% < 45 μm | 22,000 |

| State of the Sample | Unit | Air Dry | Dry | As Received | Method of Test |

|---|---|---|---|---|---|

| Total Moisture | % | - | - | 7.18 | ISO 589 [45] |

| Inherent Moisture | % | 0.96 | - | - | ASTM D 3173 |

| Ash | % | 2.37 | 2.39 | 2.22 | ISO 1171 |

| Volatile Matter | % | 5.35 | 5.40 | 5.01 | ISO 562 |

| Total Sulphur | % | 0.02 | 0.02 | 0.02 | ASTM D 4239 |

| Fixed Carbon | % | 91.32 | 92.21 | 85.59 | ASTM D 3172 |

| Mix Code | Cement | Water | ASA | SF | MK | Fine Aggregate | Coarse-1 Aggregate | Coarse-2 Aggregate |

|---|---|---|---|---|---|---|---|---|

| CS | 298 | 175 | 0 | 24.7 | 14.8 | 447 | 447 | 596 |

| ASA-1-1 | 312 | 175 | 2.7 | 12.3 | 14.8 | 450 | 450 | 600 |

| ASA-1-2 | 294 | 175 | 2.7 | 12.3 | 29.6 | 454 | 454 | 606 |

| ASA-1-3 | 294 | 175 | 2.7 | 24.7 | 14.8 | 446 | 446 | 595 |

| ASA-1-4 | 277 | 175 | 2.7 | 24.7 | 29.6 | 440 | 440 | 586 |

| ASA-1-5 | 277 | 175 | 2.7 | 37.0 | 14.8 | 441 | 441 | 588 |

| ASA-1-6 | 259 | 175 | 2.7 | 37.0 | 29.6 | 435 | 435 | 580 |

| ASA-3-1 | 305 | 175 | 8.0 | 12.3 | 14.8 | 448 | 448 | 598 |

| ASA-3-2 | 287 | 175 | 8.0 | 12.3 | 29.6 | 435 | 435 | 580 |

| ASA-3-3 | 287 | 175 | 8.0 | 24.7 | 14.8 | 444 | 444 | 592 |

| ASA-3-4 | 270 | 175 | 8.0 | 24.7 | 29.6 | 438 | 438 | 584 |

| ASA-3-5 | 270 | 175 | 8.0 | 37.0 | 14.8 | 439 | 439 | 586 |

| ASA-3-6 | 252 | 175 | 8.0 | 37.0 | 29.6 | 433 | 433 | 578 |

| ASA-5-1 | 298 | 175 | 13.4 | 12.3 | 14.8 | 446 | 446 | 595 |

| ASA-5-2 | 280 | 175 | 13.4 | 12.3 | 29.6 | 440 | 440 | 590 |

| ASA-5-3 | 280 | 175 | 13.4 | 24.7 | 14.8 | 442 | 442 | 589 |

| ASA-5-4 | 263 | 175 | 13.4 | 24.7 | 29.6 | 436 | 436 | 581 |

| ASA-5-5 | 263 | 175 | 13.4 | 37.0 | 14.8 | 437 | 437 | 583 |

| ASA-5-6 | 245 | 175 | 13.4 | 37.0 | 29.6 | 431 | 431 | 575 |

| ASA-7-1 | 291 | 175 | 18.8 | 12.3 | 14.8 | 444 | 444 | 592 |

| ASA-7-2 | 273 | 175 | 18.8 | 12.3 | 29.6 | 438 | 438 | 584 |

| ASA-7-3 | 273 | 175 | 18.8 | 24.7 | 14.8 | 440 | 440 | 586 |

| ASA-7-4 | 256 | 175 | 18.8 | 24.7 | 29.6 | 434 | 434 | 578 |

| ASA-7-5 | 256 | 175 | 18.8 | 37.0 | 14.8 | 435 | 435 | 580 |

| ASA-7-6 | 238 | 175 | 18.8 | 37.0 | 29.6 | 429 | 429 | 572 |

| Samples | Inputs | Experimental Outputs | ANN Outputs | ||||||

|---|---|---|---|---|---|---|---|---|---|

| W/C | A/C | SF/C | MK/C | ASA/C | 3th | 7th | 3th | 7th | |

| CS | 0.587 | 5.000 | 0.083 | 0.050 | 0.000 | 22.95 | 26.05 | 22.71 | 26.22 |

| ASA-1-5 | 0.633 | 5.321 | 0.134 | 0.054 | 0.010 | 23.30 | 26.7 | 23.18 | 26.56 |

| ASA-3-5 | 0.649 | 5.433 | 0.137 | 0.055 | 0.030 | 25.30 | 28.00 | 25.15 | 28.11 |

| ASA-5-4 | 0.667 | 5.533 | 0.094 | 0.113 | 0.051 | 27.85 | 29.85 | 27.39 | 29.99 |

| ASA-7-4 | 0.685 | 5.657 | 0.097 | 0.116 | 0.074 | 25.95 | 28.35 | 25.76 | 28.29 |

| ASA-7-5 | 0.685 | 5.676 | 0.145 | 0.058 | 0.074 | 24.10 | 26.80 | 23.68 | 26.79 |

| ANN | GPR | SVM | Kernel-Based | Ensemble | |

|---|---|---|---|---|---|

| R Value | 0.84 | 0.63 | 0.67 | 0.61 | 0.32 |

| MSE Value | 0.30 | 0.37 | 0.33 | 0.39 | 0.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demir, T. Evaluation of the Use of Waste Almond Shell Ash in Concrete: Mechanical and Environmental Properties. Buildings 2025, 15, 3269. https://doi.org/10.3390/buildings15183269

Demir T. Evaluation of the Use of Waste Almond Shell Ash in Concrete: Mechanical and Environmental Properties. Buildings. 2025; 15(18):3269. https://doi.org/10.3390/buildings15183269

Chicago/Turabian StyleDemir, Tuba. 2025. "Evaluation of the Use of Waste Almond Shell Ash in Concrete: Mechanical and Environmental Properties" Buildings 15, no. 18: 3269. https://doi.org/10.3390/buildings15183269

APA StyleDemir, T. (2025). Evaluation of the Use of Waste Almond Shell Ash in Concrete: Mechanical and Environmental Properties. Buildings, 15(18), 3269. https://doi.org/10.3390/buildings15183269