Research on Optimization of Intelligent Recognition Model for Bridge Cracks Based on Dual-Parameter Error Evaluation Indexes

Abstract

1. Introduction

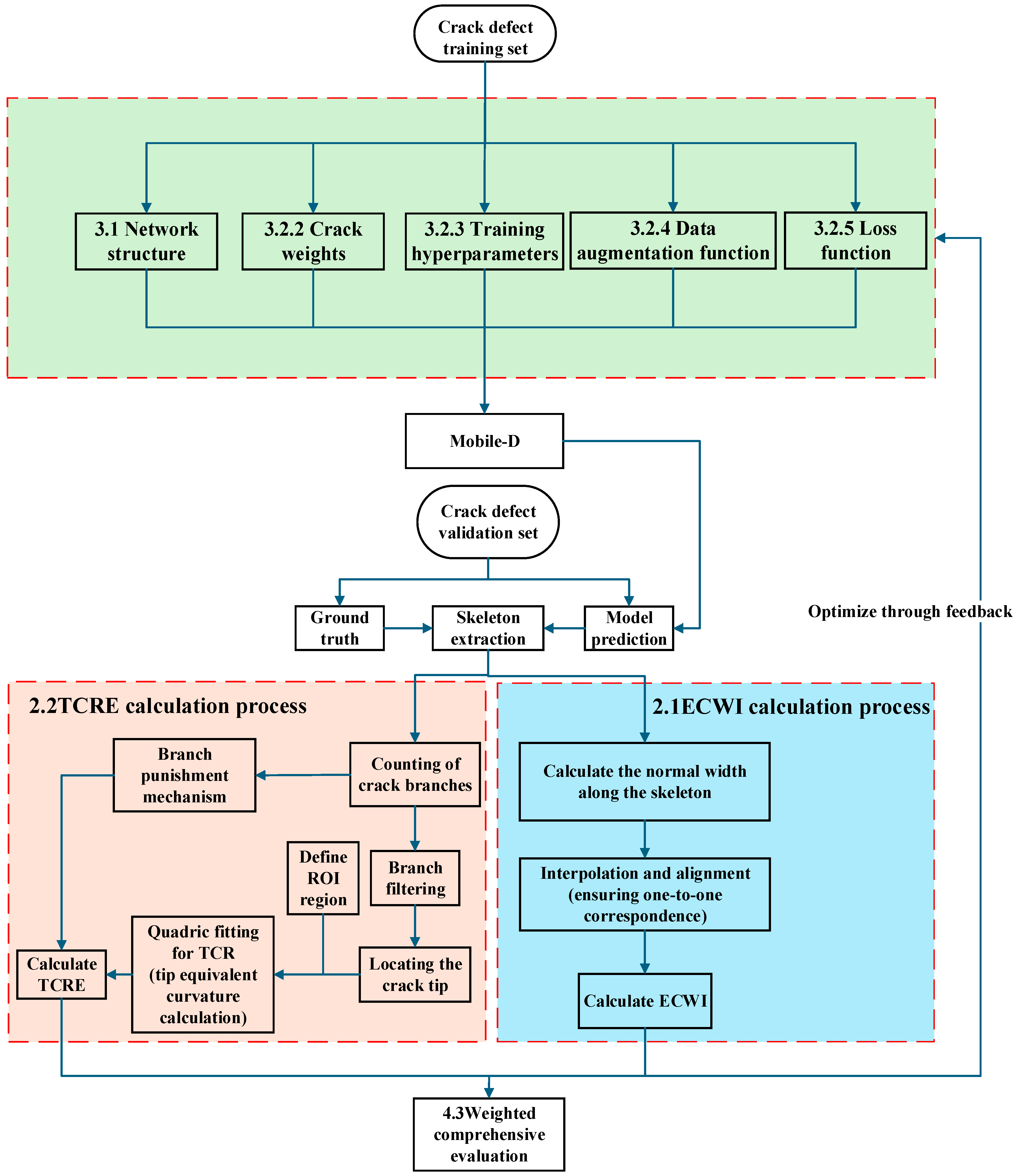

2. Dual-Parameter Evaluation Error System

2.1. Effective Crack Width Index (ECWI)

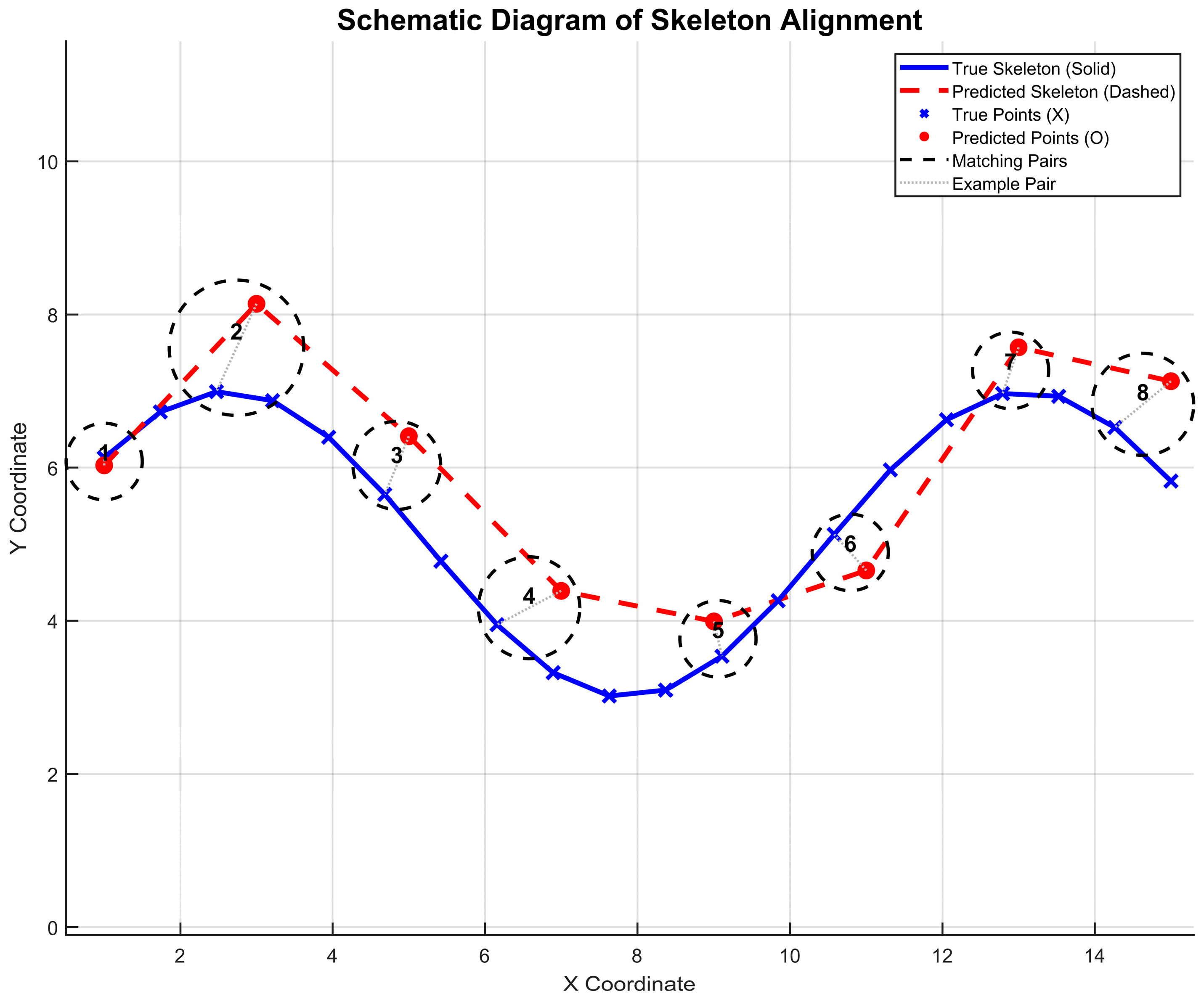

- ①

- Extract coordinates: Use the “find” function to extract the coordinates of the predicted and actual skeletons.

- ②

- Nearest neighbor matching: For each predicted skeleton point, find the nearest actual skeleton point in spatial position and use the width of this actual point as the comparison baseline. This coordinate-based nearest neighbor matching ensures that the compared width data correspond to the same spatial locations.

- ③

- Calculate ECWI: Compute the error percentage between the two sets of width data using Error Formula (1) to obtain the ECWI value.

- : Model-predicted value of concrete crack width

- : Ground truth value of concrete crack width.

2.2. Crack Tip Curvature Radius Error Index (TCRE)

- ①

- Extraction of crack skeleton endpoints.

- ②

- Selection of ROI (Region of Interest).

- ③

- Quadratic polynomial fitting and curvature calculation.

2.3. Dual-Parameter Error Evaluation Index Weight Setting

3. Model Network Structure and Framework

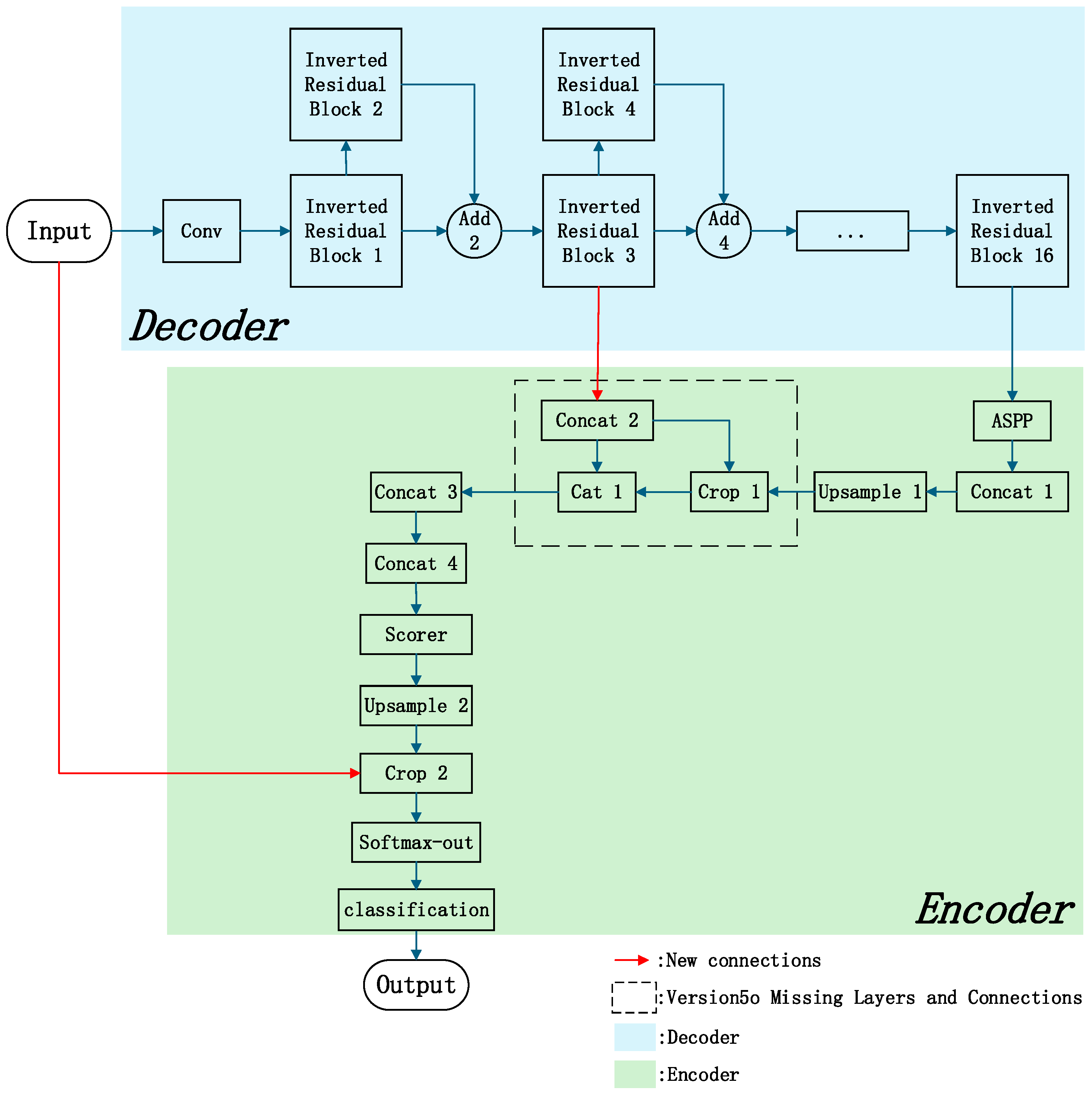

3.1. MobileNetV2-DeepLabv3+ Model

3.2. Training Dataset and Parameter Settings

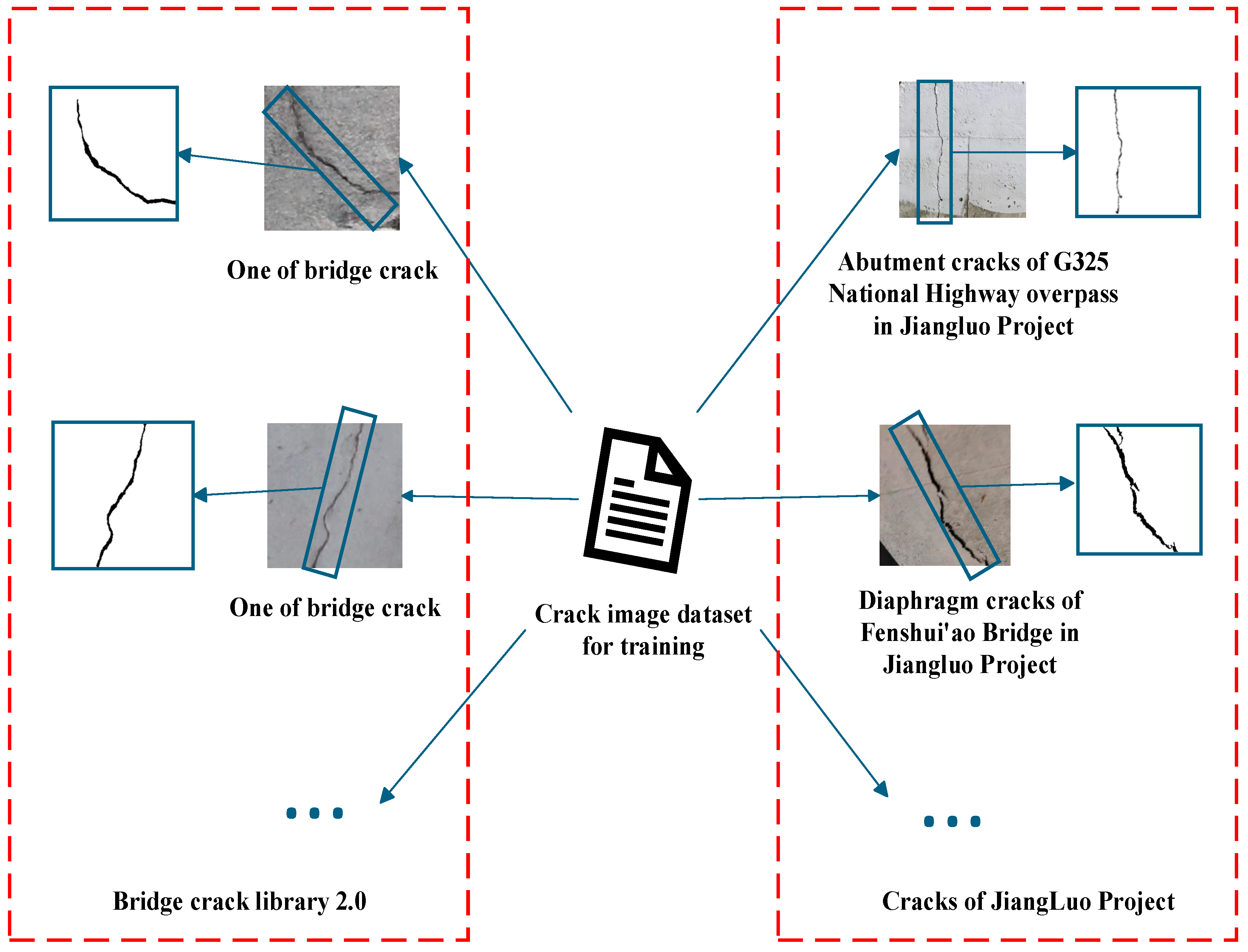

3.2.1. Training Environment and Dataset

3.2.2. Training Model Dynamic Weight Setting

3.2.3. Training Hyperparameter Settings

3.2.4. Preprocessing and Post-Processing Settings

Preprocessing Settings

- (1)

- Regarding the settings of color jitter parameters ‘Brightness’, ‘Contrast’, ‘Saturation’, and ‘Hue’, considering that there are no extreme conditions such as excessive light in the dataset, and to improve the model’s robustness against texture interference, we refer to the idea of controlling color jitter intensity in the research on image robustness enhancement by Xu et al. (CVPR 2022 Workshop) [29] and set ‘Brightness’, ‘Contrast’, and ‘Saturation’ to the conservative range [0.8, 1.0]; meanwhile, since the hue of concrete images is stable (without abrupt change characteristics), the ‘Hue’ parameter is set to 0.

- (2)

- Regarding elastic deformation, the set parameters include the maximum displacement ‘alpha’ and smoothness ‘sigma’. The adjustment of these two parameters during the iterations is shown in Table 4 below.

- (3)

- Regarding the crack width enhancement part, the width enhancement parameter was introduced starting from Version 4. Since it was observed that the actual crack width varies with shooting distance and lighting conditions (e.g., cracks appear wider in close-up shots), this enhancement was introduced to simulate such physical changes through random scaling. This was to prevent the model from overfitting to cracks of fixed widths and enable it to adapt to cracks of different scales. The dataset was initially set to have a random variation of 0.8–1.2 times (±20%), and this parameter remained unchanged in subsequent version improvements. The data supporting the effectiveness of crack width enhancement is shown in Table 5 below (selected from the summary table in Supplementary Materials Data B1).

Post-Processing Settings

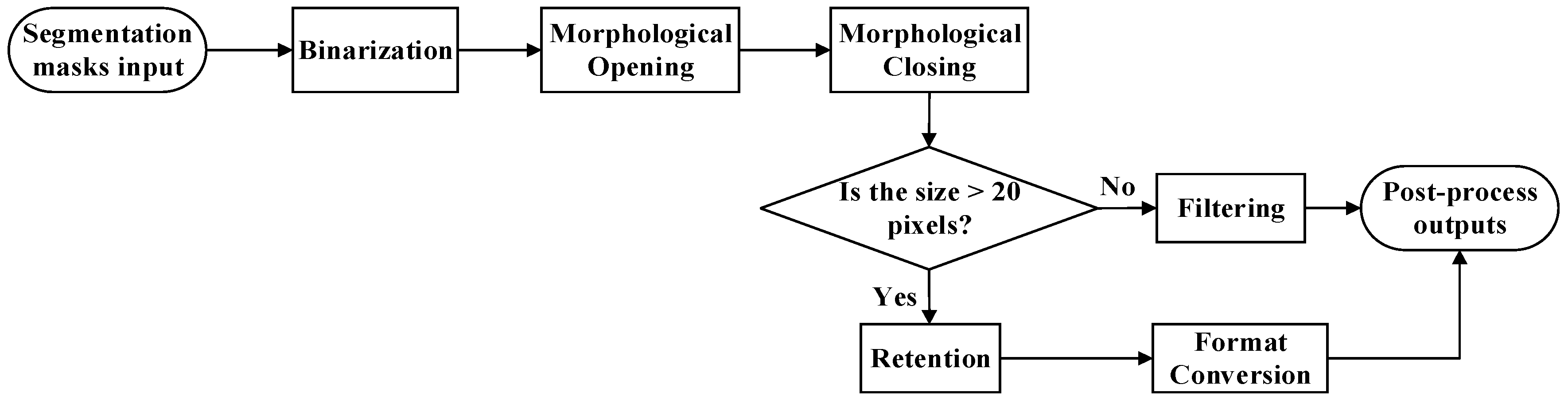

- ①

- Binarize the prediction mask: Pixels labeled as “Edge” are set to true, while the rest are set to false.

- ②

- Optimize the binary mask using morphological operations: First, an opening operation is applied to remove isolated noise and small regions; subsequently, a closing operation is used to connect fragmented target areas, forming more complete edge structures. Finally, connected noise regions with areas smaller than a threshold parameter are further filtered out [33].

- ③

- Convert the processed binary mask to classification format: Map false and true values to the “Background” and “Edge” categories, respectively. This results in a more precise and distinct segmentation, effectively improving the reliability of model predictions. The detailed post-processing workflow is illustrated in Figure 6.

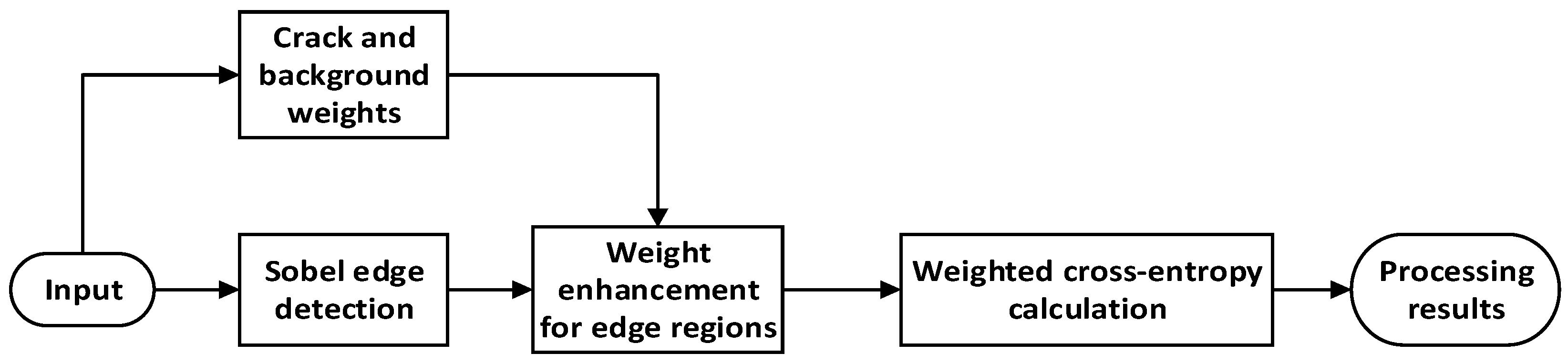

3.2.5. Selection of Loss Functions

4. Bridge Case

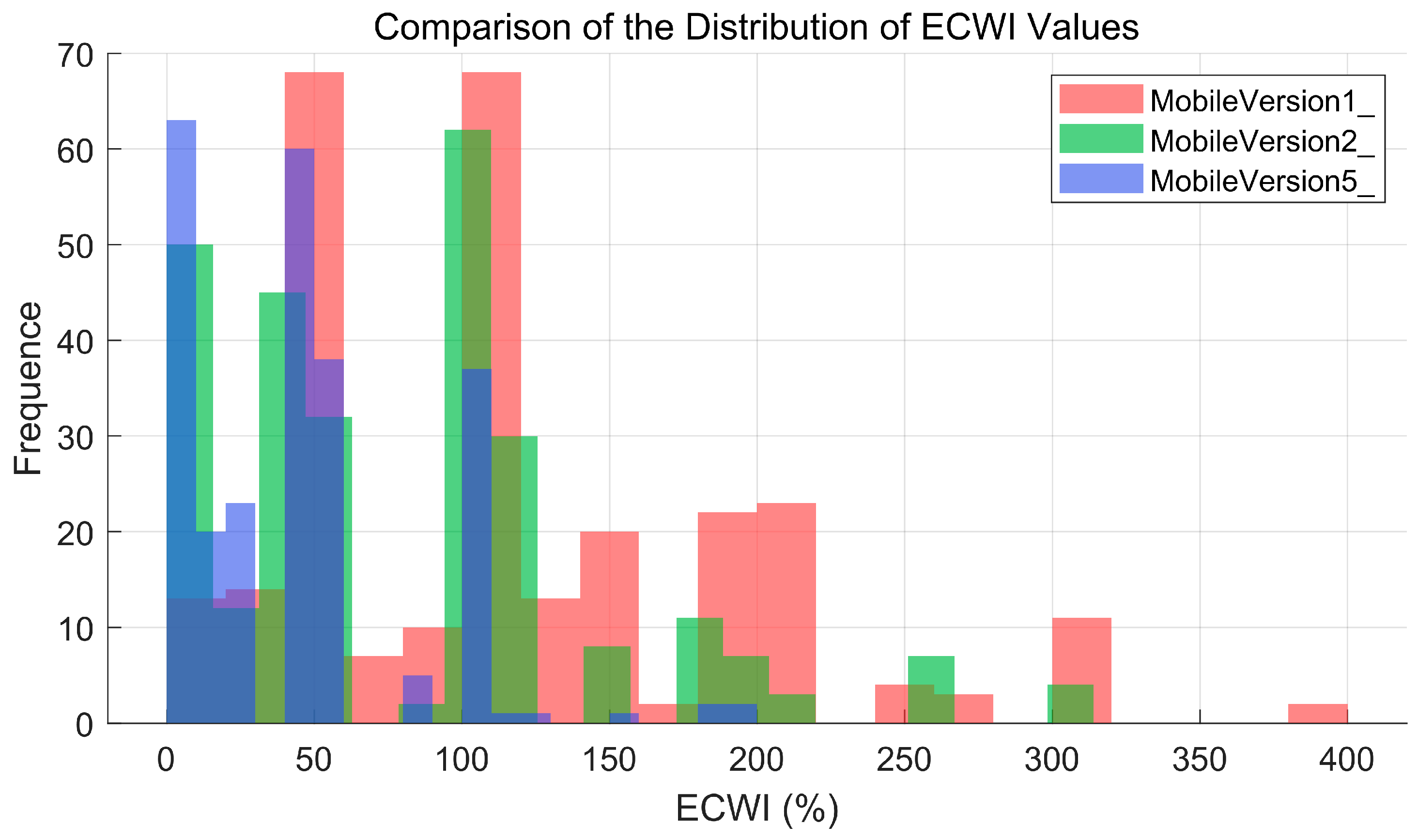

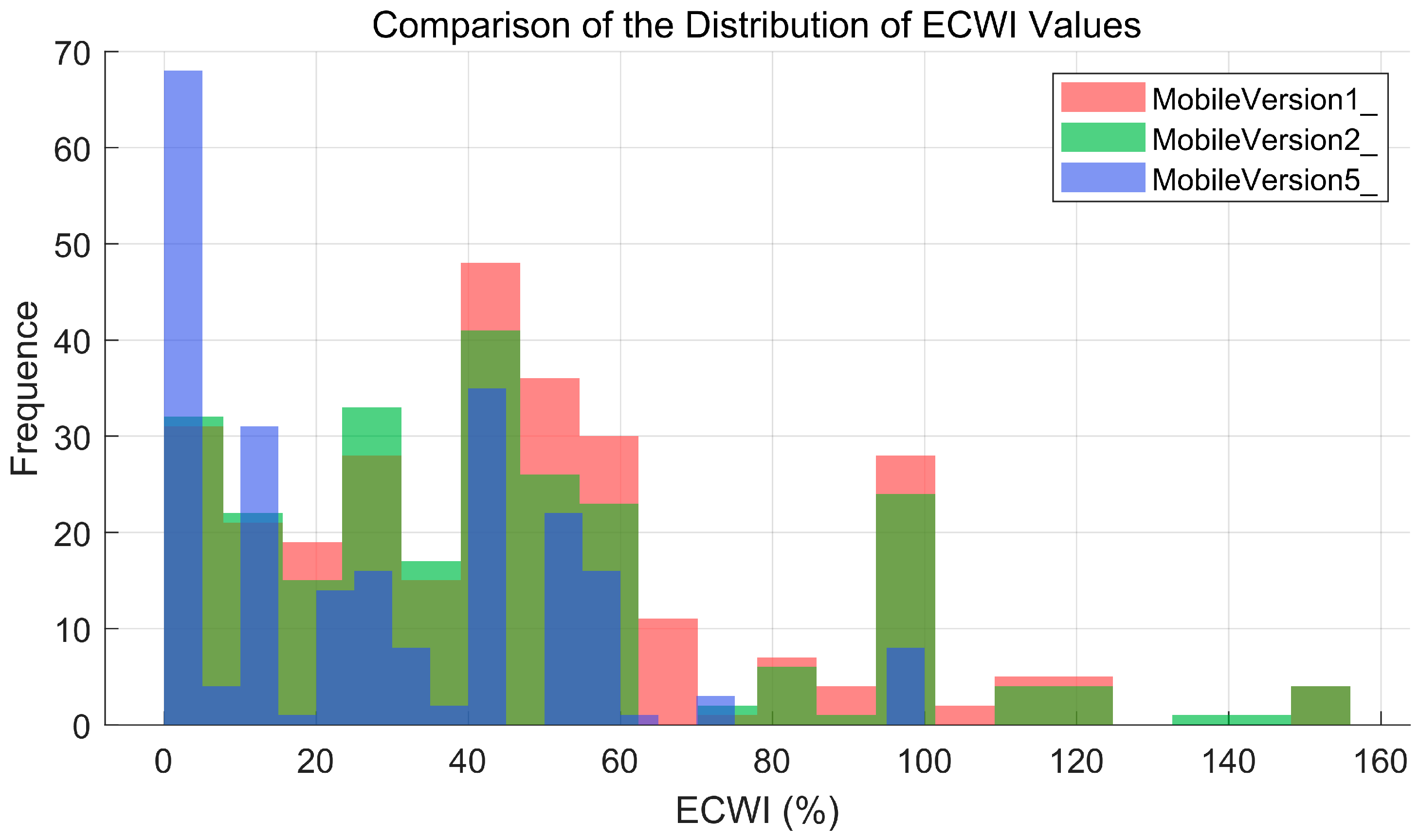

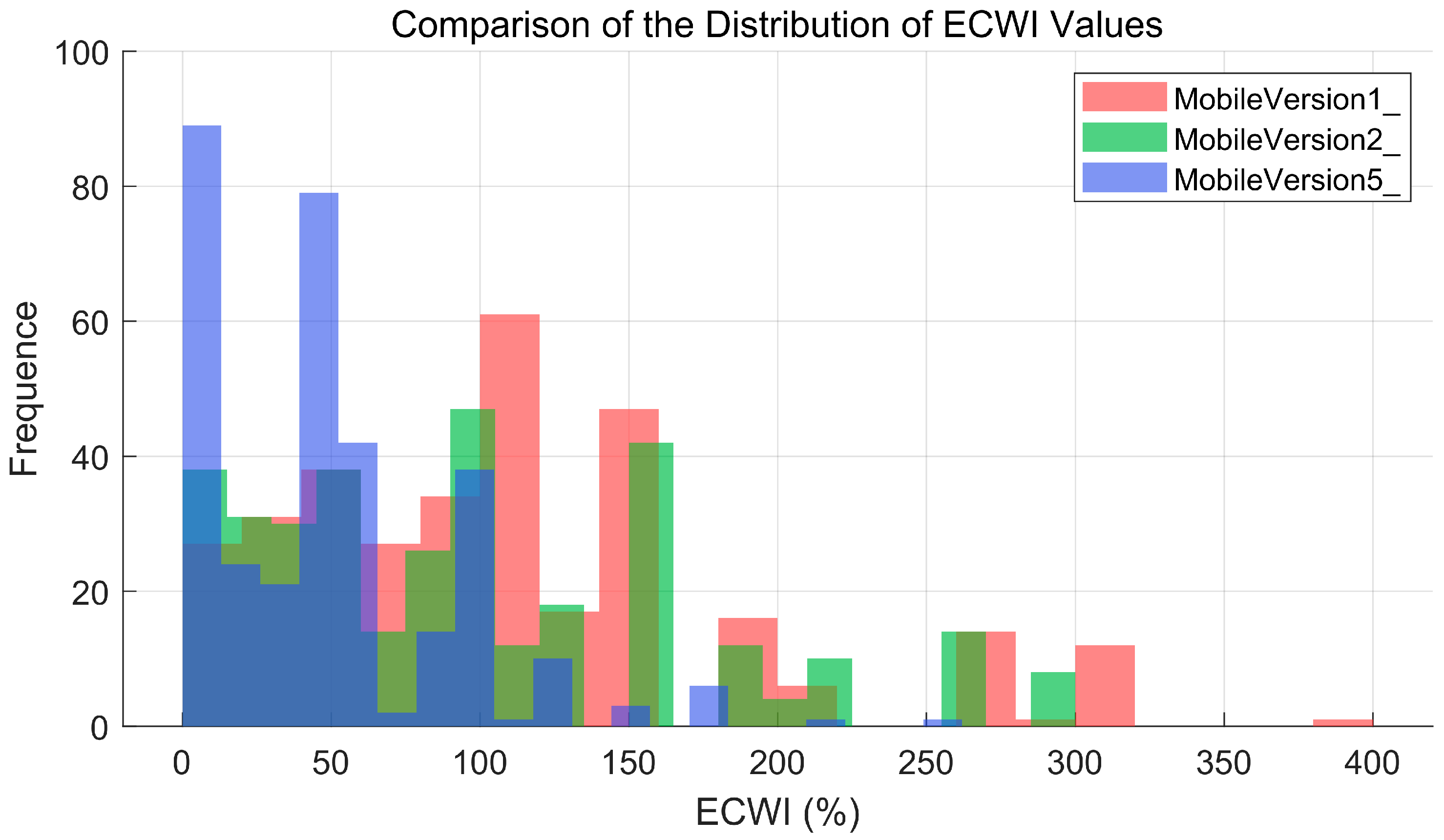

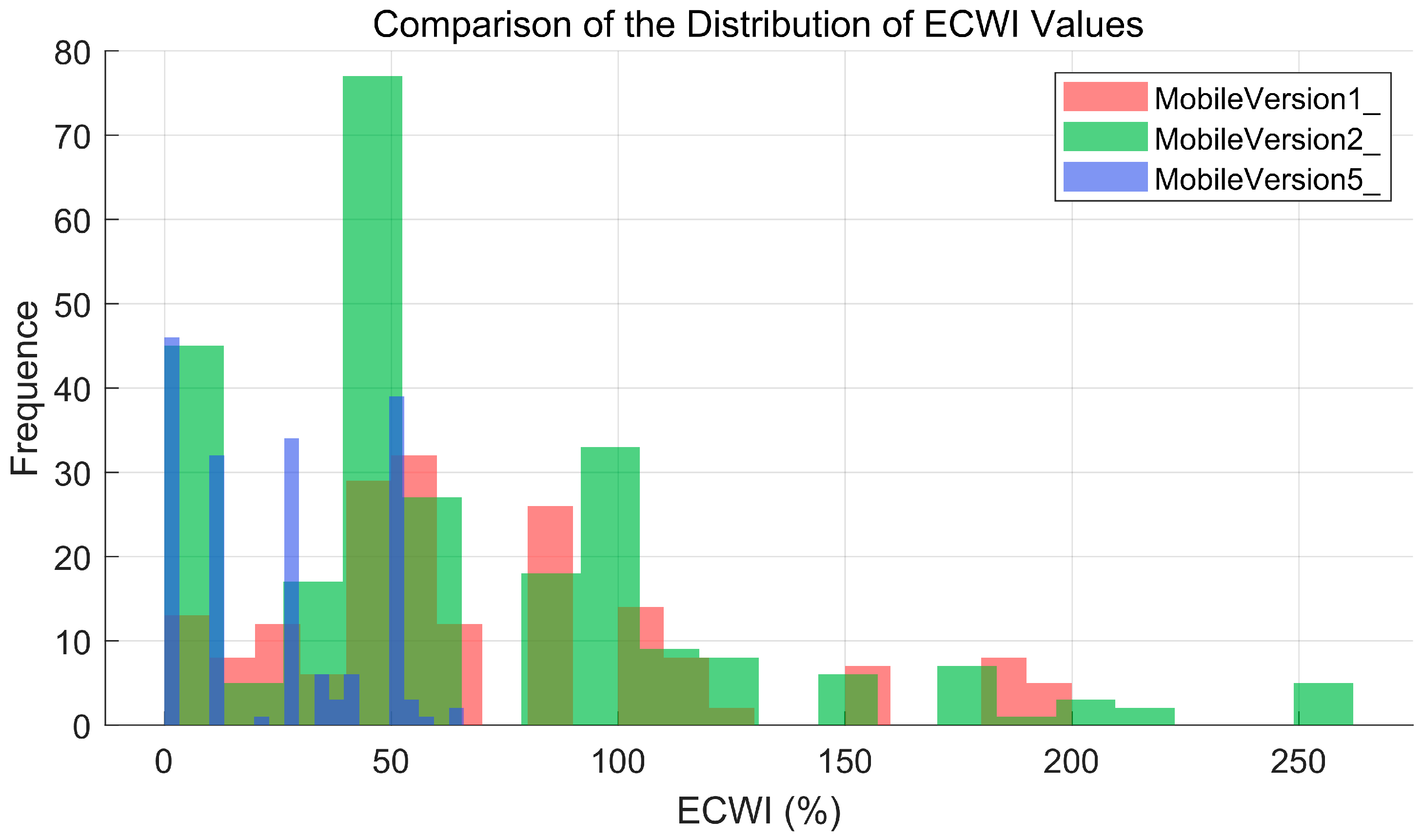

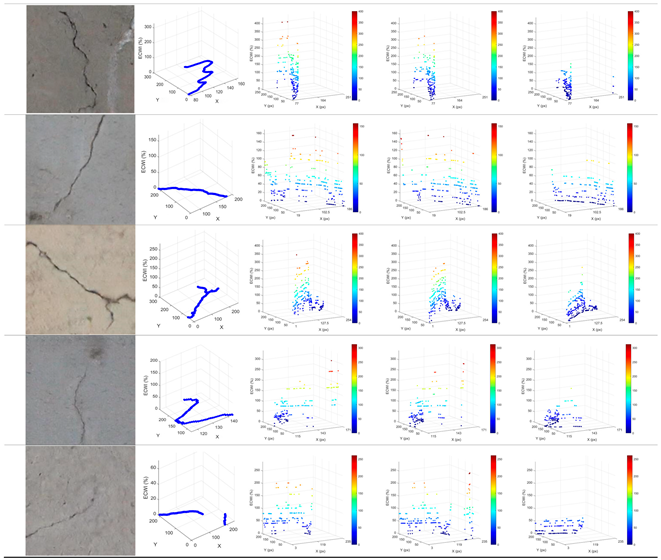

4.1. ECWI Experimental Results

4.2. TCRE Experimental Results

4.3. Weighted Comprehensive Comparison

4.4. Experiments on SDNET2018 Datasets

5. Conclusions

- (1)

- In terms of model optimization, an efficient error positive feedback optimization mechanism is established, which is applicable not only to the Mobile-D model but also to other semantic segmentation models. Through the dual-parameter comprehensive evaluation system, in-depth analysis and feedback on the detection results are conducted. Based on the analysis results, the training parameters, preprocessing function parameters, etc. are dynamically adjusted to carry out a new round of iterative training. By continuously optimizing model parameters, this mechanism effectively improves the prediction accuracy and generalization ability of the model, ensuring that the model can still maintain excellent performance in complex detection scenarios. Furthermore, when the model is applied to other datasets, its robustness and universality still perform excellently.

- (2)

- A creative geometric–mechanical dual-parameter evaluation method for crack recognition errors is proposed. Through qualitative analysis of TCRE on the key influencing factors of stress concentration errors at crack tips, the cross-disciplinary evaluation index is constructed by weighted averaging of ECWI and TCRE to assess the prediction accuracy of crack semantic segmentation models. This evaluation method complements traditional performance accuracy metrics (such as the Dice coefficient and IoU intersection ratio), enabling it to provide experimenters with a comprehensive evaluation from multiple professional perspectives. The evaluation of ECWI and TCRE can provide error references for the assessment of items related to crack defects in the bearing capacity deterioration coefficient mentioned in Article 7.7.4 [16] of the “Specification for Inspection and Evaluation of Load-bearing Capacity of Highway Bridges” (JTG/T J21-2011) in bridge inspection work. By quantifying errors generated in the detection process, it effectively reduces interference from human judgment and improves the objectivity and accuracy of bridge inspection work.

- (3)

- In terms of algorithm research, this study conducted an in-depth exploration of the implementation and optimization processes of the TCRE algorithm and ECWI algorithm. Not only was the automation of the calculation process initially realized, but through code function development, the function of outputting visualized comparison results of indicators was integrated into the algorithm code, achieving a high level of overall code integration.

- (4)

- Based on the above analysis, the current model system still has issues such as high dispersion in prediction results and poor adaptability to complex samples. In subsequent research, consideration will be given to introducing an attention mechanism module to enhance the model’s ability to perceive the curvature radius characteristics of crack endpoints, optimize the trend-capturing capability of the prediction algorithm, and thereby improve the model’s prediction accuracy and stability. Regarding model training, the optimal training configurations, such as the parameters for color jitter and elastic deformation in data augmentation, crack training weights, and training hyperparameters, still need to be further optimized and improved. For the dual-parameter evaluation system, its weighted weight values are selected in accordance with existing standards, which have certain engineering statistical significance and strong applicability. However, from the perspective of academic research, combined with model characteristics and practical applications, there is still room for optimization of this weight. In addition, the current application of TCRE only serves as a preliminary assessment of the safety of crack prediction models, and the specific mathematical relationship between TCRE and the stress field requires further in-depth research.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, T.Q.; Gou, H.Y.; Chen, X.Y.; Li, W.; Liang, H.; Chen, Z.; Zhou, S. Research progress of bridge informatization and intelligent bridges in 2020. J. Civ. Environ. Eng. (Chin. Engl.) 2021, 43, 268–279. [Google Scholar]

- Araya-Santelices, P.; Grande, Z.; Atencio, E.; Lozano-Galant, J.A. Bridge management with AI, UAVs, and BIM. Autom. Constr. 2025, 175, 106170. [Google Scholar] [CrossRef]

- Ma, T.; Xiao, F.; Zhang, C.; Zhang, J.; Zhang, H.; Xu, K.; Luo, X. Digital twin for 3D interactive building operations: Integrating BIM, IoT-enabled building automation systems, AI, and mixed reality. Autom. Constr. 2025, 176, 106277. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Shamass, R.; Guarracino, F.; Mascolo, I. Exploring the stainless-steel beam-to-column connections response: A hybrid explainable machine learning framework for characterization. Front. Struct. Civ. Eng. 2025, 19, 34–59. [Google Scholar] [CrossRef]

- Deng, Z.; Huang, M.; Wan, N.; Zhang, J. The Current Development of Structural Health Monitoring for Bridges: A Review. Buildings 2023, 13, 1360. [Google Scholar] [CrossRef]

- Le-Xuan, T.; Nguyen-Chi, T.; Bui-Tien, T.; Tran-Ngoc, H. ResUNet4T: A potential deep learning model for damage detection based on a numerical case study of a large-scale bridge using time-series data. Eng. Struct. 2025, 340, 120668. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, J.; Hu, J.; Ye, Z.; Deng, Z.; Wan, N. Nonlinear modeling of temperature-induced bearing displacement of long-span single-pier rigid frame bridge based on DCNN-LSTM. Case Stud. Therm. Eng. 2024, 53, 103897. [Google Scholar] [CrossRef]

- Huang, C.P.; Tian, W.Y.; Li, Q. Research on quantitative identification method of concrete bridge defects based on U-Net and mathematical morphology. Bridge Constr. 2025, 55, 64–71. [Google Scholar] [CrossRef]

- Ritzy, R.; Umadevi, V.A.; Girija, K.; Rajan, R. Binary-class concrete surface crack detection using a transfer learning model. Knowl.-Based Syst. 2025, 324, 113953. [Google Scholar] [CrossRef]

- Su, M.; Wan, J.; Zhou, Q.; Wang, R.; Xie, Y.; Peng, H. Utilizing pretrained convolutional neural networks for crack detection and geometric feature recognition in concrete surface images. J. Build. Eng. 2024, 98, 111386. [Google Scholar] [CrossRef]

- Inglis, C.E. Stresses in a plate due to the presence of cracks and sharp corners. Trans. Inst. Naval Archit. 1913, 55, 219–241. [Google Scholar]

- Huang, M.; Wan, N.; Zhu, H. Reconstruction of structural acceleration response based on CNN-BiGRU with squeeze-and-excitation under environmental temperature effects. J. Civil. Struct. Health Monit. 2025, 15, 985–1003. [Google Scholar] [CrossRef]

- Wan, C.; Zhou, Z.; Li, S.; Ding, Y.; Xu, Z.; Yang, Z.; Xia, Y.; Yin, F. Development of a Bridge Management System Based on the Building Information Modeling Technology. Sustainability 2019, 11, 4583. [Google Scholar] [CrossRef]

- JTG/T 3310-2019; Code for Durability Design of Concrete Structures in Highway Engineering. China Communications Press Co., Ltd.: Beijing, China, 2019.

- JTG 5120-2021; Specifications for Maintenance of Highway Bridges and Culverts. China Communications Press Co., Ltd.: Beijing, China, 2021.

- JTG/T J21-2011; Specification for Inspection and Evaluation of Load-bearing Capacity of Highway Bridges. China Communications Press Co., Ltd.: Beijing, China, 2011.

- Shu, J.; Zhang, Z.; Gonzalez, I.; Karoumi, R. The application of a damage detection method using Artificial Neural Network and train-induced vibrations on a simplified railway bridge model. Eng. Struct. 2013, 52, 408–421. [Google Scholar] [CrossRef]

- Shu, J.; Honfi, D.; Plos, M.; Zandi, K.; Magnusson, J. Assessment of a cantilever bridge deck slab using multi-level assessment strategy and decision support framework. Eng. Struct. 2019, 200, 109666. [Google Scholar] [CrossRef]

- Dong, W.; Wu, Z.; Tang, X.; Zhou, X. A comparative study on stress intensity factor-based criteria for the prediction of mixed mode I-II crack propagation in concrete. Eng. Fract. Mech. 2018, 197, 217–235. [Google Scholar] [CrossRef]

- Ince, R. Using SCB specimens to quantify nonlinear fracture characteristics in concrete and rock materials. Eng. Fract. Mech. 2025, 318, 110951. [Google Scholar] [CrossRef]

- Cisowski, A.; Kowalik, M.P. The influence of the cross-sectional geometry on stress concentration in 3D printed concrete elements: A preliminary study. Eng. Struct. 2025, 340, 120728. [Google Scholar] [CrossRef]

- Zhang, B.; Luo, Z.; Yan, L.; Zhang, Y.; Wang, Z.; Yang, Q.; Li, J. Study on the influence mechanism of polypropylene fiber on crack propagation of concrete with existing cracks under uniaxial compression. Theor. Appl. Fract. Mech. 2024, 131, 104429. [Google Scholar] [CrossRef]

- Xu, S.; Reinhardt, H. Determination of double-K criterion for crack propagation in quasi-brittle fracture, Part II: Analytical evaluating and practical measuring methods for three-point bending notched beams. Int. J. Fract. 1999, 98, 151–177. [Google Scholar] [CrossRef]

- Langenfeld, K.; Kurzeja, P.; Mosler, J. On the curvature dependence of gradient damage models: Control and opportunities. Comput. Methods Appl. Mech. Eng. 2023, 410, 115987. [Google Scholar] [CrossRef]

- JTG/T H21-2011; Standards for Technical Condition Evaluation of Highway Bridges. China Communications Press Co., Ltd.: Beijing, China, 2011.

- Sandler, M.; Howard, A.; Zhu, M.; Zhmoginov, A.; Chen, L. Mobilenetv2: Inverted residuals and linear bottlenecks. In Proceedings of the 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–23 June 2018; pp. 4510–4520. [Google Scholar]

- Jin, T.; Ye, X.W.; Li, Z.X. Establishment and evaluation of conditional GAN-based image dataset for semantic segmentation of structural cracks. Eng. Struct. 2023, 285, 116058. [Google Scholar] [CrossRef]

- Sun, D.; Dornaika, F.; Charafeddine, J. LCAMix: Local-and-contour aware grid mixing based data augmentation for medical image segmentation. Inf. Fusion 2024, 110, 102484. [Google Scholar] [CrossRef]

- Xu, Y.; Mou, C.; Hu, Y.; Xie, J.; Zhang, J. Robust Invertible Image Steganography. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), New Orleans, LA, USA, 18–24 June 2022; pp. 7875–7884. [Google Scholar]

- Pan, X.; Chen, M.; Lin, H.; Bian, X.; Feng, S.; Chen, J.; Wang, L.; Chen, X.; Liu, Z.; Lan, R. LesionMix data enhancement and entropy minimization for semi-supervised lesion segmentation of lung cancer. Appl. Soft Comput. 2024, 167 Pt A, 112244. [Google Scholar] [CrossRef]

- Shorten, C.; Khoshgoftaar, T.M. A survey on Image Data Augmentation for Deep Learning. J. Big Data 2019, 6, 60. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, J.; Li, J.; Deng, Z.; Luo, J. Damage identification of steel bridge based on data augmentation and adaptive optimization neural network. Struct. Health Monit. 2024, 24, 1674–1699. [Google Scholar] [CrossRef]

- Printemps, T.; Dabertrand, K.; Vives, J.; Valery, A. Application of a novel local and automatic PCA algorithm for diffraction pattern denoising in TEM-ASTAR analysis in microelectronics. Ultramicroscopy 2024, 267, 114059. [Google Scholar] [CrossRef]

- Chen, C.; Sun, X.; Long, H.; Hao, X. Pavement crack detection method based on improved DeepLabv3+ network. Semicond. Optoelectron. 2024, 45, 493–500. [Google Scholar] [CrossRef]

- Fan, H.-K.; Liu, X.-Y. Concrete Crack Detection Based on ST-UNet and Target Features. Comput. Syst. Appl. 2024, 33, 77–84. [Google Scholar]

- Hong, J.; Liu, X.; Liu, Z. Semantic segmentation of street view images by fusing attention and multi-scale features. Comput. Syst. Appl. 2024, 33, 94–102. [Google Scholar]

- Fang, Z.X.; Fan, H.T. Redundancy of Structural Systems in the Context of Structural Safety. Procedia Eng. 2011, 14, 2172–2178. [Google Scholar] [CrossRef]

- Möller, N.; Hansson, S.O. Principles of engineering safety: Risk and uncertainty reduction. Reliab. Eng. Syst. Saf. 2008, 93, 798–805. [Google Scholar] [CrossRef]

- Maguire, M.; Dorafshan, S.; Thomas, R.J. SDNET2018: A Concrete Crack Image Dataset for Machine Learning Applications; Utah State University: Logan, UT, USA, 2018. [Google Scholar] [CrossRef]

| Serial Number | X-Coordinate | Y-Coordinate | Predicted Width (px) | Actual Width (px) |

|---|---|---|---|---|

| 1 | 83 | 18 | 4.00 | 5.66 |

| 2 | 84 | 18 | 2.83 | 5.66 |

| 3 | 85 | 18 | 2.00 | 4.47 |

| 4 | 86 | 19 | 4.00 | 5.66 |

| 5 | 87 | 19 | 4.00 | 5.66 |

| 6 | 88 | 20 | 4.47 | 5.66 |

| 7 | 89 | 20 | 5.66 | 6.32 |

| Crack Image | Weight | Dice | IoU | PA | ECWI |

|---|---|---|---|---|---|

| No. 1 | 1:10 | 0.7562 | 0.6080 | 0.9924 | 34.05% |

| 1:20 | 0.7269 | 0.5710 | 0.9919 | 32.14% | |

| Dynamic weight | 0.7159 | 0.5575 | 0.9908 | 40.38% | |

| No. 2 | 1:10 | 0.8652 | 0.7625 | 0.9953 | 17.47% |

| 1:20 | 0.8497 | 0.7386 | 0.9951 | 18.34% | |

| Dynamic weight | 0.8498 | 0.7388 | 0.9946 | 26.37% | |

| No. 3 | 1:10 | 0.7725 | 0.6293 | 0.9861 | 48.87% |

| 1:20 | 0.7638 | 0.6179 | 0.9865 | 36.24% | |

| Dynamic weight | 0.7492 | 0.5989 | 0.9850 | 47.58% | |

| No. 4 | 1:10 | 0.8251 | 0.7023 | 0.9964 | 20.70% |

| 1:20 | 0.7966 | 0.6620 | 0.9959 | 20.45% | |

| Dynamic weight | 0.7941 | 0.6586 | 0.9957 | 28.38% | |

| No. 5 | 1:10 | 0.7593 | 0.6120 | 0.9932 | 25.91% |

| 1:20 | 0.7087 | 0.5488 | 0.9921 | 24.37% | |

| Dynamic weight | 0.6866 | 0.5227 | 0.9925 | 24.50% |

| Crack Image | Version | Dice | IoU | PA | ECWI |

|---|---|---|---|---|---|

| No. 1 | Version 1 | 0.6419 | 0.4727 | 0.9838 | 110.03% |

| Version 2 | 0.7020 | 0.5408 | 0.9879 | 88.69% | |

| No. 2 | Version 1 | 0.6415 | 0.4722 | 0.9815 | 47.59% |

| Version 2 | 0.6665 | 0.4998 | 0.9835 | 44.69% | |

| No. 3 | Version 1 | 0.7053 | 0.5447 | 0.9783 | 105.91% |

| Version 2 | 0.7125 | 0.5534 | 0.9792 | 96.33% | |

| No. 4 | Version 1 | 0.6725 | 0.5066 | 0.9902 | 79.05% |

| Version 2 | 0.7024 | 0.5413 | 0.9916 | 68.07% | |

| No. 5 | Version 1 | 0.6635 | 0.4964 | 0.9883 | 68.31% |

| Version 2 | 0.5942 | 0.4227 | 0.9835 | 65.15% |

| Version | Alpha | Sigma |

|---|---|---|

| Version 1 | 10 | 5 |

| Version 2 | 10 | 5 |

| Version 3 | 5 | 5 |

| Version 4 | 5 | 5 |

| Version 5 | 3 | 3 |

| Crack Image | Version | Dice | IoU | PA | ECWI |

|---|---|---|---|---|---|

| No. 1 | Version 3 | 0.6520 | 0.4836 | 0.9846 | 48.4% |

| Version 4 | 0.7362 | 0.5826 | 0.9911 | 21.13% | |

| No. 2 | Version 3 | 0.7537 | 0.6048 | 0.9891 | 48.21% |

| Version 4 | 0.8480 | 0.7361 | 0.9944 | 27.37% | |

| No. 3 | Version 3 | 0.6939 | 0.5313 | 0.9769 | 108.94% |

| Version 4 | 0.7435 | 0.5917 | 0.9848 | 45.34% | |

| No. 4 | Version 3 | 0.7582 | 0.6106 | 0.9935 | 60.51% |

| Version 4 | 0.8037 | 0.6718 | 0.9958 | 29.90% | |

| No. 5 | Version 3 | 0.7076 | 0.5475 | 0.9907 | 50.59% |

| Version 4 | 0.6736 | 0.5078 | 0.9923 | 26.12% |

| Image | Label | Mobile-D-Version1 | Mobile-D-Version2 | Mobile-D-Version5 |

|---|---|---|---|---|

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

| Label | Mobile-D-Version1 | Mobile-D-Version2 | Mobile-D-Version5 | |

|---|---|---|---|---|

| ||||

| Low-Error Region [1, 150] (%) | Medium-Error Region [150, 400] (%) | High-Error Region [400, 400+] (%) | Average ECWI (%) | ||

|---|---|---|---|---|---|

| 1 | Mobile-D-Version1 | 67.17% | 32.83% | 0.00% | 110.03% |

| Mobile-D-Version2 | 82.31% | 17.69% | 0.00% | 88.69% | |

| Mobile-D-Version5 | 98.83% | 1.17% | 0.00% | 40.38% | |

| 2 | Mobile-D-Version1 | 98.64% | 1.36% | 0.00% | 47.59% |

| Mobile-D-Version2 | 98.83% | 1.17% | 0.00% | 44.69% | |

| Mobile-D-Version5 | 100.00% | 0.00% | 0.00% | 26.37% | |

| 3 | Mobile-D-Version1 | 70.78% | 28.92% | 0.00% | 105.91% |

| Mobile-D-Version2 | 73.84% | 26.16% | 0.00% | 96.33% | |

| Mobile-D-Version5 | 96.68% | 3.32% | 0.00% | 47.58% | |

| 4 | Mobile-D-Version1 | 83.17% | 16.83% | 0.00% | 79.05% |

| Mobile-D-Version2 | 86.15% | 13.85% | 0.00% | 68.07% | |

| Mobile-D-Version5 | 99.43% | 0.57% | 0.00% | 28.38% | |

| 5 | Mobile-D-Version1 | 89.01% | 10.99% | 0.00% | 68.31% |

| Mobile-D-Version2 | 90.87% | 9.13% | 0.00% | 65.15% | |

| Mobile-D-Version5 | 100.00% | 0.00% | 0.00% | 24.50% | |

| Sample Number | Pixel Image of Sample | Tip Curvature Radius | Mobile-D-Version1 | Mobile-D-Version2 | Mobile-D-Version5 |

|---|---|---|---|---|---|

| 1 |  | (0.53) | (0.93) 74.3% | (0.70) 30.3% | (0.43) 20.4% |

| 4 |  | (0.23) | (0.19) 14.8% | (0.17) 26.7% | (0.16) 28.7% |

| 5 |  | (0.36) | (0.35) 1.5% | (0.25) 30.9% | (0.42) 17.0% |

| 6 |  | (0.10) | (0.30) 207.0% | (0.18) 87.6% | (0.12) 27.5% |

| 7 |  | (0.26) | (0.35) 34.8% | (0.33) 27.5% | (0.20) 22.4% |

| 8 |  | (0.49) | (2.02) 309.8% | (0.60) 22.2% | (0.36) 26.8% |

| 9 |  | (1.24) | (2.69) 116.9% | (0.52) 58.3% | (0.59) 52.4% |

| 10 |  | (0.27) | (0.61) 125.6% | (0.43) 59.1% | (0.42) 54.1% |

| Sample Number | Model Version | ECWI | TCRE | Weighted Comprehensive Evaluation Error (4:6) |

|---|---|---|---|---|

| 1 | Mobile-D-Version1 | 110.03% | 74.3% | 88.59% |

| Mobile-D-Version2 | 88.69% | 30.3% | 53.66% | |

| Mobile-D-Version3 | 48.4% | 41.8% | 44.44% | |

| Mobile-D-Version4 | 21.13% | 48.5% | 37.55% | |

| Mobile-D-Version5 | 40.38% | 20.4% | 28.39% | |

| 2 | Mobile-D-Version1 | 47.59% | ||

| Mobile-D-Version2 | 44.69% | |||

| Mobile-D-Version3 | 48.21% | |||

| Mobile-D-Version4 | 27.37% | |||

| Mobile-D-Version5 | 26.37% | |||

| 3 | Mobile-D-Version1 | 105.91% | ||

| Mobile-D-Version2 | 96.33% | |||

| Mobile-D-Version3 | 108.94% | |||

| Mobile-D-Version4 | 45.34% | |||

| Mobile-D-Version5 | 47.58% | |||

| 4 | Mobile-D-Version1 | 79.05% | 14.8% | 40.50% |

| Mobile-D-Version2 | 68.07% | 26.7% | 43.25% | |

| Mobile-D-Version3 | 60.51% | 12.8% | 31.88% | |

| Mobile-D-Version4 | 29.90% | 34.0% | 32.36% | |

| Mobile-D-Version5 | 28.38% | 28.7% | 28.57% | |

| 5 | Mobile-D-Version1 | 68.31% | 1.5% | 28.22% |

| Mobile-D-Version2 | 65.15% | 30.9% | 44.60% | |

| Mobile-D-Version3 | 50.59% | 20.5% | 32.54% | |

| Mobile-D-Version4 | 26.12% | 47.7% | 39.07% | |

| Mobile-D-Version5 | 24.50% | 17.0% | 20.00% |

| Image |  |  |  |  |  |

| Label |  |  |  |  |  |

| Precision |  |  |  |  |  |

| Dice | 0.7022 | 0.8472 | 0.8446 | 0.8485 | 0.7848 |

| ECWI | 33.43% | 14.29% | 12.41% | 22.63% | 33.83% |

| Image |  |  |  |  |  |

| Label |  |  |  |  |  |

| Precision |  |  |  |  |  |

| Dice | 0.7288 | 0.8541 | 0.8283 | 0.6307 | 0.8238 |

| ECWI | 35.47% | 28.44% | 11.48% | 12.95% | 33.63% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, K.; Wei, W. Research on Optimization of Intelligent Recognition Model for Bridge Cracks Based on Dual-Parameter Error Evaluation Indexes. Buildings 2025, 15, 3266. https://doi.org/10.3390/buildings15183266

Peng K, Wei W. Research on Optimization of Intelligent Recognition Model for Bridge Cracks Based on Dual-Parameter Error Evaluation Indexes. Buildings. 2025; 15(18):3266. https://doi.org/10.3390/buildings15183266

Chicago/Turabian StylePeng, Keke, and Wenlang Wei. 2025. "Research on Optimization of Intelligent Recognition Model for Bridge Cracks Based on Dual-Parameter Error Evaluation Indexes" Buildings 15, no. 18: 3266. https://doi.org/10.3390/buildings15183266

APA StylePeng, K., & Wei, W. (2025). Research on Optimization of Intelligent Recognition Model for Bridge Cracks Based on Dual-Parameter Error Evaluation Indexes. Buildings, 15(18), 3266. https://doi.org/10.3390/buildings15183266