Selection of the Best 3D Printing High-Performance Mortars Using Multi-Criteria Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Dosage

2.1.1. Phase 1: Mortars Without Fibers

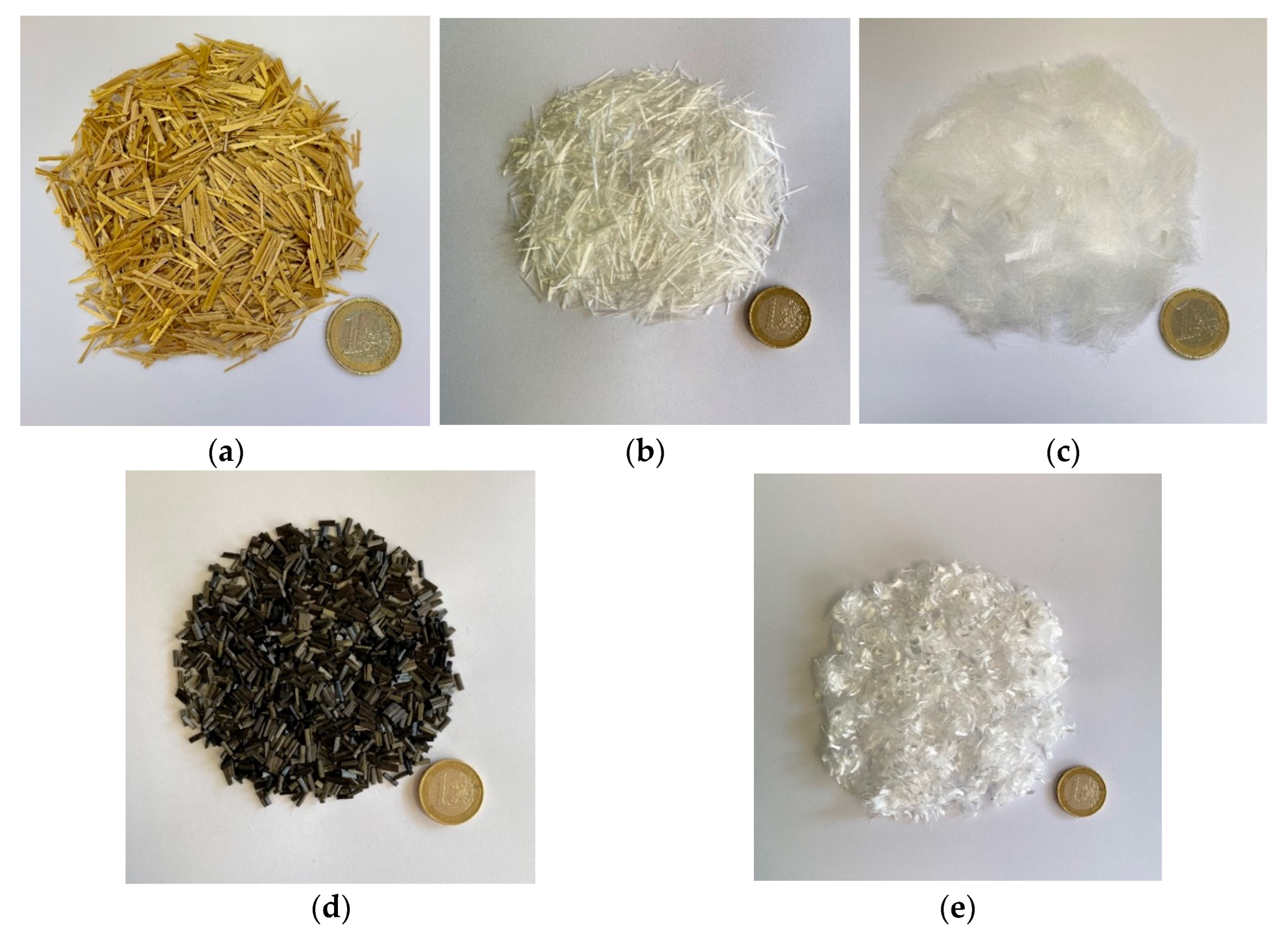

2.1.2. Phase 2: Mortars with Fibers

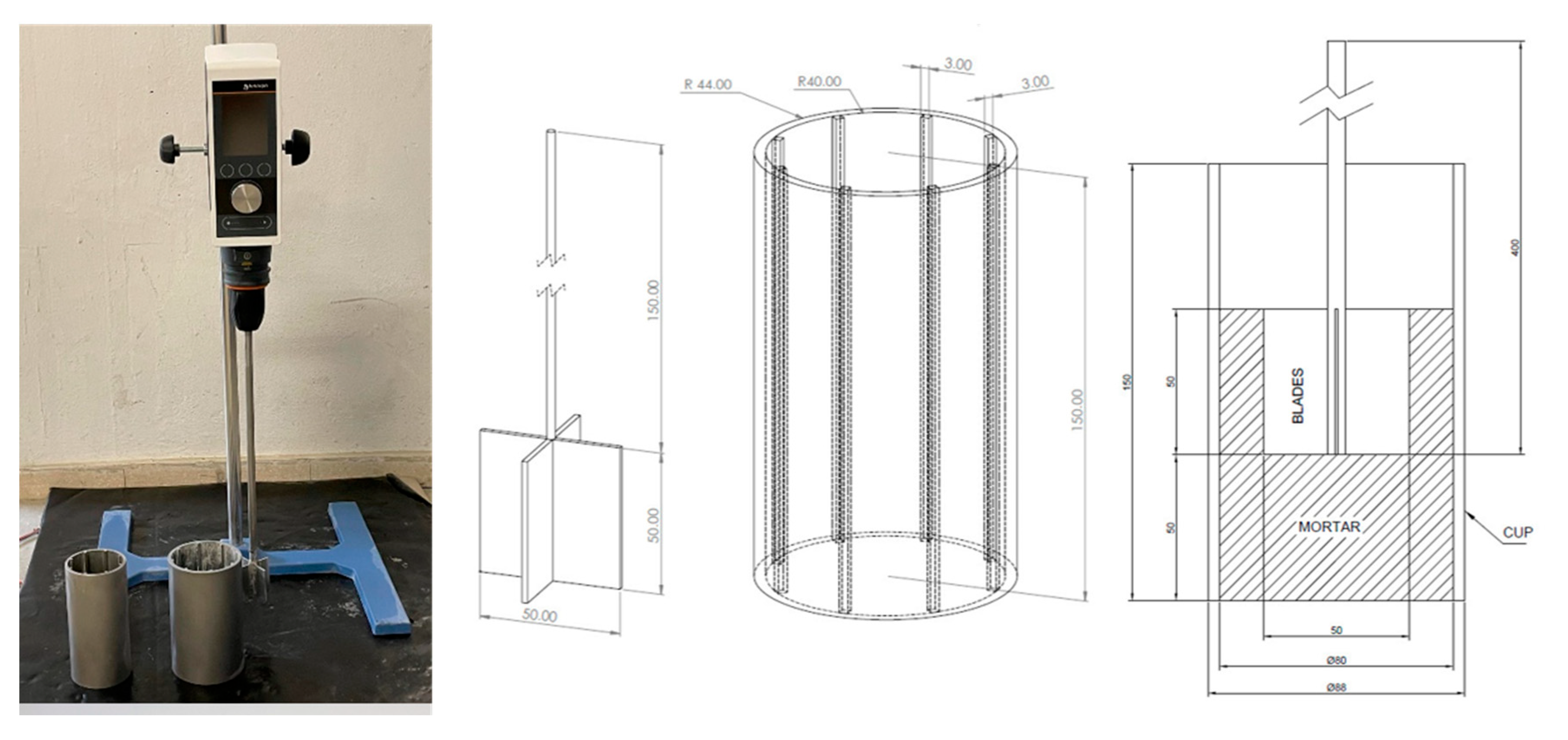

2.2. Mixing Process

2.3. Rheology

2.4. Mechanical Tests

2.5. Life Cycle Analysis

2.6. Cost

2.7. Multi-Criteria Decision-Making Analysis

2.7.1. Methodology

2.7.2. Alternatives and Criteria

2.7.3. Assessment Methods

- WASPAS

- 2.

- TOPSIS

3. Results and Discussion

3.1. Phase 1: Mortars Without Fibers

3.1.1. Rheology

3.1.2. Mechanical Tests

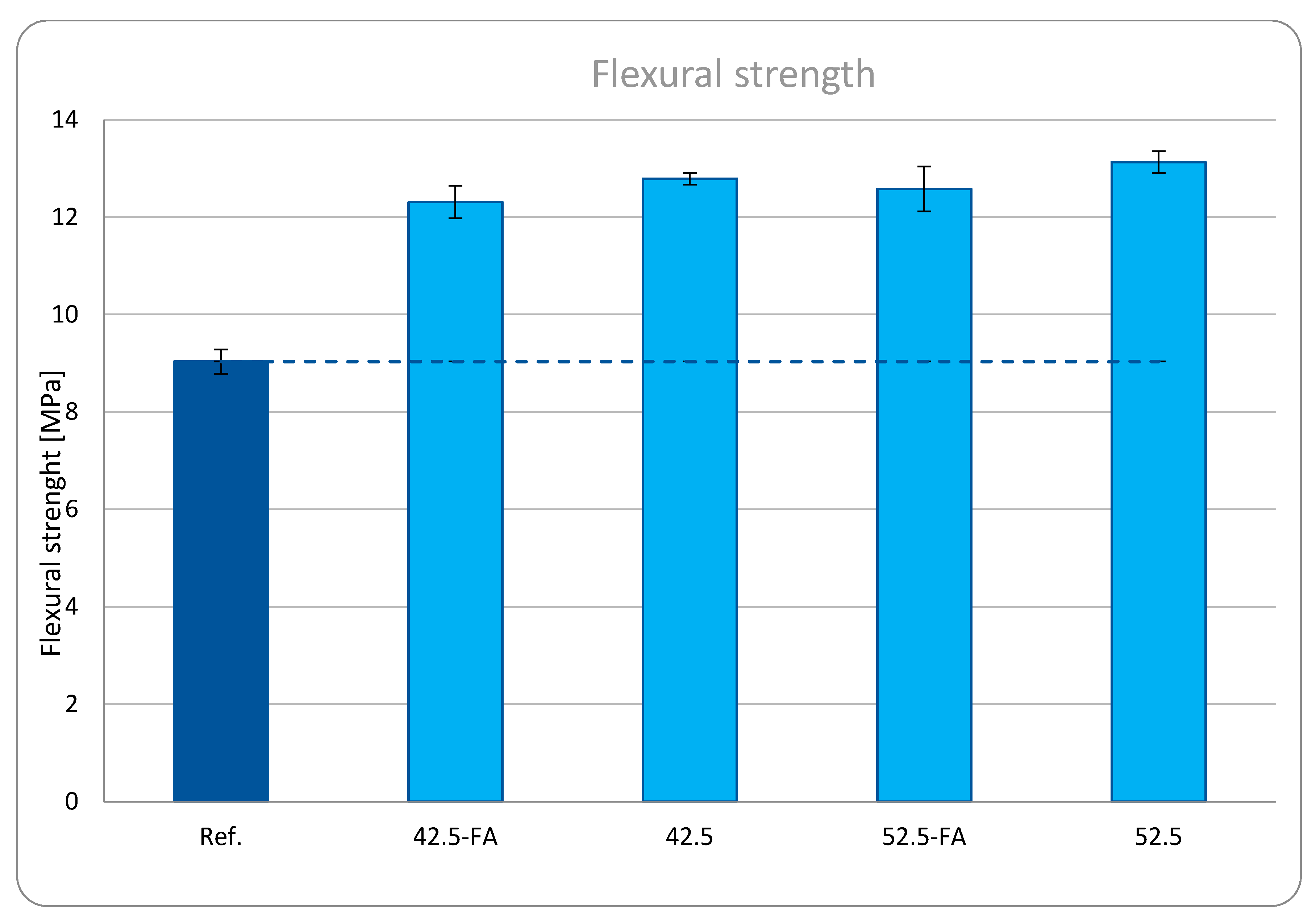

- Flexural strength

- 2.

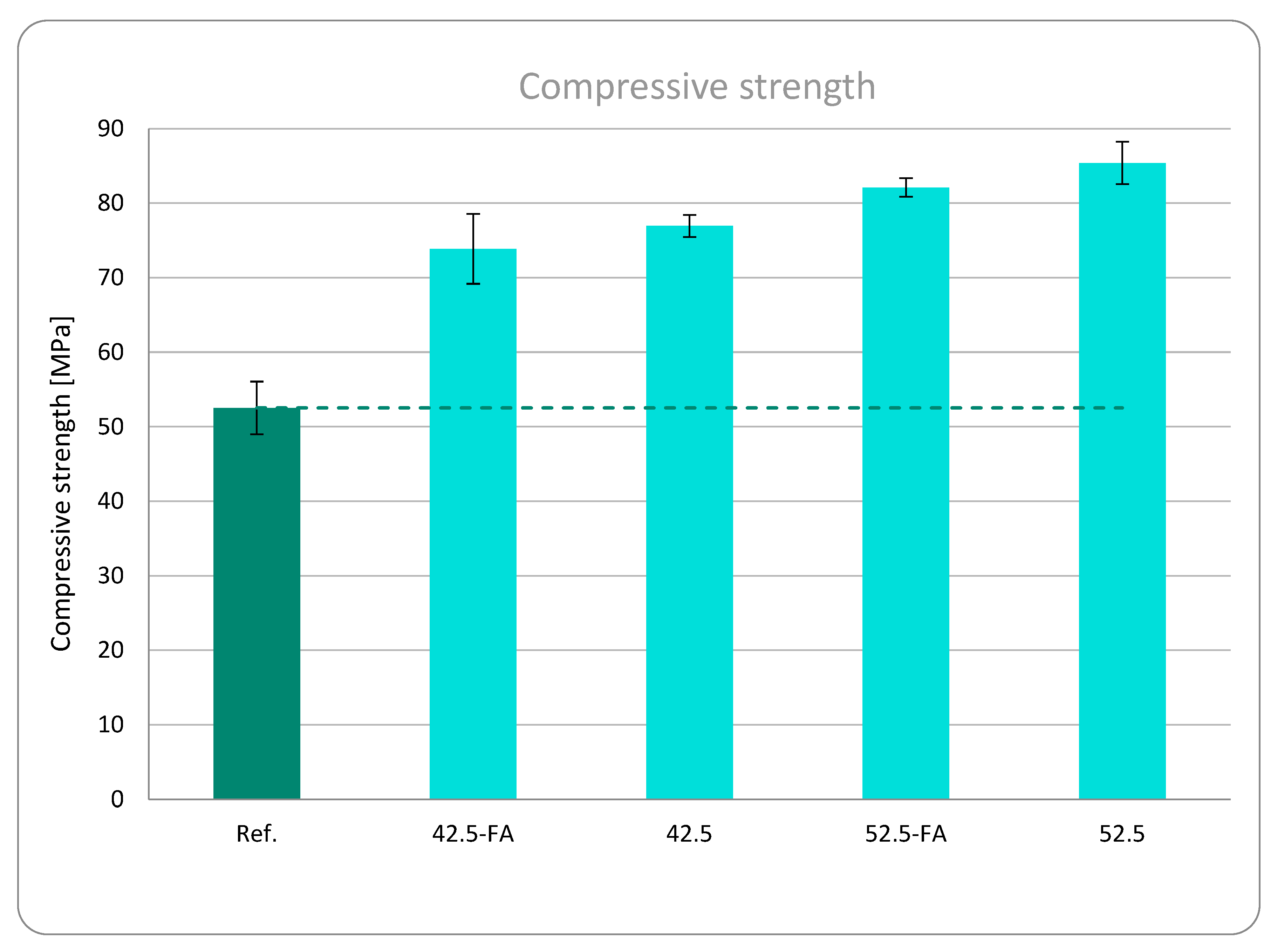

- Compressive strength

3.1.3. Life Cycle Analysis

3.1.4. Cost

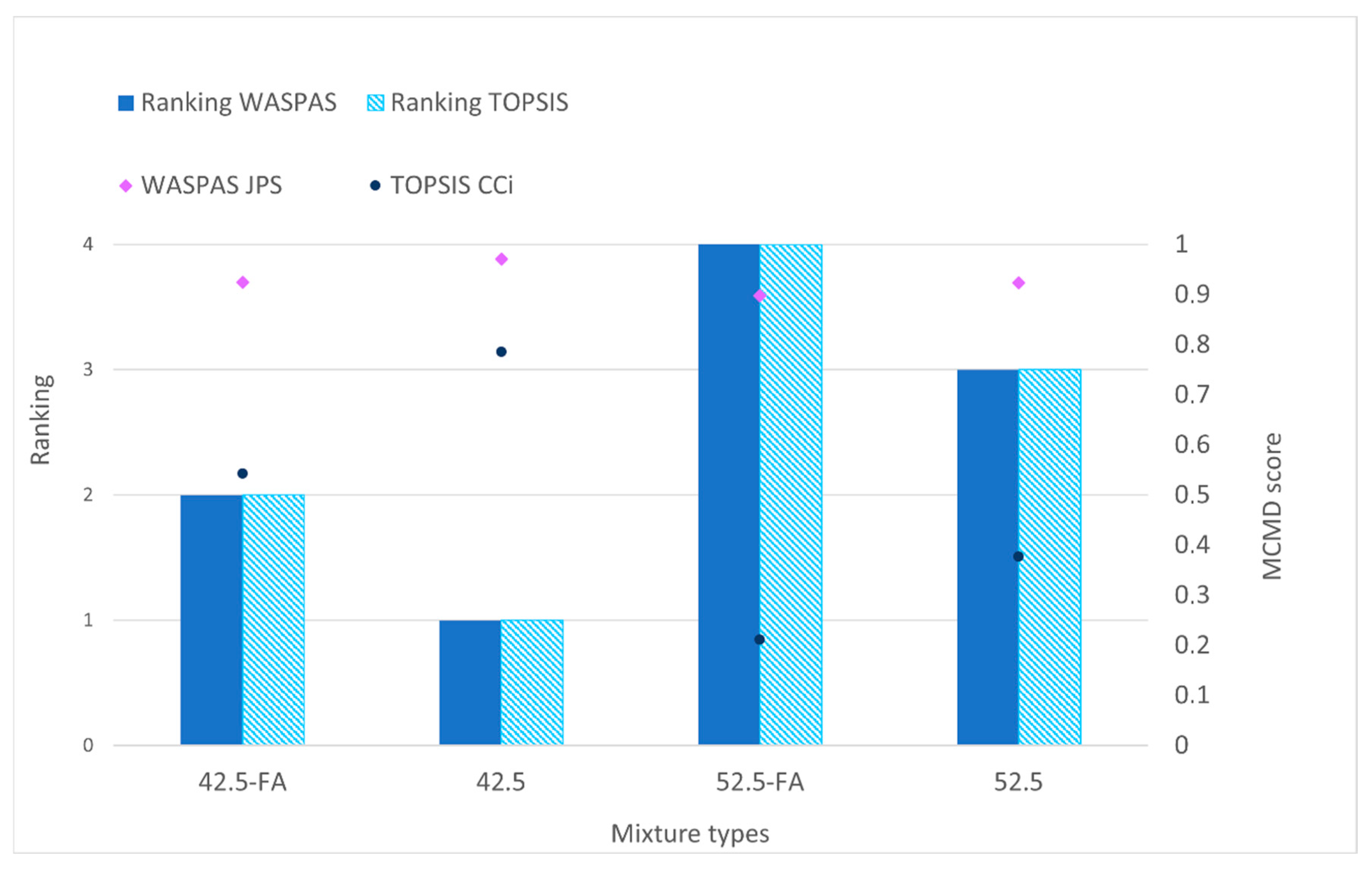

3.1.5. Multi-Criteria Decision-Making Analysis

3.1.6. Discussions

3.2. Phase 2: Mortars with Fibers

3.2.1. Rheology

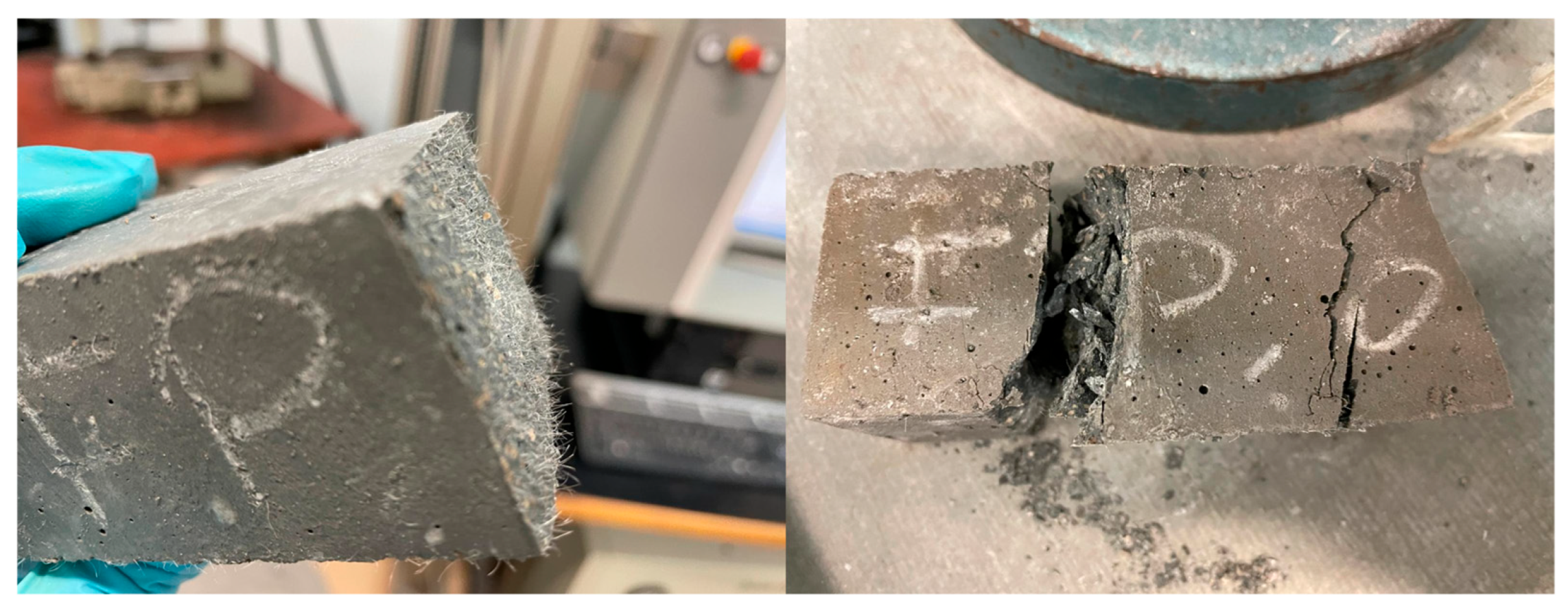

3.2.2. Mechanical Tests

- Flexural strength

- 2.

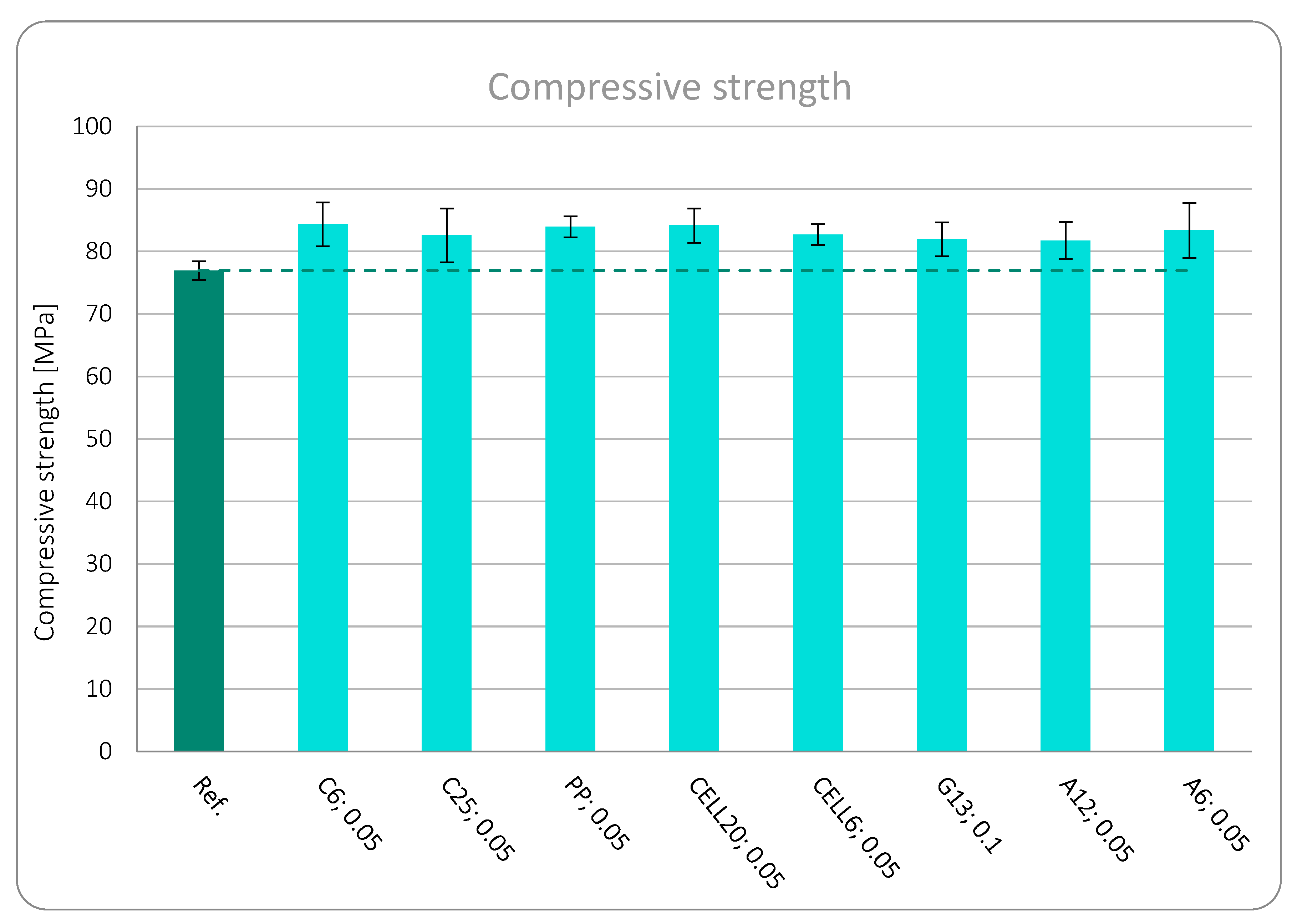

- Compressive strength

3.2.3. Life Cycle Analysis

3.2.4. Cost

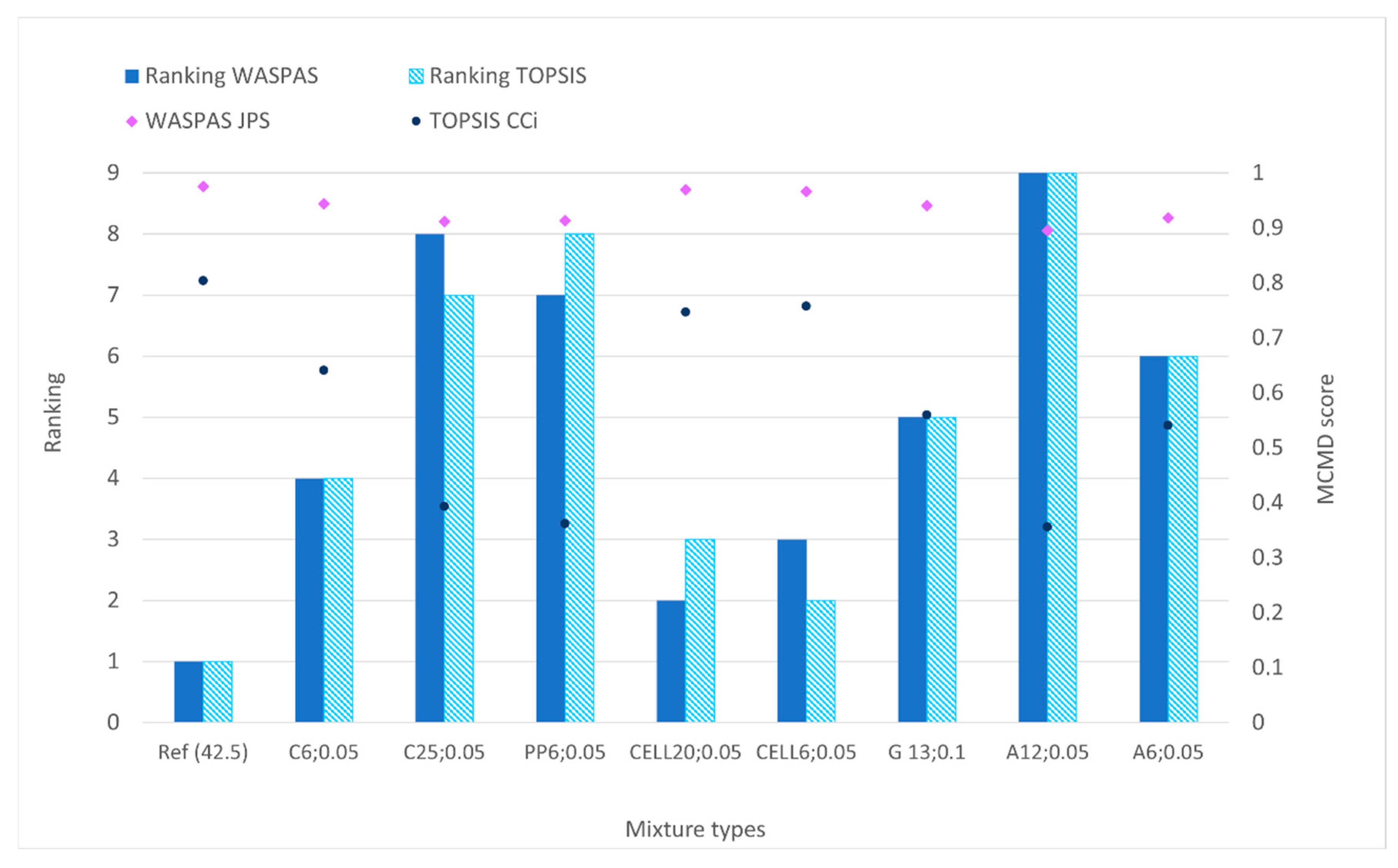

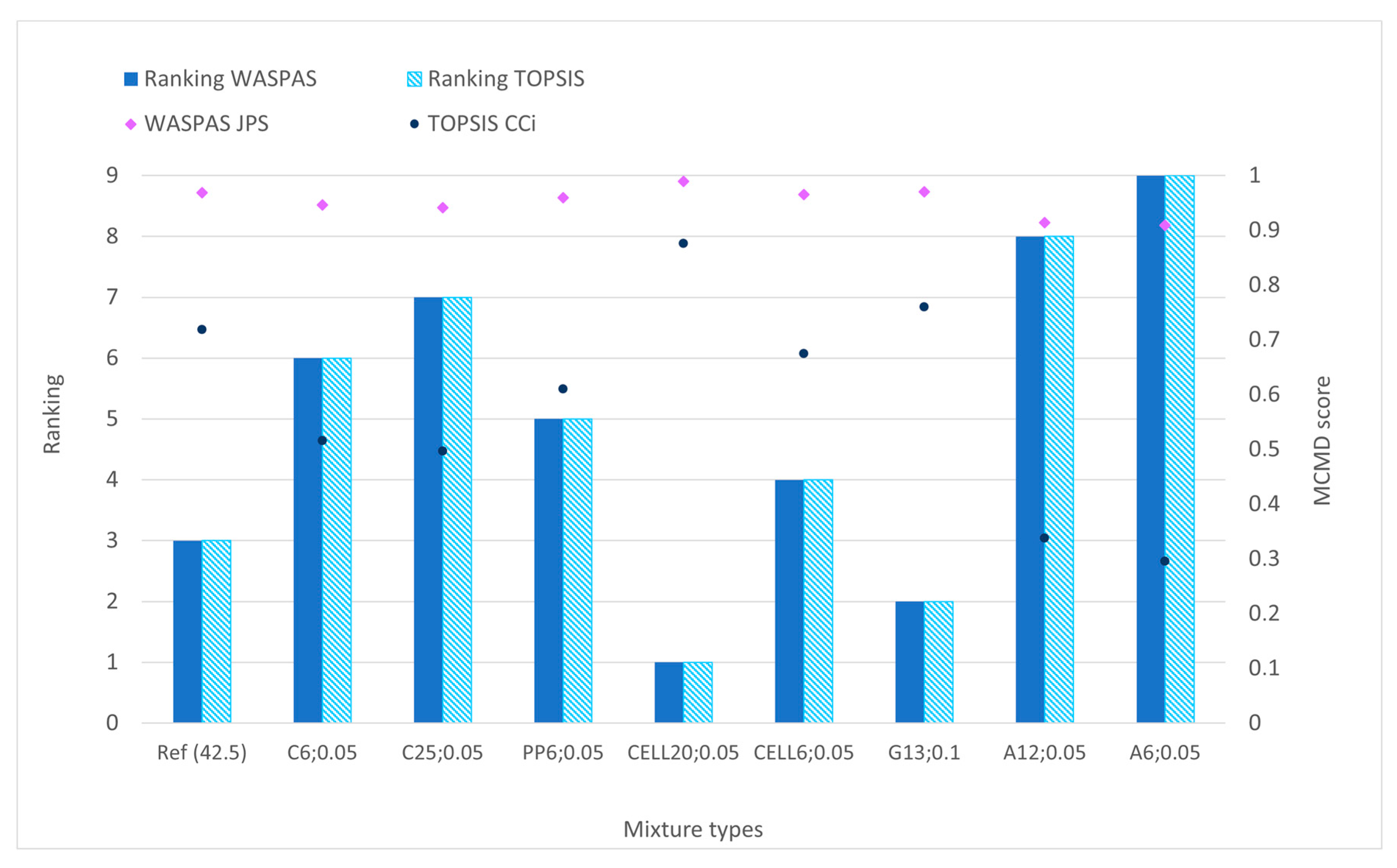

3.2.5. Multi-Criteria Decision-Making Analysis

3.2.6. Discussion

4. Conclusions

- Regarding the rheological behavior, using Cem I 52.5 makes the printability difficult since it tends to set too fast, so it is not considered adequate for 3D printing purposes. Mortar with Cem I 42.5 and no fly ash shows a good mechanical performance (up to 77 MPa of compression strength at 28 days) and a sufficient workability window to be used in high-performance 3DP applications. Adding fly ash did not show an increase in the mechanical properties in any of the mortars, although it slightly reduced their cost. Nevertheless, the MCDMA demonstrated that the optimal mortar with fibers was the one with Cem I 42.5 without fly ash.

- Adding fibers to mortars always makes the printability process difficult. Nevertheless, they can increase the compressive strength of the mortar to almost around 9% in the case of cellulose fibers of 20 mm length without compromising either the cost or the environmental impact of the mortar.

- The flexural strength of the mortar, in the particular case of high-strength mortars, is not significantly affected by adding fibers; however, these could have a potential impact on its toughness, which should be further explored.

- The rest of the fibers (glass, carbon, aramid, polypropylene) are not considered adequate for high-performance 3D-printed mortars, at least for the 3D printer used, since they do not increase its strength considerably while increasing cost and environmental impact.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Feucht, T.; Waldschmitt, B.; Lange, J.; Erven, M. 3D-Printing with Steel: Additive Manufacturing of a Bridge in situ. Ce/papers 2021, 4, 1695–1701. [Google Scholar] [CrossRef]

- Salet, T.A.M.; Ahmed, Z.Y.; Bos, F.P.; Laagland, H.L.M. Design of a 3D printed concrete bridge by testing. Virtual Phys. Prototyp. 2018, 13, 222–236. [Google Scholar] [CrossRef]

- Afolabi, A.O.; Ojelabi, R.A.; Omuh, I.O.; Tunji-Olayeni, P.F. 3D House Printing: A sustainable housing solution for Nigeria’s housing needs. J. Phys. Conf. Ser. 2019, 1299, 12012. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Rajabipour, A.; Kutay, C. 3D printing for remote housing: Benefits and challenges. Autom. Constr. 2023, 148, 104772. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Bond properties of reinforcing bar penetrations in 3D concrete printing. Autom. Constr. 2020, 120, 103394. [Google Scholar] [CrossRef]

- Gomaa, S.; Irizarry, E.M.; Ahmed, A.; Rosa, R.M.; Ahmed, H.; Burroughs, J.; Kreiger, E.; Liu, J.; Troemner, M.; Cusatis, G. 3D printing of ultra-high-performance concrete: Shape stability for various printing systems. Constr. Build. Mater. 2024, 456, 139039. [Google Scholar] [CrossRef]

- Zhou, Y.; Jiang, D.; Sharma, R.; Xie, Y.M.; Singh, A. Enhancement of 3D printed cementitious composite by short fibers: A review. Constr. Build. Mater. 2023, 362, 129763. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahi, B.; Khayat, K.H.; Ramesh, A.; Sanjayan, J.G. Rheological characterization of ultra-high performance concrete for 3D printing. Cem. Concr. Compos. 2023, 136, 104854. [Google Scholar] [CrossRef]

- Sun, H.-Q.; Zeng, J.-J.; Hong, G.-Y.; Zhuge, Y.; Liu, Y.; Zhang, Y. 3D-printed functionally graded concrete plates: Concept and bending behavior. Eng. Struct. 2025, 327, 119551. [Google Scholar] [CrossRef]

- Singh, A.; Liu, Q.; Xiao, J.; Lyu, Q. Mechanical and macrostructural properties of 3D printed concrete dosed with steel fibers under different loading direction. Constr. Build. Mater. 2022, 323, 126616. [Google Scholar] [CrossRef]

- Pham, L.; Tran, P.; Sanjayan, J. Steel fibres reinforced 3D printed concrete: Influence of fibre sizes on mechanical performance. Constr. Build. Mater. 2020, 250, 118785. [Google Scholar] [CrossRef]

- Alonso-Cañon, S.; Blanco-Fernandez, E.; Castro-Fresno, D.; Yoris-Nobile, A.I.; Castanon-Jano, L. Comparison of reinforcement fibers in 3D printing mortars using multi-criteria analysis. Int. J. Adv. Manuf. Technol. 2024, 134, 1463–1485. [Google Scholar] [CrossRef]

- Hambach, M.; Möller, H.; Volkmer, T.N.D. Portland cement paste with aligned carbon fibers exhibiting exceptionally high flexural strength. Cem. Concr. Res. 2016, 89, 80–86. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Chou, S.-Y.; Lin, W.-T.; Cheng, A.; Hebdowska-Krupa, M.; Gądek, S.; Mikuła, J. Mechanical Properties of Short Fiber-Reinforced Geopolymers Made by Casted and 3D Printing Methods: A Comparative Study. Materials 2020, 13, 579. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Chu, S.H.; Li, L.G.; Kwan, A.K.H. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 101617. [Google Scholar] [CrossRef]

- Yu, K.; McGee, W.; Ng, T.Y.; Zhu, H.; Li, V.C. 3D-printable engineered cementitious composites (3DP-ECC): Fresh and hardened properties. Cem. Concr. Res. 2021, 143, 106388. [Google Scholar] [CrossRef]

- Sun, X.; Zhou, J.; Wang, Q.; Shi, J.; Wang, H. PVA fibre reinforced high-strength cementitious composite for 3D printing: Mechanical properties and durability. Addit. Manuf. 2022, 49, 102500. [Google Scholar] [CrossRef]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V. Effect of polypropylene fibre addition on properties of geopolymers made by 3D printing for digital construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Hu, X.; Sun, H.-Q.; Liu, Y.; Chen, W.-J.; Zhuge, Y. Triaxial compressive behavior of 3D printed PE fiber-reinforced ultra-high performance concrete. Cem. Concr. Compos. 2025, 155, 105816. [Google Scholar] [CrossRef]

- Zat, T.; Schuster, S.L.; Duarte, E.S.; De Freitas Daudt, N.; Cruz, R.C.D.; Rodríguez, E.D. Rheological properties of high-performance concrete reinforced with microfibers and their effects on 3D printing process. J. Build. Eng. 2025, 105, 112406. [Google Scholar] [CrossRef]

- Cho, E.; Gwon, S.; Cha, S.; Shin, M. Impact of accelerator on rheological properties of cement composites with cellulose microfibers: 3D printing perspective. J. Build. Eng. 2025, 106, 112538. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; van Dam, B.; Zeidan, T.; De Schutter, G.; Van Tittelboom, K. Performance criteria, environmental impact and cost assessment for 3D printable concrete mixtures. Resour. Conserv. Recycl. 2022, 181, 106255. [Google Scholar] [CrossRef]

- Yu, Q.; Zhu, B.; Li, X.; Meng, L.; Cai, J.; Zhang, Y.; Pan, J. Investigation of the rheological and mechanical properties of 3D printed eco-friendly concrete with steel slag. J. Build. Eng. 2023, 72, 106621. [Google Scholar] [CrossRef]

- Rajendran, N.; Runge, T.; Bergman, R.; Nepal, P.; Ali, S.D.; Al Fahim, A.; Moradllo, M.K. Economic and environmental impact analysis of cellulose nanocrystal-reinforced cementitious mixture in 3D printing. Resour. Conserv. Recycl. 2025, 218, 108252. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous micro-fibers as intrinsic reinforcement for ductile Engineered Cementitious Composites (ECC). Compos. Part B Eng. 2020, 184, 107741. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Esmaeili, M.; Ghahari, S.A.; Najafi, M.H. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Alonso-Cañon, S.; Alonso-Estébanez, A.; Brunčič, A.; Blanco-Fernandez, E.; Castanon-Jano, L. Rheological parameter ranges for 3D printing sustainable mortars using a new low-cost rotational rheometer. Int. J. Adv. Manuf. Technol. 2025, 1–17. [Google Scholar] [CrossRef]

- Lanos, C.; Estellé, P. Vers une réelle rhéométrie adaptée aux bétons frais. Rev. Eur. Génie Civ. 2009, 13, 457–471. [Google Scholar] [CrossRef]

- Estellé, P.; Lanos, C.; Perrot, A. Processing the Couette viscometry data using a Bingham approximation in shear rate calculation. J. Nonnewton Fluid. Mech. 2008, 154, 31–38. [Google Scholar] [CrossRef]

- Estellé, P.; Lanos, C.; Perrot, A.; Amziane, S. Processing the vane shear flow data from Couette analogy. Appl. Rheol. 2008, 18, 34037-1–34037-6. [Google Scholar] [CrossRef]

- Yoris-Nobile, A.I.; Lizasoain-Arteaga, E.; Slebi-Acevedo, C.J.; Blanco-Fernandez, E.; Alonso-Cañon, S.; Indacoechea-Vega, I.; Castro-Fresno, D. Life cycle assessment (LCA) and multi-criteria decision-making (MCDM) analysis to determine the performance of 3D printed cement mortars and geopolymers. J. Sustain. Cem. Based Mater. 2022, 12, 609–626. [Google Scholar] [CrossRef]

- EN 196-1:2016; Methods of Testing Cement. Part 1: Determination of Strength. CEN-European Committee for Standardiztion: Brussels, Belgium, 2016.

- Wang, C.; Chen, B.; Vo, T.L.; Rezania, M. Mechanical anisotropy, rheology and carbon footprint of 3D printable concrete: A review. J. Build. Eng. 2023, 76, 107309. [Google Scholar] [CrossRef]

- Yoris-Nobile, A.I. Manufacture of Artificial Reefs by 3D Printing Using Sustainable Mortars. Ph.D. Thesis, Universidad de Cantabria, Santander, Spain, 2023. Available online: https://hdl.handle.net/10902/28426 (accessed on 1 September 2023).

- Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J.; Zakarevicius, A. Optimization of weighted aggregated sum product assessment. Elektron. Ir Elektrotechnika 2012, 122, 3–6. [Google Scholar] [CrossRef]

- Mardani, A.; Nilashi, M.; Zakuan, N.; Loganathan, N.; Soheilirad, S.; Saman, M.Z.M.; Ibrahim, O. A systematic review and meta-Analysis of SWARA and WASPAS methods: Theory and applications with recent fuzzy developments. Appl. Soft. Comput. 2017, 57, 265–292. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Multiple Attribute Decision Making. In Methods and Applications A State-of-the-Art Survey; Springer: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Salih, M.M.; Zaidan, B.B.; Zaidan, A.A.; Ahmed, M.A. Survey on fuzzy TOPSIS state-of-the-art between 2007 and 2017. Comput. Oper. Res. 2019, 104, 207–227. [Google Scholar] [CrossRef]

- Safiuddin, M.; Abdel-Sayed, G.; Hearn, N. Flexural and Impact Behaviors of Mortar Composite Including Carbon Fibers. Materials 2022, 15, 1657. [Google Scholar] [CrossRef]

- Park, J.-G.; Seo, D.-J.; Heo, G.-H. Impact Resistance and Flexural Performance Properties of Hybrid Fiber-Reinforced Cement Mortar Containing Steel and Carbon Fibers. Appl. Sci. 2022, 12, 9439. [Google Scholar] [CrossRef]

| Mixtures | Cement Type | Limestone Aggregate | Water | Mastersure 950 | Masterease 5025 | Fly Ash | MS 610 |

|---|---|---|---|---|---|---|---|

| 42.5-FA | CEM I 42.5 R | 2 | 0.4 | 0.0083 | 0.0076 | 0.2 | 0.1 |

| 42.5 | CEM I 42.5 R | 2 | 0.4 | 0.0083 | 0.0076 | - | 0.1 |

| 52.5-FA | CEM I 52.5 R | 2 | 0.4 | 0.0086 | 0.0078 | 0.2 | 0.1 |

| 52.5 | CEM I 52.5 R | 2 | 0.4 | 0.0085 | 0.0079 | - | 0.1 |

| Type | Color | Length [mm] | Diameter [μm] | Density [g/cm3] | Tensile Strength [MPa] | Modulus [GPa] | Elongation [%] | |

|---|---|---|---|---|---|---|---|---|

| Aramid | Non-bundled short cut | Gold | 6 | 21 | 1.39 | 3200 | 73 | 4.3 |

| Non-bundled short cut | Gold | 12 | 21 | 1.39 | 3200 | 73 | 4.3 | |

| Carbon | Chopped | Black | 6 | 7 | 1.8 | 4280 | 232 | 1.8 |

| Chopped | Black | 25 | 7 | 1.78 | 4300 | 234 | 1.8 | |

| Cellulose | Round monofilament | White | 6 | 18–48 | 0.91 | 460 | 3.85 | 15 |

| Round monofilament | White | 20 | 18–48 | 0.91 | 460 | 3.85 | 15 | |

| Glass | Multifilament | White | 13.1 | 13.5 | 2.68 | 1620 | 74 | |

| Polypropylene | Monofilament | White | 6 | 31 | 0.91 | 1.5 |

| Mixtures | Cement CEM I 42.5 R | Limestone Aggregate | Water | Mastersure 950 | Masterease 5025 | MS 610 | Fibers (%) |

|---|---|---|---|---|---|---|---|

| C6; 0.05 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.05% |

| C25; 0.05 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.05% |

| PP 6; 0.05 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.05% |

| CELL20; 0.05 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.05% |

| CELL6; 0.05 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.05% |

| G 13; 0.1 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.1% |

| A12; 0.05 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.05% |

| A6; 0.05 | 1 | 2 | 0.4 | 0.0085 | 0.0076 | 0.1 | 0.05% |

| 0:00:00 | Dry materials: cement, aggregates, MasterRoc MS 610, and fly ash; |

| 0:00:15 | Water gradually added; |

| 0:02:00 | Superplasticizers Mastersure 950 and MasterEase 5025; |

| 0:06:00 | Change mixer speed to medium; |

| 0:07:00 | End of process. |

| 0:00:00 | Dry materials: cement, aggregates, and MasterRoc MS 610; |

| 0:00:15 | Water gradually added; |

| 0:02:00 | Superplasticizers Mastersure 950 and MasterEase 5025; |

| 0:03:30 | Fibers added gradually; |

| 0:05:00 | Change mixer speed to medium; |

| 0:07:00 | End of process. |

| Material | Source |

|---|---|

| Cement | Cement, Portland [EU without Switzerland] production, cut-off, Ecoinvent |

| Limestone aggregate | Limestone, crushed, washed [CH] production, cut-off, Ecoinvent |

| Water | Tap water [EU without Switzerland] production, conventional treatment, cut-off, Ecoinvent |

| Fly ash | Average of EPD-IES-0020837 and EPD-S-P-10674 |

| MS610 | EPD-S-P-05963 |

| Carbon fibers | EF Database 3.1: Carbon fiber production [GLO] technology mix, production mix at plant (100% active substance) |

| Cellulose fibers | cellulose fiber {RoW}| market for cellulose fiber | cut-off, U, Ecoinvent v3.10 |

| Glass fibers | Glass fiber {GLO}|market for|cut-off, U, Ecoinvent v3.10 |

| Polypropylene fibers | Polypropylene, granulate {GLO}|market for|cut-off, U, Ecoinvent v3.10 |

| Aramid fibers | EF Database 3.1: Aramid fiber [EU + EFTA + UK] low-temperature solution polymerization of m-phenylene diamine with isophthaloyl chloride |

| Material | Distance (Km) |

|---|---|

| Cement | 100 |

| Limestone aggregate | 50 |

| Water | - |

| Fly ash | 25 |

| MS610 | 400 |

| Material | Cement CEM I 52.5 R | Cement CEM I 42.5 R | Limestone Aggregate | Fly Ash | Mastersure 950 | MasterEase 5025 | MS 610 |

|---|---|---|---|---|---|---|---|

| Cost (EUR/kg) | 0.13 | 0.12 | 0.01 | 0.08 | 2.63 | 2.63 | 1.40 |

| Fibers | Carbon | Cellulose | Glass | Polypropylene | Aramid |

|---|---|---|---|---|---|

| Cost (EUR/kg) | 26.0 | 1.35 | 5.80 | 23.20 | 39.00 |

| Mixtures | Yield Stress [Pa] | Viscosity [Pa·s] | Printability Index = Yield Stress × Viscosity [Pa2·s] |

|---|---|---|---|

| 42.5-FA | 480.27 | 15.54 | 7463.40 |

| 42.5 | 422.02 | 14.65 | 6182.59 |

| 52.5-FA | 723.15 | 13.23 | 9567.27 |

| 52.5 | 686.35 | 12.68 | 8702.92 |

| Mixtures | Flexural Strength (MPa) | Compression Strength (MPa) | ||

|---|---|---|---|---|

| Mean | SD | Mean | SD | |

| 42.5-FA | 12.31 | 0.34 | 73.86 | 4.68 |

| 42.5 | 12.79 | 0.12 | 76.95 | 1.49 |

| 52.5-FA | 12.58 | 0.46 | 82.09 | 1.25 |

| 52.5 | 13.13 | 0.22 | 85.39 | 2.84 |

| Individual LCA Values With Their Own Units | Normalization Factors | Weighing Factors | Normalized and Weighed LCA Values (Points/T) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 42.5, FA | 42.5 | 52.5, FA | 52.5 | 42.5, FA | 42.5 | 52.5, FA | 52.5 | ||||

| Acidification | mol H+ eq. | 7.94 × 10−1 | 7.95 × 10−1 | 8.05 × 10−1 | 8.07 × 10−1 | 1.80 × 10−2 | 0.062 | 8.86 × 10−4 | 8.87 × 10−4 | 8.98 × 10−4 | 9.00 × 10−4 |

| Climate change | kg CO2 eq. | 2.73 × 102 | 2.84 × 102 | 2.78 × 102 | 2.89 × 102 | 1.32 × 10−4 | 0.2106 | 7.60 × 10−3 | 7.92 × 10−3 | 7.74 × 10−3 | 8.07 × 10−3 |

| Ecotoxicity, freshwater | CTUe | 2.62 × 102 | 2.43 × 102 | 2.66 × 102 | 2.47 × 102 | 1.76 × 10−5 | 0.0192 | 8.88 × 10−5 | 8.23 × 10−5 | 9.00 × 10−5 | 8.35 × 10−5 |

| Particulate matter | Disease incidences | 5.57 × 10−6 | 4.58 × 10−6 | 5.63 × 10−6 | 4.64 × 10−6 | 1.68 × 103 | 0.0896 | 8.38 × 10−4 | 6.89 × 10−4 | 8.47 × 10−4 | 6.98 × 10−4 |

| Eutrophication, marine | kg N eq. | 2.13 × 10−1 | 2.12 × 10−1 | 2.16 × 10−1 | 2.15 × 10−1 | 5.12 × 10−2 | 0.0296 | 3.23 × 10−4 | 3.21 × 10−4 | 3.27 × 10−4 | 3.26 × 10−4 |

| Eutrophication, freshwater | kg P eq. | 2.07 × 10−2 | 2.15 × 10−2 | 2.11 × 10−2 | 2.19 × 10−2 | 6.22 × 10−1 | 0.028 | 3.61 × 10−4 | 3.75 × 10−4 | 3.68 × 10−4 | 3.82 × 10−4 |

| Eutrophication, terrestrial | mol N eq. | 2.43 × 10 | 2.42 × 10 | 2.46 × 10 | 2.46 × 10 | 5.66 × 10−3 | 0.0371 | 5.09 × 10−4 | 5.08 × 10−4 | 5.17 × 10−4 | 5.16 × 10−4 |

| Human toxicity, cancer | CTUh | 1.76 × 10−8 | 1.79 × 10−8 | 1.79 × 10−8 | 1.82 × 10−8 | 5.80 × 104 | 0.0213 | 2.18 × 10−5 | 2.21 × 10−5 | 2.21 × 10−5 | 2.25 × 10−5 |

| Human toxicity, non-cancer | CTUh | 8.04 × 10−8 | 5.30 × 10−8 | 8.08 × 10−8 | 5.33 × 10−8 | 7.77 × 103 | 0.0184 | 1.15 × 10−5 | 7.57 × 10−6 | 1.15 × 10−5 | 7.62 × 10−6 |

| Ionizing radiation | kBq U235 eq. | 8.09 × 10 | 8.52 × 10 | 8.20 × 10 | 8.62 × 10 | 2.37 × 10−4 | 0.0501 | 9.61 × 10−5 | 1.01 × 10−4 | 9.73 × 10−5 | 1.02 × 10−4 |

| Land use | Pt | 3.14 × 102 | 3.28 × 102 | 3.18 × 102 | 3.32 × 102 | 1.22 × 10−6 | 0.0794 | 3.04 × 10−5 | 3.17 × 10−5 | 3.08 × 10−5 | 3.22 × 10−5 |

| Ozone depletion | kg CFC 11 eq. | 1.16 × 10−5 | 1.22 × 10−5 | 1.17 × 10−5 | 1.24 × 10−5 | 1.91 × 101 | 0.0631 | 1.40 × 10−5 | 1.47 × 10−5 | 1.42 × 10−5 | 1.49 × 10−5 |

| Photochemical ozone formation | kg NMVOC eq. | 5.71 × 10−1 | 5.67 × 10−1 | 5.79 × 10−1 | 5.76 × 10−1 | 2.45 × 10−2 | 0.0478 | 6.68 × 10−4 | 6.63 × 10−4 | 6.78 × 10−4 | 6.73 × 10−4 |

| Resource use, fossils | MJ | 1.24 × 103 | 1.27 × 103 | 1.26 × 103 | 1.28 × 103 | 1.54 × 10−5 | 0.0832 | 1.59 × 10−3 | 1.62 × 10−3 | 1.61 × 10−3 | 1.64 × 10−3 |

| Resource use, minerals, and metals | kg Sb eq. | 1.94 × 10−4 | 2.03 × 10−4 | 1.97 × 10−4 | 2.06 × 10−4 | 1.57 × 101 | 0.0755 | 2.31 × 10−4 | 2.41 × 10−4 | 2.33 × 10−4 | 2.44 × 10−4 |

| Water use | m3 | 2.02 × 101 | 2.11 × 101 | 2.05 × 101 | 2.14 × 101 | 8.72 × 10−5 | 0.0851 | 1.50 × 10−4 | 1.56 × 10−4 | 1.52 × 10−4 | 1.59 × 10−4 |

| Total (Points) | 1.342 × 10−2 | 1.364 × 10−2 | 1.364 × 10−2 | 1.387 × 10−2 | |||||||

| Mixture | Cost (EUR/T) |

|---|---|

| 42.5-FA | 90.91 |

| 42.5 | 91.22 |

| 52.5-FA | 93.94 |

| 52.5 | 94.73 |

| Mixtures | Non-Beneficial Criteria | Beneficial Criteria | Beneficial Criteria | Non-Beneficial Criteria | Non-Beneficial Criteria |

|---|---|---|---|---|---|

| Printability Index | Flexural Strength | Compression Strength | Cost | LCA | |

| (Pa2·s) | (MPa) | (MPa) | (EUR/T) | (Points/T) | |

| 42.5-FA | 7463.40 | 12.31 | 73.86 | 90.91 | 0.01342 |

| 42.5 | 6182.59 | 12.79 | 76.95 | 91.22 | 0.01364 |

| 52.5-FA | 9567.27 | 12.58 | 82.09 | 93.94 | 0.01364 |

| 52.5 | 8702.92 | 13.13 | 85.39 | 94.73 | 0.01387 |

| Mixture | Yield Stress [Pa] | Viscosity [Pa·s] | Printability Index = Yield Stress × Viscosity [Pa2·s] |

|---|---|---|---|

| Ref (“42.5”) | 422.02 | 14.65 | 6182.59 |

| C6; 0.05 | 498.41 | 13.28 | 6618.88 |

| C25; 0.05 | 546.24 | 14.23 | 7773.00 |

| PP6; 0.05 | 652.56 | 12.85 | 8385.40 |

| CELL20; 0.05 | 598.14 | 11.59 | 6932.44 |

| CELL6; 0.05 | 594.25 | 10.72 | 6370.36 |

| G13; 0.1 | 689.25 | 10.87 | 7492.15 |

| A12; 0.05 | 468.27 | 16.12 | 7548.51 |

| A6; 0.05 | 489.36 | 13.23 | 6474.23 |

| Mixtures | Flexural Strength (MPa) | Compression Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| Mean | SD | Increment | Mean | SD | Increment | |

| Ref. (“42.5”) | 12.79 | 0.34 | 76.95 | 1.49 | ||

| C6; 0.05 | 13.26 | 0.56 | 3.64% | 84.33 | 3.50 | 9.59% |

| C25; 0.05 | 13.26 | 0.50 | 3.64% | 82.57 | 4.31 | 7.30% |

| PP; 0.05 | 12.82 | 0.17 | 0.23% | 83.94 | 1.70 | 9.08% |

| CELL20; 0.05 | 12.80 | 0.63 | 0.08% | 84.16 | 2.74 | 9.37% |

| CELL6; 0.05 | 11.80 | 0.47 | −7.74% | 82.70 | 1.67 | 7.47% |

| G13; 0.1 | 12.97 | 0.43 | 1.37% | 81.93 | 2.72 | 6.47% |

| A12; 0.05 | 13.16 | 0.74 | 2.89% | 81.74 | 2.95 | 6.22% |

| A6; 0.05 | 12.62 | 0.17 | −1.33% | 83.36 | 4.42 | 8.33% |

| AVERAGE= | 0.35% | AVERAGE= | 7.98% | |||

| CI= | [−2.77%; 3.47%] | CI= | [6.89%; 9.07%] | |||

| Individual LCA Values with Their Own Units | Normalization Factors | Weighing Factors | Normalized and Weighed LCA Values (Points/T) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C6; 0.05 | C25; 0.05 | PP6; 0.05 | CELL20; 0.05 | CELL6; 0.05 | G13; 0.1 | A12; 0.05 | A6; 0.05 | C6; 0.05 | C25; 0.05 | PP6; 0.05 | CELL20; 0.05 | CELL6; 0.05 | G13; 0.1 | A12; 0.05 | A6; 0.05 | ||||

| Acidification | mol H+ eq. | 8.68 × 10−1 | 8.68 × 10−1 | 8.00 × 10−1 | 7.96 × 10−1 | 7.96 × 10−1 | 8.04 × 10−1 | 8.41 × 10−1 | 8.41 × 10−1 | 1.80 × 10−2 | 0.062 | 9.68 × 10−4 | 9.68 × 10−4 | 8.92 × 10−4 | 8.88 × 10−4 | 8.88 × 10−4 | 8.97 × 10−4 | 9.38 × 10−4 | 9.38 × 10−4 |

| Climate change | kg CO2 eq. | 3.00 × 102 | 3.00 × 102 | 2.85 × 102 | 2.84 × 102 | 2.84 × 102 | 2.85 × 102 | 3.02 × 102 | 3.02 × 102 | 1.32 × 10−4 | 0.2106 | 8.37 × 10−3 | 8.37 × 10−3 | 7.95 × 10−3 | 7.92 × 10−3 | 7.92 × 10−3 | 7.95 × 10−3 | 8.43 × 10−3 | 8.43 × 10−3 |

| Ecotoxicity, freshwater | CTUe | 3.57 × 102 | 3.57 × 102 | 2.46 × 102 | 2.44 × 102 | 2.44 × 102 | 2.47 × 102 | 9.83 × 102 | 9.83 × 102 | 1.76 × 10−5 | 0.0192 | 1.21 × 10−4 | 1.21 × 10−4 | 8.32 × 10−5 | 8.25 × 10−5 | 8.25 × 10−5 | 8.35 × 10−5 | 3.33 × 10−4 | 3.33 × 10−4 |

| Particulate matter | Disease incidences | 5.85 × 10−6 | 5.85 × 10−6 | 4.62 × 10−6 | 4.59 × 10−6 | 4.59 × 10−6 | 4.67 × 10−6 | 6.41 × 10−6 | 6.41 × 10−6 | 1.68 × 103 | 0.0896 | 8.81 × 10−4 | 8.81 × 10−4 | 6.96 × 10−4 | 6.91 × 10−4 | 6.91 × 10−4 | 7.02 × 10−4 | 9.65 × 10−4 | 9.65 × 10−4 |

| Eutrophication, marine | kg N eq. | 2.33 × 10−1 | 2.33 × 10−1 | 2.13 × 10−1 | 2.12 × 10−1 | 2.12 × 10−1 | 2.14 × 10−1 | 4.34 × 10−1 | 4.34 × 10−1 | 5.12 × 10−2 | 0.0296 | 3.53 × 10−4 | 3.53 × 10−4 | 3.22 × 10−4 | 3.21 × 10−4 | 3.21 × 10−4 | 3.24 × 10−4 | 6.57 × 10−4 | 6.57 × 10−4 |

| Eutrophication, freshwater | kg P eq. | 2.18 × 10−2 | 2.18 × 10−2 | 2.17 × 10−2 | 2.15 × 10−2 | 2.15 × 10−2 | 2.19 × 10−2 | 2.36 × 10−2 | 2.36 × 10−2 | 6.22 × 10−1 | 0.028 | 3.79 × 10−4 | 3.79 × 10−4 | 3.78 × 10−4 | 3.75 × 10−4 | 3.75 × 10−4 | 3.81 × 10−4 | 4.12 × 10−4 | 4.12 × 10−4 |

| Eutrophication, terrestrial | mol N eq. | 2.58 × 10 | 2.58 × 10 | 2.43 × 10 | 2.42 × 10 | 2.42 × 10 | 2.44 × 10 | 2.52 × 10 | 2.52 × 10 | 5.66 × 10−3 | 0.0371 | 5.41 × 10−4 | 5.41 × 10−4 | 5.10 × 10−4 | 5.08 × 10−4 | 5.08 × 10−4 | 5.12 × 10−4 | 5.29 × 10−4 | 5.29 × 10−4 |

| Human toxicity, cancer | CTUh | 2.84 × 10−8 | 2.84 × 10−8 | 1.80 × 10−8 | 1.80 × 10−8 | 1.80 × 10−8 | 1.80 × 10−8 | 2.90 × 10−8 | 2.90 × 10−8 | 5.80 × 104 | 0.0213 | 3.51 × 10−5 | 3.51 × 10−5 | 2.22 × 10−5 | 2.22 × 10−5 | 2.22 × 10−5 | 2.23 × 10−5 | 3.59 × 10−5 | 3.59 × 10−5 |

| Human toxicity, non-cancer | CTUh | 1.14 × 10−7 | 1.14 × 10−7 | 5.35 × 10−8 | 5.30 × 10−8 | 5.30 × 10−8 | 5.34 × 10−8 | 2.66 × 10−7 | 2.66 × 10−7 | 7.77 × 103 | 0.0184 | 1.62 × 10−5 | 1.62 × 10−5 | 7.65 × 10−6 | 7.58 × 10−6 | 7.58 × 10−6 | 7.63 × 10−6 | 3.80 × 10−5 | 3.80 × 10−5 |

| Ionizing radiation | kBq U235 eq. | 9.58 × 10 | 9.58 × 10 | 8.54 × 10 | 8.53 × 10 | 8.53 × 10 | 8.63 × 10 | 1.06 × 101 | 1.06 × 101 | 2.37 × 10−4 | 0.0501 | 1.14 × 10−4 | 1.14 × 10−4 | 1.01 × 10−4 | 1.01 × 10−4 | 1.01 × 10−4 | 1.02 × 10−4 | 1.26 × 10−4 | 1.26 × 10−4 |

| Land use | Pt | 3.30 × 102 | 3.30 × 102 | 3.29 × 102 | 3.28 × 102 | 3.28 × 102 | 3.32 × 102 | 3.04 × 102 | 3.04 × 102 | 1.22 × 10−6 | 0.0794 | 3.20 × 10−5 | 3.20 × 10−5 | 3.19 × 10−5 | 3.18 × 10−5 | 3.18 × 10−5 | 3.21 × 10−5 | 2.94 × 10−5 | 2.94 × 10−5 |

| Ozone depletion | kg CFC 11 eq. | 1.23 × 10−5 | 1.23 × 10−5 | 1.22 × 10−5 | 1.22 × 10−5 | 1.22 × 10−5 | 1.23 × 10−5 | 1.22 × 10−5 | 1.22 × 10−5 | 1.91 × 101 | 0.0631 | 1.48 × 10−5 | 1.48 × 10−5 | 1.47 × 10−5 | 1.47 × 10−5 | 1.47 × 10−5 | 1.48 × 10−5 | 1.47 × 10−5 | 1.47 × 10−5 |

| Photochemical ozone formation | kg NMVOC eq. | 6.01 × 10−1 | 6.01 × 10−1 | 5.69 × 10−1 | 5.67 × 10−1 | 5.67 × 10−1 | 5.72 × 10−1 | 5.99 × 10−1 | 5.99 × 10−1 | 2.45 × 10−2 | 0.0478 | 7.03 × 10−4 | 7.03 × 10−4 | 6.66 × 10−4 | 6.64 × 10−4 | 6.64 × 10−4 | 6.69 × 10−4 | 7.00 × 10−4 | 7.00 × 10−4 |

| Resource use, fossils | MJ | 1.53 × 103 | 1.53 × 103 | 1.30 × 103 | 1.27 × 103 | 1.27 × 103 | 1.28 × 103 | 1.46 × 103 | 1.46 × 103 | 1.54 × 10−5 | 0.0832 | 1.96 × 10−3 | 1.96 × 10−3 | 1.67 × 10−3 | 1.62 × 10−3 | 1.62 × 10−3 | 1.64 × 10−3 | 1.87 × 10−3 | 1.87 × 10−3 |

| Resource use, minerals, and metals | kg Sb eq. | 2.21 × 10−4 | 2.21 × 10−4 | 2.10 × 10−4 | 2.05 × 10−4 | 2.05 × 10−4 | 2.14 × 10−4 | 2.39 × 10−4 | 2.39 × 10−4 | 1.57 × 101 | 0.0755 | 2.62 × 10−4 | 2.62 × 10−4 | 2.50 × 10−4 | 2.43 × 10−4 | 2.43 × 10−4 | 2.54 × 10−4 | 2.83 × 10−4 | 2.83 × 10−4 |

| Water use | m3 | 3.29 × 101 | 3.29 × 101 | 2.15 × 101 | 2.11 × 101 | 2.11 × 101 | 2.13 × 101 | 2.68 × 101 | 2.68 × 101 | 8.72 × 10−5 | 0.0851 | 2.44 × 10−4 | 2.44 × 10−4 | 1.60 × 10−4 | 1.57 × 10−4 | 1.57 × 10−4 | 1.58 × 10−4 | 1.99 × 10−4 | 1.99 × 10−4 |

| Total (Points) | 1.499 × 10−2 | 1.499 × 10−2 | 1.375 × 10−2 | 1.365 × 10−2 | 1.365 × 10−2 | 1.375 × 10−2 | 1.556 × 10−2 | 1.556 × 10−2 | |||||||||||

| Mixture | Cost (EUR/T) |

|---|---|

| Ref (“42.5”) | 91.22 |

| C6; 0.05 | 103.67 |

| C25; 0.05 | 103.67 |

| PP6; 0.05 | 102.77 |

| CELL20; 0.05 | 91.85 |

| CELL6; 0.05 | 91.85 |

| G13; 0.1 | 96.93 |

| A12; 0.05 | 110.67 |

| A6; 0.05 | 110.67 |

| Mixtures | Non-Beneficial Criteria | Beneficial Criteria | Beneficial Criteria | Non-Beneficial Criteria | Non-Beneficial Criteria |

|---|---|---|---|---|---|

| Printability Index | Flexural Strength | Compression Strength | Cost | LCA | |

| (Pa2·s) | (MPa) | (MPa) | (EUR/T) | (Points/T) | |

| Ref (“42.5”) | 6182.59 | 12.79 | 76.95 | 91.22 | 0.01364 |

| C6; 0.05 | 6618.88 | 13.26 | 84.33 | 103.67 | 0.01499 |

| C25; 0.05 | 7773.00 | 13.26 | 82.57 | 103.67 | 0.01499 |

| PP6; 0.05 | 8385.40 | 12.82 | 83.94 | 102.77 | 0.01375 |

| CELL20; 0.05 | 6932.44 | 12.80 | 84.16 | 91.85 | 0.01365 |

| CELL6; 0.05 | 6370.36 | 11.80 | 82.70 | 91.85 | 0.01365 |

| G13; 0.1 | 7492.15 | 12.97 | 81.93 | 96.93 | 0.01375 |

| A12; 0.05 | 7548.51 | 13.16 | 81.74 | 110.67 | 0.01556 |

| A6; 0.05 | 6474.23 | 12.62 | 83.36 | 110.67 | 0.01556 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso-Cañon, S.; Blanco-Fernandez, E.; Cuesta-Astorga, E.; Indacoechea-Vega, I.; Salas-Alvarez, J. Selection of the Best 3D Printing High-Performance Mortars Using Multi-Criteria Analysis. Buildings 2025, 15, 3307. https://doi.org/10.3390/buildings15183307

Alonso-Cañon S, Blanco-Fernandez E, Cuesta-Astorga E, Indacoechea-Vega I, Salas-Alvarez J. Selection of the Best 3D Printing High-Performance Mortars Using Multi-Criteria Analysis. Buildings. 2025; 15(18):3307. https://doi.org/10.3390/buildings15183307

Chicago/Turabian StyleAlonso-Cañon, Sara, Elena Blanco-Fernandez, Eva Cuesta-Astorga, Irune Indacoechea-Vega, and Joaquin Salas-Alvarez. 2025. "Selection of the Best 3D Printing High-Performance Mortars Using Multi-Criteria Analysis" Buildings 15, no. 18: 3307. https://doi.org/10.3390/buildings15183307

APA StyleAlonso-Cañon, S., Blanco-Fernandez, E., Cuesta-Astorga, E., Indacoechea-Vega, I., & Salas-Alvarez, J. (2025). Selection of the Best 3D Printing High-Performance Mortars Using Multi-Criteria Analysis. Buildings, 15(18), 3307. https://doi.org/10.3390/buildings15183307