Study on Punching Shear Performance of Concrete-Filled Steel Tubular Column-Slab Column Joints in Metro Stations

Abstract

1. Introduction

2. Test Overview

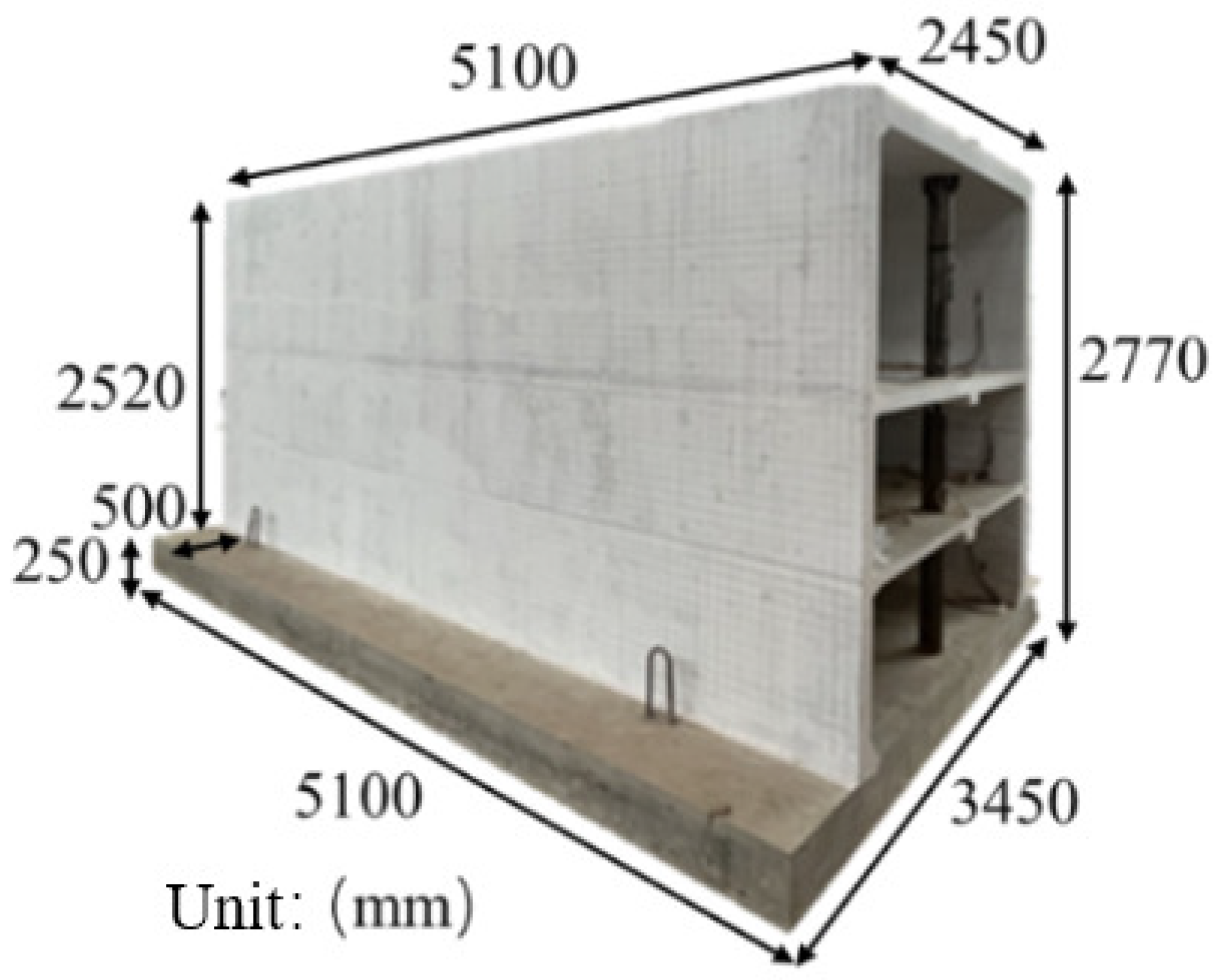

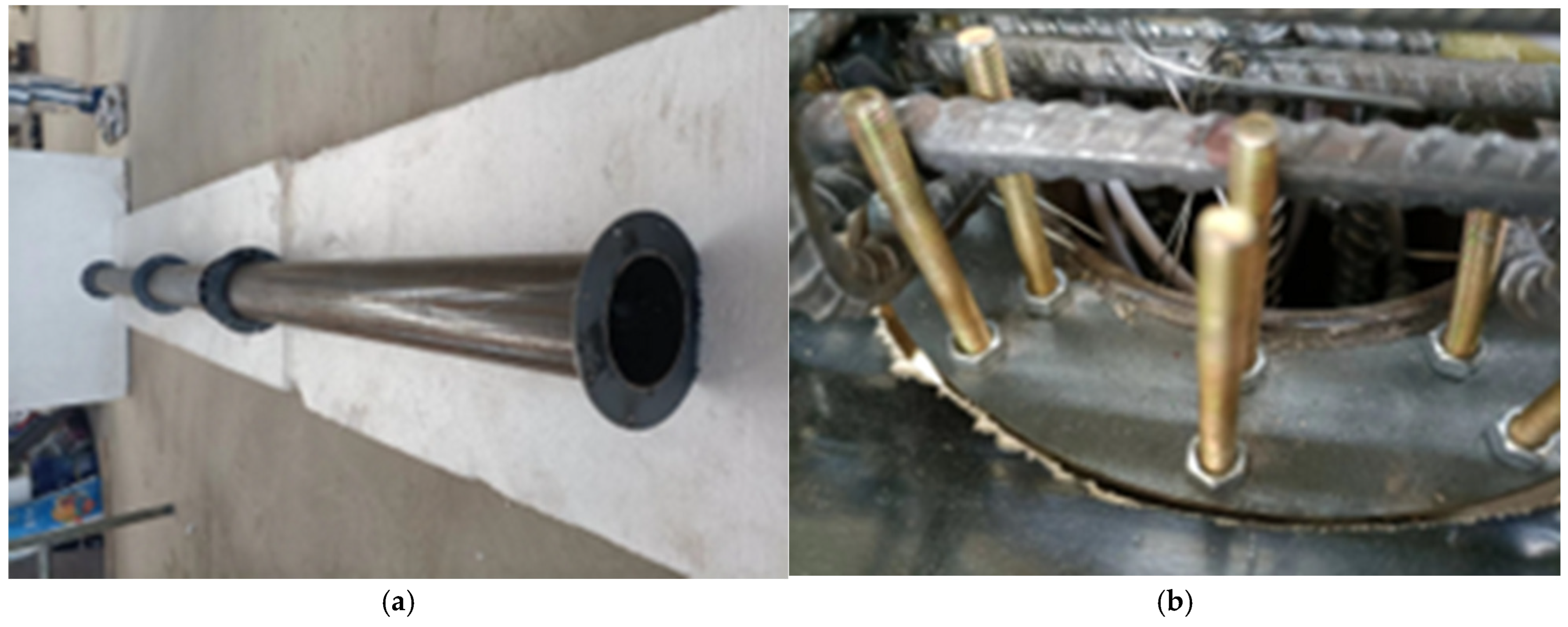

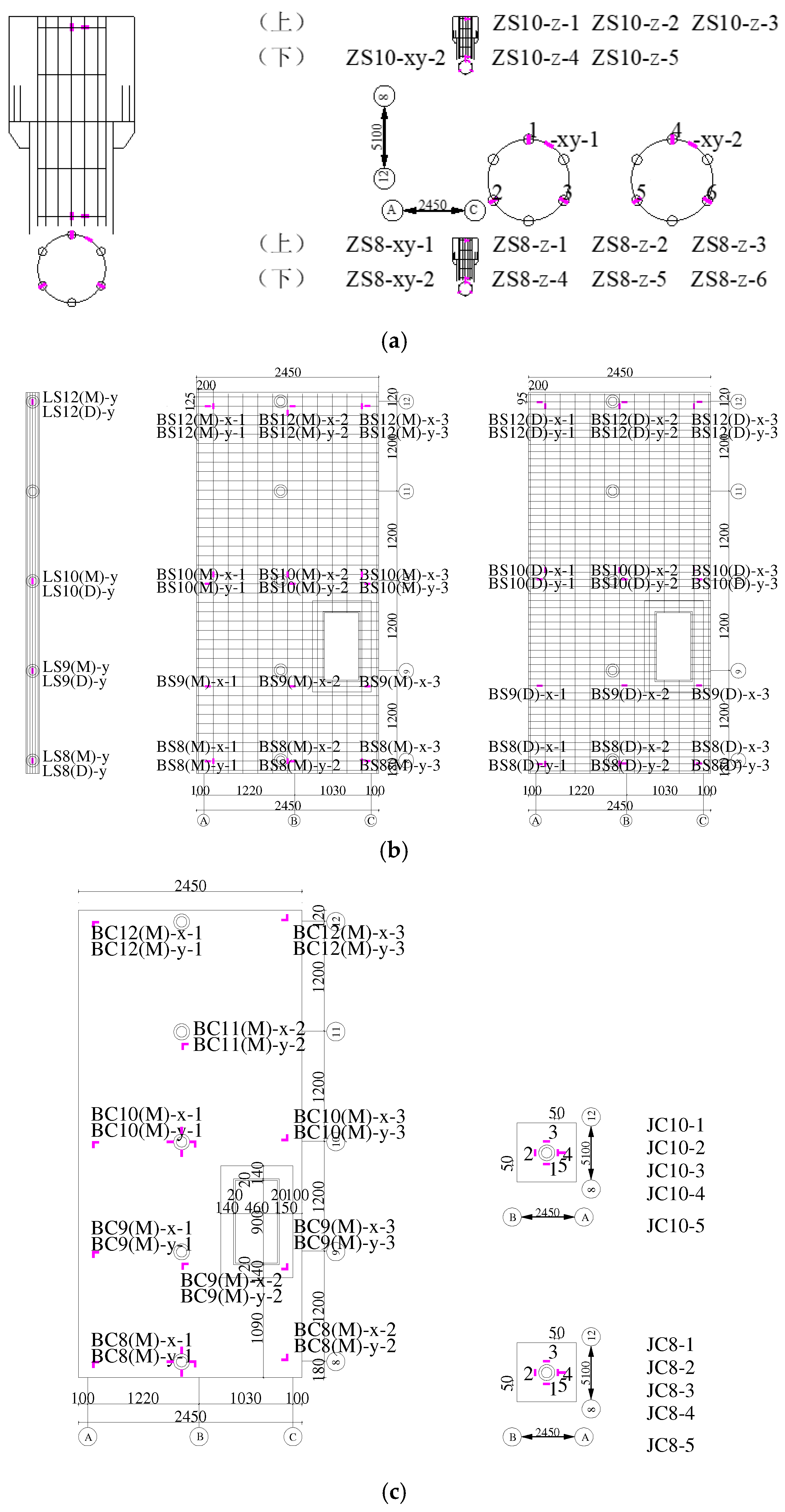

2.1. Specimen Design

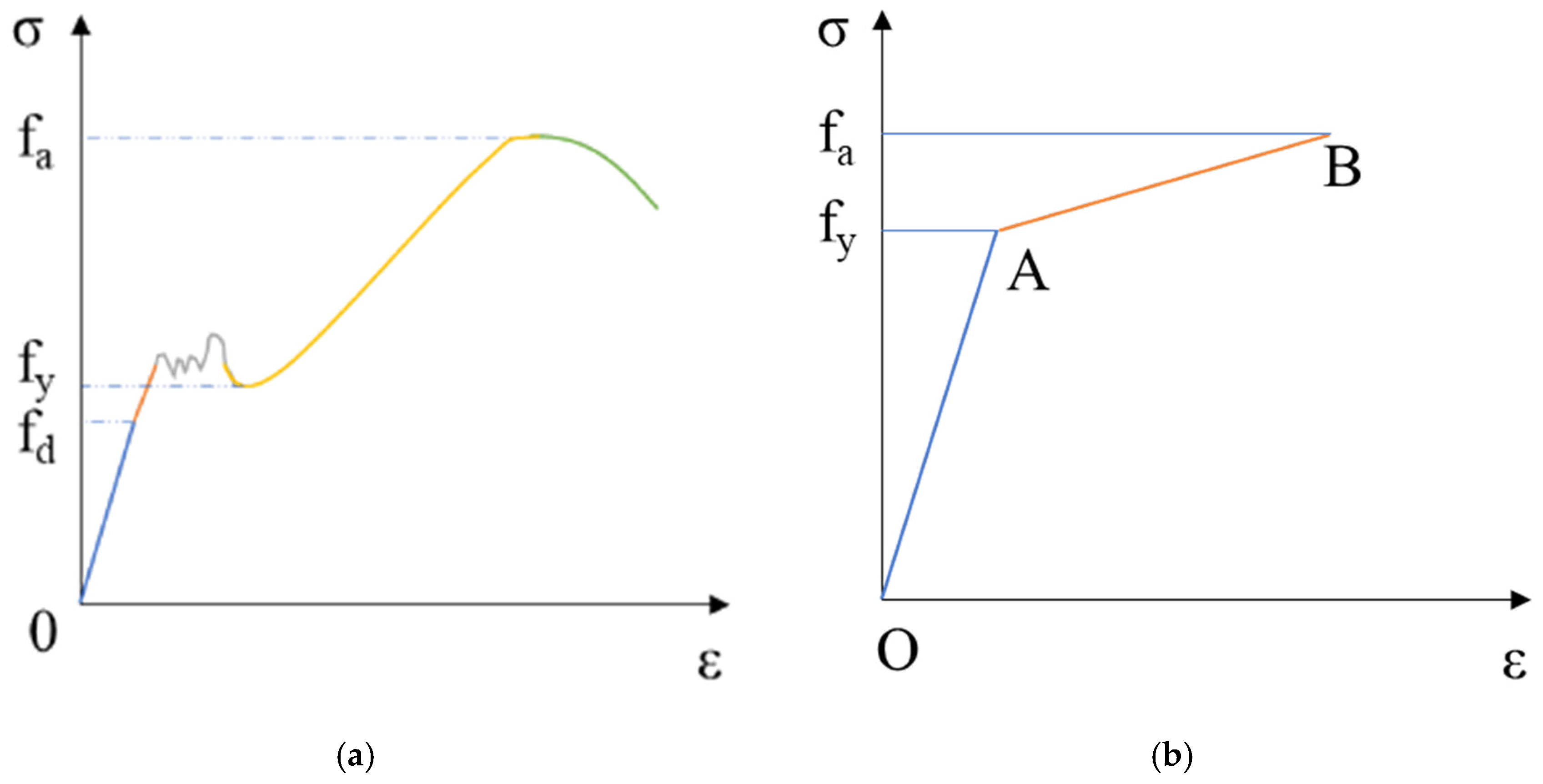

2.2. Material Properties of Specimen

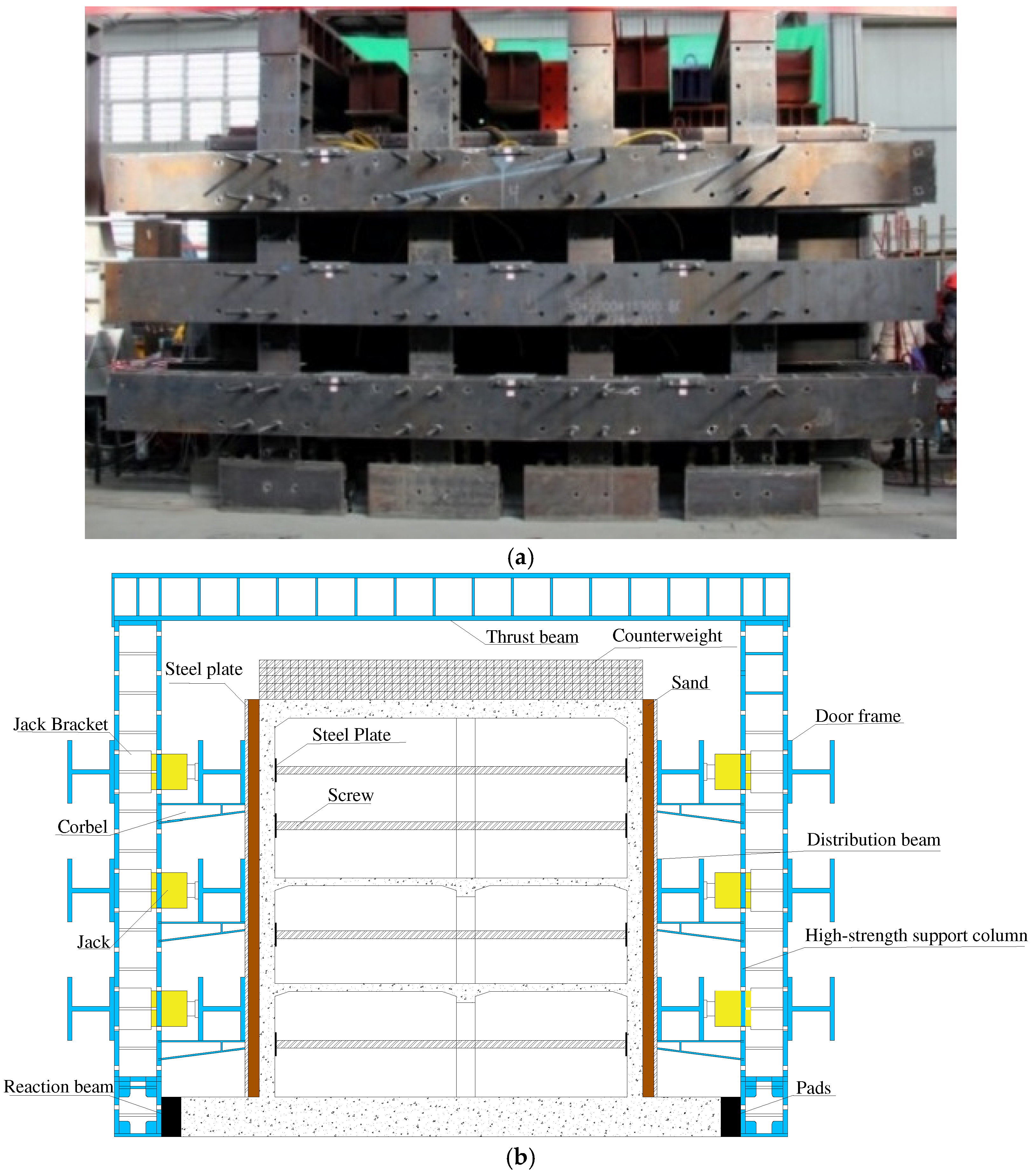

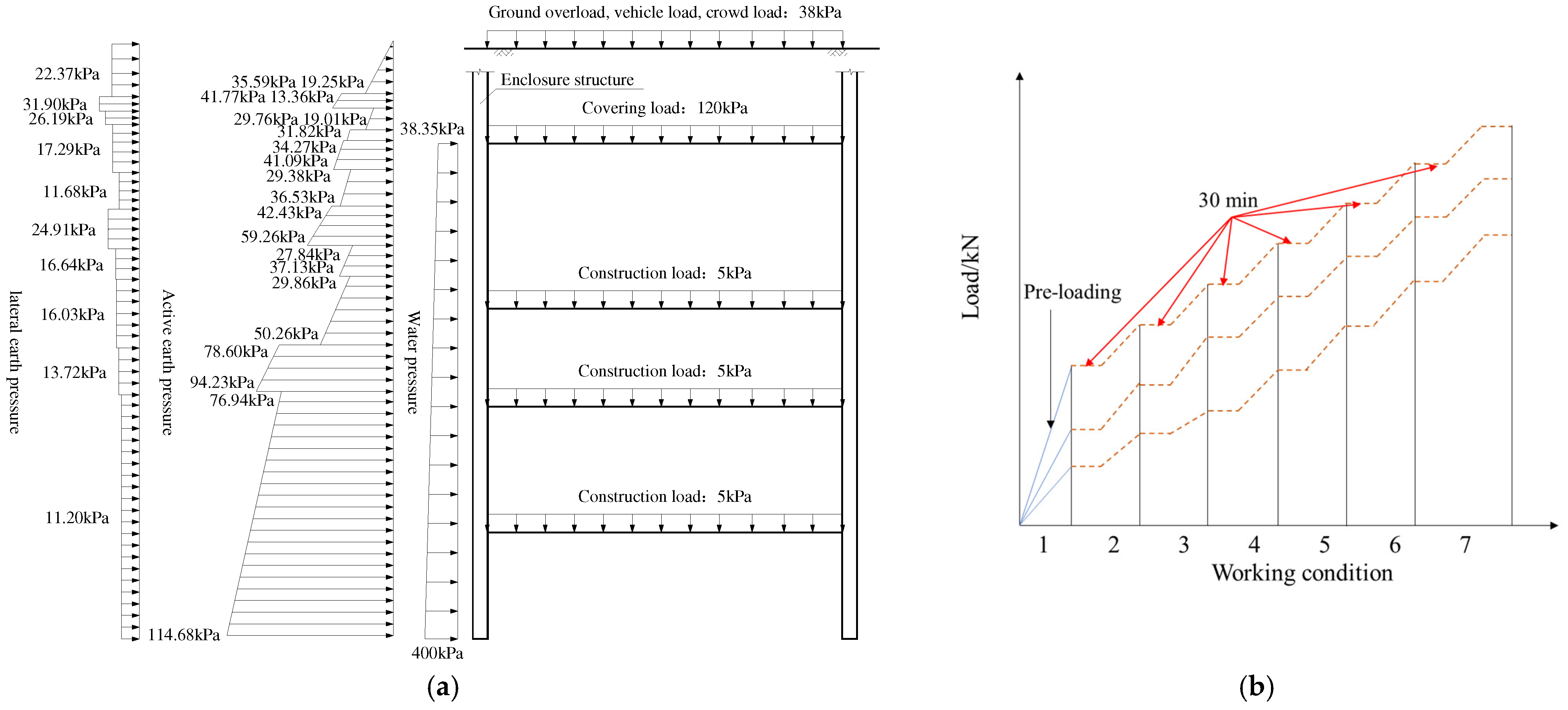

2.3. Loading Devices and Systems

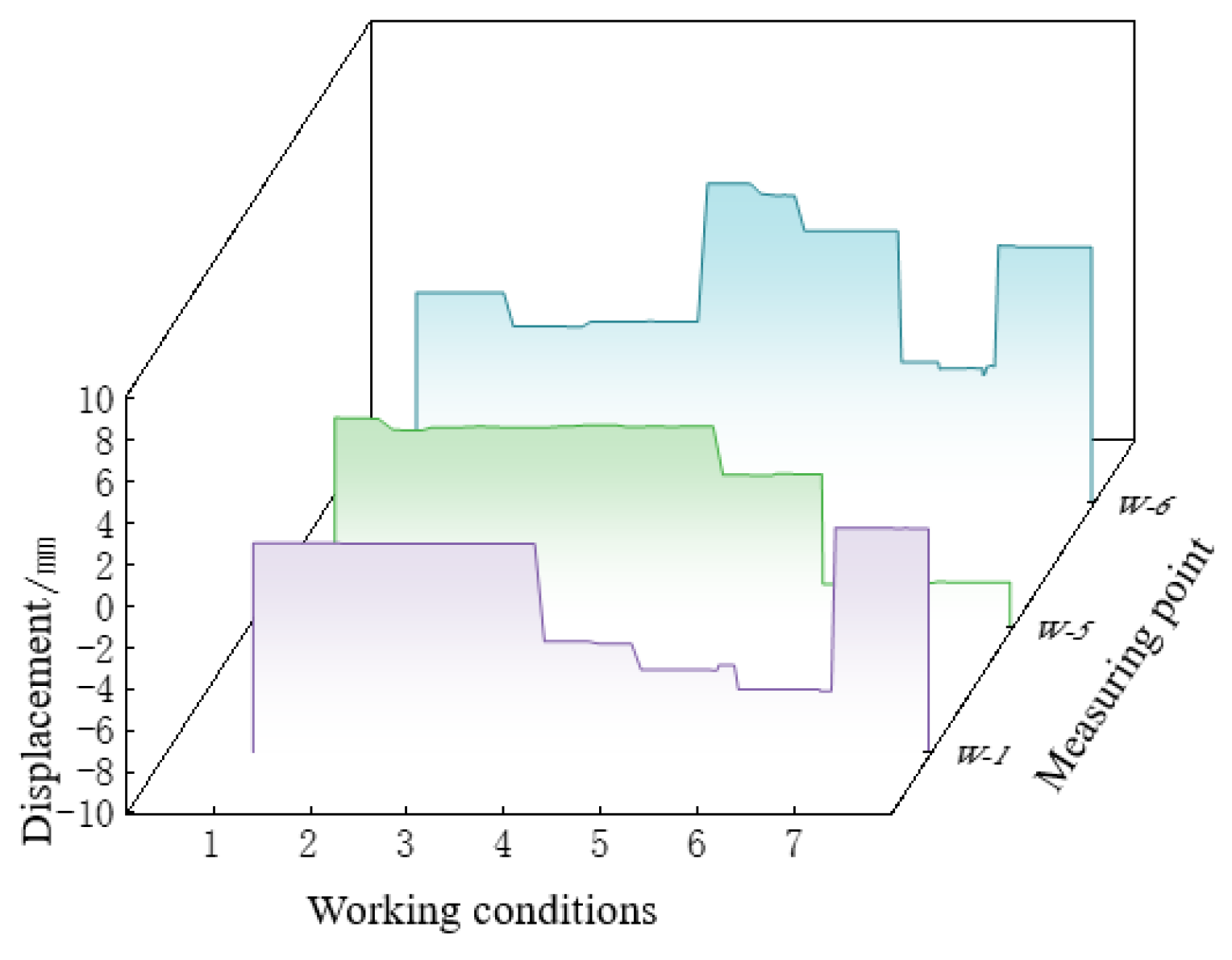

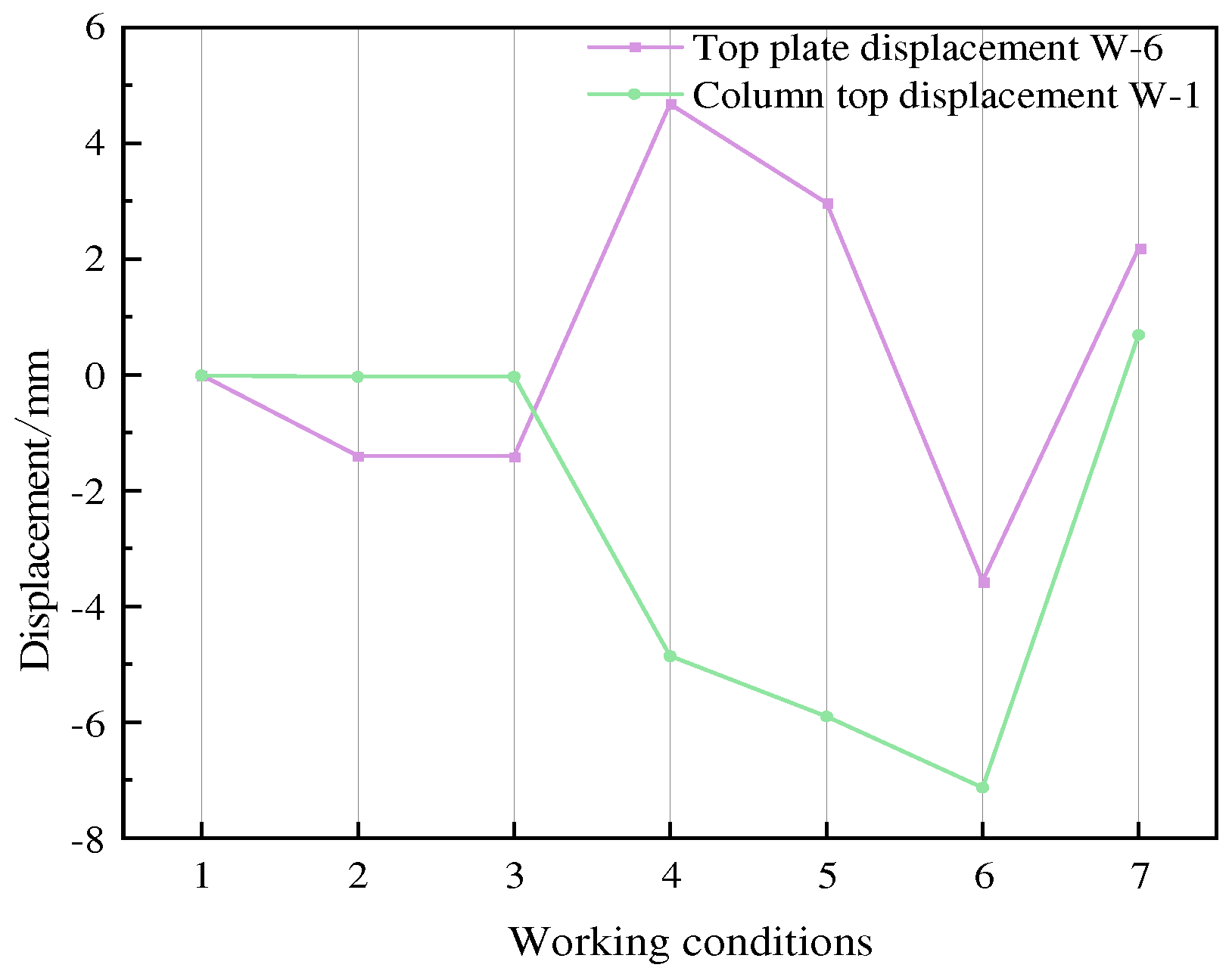

2.4. Measurement Programme

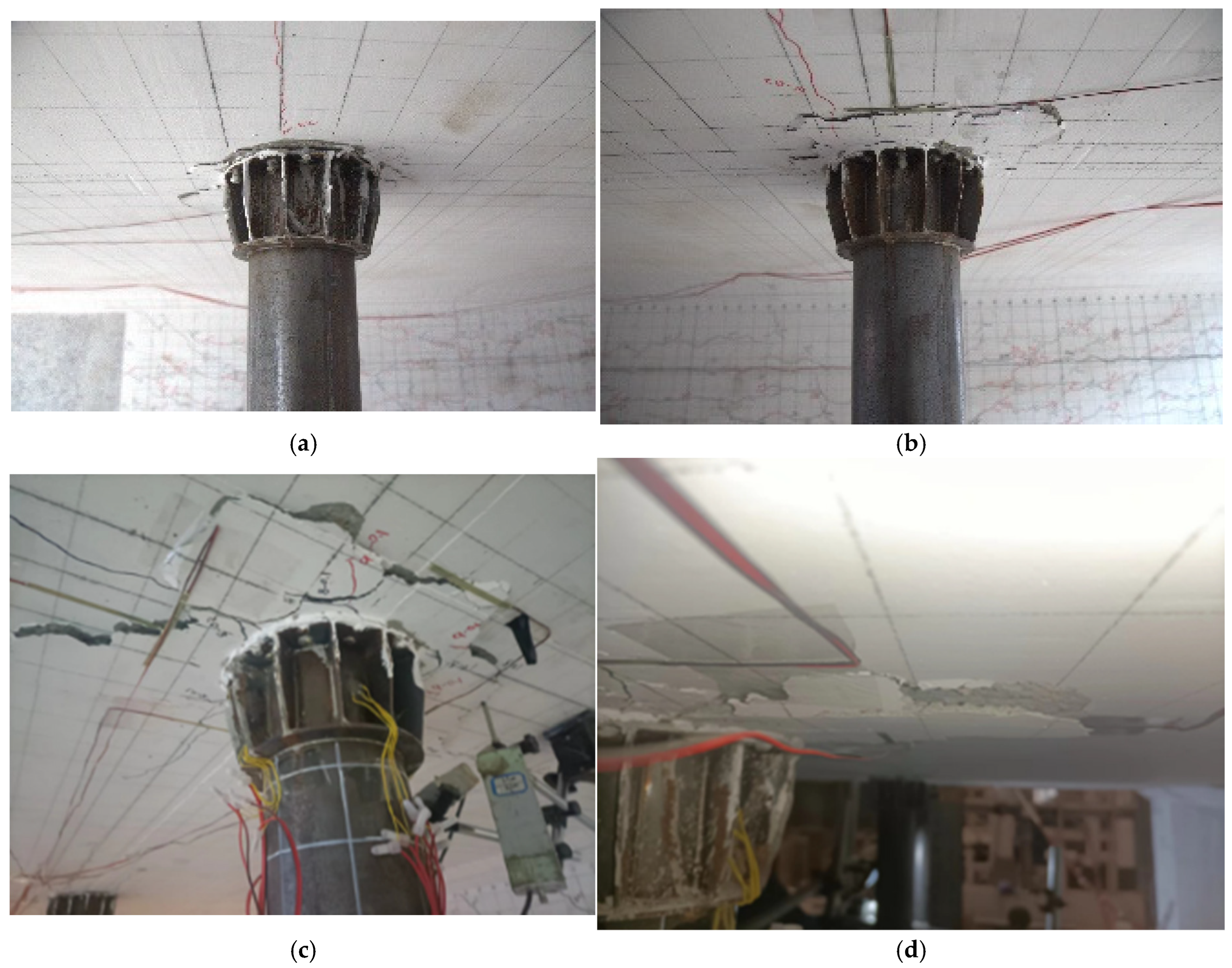

3. Test Phenomena and Damage Characteristics

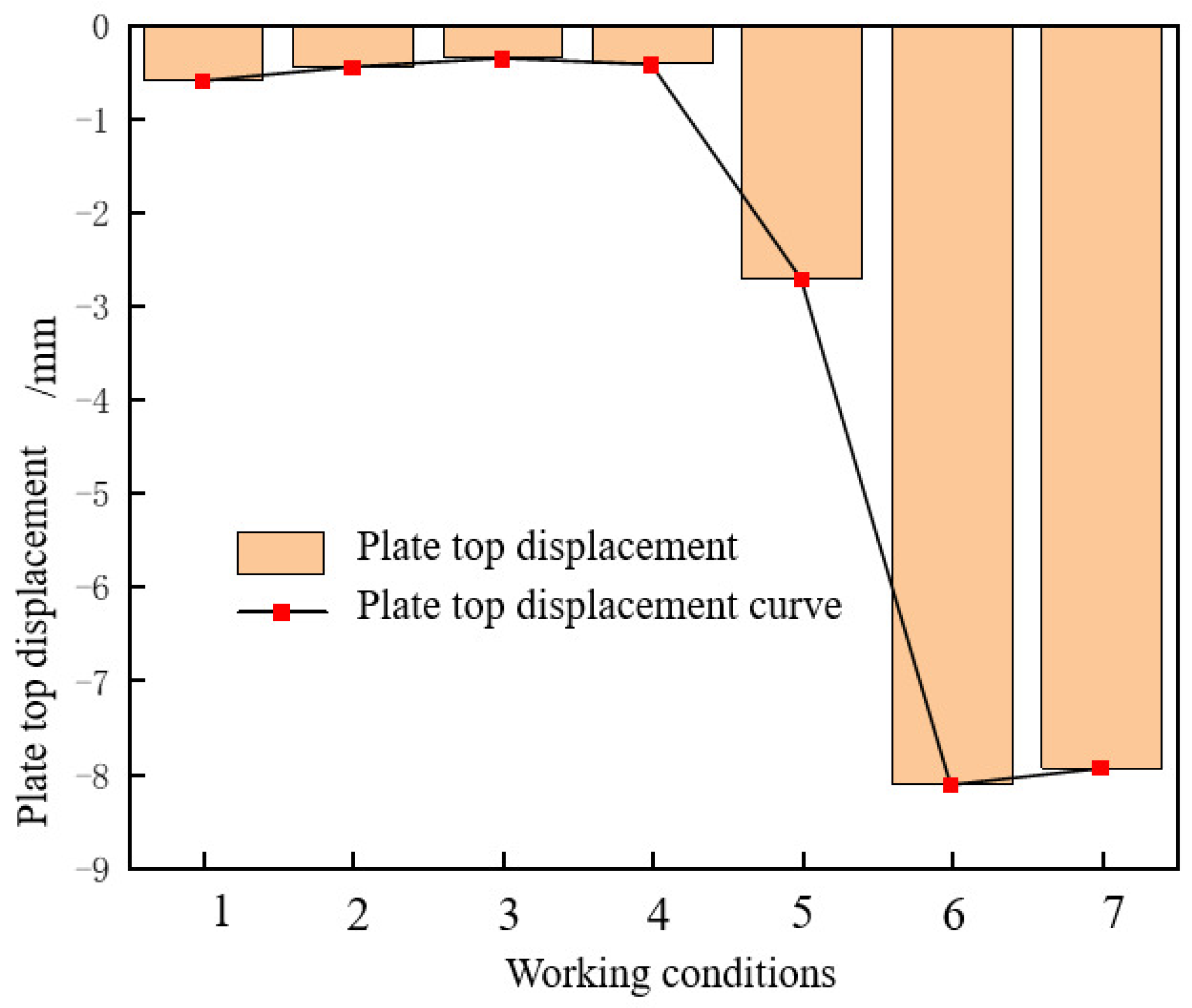

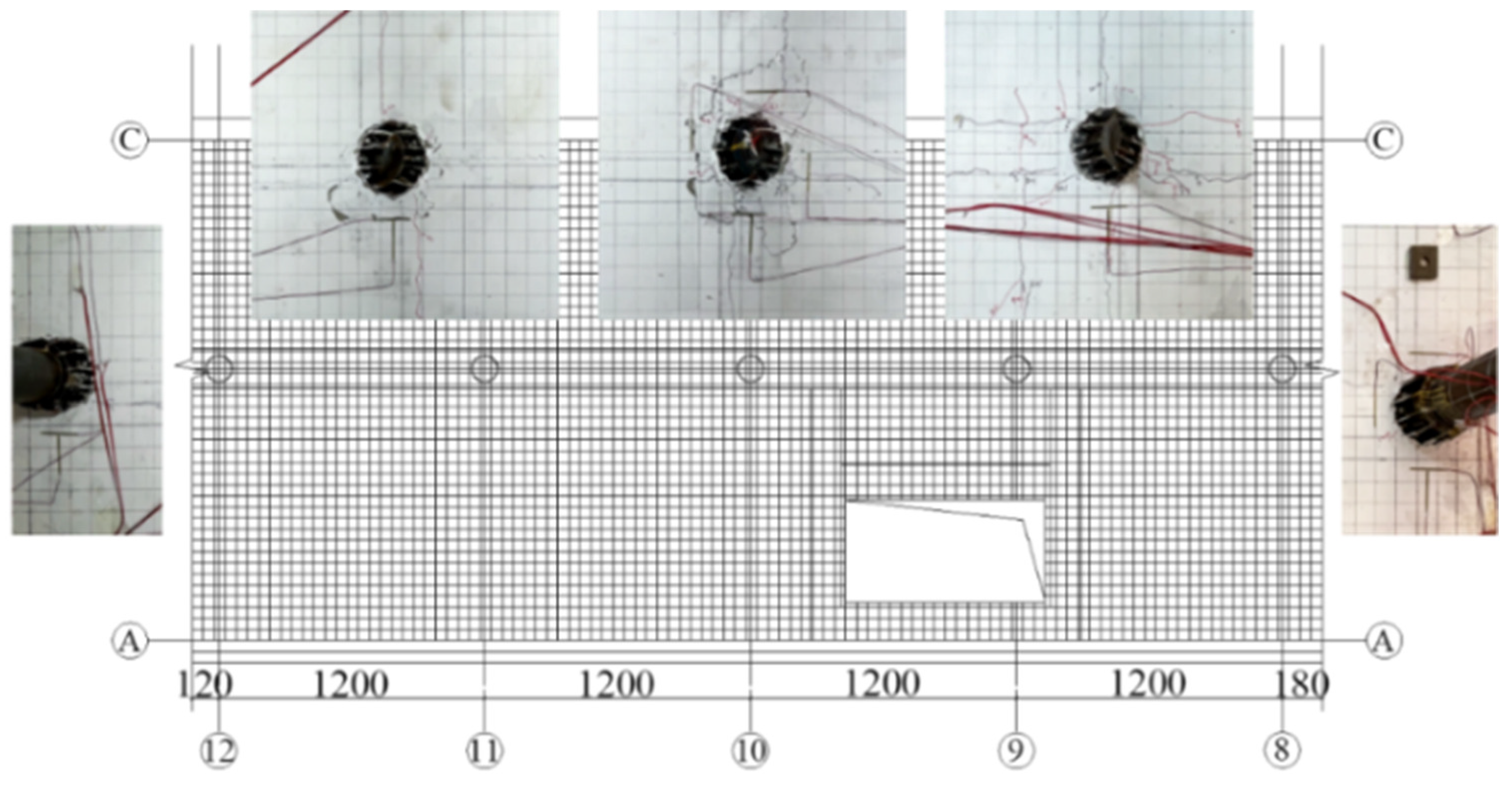

3.1. Test Phenomena

3.2. Damage Characteristics

4. Strain and Load Bearing Capacity Analysis

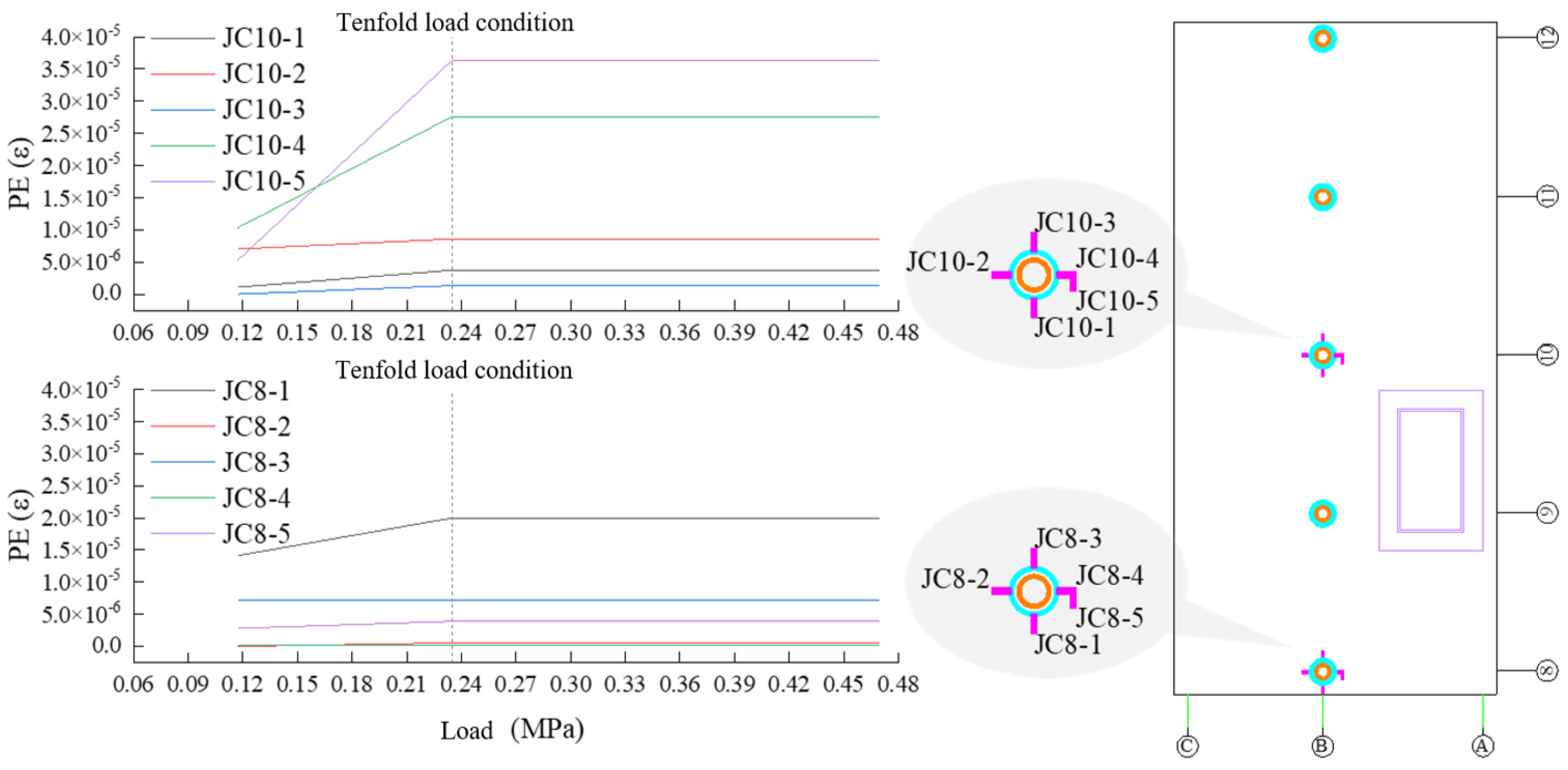

4.1. Node

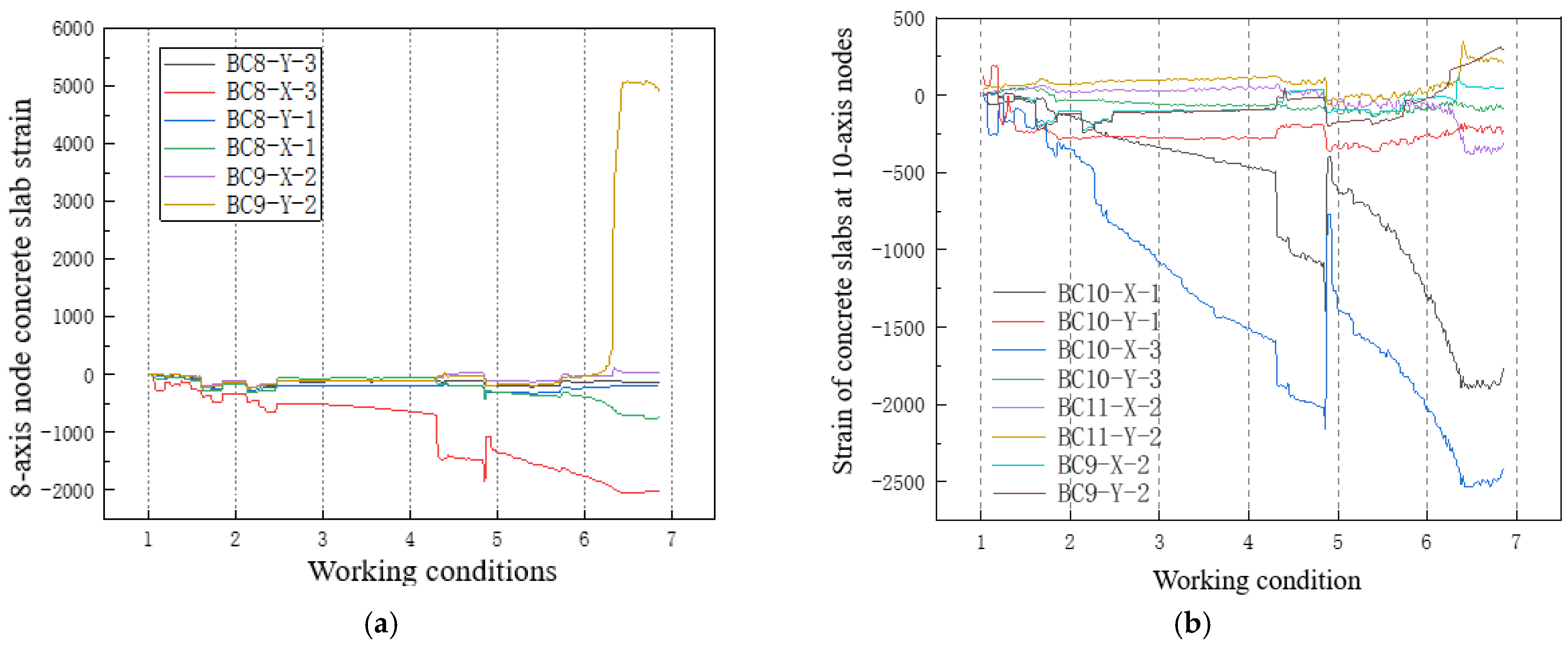

4.2. Concrete Slab

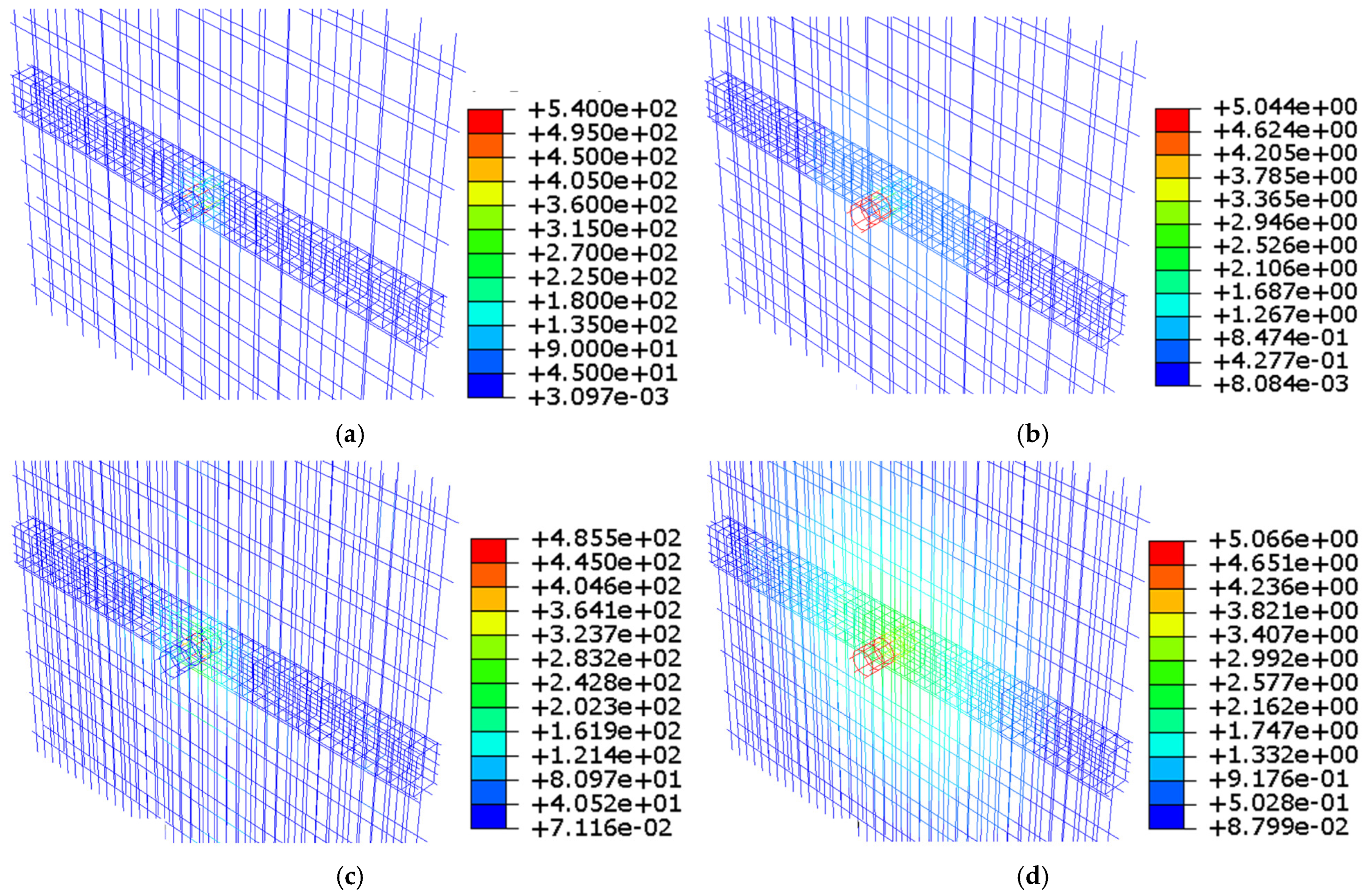

4.3. Beam Reinforcement

5. Finite Element Comparative Analysis

5.1. Finite Element Analysis Model

- (1)

- Ensure consistency between numerical simulation and experimental conditions: By aligning the geometry, component types, and boundary conditions with the laboratory model, we ensure that simulation results accurately reflect the stress and deformation behavior of the components during the test. Simplify the processing of minor components such as reaction beams and reaction frames to reduce modeling complexity while maintaining the overall stress characteristics.

- (2)

- Verify the bearing mechanism of the joint under earth pressure and subsequent loading: By applying equivalent earth pressure on both sides of the distributed beam in the model, we simulated actual construction conditions and analyzed the bearing capacity and failure modes of the column-end-plate joint. This also provided data support for structural redundancy research and explored the ultimate bearing capacity and failure mechanisms of the joint under different load levels.

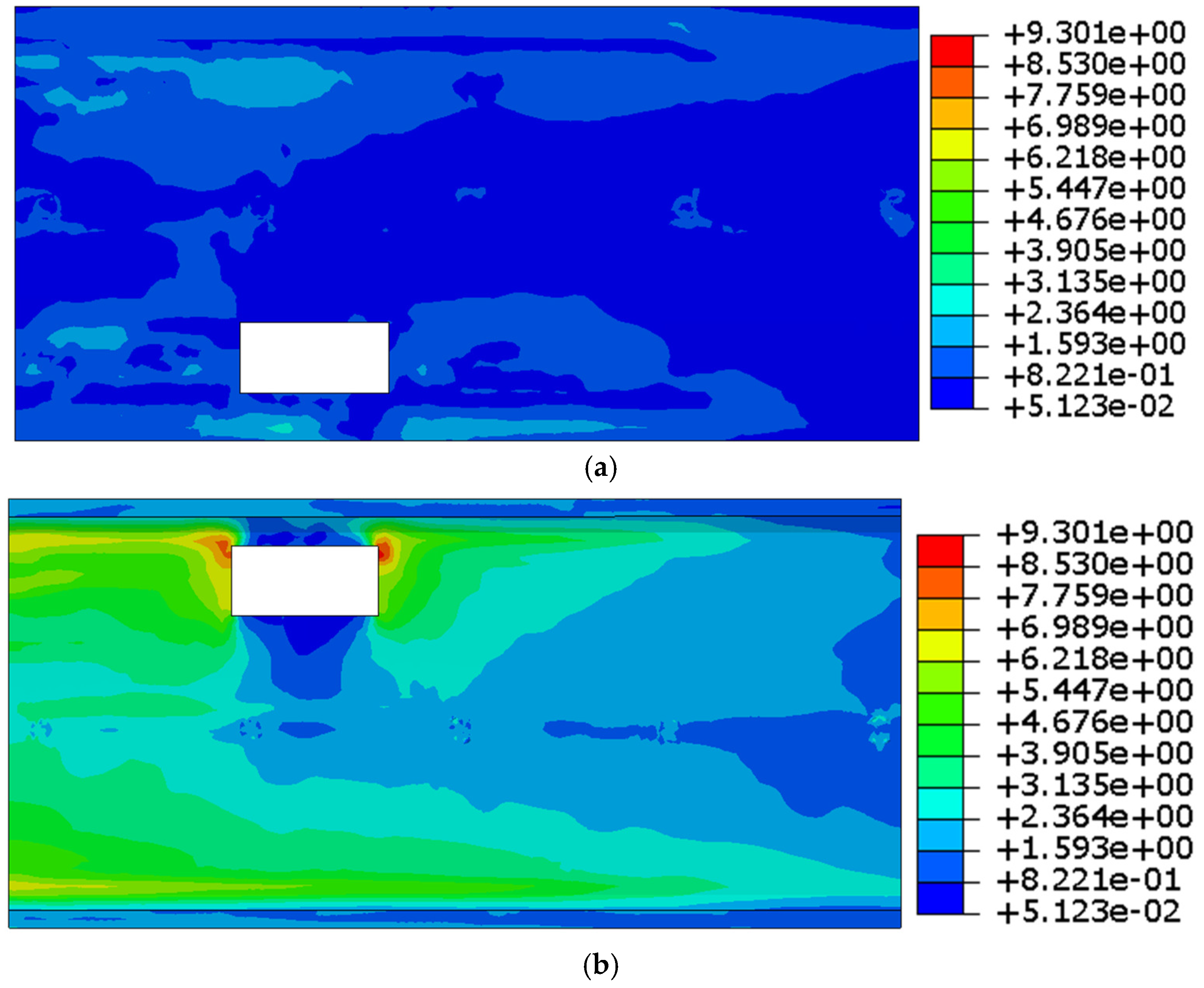

5.2. Failure Modes of Column End Plate Nodes

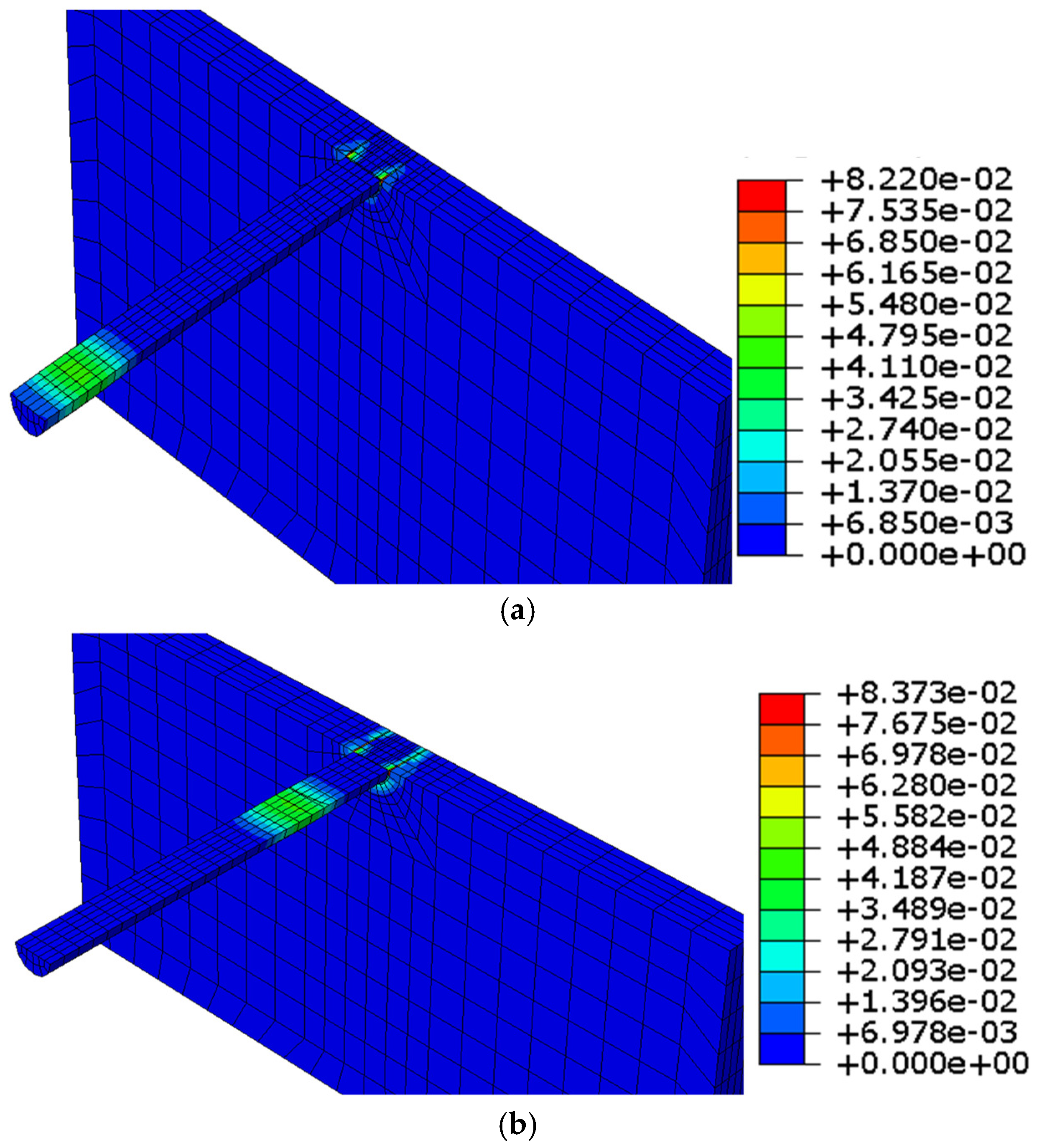

5.3. Stress-Strain Analysis

5.4. Parameter Optimization Analysis

6. Conclusions

- (1)

- The test shows that the cracks in the column end plate nodes first appear at the central axis node and gradually expand, eventually forming an annular crack in the top plate, accompanied by staggered failure; the side column nodes are mainly characterized by significant displacement and limited crack development due to insufficient edge constraints. The overall top plate has deformation characteristics of arching in the middle and warping at the edges.

- (2)

- The node strain analysis found that the stress concentration in the local area of the plate edge is significant, and the central axis node is subjected to both circumferential tension and radial compression, showing a significant stress gradient. The strain of the bottom reinforcement of the beam is generally greater than that of the surface reinforcement, and the stress is most concentrated near the opening, which verifies that the node is a weak point under load.

- (3)

- The finite element simulation results are highly consistent with the experimental observations and can better reflect the crack expansion path and damage distribution law. The results show that the steel pipe and flange work together to form a stable force transmission system. Even after local concrete failure, the steel pipe can still provide effective constraints to the core concrete.

- (4)

- The parameter optimization analysis shows that increasing the steel bar diameter and using high-strength steel bars can significantly improve the plastic strain and displacement bearing capacity of the node; the effect of increasing the steel bar arrangement parallel to the beam direction is particularly obvious. The research results provide a reliable reference for the design and construction optimization of slab-column joints in subway stations.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, Y. Application of cover excavation method in shallow buried subway station construction. World Tunn. 1995, 5, 2–11. [Google Scholar]

- Wang, X.; Wang, B.; Yuan, Y.; Yang, T.; Dong, G.; Shi, C. Study on the Effect of EICP Combined with Nano-SiO2 and Soil Stabilizer on Improving Loess Surface Strength. Buildings 2025, 15, 1998. [Google Scholar] [CrossRef]

- Zhou, D.; Mei, Y.; Ke, X.; Liu, Z.; Xu, W. Study on the Structural Behavior and Reinforcement Design of Openings in Subway Station Floor Slabs. J. Build. Eng. 2024, 98, 110994. [Google Scholar] [CrossRef]

- Wang, X.; Chen, C. Vibration Table Test of Prefabricated L-Shaped Column Concrete Structure. Buildings 2025, 15, 2329. [Google Scholar] [CrossRef]

- Wang, J. Key Technology of Subway Steel Structure construction with reverse excavation method. Equip. Maint. Technol. 2024, 2, 91–93. [Google Scholar]

- Guo, H.; Zhang, J.; Shi, X. Analysis of key technologies in construction of Shenzhen Metro Dayun Junction Station. Tunn. Constr. (In Chinese & English). 2023, 43 (Suppl. S1), 451–456. [Google Scholar]

- Zhang, Y.; Zhang, S.; Jia, J. Study on deformation mechanism of deep foundation pit wall in subway station cover excavation. Build. Struct. 2022, 52 (Suppl. S2), 2401–2405. [Google Scholar]

- Xia, Y. Research on high-precision sag adjustment Technology of concrete filled steel tube column with reverse cutting method. Constr. Technol. 2022, 51, 128–131, (In Chinese & English). [Google Scholar]

- Shi, X. Research on Displacement Law of Vertical Support System of Subway Station with Cover Excavation and Reverse Construction. Master’s. Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

- Ma, Y.; Ling, T. Research on attitude control technology of steel pipe column in subway station. Eng. Constr. 2021, 53, 56–61. [Google Scholar]

- Li, Y.; Li, Y.; Zhou, D. Experimental study on mechanical behavior of plate-column joints with support plates and dark beams after punching. Earthq. Eng. Eng. Vib. 2020, 40, 178–186. [Google Scholar]

- Zhao, Y.; Li, X.; Zhang, J. Research on punching resistance of concrete slab with carbon fiber reinforced composite mesh bars. Ind. Build. 2019, 49, 90–94. [Google Scholar]

- Fukumoto, T.; Morita, K. Elastoplastic Behavior of Panel Zone inSteel Beam to Concrete Filled Steel Tube Column Moment Connections. J. Struct. Eng. 2005, 131, 1841–1853. [Google Scholar] [CrossRef]

- Lu, X.-L.; Li, X.-P.; Yu, Y. Design method of joint joints between rectangular concrete-filled steel tube column and steel beam. Build. Struct. 2005, 1, 7–9+12. [Google Scholar]

- Lu, X.; Li, X. Test and design method of external ring beam joint for concrete-filled square steel tube column. J. Build. Struct. 2003, 1, 7–13. [Google Scholar]

- Shuailong, F.; Huashan, Q.; Gaoxing, H.; Lei, Z.; Bing, C.; Yuan, F. Axial Compression Performance of Prefabricated Square Semi-Continuous CFST Columns with High-Strength Bolts. J. Constr. Steel Res. 2025, 234, 109719. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, J.; Miao, Y.; Zhou, B.; Huang, W.; He, Y.; Lu, Q.; Wang, Y. Performance of T-Shaped CFST Columns with Embedded T-Shaped Steel Skeleton under Axial Compression. J. Constr. Steel Res. 2024, 215, 108554. [Google Scholar] [CrossRef]

- GB 50010-2010: 440P. B5; Code for Design of Concrete Structures. China Academy of Building Science: Beijing, China; Tsinghua University: Beijing, China; Tongji University: Shanghai, China, 2010.

- GB/T 228.1-2010; Metal Materials Tensile Test Part 1: Room Temperature Test Method. Standards Press of China: Beijing, China, 2010.

- Yankelevsky, D.Z.; Karinski, Y.S.; Feldgun, V.R. Dynamic Punching Shear Failure of a RC Flat Slab-Column Connection Under a Collapsing Slab Impact. Int. J. Impact Eng. 2020, 135, 103401. [Google Scholar] [CrossRef]

| Material Type | /MPa | /MPa | /MPa | /MPa |

|---|---|---|---|---|

| C35 concrete | 46.21 | 35.07 | 3.24 | 3.3 × 104 |

| C60 concrete | 62.30 | 40.27 | 6.72 | 3.6 × 104 |

| Reinforcement Construction | Steel Bar Stress Form | Number of Reinforcement | Reinforcement Ratio (%) | |

|---|---|---|---|---|

| Column | Strength bars | 5Φ8 | 2.22 | |

| Stirrups | Φ8@445 | 0.20 | ||

| Plate | Upper longitudinal reinforcement | Φ8@200 | 0.21 | |

| Upper transverse reinforcement | Φ8@125 | 0.33 | ||

| Lower longitudinal reinforcement | Φ8@200 | 0.21 | ||

| Lower transverse reinforcement | Φ8@125 | 0.33 | ||

| Φ8@95 | 0.43 | |||

| Tie bars | Φ8@400 × 400 | \ | ||

| Additional reinforcement of support | Left | Φ8@95 | 0.43 | |

| Middle | Φ8@95 | 0.43 | ||

| Right | Φ8@95 | 0.43 | ||

| Sample | Material Grade | Standard | Yielding Strength /(MPa) | Maximum Intensity /(MPa) | Modulus of| Elasticity/(MPa) |

|---|---|---|---|---|---|

| plate steel | Q235 | thickness 3 mm | 227 | 378 | 2.09 × 105 |

| steel reinforcement | HRB400 | Φ8 | 421.17 | 671.16 | 2 × 105 |

| plug | ML5 | Φ10 | 315.31 | 344.75 | 0.16 |

| Single Jack/(kN) | Single-Story Total/(kN) | |||||

|---|---|---|---|---|---|---|

| Negative Layer | Negative 2nd Floor | Negative 3rd Floor | Negative Layer | Negative 2nd Floor | Negative 3rd Floor | |

| Working condition 1 | 15.97 | 28.71 | 52.63 | 95.82 | 172.26 | 315.78 |

| Working condition 2 | 23.955 | 43.065 | 78.945 | 143.73 | 258.39 | 473.67 |

| Working condition 3 | 39.925 | 71.775 | 131.575 | 239.55 | 430.65 | 789.45 |

| Working condition 4 | 47.91 | 86.13 | 157.89 | 287.46 | 516.78 | 947.34 |

| Working condition 5 | 63.88 | 114.84 | 210.52 | 383.28 | 689.04 | 1263.12 |

| Working condition 6 | 119.775 | 215.325 | 394.725 | 718.65 | 1291.95 | 2368.35 |

| Working condition 7 | 383.28 | 689.04 | 1263.12 | 2299.68 | 4134.24 | 7578.72 |

| Analytical Factor | Model Number | Variable |

|---|---|---|

| Bar diameter | Blank group | 8 mm |

| Model1-1 | 6 mm | |

| Model1-2 | 10 mm | |

| Bar spacing | Blank group | The bar spacing of parallel beams is 200 mm; Vertical beam bottom bar spacing 95 mm, gluten spacing 125 mm. |

| Model2-1 | The bar spacing of parallel beams is 100 mm, and the rest is unchanged. | |

| Model2-2 | Vertical beam bottom bar spacing 47.5 mm, gluten spacing 62.5 mm, other unchanged. | |

| Reinforcement material | Blank group | HRB400 |

| Model3-1 | HRB355 | |

| Model3-2 | HRB500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, W.; Ruan, Y.; Li, Y.; Liang, R.; Xiao, C.; Mei, Y.; Lu, H. Study on Punching Shear Performance of Concrete-Filled Steel Tubular Column-Slab Column Joints in Metro Stations. Buildings 2025, 15, 3219. https://doi.org/10.3390/buildings15173219

Mao W, Ruan Y, Li Y, Liang R, Xiao C, Mei Y, Lu H. Study on Punching Shear Performance of Concrete-Filled Steel Tubular Column-Slab Column Joints in Metro Stations. Buildings. 2025; 15(17):3219. https://doi.org/10.3390/buildings15173219

Chicago/Turabian StyleMao, Wufeng, Yanmei Ruan, Yuhui Li, Rui Liang, Chenyang Xiao, Yuan Mei, and Hongping Lu. 2025. "Study on Punching Shear Performance of Concrete-Filled Steel Tubular Column-Slab Column Joints in Metro Stations" Buildings 15, no. 17: 3219. https://doi.org/10.3390/buildings15173219

APA StyleMao, W., Ruan, Y., Li, Y., Liang, R., Xiao, C., Mei, Y., & Lu, H. (2025). Study on Punching Shear Performance of Concrete-Filled Steel Tubular Column-Slab Column Joints in Metro Stations. Buildings, 15(17), 3219. https://doi.org/10.3390/buildings15173219