Eco-Friendly Self-Compacting Concrete Incorporating Waste Marble Sludge as Fine and Coarse Aggregate Substitute

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design and Mixing Procedure

2.3. Experimental Procedures

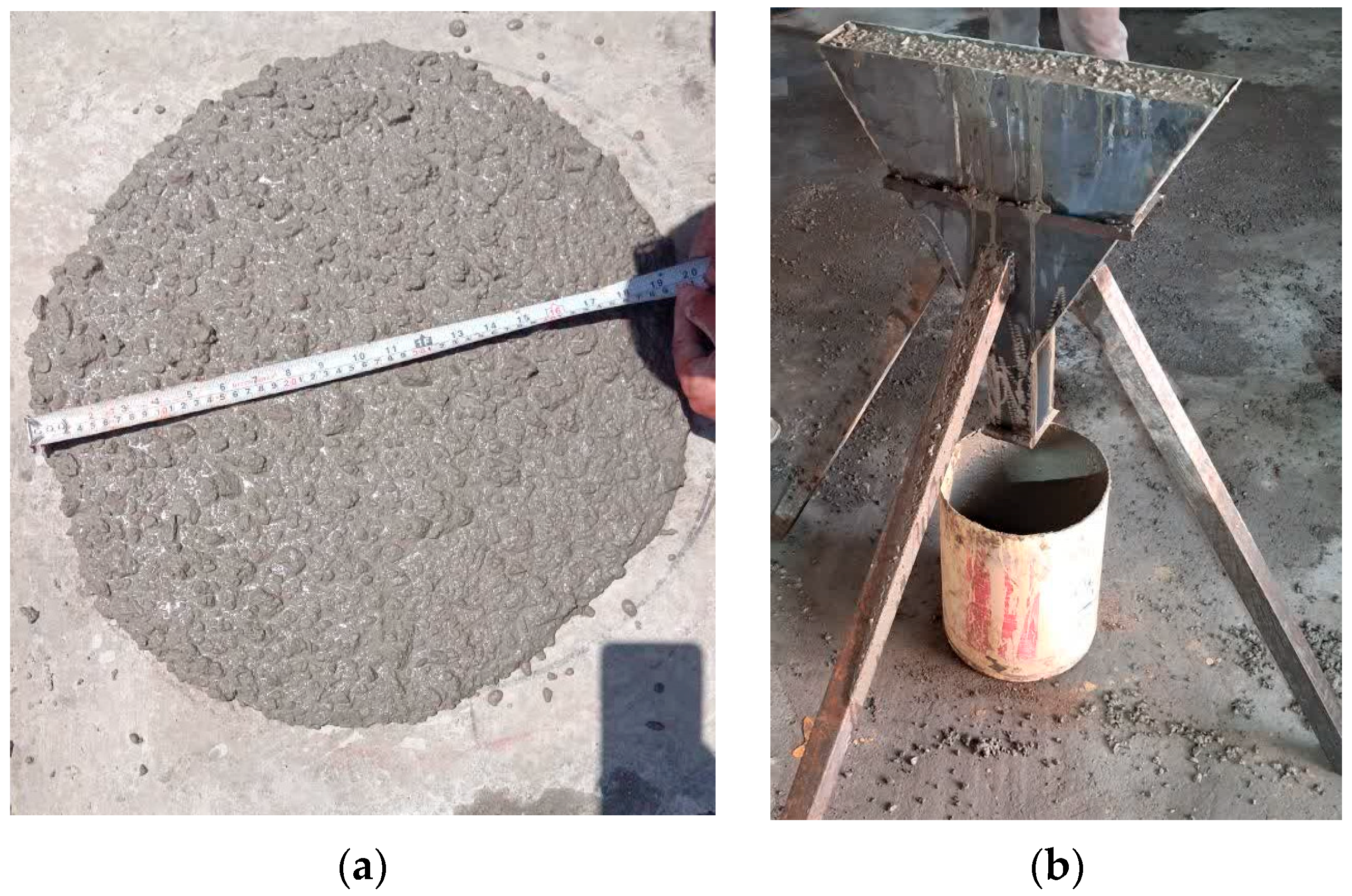

2.3.1. Fresh Properties Tests

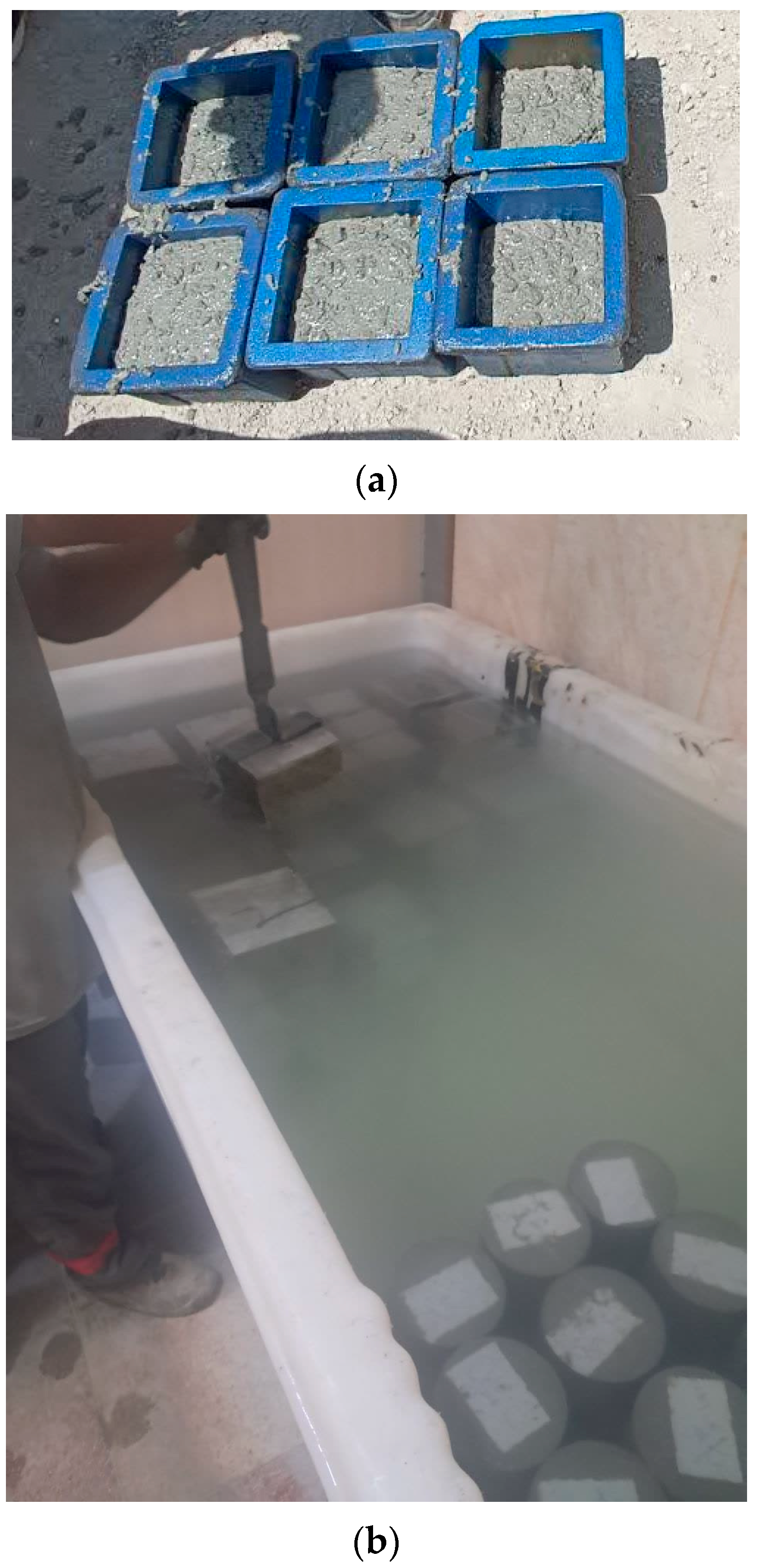

2.3.2. Hardened Properties Tests

3. Results

3.1. Fresh Properties Results

3.1.1. Slump Flow Test

3.1.2. T50 Time

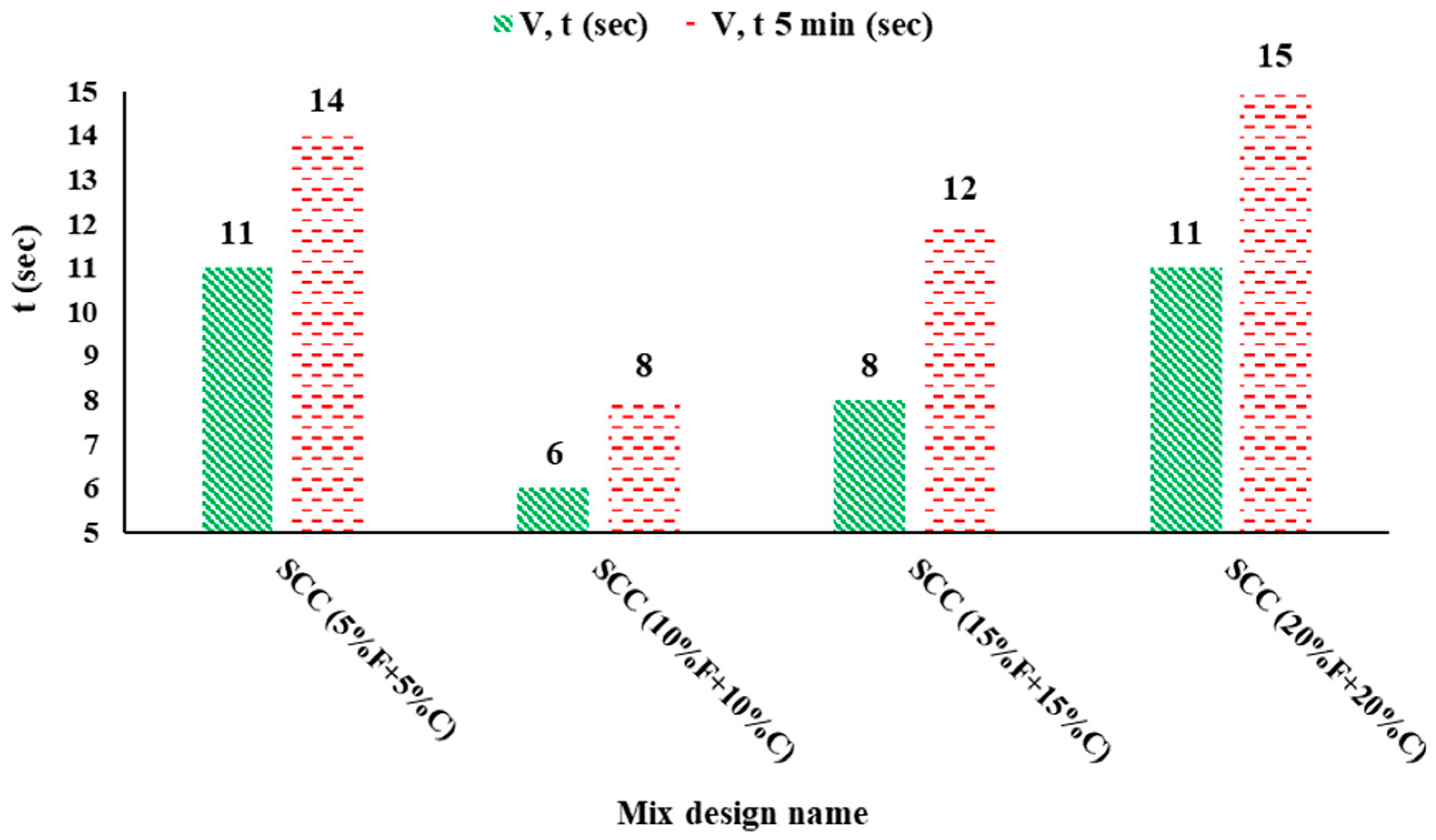

3.1.3. V-Funnel Flow Time

3.2. Hardened Properties Results

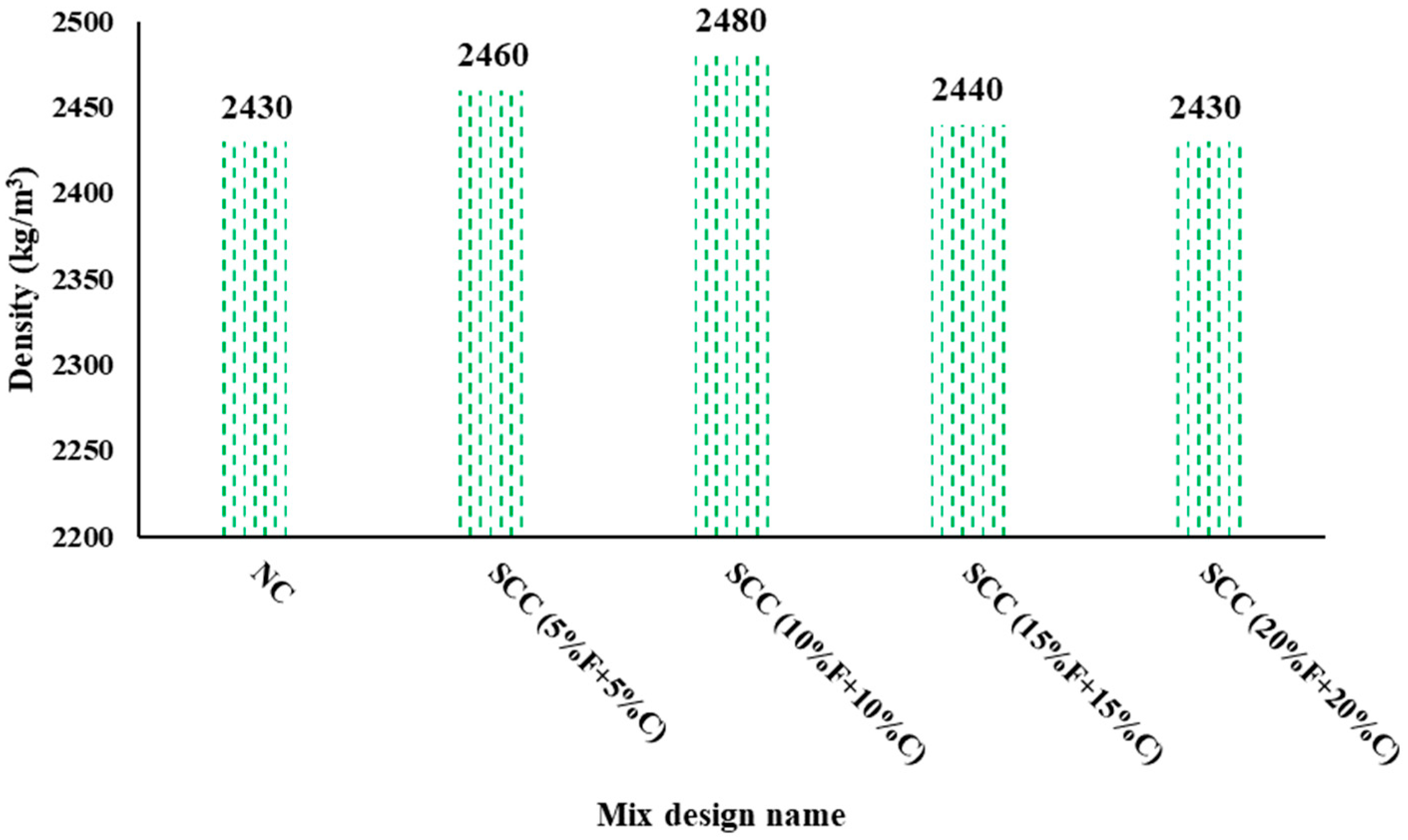

3.2.1. Density

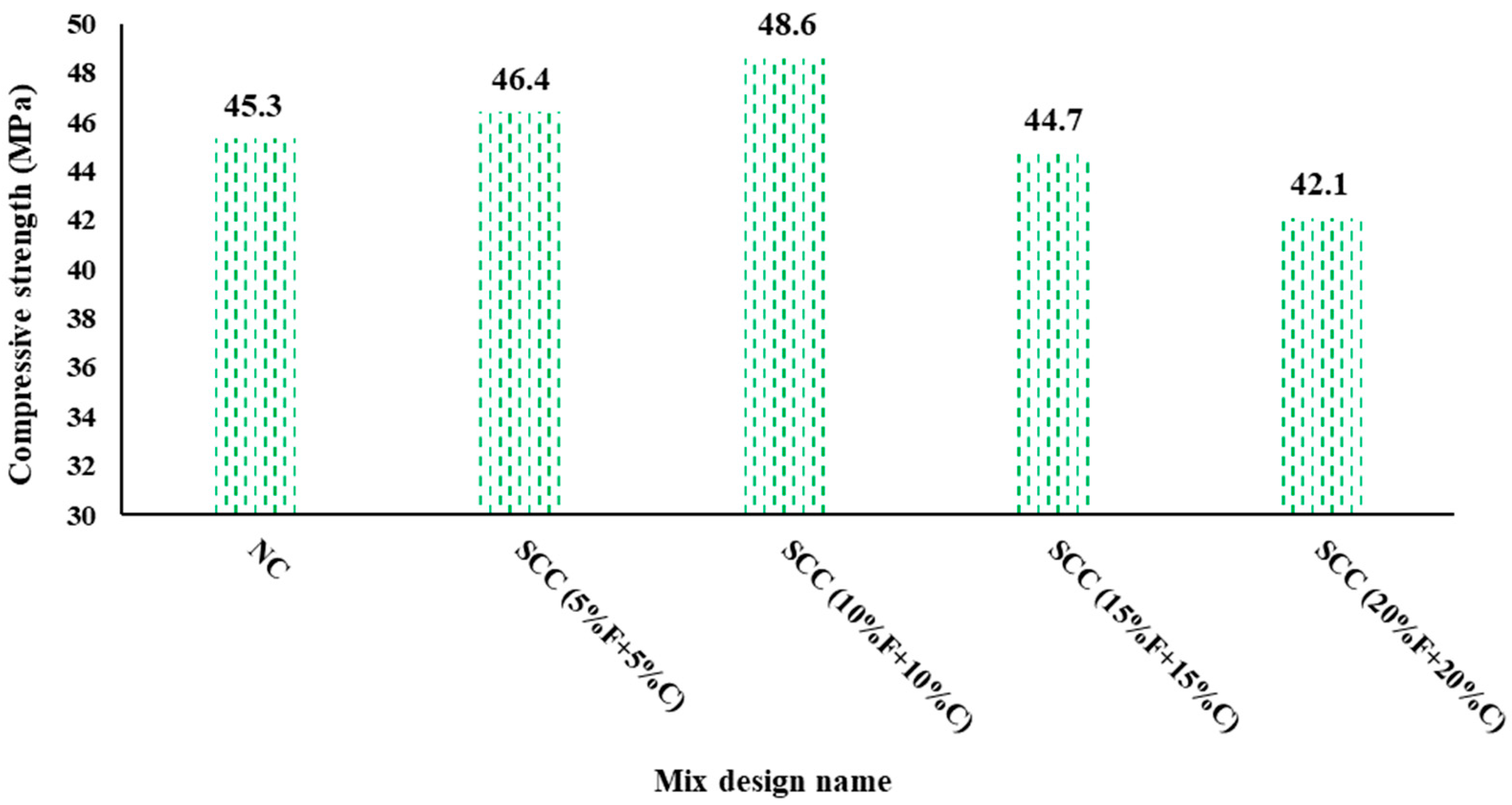

3.2.2. Compressive Strength

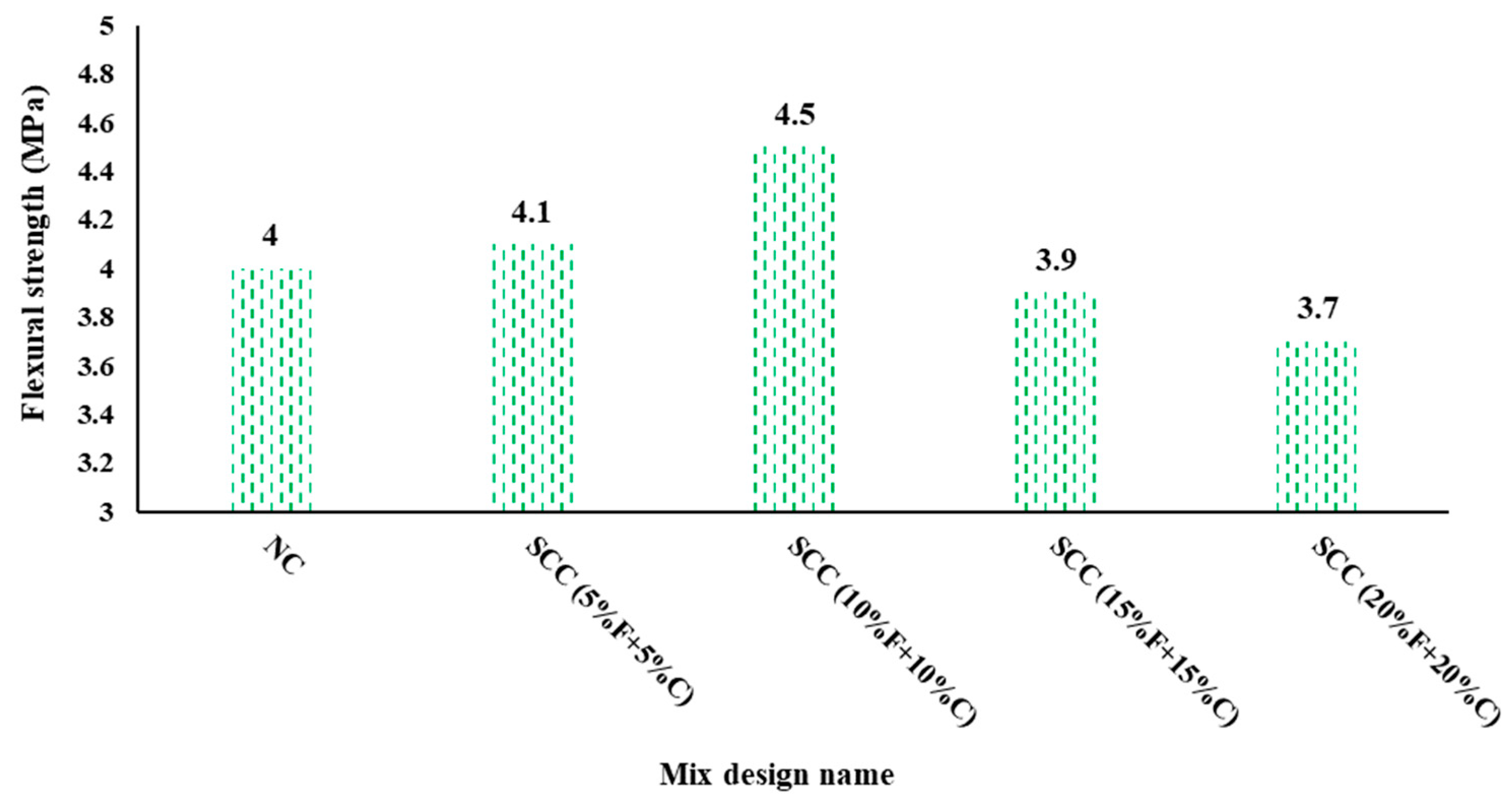

3.2.3. Flexural Strength

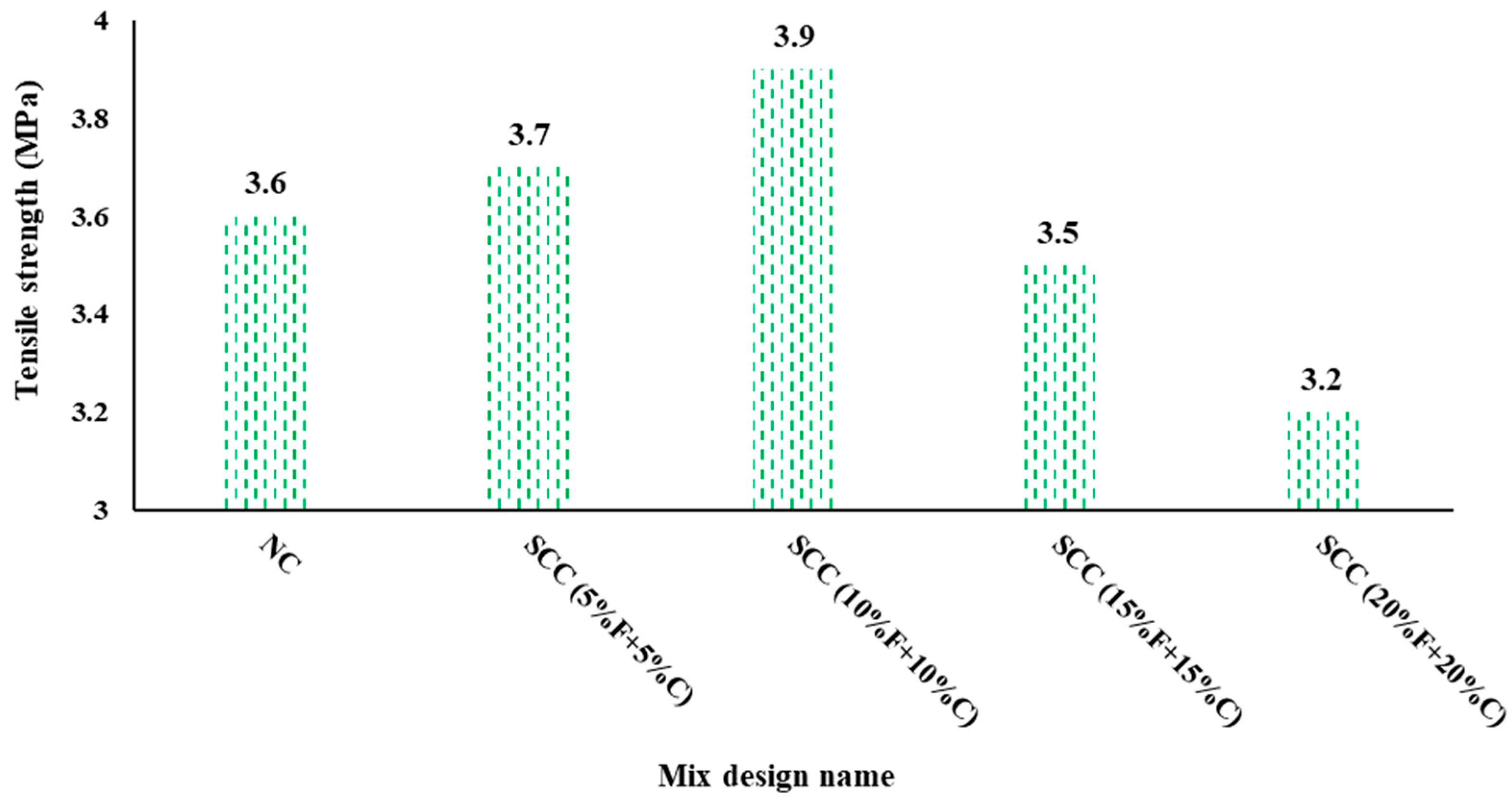

3.2.4. Tensile Strength

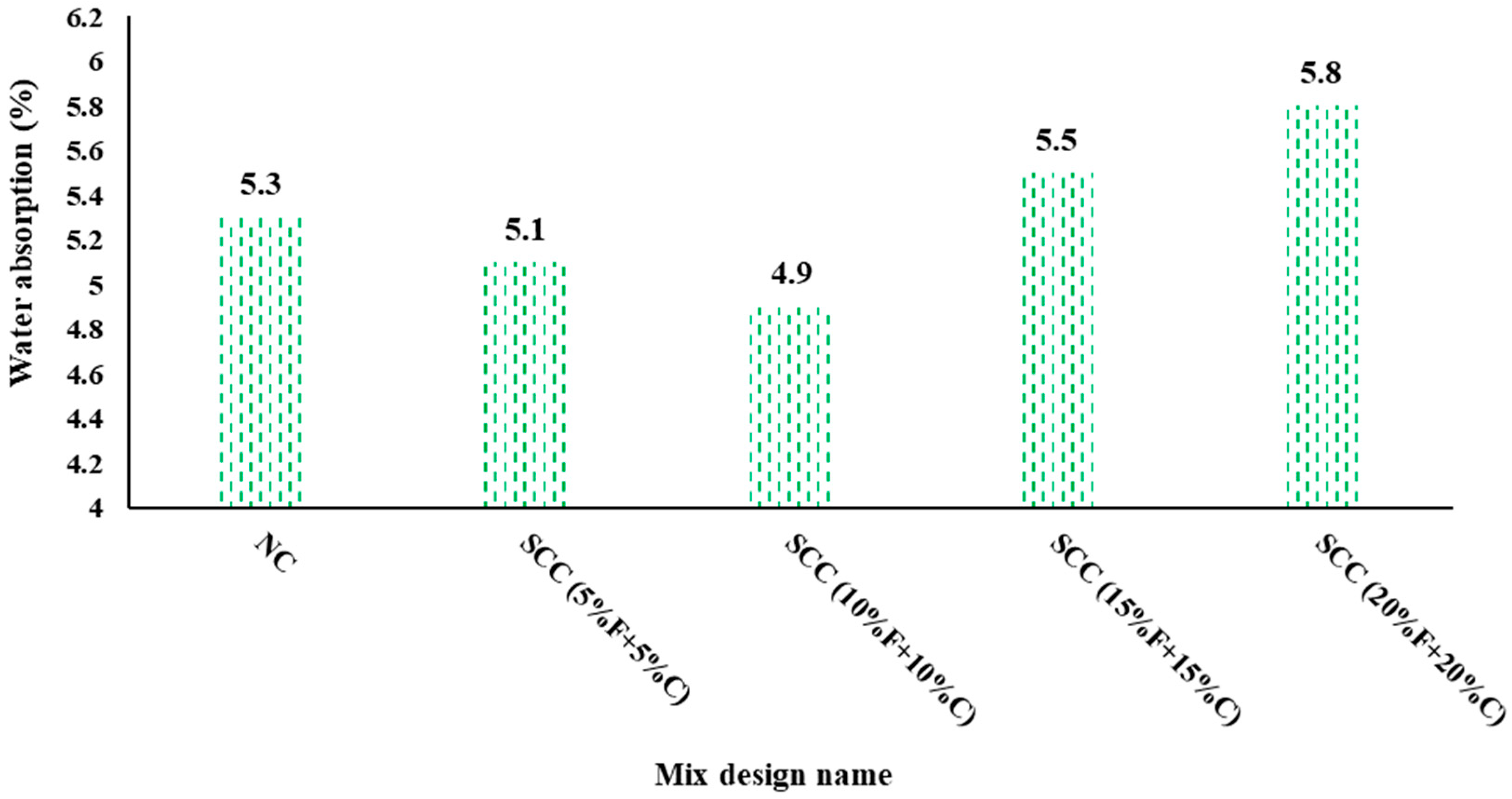

3.2.5. Water Absorption

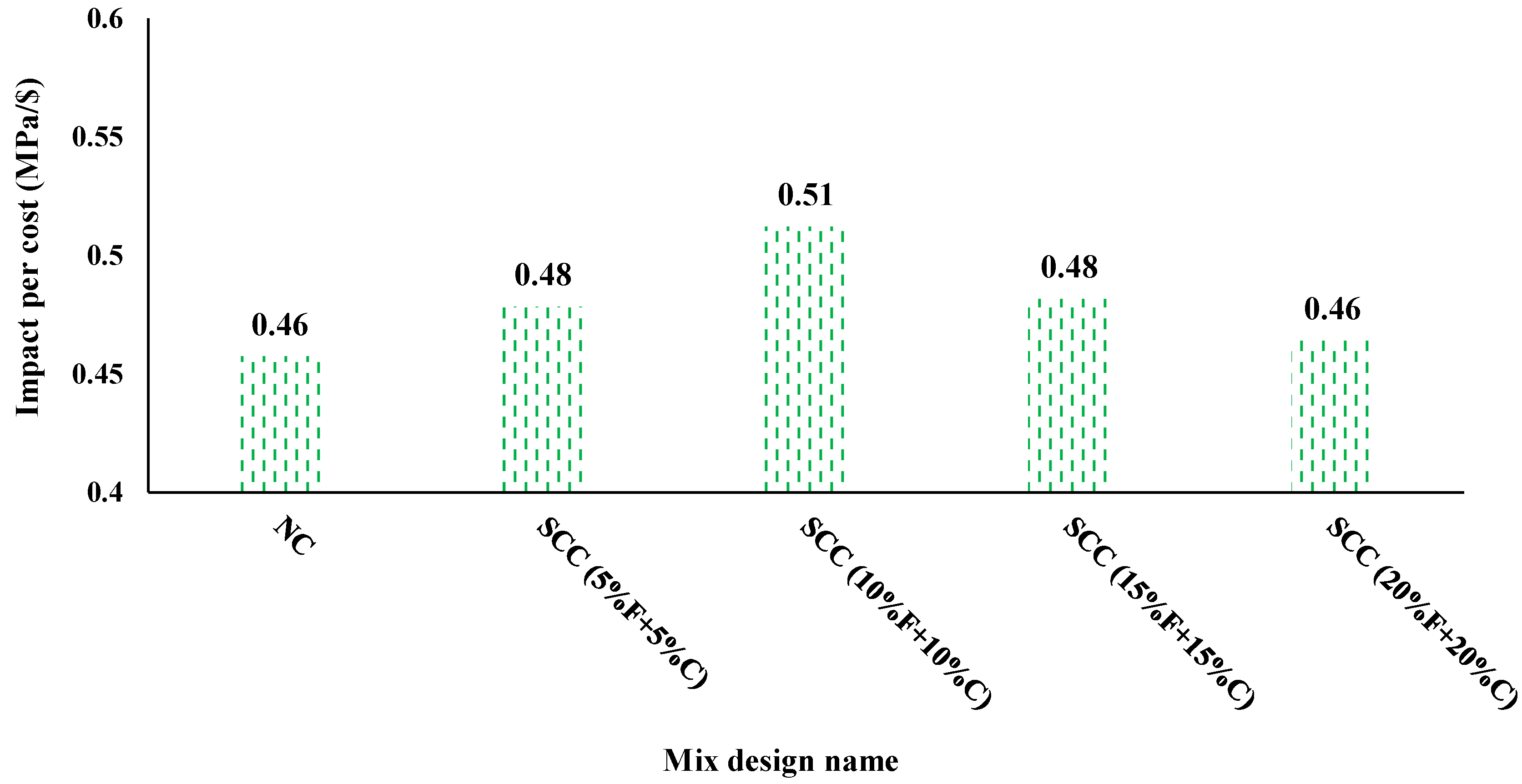

3.2.6. Cost Analysis

4. Conclusions

5. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ITZ | Interfacial transition zone |

| SCC | Self-compacting concrete |

| WMS | Waste marble sludge |

References

- Al-Numan, B.S.O. Construction industry role in natural resources depletion and how to reduce it. In Natural Resources Deterioration in MENA Region: Land Degradation, Soil Erosion, and Desertification; Springer: Berlin/Heidelberg, Germany, 2024; pp. 93–109. [Google Scholar]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; de Azevedo, A.R.G.; Klyuev, S.; Vatin, N.; Karelina, M. Capacity to develop recycled aggregate concrete in South East Asia. Buildings 2021, 11, 234. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H. Impact of Fibers on the Mechanical and Environmental Properties of High-Performance Concrete Incorporating Zeolite. J. Compos. Sci. 2025, 9, 222. [Google Scholar] [CrossRef]

- Rostampour, M.A.; Davood, M.; Hadi, B.; Hasan, M. Crack Assessment Using Acoustic Emission in Cement-Free High-Performance Concrete Under Mechanical Stress. J. Compos. Sci. 2025, 9, 380. [Google Scholar] [CrossRef]

- Mostafaei, H.; Chamasemani, N.F.; Mashayekhi, M.; Hamzehkolaei, N.S.; Santos, P. Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling. Appl. Sci. 2025, 15, 2479. [Google Scholar] [CrossRef]

- Shabani, K.; Bahmani, M.; Fatehi, H.; Chang, I. Improvement of the geotechnical engineering properties of dune sand using a plant-based biopolymer named serish. Geomech. Eng. 2022, 29, 535–548. [Google Scholar]

- Kırgız, M.S.; Khatib, J.; de Sousa Galdino, A.G.; Kenai, S.; Ashteyat, A.; Campilho, R.D.S.G.; Lezcano, R.A.G.; Bamigboye, G.O.; Nagaprasad, N.; Ramaswamy, K. Waste marble sludge and calcined clay brick powders in conventional cement farina production for cleaner built environment. Sci. Rep. 2025, 15, 3467. [Google Scholar] [CrossRef] [PubMed]

- Agenda, I. Shaping the Future of Construction a Breakthrough in Mindset and Technology; The World Economic Forum: Davos-Klosters, Switzerland, 2016; pp. 11–16. [Google Scholar]

- Birkeland, J. Positive Development: From Vicious Circles to Virtuous Cycles Through Built Environment Design; Routledge: London, UK, 2012. [Google Scholar]

- Du Plessis, C. Towards a regenerative paradigm for the built environment. Build. Res. Inf. 2012, 40, 7–22. [Google Scholar] [CrossRef]

- Mostafaei, H.; Ashoori Barmchi, M.; Bahmani, H. Seismic Resilience and Sustainability: A Comparative Analysis of Steel and Reinforced Structures. Buildings 2025, 15, 1613. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Santos, P.; Fallah Chamasemani, N. Enhancing the mechanical properties of Ultra-High-Performance Concrete (UHPC) through silica sand replacement with steel slag. Buildings 2024, 14, 3520. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- França, W.T.; Barros, M.V.; Salvador, R.; de Francisco, A.C.; Moreira, M.T.; Piekarski, C.M. Integrating life cycle assessment and life cycle cost: A review of environmental-economic studies. Int. J. Life Cycle Assess. 2021, 26, 244–274. [Google Scholar] [CrossRef]

- Mostafaei, H.; Kelishadi, M.; Bahmani, H.; Wu, C.; Ghiassi, B. Development of sustainable HPC using rubber powder and waste wire: Carbon footprint analysis, mechanical and microstructural properties. Eur. J. Environ. Civ. Eng. 2025, 29, 399–420. [Google Scholar] [CrossRef]

- Zeyad, A.M. Sustainable concrete Production: Incorporating recycled wastewater as a green building material. Constr. Build. Mater. 2023, 407, 133522. [Google Scholar] [CrossRef]

- Mostafaei, H.; Bahmani, H. Sustainable high-performance concrete using zeolite powder: Mechanical and carbon footprint analyses. Buildings 2024, 14, 3660. [Google Scholar] [CrossRef]

- Saffari, R.; Habibagahi, G.; Nikooee, E.; Niazi, A. Biological stabilization of a swelling fine-grained soil: The role of microstructural changes in the shear behavior. Iran. J. Sci. Technol. Trans. Civ. Eng. 2017, 41, 405–414. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Attri, G.K.; Gupta, R.C.; Shrivastava, S. Comparative environmental impacts of recycled concrete aggregate and manufactured sand production. Process Integr. Optim. Sustain. 2022, 6, 737–749. [Google Scholar] [CrossRef]

- Wilburn, D.R.; Goonan, T.G. Aggregates from natural and recycled sources. US Geol. Surv. Circ. 1998, 1176, 36. [Google Scholar]

- Kirthika, S.K.; Singh, S.K.; Chourasia, A. Alternative fine aggregates in production of sustainable concrete-A review. J. Clean. Prod. 2020, 268, 122089. [Google Scholar]

- Mostafaei, H.; Bahmani, H.; Mostofinejad, D. Damping Behavior of Fiber-Reinforced Concrete: A Comprehensive Review of Mechanisms, Materials, and Dynamic Effects. J. Compos. Sci. 2025, 9, 254. [Google Scholar] [CrossRef]

- Okeke, I.J.; Kamath, D.; Nimbalkar, S.U.; Cresko, J. The Role of Low-Carbon Fuels and Carbon Capture in Decarbonizing the US Clinker Manufacturing for Cement Production: CO2 Emissions Reduction Potentials. Energies 2024, 17, 5233. [Google Scholar] [CrossRef]

- Akintayo, B.D.; Babatunde, O.M.; Olanrewaju, O.A. Comparative analysis of cement production methods using a life cycle assessment and a multicriteria decision-making approach. Sustainability 2024, 16, 484. [Google Scholar] [CrossRef]

- Adaloudis, M.; Roca, J.B. Sustainability tradeoffs in the adoption of 3D Concrete Printing in the construction industry. J. Clean. Prod. 2021, 307, 127201. [Google Scholar] [CrossRef]

- Mostafaei, H.; Rostampour, M.A.; Chamasemani, N.F.; Wu, C. An In-Depth Exploration of Carbon Footprint Analysis in the Construction Sector with Emphasis on the Dam Industry. In Carbon Footprint Assessments: Case Studies & Best Practices; Springer: Berlin/Heidelberg, Germany, 2024; pp. 45–80. [Google Scholar]

- Karalar, M.; Başaran, B.; Aksoylu, C.; Zeybek, Ö.; Althaqafi, E.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Umiye, O.A.; Özkılıç, Y.O. Utilizing recycled glass powder in reinforced concrete beams: Comparison of shear performance. Sci. Rep. 2025, 15, 6919. [Google Scholar] [CrossRef]

- Almeshal, I.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M.; Alharthai, M. Ductility and strength of reinforced concrete beams strengthened with aluminum CNC waste. Struct. Concr. 2024, 25, 3232–3245. [Google Scholar] [CrossRef]

- Zeybek, O.; Basaran, B.; Aksoylu, C.; Karalar, M.; Althaqafi, E.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Umiye, O.A.; Özkılıç, Y.O. Shear performance in reinforced concrete beams with partial aggregate substitution using waste glass: A comparative analysis via digital imaging processing and a theoretical approach. Acs Omega 2024, 9, 41662–41675. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Althaqafi, E.; Bahrami, A.; Aksoylu, C.; Karalar, M.; Özdöner, N.; Shcherban, E.M.; Stel’makh, S.A.; Beskopylny, A.; Thomas, B.S. Influence of ceramic waste powder on shear performance of environmentally friendly reinforced concrete beams. Sci. Rep. 2024, 14, 10401. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Mostofinejad, D. Review of Energy Dissipation Mechanisms in Concrete: Role of Advanced Materials, Mix Design, and Curing Conditions. Sustainability 2025, 17, 6723. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Ou, J. Self-compacting concrete. In Smart and Multifunctional Concrete Toward Sustainable Infrastructures; Springer: Berlin/Heidelberg, Germany, 2017; pp. 11–36. [Google Scholar]

- Daczko, J. Self-Consolidating Concrete: Applying What We Know; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Bahmani, H.; Mostofinejad, D. Sustainable self-compacting concrete: Performance optimization using calcium oxide-activated slag and sugar factory lime waste. Constr. Build. Mater. 2025, 492, 142956. [Google Scholar] [CrossRef]

- Umar, M.; Qian, H.; Khan, M.N.A.; Siddique, M.S.; Almujibah, H.; A. Elshekh, A.E.; Bashir, M.O.; Vatin, N.I. Strength and durability of concrete with bentonite clay and quarry dust. Front. Mater. 2025, 11, 1458836. [Google Scholar] [CrossRef]

- Althoey, F.; Ansari, W.S.; Sufian, M.; Deifalla, A.F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- da Silva Rego, J.H.; Sanjuán, M.Á.; Mora, P.; Zaragoza, A.; Visedo, G. Carbon dioxide uptake by brazilian cement-based materials. Appl. Sci. 2023, 13, 10386. [Google Scholar] [CrossRef]

- Soomro, M.; Tam, V.W.Y.; Evangelista, A.C.J. Production of cement and its environmental impact. In Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2023; pp. 11–46. [Google Scholar]

- Alyhya, W.S. Self-Compacting Concrete: Mix Proportioning, Properties and Its Flow Simulation in the V-Funnel. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2016. [Google Scholar]

- Long, G.; Gao, Y.; Xie, Y. Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Tripathi, D.; Kumar, R.; Mehta, P.K. Development of an environmental-friendly durable self-compacting concrete. Environ. Sci. Pollut. Res. 2022, 29, 54167–54180. [Google Scholar] [CrossRef]

- Witkowski, H. Sustainability of self-compacting concrete. Archit. Civ. Eng. Environ. 2015, 8, 83–88. [Google Scholar]

- Li, J.; Zhang, J.; Ni, S.; Liu, L.; Walubita, L.F. Mechanical performance and environmental impacts of self-compacting concrete with recycled demolished concrete blocks. J. Clean. Prod. 2021, 293, 126129. [Google Scholar] [CrossRef]

- El-Haggar, S.M. Industrial Solid Wastes Utilization and Disposal. In Environmental Engineering: Environmental Health and Safety for Municipal Infrastructure, Land Use and Planning, and Industry, 6th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Nemerow, N.L.; Agardy, F.J.; Sullivan, P.J.; Salvato, J.A. Environmental Engineering: Environmental Health and Safety for Municipal Infrastructure, Land Use and Planning, and Industry; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Kore, S.D.; Vyas, A.K.; Kabeer Ki, S.A. A brief review on sustainable utilisation of marble waste in concrete. Int. J. Sustain. Eng. 2020, 13, 264–279. [Google Scholar] [CrossRef]

- Akbar, M.; Hussain, Z.; Imran, M.; Bhatti, S.; Anees, M. Concrete matrix based on marble powder, waste glass sludge, and crumb rubber: Pathways towards sustainable concrete. Front. Mater. 2024, 10, 1329386. [Google Scholar] [CrossRef]

- Makul, N. Recycled Aggregate Concrete: Technology and Properties; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Shreyas, K. Impact of marble dust on cement concrete. Int. J. Sci. Technol. Eng. IJSTE 2017, 4, 6–11. [Google Scholar]

- Khichad, J.S.; Vishwakarma, R.J.; Sain, A. Investigation of Marble Dust Effect on the Mechanical Properties of Concrete: A Critical Review. In Proceedings of the 3rd International Conference on Advances in Concrete, Structural & Geotechnical Engineering; Springer: Berlin/Heidelberg, Germany, 2024; pp. 277–291. [Google Scholar]

- Ahmad, J.; Zhou, Z.; Deifalla, A.F. Self-compacting concrete with partially substitution of waste marble: A review. Int. J. Concr. Struct. Mater. 2023, 17, 25. [Google Scholar] [CrossRef]

- Jweihan, Y.S.; Al-Kheetan, M.J.; Rabi, M. Empirical model for the retained stability index of asphalt mixtures using hybrid machine learning approach. Appl. Syst. Innov. 2023, 6, 93. [Google Scholar] [CrossRef]

- Shamass, R.; Limbachiya, V.; Ajibade, O.; Rabi, M.; Lopez, H.U.L.; Zhou, X. Carbonated aggregates and basalt fiber-reinforced polymers: Advancing sustainable concrete for structural use. Buildings 2025, 15, 775. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Jweihan, Y.S.; Rabi, M.; Ghaffar, S.H. Durability enhancement of concrete with recycled concrete aggregate: The role of Nano-ZnO. Buildings 2024, 14, 353. [Google Scholar] [CrossRef]

- Yu, Y.; Zheng, Y.; Zhao, X.-Y. Mesoscale modeling of recycled aggregate concrete under uniaxial compression and tension using discrete element method. Constr. Build. Mater. 2021, 268, 121116. [Google Scholar] [CrossRef]

- ASTM C39-12; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C78; Standard Test Method for Flexural Strength of Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2001.

- Naseri, H.; Jahanbakhsh, H.; Hosseini, P.; Nejad, F.M. Designing sustainable concrete mixture by developing a new machine learning technique. J. Clean. Prod. 2020, 258, 120578. [Google Scholar] [CrossRef]

| Chemical Composition (% by Weight) | WMS |

|---|---|

| Aluminum oxide (Al2O3) | 0.02 |

| Silicon dioxide (SiO2) | 0.07 |

| Iron oxide (Fe2O3) | 0.02 |

| Calcium oxide (CaO) | 56.7 |

| Sulfur trioxide (SO3) | - |

| Magnesium oxide (MgO) | 0.49 |

| Loss on ignition (LOI) | 43.36 |

| Designation | Cement | Coarse Aggregates | Fine Aggregates | WMS | W/C | SP |

|---|---|---|---|---|---|---|

| NC | 400 | 600 | 1300 | - | 0.35 | 3.6 |

| SCC (5%F + 5%C) | 400 | 570 | 1235 | 95 | 0.35 | 3.6 |

| SCC (10%F + 10%C) | 400 | 540 | 1170 | 190 | 0.35 | 3.6 |

| SCC (15%C + 15%F) | 400 | 510 | 1105 | 285 | 0.35 | 3.6 |

| SCC (20%C + 20%F) | 400 | 480 | 1040 | 380 | 0.35 | 3.6 |

| Mix Design | NC | SCC (5%F + 5%C) | SCC (10%F + 10%C) | SCC (15%F + 15%C) | SCC (20%F + 20%C) |

|---|---|---|---|---|---|

| Slump (mm) | 480 | 540 | 690 | 630 | 570 |

| Mix Design | SCC (5%F + 5%C) | SCC (10%F + 10%C) | SCC (15%F + 15%C) | SCC (20%F + 20%C) |

|---|---|---|---|---|

| T50 (sec) | 7 | 2 | 4 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahmani, H.; Mostafaei, H. Eco-Friendly Self-Compacting Concrete Incorporating Waste Marble Sludge as Fine and Coarse Aggregate Substitute. Buildings 2025, 15, 3218. https://doi.org/10.3390/buildings15173218

Bahmani H, Mostafaei H. Eco-Friendly Self-Compacting Concrete Incorporating Waste Marble Sludge as Fine and Coarse Aggregate Substitute. Buildings. 2025; 15(17):3218. https://doi.org/10.3390/buildings15173218

Chicago/Turabian StyleBahmani, Hadi, and Hasan Mostafaei. 2025. "Eco-Friendly Self-Compacting Concrete Incorporating Waste Marble Sludge as Fine and Coarse Aggregate Substitute" Buildings 15, no. 17: 3218. https://doi.org/10.3390/buildings15173218

APA StyleBahmani, H., & Mostafaei, H. (2025). Eco-Friendly Self-Compacting Concrete Incorporating Waste Marble Sludge as Fine and Coarse Aggregate Substitute. Buildings, 15(17), 3218. https://doi.org/10.3390/buildings15173218