Chloride Diffusion and Corrosion Assessment in Cracked Marine Concrete Bridges Using Extracted Crack Morphologies

Abstract

1. Introduction

2. Extraction of Typical Flexural Crack Morphologies

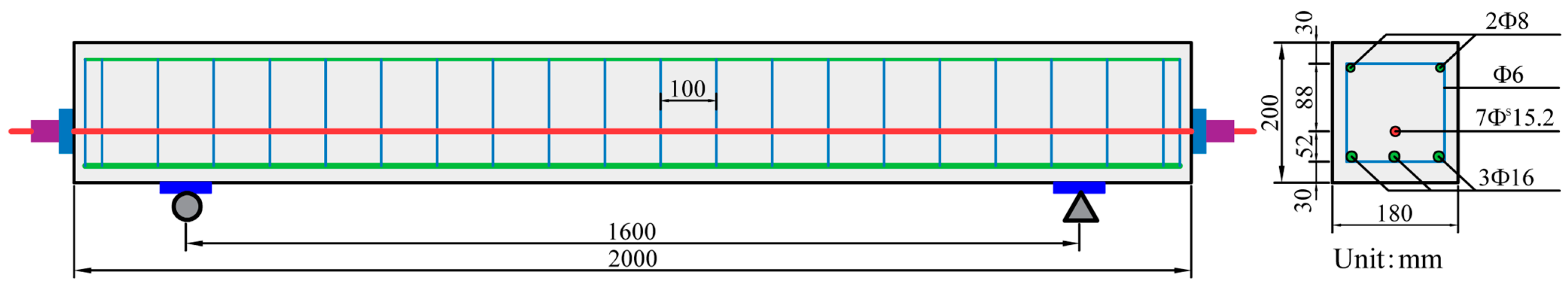

2.1. Specimen Design

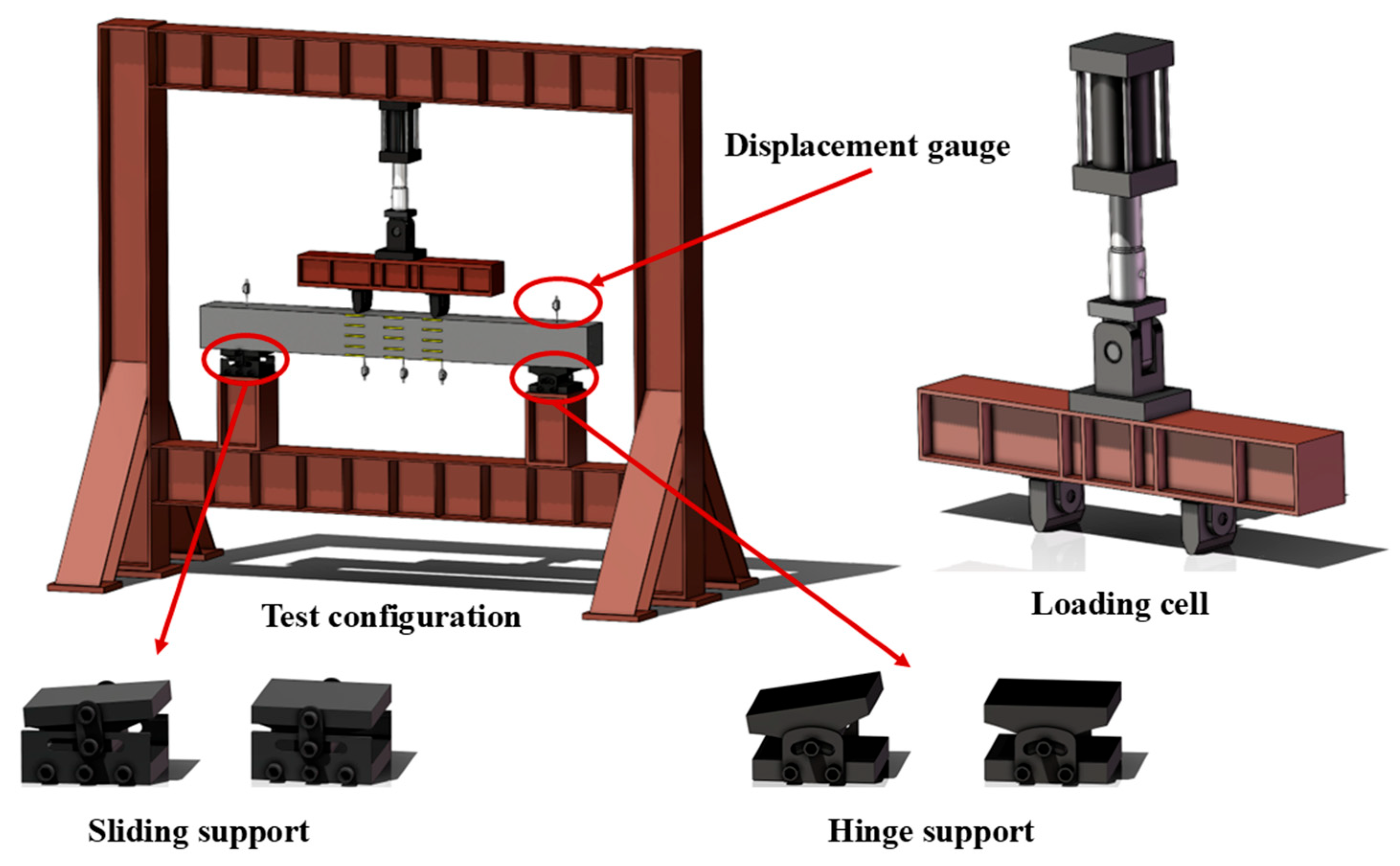

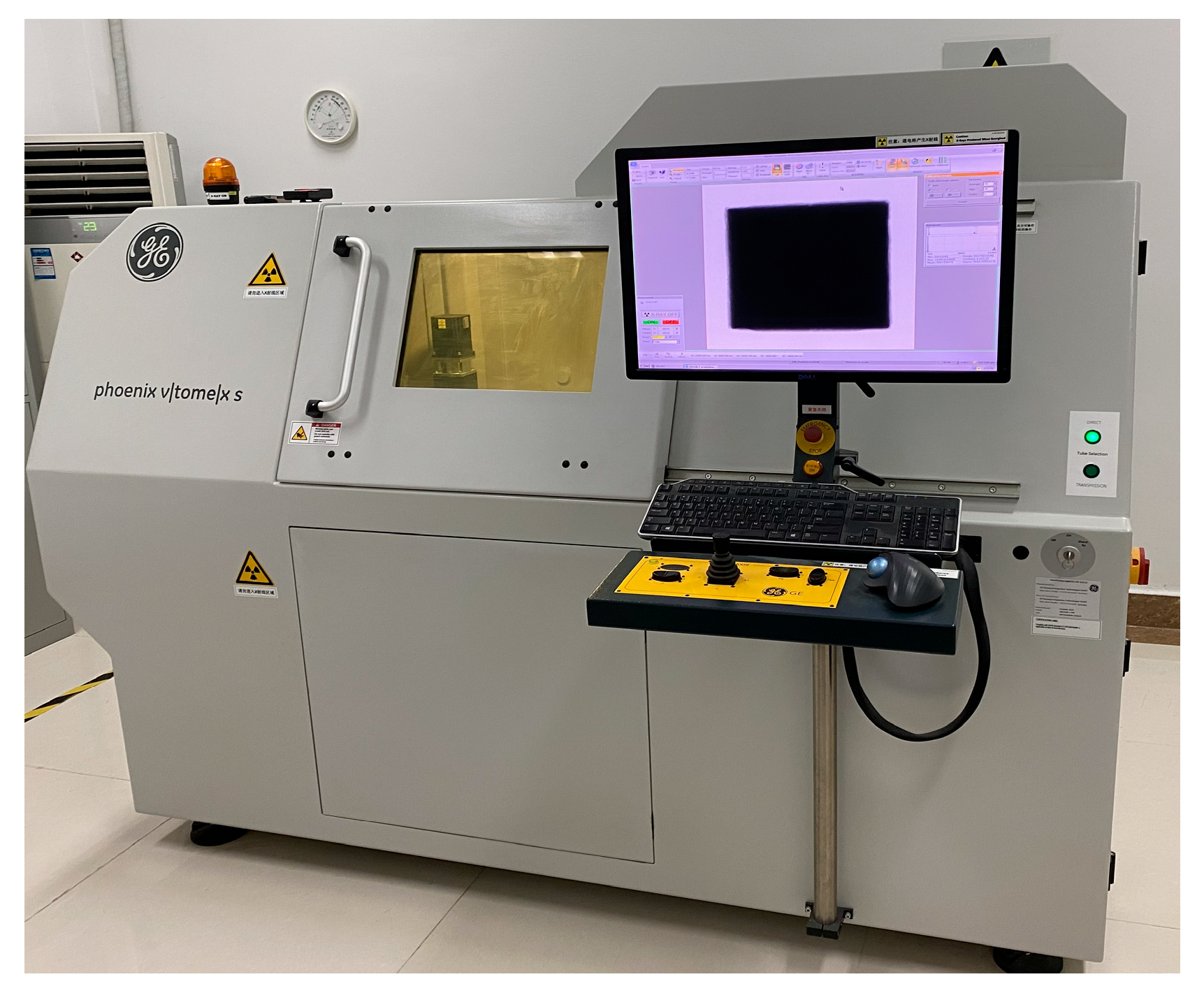

2.2. Testing Procedure

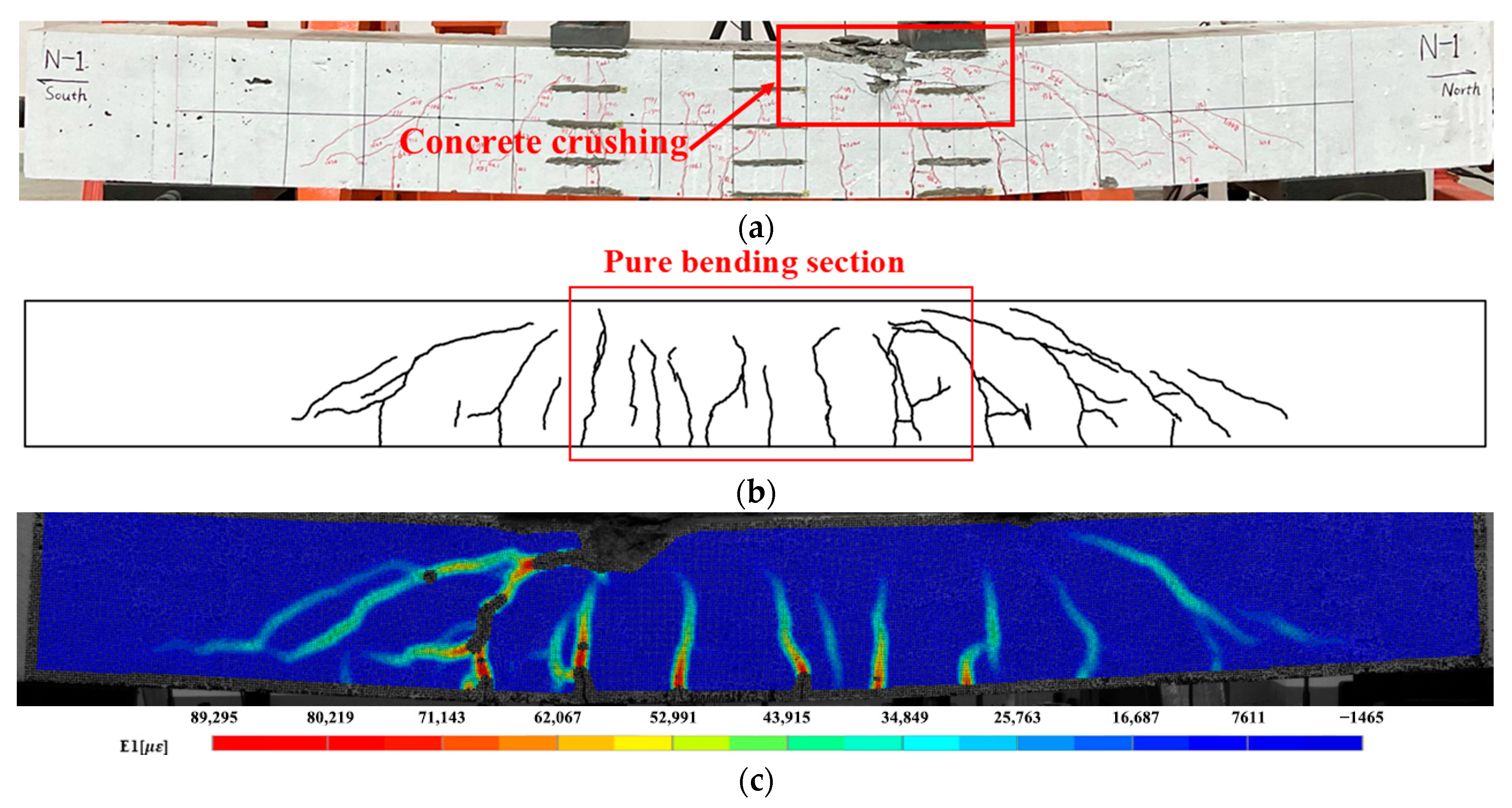

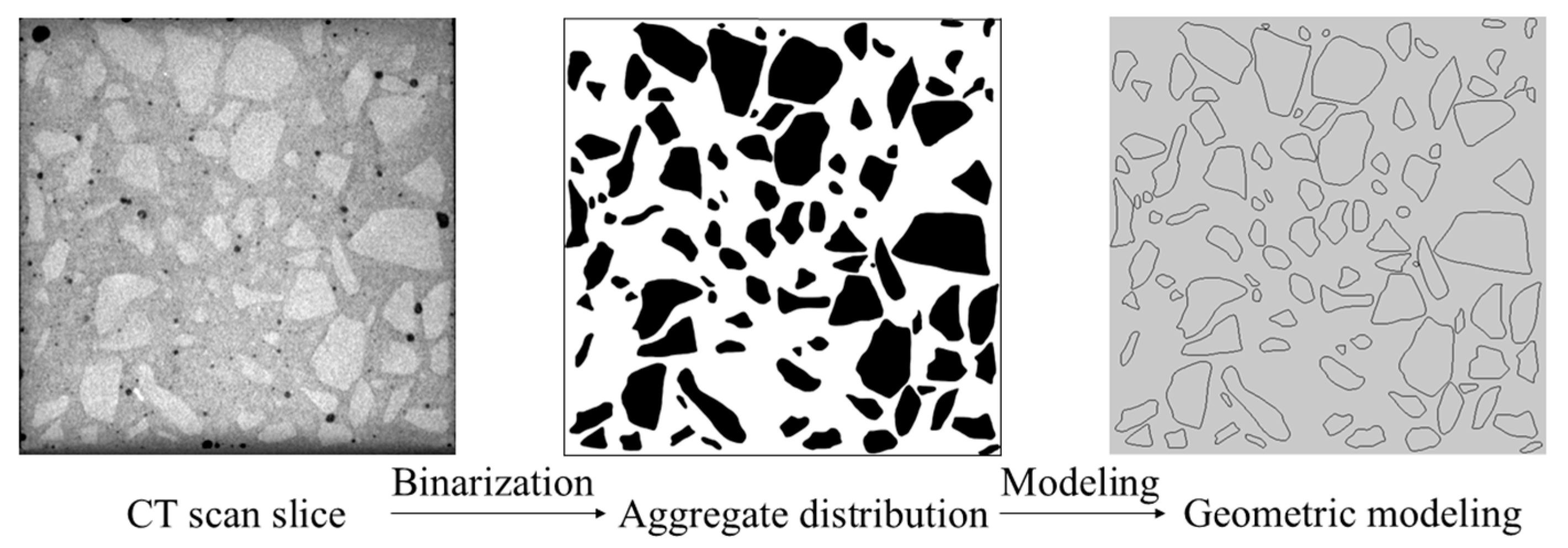

2.3. Method for Extracting Crack Morphology

2.4. Crack Morphology Models

3. Chloride Diffusion Model Based on Long-Term Exposure Testing

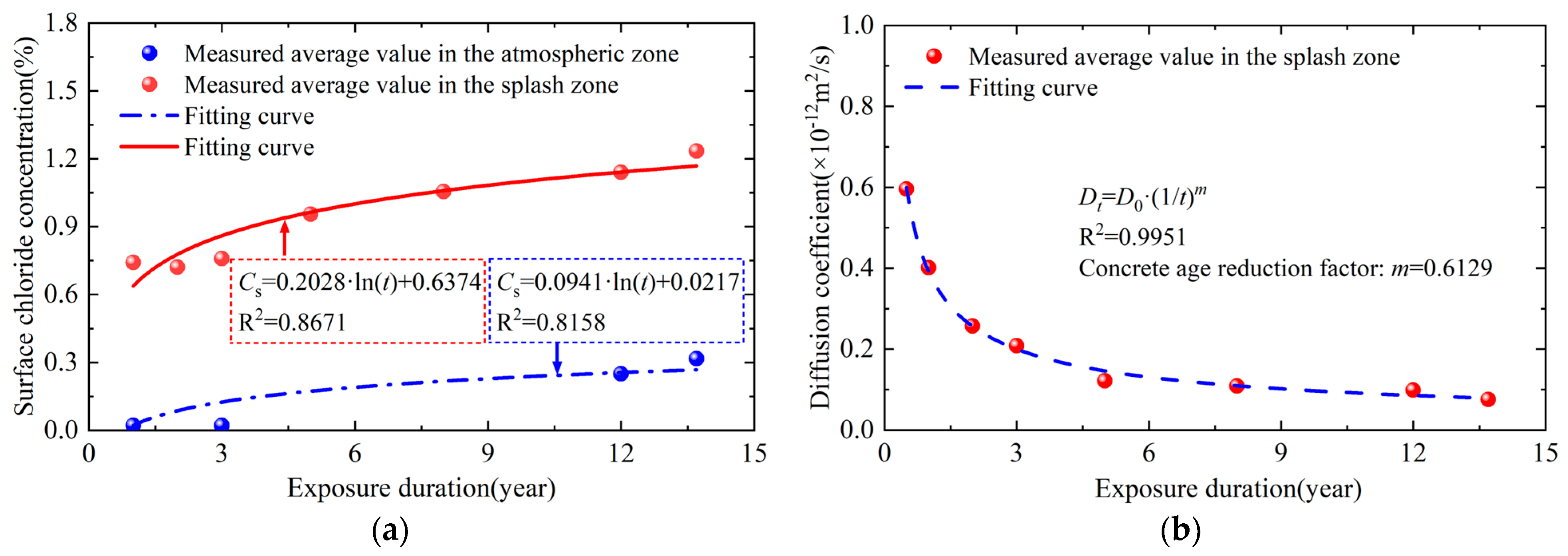

3.1. Long-Term Exposure Test Results

3.2. Corrected Chloride Diffusion Model

3.3. Chloride Diffusion Model in Cracked Concrete

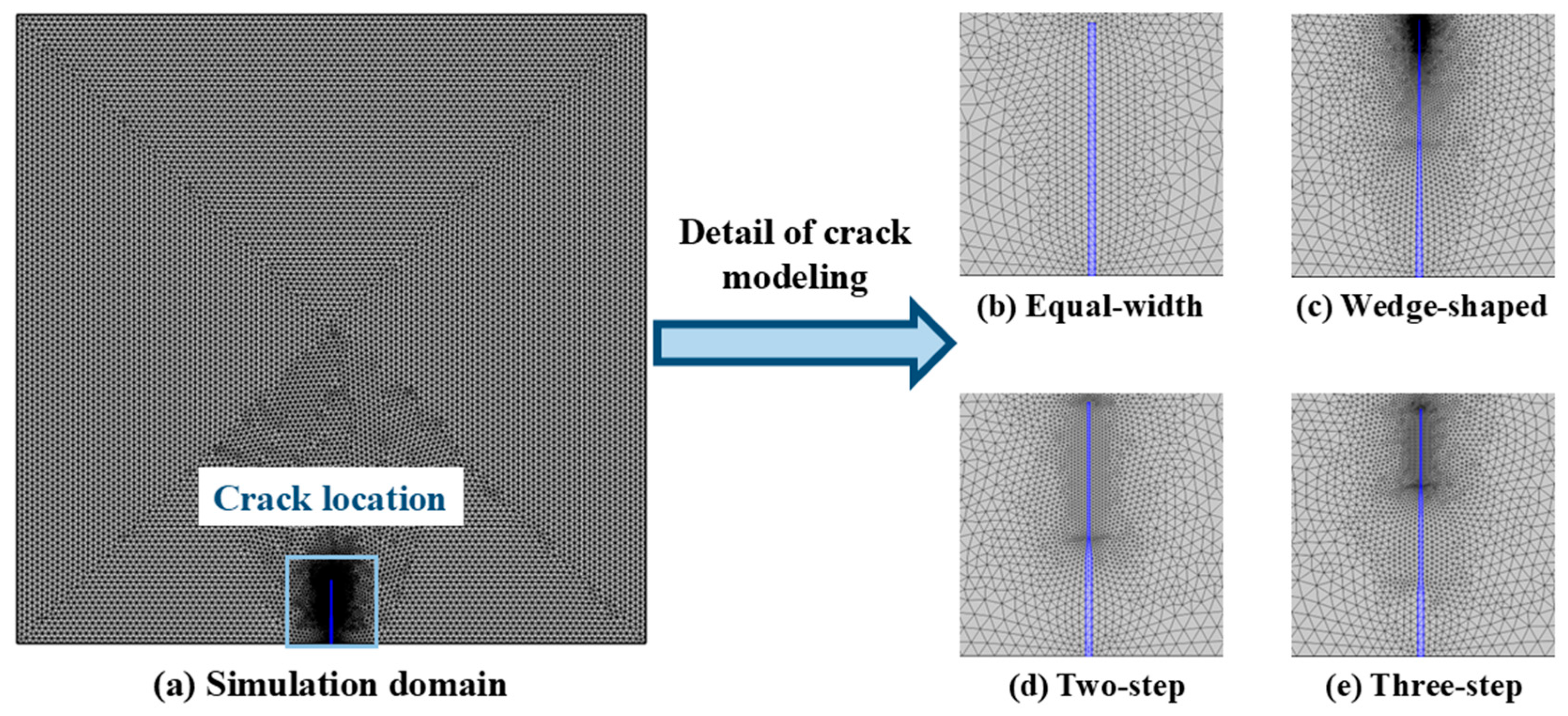

4. Chloride Diffusion Simulation Method in Cracked State

4.1. Simulation Method and Validation of Uncracked State

4.2. Simulation Method of Cracked State

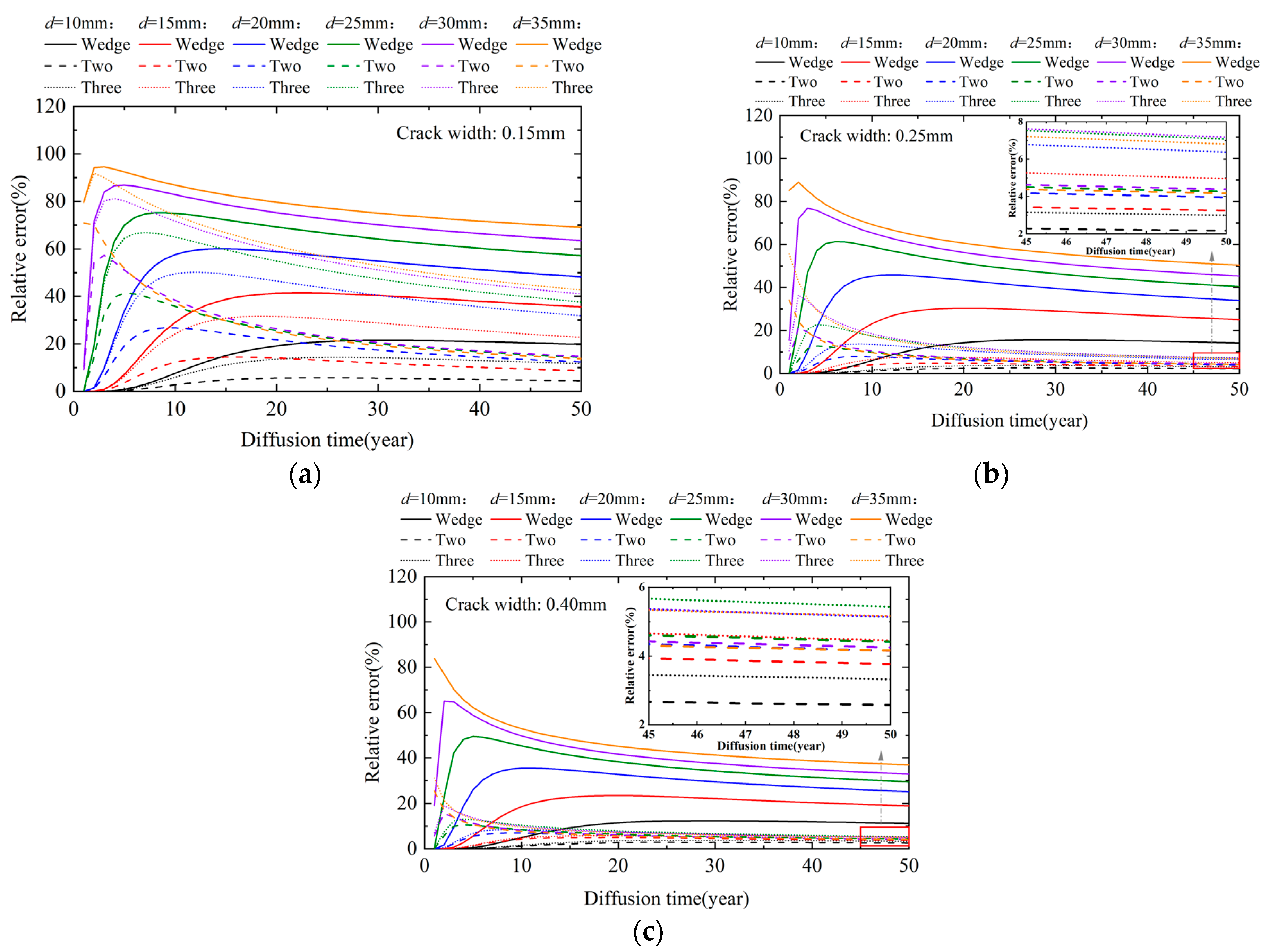

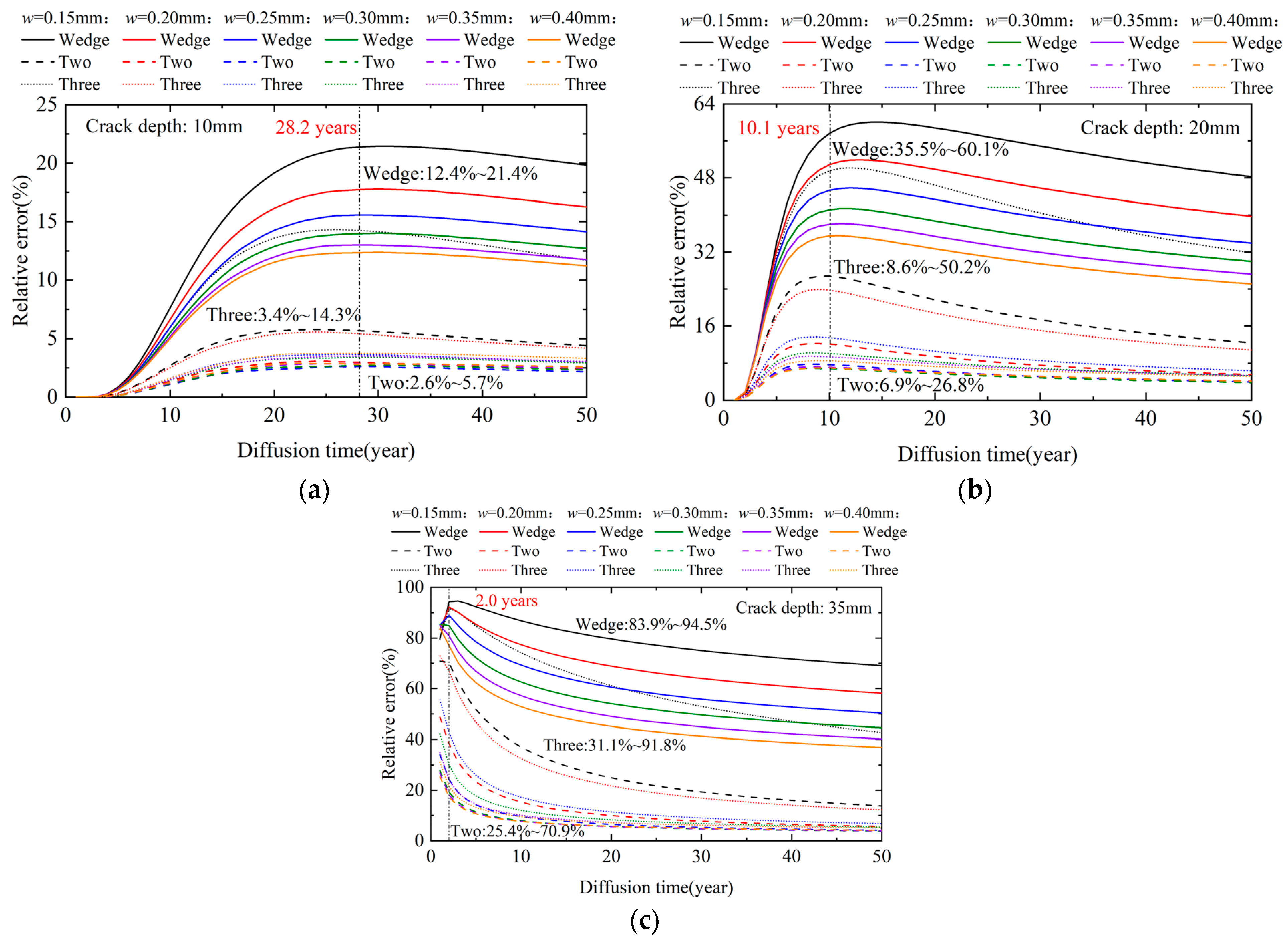

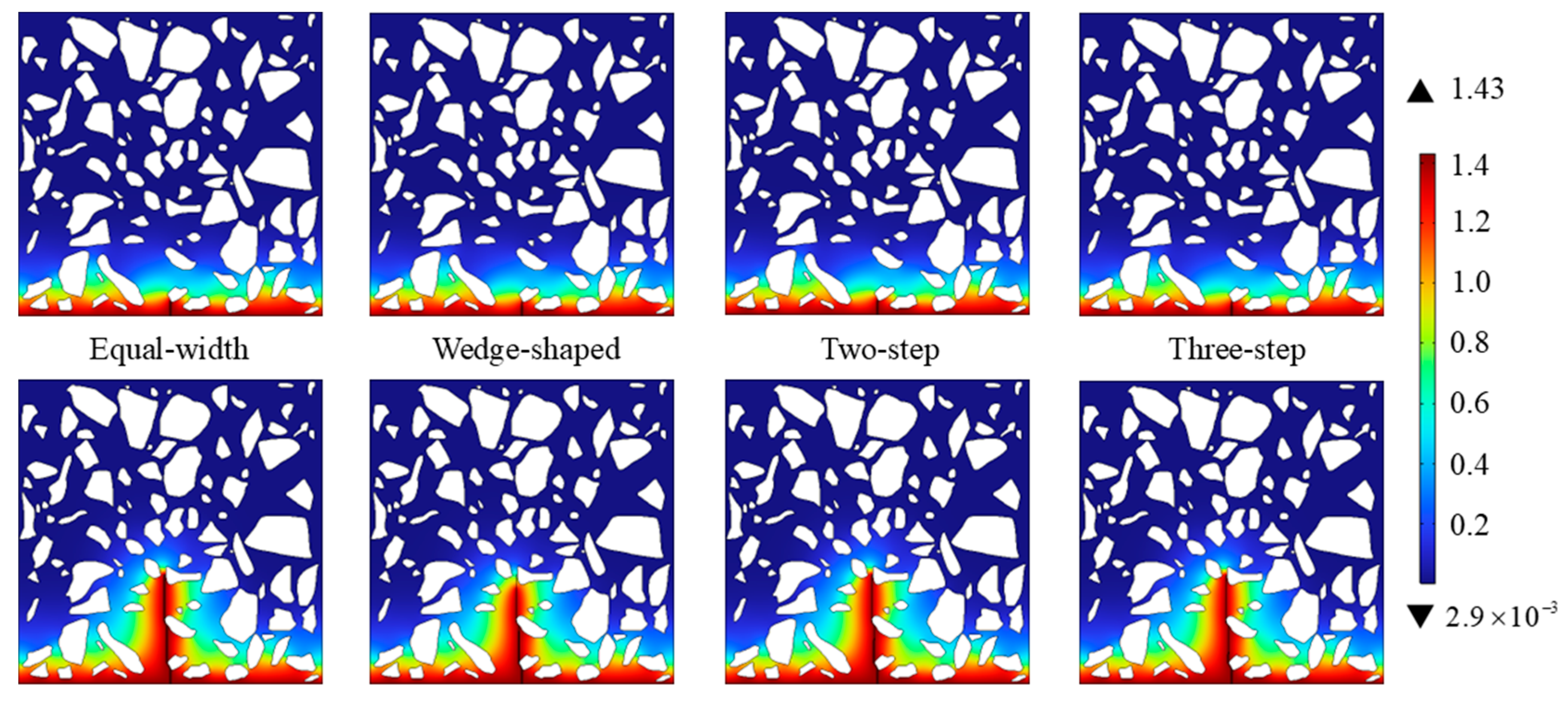

4.3. Effect of Crack Morphology on Chloride Diffusion Behavior

5. Corrosion Initiation Assessment Method

5.1. Development of Assessment Method

5.2. Chloride Concentration Threshold

6. Case Study

6.1. Overview of the Prototype Bridge

6.2. Numerical Simulation

6.3. Results Discussion

7. Conclusions

- (1)

- A crack database containing 51 samples was established. The samples were categorized into four typical crack morphologies: equal-width, wedge-shaped, two-step, and three-step cracks.

- (2)

- A numerical simulation for chloride diffusion in cracked concrete was performed, and a full factorial experiment with varying parameters was conducted. With the equal-width crack model as a reference, the wedge-shaped crack model exhibited the largest relative error, whereas the two-step crack model exhibited the smallest. The maximum relative error between the equal-width and wedge-shaped crack models was 94.5%.

- (3)

- An increase in the crack width prolongs the diffusion path of chloride ions, thereby enhancing the effect of crack morphology on chloride diffusion behavior. In contrast, an increase in crack depth expands the diffusion region and weakens this effect.

- (4)

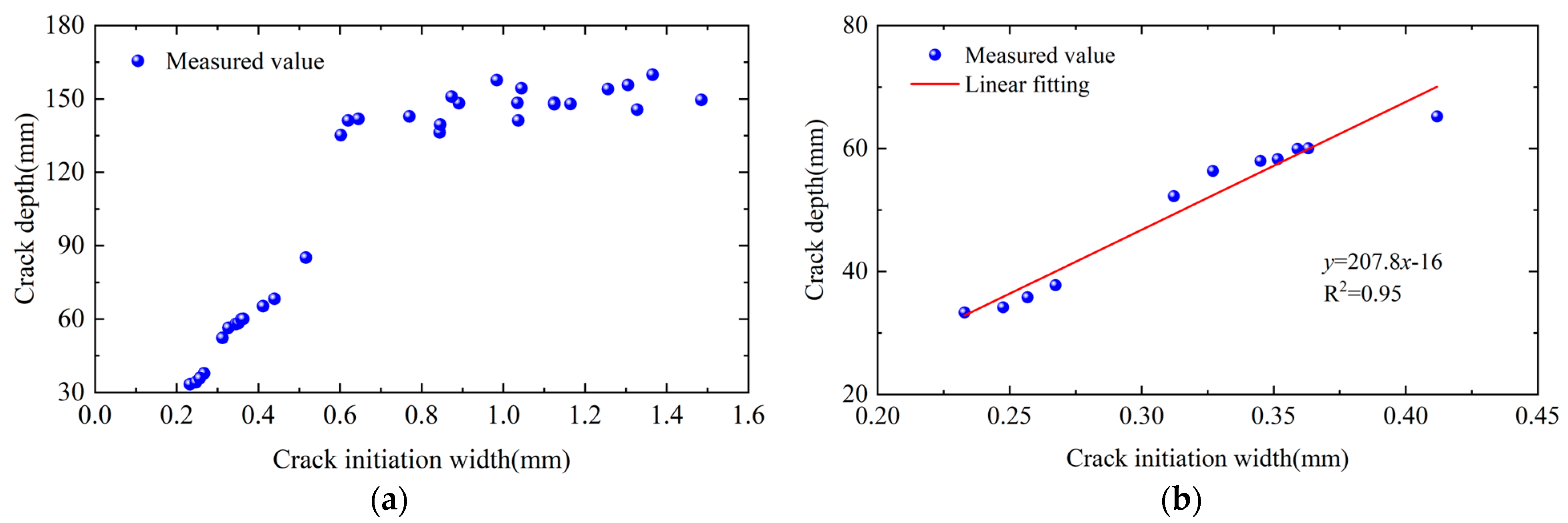

- When the crack initiation width of the flexural crack in the pure bending section extracted from the destructive test was less than 0.5 mm, a clear linear relationship was observed between the crack-initiation width and crack depth.

- (5)

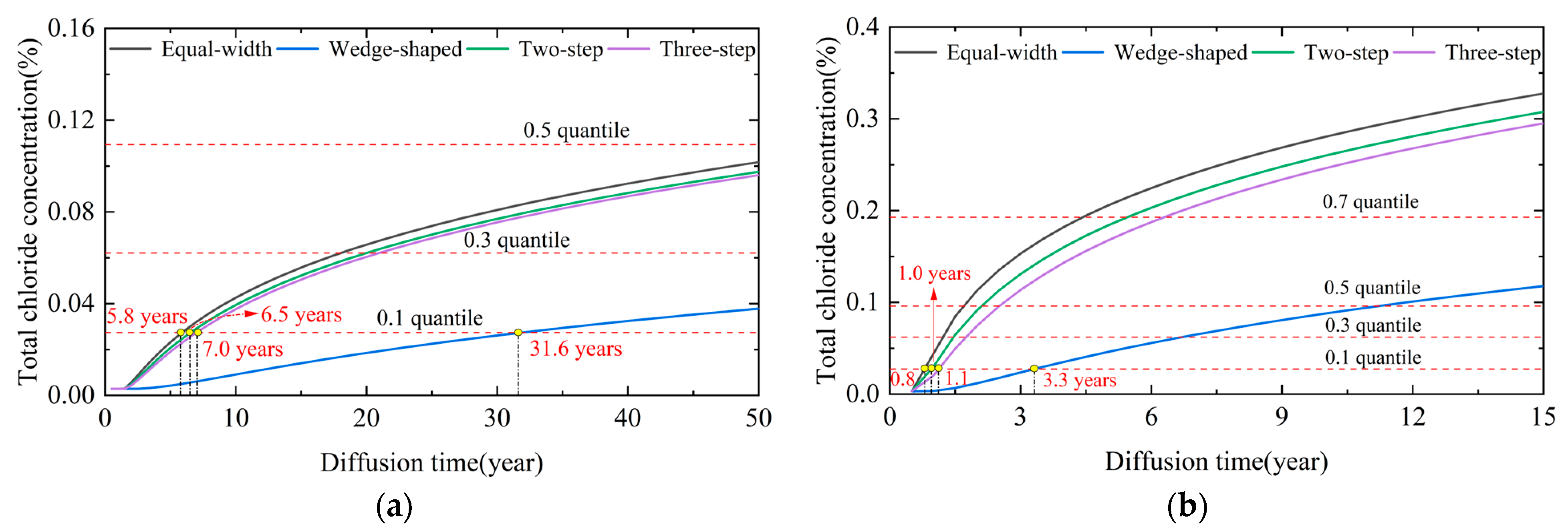

- A corrosion initiation assessment method for rebars based on the guarantee rate was proposed, and a case analysis was conducted. The equal-width crack model exhibited the earliest corrosion initiation time, whereas the wedge-shaped crack model exhibited the latest. When the chloride threshold concentration was set to 0.1 quantile, the differences in the corrosion initiation time between the equal-width and wedge-shaped crack models in the atmospheric and splash zones were 25.8 and 2.5 years, respectively.

- (6)

- Equal-width cracks should be prioritized for monitoring and timely repair, while wide or deep cracks also require focused inspection and protective measures to mitigate chloride ingress. Furthermore, the proposed methodology, when combined with monitoring data from in-service bridges, enables a more accurate estimation of reinforcement corrosion initiation time. Future research should focus on coupled deterioration mechanisms and incorporating probabilistic or data-driven approaches to improve corrosion initiation assessment of cracked concrete structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, H.; Jin, X.; Fu, C.; Jin, N.; Xu, Y.; Huang, T. Chloride penetration in concrete exposed to cyclic drying-wetting and carbonation. Constr. Build. Mater. 2016, 112, 457–463. [Google Scholar] [CrossRef]

- Gašpárek, J.; Húlek, L.; Paulík, P.; Janotka, I. Theoretical prediction of chloride diffusion into concrete compared to natural chloride contamination of existing bridges. Structures 2023, 57, 105080. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, F.; Wang, L.; Zhang, J.; Zhang, X. Influence of corrosion-induced cracking on structural behavior of reinforced concrete arch ribs. Eng. Struct. 2016, 117, 184–194. [Google Scholar] [CrossRef]

- Jee, A.A.; Pradhan, B. Long term effect of chloride and sulfates concentration, and cation allied with sulfates on corrosion performance of steel-reinforced in concrete. J. Build. Eng. 2022, 56, 104813. [Google Scholar] [CrossRef]

- Fu, C.; Ling, Y.; Wang, K. An innovation study on chloride and oxygen diffusions in simulated interfacial transition zone of cementitious material. Cem. Concr. Compos. 2020, 110, 103585. [Google Scholar] [CrossRef]

- Guzmán, S.; Gálvez, J.C.; Sancho, J.M. Modelling of chloride ingress into concrete through a single-ion approach. application to an idealized surface crack pattern. Int. J. Numer. Anal. Methods Geomech. 2014, 38, 1683–1706. [Google Scholar] [CrossRef]

- Jang, S.Y.; Kim, B.S.; Oh, B.H. Effect of crack width on chloride diffusion coefficients of concrete by steady-state migration tests. Cem. Concr. Res. 2011, 41, 9–19. [Google Scholar] [CrossRef]

- Marsavina, L.; Audenaert, K.; De Schutter, G.; Faur, N.; Marsavina, D. Experimental and numerical determination of the chloride penetration in cracked concrete. Constr. Build. Mater. 2009, 23, 264–274. [Google Scholar] [CrossRef]

- Wang, X.; Ba, M.; Yi, B.; Liu, J. Experimental and numerical investigation on the effect of cracks on chloride diffusion and steel corrosion in concrete. J. Build. Eng. 2024, 86, 108521. [Google Scholar] [CrossRef]

- Šavija, B.; Schlangen, E.; Pacheco, J.; Millar, S.; Eichler, T.; Wilsch, G. Chloride ingress in cracked concrete: A laser induced breakdown spectroscopy (LIBS) study. J. Adv. Concr. Technol. 2014, 12, 425–442. [Google Scholar] [CrossRef]

- Picandet, V.; Khelidj, A.; Bellegou, H. Crack effects on gas and water permeability of concretes. Cem. Concr. Res. 2009, 39, 537–547. [Google Scholar] [CrossRef]

- Song, H.-W.; Kwon, S.-J.; Byun, K.-J.; Park, C.-K. Predicting carbonation in early-aged cracked concrete. Cem. Concr. Res. 2006, 36, 979–989. [Google Scholar] [CrossRef]

- Audenaert, K.; Schutter, G.D.; Marsavina, L.; Boel, V. Influence of cracks and crack width on penetration depth of chlorides in concrete. Eur. J. Environ. Civ. Eng. 2009, 13, 561–572. [Google Scholar] [CrossRef]

- Yan, Y.; Jin, W.; Chen, J. Experiments of chloride ingression in flexural reinforced concrete beams. Adv. Struct. Eng. 2012, 15, 277–286. [Google Scholar] [CrossRef]

- Ismail, M.; Toumi, A.; François, R.; Gagné, R. Effect of crack opening on the local diffusion of chloride in cracked mortar samples. Cem. Concr. Res. 2008, 38, 1106–1111. [Google Scholar] [CrossRef]

- Jones, S.; Martys, N.; Lu, Y.; Bentz, D. Simulation studies of methods to delay corrosion and increase service life for cracked concrete exposed to chlorides. Cem. Concr. Compos. 2015, 58, 59–69. [Google Scholar] [CrossRef]

- Huang, T.; Feng, S.; Wang, M.; Peng, Z. Study on the effect of cracking parameters on the migration characteristics of chloride ions in cracked concrete. Buildings 2024, 14, 1738. [Google Scholar] [CrossRef]

- Bentz, D.P.; Garboczi, E.J.; Lu, Y.; Martys, N.; Sakulich, A.R.; Weiss, W.J. Modeling of the influence of transverse cracking on chloride penetration into concrete. Cem. Concr. Compos. 2013, 38, 65–74. [Google Scholar] [CrossRef]

- Long, G.; Yuan, Y.; Xin, G.; Wang, F.; Huang, P. Experimental based time-dependent reliability assessment of corrosion initiation for pc girders in frozen marine environment. Constr. Build. Mater. 2023, 408, 133461. [Google Scholar] [CrossRef]

- Djerbi, A.; Bonnet, S.; Khelidj, A.; Baroghel-bouny, V. Influence of traversing crack on chloride diffusion into concrete. Cem. Concr. Res. 2008, 38, 877–883. [Google Scholar] [CrossRef]

- Park, S.-S.; Kwon, S.-J.; Jung, S.H. Analysis technique for chloride penetration in cracked concrete using equivalent diffusion and permeation. Constr. Build. Mater. 2012, 29, 183–192. [Google Scholar] [CrossRef]

- Sun, G.; Zhang, Y.; Sun, W.; Liu, Z.; Wang, C. Multi-scale prediction of the effective chloride diffusion coefficient of concrete. Constr. Build. Mater. 2011, 25, 3820–3831. [Google Scholar] [CrossRef]

- Peng, J.; Hu, S.; Zhang, J.; Cai, C.S.; Li, L. Influence of cracks on chloride diffusivity in concrete: A five-phase mesoscale model approach. Constr. Build. Mater. 2019, 197, 587–596. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.; Guo, W. Effect of aggregate characteristics on chloride diffusion in concrete based on mesoscale numerical simulation. Constr. Build. Mater. 2025, 472, 140839. [Google Scholar] [CrossRef]

- GB 175-2023; Common Portland Cement. Standards Press of China: Beijing, China, 2023. (In Chinese)

- GB/T 1596-2017; Fly Ash Used for Cement and Concrete. Standards Press of China: Beijing, China, 2017. (In Chinese)

- Yuan, Y.; Yi, T.; Xin, G.; Long, G.; Ma, N. Study on real-time safety assessment methods of concrete bridges by deflection monitoring. China Civ. Eng. J. 2025, 58, 68–82. (In Chinese) [Google Scholar] [CrossRef]

- GB/T 5224-2023; Steel Strand for Prostressed Concrete. Standards Press of China: Beijing, China, 2023. (In Chinese)

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- GB/T 50152-2012; Standard for Test Method of Concrete Structures. China Architecture & Building Press: Beijing, China, 2012. (In Chinese)

- JTG 3362-2018; Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. People’s Communications Publishing House Co., Ltd.: Beijing, China, 2018. (In Chinese)

- Gu, Q.; Wu, R.; Ren, J.; Tan, Y.; Tian, S.; Wen, S. Effect of position of non-contact lap splices on in-plane force transmission Performance of Horizontal Joints in Precast Concrete Double-Face Superposed Shear Wall Structures. J. Build. Eng. 2022, 51, 104197. [Google Scholar] [CrossRef]

- Gu, L.; Shao, X. Theoretical analysis of crack propagation measurement for brittle materials based on virtual principal strain field. Acta Mech. Solida Sin. 2022, 35, 842–850. [Google Scholar] [CrossRef]

- Liu, Y. Research on Dynamic Extended Subpixel Measurement of Structural Cracks Based on Machine Vision. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2025. (In Chinese). [Google Scholar]

- Wally, G.B.; Larrossa, M.D.C.; Pinheiro, L.C.D.L.; Real, M.D.V.; Magalhães, F.C. 6-Month evaluation of concrete aging factor using chloride migration test: Effects of binder type and w/b ratio. Materialia 2023, 30, 101841. [Google Scholar] [CrossRef]

- Amey, S.L.; Johnson, D.A.; Miltenberger, M.A.; Farzam, H. Predicting the service life of concrete marine structures: An environmental methodology. Struct. J. 1998, 95, 205–214. [Google Scholar] [CrossRef]

- Bitaraf, M.; Mohammadi, S. Analysis of chloride diffusion in concrete structures for prediction of initiation time of corrosion using a new meshless approach. Constr. Build. Mater. 2008, 22, 546–556. [Google Scholar] [CrossRef]

- Ishida, T.; Iqbal, P.O.; Anh, H.T.L. Modeling of chloride diffusivity coupled with non-linear binding capacity in sound and cracked concrete. Cem. Concr. Res. 2009, 39, 913–923. [Google Scholar] [CrossRef]

- Jin, L.; Du, X.; Li, Y. Study on chloride diffusivity coefficient in cracks within saturated concrete. Eng. Mech. 2016, 33, 50–56, 73. (In Chinese) [Google Scholar] [CrossRef]

- Chen, S.; Zhuang, H.; Zhou, Y.; Li, S.; Li, C. Numerical simulation of chloride-induced reinforcement corrosion in cracked concrete based on mesoscopic model. Constr. Build. Mater. 2024, 441, 137408. [Google Scholar] [CrossRef]

- COMSOL Multiphysics®, v. 6.1; COMSOL AB: Stockholm, Sweden, 2022. Available online: https://www.comsol.com (accessed on 3 May 2025).

- Shi, D.; Chen, X.; Shao, W. Corrosion initiation life prediction of rc square piles based on a dual time-dependent bidirectional chloride diffusion model. Constr. Build. Mater. 2021, 275, 122192. [Google Scholar] [CrossRef]

- Shao, W.; Shi, D.; Tang, P. Probabilistic lifetime assessment of rc pipe piles subjected to chloride environments. J. Mater. Civ. Eng. 2018, 30, 04018297. [Google Scholar] [CrossRef]

- Loreto, G.; Benedetti, M.D.; Luca, A.D.; Nanni, A. Assessment of reinforced concrete structures in marine environment: A case study. Corros. Rev. 2019, 37, 57–69. [Google Scholar] [CrossRef]

- Hamidane, H.; Chateauneuf, A.; Messabhia, A.; Ababneh, A. Reliability analysis of corrosion initiation in reinforced concrete structures subjected to chlorides in presence of epistemic uncertainties. Struct. Saf. 2020, 86, 101976. [Google Scholar] [CrossRef]

- Meira, G.R.; Andrade, C.; Vilar, E.O.; Nery, K.D. Analysis of chloride threshold from laboratory and field experiments in marine atmosphere zone. Constr. Build. Mater. 2014, 55, 289–298. [Google Scholar] [CrossRef]

- Alonso, M.C.; Sanchez, M. Analysis of the variability of chloride threshold values in the literature. Mater. Corros. 2009, 60, 631–637. [Google Scholar] [CrossRef]

- Zhu, Y.; Macdonald, D.D.; Yang, J.; Qiu, J.; Engelhardt, G.R. Corrosion of rebar in concrete. Part II: Literature survey and statistical analysis of existing data on chloride threshold. Corros. Sci. 2021, 185, 109439. [Google Scholar] [CrossRef]

- Angst, U.; Elsener, B.; Larsen, C.K.; Vennesland, Ø. Critical chloride content in reinforced concrete—A Review. Cem. Concr. Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

| Composition | Alkali Content | Free CaO | SiO2 | MgO | SO3 | Chloride Ions | Loss on Ignition |

|---|---|---|---|---|---|---|---|

| (%) | 0.77 | 2.16 | 0.79 | 1.92 | 2.05 | 0.019 | 1.94 |

| Composition | Free CaO | CaO | Al2O3 | MgO | SO3 | Fe2O3 | SiO2 | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|

| (%) | 0.62 | 3.03 | 24.12 | 0.55 | 0.63 | 5.76 | 60.81 | 2.59 |

| Water-to-Binder Ratio | Cement (kg) | Fly Ash (kg) | Slag (kg) | Fine Aggregate (kg) | Coarse Aggregate (kg) | Water (kg) | Water Reducer (kg) |

|---|---|---|---|---|---|---|---|

| 0.31 | 240 | 50 | 185 | 730 | 1015 | 146 | 4.98 |

| Parameter | Symbol | Mean | Standard Deviation | Coefficient of Variation |

|---|---|---|---|---|

| Linear slope of crack width along crack depth | −0.00873 | 0 | 0 | |

| (two-step) | 0.387 | 0.107 | 0.276 | |

| (three-step) | 0.613 | 0.060 | 0.098 | |

| (three-step) | 0.254 | 0.028 | 0.110 | |

| (two-step) | 0.385 | 0.082 | 0.213 | |

| (two-step) | 0.462 | 0.099 | 0.214 | |

| (three-step) | 0.256 | 0.075 | 0.293 | |

| (three-step) | 0.313 | 0.081 | 0.259 | |

| (three-step) | 0.639 | 0.099 | 0.155 | |

| (three-step) | 0.690 | 0.098 | 0.142 |

| Parameter 1: Crack Morphology | Parameter 2: Crack Width (mm) | Parameter 3: Crack Depth (mm) |

|---|---|---|

| Equal-width | 0.15 | 10 |

| Wedge-shaped | 0.20 | 15 |

| Two-step | 0.25 | 20 |

| Three-step | 0.30 | 25 |

| / | 0.35 | 30 |

| / | 0.40 | 35 |

| Parameter Combination | Crack Initiation Width (mm) | Crack Depth (mm) |

|---|---|---|

| 1 | 0.100 | 5 |

| 2 | 0.125 | 10 |

| 3 | 0.150 | 15 |

| 4 | 0.170 | 20 |

| 5 | 0.200 | 25 |

| 6 | 0.220 | 30 |

| 7 | 0.250 | 36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Huang, P.; Yuan, Y.; Wang, D.; Yang, Y.; Liu, X. Chloride Diffusion and Corrosion Assessment in Cracked Marine Concrete Bridges Using Extracted Crack Morphologies. Buildings 2025, 15, 3214. https://doi.org/10.3390/buildings15173214

Wang X, Huang P, Yuan Y, Wang D, Yang Y, Liu X. Chloride Diffusion and Corrosion Assessment in Cracked Marine Concrete Bridges Using Extracted Crack Morphologies. Buildings. 2025; 15(17):3214. https://doi.org/10.3390/buildings15173214

Chicago/Turabian StyleWang, Xixi, Pingming Huang, Yangguang Yuan, Di Wang, Yulong Yang, and Xing Liu. 2025. "Chloride Diffusion and Corrosion Assessment in Cracked Marine Concrete Bridges Using Extracted Crack Morphologies" Buildings 15, no. 17: 3214. https://doi.org/10.3390/buildings15173214

APA StyleWang, X., Huang, P., Yuan, Y., Wang, D., Yang, Y., & Liu, X. (2025). Chloride Diffusion and Corrosion Assessment in Cracked Marine Concrete Bridges Using Extracted Crack Morphologies. Buildings, 15(17), 3214. https://doi.org/10.3390/buildings15173214