Safety Resilience Evaluation of Deep Foundation Pit Construction Based on Extension Cloud Model

Abstract

1. Introduction

2. Literature Review

2.1. Deep Foundation Pit Safety Management

2.2. Resilience Related Research

2.3. Research Gap

- (1)

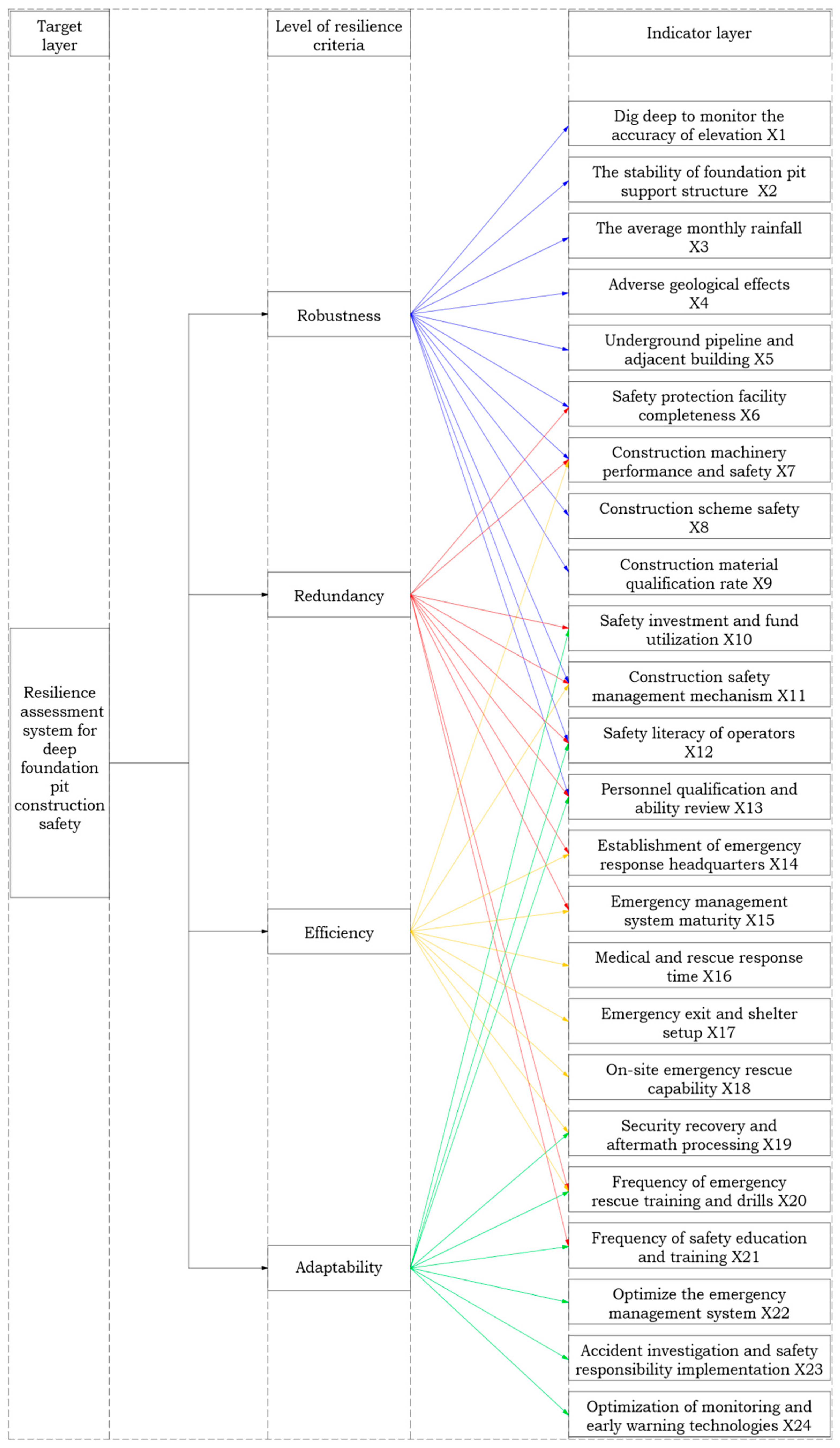

- While safety management remains a critical focus in deep foundation pit construction, research on construction safety resilience requires further exploration. Current studies primarily concentrate on identifying risk factors, implementing preventive measures, and conducting safety assessments during the construction process. However, these efforts predominantly emphasize pre-construction and mid-construction phases while neglecting post-construction recovery capabilities and the development of rapid response mechanisms for emergency situations. This study establishes an indicator system across four dimensions of deep foundation pit resilience, conducting comprehensive analysis throughout the entire construction process. It specifically evaluates and addresses safety-related resilience challenges encountered during construction. By extending the scope of existing research through full-process analysis, the paper innovatively incorporates the entire construction cycle into unified safety resilience calculations and evaluations, ultimately deriving conclusive findings.

- (2)

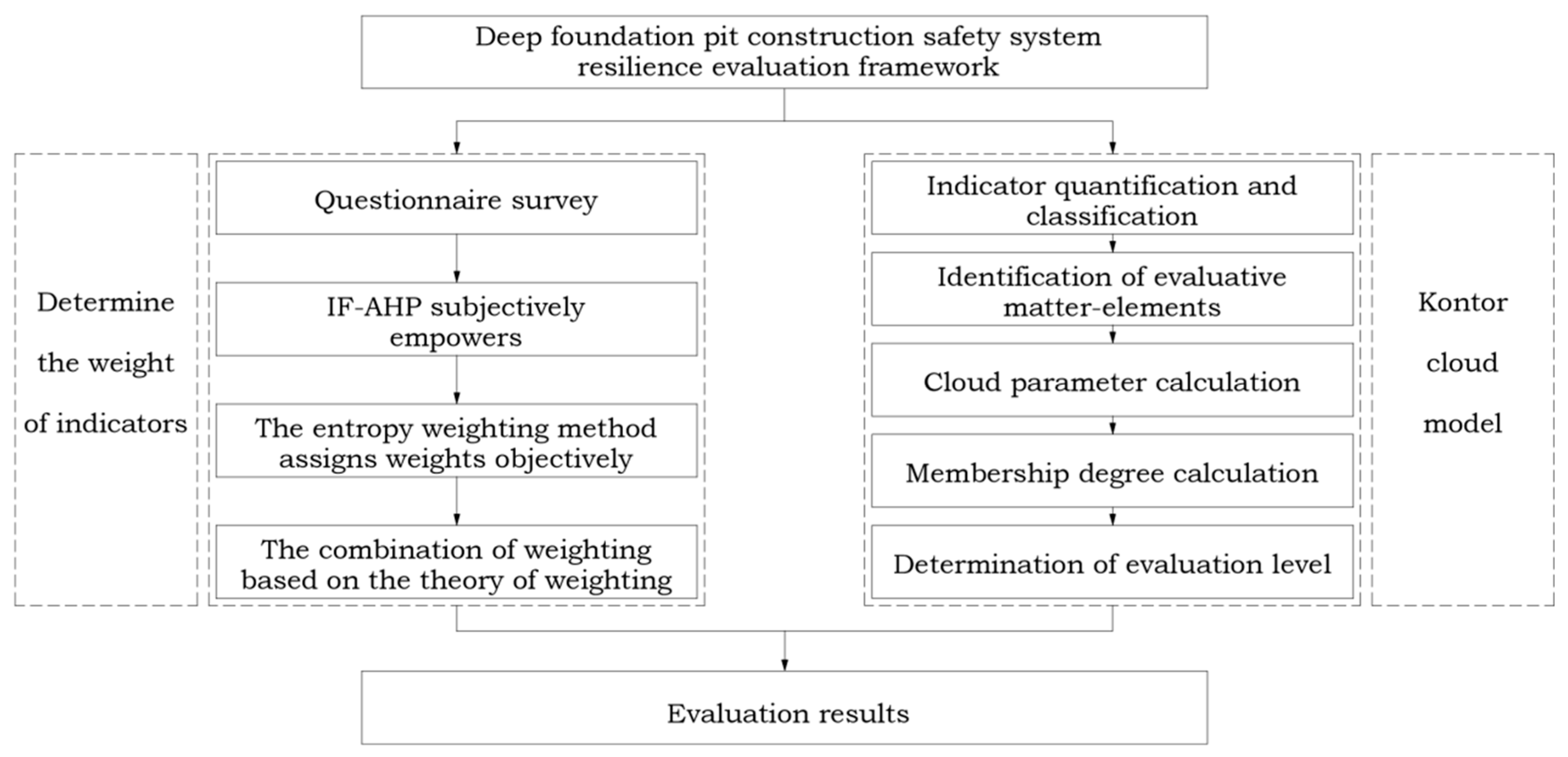

- The depth and breadth of the application of resilience theory in the field of deep foundation pit safety are insufficient. At present, although the concept of resilience is combined with the research on the safety of deep foundation pit construction, the index body is not constructed and calculated based on the actual resilience characteristics, and the many-to-many relationship between the index and the criterion layer is ignored. This study employs a research methodology that integrates subjective and objective approaches through the use of IF-AHP and entropy weighting, selecting indicators from existing research cases to calculate comprehensive weight values of indicator layers relative to the objective layer, thereby enhancing the applicability of the evaluation system. Through extensive quantification of indicators and alignment with practical scenarios, we establish a many-to-many relationship between indicators and the standard layer.

- (3)

- In the research on the safety of deep foundation pit construction, the weighting methods are mainly concentrated in the entropy weighting method, analytic hierarchy process, G1 method (sequence relationship method), gray correlation analysis method, Delphi method, etc. The above methods are not comprehensive enough to reflect the safety and resilience management of deep foundation pit, so it is urgent to have a more comprehensive method for the safety evaluation of deep foundation pit. The extension cloud model effectively addresses the randomness and fuzziness of evaluation indicators, resolving contradictions and incompatibilities within assessment systems. This study employs cloud membership functions to classify resilience indicators for deep foundation pits, significantly addressing multidimensional uncertainty issues in their indicator systems and enhancing the accuracy of research conclusions. While safety resilience emphasizes dynamic adaptability, our model provides robust support for comprehensive risk identification, enables quantitative quantification of resilience levels with inherent uncertainties, and dynamically reflects resilience evolution. These advancements effectively overcome limitations in existing studies, such as incomplete evaluations and static identification approaches.

3. Deep Foundation Pit Construction Safety Resilience

3.1. Security Resilience Connotation/Definition

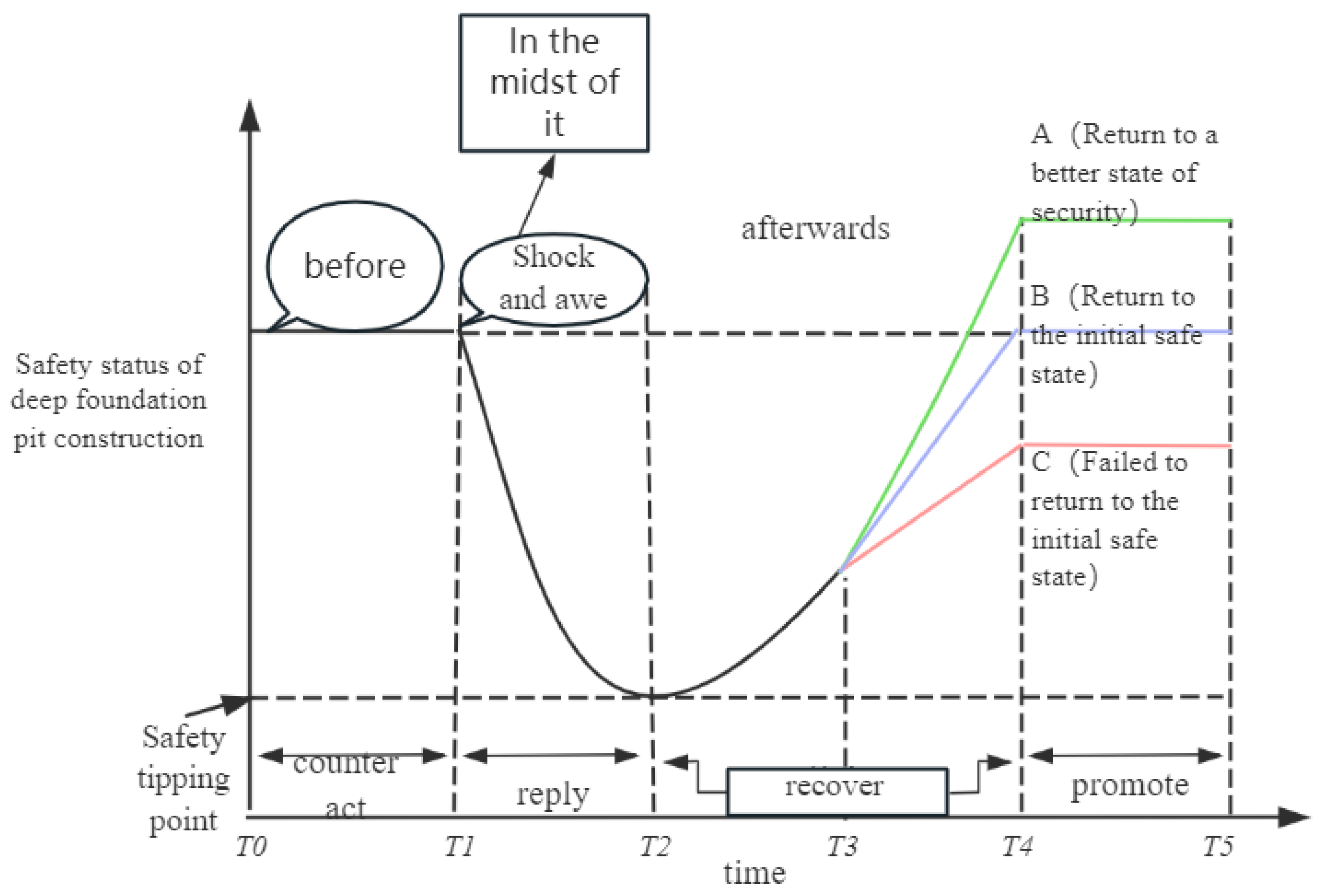

3.2. Conceptual Curve and Characteristics of Security Resilience

- (1)

- During the T0 to T1 phase, the system is in the pre-event stage, free from risk disturbances and in a safe state. This phase corresponds to the inherent characteristic of resilience—robustness. Robustness is defined as the system’s ability to resist disturbances caused by disaster factors, which means the system’s capability to maintain structural stability and functional integrity when faced with external disturbances. Robustness forms the foundation for the system’s resistance to external risks and directly determines the probability of safety incidents [32]. The higher the robustness, the more adequate the system’s own safety redundancy, and the stronger its ability to remain safe after being disturbed, thereby significantly reducing the likelihood of safety accidents.

- (2)

- During the T1~T2 phase, the system enters the mid-phase, where the risk impact has exceeded its capacity, leading to partial structural damage and a gradual decline in system safety. This phase corresponds to the core characteristic of resilience—redundancy. Redundancy is defined as the system ability to respond to external shocks, which involves setting up backup resources and emergency response mechanisms to ensure safety. It refers to the capability to promptly self-regulate and mitigate disasters, ensuring that the system can continue operating after partial damage and provide conditions for subsequent recovery. The higher the redundancy, the faster the system can regain self-control, reducing further impacts on safety and minimizing the decline in safety status, as well as the casualties and property losses caused by initial damage.

- (3)

- In the T2~T4 phase, the system enters the post-incident stage, having already suffered a certain degree of damage. It is imperative to take measures to restore and repair the damaged structures and functions, gradually returning to a relatively stable and safe state. This phase corresponds to the key characteristic of resilience—efficiency. Efficiency is defined as the system’s ability to recover from an incident, meaning the speed and efficiency with which the system can gradually return to its initial safe state or reach a new equilibrium after being impacted by damage. The higher the efficiency, the more quickly the system can identify and repair damaged parts, prevent further losses and delays, and accelerate the recovery to a safe and controllable state [32].

- (4)

- In the T4~T5 phase, if the system has strong recovery capabilities after an incident, it can quickly return to the initial safe state (B). If the system has extremely strong recovery and enhancement capabilities, it can recover to a better safe state (A). However, if the system’s recovery and enhancement capabilities are weak, it cannot return to the initial safe state (C). This phase corresponds to the critical characteristic of resilience—adaptability, which is defined as the system’s ability to improve after external shocks. It refers to the system’s capacity to learn from incidents, continuously enhance construction safety resilience, and improve its long-term safety resilience capabilities, thereby significantly reducing the likelihood of similar accidents recurring [33].

4. Construction of Resilience Index System

4.1. Selection of Evaluation Indicators

4.2. Reliability and Validity Analysis of Questionnaire

5. Determination of the Weight of Resilience Indicators

5.1. Method Comparison and Selection

5.2. IF-AHP Method Is Used to Calculate Subjective Weights

- (1)

- According to the resilience evaluation system mentioned above, opinions of many experts were collected, and the 5-point scale method from 0.1 to 0.9 was used to score the pairwise comparison of the first and second level indicators, respectively. After the weighted average, the judgment matrix AM = (aij) n×n was obtained, and the elements on the main diagonal were all 0.5, and .

- (2)

- Based on the judgment matrix AM, a fuzzy consistency judgment matrix BM = (bij) n×n was constructed, where Bij is the element in the i-th row and j-th column of the judgment matrix AM, where () represents the sum of the rows in the judgment matrix AM. Then, divide the two elements on the main diagonal of matrix BM to obtain an inverse matrix CM = (cij)n×n, where cij is the element in the i-th row and j-th column of the inverse matrix CM, calculated as cij = bij/bji.

- (3)

- The column vector = [ …]T is obtained by using the square root method and normalized to obtain the single ranking weight vector H = [ … ]T of the evaluation index layer.

- (4)

- Assuming the indicator system has a total of i criterion levels (I1, I2, …, Ii), Level I1 has m indicators (Ii1, Ii2, …, Iim) with the hierarchical single-sorting weight being ; Level I2 has n indicators (I21, I22, …, I2n) with the hierarchical single-sorting weight being ; then the hierarchical total ranking indicator weight for the i-th indicator in Level L2 is .

5.3. Objective Weight Is Calculated by Entropy Weighting Method

- (1)

- Construct an m × n decision matrix X, where each row represents an evaluation sample and each column represents an evaluation index. That is, m experts are invited to score the n evaluation indexes, which can be expressed as follows:Xij represents the score of expert i on indicator j.

- (2)

- The data is standardized to ensure dimensionless values, as required by the entropy weight method. In this study, the indicators are categorized into positive and negative indicators. For each indicator, the data is standardized using the following formulas:Min Xi is the minimum value of the i-th index. Max Xi is the maximum value of the i-th index. Xij * is the j-th sample data of the i-th index.

- (3)

- Calculate the information entropy of each index, process the standardized data, and calculate the proportion of each index in each scheme. If the standardized matrix is known, then the proportion of the j-th index in the i-th evaluation object can be calculated by counting the entropy value of the j-th index, which is based on the following:

- (4)

- Calculate the entropy weight of each index, where the entropy value is used to measure the information amount of the j-th index. The larger the entropy, the smaller the information amount of the index, and the smaller the weight. The weight is calculated according to the entropy value of each index, and the calculation formula of entropy weight is as follows:where Ej represents the information utility value.

5.4. Calculate the Combination Weight Based on the Variable Weighting Theory

- (1)

- Determine the subjective and objective weight coefficients, where the weights of subjective and objective weights are ɑ and β, respectively. These represent the manager’s preference for these two types of weights, with ɑ + β = 1. The higher the value of ɑ, the more the manager prefers subjective judgment; when ɑ = 0.5, it indicates that both weights are equal. In practical applications, α and β can be dynamically adjusted according to decision-making needs, making the weight calculation better suited to specific decision contexts [39].

- (2)

- This paper has given the calculation method of subjective and objective weights based on IF-AHP and entropy weighting method. Let the subjective weight of the j-th index be, and the objective weight be. When these weights are brought into the formula, the constant weight of the index can be calculated.

- (3)

- When calculating the weighted combination weight for more complex hierarchical structures with the integration of the weights of indicators at each level, the difference between the weights at the same level may be reduced, thus affecting the accuracy of the evaluation results. To solve this problem, the weighted combination weight can be calculated as follows: To adjust the weight of the constant weight combination and highlight the importance of key indicators. The variable weight coefficient for the i-th indicator is found here, reflecting its importance. When managers place greater emphasis on the balance between indicators, 0 < < 0.5; if managers do not pay attention to the balance between indicators, then set 0.5 < < 1; at this point, if = 1, the formula will revert to the constant weight model.

6. Build a Resilience Evaluation Model

6.1. Extensional Cloud Model Theory

6.2. Rupture Grade Classification

- (1)

- Construction safety resilience classification.

- (2)

- Classification of resilience indicators

6.3. Determination of Items to Be Evaluated

6.4. Cloud Parameter Calculation

6.5. Cloud Membership Degree Calculation

6.6. Evaluation Level Determination

7. Case-Based Verification

7.1. Determine the Characteristic Parameters of the Extendable Cloud

7.2. Determination of Index Weight

7.3. Determination of Resilience Grade

7.4. Evaluation Result Analysis

- (1)

- Through the IF-AHP entropy weight method, the combined weights were calculated, revealing the impact on safety resilience ranks as follows: robustness (0.295) > redundancy (0.262) > efficiency (0.233) > adaptability (0.209) (as can be seen in Table 10). To enhance the safety resilience of deep foundation pit construction, it is crucial to strengthen the inherent disaster resistance of deep foundation pits while improving their ability to respond to risk impacts or accidents. According to the overall ranking results in Table 5, emphasis should be placed on construction safety management mechanisms, worker safety awareness, and the maturity of emergency management systems during deep foundation pit construction, with the aim of enhancing the safety resilience of the deep foundation pit system.

- (2)

- According to the maximum membership principle of Cantor Cloud, the final determination of the safety resilience of this deep foundation pit construction is Level IV, indicating that the safety resilience of this deep foundation pit project is relatively high. The robustness of the first-level indicator is Level III, while the redundancy, efficiency, and adaptability resilience levels are Level IV. Therefore, there is considerable room for improvement in the robustness of this project, and further progress is needed in redundancy, efficiency, and adaptability.

- (3)

- The secondary indicators of the project, including the stability of the foundation pit support structure and the resilience to adverse engineering geological impacts, are relatively low. The construction site is adjacent to a river, and the engineering geology and surrounding environment are complex. It is necessary to reduce the loading on the foundation pit slopes and set up monitoring points to fully control safety conditions. The resilience of the construction safety management mechanism, safety investment amount and usage, emergency command center set up, and the completeness of the emergency management system are also relatively low. There are deficiencies in the safety system, and greater emphasis should be placed on safety management, with improved emergency response plans, clear responsibility assignments, and reasonable budgeting for safety costs. The resilience of monitoring and early warning technology is relatively low, as the project uses manual monitoring methods, which are inefficient and may result in errors. Intelligent monitoring technologies should be strengthened.

8. Discussion

8.1. Theoretical Implications

- (1)

- This study has made significant contributions to the safety theory of deep foundation pit construction by supplementing and refining existing frameworks. While previous research predominantly focused on risk management during construction processes—identifying, evaluating, and controlling individual risk factors—it overlooked the inherent interconnections between these elements and failed to examine construction safety management as an integrated system undergoing dynamic changes. Innovatively adopting a systemic resilience perspective, this research comprehensively identifies multiple factors influencing construction safety management. By establishing a robust indicator system, it injects fresh perspectives into the theoretical framework of deep foundation pit construction safety.

- (2)

- The resilient theory has been effectively applied in deep foundation pit construction safety. While its current applications in construction engineering primarily focus on fire protection and earthquake resistance, research on its implementation in deep foundation pit construction remains limited. This study establishes a scientific and systematic resilience index system and evaluation model for construction safety, enabling quantitative assessment of resilience indicators and precise classification of resilience levels. These advancements provide robust theoretical support and practical references for enhancing safety management in deep foundation pit construction.

- (3)

- The introduction of resilience theory has provided a new perspective for safety assessment in deep foundation pit construction, emphasizing the system’s ability to resist, respond to, recover from, and adapt to risk impacts. By thoroughly investigating how construction safety management systems perform under adverse risks or accidents, and focusing on the manifestation of system resilience throughout the entire accident process, we can achieve comprehensive dynamic control over construction safety.

8.2. Practical Implications

- (1)

- During deep foundation pit construction, due to the inherent engineering characteristics of such projects, even minor oversights may lead to major safety accidents including pit collapse, settlement and tilting of surrounding structures, and rupture of underground pipelines. These incidents can severely impact both public safety and property protection as well as the normal operation of urban infrastructure. This study provides practical guidance to effectively prevent such accidents from occurring.

- (2)

- By comparing various safety assessment methodologies and modeling approaches, this study developed an evaluation framework that effectively identifies critical factors affecting safety resilience in deep foundation pit construction. The model enables precise classification of resilience levels. These findings are crucial for enhancing the system’s construction safety recovery capabilities and risk resistance capacity, which significantly contributes to reducing major accidents and mitigating potential hazards.

- (3)

- This paper systematically integrates construction safety management and explores the resilience changes in the system throughout the accident development process. The study on the safety resilience of deep foundation pit construction can improve the system’s ability to resist and respond to risks, and enhance the ability to quickly restore the safety state after the accident.

8.3. Limitation and Future Research Directions

- (1)

- This study primarily relies on qualitative indicators when constructing a safety resilience evaluation system for deep foundation pit construction, which results in a lack of quantitative basis for practical applications. While qualitative indicators help assess system resilience at the macro level, their limitation lies in the difficulty of conducting detailed analyses. Therefore, future research could incorporate more quantitative indicators and employ precise numerical methods to analyze safety resilience during construction processes, thereby enhancing the accuracy and operability of evaluations.

- (2)

- This study primarily investigates the resilience of construction safety systems when exposed to risk disturbances or accidents, though it does not restrict specific risk types or accident categories. Given that different risk scenarios may exert varying impacts on system resilience, future research could adopt targeted risk scenarios or accident types as case studies for specialized security resilience assessments. Such approaches would enhance the model’s applicability and practical value through evidence-based analysis.

- (3)

- Given the significant variations in geological conditions and project contexts across deep foundation pit engineering, developing targeted safety resilience assessment systems tailored to distinct geological characteristics and engineering types has become an urgent challenge. Future research should focus on different deep foundation pit engineering categories and geological environments, integrating specific project scenarios to conduct in-depth safety resilience studies. This approach will gradually establish replicable evaluation standards and methodologies, ultimately providing more precise resilience management solutions for practical engineering projects.

9. Conclusions

- (1)

- In light of China’s current research status on deep foundation pit engineering and the characteristics of such projects, this paper highlights the necessity for evaluating the resilience of safety systems in deep foundation pit construction. It systematically reviews relevant literature on resilience assessment, defines the resilience of safety systems in deep foundation pit construction, and clarifies key resilience characteristics and common safety conditions, thereby laying a solid foundation for advancing theoretical research in safety management of deep foundation pit construction.

- (2)

- Based on the accident analysis and literature research, 24 resilience influencing factors are identified from the four characteristics of robustness, redundancy, efficiency, and adaptability and resilience. Through the IF-AHP entropy weight method, the combined weights were calculated, revealing that the impact on safety resilience ranks as follows: robustness (0.295) > redundancy (0.262) > efficiency (0.233) > adaptability (0.209). Additionally, a cross-criterion layer index system suitable for the safety of deep foundation pit construction is constructed, and the connotation of each resilience index is explained in detail.

- (3)

- This study employs a combined subjective–objective weighting method integrating entropy weighting and IFAHP to quantify the weights of resilience indicators. Based on relevant standards, specifications, expert opinions, and practical case studies, the evaluation metrics were transformed into cloud maps through membership degree calculations, ultimately determining the resilience levels for deep foundation pit construction safety. The system categorizes safety resilience into five distinct tiers, providing clear quantitative benchmarks for practical assessments. To address the inherent ambiguity and randomness in deep foundation pit safety evaluations, this research introduces an expandable cloud model. According to Table 9 and Table 10, through cloud map generation and membership degree calculations, the resilience levels for deep foundation pit construction safety are systematically established.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, X.; Wang, S.; Wang, J. A decision method for construction safety risk management based on ontology and improved CBR: Example of a subway project. Int. J. Environ. Res. Public Health 2020, 17, 3928. [Google Scholar] [CrossRef]

- Meng, G.; Li, X.; Liu, H. Risk identification and assessment during the excavation of the deep foundation pit. Adv. Mater. Sci. Eng. 2021, 2021, 4291356. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Wang, Q. Dynamic risk analysis of deep foundation pit leakage in water-rich sand layer based on Bayesian network. J. Hohai Univ. Nat. Sci. 2024, 52, 60–68. [Google Scholar]

- Shen, L.; Xue, Z.; Tang, L.; Ge, H. Research on Resilience Evaluation and Enhancement of Deep Foundation Pit Construction Safety System. Buildings 2022, 12, 1922. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, F.; Wang, B.; He, X. Resilience evaluation for deep foundation pit of metro station under influence of multiple factors. China Saf. Sci. J. 2019, 29, 154–159. [Google Scholar]

- Chen, Z.; Wang, Y.; Lai, R. Safety risk management of subway project under toughness concept. Constr. Technol. 2023, 52, 103–109. [Google Scholar]

- Zhang, Y.; Xing, X.; Antwi-Afari, M.F. A hybrid approach for optimizing deep excavation safety measures based on Bayesian network and design structure matrix. Adv. Eng. Inform. 2023, 58, 102223. [Google Scholar] [CrossRef]

- Chen, D.; Zhou, J.; Duan, P.; Zhang, J. Integrating knowledge management and BIM for safety risk identification of deep foundation pit construction. Eng. Constr. Archit. Manag. 2023, 30, 3242–3258. [Google Scholar] [CrossRef]

- Wu, B.; Wei, Y.; Meng, G. Multi-Source Monitoring Data Fusion Comprehensive Evaluation Method for the Safety Status of Deep Foundation Pit. Sustainability 2023, 15, 11809. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Xu, Z. Field Pumping and Recharge Test Study for Confined Aquifers in Super-Large Deep Foundation Pit Group Sites. Buildings 2025, 15, 1383. [Google Scholar] [CrossRef]

- He, X.; Zuo, C.; Luo, X. Efficiency of pile barriers to mitigate supported excavation effects on existing tunnels. Tunn. Undergr. Space Technol. 2025, 159, 106447. [Google Scholar] [CrossRef]

- Tuan, P.N.; Xuan, T.D.; Nguyen, T. Overall assessment of deformation and force of diaphragm wall joints during the stages of deep excavation construction. Int. J. Comput. Civ. Struct. Eng. 2024, 20, 163–176. [Google Scholar]

- Wu, B.; Du, J.; Wen, X.; Zhao, Y. Safety risk assessment of deep foundation pit construction in water-rich soft soil layers based on improved entropy-weighted DEMATEL-ISM. China Sci. Technol. Work. Saf. 2023, 19, 106–114. [Google Scholar]

- Hu, Y.; Liu, J.; Wang, X. Research on safety risk identification of deep foundation pit construction based on BIM and knowledge graph. Met. Mines 2023, 2023, 180–186. [Google Scholar]

- Liu, B.; Liu, Z.; Long, R. Risk identification and evaluation of deep foundation pit excavation based on WBS-RBS-G1 method. Highw. Traffic Technol. 2021, 37, 119–125. [Google Scholar]

- Zhang, X.; Yu, W. Analysis of safety supervision ideas for deep foundation pit construction in urban rail transit engineering. Mod. Tunn. Technol. 2021, 58 (Suppl. S2), 197–200. [Google Scholar]

- Huang, R.; Han, Y. Differentiated Optimization Policies for Water–Energy–Food Resilience Security: Empirical Evidence Based on Shanxi Province and the GWR Model. Water 2025, 17, 1540. [Google Scholar] [CrossRef]

- Huang, R.; Liu, H. Evaluation and External Driving Factors Analysis of Water–Energy–Food Resilience Security—Based on Spatial Durbin Model and Four Provinces Along the Yellow River. Sustainability 2024, 16, 10126. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, Z.; Sun, Z.; Yang, P. Renewal Needs and Solutions for Urban Old Communities under the Guidance of Resilient Security. J. Landsc. Res. 2024, 16, 15–18, 26. [Google Scholar]

- Chan, C.P.A.; Guan, J.; Choi, Y.N.T. Moderating Effects of Individual Learning Ability and Resilient Safety Culture on the Relationship between the Educational Level and Safety Performance of Construction Workers. Buildings 2023, 13, 3026. [Google Scholar] [CrossRef]

- Trinh, M.T.; Feng, Y. A Maturity Model for Resilient Safety Culture Development in Construction Companies. Buildings 2022, 12, 733. [Google Scholar] [CrossRef]

- Chen, Q.; Huang, Q.; Chen, Z.; Wang, Z. Resilience evaluation of subway engineering system based on Bayesian network. J. Saf. Sci. China 2018, 28, 98–103. [Google Scholar]

- Wang, J.; Zhi, T.; Na, J.; Guo, Y.; Han, M.; Zhao, Z. Research on Resilience Evaluation Methods for Fire Engineering in Historical and Cultural Districts: A Case Study of Nanjing Lotus Pond. J. Saf. Environ. Sci. 2023, 23, 317–325. [Google Scholar]

- Ma, B.; Li, J.; Miao, C. Risk management strategies for deep foundation pit construction in water-rich soft soil based on the concept of resilience. Constr. Econ. 2023, 44 (Suppl. S2), 127–130. [Google Scholar]

- Chen, W. Research on Construction Safety Evaluation of Prefabricated Buildings Based on Elasticity Perspective. Ph.D. Thesis, Lanzhou University of Technology, Lanzhou, China, 2024. [Google Scholar]

- Hughes, L. The effects of event occurrence and duration on resilience and adaptation in energy systems. Energy 2015, 84, 443–454. [Google Scholar] [CrossRef]

- Trnka, J.; Lundberg, J.; Jungert, E. Design and evaluation of a role improvisation exercise for crisis and disaster response teams. Int. J. Inf. Technol. Manag. 2016, 15, 251–271. [Google Scholar] [CrossRef]

- Liu, K.; Liu, Y.; Kou, Y. Study on construction safety management in mega projects from the perspective of resilient governance. Saf. Sci. 2024, 173, 106442. [Google Scholar] [CrossRef]

- Macaskill, K.; Guthrie, P. Multiple interpretations of resilience in disaster risk management. Procedia Econ. Financ. 2014, 18, 667–674. [Google Scholar] [CrossRef]

- Pan, H.; He, J.; Chen, M.; Miao, W. Research on the construction risk of metro station foundation pit based on mutation level method. J. Undergr. Space Eng. 2017, 13, 840–845. [Google Scholar]

- Tao, L.; Hu, G.; Jiao, B. Research on the Interaction and Deformation Control of the Adjacent Deep Foundation Pits Excavation. J. Munic. Technol. 2024, 42, 81–88, 98. [Google Scholar]

- Zhou, B.; Ren, Y. Modeling and Application of Project Construction Management Based on BIM. Constr. Technol. 2017, 46, 143–150. [Google Scholar]

- He, J.; Ding, J.; Wang, Y. Deep foundation pit construction technology for silty soil areas. Archit. Eng. Technol. Des. 2024, 12, 20–22. [Google Scholar]

- GB 50202-2018; Standard for Acceptance of Construction Quality of Building Foundation. Ministry of Housing and Urban-Rural Development: Beijing, China, 2018.

- JGJ 311-2013; Technical Code for Construction Safety of Deep Building Foundation Excavations. Ministry of Housing and Urban-Rural Development: Beijing, China, 2013.

- JGJ 59-2011; Standard for Construction Safety Inspection. Ministry of Housing and Urban-Rural Development: Beijing, China, 2011.

- JGJ 120-2012; Technical Specification for Retaining and Protection of Building Foundation Excavations. Ministry of Housing and Urban-Rural Development: Beijing, China, 2012.

- Gong, Y.; Lu, W.; Tao, H. Research on construction risk of subway deep foundation pit based on CIM-AHP model. J. Hefei Univ. Technol. Nat. Sci. 2022, 45, 1422–1427. [Google Scholar]

- Li, D.; Liu, C. Study on the Universality of the Normal Cloud Model. Eng. Sci. 2004, 6, 28–34. [Google Scholar]

- Sun, C.; Liu, P.; Guo, Y. Implementing Large-diameter Well Dewatering Systems for Deep Excavation Construction. Constr. Mech. 2025, 46, 99–102. [Google Scholar]

- Zhou, Y.-G. Application Analysis of Deep Foundation Pit Construction Technology in Iron Related Building Construction Projects. Value Eng. 2025, 44, 135–138. [Google Scholar]

- Han, A. Study on Deformation Control of Deep Foundation Pit Construction Adjacent to Subway in Soft Soil Area. Build. Constr. 2024, 46, 1072–1075. [Google Scholar]

- Sun, L.; Xie, H.-P.; Yu, Y.-Z. Influencing Factors of Engineering Construction Safety Management Based on Resilience. J. Civ. Eng. Manag. 2020, 37, 60–65. [Google Scholar]

| Descriptive Indicators | Related Content | Number of Respondents | Percentage Point |

|---|---|---|---|

| Age | 25 years old and under | 22 | 11.46% |

| 26 to 30 years old | 30 | 15.63% | |

| Age 31 to 45 | 50 | 26.03% | |

| Age 46 to 55 | 60 | 31.25% | |

| Age 56 and older | 30 | 15.63% | |

| Work experience | Under 6 years old | 30 | 15.63% |

| Six to 10 years | 64 | 33.33% | |

| 11 to 20 years | 70 | 36.46% | |

| More than 20 years | 28 | 14.58% | |

| Type of affiliation | Developers | 56 | 29.17% |

| Contractors | 75 | 39.06% | |

| Colleges | 31 | 16.14% | |

| Other units | 30 | 15.63% |

| Weighting Method | Strong Point | Weak Point | |

|---|---|---|---|

| Subjectivity | Delphi method |

|

|

| Brainstorming method |

|

| |

| ANP law |

|

| |

| AHP law |

|

| |

| IF-AHP law |

|

| |

| Objective | Entropy weight method |

|

|

| Principal component analysis |

|

| |

| Maximum likelihood method |

|

| |

| Factor analysis |

|

| |

| Deviation method |

|

|

| Rigidity Grade | Resilience | Descriptive Grade |

|---|---|---|

| Level I | Lower resilience | The system’s resistance is extremely weak. In the face of external shocks or risks, it has almost no capacity for proactive defense and cannot effectively prevent accidents from occurring or spreading; its response capability is poor, lacking effective emergency measures and response capabilities, making it unable to quickly identify and respond to emergencies; recovery ability is very weak, and once a fault or accident occurs, the system takes a slow and difficult time to return to normal; improvement capability is virtually zero, with a lack of targeted enhancement and optimization measures, preventing the system from learning from past events and making improvements. |

| Level II | Low resilience | The system has weak resistance and can respond to external shocks to a certain extent, but it is easily disturbed and lacks adequate prevention when events occur; the response ability is weak, although risks can be identified, but the emergency response is not fast enough, and the response measures may be delayed or incomplete; the recovery ability is weak. The recovery process is relatively slow, and may be restricted by many parties, so it is difficult to return to normal operation in a short time; the improvement ability is weak, the system is difficult to effectively summarize experience after the event, the improvement measures lag behind, and the improvement is difficult. |

| Level III | General resilience | The system’s resistance is average, capable of handling medium-scale impacts. However, it still has certain limitations when facing more complex emergencies; its response capability is average, able to conduct initial emergency responses, but the methods for dealing with emergencies are limited and not always implemented in a timely manner; its recovery capability is average, the system can return to normal status, but the recovery speed is slow, requiring a considerable amount of time to address subsequent issues; its improvement capability is average, although the system can learn some lessons from incidents, the measures for enhancement and optimization are not systematic or efficient enough, making it difficult to rapidly improve response capabilities. |

| Level IV | High resilience | The system has strong resistance capabilities, capable of handling most emergencies and effectively preventing their escalation or causing greater losses; it also has robust response capabilities, able to quickly identify risks and take appropriate emergency measures, with a relatively complete response mechanism that can swiftly activate emergency plans; it has strong recovery capabilities, allowing the system to rapidly return to normal operation after encountering risk events, minimizing the impact on construction progress; it has strong enhancement capabilities, enabling the system to optimize based on post-event summaries and analyses, improving its ability to handle future risks, and continuously strengthening safety resilience. |

| Level V | Higher resilience | The system has an extremely strong resistance capability, effectively blocking most external disturbances and promptly identifying and addressing potential risk sources to prevent problems from occurring; it also possesses an exceptionally strong response capability, able to quickly identify and handle complex or changing risks, taking effective measures to resolve issues with high flexibility and adaptability; the recovery capability is also very strong, allowing the system to rapidly return to normal operation after emergencies, ensuring that construction progress and safety management are not long-term affected; the enhancement capability is extremely strong, enabling continuous optimization of emergency response mechanisms and management systems through post-event evaluation and summary, progressively improving preparedness for complex risks, and possessing robust self-improvement and optimization mechanisms. |

| Specialist | Work Unit | Working Life | Academic Title | Number of Deep Foundation pit Engineering Projects Participated in |

|---|---|---|---|---|

| 1 | Colleges | 14 | Inculcation | 9 |

| 2 | Colleges | 9 | Adjunct professor | 5 |

| 3 | Design unit | 10 | Design Director | 6 |

| 4 | Design unit | 11 | Design Director | 5 |

| 5 | Builder | 12 | Project Director | 7 |

| 6 | Builder | 12 | Technical Director | 8 |

| 7 | Supervision unit | 10 | Supervising engineer | 6 |

| 8 | Supervision unit | 14 | Supervising engineer | 8 |

| 9 | Real estate agency | 15 | Project manager | 11 |

| 10 | Real estate agency | 14 | General Manager of Engineering | 10 |

| Secondary Indicators | I | II | III | IV | V |

|---|---|---|---|---|---|

| X1 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X2 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X3 | [80, 100] | [60, 80) | [40, 60) | [20, 40) | [0, 20) |

| X4 | [80, 100] | [60, 80) | [40, 60) | [20, 40) | [0, 20) |

| X5 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X6 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X7 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X8 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X9 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X10 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X11 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X12 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X13 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X14 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X15 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X16 | [90, 100] | [80, 90) | [60, 80) | [30, 60) | [0, 30) |

| X17 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X18 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X19 | [80, 100] | [60, 80) | [40, 60) | [20, 40) | [0, 20) |

| X20 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X21 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X22 | [0, 20) | [20, 40) | [40, 60) | [60, 80) | [80, 100] |

| X23 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| X24 | [0, 30) | [30, 60) | [60, 80) | [80, 90) | [90, 100] |

| Stratum | Unit Weight γ (kN/m3) | Peak Strength Indicators (Direct Shear, Consolidated Quick Shear) | Saturated Uniaxial Compressive Strength Standard Value (MPa) | |

|---|---|---|---|---|

| Cohesion C (kPa) | Friction Angle Φ (°) | |||

| Miscellaneous Fill | 18.0 | 5 | 5.0 | |

| Silty Clay | 19.2 | 23 | 8.0 | |

| Medium Sand | 19.5 | 0 | 20.0 | |

| Coarse Sand | 19.5 | 0 | 30.0 | |

| Gravelly Sand | 19.5 | 0 | 35.0 | |

| Highly Weathered Sandy Conglomerate | 1.97 | |||

| Moderately Weathered Sandy Conglomerate | 4.71 | |||

| Evaluating Indicator | I | II | III | IV | V |

|---|---|---|---|---|---|

| X1 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X2 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X3 | (90, 3.33, 0.1) | (70, 3.33, 0.1) | (50, 3.33, 0.1) | (30, 3.33, 0.1) | (10, 3.33, 0.1) |

| X4 | (90, 3.33, 0.1) | (70, 3.33, 0.1) | (50, 3.33, 0.1) | (30, 3.33, 0.1) | (10, 3.33, 0.1) |

| X5 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X6 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X7 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X8 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X9 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X10 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X11 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X12 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X13 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X14 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X15 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X16 | (95, 1.67, 0.1) | (85, 1.67, 0.1) | (70, 3.33, 0.1) | (45, 5, 0.1) | (15, 5, 0.1) |

| X17 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X18 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X19 | (90, 3.33, 0.1) | (70, 3.33, 0.1) | (50, 3.33, 0.1) | (30, 3.33, 0.1) | (10, 3.33, 0.1) |

| X20 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X21 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X22 | (10, 3.33, 0.1) | (30, 3.33, 0.1) | (50, 3.33, 0.1) | (70, 3.33, 0.1) | (90, 3.33, 0.1) |

| X23 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| X24 | (15, 5, 0.1) | (45, 5, 0.1) | (70, 3.33, 0.1) | (85, 1.67, 0.1) | (95, 1.67, 0.1) |

| Level II Indicators | Level I Indicator | ||||

|---|---|---|---|---|---|

| Robustness | Redundancy | Efficiency | Adaptability | Weight | |

| 0.295 | 0.262 | 0.233 | 0.209 | ||

| X1 | 0.115 | - | - | - | 0.034 |

| X2 | 0.134 | - | - | - | 0.040 |

| X3 | 0.079 | - | - | - | 0.023 |

| X4 | 0.096 | - | - | - | 0.028 |

| X5 | 0.058 | - | - | - | 0.017 |

| X6 | 0.083 | 0.124 | - | - | 0.057 |

| X7 | 0.038 | 0.075 | 0.061 | - | 0.045 |

| X8 | 0.129 | - | - | - | 0.038 |

| X9 | 0.067 | - | - | - | 0.020 |

| X10 | - | 0.122 | - | 0.093 | 0.052 |

| X11 | 0.068 | 0.134 | 0.091 | - | 0.077 |

| X12 | 0.077 | 0.097 | - | 0.114 | 0.072 |

| X13 | 0.056 | 0.069 | - | 0.085 | 0.052 |

| X14 | - | 0.110 | 0.099 | - | 0.052 |

| X15 | - | 0.154 | 0.118 | - | 0.068 |

| X16 | - | - | 0.167 | - | 0.039 |

| X17 | - | - | 0.135 | - | 0.031 |

| X18 | - | - | 0.188 | - | 0.044 |

| X19 | - | - | 0.050 | 0.067 | 0.026 |

| X20 | - | 0.102 | 0.091 | 0.087 | 0.066 |

| X21 | - | 0.062 | - | 0.112 | 0.040 |

| X22 | - | - | - | 0.170 | 0.036 |

| X23 | - | - | - | 0.110 | 0.023 |

| X24 | - | - | - | 0.161 | 0.034 |

| Secondary Indicators | Rating Value | Weight | I | II | III | IV | V | Grade |

|---|---|---|---|---|---|---|---|---|

| X1 | 80.7 | 0.034 | 0.0000 | 0.0000 | 0.0000 | 0.0057 | 0.0203 | 5 |

| X2 | 79.2 | 0.04 | 0.0000 | 0.0000 | 0.0221 | 0.0023 | 0.0000 | 3 |

| X3 | 34.2 | 0.023 | 0.0000 | 0.0000 | 0.0000 | 0.4514 | 0.0000 | 4 |

| X4 | 52.2 | 0.028 | 0.0000 | 0.0000 | 0.8040 | 0.0000 | 0.0000 | 3 |

| X5 | 82.8 | 0.017 | 0.0000 | 0.0000 | 0.0000 | 0.0006 | 0.0964 | 5 |

| X6 | 80.3 | 0.057 | 0.0000 | 0.0000 | 0.0083 | 0.0190 | 0.0000 | 4 |

| X7 | 80.7 | 0.045 | 0.0000 | 0.0000 | 0.0057 | 0.0370 | 0.0000 | 4 |

| X8 | 81.2 | 0.038 | 0.0000 | 0.0000 | 0.0035 | 0.0754 | 0.0000 | 4 |

| X9 | 80.2 | 0.02 | 0.0000 | 0.0000 | 0.0000 | 0.0091 | 0.0130 | 5 |

| X10 | 76.1 | 0.052 | 0.0000 | 0.0000 | 0.0000 | 0.1868 | 0.0002 | 3 |

| X11 | 78.7 | 0.077 | 0.0000 | 0.0000 | 0.0330 | 0.0008 | 0.0000 | 3 |

| X12 | 78.3 | 0.072 | 0.0000 | 0.0000 | 0.0000 | 0.0449 | 0.0021 | 4 |

| X13 | 80.9 | 0.052 | 0.0000 | 0.0000 | 0.0000 | 0.0046 | 0.0239 | 5 |

| X14 | 78.9 | 0.052 | 0.0000 | 0.0000 | 0.0281 | 0.0013 | 0.0000 | 3 |

| X15 | 77.2 | 0.068 | 0.0000 | 0.0000 | 0.0965 | 0.0000 | 0.0000 | 3 |

| X16 | 70.5 | 0.039 | 0.0000 | 0.0000 | 0.9888 | 0.0000 | 0.0000 | 3 |

| X17 | 76.8 | 0.031 | 0.0000 | 0.0000 | 0.1241 | 0.0000 | 0.0000 | 3 |

| X18 | 79.4 | 0.044 | 0.0000 | 0.0000 | 0.0187 | 0.0037 | 0.0000 | 3 |

| X19 | 26.6 | 0.026 | 0.0000 | 0.0000 | 0.0000 | 0.5933 | 0.0000 | 4 |

| X20 | 73.4 | 0.066 | 0.0000 | 0.0000 | 0.0000 | 0.5938 | 0.0000 | 4 |

| X21 | 78.3 | 0.04 | 0.0000 | 0.0000 | 0.0000 | 0.0447 | 0.0021 | 4 |

| X22 | 74 | 0.036 | 0.0000 | 0.0000 | 0.0000 | 0.4867 | 0.0000 | 4 |

| X23 | 80.1 | 0.023 | 0.0000 | 0.0000 | 0.0100 | 0.0135 | 0.0000 | 4 |

| X24 | 75.2 | 0.034 | 0.0000 | 0.0000 | 0.2959 | 0.0000 | 0.0000 | 3 |

| Weight | I | II | III | IV | V | Grade | |

|---|---|---|---|---|---|---|---|

| Robustness | 0.295 | 0.0000 | 0.0000 | 0.0813 | 0.0805 | 0.0198 | 3 |

| Redundancy | 0.262 | 0.0000 | 0.0000 | 0.0346 | 0.2185 | 0.0072 | 4 |

| Efficiency | 0.233 | 0.0000 | 0.0000 | 0.1624 | 0.2260 | 0.0000 | 4 |

| Adaptability | 0.209 | 0.0000 | 0.0000 | 0.0311 | 0.3402 | 0.0072 | 4 |

| Objective level | 0.0000 | 0.0000 | 0.0774 | 0.2048 | 0.0092 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Mao, J.; Wang, L.; Gu, J. Safety Resilience Evaluation of Deep Foundation Pit Construction Based on Extension Cloud Model. Buildings 2025, 15, 3216. https://doi.org/10.3390/buildings15173216

Guo X, Mao J, Wang L, Gu J. Safety Resilience Evaluation of Deep Foundation Pit Construction Based on Extension Cloud Model. Buildings. 2025; 15(17):3216. https://doi.org/10.3390/buildings15173216

Chicago/Turabian StyleGuo, Xiaojian, Jiayi Mao, Luyun Wang, and Jianglin Gu. 2025. "Safety Resilience Evaluation of Deep Foundation Pit Construction Based on Extension Cloud Model" Buildings 15, no. 17: 3216. https://doi.org/10.3390/buildings15173216

APA StyleGuo, X., Mao, J., Wang, L., & Gu, J. (2025). Safety Resilience Evaluation of Deep Foundation Pit Construction Based on Extension Cloud Model. Buildings, 15(17), 3216. https://doi.org/10.3390/buildings15173216