Abstract

The development of sustainable and energy-efficient asphalt pavements is essential to address the growing demand for climate-neutral transportation infrastructure. This study investigates the structural design and functional performance of low rolling resistance asphalt mixtures utilizing reclaimed asphalt pavement (RAP) and warm mix asphalt (WMA) technologies. Ten mixtures with WMA additive—including asphalt concrete (AC) and stone mastic asphalt (SMA) with and without RAP—were evaluated for volumetric and mechanical performance. Laboratory results show that RAP addition did not compromise compaction nor indirect tensile strength ratio (ITSR), and in some cases improved these properties. SMA and SMA RAP-modified mixtures achieved the highest resistance to rutting (as low as 5.0% rut depth), while AC and SMA mixtures both demonstrated low rolling resistance (coefficients of energy loss 0.00604–0.00636). Resistance to low-temperature cracking was strong for all mixtures, with thermal stress restrained specimen test (TSRST) fracture temperatures ranging from −32.8 °C to −36.0 °C. SMA mixtures generally exhibited superior resistance to fatigue (up to 63 με at 1 million cycles). Overall, three asphalt mixtures with different particle size distribution containing 14% RAP and a WMA additive (SMA 8 S_1 R, SMA 8 S_3 R, and AC 11 VS_2 R) demonstrated the best balance of rolling resistance, durability, and circularity, and are recommended for field trials to support climate-neutral and sustainable road infrastructure. These results encourage broader adoption of circular practices in road infrastructure projects, contributing to lower emissions and life-cycle costs.

1. Introduction

The transportation sector remains one of the most pressing challenges in climate change mitigation, as it is the only sector in the European Union where greenhouse gas (GHG) emissions continue to exceed 1990 levels [1]. Currently, transport accounts for approximately 30% of total GHG emissions across the EU, with road transport contributing nearly 73% of this share [2]. These figures underscore the urgent need to implement more sustainable and energy-efficient practices in the sector.

One of the primary contributors to vehicular energy loss is rolling resistance, defined as the force resisting the motion of a tire as it rolls over a pavement surface [3]. Rolling resistance is primarily caused by energy losses due to viscoelastic deformation of the pavement and tire, surface texture, and hysteresis effects as the tire rolls. It has a direct impact on fuel consumption and GHG emissions. Even small reductions in rolling resistance can yield significant fuel savings and emissions reductions when aggregated over thousands of vehicles and many kilometres of asphalt pavements. Studies suggest that reducing rolling resistance through optimized tire or pavement texture can lower fuel consumption by up to 20%, thereby substantially lowering associated GHG emissions [4,5,6]. Consequently, asphalt mixtures with low-rolling resistance properties are gaining interest as a promising pathway to climate-neutral road infrastructure. However, despite the recognized benefits, designing an asphalt mixture that achieves lower rolling resistance while maintaining other essential properties (such as skid resistance for safety and structural durability) is a complex challenge.

Current research on rolling resistance largely focuses on the evaluations of rolling resistance of existing standard road pavements, measurement methodology itself and the influence of external factors such as tire properties, pavement properties, and operating conditions [7,8,9,10,11,12]. As a result, they lack the evaluation of changes in rolling resistance over time under real traffic conditions (the longest analysed period is only 3 years) and long-term performance analysis in terms of resistance to ravelling, rutting, low temperature cracking, fatigue, etc. In addition to this, they rarely extend to the intentional design of asphalt mixtures that minimize rolling resistance.

While the topic has received limited attention in the literature, several studies have addressed the development of low rolling resistance asphalt mixtures. In Denmark, two asphalt mixtures—SMA 6 COOEE+ and SMA 8 COOEE+—were specifically designed to reduce rolling resistance, with test sections constructed between 2012 and 2014 [13,14]. These studies confirmed that rolling resistance can be reduced by optimizing the particle size distribution, particularly the proportion passing the 4 mm sieve. However, an increase in mean profile depth (MPD) in Stensved test section constructed in 2012, along with cracks identified in the aggregates, revealed issues related to the aggregate quality. As a result, stronger aggregates were used in other test sections. Nevertheless, the authors did not outline specific requirements or guidelines for aggregate selection. Although the initial findings were promising, publicly available structural and functional performance data are only available up to 2016. A similar initiative was undertaken in the Netherlands, where an optimized thin surface mixture with a nominal maximum aggregate size of 5 mm was developed for the same purpose [15]. To promote reductions in rolling resistance, it was recommended that specifications for new asphalt pavements include a requirement limiting the MPD to a maximum of 1.2 mm. In 2019, the United Kingdom introduced a newly designed SMA mixture, namely 10 mm SuperCurve, which featured a smaller aggregate size (10 mm) and optimized gradation aimed at reducing rolling resistance [16]. It was constructed as a test section and compared to the conventional 14 mm SuperHitex mixture, a widely used SMA surface course mixture known for its durability and skid resistance. The results showed a reduction in the rolling resistance coefficient by up to 6%. Despite these promising developments, significant uncertainties remain regarding the long-term effectiveness of rolling resistance reduction, overall road pavement durability, and the impact of different bituminous binders and aggregate types on the mechanical and functional properties of low rolling resistance asphalt mixtures. Furthermore, the integration of sustainable technologies, such as reclaimed asphalt pavement (RAP) and warm mix asphalt (WMA), has not yet been fully explored in the context of low rolling resistance asphalt mixtures, despite their recognized potential to deliver substantial environmental and economic benefits in support of current sustainability and circular economy goals [17,18,19]. The use of RAP enhances resource efficiency and reduces construction waste by reusing existing asphalt pavement, while WMA technologies lower production and compaction temperatures, thereby decreasing energy consumption and associated emissions [20,21,22]. For example, reducing the mixing temperature by 40 °C (130 °C for WMA vs. 170 °C for HMA) can lead to approximately 15% lower fuel consumption for aggregate drying and heating, accompanied by similar reductions in CO2 emissions [23]. Other studies have reported even greater CO2 emission reductions, ranging from 25% to 70%, depending on the specific WMA technology used, as well as the type and dosage of additive [24,25,26]. When WMA and RAP technologies are applied in combination, the carbon footprint can be reduced by more than 50%, depending on the specific WMA technology and the proportion of RAP used [27]. In addition to this, it has been demonstrated that WMA and RAP technologies do not compromise the mechanical properties of asphalt mixtures, particularly those used to construct base and binder courses [20,22,28,29]. In fact, these technologies can even improve compactability, stiffness, resistance to moisture, and resistance to rutting [30,31,32]. Meanwhile, resistance to fatigue and thermal cracking are highly dependent on factors such as aggregate quality, binder type, RAP content, and the type and dosage of WMA additive used [29].

Most of the existing studies with WMA and RAP technologies focus on asphalt mixtures for structural layers, while limited attention has been given to wearing courses, especially those designed to reduce rolling resistance. The combined effects of WMA and RAP in such surface layers remain largely unexplored. Further research is needed to assess whether the integration of WMA and RAP technologies can maintain or even enhance the functional and mechanical performance of wearing courses without compromising their ability to reduce rolling resistance. This paper addresses these critical knowledge gaps by developing asphalt mixtures specifically designed to reduce rolling resistance, with a particular focus on the incorporation of RAP and WMA technologies. It presents a comprehensive evaluation of key performance parameters, including rolling resistance, water sensitivity, resistance to rutting, low-temperature cracking, and fatigue behaviour. The findings aim to support both academia and industry in advancing pavement sustainability, aligning with international decarbonization targets, and ensuring the long-term functional and environmental performance of road infrastructure.

2. Materials and Methods

2.1. Materials

The asphalt mixtures were produced using granite aggregates of different fractions (0–2 mm, 2–5 mm, 5–8 mm, and 8–11 mm), polymer-modified bitumen (PMB 45/80-65), and reclaimed asphalt pavement (RAP). Warm mix asphalt (WMA) additive and adhesive agent were included in all mixtures, while cellulose fibres were added into SMA mixtures to prevent binder drainage. Table 1 presents the properties of the aggregates.

Table 1.

Properties of aggregates.

The RAP used for the production of asphalt mixtures was obtained by milling the asphalt layer from the SMA 11 S mixture installed more than 10 years ago. The binder content of the RAP, determined according to EN 12697-1, was 6.48% by mass. The particle size distribution (gradation) of the RAP, assessed according to EN 933-1, is presented in Table 2.

Table 2.

Gradation of RAP.

Table 3 shows the properties of neat binder PMB 45/80-65 and the PMB binder recovered from RAP.

Table 3.

Properties of binder.

The neat PMB 45/80-65 has a penetration value of 58.0 dmm and a softening point of 81.0 °C, which corresponds to higher flexibility and heat resistance relative to the RAP-recovered binder, which features a penetration value of 41 dmm and a softening point of 61 °C, characteristics associated with increased stiffness and greater susceptibility to aging. Regarding elastic recovery, neat PMB measures at 90.3%, while the recovered PMB measures at 31.7%, reflecting the reduction in elasticity due to binder aging in RAP.

The physical and mechanical properties of both the aggregates and the fresh binder indicate that these materials are of the highest quality available on the market and are representative of those typically employed in the production of premium-grade asphalt mixtures.

Table 4, Table 5 and Table 6 present the properties of warm mix asphalt additive, cellulose fibre, and adhesive agent. The optimal dosage of the WMA additive was established at 0.5% by bitumen mass based on preliminary laboratory testing and manufacturer recommendations. In line with previous research, a cellulose fibre content of 0.3% by asphalt mixture mass was selected to effectively prevent binder drainage, while an adhesive additive dosage of 0.3% by binder mass was chosen to ensure sufficient adhesion within the mixture.

Table 4.

Properties of WMA additive.

Table 5.

Properties of cellulose fibre.

Table 6.

Properties of adhesive agent.

2.2. Asphalt Mixture Design and Production

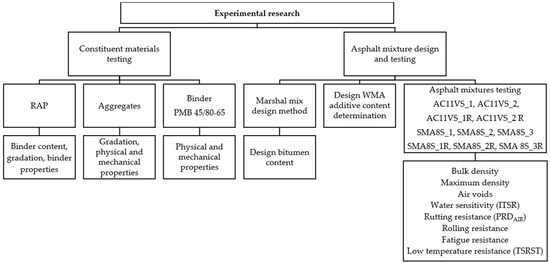

Ten asphalt mixtures with nominal aggregate size of 8 mm and 11 mm were designed: four of them were AC 11 VS (V indicates “wearing layer”, “S” indicates suitability for high-load traffic conditions) mixtures (without RAP and with RAP) and the other six were SMA 8 S (“S” indicates suitability for high-load traffic conditions) mixtures (without RAP and with RAP). The flowchart of the experimental research is given in Figure 1.

Figure 1.

Flowchart of the experimental research.

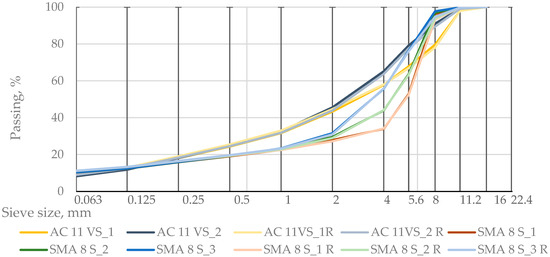

Figure 2 shows the particle size distributions for all mixtures. SMA 8 S was designed with three different coarse particle fractions, and AC 11 VS with two. Key gradation differences appeared at the 4 mm, 5.6 mm, and 8 mm sieves, which are most relevant for surface texture. Asphalt mixtures containing RAP were designed to match the gradations of those without RAP. RAP binder content was established according to EN 12697-1

Figure 2.

Asphalt mixture gradations.

Design binder content for each asphalt mixture was determined by initial tests: at first, three different binder contents were chosen for each mixture according to literature analysis and experience, and after that, volumetric properties tests were performed. According to volumetric properties results (Table 7), optimal binder content was selected as follows for each of the asphalt mixtures: 6.0% for AC 11 VS and 7.1% for SMA 8 S by mass of asphalt mixture.

Table 7.

Results of initial asphalt mixture volumetric property tests.

The detailed compositions of 10 asphalt mixtures (AC and SMA types, with and without RAP) are shown in Table 8.

Table 8.

Compositions of designed asphalt mixtures.

Mixtures were produced under controlled laboratory conditions using a standardized laboratory mixer GZM 15 manufactured by Baustoff-Prüfsysteme Wennigsen GmbH. Prior to mixing, all aggregates were dried at 110 °C until constant mass was achieved and subsequently heated to 125 °C. Reclaimed asphalt pavement (RAP) and cellulose fibres (where applicable) were dried separately at 40 °C until constant mass, then premixed with the heated aggregates. Bitumen was preheated to 160 °C for four hours, after which an adhesive agent was incorporated at a dosage of 0.3% by bitumen mass. Subsequently, 0.5% of a warm mix asphalt (WMA) additive was blended into the bitumen prior to mixing.

The prepared bitumen was then added to the aggregate–RAP blend and mixed for five minutes to ensure homogeneity. For all WMA mixtures, mixing was conducted at a reduced temperature of 130 °C, compared to the conventional hot mix asphalt (HMA) temperature of 175 °C.

2.3. Test Methods

For each asphalt mixture, three replicate specimens were subjected to the specified tests. Asphalt mixture specimens were compacted and formed at 125 °C. For the determination of bulk density, air voids content, and water sensitivity, specimens were prepared using a Marshall compactor manufactured by infraTest Prüftechnik GmbH. For resistance to rutting, fatigue, and low-temperature cracking (TSRST) tests as well as for evaluation of rolling resistance, larger slab specimens were produced using a sector compactor to achieve 100% degree of compaction. The density of each slab was checked following compaction to ensure consistency.

Prior to TSRST testing, beams were cut from the compacted slabs using a table saw. For resistance to fatigue tests, cylindrical cores were first drilled from the slabs, and then the sides of each core were trimmed with a table saw to obtain the final test specimens.

2.3.1. Bulk Density and Air Voids Content

The air voids content of each SMA and AC mixture was determined per EN 12697-8, using the maximum density (EN 12697-5, volumetric method) and bulk density (EN 12697-6). Bulk density specimens were prepared with a Marshall compactor (EN 12697-30), applying 50 blows per side.

2.3.2. Water Sensitivity

Water sensitivity was assessed using the EN 12697-12 method A standard. Indirect tensile strength testing was performed in accordance with EN 12697-23. For each asphalt mixture, six specimens were compacted by a Marshall compactor manufactured by infraTest Prüftechnik GmbH applying 35 blows on each side, as specified by EN 12697-30. The height and diameter of the specimens were measured following EN 12697-29. The specimens were then divided into two groups: three specimens were kept at room temperature before being conditioned in a climatic chamber at +25 °C for at least two hours prior to testing, while the remaining three were submerged in water at +40 °C for 72 h before testing. Following conditioning, all specimens were placed in a specialized mould and subjected to compression at a strain rate of 50 ± 2 mm/min until failure occurred. Water sensitivity was quantified as the ratio of indirect tensile strength (ITSR), representing the percentage ratio between the tensile strength of dry and wet specimens.

2.3.3. Rolling Resistance (Energy Loss Test)

Rolling resistance was evaluated using a drop-bounce method with a loaded car wheel. A suitable test wheel (Michelin Primacy 4 size 205/55R16 tire) was equipped with an adjustable mass and suspended at a defined height above a fixed pavement specimen (Figure 3). Upon release, the wheel was allowed to repeatedly impact and rebound from the pavement surface. A laser sensor continuously recorded the vertical movement of the wheel axis relative to its static position. The decay in bounce amplitude was analysed to determine energy losses within the system. Test parameters such as wheel mass, drop height, and specimen rigidity were set to simulate real-world dynamic tire deflections. The area between the upper and lower envelope curves of the oscillation trajectory was used as a quantitative measure of rolling resistance.

Figure 3.

Rolling resistance (energy loss) test facility [33].

Specimens for the rolling resistance test were prepared in two stages (Figure 4). First, asphalt mixture slabs (40 × 260 × 410 mm) were compacted using a slab compactor manufactured by infraTest Prüftechnik GmbH following EN 12697-33 requirements. After cooling, the asphalt slabs were affixed with binder to the prepared concrete base plate.

Figure 4.

Specimen prepared for rolling resistance (energy loss) test.

2.3.4. Resistance to Rutting

The test to evaluate the resistance to rutting followed EN 12697-22 using a small wheel tracking device (manufactured by infraTest Prüftechnik GmbH) in air. Asphalt mixture slabs (40 × 260 × 410 mm) were compacted per EN 12697-33. A 710 N pneumatic wheel moved back and forth over each slab at 60 °C until 30,000 load cycles were completed.

2.3.5. Low Temperature Cracking

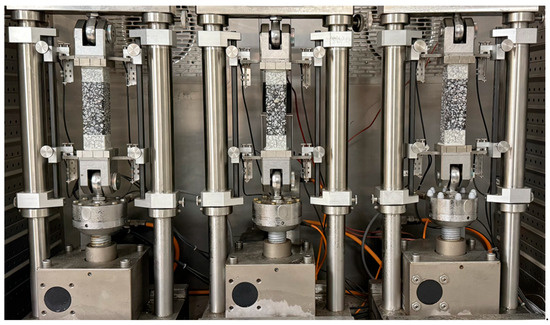

Resistance to low-temperature cracking was evaluated by TSRST following EN 12697-46 (Figure 5). Three prismatic specimens (40 mm square, 160 mm long) were cut from lab-compacted slabs made with a roller compactor (EN 12697-33). Each specimen was fixed at a constant length while cooled at 10 °C/h. As thermal stress increased due to restrained shrinkage, cracking occurred once tensile strength was exceeded. Failure temperature and stress were recorded.

Figure 5.

The thermal stress restrained specimen test (TSRST).

2.3.6. Resistance to Fatigue

Resistance to fatigue was tested following EN 12697-24 and FGSV 430 (2009). For each asphalt mixture, twelve cylindrical specimens (100 mm diameter, 40 mm height) were cut from roller-compacted slabs. Using a 10 Hz haver sinusoidal load at 20 °C, specimens underwent repeated compressive loading perpendicular to their diameter. Vertical load and horizontal deformation were monitored throughout. Testing stopped when stiffness dropped by over 50%.

3. Results and Discussion

The reported results reflect the average values obtained from three replicate specimens for each mixture and test. Where relevant, the figures display the minimum and maximum values measured among the replicates to indicate the range and reproducibility of the data.

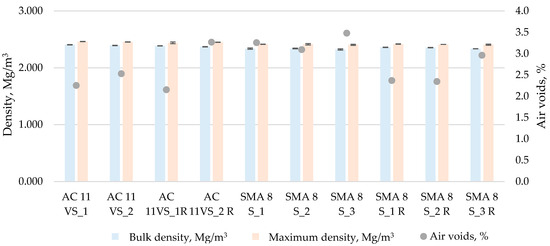

3.1. Bulk Density and Air Voids Content

Figure 6 presents the bulk density, maximum density, and air voids content for each asphalt mixture. AC mixtures (such as AC 11 VS_1 and AC 11 VS_2) displayed the highest bulk and maximum densities (2.401–2.462 Mg/m3), a tendency also reported in previous studies, where continuous aggregate gradation combined with relatively lower binder content was found to promote dense aggregate packing and higher mixture compactibility [17]. By contrast, SMA mixtures had lower densities (2.324–2.418 Mg/m3), reflecting their gap-graded aggregate skeleton, higher binder and filler content, and addition of fibers, characteristics widely recognized in the literature as typical for SMA design [34,35]. Previous studies have shown that the gap-graded structure of SMA, while reducing overall mixture density, improves stone-on-stone contact and is known to enhance resistance to rutting.

Figure 6.

Results of density and air voids content.

Air void content varied from 2.2% to 3.5% across the tested mixtures. AC mixtures, particularly those without RAP (e.g., AC 11 VS_1 at 2.3%), achieved the lowest air voids, indicative of high compaction and minimal permeability. Similar trends have been reported in previous studies, where dense-graded mixtures exhibited lower air voids due to better aggregate interlock and compaction efficiency [19,34]. The addition of RAP in AC 11VS_1R slightly reduced air voids further (2.2%), which can be attributed to the stiffer aged binder in RAP that may enhance aggregate orientation and reduce compacted air volume. SMA mixtures, on the other hand, consistently showed higher air void contents (up to 3.5% in SMA 8 S_3). This outcome is largely the result of their gap-graded structure and higher binder content, which, as reported in previous studies, can trap more air during compaction [34]. RAP incorporation in SMA mixtures (e.g., SMA 8 S_1 R, SMA 8 S_2 R) yielded a mixed effect, sometimes marginally reducing air voids (suggesting increased compaction) or slightly increasing them. These findings align with previous research indicating that moderate RAP levels, when combined with appropriate binder selection, do not significantly impair compactibility or volumetric properties [19].

Binder content in SMA mixtures was higher than in AC mixtures, a characteristic consistently noted in previous studies as typical for SMA designs to ensure durability and flexibility [34,35]. This higher binder content, along with the addition of cellulose fibre, helps prevent drain-down and improves mixture cohesion but may also contribute to higher air voids due to lower compaction efficiency compared to dense-graded AC. The results demonstrate that both aggregate gradation and mixture composition—particularly binder and RAP content—play crucial roles in determining the volumetric properties of asphalt mixtures. Well-designed AC mixtures with proper compaction exhibit low air voids and high density, favouring long-term durability [28,29]. SMA mixtures, by contrast, balance higher air voids and lower density with improved deformation resistance, provided that binder and fibre contents are optimized. The inclusion of RAP, if not excessive, is compatible with high-performance requirements for both mixture types.

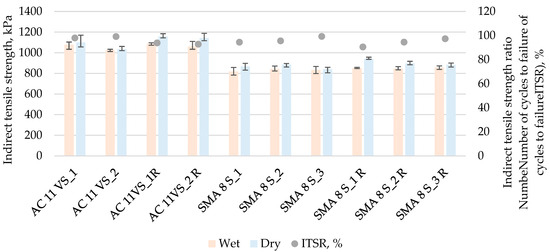

3.2. Water Sensitivity

Figure 7 summarizes the indirect tensile strength (ITS) values for both wet and dry specimens, as well as the corresponding indirect tensile strength ratio (ITSR) for all tested asphalt mixtures. AC mixtures displayed the highest ITS values, both in wet and dry conditions. For example, AC 11 VS_1 reached 1078 kPa (wet) and 1100 kPa (dry), indicating its cohesive strength. The use of reclaimed asphalt pavement (RAP) had minimal effect on ITS for AC mixtures, as AC 11VS_1R exhibited similar or slightly increased results (1087 kPa wet, 1159 kPa dry), which aligns with previous research showing that moderate RAP contents in polymer-modified asphalt can maintain or even improve tensile strength [19]. SMA mixtures demonstrated somewhat lower ITS values (e.g., SMA 8 S_3: 835 kPa wet, 841 kPa dry), a trend also observed in previous studies and attributed to the effects of higher binder content and gap-graded aggregate structure [35].

Figure 7.

Results of water sensitivity.

Higher values in AC mixtures were linked to dense gradation, lower binder content, and PMB–aggregate adhesion, while slightly lower values in RAP-containing SMA were associated with the stiffer aged binder affecting tensile flexibility.

The ITSR is a crucial indicator of an asphalt mixture’s resistance to moisture-induced damage. An ITSR value of 90% is required for the wearing layer asphalt mixture to ensure satisfactory water sensitivity performance. In this study, all mixtures met or exceeded the 90% threshold. The ITSR values ranged from 90.5% (SMA 8 S_1 R) up to 99.2% (AC 11 VS_2, SMA 8 S_3), demonstrating excellent resistance to moisture damage across the board, which is consistent with previous studies reporting high water resistance in both dense-graded and SMA mixtures incorporating polymer-modified binders and performance-enhancing additives [22,35]. The lowest ITSR values, observed in SMA mixtures containing RAP, still satisfied the specification, but suggest that these mixtures may benefit from the use of anti-stripping agents or improved binder–aggregate compatibility, particularly when higher RAP contents are used. The observed results emphasize the influence of mixture composition on ITS and ITSR. Dense-graded AC mixtures, with lower binder content and optimized gradation, showed higher tensile strength and water resistance. All tested asphalt mixtures—both AC and SMA, with or without RAP—demonstrated ITSR values above the 90% criterion, confirming compliance with relevant European standards and suitability for practical application in pavement structures.

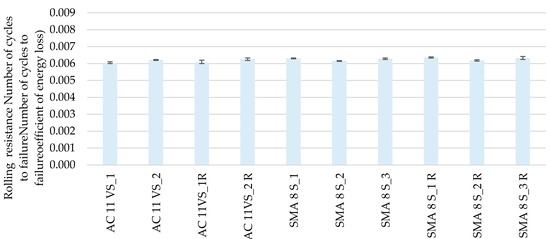

3.3. Rolling Resistance (Energy Loss Test)

Figure 8 presents the rolling resistance values for each asphalt mixture, expressed as the coefficient of energy loss measured under laboratory conditions. Rolling resistance is a key functional property for road surfaces, as it directly affects vehicle fuel consumption and, by extension, greenhouse gas emissions and operational costs, a relationship well-documented in previous research [12]. All tested mixtures exhibited low coefficients of energy loss, generally ranging from 0.0060 to 0.0064. The lowest rolling resistance was observed in AC 11 VS_1 (0.00603) and AC 11 VS_1 R (0.00607). These results are consistent with the literature, where dense-graded asphalt concretes and well-optimized SMA mixtures are known to provide favourable rolling resistance, supporting energy-efficient transportation [12,36]. The composition of the mixtures—including aggregate gradation, air void content, binder type, and RAP percentage—does not have a significant effect on rolling resistance. Minimal differences between mixtures reflected the stabilizing effect of PMB, the optimized surface texture from gradation design, and the absence of RAP-induced surface roughness. Mixtures with denser aggregate packing and lower air voids, such as AC 11 VS_1 and AC 11VS_1R, tend to reduce energy loss due to their smoother surface texture and lower hysteresis under load. The inclusion of RAP in both AC and SMA mixtures did not lead to a significant increase in rolling resistance, suggesting that the proper selection of RAP content can preserve or even improve functional surface performance [36]. SMA mixtures, especially those with higher binder content and optimized stone-on-stone contact, demonstrated comparable rolling resistance to conventional AC, confirming that sustainable designs need not compromise surface efficiency [36]. Maintaining low rolling resistance is essential not only for reducing fuel consumption but also for minimizing emissions and contributing to the circular economy by prolonging pavement life and enhancing user comfort [12]. The results of this study confirm that both AC and SMA mixtures, even with moderate RAP content, can achieve rolling resistance values in line with international best practices, provided that mixture design is carefully controlled.

Figure 8.

Results of rolling resistance (energy loss).

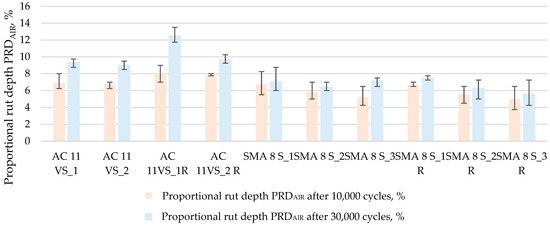

3.4. Resistance to Rutting

Figure 9 summarizes the resistance to rutting of all tested asphalt mixtures, measured as proportional rut depth (PRDAIR) after 10,000 and 30,000 cycles. Resistance to rutting is an essential property that indicates a pavement’s ability to withstand permanent deformation caused by repeated traffic loading. The proportional rut depths after 10,000 cycles varied from 5.0% to 8.0%, and after 30,000 cycles from 5.6% to 12.5%. RAP’s stiff binder and SMA’s stone-on-stone skeleton improved deformation resistance, particularly in SMA with RAP, while AC mixtures without RAP showed higher rut depths due to lower stiffness. In general, SMA mixtures exhibited lower rut depths compared to AC mixtures, particularly at higher loading cycles, which is consistent with the well-documented benefit of stone mastic asphalts’ stone-on-stone aggregate structure for resisting deformation [35].

Figure 9.

Results of resistance to rutting.

The lowest rutting values were typically observed in SMA mixtures with optimized gradation and binder content, while the highest rutting values were associated with dense-graded AC mixtures, especially those with lower binder stiffness or less optimized aggregate packing. The results highlight the strong effect of mixture composition on rutting performance. SMA mixtures, with their gap-graded skeleton, higher binder content, and fibre reinforcement, displayed enhanced resistance to rutting under repeated loading, reflecting their suitability for heavily trafficked pavements [35]. Incorporation of RAP generally resulted in comparable or even improved resistance to rutting in both AC and SMA mixtures. This is attributed to the stiffening effect of aged binder present in RAP, which increases overall mixture stiffness and resistance to deformation, a finding that aligns with prior studies [19]. However, it is essential to balance RAP content and binder selection to avoid excessive stiffness, which may negatively impact other performance parameters.

These findings demonstrate that careful optimization of aggregate gradation, binder content, and RAP incorporation can yield asphalt mixtures with high resistance to rutting, supporting both durability and sustainability objectives. The results confirm trends reported in the literature that both SMA and AC mixtures, when properly engineered, can deliver robust performance under traffic loading and environmental stresses [22,34].

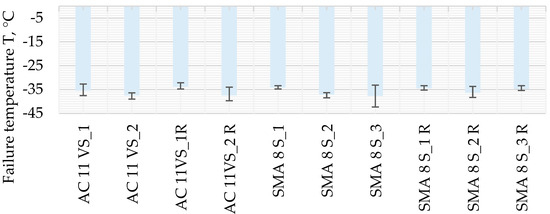

3.5. Low Temperature Cracking (TSRST)

Figure 10 presents the results of the thermal stress restrained specimen test (TSRST) for all asphalt mixtures, reported as the critical temperature at which fracture occurs under restrained cooling. The TSRST is widely recognized as a direct measure of an asphalt mixture’s resistance to thermal cracking, a critical property in cold climates [36]. The TSRST results (Figure 10) demonstrated that all tested asphalt mixtures possess good resistance to thermal cracking, with critical cracking temperatures ranging from −32.8 °C to −36.0 °C. The best low-temperature performance (i.e., most negative fracture temperature) was observed for AC 11 VS_2 (−36.0 °C) and SMA 8 S_2 (−35.9 °C).

Figure 10.

Results of critical low temperature (TSRST).

The inclusion of RAP had a modest effect on low-temperature performance. In some cases, RAP-modified mixtures fractured at slightly higher temperatures (i.e., performed less well), which can be attributed to the stiffer aged binder present in RAP increasing susceptibility to thermal stress. However, the differences between RAP and non-RAP mixtures were not substantial, suggesting that RAP levels used in this study were within acceptable limits to avoid severe embrittlement.

These results confirm that all tested mixtures possess sufficient resistance to low-temperature cracking for climates experiencing severe winter conditions, a conclusion consistent with previous studies indicating that mixtures with critical cracking temperatures below expected in-service pavement temperatures perform reliably in cold regions [22]. The use of SMA design and high-quality binders can further enhance resistance to thermal cracking, even when incorporating moderate RAP content.

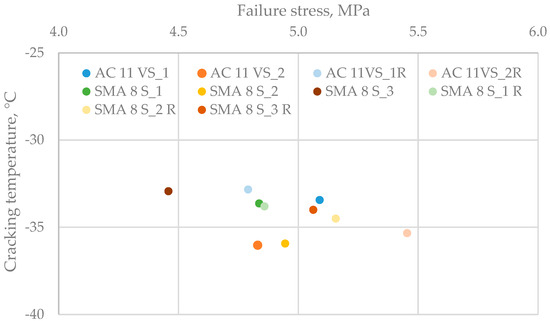

Figure 11 summarizes the relationship between failure stress and cracking temperature for the evaluated asphalt mixtures, based on TSRST results. The average failure stress ranged from 4.5 to 5.5 MPa, while the corresponding average cracking temperatures ranged from −32.9 °C to −35.9 °C. Mixtures with higher average failure stress (e.g., AC 11VS_2R: 5.5 MPa) generally exhibited lower (more negative) cracking temperatures (−35.3 °C), indicating enhanced resistance to thermal cracking. Conversely, mixtures with lower average failure stress, such as AC 11VS_1R (4.79 MPa, −32.8 °C), fractured at higher (less negative) temperatures, reflecting a reduced ability to withstand low-temperature shrinkage stress.

Figure 11.

Cracking temperature depending on failure stress.

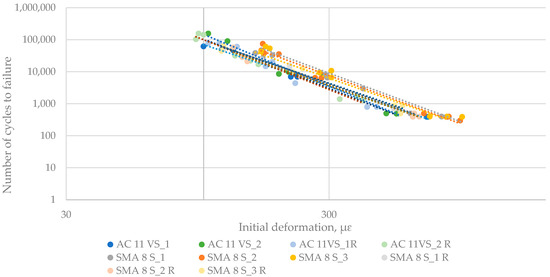

3.6. Resistance to Resistance

Figure 12 presents the results of resistance to fatigue for all tested asphalt mixtures, expressed as the strain amplitude (ε6, in microstrain) corresponding to one million loading cycles. Resistance to fatigue is a key mechanical property that indicates a pavement’s ability to withstand repeated traffic loading without developing structural cracks. The mixtures demonstrated a range of fatigue resistance values, with ε6 varying from 35 to 63 με. SMA mixtures, particularly SMA 8 S_3 (63 με), exhibited the highest fatigue resistance, a tendency also reported in previous studies and attributed to the beneficial effects of higher binder content and improved aggregate structure in these mixes [35]. AC mixtures, such as AC 11 VS_1 (38 με), generally showed lower fatigue strain levels, indicating a reduced ability to endure repeated flexural stresses compared to SMA designs. Higher binder content and cellulose in SMA supported superior fatigue life, but RAP’s stiff binder reduced strain capacity in certain SMA mixtures; AC mixtures were less sensitive to RAP in fatigue.

Figure 12.

Results of resistance to fatigue.

Mixture composition played a significant role in fatigue performance. SMA mixtures, which feature higher binder content, a gap-graded aggregate skeleton, have been widely reported in previous studies to offer superior resistance to fatigue compared to dense-graded asphalt concretes [35]. RAP inclusion had a complex effect: in some mixtures, the increased stiffness from aged binder in RAP led to reduced fatigue strain (e.g., SMA 8 S_1 R at 35 με), as excessive stiffness can decrease the mix’s ability to dissipate strain energy under repeated loading. Inclusion of RAP can be compatible with high fatigue resistance if total binder content, binder grade, and mixture design are appropriately managed.

Across all tests, the observed differences between mixtures can be attributed to variations in mixture composition, including the presence of reclaimed asphalt pavement (RAP), polymer-modified bitumen (PMB 45/80-65), and performance-enhancing additives such as adhesive agents, warm-mix additives, and cellulose fibres. The incorporation of RAP often introduced a stiffer aged binder, which in some cases improved stiffness-dependent properties such as resistance to rutting and compaction, while in others—particularly in SMA mixtures—this stiffening slightly reduced fatigue flexibility or moisture damage tolerance. Polymer-modified bitumen contributed to enhanced cohesion, elasticity, and moisture resistance, supporting high ITS values. WMA additives allowed lower mixing temperatures without loss of workability, while cellulose fibres in SMA helped retain binder and prevent drain-down, influencing volumetric and mechanical performance.

Considering all properties evaluated, mixtures SMA 8 S_1 R, SMA 8 S_3 R, and AC 11 VS_2 R stand out as optimal selections. These mixtures provide the best balance between low rolling resistance, robust structural performance (rutting and fatigue), and effective use of recycled materials. This approach is closely aligned with the principles of the circular economy and presents considerable potential for advancing sustainable road infrastructure.

4. Conclusions

This study comprehensively evaluated low rolling resistance asphalt mixtures incorporating reclaimed asphalt pavement (RAP) and warm mix asphalt (WMA)additive. The main findings and tendencies are summarized below:

- All tested asphalt mixtures achieved satisfactory compaction and air voids content. Dense-graded asphalt concrete (AC) mixtures typically displayed higher bulk density (2.370–2.406 Mg/m3) and lower air voids (2.2–3.3), reflecting efficient aggregate packing, while stone mastic asphalt (SMA) mixtures showed greater air voids (2.3–3.5) and slightly lower densities (2.324–2.360 Mg/m3), in line with their gap-graded design and higher binder content. The use of RAP dd not notably affect compaction or volume, supporting recycled materials’ suitability.

- All AC and SMA mixtures, irrespective of RAP present, exhibited strong mechanical performance, with indirect tensile strength ratio above 90% and meeting the requirements for water sensitivity. SMA mixtures, with and without RAP, generally showed about 1.7 times higher resistance to rutting than AC mixtures, attributable to their optimized aggregate skeletons. The incorporation of RAP in SMA mixtures resulted in improved resistance to rutting but reduced resistance to fatigue due to increased mixture stiffness. In contrast, RAP addition in AC mixtures, produced inconsistent effects on resistance to fatigue and tended to reduce resistance to rutting. These findings underscore the importance of carefully balancing asphalt mixtures with RAP depending on the targeted performance properties and mixture type.

- All mixtures demonstrated effective resistance to low-temperature cracking, with critical cracking temperatures ranging from −36.0 °C to −32.8 °C, indicating suitability for cold climate applications. Mixtures with higher failure stress generally showed greater resistance to thermal cracking. The incorporation of RAP did not accelerate the embrittlement of asphalt specimens.

- All mixtures demonstrated low rolling resistance (coefficients of energy loss varied from 0.0060 to 0.0064), thereby facilitating the design of pavements that contribute to lower energy consumption and reduced environmental impact. The incorporation of RAP and the application of WMA additive did not adversely affect the functional performance of the developed mixtures.

- The results highlight that asphalt mixture design approaches incorporating RAP and WMA additive, can produce asphalt mixtures with balanced physical, mechanical, and functional properties. These tendencies support the transition to sustainable, durable, and climate-neutral road infrastructure.

In conclusion, this study showed that specific mixtures (SMA 8 S_1 R, SMA 8 S_3 R, and AC 11 VS_2 R) effectively reduce rolling resistance without compromising mechanical durability. These mixtures are recommended for future practical implementations aimed at advancing sustainable and resilient asphalt mixture design. Further research should focus on field validation of these mixtures and ongoing optimization of RAP content and binder systems to enhance the environmental and operational benefits of asphalt pavements.

Author Contributions

Conceptualization, J.Š. and O.Š.; methodology, J.Š. and O.Š.; formal analysis, L.Ž., I.K. and R.M.; writing—original draft preparation, L.Ž., I.K. and R.M.; writing—review and editing, J.Š., O.Š. and D.Č.; visualization, I.K.; supervision, D.Č.; project administration, J.Š.; funding acquisition, J.Š. All authors have read and agreed to the published version of the manuscript.

Funding

Research was conducted as part of the execution of Project “Mission-driven Implementation of Science and Innovation Programmes” (No. 02-002-P-0001), funded by the Economic Revitalization and Resilience Enhancement Plan “New Generation Lithuania”.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- European Commision Climate Change—Driving Forces. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Climate_change_-_driving_forces#General_overview (accessed on 7 July 2025).

- European Environment Agency. Sustainability of Europe’s Mobility Systems; European Environment Agency: Copenhagen, Denmark, 2024. [Google Scholar]

- Andersen, L.G.; Larsen, J.K.; Fraser, E.S.; Schmidt, B.; Dyre, J.C. Rolling Resistance Measurement and Model Development. J. Transp. Eng. 2015, 141, 04014075. [Google Scholar] [CrossRef]

- Świeczko-Żurek, B.; Ronowski, G.; Ejsmont, J. Tyre Rolling Resistance and Its Influence on Fuel Consumption. Combust. Engines 2017, 168, 62–67. [Google Scholar] [CrossRef] [PubMed]

- Trupia, L.; Parry, T.; Neves, L.C.; Lo Presti, D. Rolling Resistance Contribution to a Road Pavement Life Cycle Carbon Footprint Analysis. Int. J. Life Cycle Assess. 2017, 22, 972–985. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Lee, I.-S.; Kendall, A.; Harvey, J.; Lee, E.-B.; Kim, C. Life Cycle Energy Consumption and GHG Emission from Pavement Rehabilitation with Different Rolling Resistance. J. Clean. Prod. 2012, 33, 86–96. [Google Scholar] [CrossRef]

- Sohaney, R.C.; Otto Rasmussen, R. Pavement Texture Evaluation and Relationships to Rolling Resistanc e at MnROAD; MN/RC 2013-16 2; Minnesota Department of Transportation: Saint Paul, MN, USA, 2013. [Google Scholar]

- Haider, M.; Conter, M.; Green, M.; Schmidt, B.; Sandberg, U. Status of the EU-Project ROSANNE. Transp. Res. Procedia 2016, 14, 2946–2955. [Google Scholar] [CrossRef][Green Version]

- Nielsen, N.R.; Chatti, K.; Nielsen, C.P.; Zaabar, I.; Hjorth, P.G.; Hecksher, T. Method for Direct Measurement of Structural Rolling Resistance for Heavy Vehicles. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 371–380. [Google Scholar] [CrossRef]

- Ydrefors, L.; Hjort, M.; Kharrazi, S.; Jerrelind, J.; Stensson Trigell, A. Rolling Resistance and Its Relation to Operating Conditions: A Literature Review. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 2931–2948. [Google Scholar] [CrossRef]

- Carlson, A.; Vieira, T. The Effect of Water and Snow on the Road Surface on Rolling Resistance. VTI Rapport 971 A; VTI: Linköping, Sweden, 2021. [Google Scholar]

- Sun, Z.; Premarathna, W.A.A.S.; Anupam, K.; Kasbergen, C.; Erkens, S.M.J.G. A State-of-the-Art Review on Rolling Resistance of Asphalt Pavements and Its Environmental Impact. Constr. Build. Mater. 2024, 411, 133589. [Google Scholar] [CrossRef]

- Pettinari, M.; Lund-Jensen, B.B.; Schmidt, B. Low Rolling Resistance Pavements in Denmark. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016; Czech Technical University in Prague: Prague, Czech Republic, 2016. [Google Scholar]

- Pettinari, M.; Schmidt, B. Development and Implementation of Low Rolling Resistance Pavement in Denmark. Asf. y Paviment 2017, VII, 43–49. [Google Scholar]

- Mookhoek, S.D.; van Kanten-Roos, W.; Bijleveld, F. Making Roads Resistance Energy Efficient by Reducing Rolling; TNO: Hague, The Netherlands, 2017. [Google Scholar]

- Scottish Road Research Board. The Effect of Rolling Resistance on Carbon Emissions; Scottish Road Research Board: Edinburgh, Scottish, 2024. [Google Scholar]

- Mattinzioli, T.; Sol-Sánchez, M.; Jiménez del Barco Carrión, A.; Moreno-Navarro, F.; Rubio-Gámez, M.d.C.; Martínez, G. Analysis of the GHG Savings and Cost-Effectiveness of Asphalt Pavement Climate Mitigation Strategies. J. Clean. Prod. 2021, 320, 128768. [Google Scholar] [CrossRef]

- Riekstins, A.; Haritonovs, V.; Straupe, V.; Izaks, R.; Merijs-Meri, R.; Zicans, J. Comparative Environmental and Economic Assessment of a Road Pavement Containing Multiple Sustainable Materials and Technologies. Constr. Build. Mater. 2024, 432, 136522. [Google Scholar] [CrossRef]

- Wu, S.; Bhatt, B.; Kenney, C. Towards Carbon Neutrality: A Comprehensive Review of Sustainable Materials for Asphalt Pavement. Road Mater. Pavement Des. 2024, 629, 1–30. [Google Scholar] [CrossRef]

- Wang, D.; Riccardi, C.; Jafari, B.; Cannone Falchetto, A.; Wistuba, M.P. Investigation on the Effect of High Amount of Re-Recycled RAP with Warm Mix Asphalt (WMA) Technology. Constr. Build. Mater. 2021, 312, 125395. [Google Scholar] [CrossRef]

- Rathore, M.; Haritonovs, V.; Zaumanis, M. Performance Evaluation of Warm Asphalt Mixtures Containing Chemical Additive and Effect of Incorporating High Reclaimed Asphalt Content. Materials 2021, 14, 3793. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, A.; Behnood, A.; Nowruzi, A.; Haghshenas, H. Performance Evaluation of Asphalt Mixtures Containing Warm Mix Asphalt (WMA) Additives and Reclaimed Asphalt Pavement (RAP). Constr. Build. Mater. 2021, 268, 121200. [Google Scholar] [CrossRef]

- Ferrotti, G.; Mancinelli, E.; Passerini, G.; Canestrari, F. Comparison of Energy and Environmental Performance between Warm and Hot Mix Asphalt Concrete Production: A Case Study. Constr. Build. Mater. 2024, 418, 135453. [Google Scholar] [CrossRef]

- Mallick, R.B.; Bergendahl, J. A Laboratory Study on CO2 Emission from Asphalt Binder and Its Reduction with the Use of Warm Mix Asphalt. Int. J. Sustain. Eng. 2009, 2, 275–283. [Google Scholar] [CrossRef]

- Cheraghian, G.; Cannone Falchetto, A.; You, Z.; Chen, S.; Kim, Y.S.; Westerhoff, J.; Moon, K.H.; Wistuba, M.P. Warm Mix Asphalt Technology: An up to Date Review. J. Clean. Prod. 2020, 268, 122128. [Google Scholar] [CrossRef]

- Wu, S.; Tahri, O.; Shen, S.; Zhang, W.; Muhunthan, B. Environmental Impact Evaluation and Long-Term Rutting Resistance Performance of Warm Mix Asphalt Technologies. J. Clean. Prod. 2021, 278, 123938. [Google Scholar] [CrossRef]

- Bizarro, D.E.G.; Steinmann, Z.; Nieuwenhuijse, I.; Keijzer, E.; Hauck, M. Potential Carbon Footprint Reduction for Reclaimed Asphalt Pavement Innovations: LCA Methodology, Best Available Technology, and Near-Future Reduction Potential. Sustainability 2021, 13, 1382. [Google Scholar] [CrossRef]

- Pouget, S.; Marsac, P.; Pedraza, A.; Sauzéat, C.; Di Benedetto, H.; Gaudefroy, V.; Boulangé, L.; Pévère, A.; Mouillet, V. Advanced Characterisation of Multi-Recycled Warm Asphalt Pavement (MRWAP) with High Content of Recycled Asphalt Pavement. Road Mater. Pavement Des. 2023, 24, 388–409. [Google Scholar] [CrossRef]

- Guo, M.; Liu, H.; Jiao, Y.; Mo, L.; Tan, Y.; Wang, D.; Liang, M. Effect of WMA-RAP Technology on Pavement Performance of Asphalt Mixture: A State-of-the-Art Review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- El Sharkawy, S.A.; Wahdan, A.H.; Galal, S.A. Utilisation of Warm-Mix Asphalt Technology to Improve Bituminous Mixtures Containing Reclaimed Asphalt Pavement. Road Mater. Pavement Des. 2017, 18, 477–506. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M. Comparative Evaluation of Warm Mix Asphalt Containing High Percentages of Reclaimed Asphalt Pavement. Constr. Build. Mater. 2013, 44, 92–100. [Google Scholar] [CrossRef]

- Guo, N.; You, Z.; Tan, Y.; Zhao, Y. Performance Evaluation of Warm Mix Asphalt Containing Reclaimed Asphalt Mixtures. Int. J. Pavement Eng. 2017, 18, 981–989. [Google Scholar] [CrossRef]

- Ejsmont, J.; Owczarzak, W. Engineering Method of Tire Rolling Resistance Evaluation. Measurement 2019, 145, 144–149. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Laboratory Evaluation of Hot-Mix Asphalt Containing Construction and Demolition Waste. Constr. Build. Mater. 2013, 43, 497–505. [Google Scholar] [CrossRef]

- Škulteckė, J.; Vaitkus, A.; Šernas, O. Laboratory Investigation on the Use of Wood Waste Fibres in SMA Mixtures. Constr. Build. Mater. 2023, 400, 132727. [Google Scholar] [CrossRef]

- Sandberg, U.; Jerzy, E. Tyre/Road Noise. Reference Book; INFORMEX: Kisa, Sweden, 2002; ISBN 9163126109/9789163126109. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).