1. Introduction

Due to the more flexible spatial layout of staggered-story frame buildings, which allows for the full utilization of the indoor space with more functional partitions and a stronger sense of hierarchy, an increasing number of users and developers are considering the adoption of staggered-story buildings. However, because the floor slabs of staggered-story buildings are interleaved with each other, short members that are unfavorable for earthquake resistance are prone to form, which reduces the structure’s ability to coordinate deformation. In view of the advantages of such structures in terms of variable spatial layout, it has become a key issue for structural engineers and researchers to find ways to avoid or overcome the adverse effects caused by staggered stories, improve the seismic performance of the structure, and maximize its advantages [

1].

In China, a growing number of landmark buildings have adopted staggered-story designs. Due to complex issues such as staggered stories and sloped roofs in the Press Center of the Shanghai Cooperation Organization (SCO) Qingdao Summit, Liu et al. [

2] designed staggered inclined columns as ST-RC columns and controlled their axial compression ratio within 0.4 to enhance their ductility and seismic performance. A certain opera house in Shanghai adopted a staggered-story design due to its functional characteristics, leading to issues such as structural torsional irregularity, local discontinuity of floor slabs, and discontinuity of vertical lateral force-resisting members. To ensure that the theater would not collapse during strong earthquakes, Jia [

3] conducted a static elastic–plastic seismic analysis on it. The research results showed that the maximum inter-story drift ratios of the structure after a rare earthquake all met the code [

4] requirement of not exceeding 1/50; at the performance check after a rare earthquake, the plastic hinges were mainly distributed on frame beams and individual frame columns, with an overall low degree of damage, and no obvious plastic hinges were found on the staggered-story columns, which satisfied the design concept of “no collapse under strong earthquakes”. Due to the existence of a cinema in Joy City in Yinchuan, three staggered-floor slabs were formed at the top of the structure, resulting in a staggered-story frame building. Liu et al. [

5] conducted an elastic time–history analysis and a pushover analysis on it. The research results indicated that under the elastic time–history analysis, the base shear of the structure met the code [

4] requirements; under the static elastic–plastic analysis, the inter-story drift ratios did not exceed the code requirement of 1/100. Local bending of the plastic hinges appeared at the beam ends, while the columns remained elastic, and the yield mechanism conformed to the seismic concept of structural design. The elevation setback from the second floor to the roof of the terminal building of Longnan Chengzhou Airport caused staggered stories. Wang et al. [

6] used YJK, PM-SAP, and SAP2000 24 software to conduct a seismic analysis during frequent earthquakes, fortification earthquakes, and rare earthquakes, and they carried out a performance-based design for the frame columns at the staggered-story positions of the terminal building. The research results showed that the staggered-story positions met the design requirements for moderate earthquakes; under different structural seismic performance levels, the staggered-story frame columns met the elastic design requirements during frequent and fortification earthquakes, and during rare earthquakes, the flexural part of the staggered-floor columns yielded while the shear part did not yield. In a school library in Qingpu District, Shanghai, the floor of the reading area on the second floor and the floor of the multi-functional hall forms a staggered story, resulting in floor slab discontinuity. Wang et al. [

7] conducted elastic and elastic–plastic analyses on it. The research results showed that under the elastic analysis, the relevant parameters such as the building’s period ratio, base shear, and maximum inter-story drift ratios all met the requirements of the code [

4]; designed according to the moderate earthquake elastic seismic performance target, the shear and flexural bearing capacities of they key members met the moderate earthquake elastic design requirements, and the ordinary frame columns met the moderate earthquake design requirements of elastic shear and no yielding flexure. In the elastic–plastic analysis, the inter-story drift ratios of the building were all less than the code [

4] requirement of 1/50; most of the members were slightly damaged, a few were moderately damaged, and individual short columns were severely damaged. Overall, the building could meet the requirement of no collapse during rare earthquakes. A bookstore in Wangfujing, Beijing, has the problem of bidirectional staggered floors. Zhou et al. [

8] carried out an elastic–plastic analysis during strong earthquakes. The research results showed that the maximum inter-story drift ratios of the building were all less than the limit of 1/50; the preset key members were in an undamaged state, and only part of the bottom frame columns entered the plastic stage, with no damage exceeding slight damage.

It is worth mentioning that conducting a performance-based seismic evaluation on buildings helps us understand their damage status. Zameeruddin [

9], Giannakouras [

10], and Yalçın et al. [

11] explored the state of plastic hinges to evaluate the damage of frame buildings through a finite element analysis. Radman et al. [

12], via a finite element analysis, classified members’ damage into three levels—Immediate Occupancy (IO), Life Safety (LS), and Collapse Prevention (CP)—for evaluation, while Chourasia et al. [

13] did it through experiments. Etli et al. [

14] evaluated the seismic performance of frame buildings from multiple perspectives such as inter-story drift, ductility coefficient, and the elastic–plastic relationship of the load-displacement curve. Chong et al. [

15] clarified the damage levels of concrete members in accordance with the ASCE/SEI 41–17 [

16] specification. When different codes are adopted as the basis for an analysis, attention should be paid to the differences between the codes. Chinese codes focus more on local engineering experience and safety thresholds, while international codes emphasize universality to a greater extent. In practical engineering, it is necessary to select the design method according to the code requirements of the project location, combined with material properties and structural needs; when necessary, the feasibility of a cross-code application should be verified through tests. Therefore, this paper refers to Chinese codes.

Most researchers utilize the “three-level, two-stage” seismic design concept, whose primary focus is safeguarding human life when structures are exposed to seismic events. Nevertheless, as society advances, there has been a growing demand for the enhanced seismic performance of buildings.

In addition, due to the unfavorable impact of short columns on seismic resistance in staggered-story buildings, the damage to the columns between the staggered stories is significantly greater than that of other columns [

17]. Some scholars have adjusted the relevant parameters of staggered-story buildings to improve their seismic performance. Chen et al. [

18] explored the seismic performance of staggered-story frame buildings by changing the floor and the thickness of the floor slab where the staggered story is located. The findings of the study indicated that a lower floor position for the staggered-story building had more favorable outcomes; notably, the seismic performance of the staggered-story building does not diminish as the thickness of the staggered-story floor slab increases, and the optimal slab thickness ought to be identified via a finite element simulation analysis. Cheng et al. [

19] established three staggered-story buildings with different heights and used the time–history analysis method to study the torsional effect on the building during one-dimensional, two-dimensional, and three-dimensional earthquakes. The research results indicated that due to the asymmetric characteristics of staggered-story buildings, the stiffness center deviated from the mass center, which not only caused horizontal vibration but also produced obvious torsion. Yao et al. [

20] studied the influence of parameters, such as the steel ratio in staggered-story buildings, on the axial compression capacity of frame columns and concluded that the steel ratio has a significant impact on the axial compression of frame columns. Li et al. [

21] studied the influence of changes in column section size on staggered-story buildings during earthquakes. The research results showed that appropriately reducing the section size of the middle column was beneficial to controlling the structural shear force and displacement.

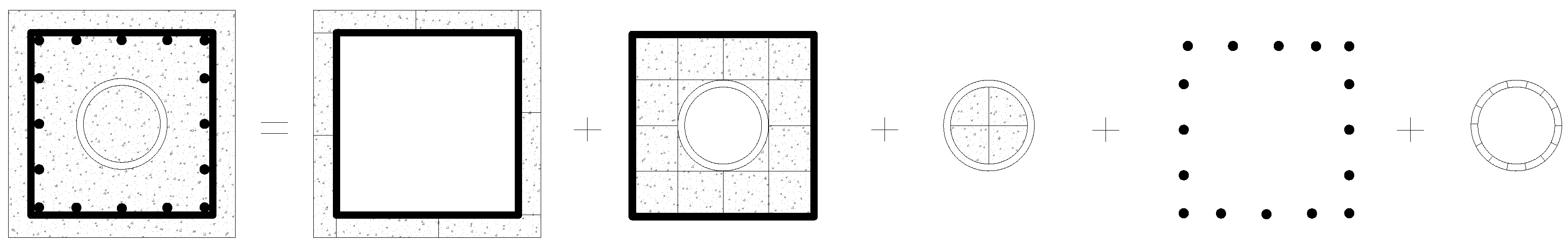

From these engineering examples, it can be seen that buildings with staggered stories are more prone to torsion due to discontinuous floor slabs, which greatly increases the probability of member damage. However, the traditional design method based on the members’ bearing capacity cannot fully explain the structural performance. Moreover, the existence of short columns makes the building more prone to brittle failure. Therefore, based on an engineering example, this paper establishes an elastic–plastic analysis model. Setting ST-RC columns has become a relatively ideal choice, as they can develop the ductility of short columns. On this basis, by changing the confinement coefficient, defining the damage mode of the members, and using specific quantitative indicators to evaluate the seismic performance of ST-RC short columns during strong earthquakes, the damage status of short columns can be understood, providing a reference for the selection of the confinement coefficient of ST-RC columns.

3. Seismic Performance Evaluation on Confinement Coefficients of Staggered Columns

In practical engineering, the staggered-floor frame structure exhibits prominent shear force values due to the presence of short columns, which are prone to damage during seismic action. However, the utilization of ST-RC columns helps overcome the problem of inadequate ductility associated with short members. The high ductility is the result of the combined effect of three factors: “constraint enhancement”, “material synergy”, and “energy dissipation optimization”. The confinement effect of the inner steel tube on the concrete lays the foundation for the plastic deformation; the outer composite layer supplements ductility through steel bar energy dissipation and secondary constraint; and the reasonable design of the composite section and interface synergy ensure stability during the deformation process. Ultimately, the members can withstand a large plastic deformation without sudden failure during seismic action, thus guaranteeing structural stability. Therefore, whether the confinement coefficient design is reasonable determines whether the ST-RC columns can function effectively.

3.1. Definition of Confinement Coefficients for ST-RC Columns

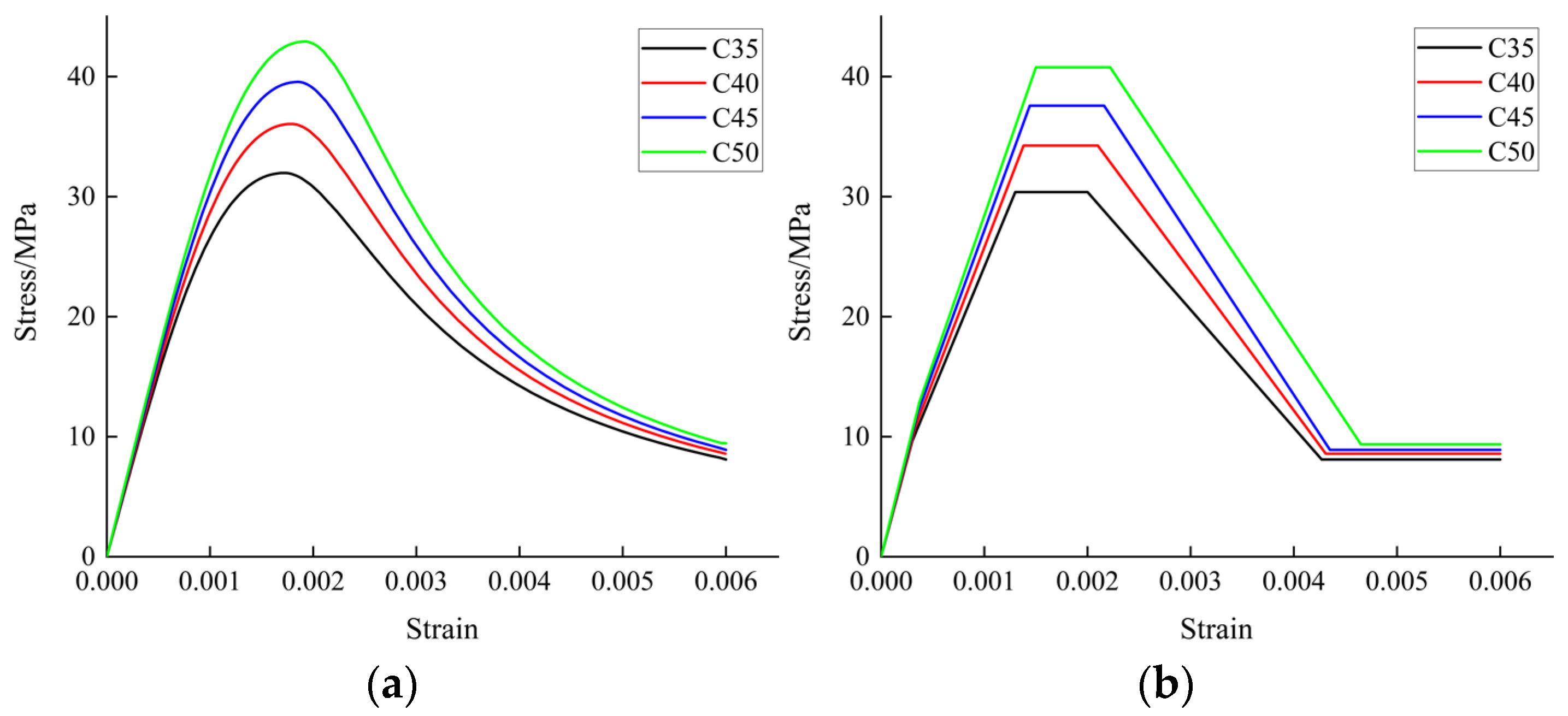

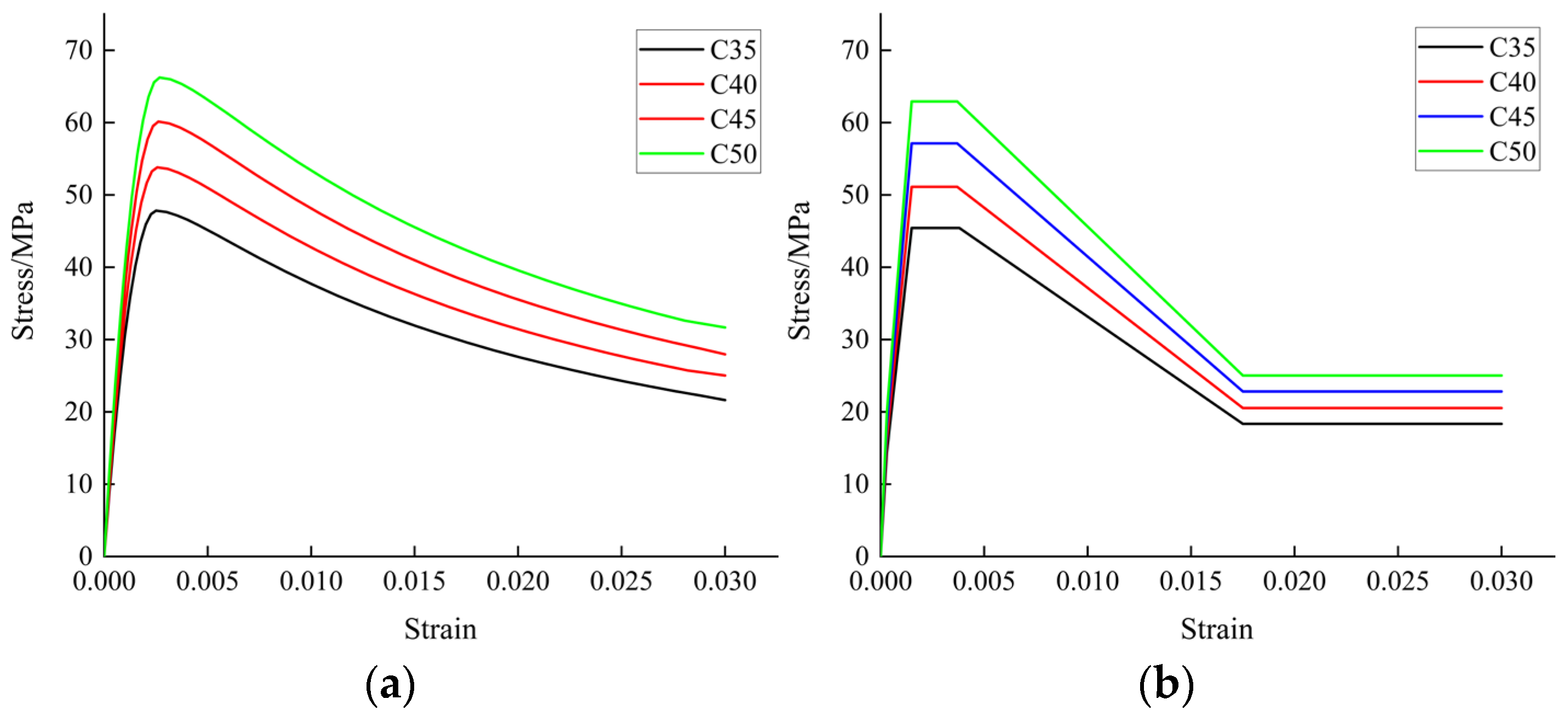

The confinement coefficient θ is defined as the ratio of the product of the area of the steel tube and the design value of the strength of the steel to the product of the area of the concrete and the design value of the strength of the concrete in the cross-section of the member [

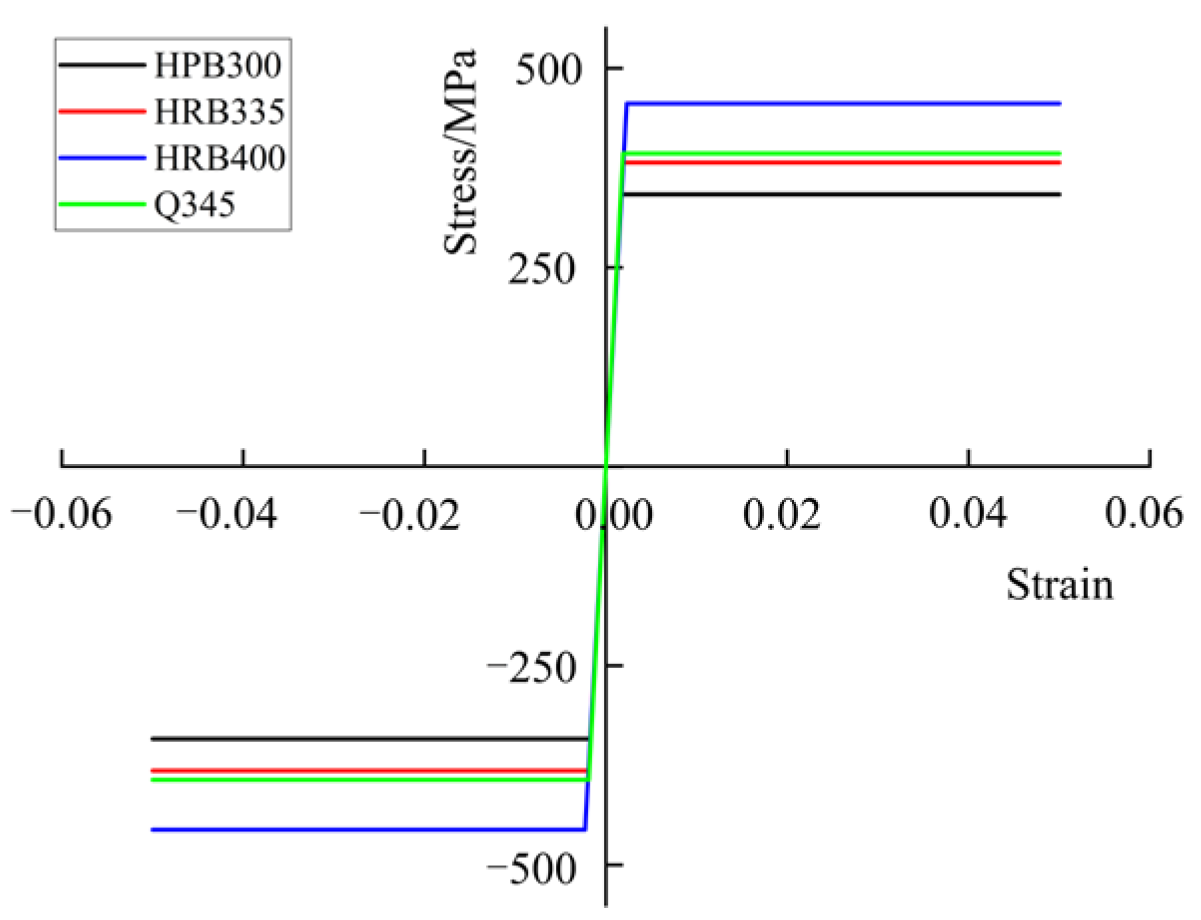

52], and the formulas are shown in Equations (4) and (5). The proposed ST-RC columns to be studied have an internal and external concrete strength class of C50. Q345 steel is selected and the steel tube dimensions are a diameter D and wall thickness t of 377 mm and 14 mm, respectively. For compressed ST-RC columns, the steel tube diameter D and thickness t should meet the provisions of the “technical code for concrete filled steel tubular structures” [

52].

where

αsc is the steel content of the steel tube concrete elements,

As is the cross-sectional area of the steel tube, θ is θ,

Ac is the cross-sectional area of the concrete in the steel tube, and

f is the yield strength of the steel tube.

For the purpose of studying how θ influences the columns in a staggered-story building, the t of the columns is kept constant and the D is adjusted; it is divided into four groups, where the third group is the original θ of the columns, as shown in

Table 13.

As presented in

Table 13, the D/t ratio of the five ST-RC columns is not greater than 91.96, meeting the code [

52] requirements. The θ values of the four groups of ST-RC columns are between 1.087 and 1.307, which is more reasonable.

3.2. Determination of Key Column Members

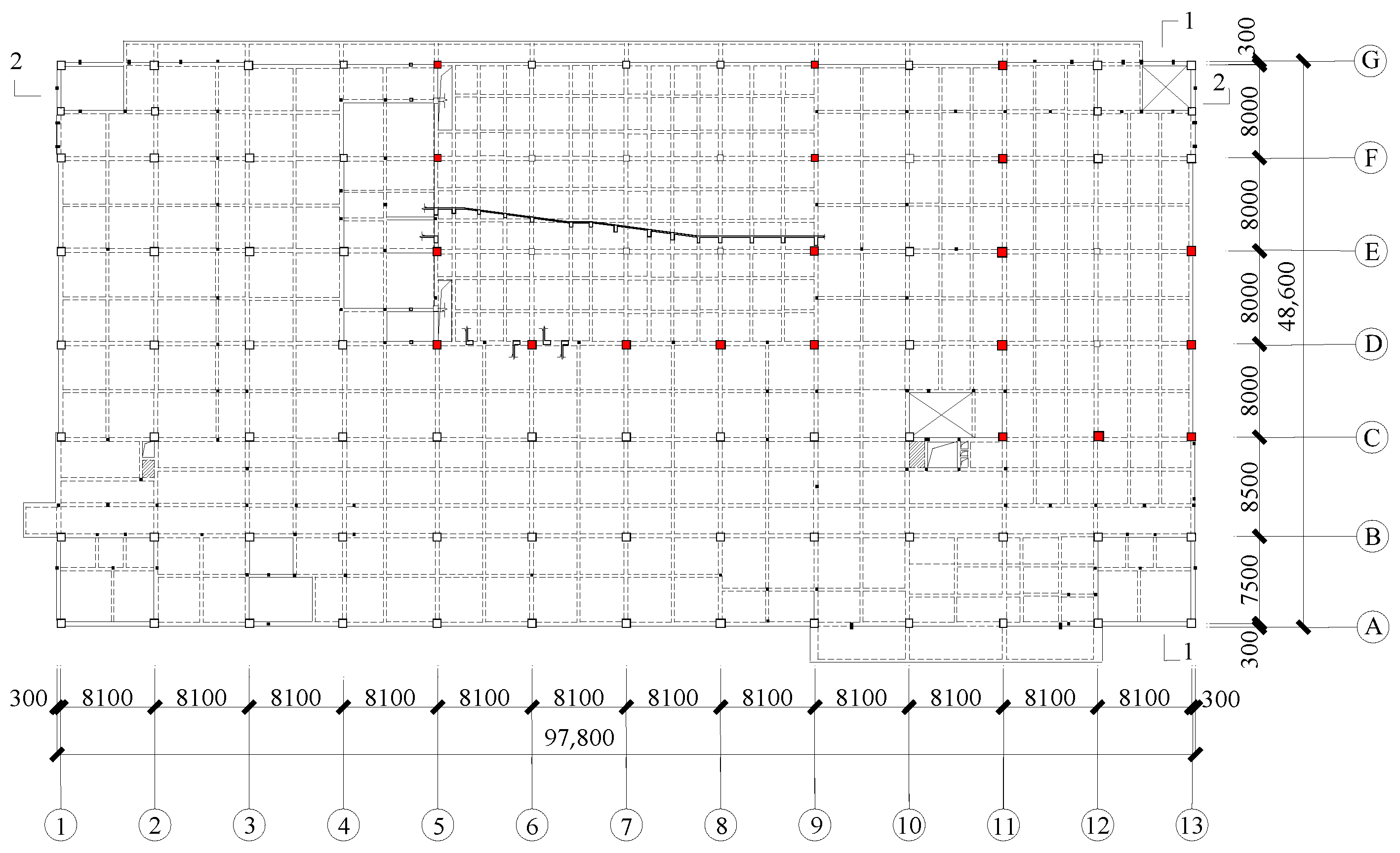

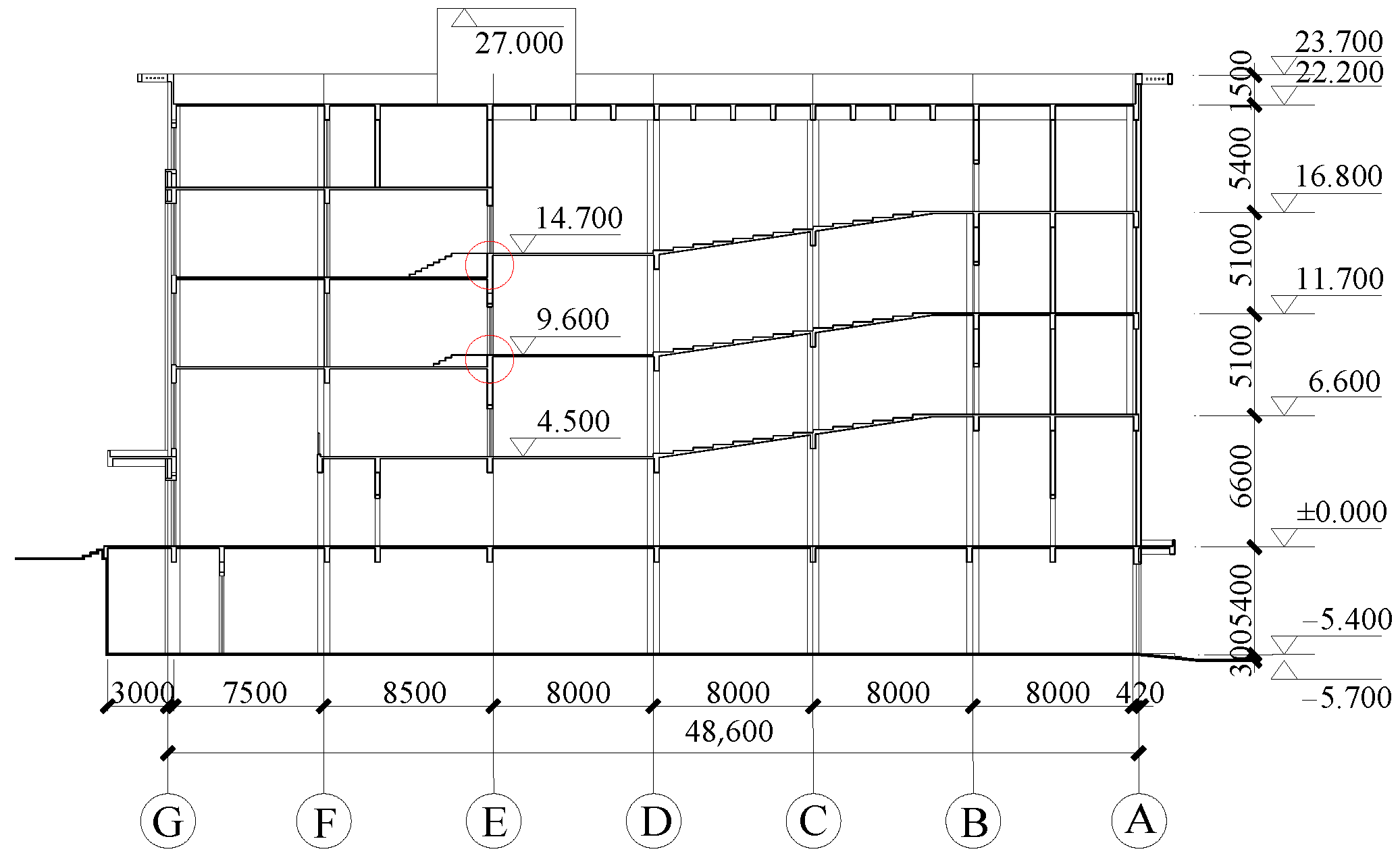

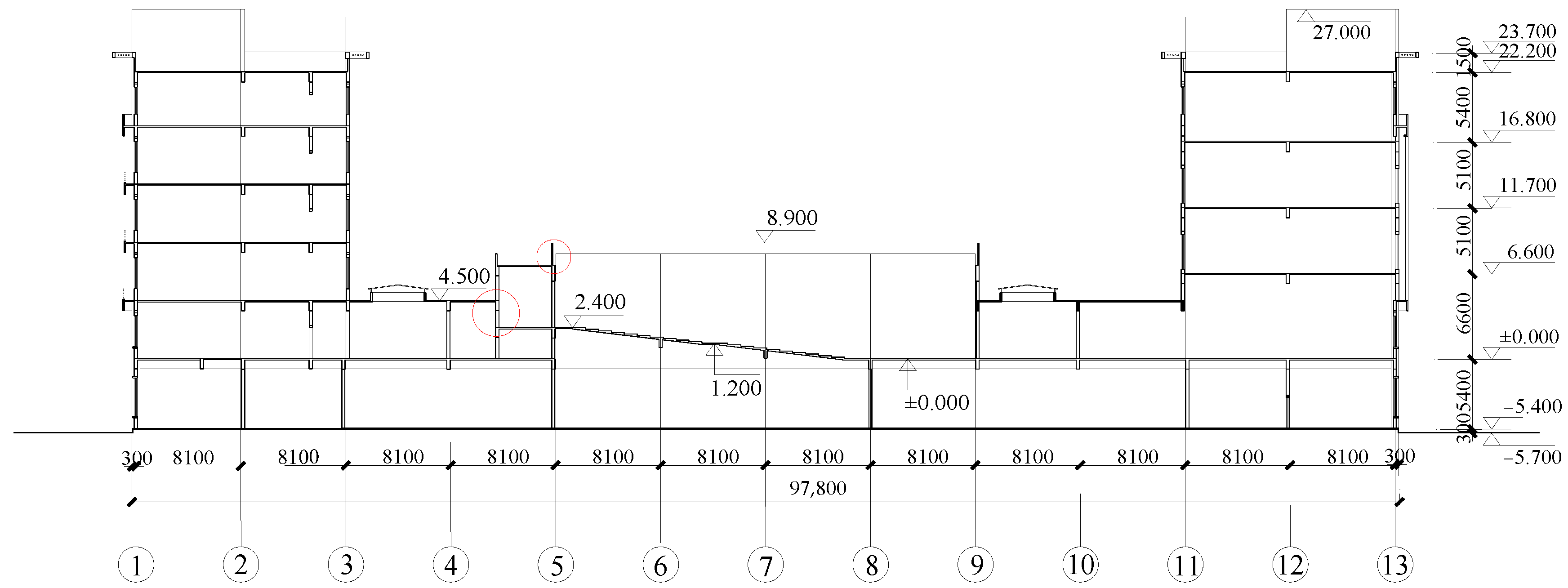

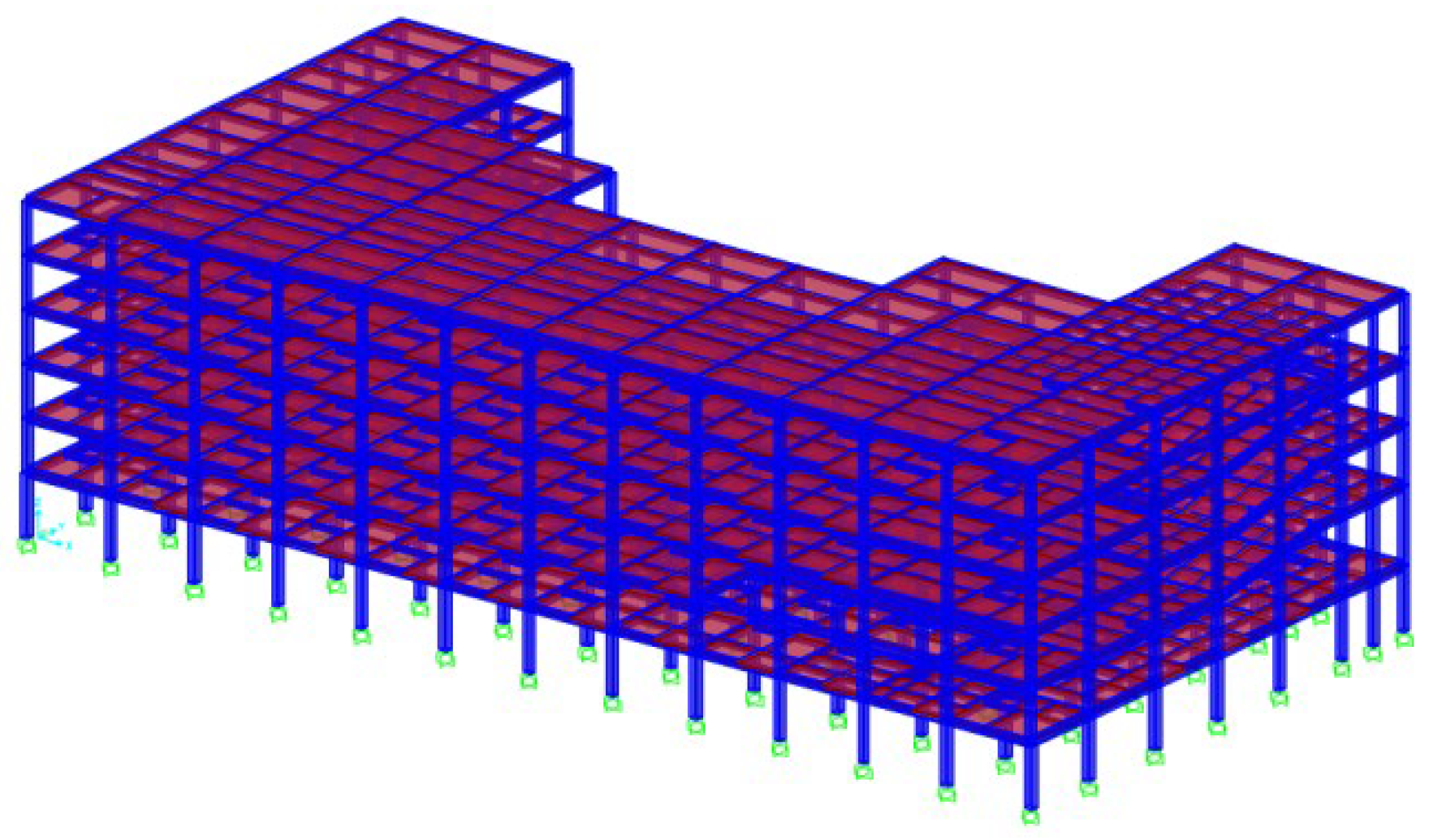

Based on the elastic–plastic analysis results [

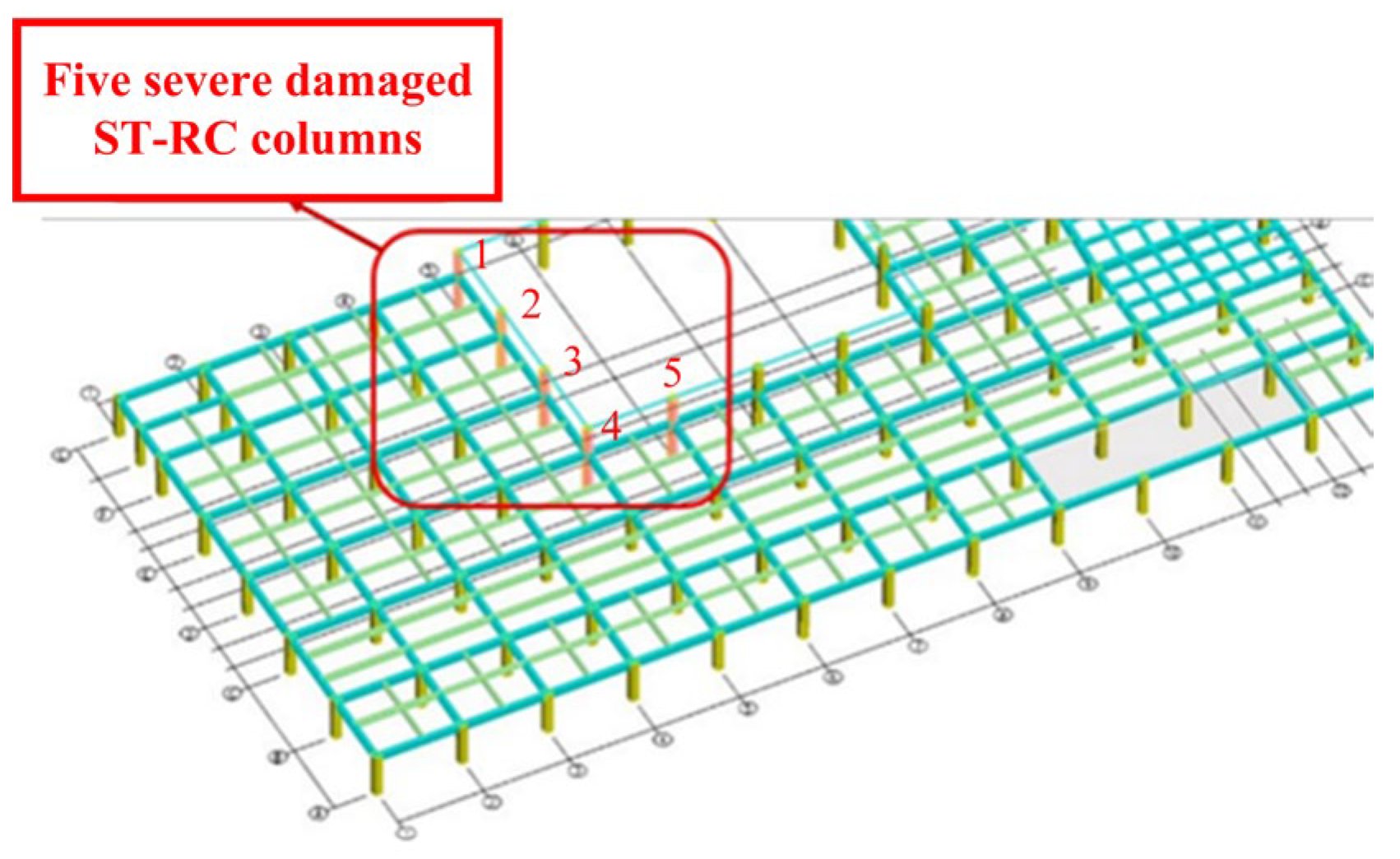

53],

Figure 16 presents the five most severely damaged ST-RC columns. By varying the steel tube diameter of these five columns, the influence of θ on the seismic performance of the columns is studied, thereby evaluating the damage status of the columns.

3.3. Classification of Performance Evaluation for ST-RC Column Members

The seismic evaluation is conducted using a performance-based evaluation method, combined with multi-level performance objectives formulated based on the building’s functional classification and service requirements. The minimum seismic performance level of the structure during rare earthquakes is Level 4. At this Level, key components suffer mild damage, ordinary vertical components and important horizontal components experience partial moderate damage, and energy-dissipating components sustain moderate or partial severe damage [

54].

In accordance with “Specification for performance-based seismic design of reinforced concrete building structure” [

54], which is based on ASCE 41, column damage mechanisms are classified into three distinct modes based on the shear-to-span ratio and the bending–shear ratio parameters, namely the bending-controlled, bending–shear-controlled, and shear-controlled failure modes.

Table 14 presents the division principles for the failure modes of column members.

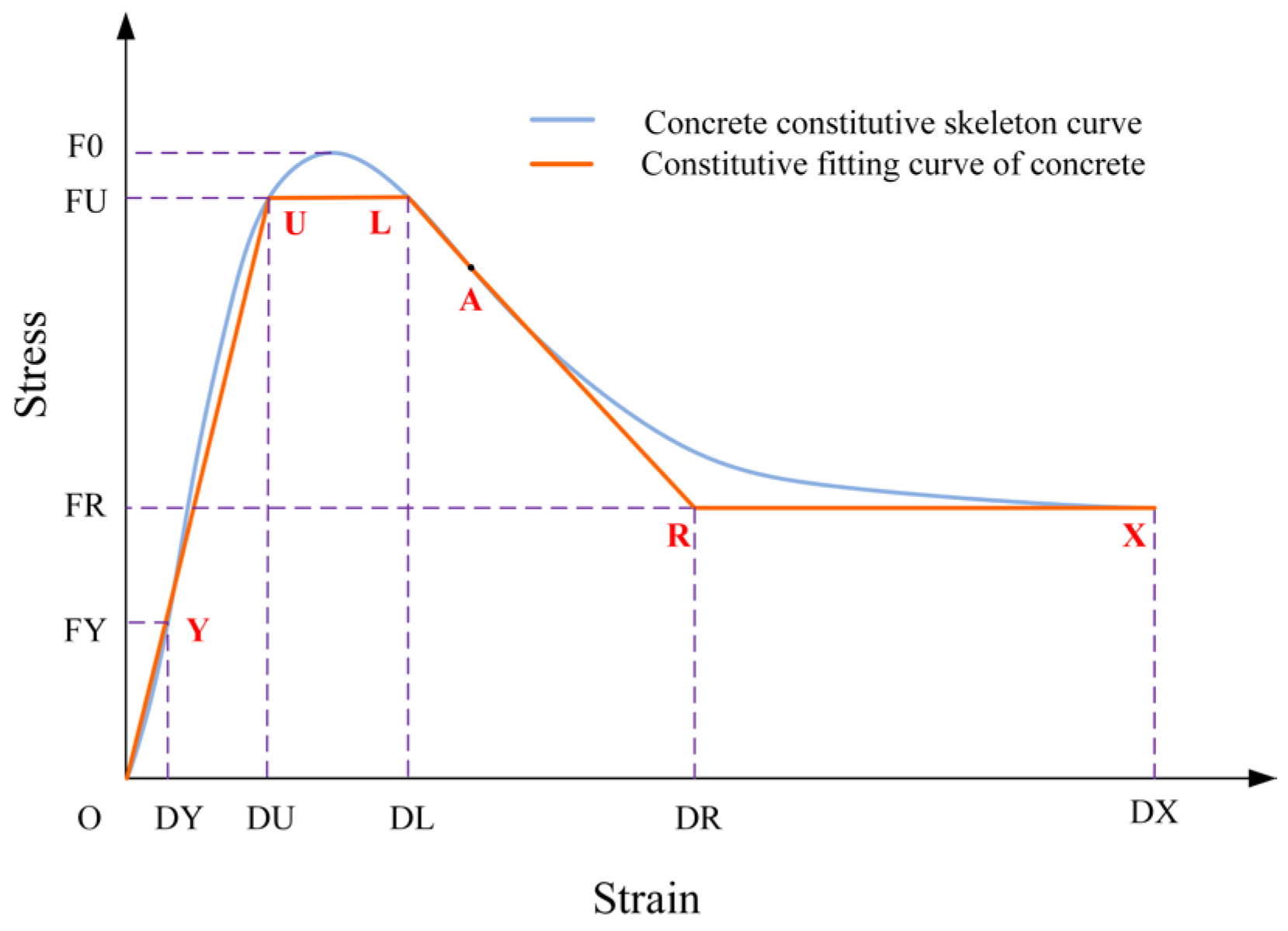

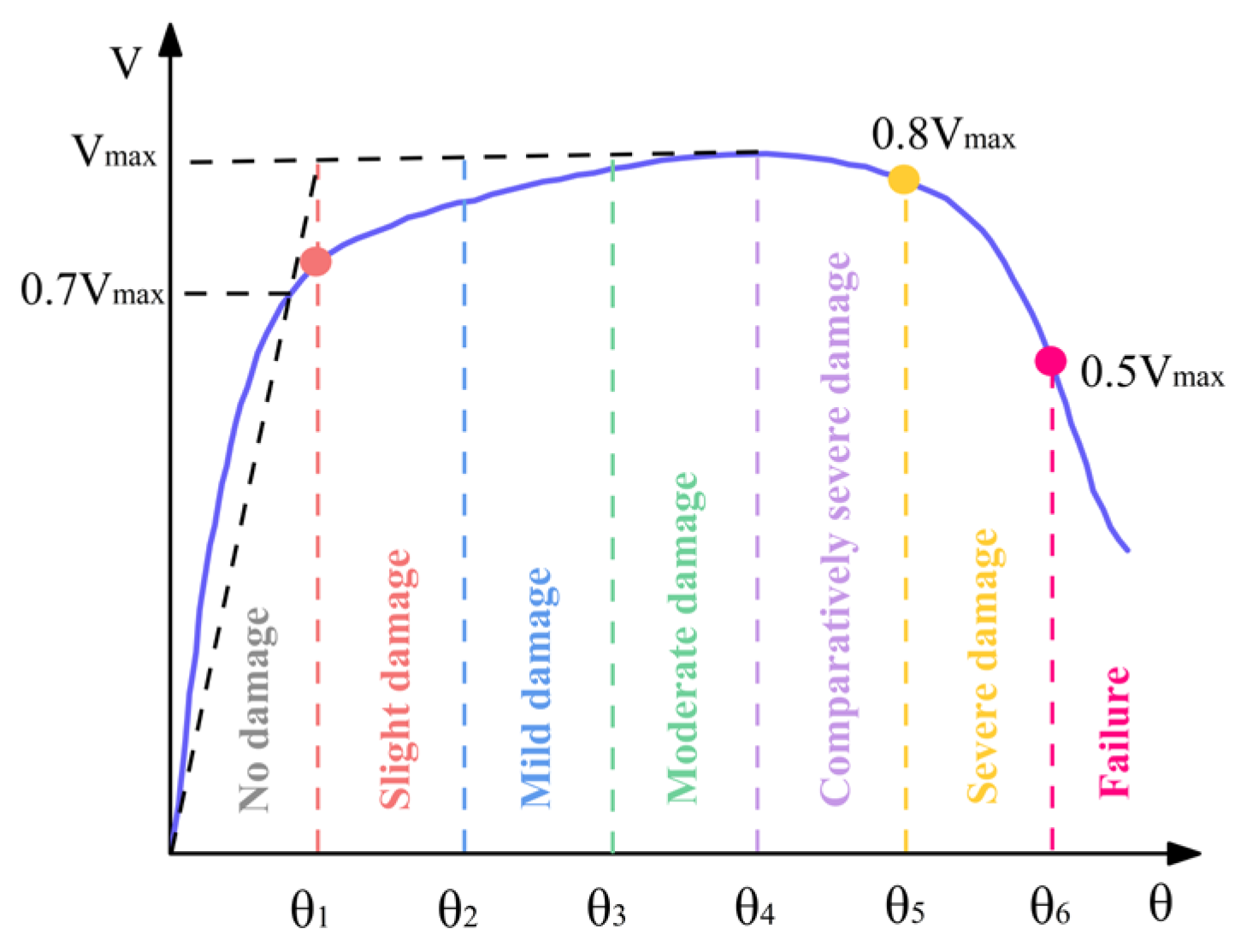

Bending-controlled and bending–shear-controlled failures exhibit ductile behavior, where the plastic displacement angle effectively characterizes both the variation in load-carrying capacity and the degree of damage. The seismic performance of reinforcement concrete members is evaluated through force–inter-story drift ratios (V–θ) skeleton curves, with

Figure 17 illustrating the corresponding performance states and the limit of the plastic inter-story drift ratios. The explanation for each limit value in the Figure is as follows; for details, please refer to Reference [

55], a book that has referenced codes and standards such as ASCE 41 and Eurocode 8.

“No damage” corresponds to the member being in an elastic state, which aligns with the “no damage under minor earthquakes” requirement in the “three-level seismic fortification criteria”.

“Slight damage” can be considered to correspond to “IO” as defined in FEMA 273. In this state, the structural damage is deemed very limited, and the strength of the main vertical and lateral load-resisting members remains the same as before the earthquake.

“Mild damage” can be regarded as equivalent to the “Damage Control Range” between IO and LS in the U.S. performance level system; however, the value defined herein is a single level limit rather than a range.

“Moderate damage” is considered to occur before reaching the LS level in the U.S. system. In this state, the concrete cover on the member surface peels off over a large area, while the core concrete is not severely crushed. Timely repair is required for the structure to continue safe use.

“Comparatively severe damage” can be considered equivalent to the “Limited Safety Range” in the U.S. performance levels, but the value herein represents a specific performance level point rather than a range.

“Severe damage” can be regarded as equivalent to the “CP” level. In this state, the structure suffers severe damage: the stiffness and strength of the lateral load-resisting system decrease significantly, and the structure has large residual deformation. However, the degradation of the vertical load-bearing capacity is slight, and the main system for resisting gravity continues to function.

“Failure” means that the load-bearing capacity, stiffness, or stability of a member decreases to a critical state where it can no longer meet the design functional requirements.

The curve in

Figure 17 allows for the derivation of the columns’ deformation limits, and

Table 15 sets out the elastic–plastic drift angle limits for the columns.

In contrast, shear-controlled failures demonstrate brittle characteristics and must satisfy both shear capacity requirements and minimum shear section criteria. The performance checking method for the shear-controlled members is shown in

Table 16.

The formulas for the no yielding check and minimum cross-section check are shown in Equations (6)–(8).

Minimum cross-section check:

For the meanings of the parameters in these Equations, refer to Reference [

54].

3.4. Review of Positive Sections of ST-RC Columns

Presented in

Table 17 are the statistics regarding the performance states of the ST-RC columns’ positive sections on the building’s second floor, based on the average value of the seismic load cases. All four groups of columns exhibit a positive section deformation that does not surpass moderate damage. With an increase in θ, the damage level of the columns reduces progressively; among these cases, when θ is 1.307 and 1.224, 100% of the columns remain undamaged, reaching the ideal state. From

Table 17, it is evident that no column failure has occurred, indicating the absence of collapse in the weak regions of the building.

Table 18 provides statistical data on the performance states of all the ST-RC columns under the average value of the seismic conditions. All the columns meet the criterion that their positive section deformation remains within the range of no moderate damage. A decrease in θ is accompanied by a gradual increase in the damage degree of the columns; this finding indicates that an increase in the steel tube diameter of the columns leads to a reduction in their confinement capacity on the concrete. As shown in

Table 18, the second group of columns achieves the optimal performance state. Furthermore, continuing to reduce the diameter will conversely impair the load-bearing capacity of the columns. Therefore, it is recommended that for a staggered-story building, the θ value of the columns should be increased to 1.224 to further minimize the damage state of the members. In the average seismic condition, the columns with four groups of θ values all do not suffer collapse failure.

3.5. Review of Inclined Sections of ST-RC Columns

Table 19 presents the performance status statistics of the inclined sections of the ST-RC columns on the second floor of the structure for the average values of the seismic conditions. The extent of the damage to the columns gradually increases as θ decreases, i.e., the fourth group is the most severely damaged; however, no collapse occurred.

Table 20 presents the performance status statistics of all the ST-RC columns for the average seismic conditions. The capacity of the inclined section that meets the requirements of performance Level 4 does not exceed “minimum cross-section check.” As θ decreases, the degree of the shear damage in the inclined section of the columns gradually increases.

3.6. Shear Analysis of ST-RC Columns

The ST-RC columns circled in

Figure 16 are numbered. That is, from the top to the bottom, the columns are ST-RC1, ST-RC2, ST-RC3, and ST-RC4, and the column on the right is ST-RC5.

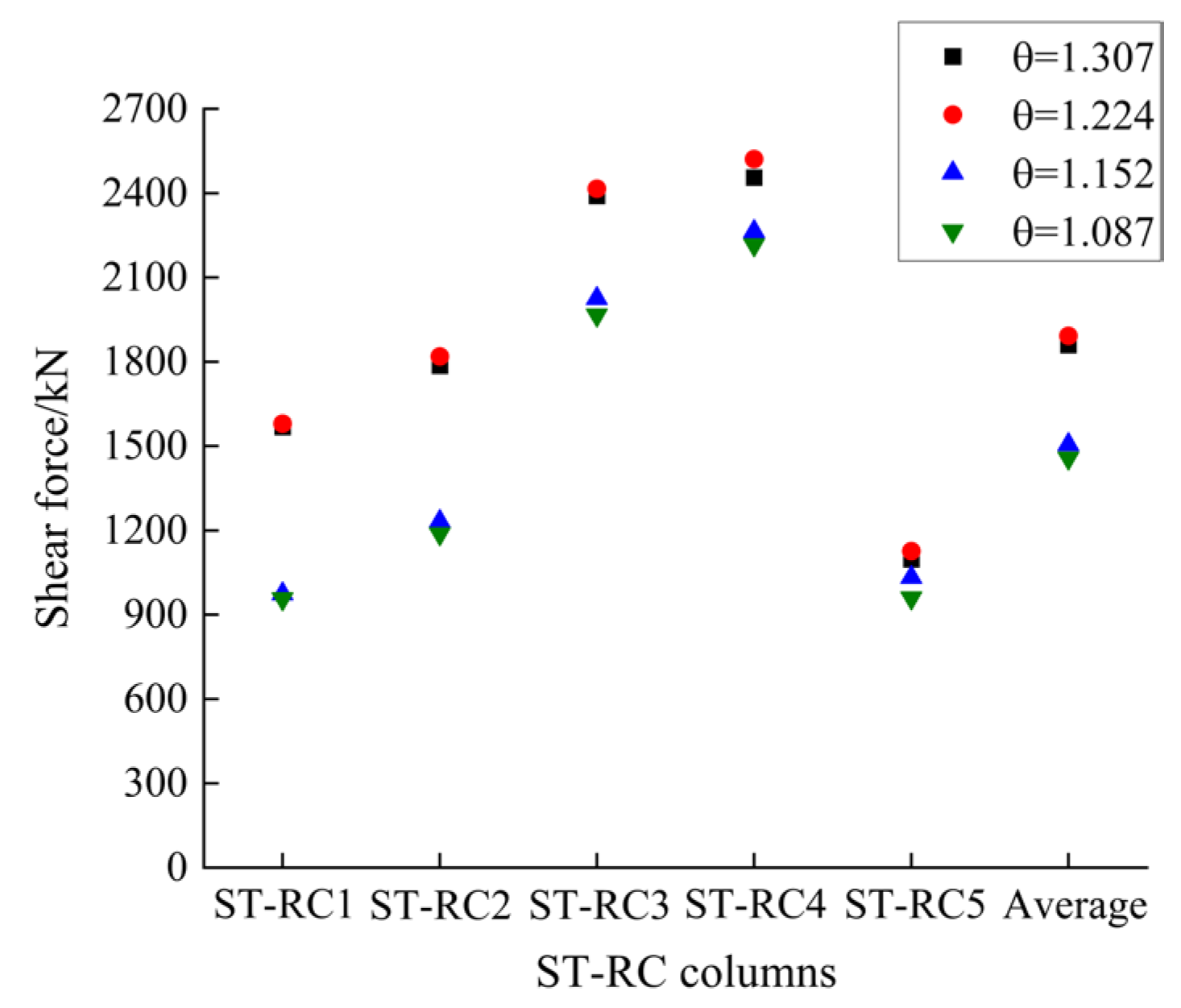

As shown in

Figure 18, the shear forces of these five columns at four sets of θ are θ = 1.224, 1.307, 1.152, and 1.087, from the largest to the smallest. When θ is 1.224, the shear force of the ST-RC columns is greater than that when θ is 1.307, which indicates that the columns with a θ of 1.224 have the maximum stiffness. Therefore, under the same shear force, the damage is the smallest. The shear forces borne by the ST-RC columns are close when the θ values are 1.224 and 1.307, and they are also close when the θ values are 1.152 and 1.087.

Θ increases by approximately 7% for every 20 mm reduction in the diameter of the steel tube in the column. When θ increases from 1.087 to 1.152, the shear force borne by the columns increases by 3%; when θ increases from 1.152 to 1.224, the shear force borne by the columns increases by 20%; when θ increases from 1.224 to 1.307, the shear force borne by the columns decreases by 1%. It can be seen that as θ increases, the shear force borne by the columns does not show a linear increase, and when θ reaches 1.224, the shear force reaches a peak.

The main reason for this is that when the steel tube D/t exceeds the critical value, the steel tube is prone to local outward bulging during the stress process, resulting in the failure of the constraint effect. The Chinese code [

52] also clearly states that D/t must meet the limit requirements to avoid the risk of local buckling. Based on their experimental results, Ou et al. [

56] also indicated that as θ increases, the bearing capacity first increases and then decreases. The experimental research by Zhou et al. [

57] also showed that an increase in θ may lead to stress concentration due to the radial deformation of the steel tube, which instead reduces the bearing capacity of the component. The research by Li et al. [

58] showed that when θ increases to a certain range, the growth of the bearing capacity of the ST-RC column tends to be gradual.

All the above conclusions prove that a larger θ does not necessarily lead to a more obvious improvement in the bearing capacity of the ST-RC column; instead, when it exceeds a certain limit, it will reduce the bearing capacity of the member, causing equally serious damage to the structure. In practical construction, it is necessary to optimize the fabrication accuracy of the stirrups, improve the construction technology of the joint zones (such as adopting prefabricated reinforcement cages and positioning fixtures), and strengthen worker training and process monitoring. Only by doing so can the challenges be minimized to the greatest extent, θ be ensured to meet the design requirements, and the structural mechanical performance be guaranteed.

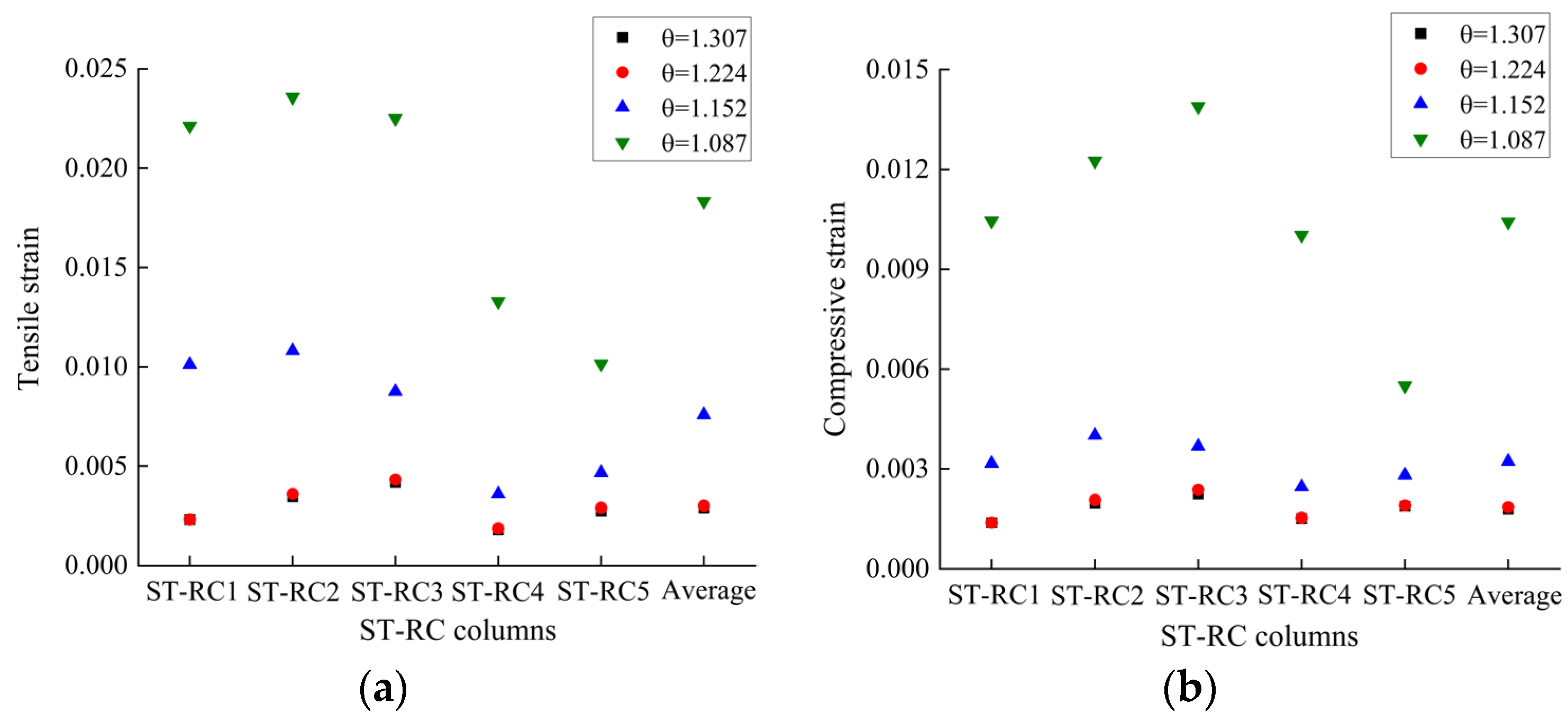

3.7. Deformation Analysis of ST-RC Columns

Figure 19 shows the tensile and compressive strains of the ST-RC columns with different θ values. With an increase in θ, the tensile and compressive strains of the columns decrease. When θ is 1.224, the tensile and compressive strains of the columns are minimized. This indicates that the column shear force increases with an increase in θ, but the speed of the shear increase is not as fast as the speed of increase of the column section bearing capacity. As shown in

Figure 19, when θ increases from 1.087 to 1.152, the tensile and compressive strains of the columns decrease by 2.4–3 times. When θ increases from 1.152 to 1.224, the tensile and compressive strains of the columns decrease by 1.8–2.6 times. Furthermore, when θ increases from 1.224 to 1.307, the tensile and compressive strains of the columns increase by approximately 2%. It can be seen from this that after θ reaches 1.224, the improvements in the tensile and compressive strains of the columns are not significant. If θ continues to increase, it will instead result in a waste of steel and an increase in construction costs, which is not an economical choice.