MAML Bridges the Data Gap in Deep Learning-Based Structural Health Monitoring

Abstract

1. Introduction

2. Related Work

2.1. Meta-Learning

2.2. Data-Driven SHM

3. Methodology

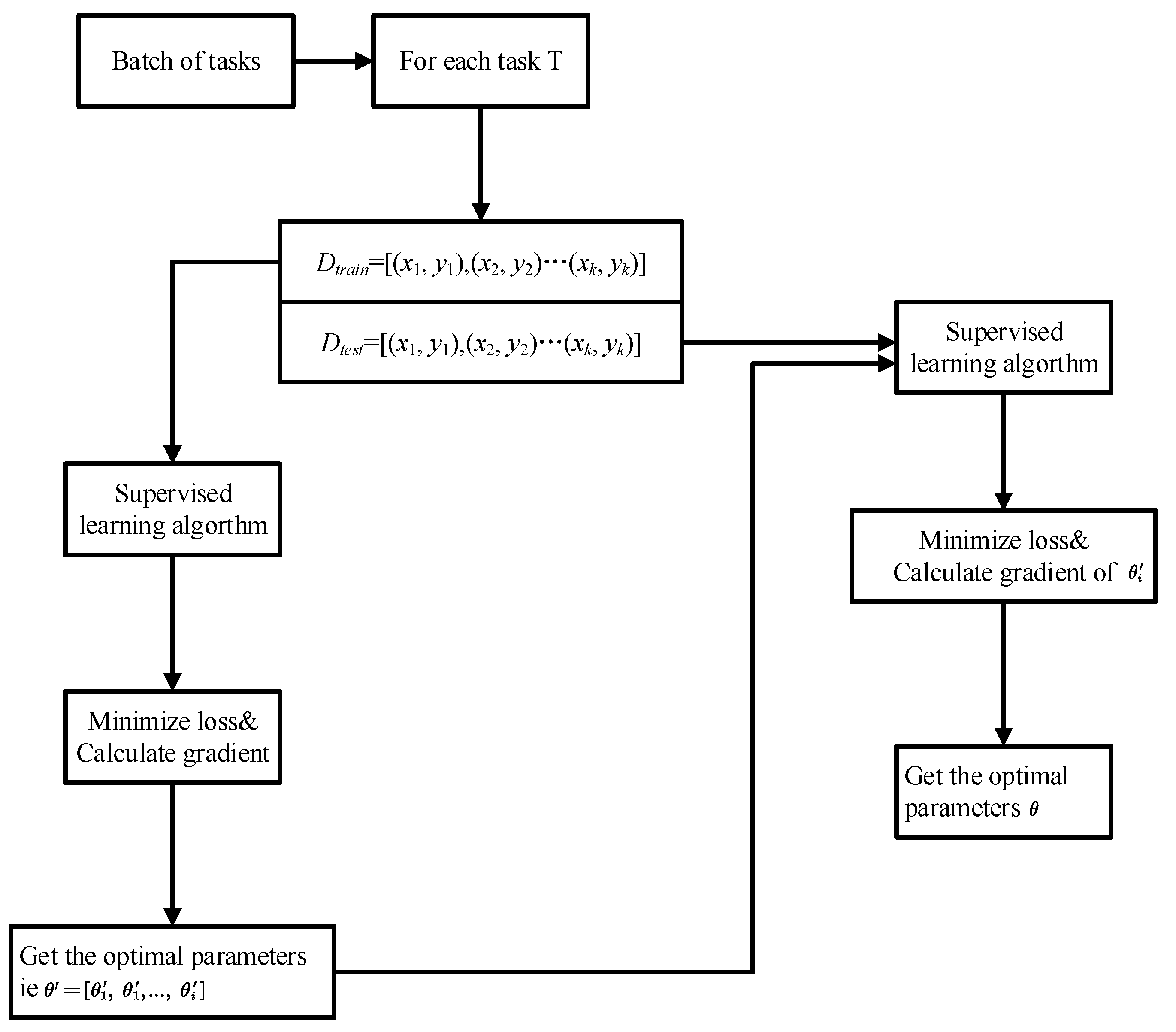

MAML

4. Experimental Design

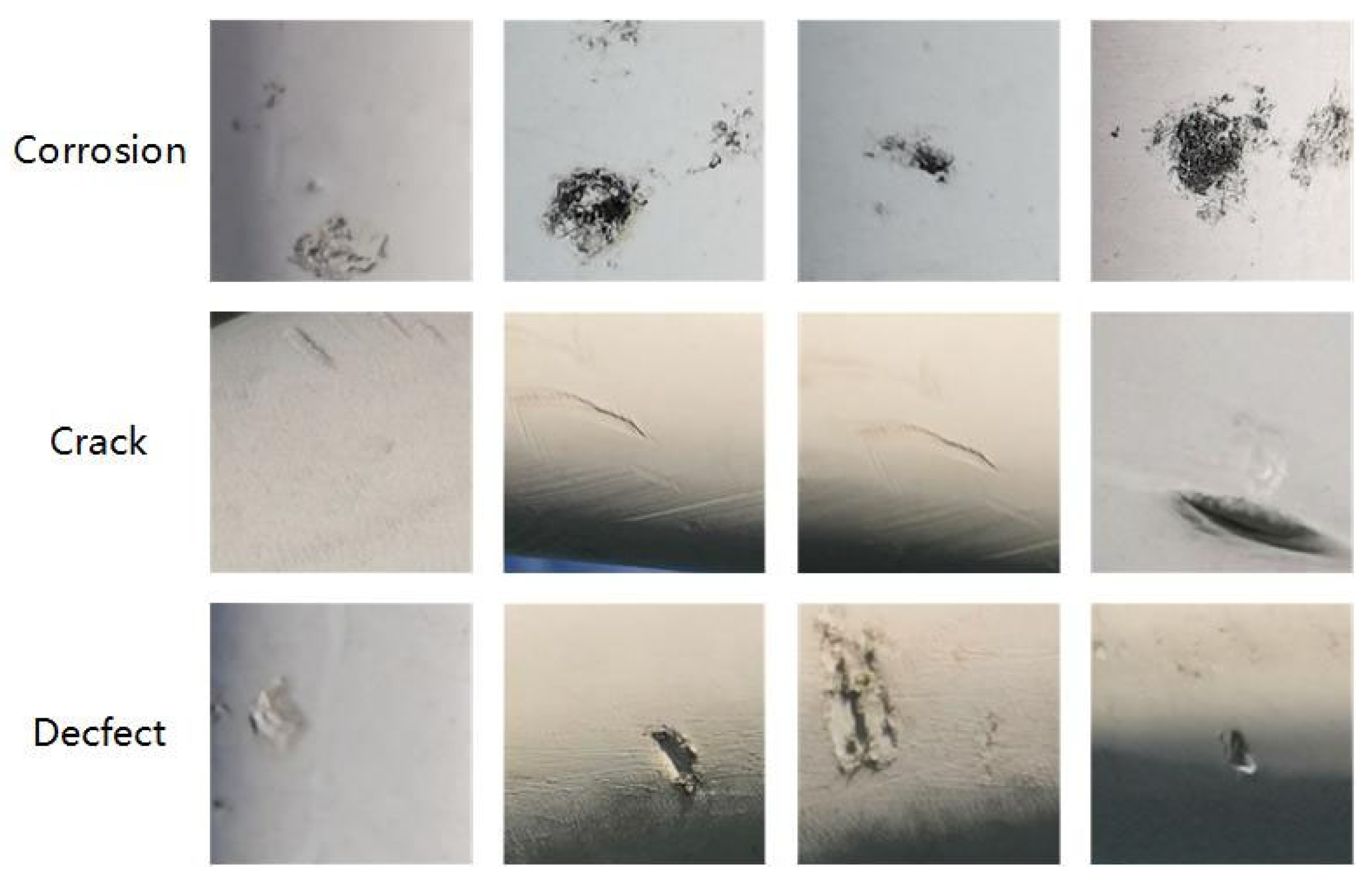

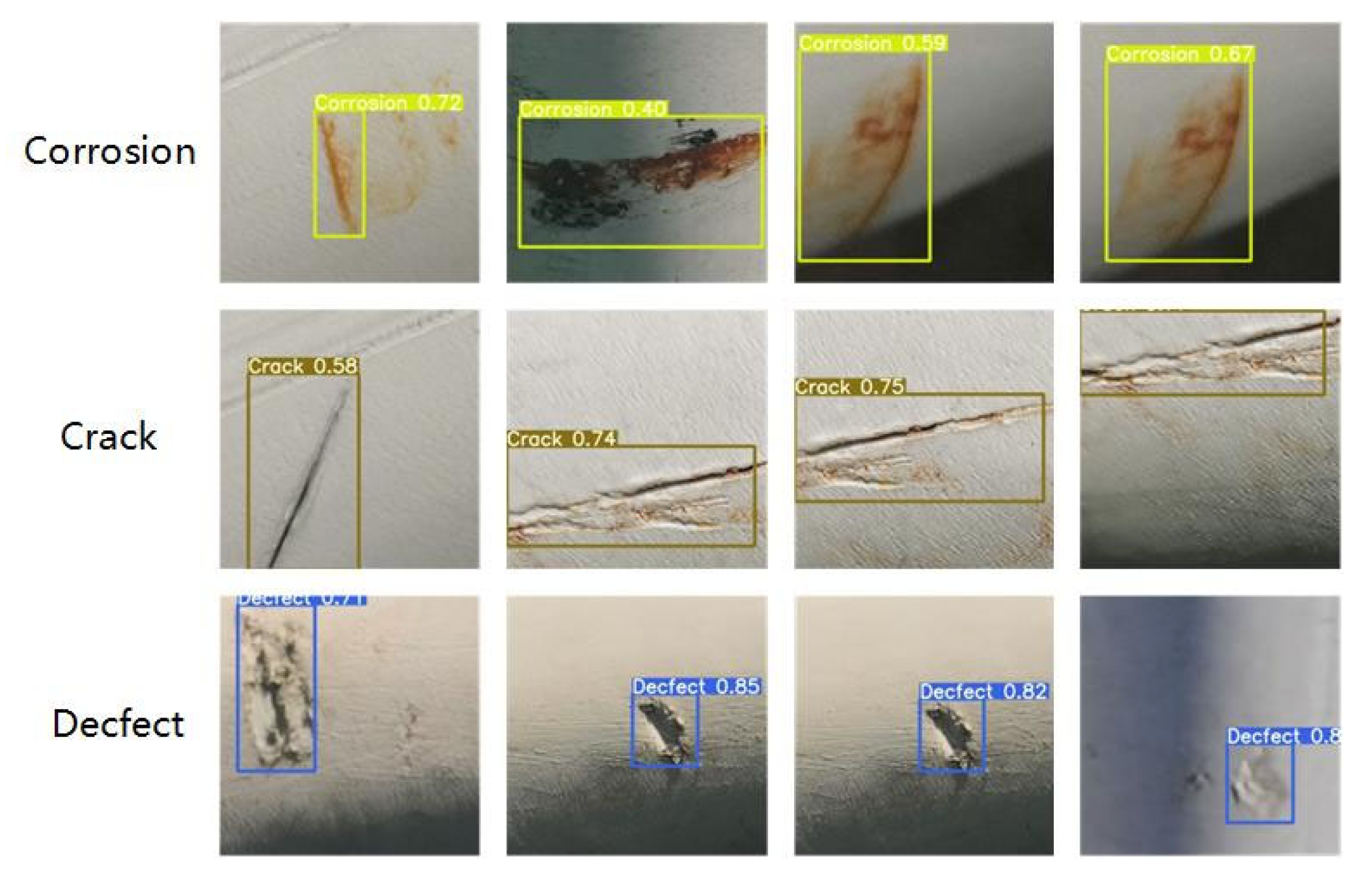

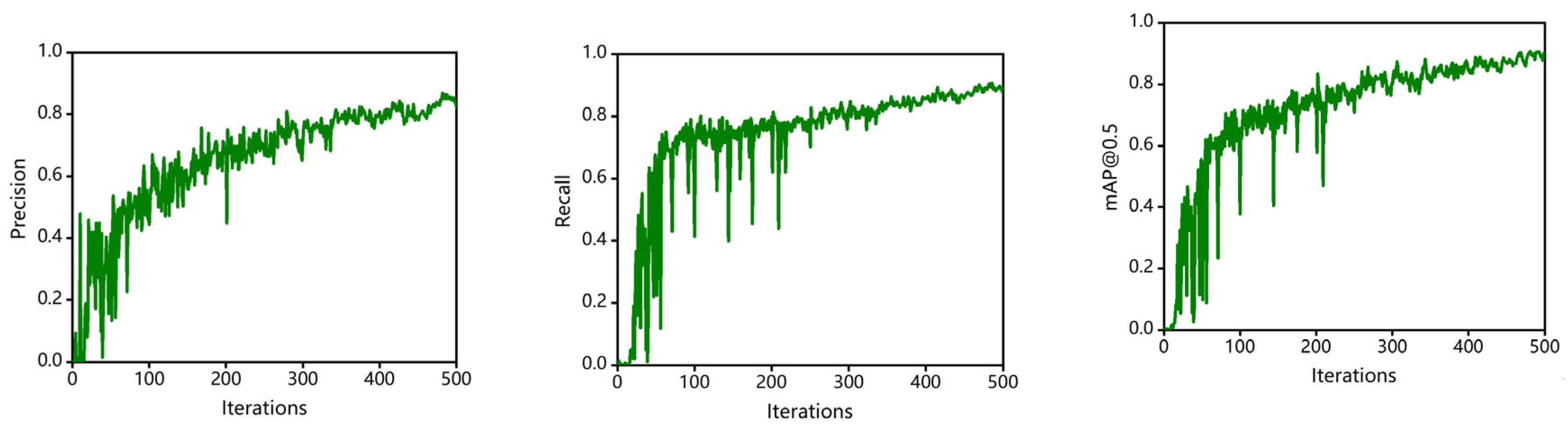

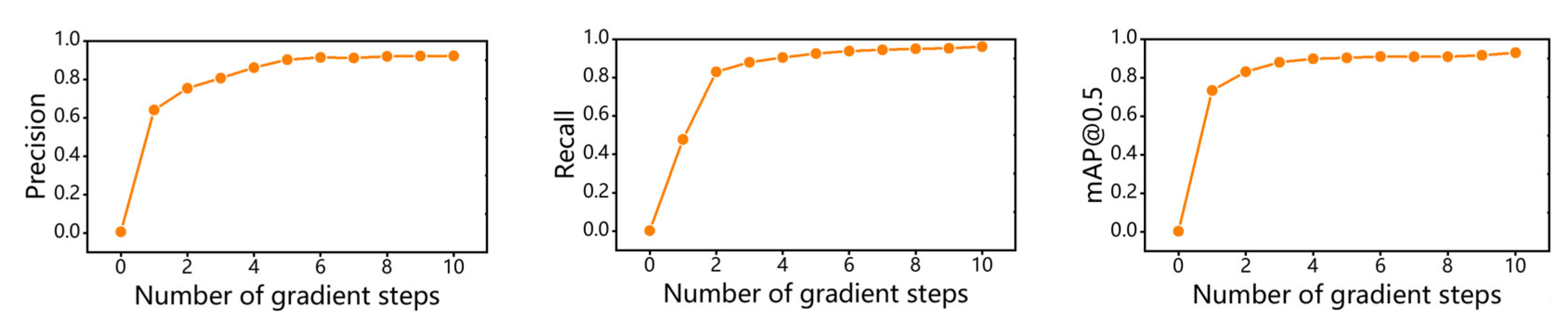

4.1. Experiment 1: Bridge Steel Structure Damage Detection

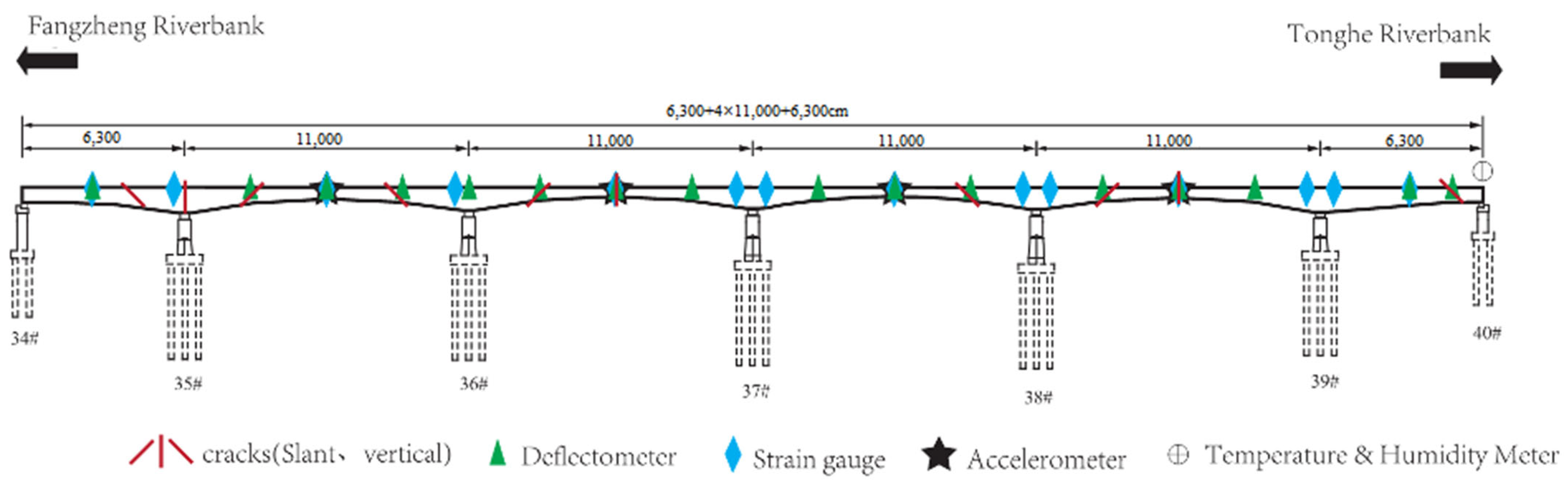

4.2. Experiment 2: Bridge Strain Response Prediction

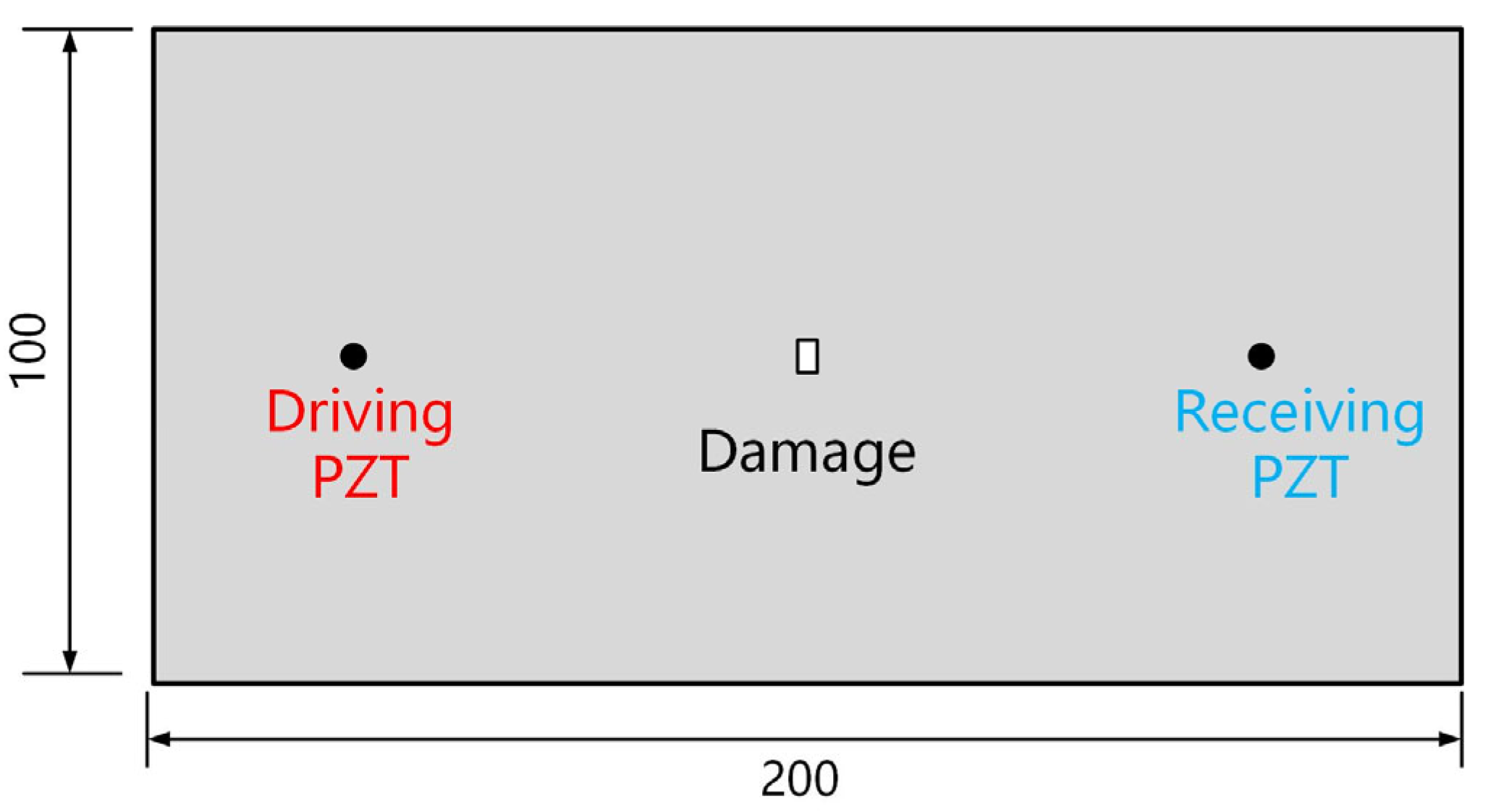

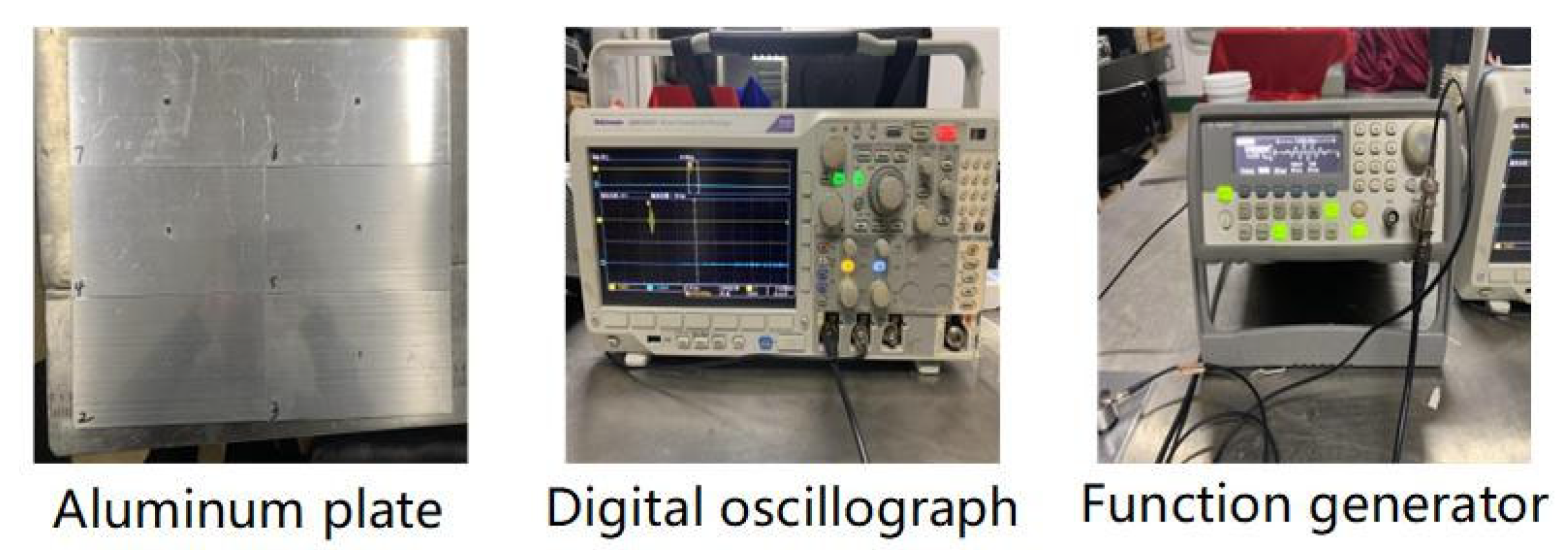

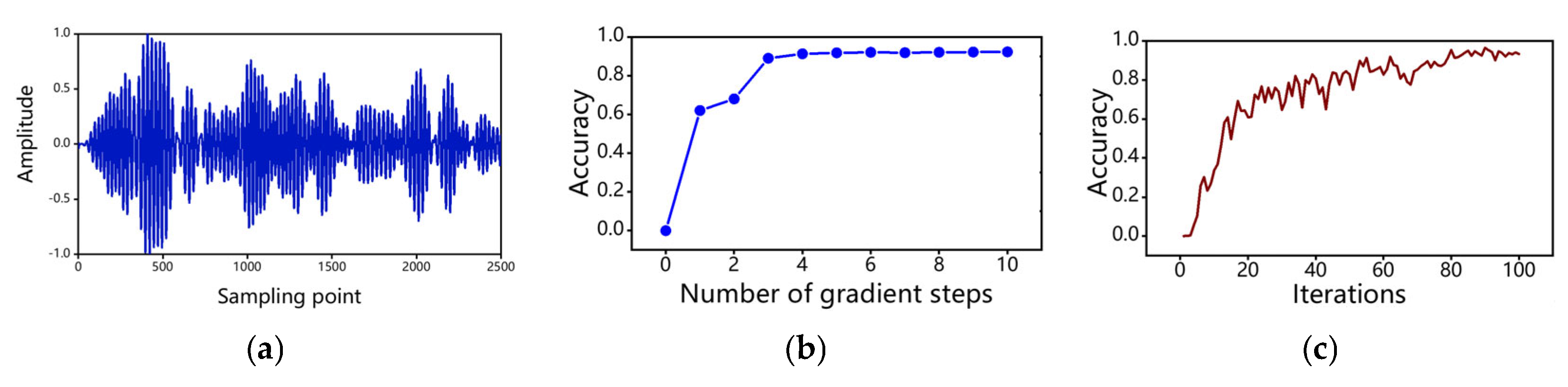

4.3. Experiment 3: Guided Wave Signal Classification

5. Experimental Results and Analysis

5.1. Experiment 1

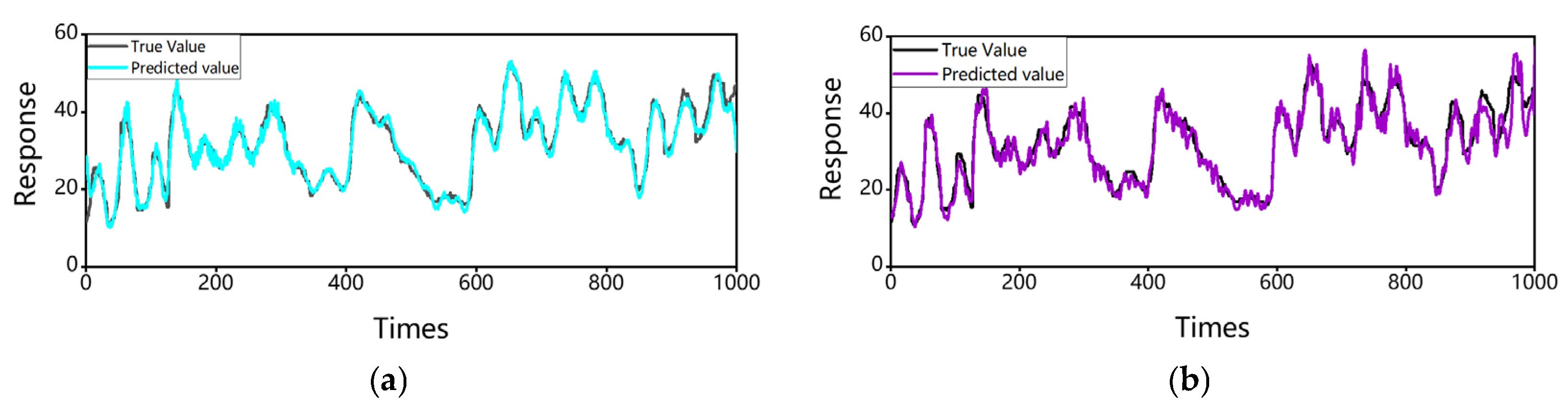

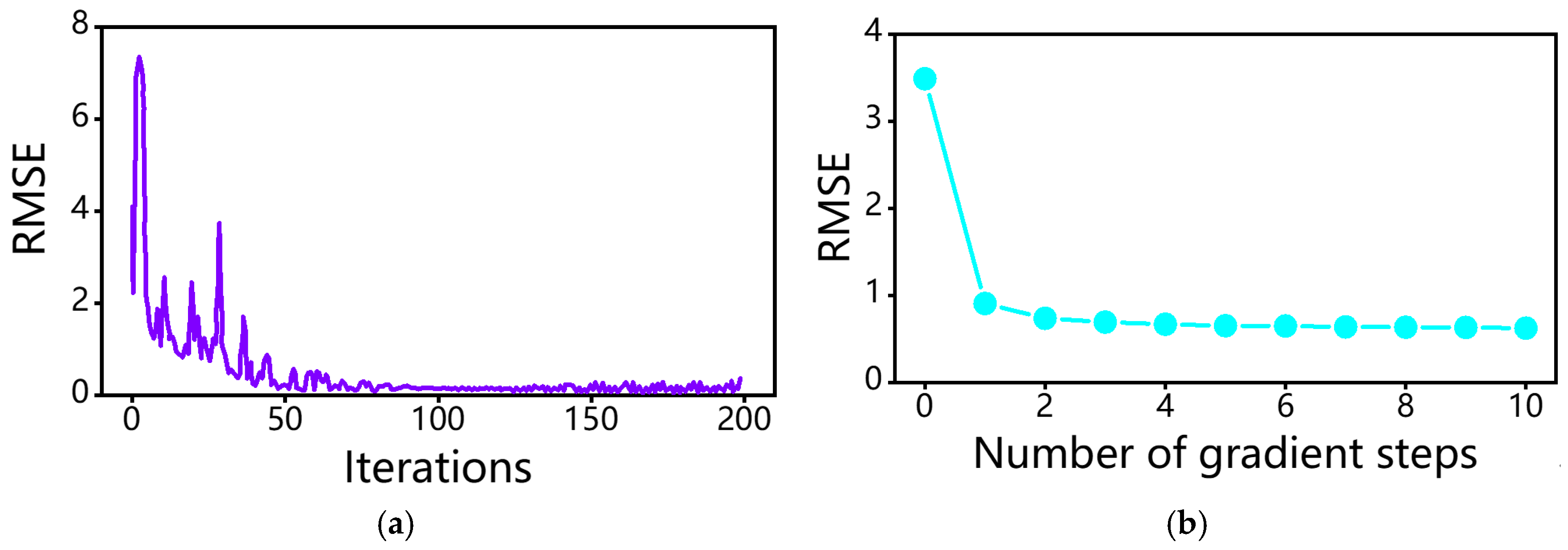

5.2. Experiment 2

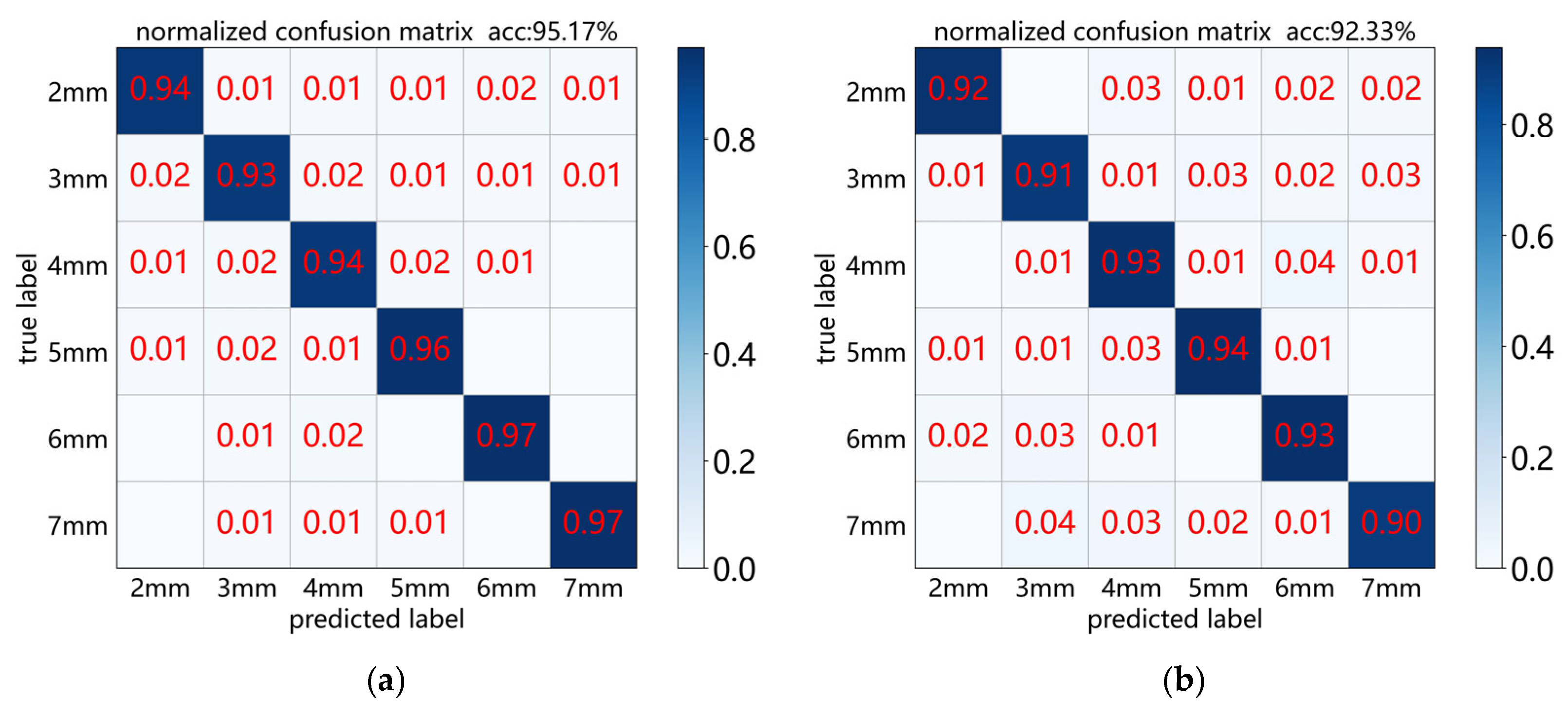

5.3. Experiment 3

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S.; Nagarajaiah, S. Review of bridge structural health monitoring aided by big data and artificial intelligence: From condition assessment to damage detection. J. Struct. Eng. 2020, 146, 04020073. [Google Scholar] [CrossRef]

- Zarbaf, S.E.H.A.M.; Norouzi, M.; Allemang, R.J.; Hunt, V.J.; Helmicki, A.; Venkatesh, C. Ironton-Russell Bridge: Application of Vibration-Based Cable Tension Estimation. J. Struct. Eng. 2018, 144, 04018066. [Google Scholar] [CrossRef]

- Altunok, E.; Taha, M.M.R.; Ross, T.J. Possibilistic approach for damage detection in structural health monitoring. J. Struct. Eng. 2007, 133, 1247–1256. [Google Scholar] [CrossRef]

- Santos, J.P.; Cremona, C.; Orcesi, A.D.; Silveira, P. Early Damage Detection Based on Pattern Recognition and Data Fusion. J. Struct. Eng. 2017, 143, 04016162. [Google Scholar] [CrossRef]

- Ye, X.W.; Jin, T.; Yun, C.B. A review on deep learning-based structural health monitoring of civil infrastructures. Smart Struct. Syst. 2019, 24, 567–585. [Google Scholar] [CrossRef]

- Li, Y.; Bao, T.; Chen, H.; Zhang, K.; Shu, X.; Chen, Z.; Hu, Y. A large-scale sensor missing data imputation framework for dams using deep learning and transfer learning strategy. Measurement 2021, 178, 109377. [Google Scholar] [CrossRef]

- Azimi, M.; Eslamlou, A.D.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef] [PubMed]

- Kaya, Y.; Safak, E. Real-time analysis and interpretation of continuous data from structural health monitoring (SHM) systems. Bull. Earthq. Eng. 2015, 13, 917–934. [Google Scholar] [CrossRef]

- Cremona, C.; Santos, J. Structural health monitoring as a big-data problem. Struct. Eng. Int. 2018, 28, 243–254. [Google Scholar] [CrossRef]

- Finn, C.; Abbeel, P.; Levine, S. Model-agnostic meta-learning for fast adaptation of deep networks. In Proceedings of the International Conference on Machine Learning, Sydney, Australia, 6–11 August 2017; pp. 1126–1135. [Google Scholar]

- Zhang, Y.; Guo, Z.; Wu, J.; Tian, Y.; Tang, H.; Guo, X. Real-time vehicle detection based on improved yolo v5. Sustainability 2022, 14, 12274. [Google Scholar] [CrossRef]

- Greff, K.; Srivastava, R.K.; Koutník, J.; Steunebrink, B.R.; Schmidhuber, J. LSTM: A search space odyssey. IEEE Trans. Neural Netw. Learn. Syst. 2016, 28, 2222–2232. [Google Scholar] [CrossRef]

- Zhao, J.-Y.; Dong, G.-S.; Luo, Y.; Wan, H.-P. An improved multi-task approach for SHM missing data reconstruction using attentive neural process and meta-learning. J. Civ. Struct. Health Monit. 2025, 15, 813–829. [Google Scholar] [CrossRef]

- Entezami, A.; Sarmadi, H.; Behkamal, B. Long-term health monitoring of concrete and steel bridges under large and missing data by unsupervised meta learning. Eng. Struct. 2023, 279, 115616. [Google Scholar] [CrossRef]

- Xu, Y.; Fan, Y.; Bao, Y.; Li, H. Task-aware meta-learning paradigm for universal structural damage segmentation using limited images. Eng. Struct. 2023, 284, 115917. [Google Scholar] [CrossRef]

- Che, C.; Wang, H.; Ni, X.; Xiong, M. Few-shot structural repair decision of civil aircraft based on deep meta-learning. Eng. Appl. Artif. Intell. 2023, 125, 106695. [Google Scholar] [CrossRef]

- Tsialiamanis, G.; Sbarufatti, C.; Dervilis, N.; Worden, K. On a meta-learning population-based approach to damage prognosis. Mech. Syst. Signal Process. 2024, 209, 111119. [Google Scholar] [CrossRef]

- Wang, L.; Huang, D.; Huang, K.; Civera, M. Online meta-learning approach for sensor fault diagnosis using limited data. Smart Mater. Struct. 2024, 33, 085016. [Google Scholar] [CrossRef]

- Hassani, S. Meta-model structural monitoring with cutting-edge AAE-VMD fusion alongside optimized machine learning methods. Struct. Health Monit. 2024, 23, 14759217241263954. [Google Scholar] [CrossRef]

- Fisher, W.D.; Camp, T.K.; Krzhizhanovskaya, V.V. Crack detection in earth dam and levee passive seismic data using support vector machines. Procedia Comput. Sci. 2016, 80, 577–586. [Google Scholar] [CrossRef]

- Shi, Y.; Cui, L.; Qi, Z.; Meng, F.; Chen, Z. Automatic road crack detection using random structured forests. IEEE Trans. Intell. Transp. Syst. 2016, 17, 3434–3445. [Google Scholar] [CrossRef]

- Smith, S.; Wang, G.; Wu, D. Bayesian approach to breathing crack detection in beam structures. Eng. Struct. 2017, 148, 829–838. [Google Scholar] [CrossRef]

- Kaiming, H.; Xiangyu, Z.; Shaoqing, R.; Jian, S. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Badrinarayanan, V.; Kendall, A.; Cipolla, R. SegNet: A Deep Convolutional Encoder-Decoder Architecture for Image Segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 2481–2495. [Google Scholar] [CrossRef]

- Chen, L.-C.; Papandreou, G.; Kokkinos, I.; Murphy, K.; Yuille, A.L. DeepLab: Semantic Image Segmentation with Deep Convolutional Nets, Atrous Convolution, and Fully Connected CRFs. IEEE Trans. Pattern Anal. Mach. Intell. 2018, 40, 834–848. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, X.; Li, W.; Zhang, S.; Jia, Y. Automatic detection of moisture damages in asphalt pavements from GPR data with deep CNN and IRS method. Autom. Constr. 2020, 113, 103119. [Google Scholar] [CrossRef]

- Mangalathu, S.; Jeon, J.-S. Ground motion-dependent rapid damage assessment of structures based on wavelet transform and image analysis techniques. J. Struct. Eng. 2020, 146, 04020230. [Google Scholar] [CrossRef]

- Li, S.; Zhao, X.; Zhou, G. Automatic pixel-level multiple damage detection of concrete structure using fully convolutional network. Comput.-Aided Civ. Infrastruct. Eng. 2019, 34, 616–634. [Google Scholar] [CrossRef]

- Liu, J.; Yang, X.; Lau, S.; Wang, X.; Luo, S.; Lee, V.C.S.; Ding, L. Automated pavement crack detection and segmentation based on two-step convolutional neural network. Comput.-Aided Civ. Infrastruct. Eng. 2020, 35, 1291–1305. [Google Scholar] [CrossRef]

- Bandara, R.P.; Chan, T.H.; Thambiratnam, D.P. Structural damage detection method using frequency response functions. Struct. Health Monit. 2014, 13, 418–429. [Google Scholar] [CrossRef]

- Pathirage, C.S.N.; Li, J.; Li, L.; Hao, H.; Liu, W.; Ni, P. Structural damage identification based on autoencoder neural networks and deep learning. Eng. Struct. 2018, 172, 13–28. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. Xgboost: A scalable tree boosting system. In Proceedings of the 22nd ACM Sigkdd International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

- Chen, T.; He, T.; Benesty, M.; Khotilovich, V.; Tang, Y.; Cho, H. Xgboost: Extreme gradient boosting. R Package Version 0.4-2 2015, 1, 1–4. [Google Scholar]

- Wang, H.; Wu, T. Knowledge-enhanced deep learning for wind-induced nonlinear structural dynamic analysis. J. Struct. Eng. 2020, 146, 04020235. [Google Scholar] [CrossRef]

- Zhao, H.; Ding, Y.; Li, A.; Sheng, W.; Geng, F. Digital modeling on the nonlinear mapping between multi-source monitoring data of in-service bridges. Struct. Control Health Monit. 2020, 27, e2618. [Google Scholar] [CrossRef]

- Gulgec, N.S.; Takáč, M.; Pakzad, S.N. Structural sensing with deep learning: Strain estimation from acceleration data for fatigue assessment. Comput.-Aided Civ. Infrastruct. Eng. 2020, 35, 1349–1364. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Zhu, Z.; He, Z.; Ding, X.; Tang, C. A Review of Non-Destructive Damage Detection Methods for Steel Wire Ropes. Appl. Sci. 2019, 9, 2771. [Google Scholar] [CrossRef]

- Sen, D.; Aghazadeh, A.; Mousavi, A.; Nagarajaiah, S.; Baraniuk, R.; Dabak, A. Data-driven semi-supervised and supervised learning algorithms for health monitoring of pipes. Mech. Syst. Signal Process. 2019, 131, 524–537. [Google Scholar] [CrossRef]

- He, G.; Ding, K.; Lin, H. Fault feature extraction of rolling element bearings using sparse representation. J. Sound Vib. 2016, 366, 514–527. [Google Scholar] [CrossRef]

- Liao, Y.; Huang, R.; Li, J.; Chen, Z.; Li, W. Deep semisupervised domain generalization network for rotary machinery fault diagnosis under variable speed. IEEE Trans. Instrum. Meas. 2020, 69, 8064–8075. [Google Scholar]

- Hong, X.; Zhang, B.; Liu, Y.; Qi, H.; Li, W. Deep-learning-based guided wave detection for liquid-level state in porcelain bushing type terminal. Struct. Control Health Monit. 2021, 28, e2651. [Google Scholar] [CrossRef]

- Zhang, Z.; Pan, H.; Wang, X.; Lin, Z. Machine learning-enriched lamb wave approaches for automated damage detection. Sensors 2020, 20, 1790. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Yuan, S.; Chen, J.; Ren, Y. Guided wave-convolutional neural network based fatigue crack diagnosis of aircraft structures. Sensors 2019, 19, 3567. [Google Scholar] [CrossRef]

- Everingham, M.; Eslami, S.A.; Van Gool, L.; Williams, C.K.; Winn, J.; Zisserman, A. The pascal visual object classes challenge: A retrospective. Int. J. Comput. Vis. 2015, 111, 98–136. [Google Scholar] [CrossRef]

- San, B.-B.; Xu, F.; Shan, Z.-W.; Qiu, Y. Axial Mechanical Properties of H-Shaped Steel Columns Subject to Corrosion Random Field. J. Build. Eng. 2025, 111, 113487. [Google Scholar] [CrossRef]

- Shan, Z.-W.; Li, W.-J.; Guo, T.; Lu, H.; Chen, W.; Su, R. Strengthening design method of randomly corroded steel tubes subjected to axial compressive loading. Structures 2025, 79, 109436. [Google Scholar] [CrossRef]

- Rocha, D.S.C. Aprendizado de Máquina Aplicado ao Reconhecimento Automático de Falhas em Máquinas Rotativas; Universidade Federal de Minas Gerais: Belo Horizonte, Brazil, 2018. [Google Scholar]

| Model | Data Split | Training Settings and Platform | Evaluation Metrics |

|---|---|---|---|

| YOLOV5 | 923 images | Batch size = 16, epochs = 500, lr = 0.001, momentum = 0.9, weight decay = 0.0005, optimizer: SGD | Precision, Recall, mAP@0.5 |

| MAML + YOLOV5 | VOC2012 | 3-way 3-shot; parameter tuning ≈ 5–10 times | Precision, Recall, mAP@0.5 |

| LSTM | 50k samples | Batch size = 500, epochs = 200, dropout = 0.2, lr = 0.001 | MAE |

| MAML + LSTM | 10 tasks | 500 samples/task, 24 steps input, 2 output steps | MAE |

| 1DCNN | 1k/class | lr = 0.003, Adam optimizer, activation: tanh | Accuracy |

| MAML + 1DCNN | MaFaulDa | 6-way 6-shot, parameter tuning ≈ 3 times | Accuracy |

| Experiment | Training Method | Number of Samples | Result Evaluation |

|---|---|---|---|

| Bridge steel structure surface damage detection | YOLOV5 | 300/class | Precision: 85.2% Recall: 89.1% mAP: 90.0% |

| MAML- YOLOV5 | 100/class | Precision: 92.3% Recall: 96.2% mAP: 93.0% | |

| Bridge strain response prediction | LSTM | 50,000 | Mean value of absolute error: 1.532 |

| MAML- YOLOV5 | 1000 | Mean value of absolute error: 2.108 | |

| Guided wave signal classification | 1DCNN | 1000/class | Accuracy: 95.17 |

| MAML-1DCNN | 80/class | Accuracy: 92.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, X.; Liu, H.; Wang, J.; Wen, X.; Ge, Z.; Chen, W.; Fan, X.; Wang, Z.; Li, Z. MAML Bridges the Data Gap in Deep Learning-Based Structural Health Monitoring. Buildings 2025, 15, 3163. https://doi.org/10.3390/buildings15173163

Yu X, Liu H, Wang J, Wen X, Ge Z, Chen W, Fan X, Wang Z, Li Z. MAML Bridges the Data Gap in Deep Learning-Based Structural Health Monitoring. Buildings. 2025; 15(17):3163. https://doi.org/10.3390/buildings15173163

Chicago/Turabian StyleYu, Xianzheng, Hua Liu, Jinghang Wang, Xiaoguang Wen, Zhixiang Ge, Wenlong Chen, Xiaolin Fan, Zhongrui Wang, and Ziqi Li. 2025. "MAML Bridges the Data Gap in Deep Learning-Based Structural Health Monitoring" Buildings 15, no. 17: 3163. https://doi.org/10.3390/buildings15173163

APA StyleYu, X., Liu, H., Wang, J., Wen, X., Ge, Z., Chen, W., Fan, X., Wang, Z., & Li, Z. (2025). MAML Bridges the Data Gap in Deep Learning-Based Structural Health Monitoring. Buildings, 15(17), 3163. https://doi.org/10.3390/buildings15173163