A Submerged Building Strategy for Low-Carbon Data Centers in Coal Mining Subsidence Areas: System Design and Energy–Carbon Performance Assessment

Abstract

1. Introduction

- Subsided water bodies have yet to be incorporated into infrastructure deployment logic;

- Despite their potential, liquid cooling systems lack integrated frameworks with building and environmental systems;

- Tri-integrated architectural models—spatial, structural, and systemic—have not been quantitatively evaluated for their role in advancing carbon neutrality.

2. Methodology

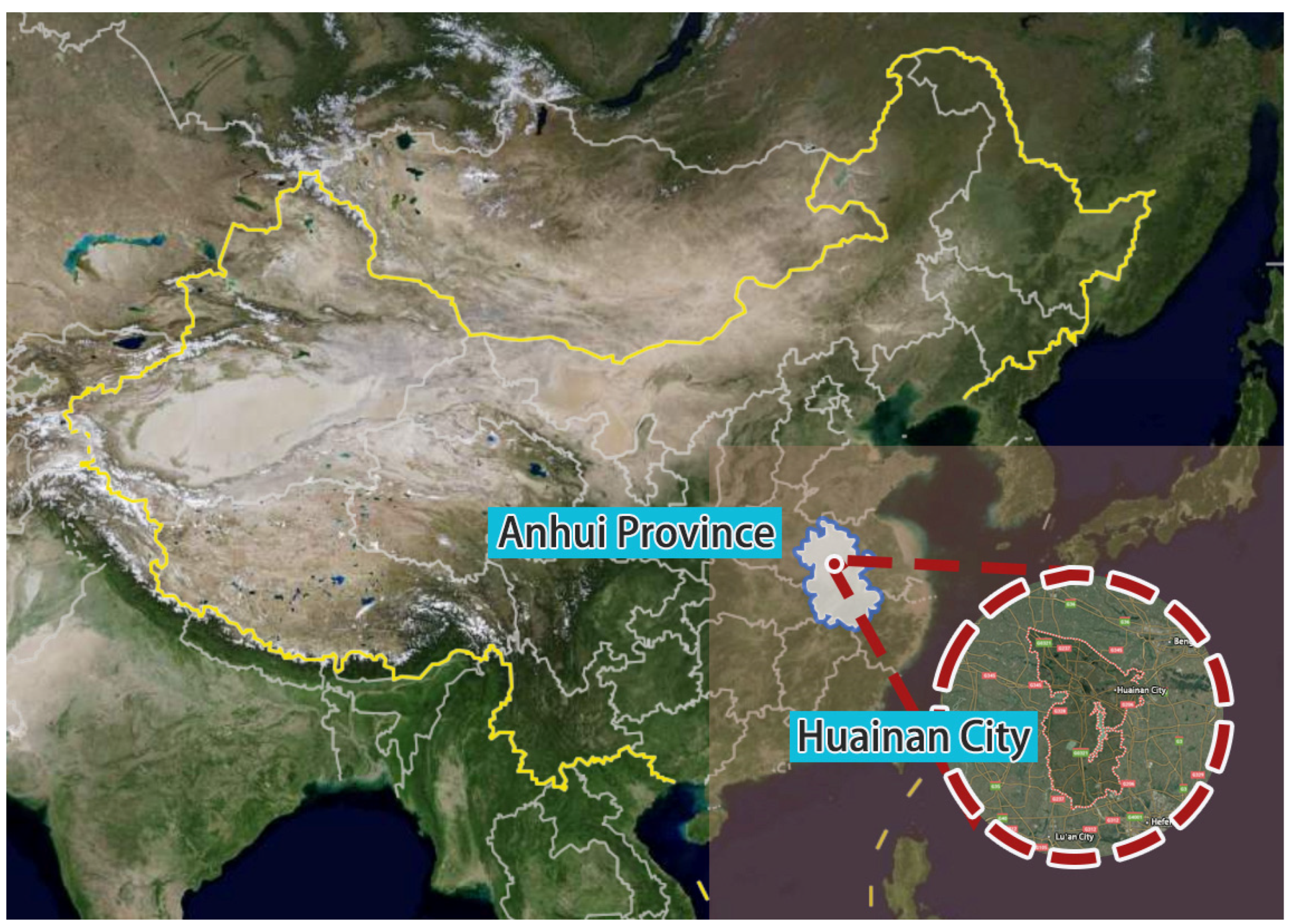

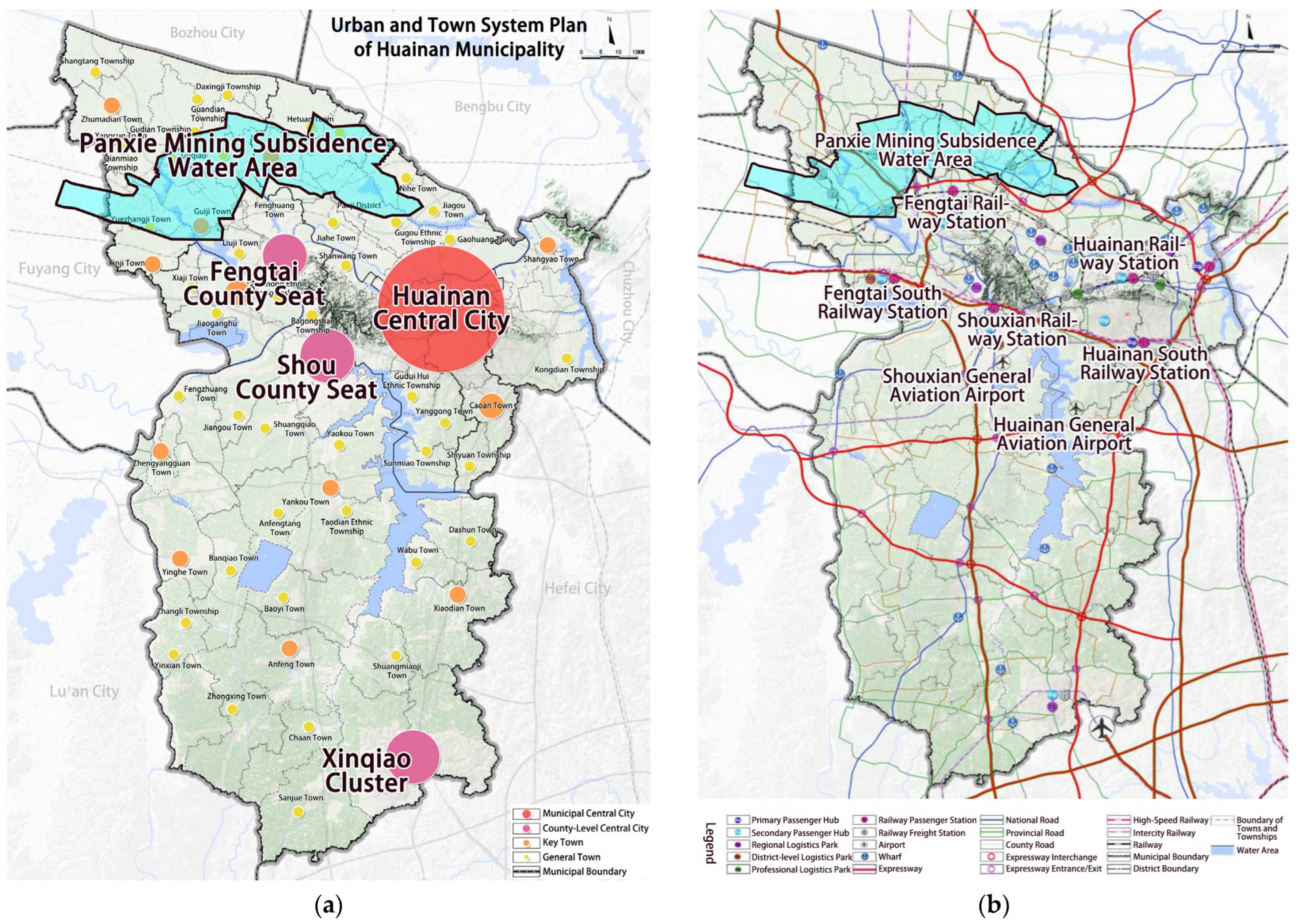

2.1. Site Selection and Regional Context

- Relatively stable hydrological conditions are suitable for constructing an external thermal sink for cooling systems;

- Preliminary planning control is already in place, making infrastructural access for data centers technically feasible;

- The terrain characteristics support a “submerged deployment with shoreline connection” configuration, offering potential for experimental implementation.

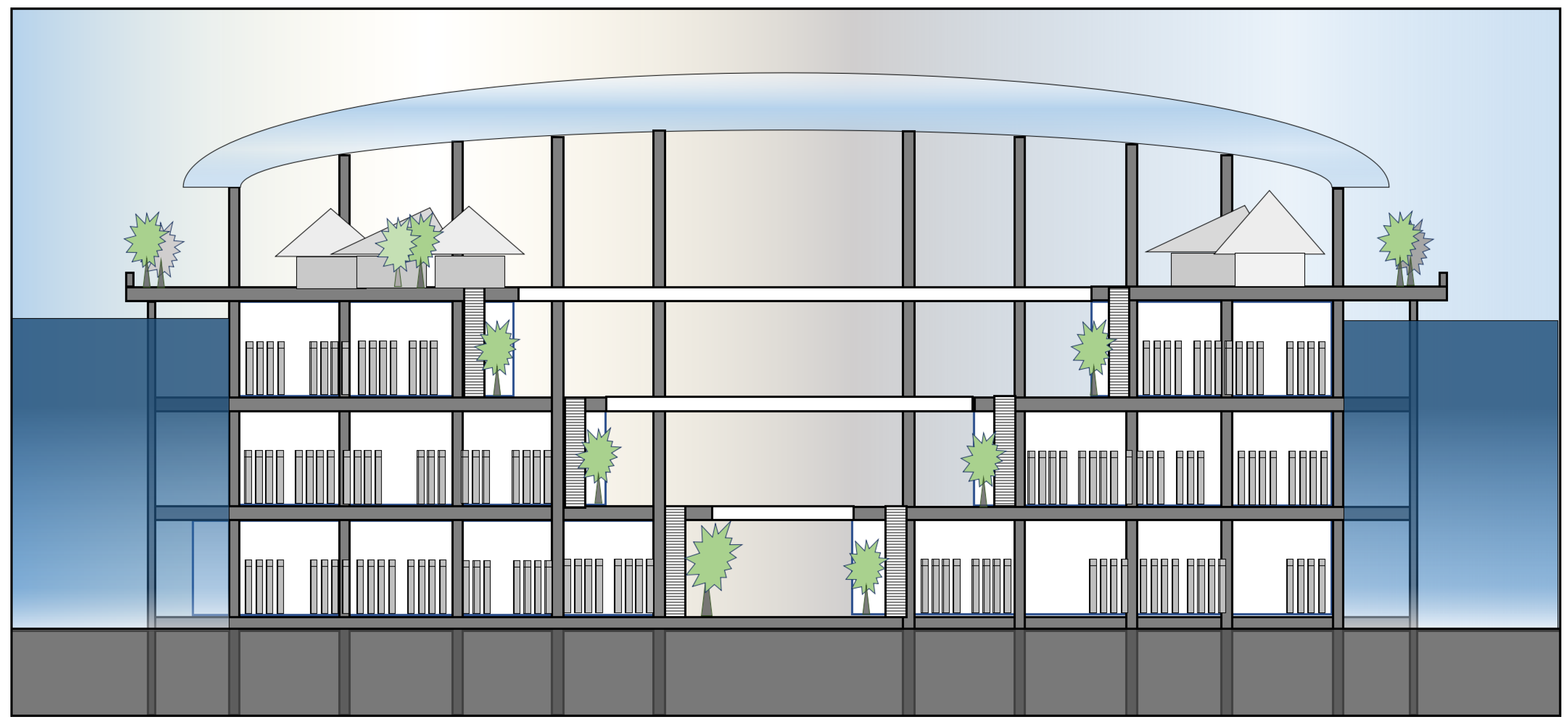

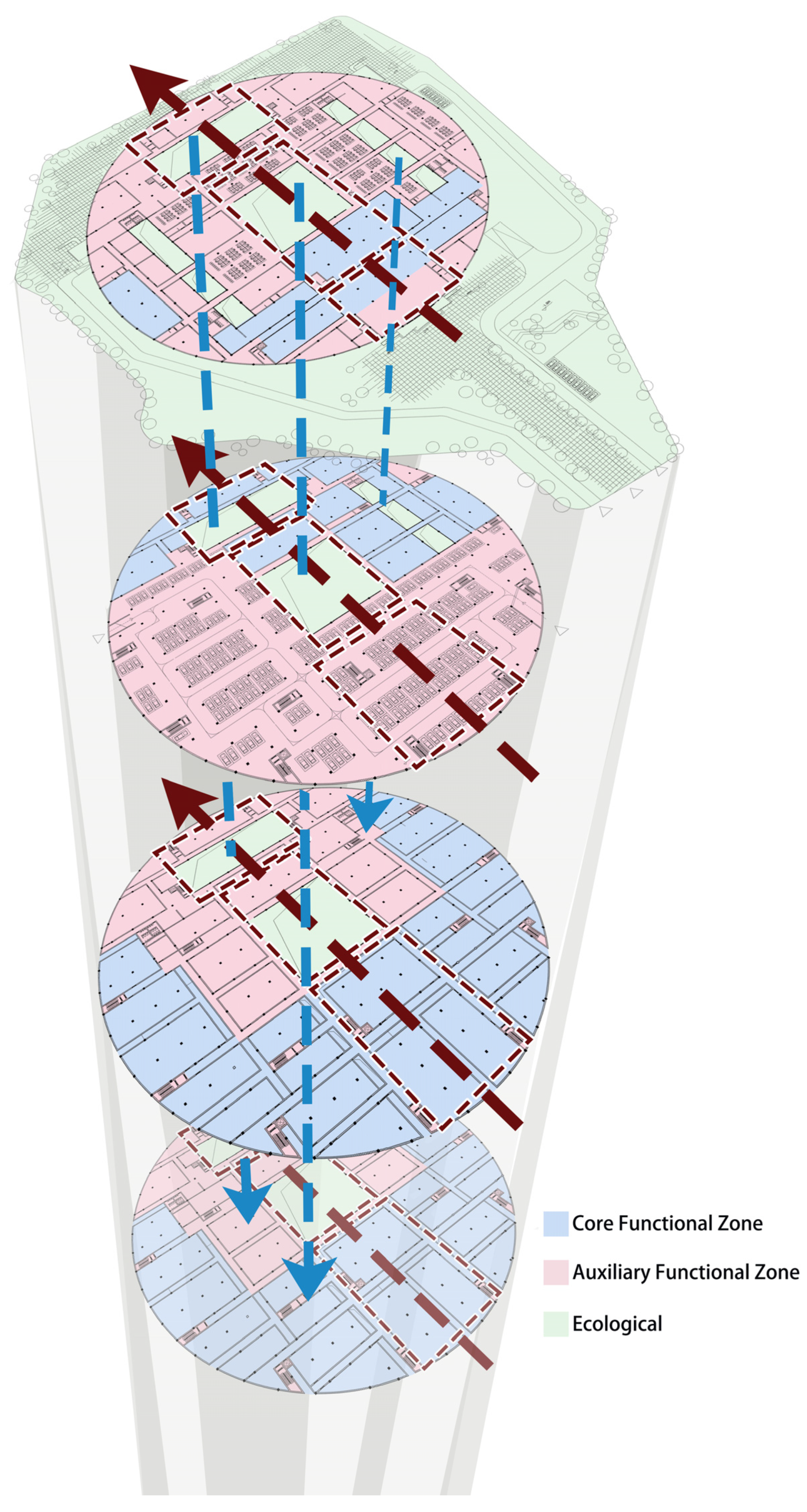

2.2. Building Layout and Structural Strategy

- (a)

- Two water-exposed sides, with a 1500 mm cold aisle and a 1000 mm hot aisle;

- (b)

- Two water-exposed sides, with a 1500 mm cold aisle and a 1200 mm hot aisle;

- (c)

- Three water-exposed sides, with a 1500 mm cold aisle and a 1000 mm hot aisle.

2.3. Model Framework and Boundary Conditions

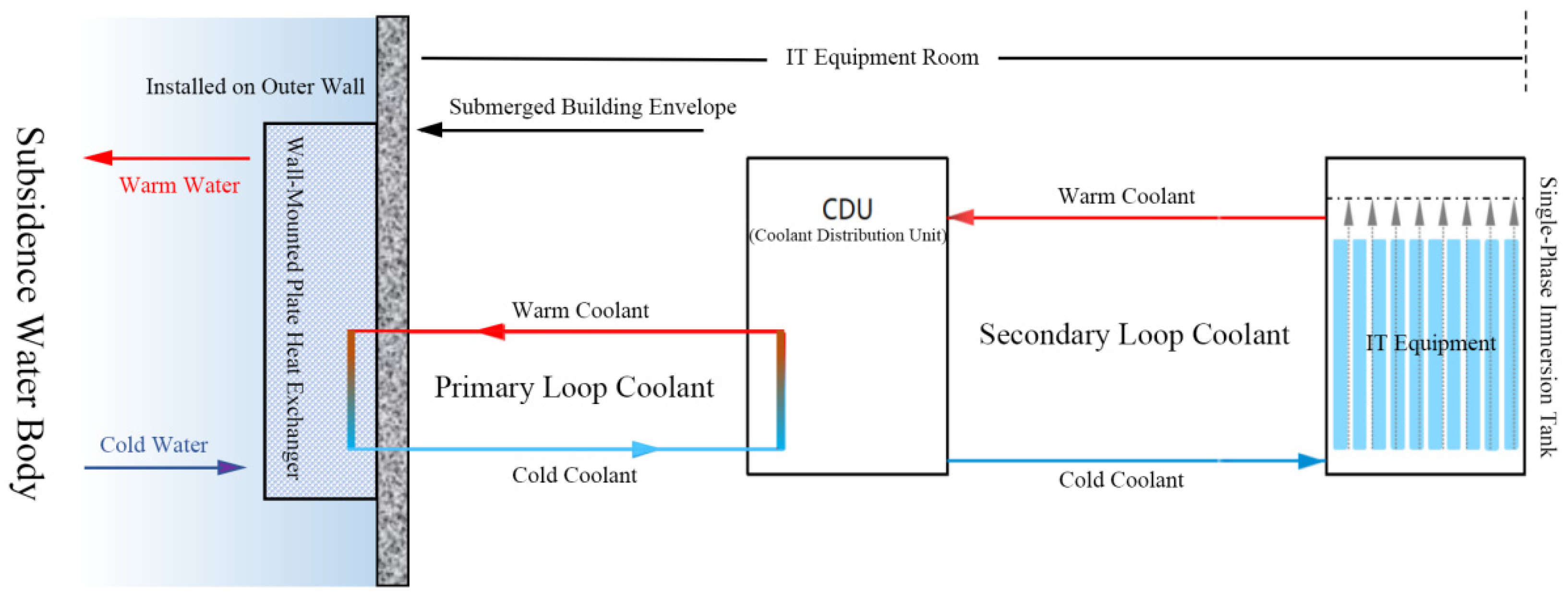

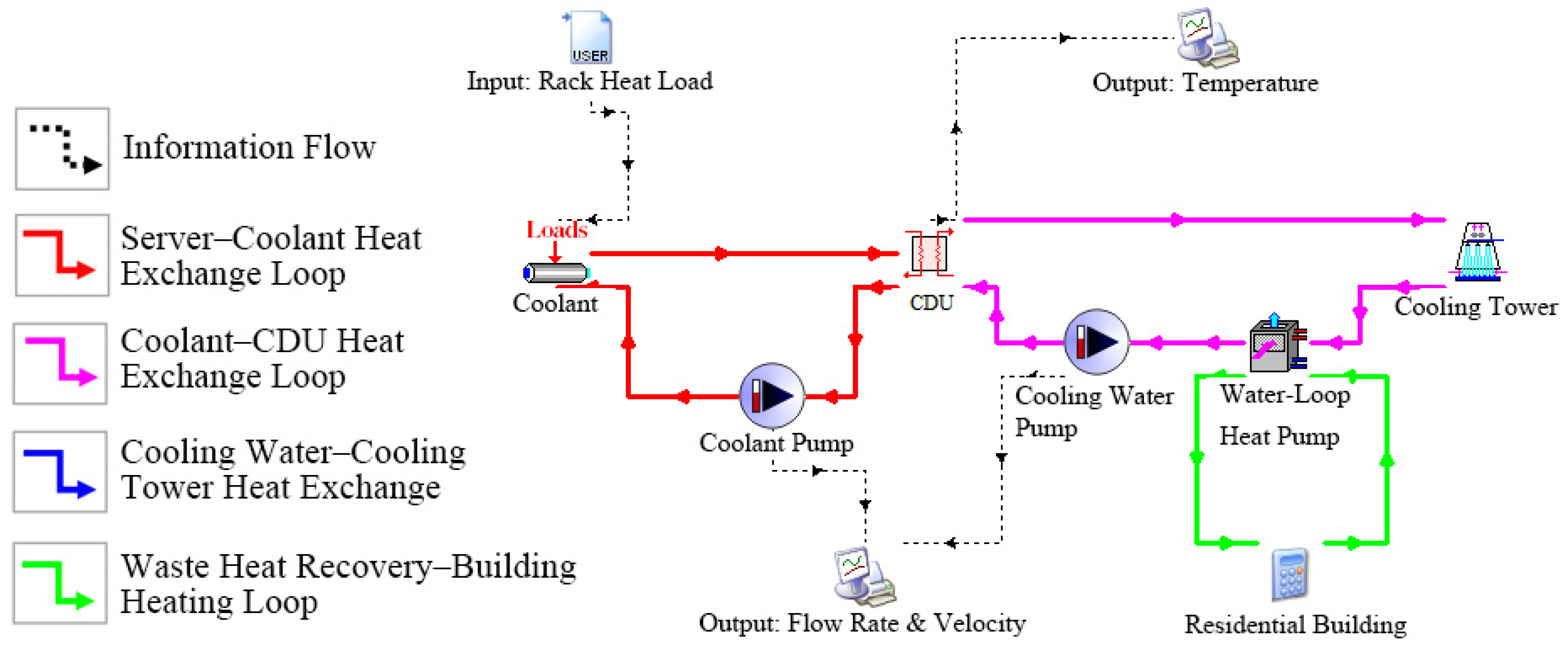

2.4. Heat Exchange Model and Simulation Implementation

- (1)

- Conductive heat exchange between the IT equipment and the immersion coolant;

- (2)

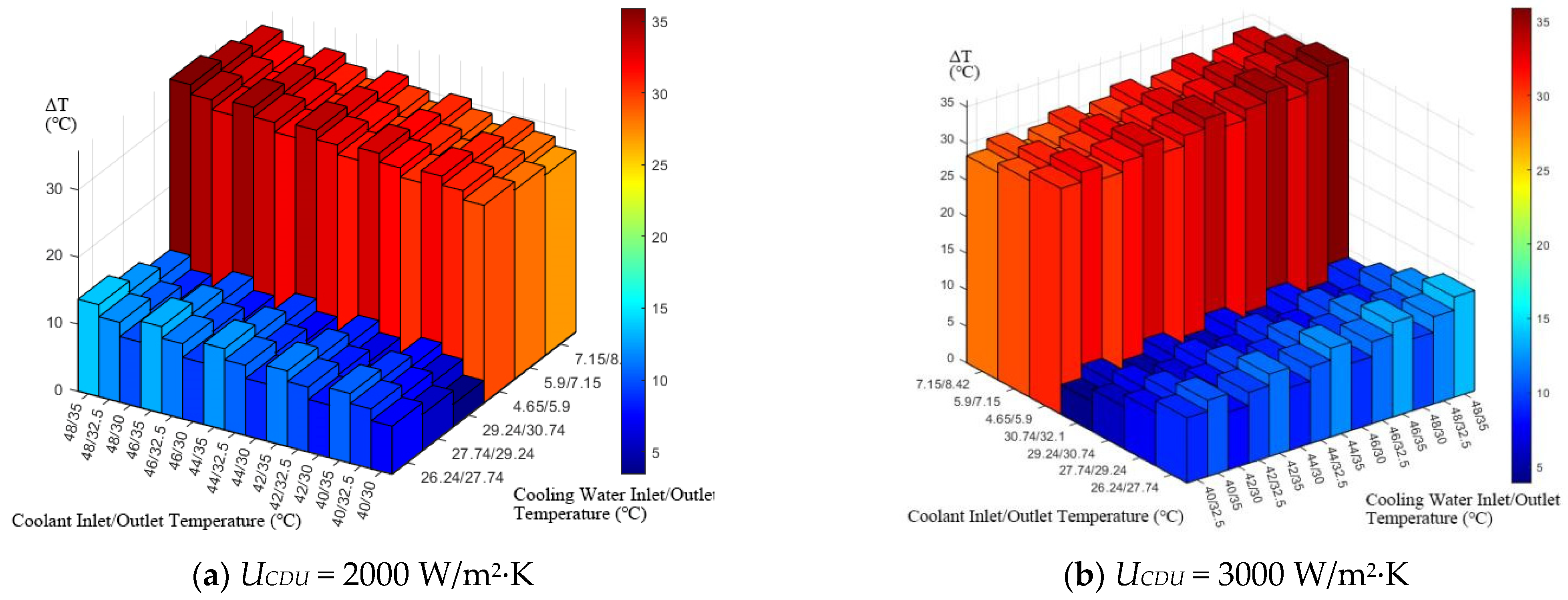

- Convective heat exchange within the CDU between the immersion coolant and the secondary cooling water;

- (3)

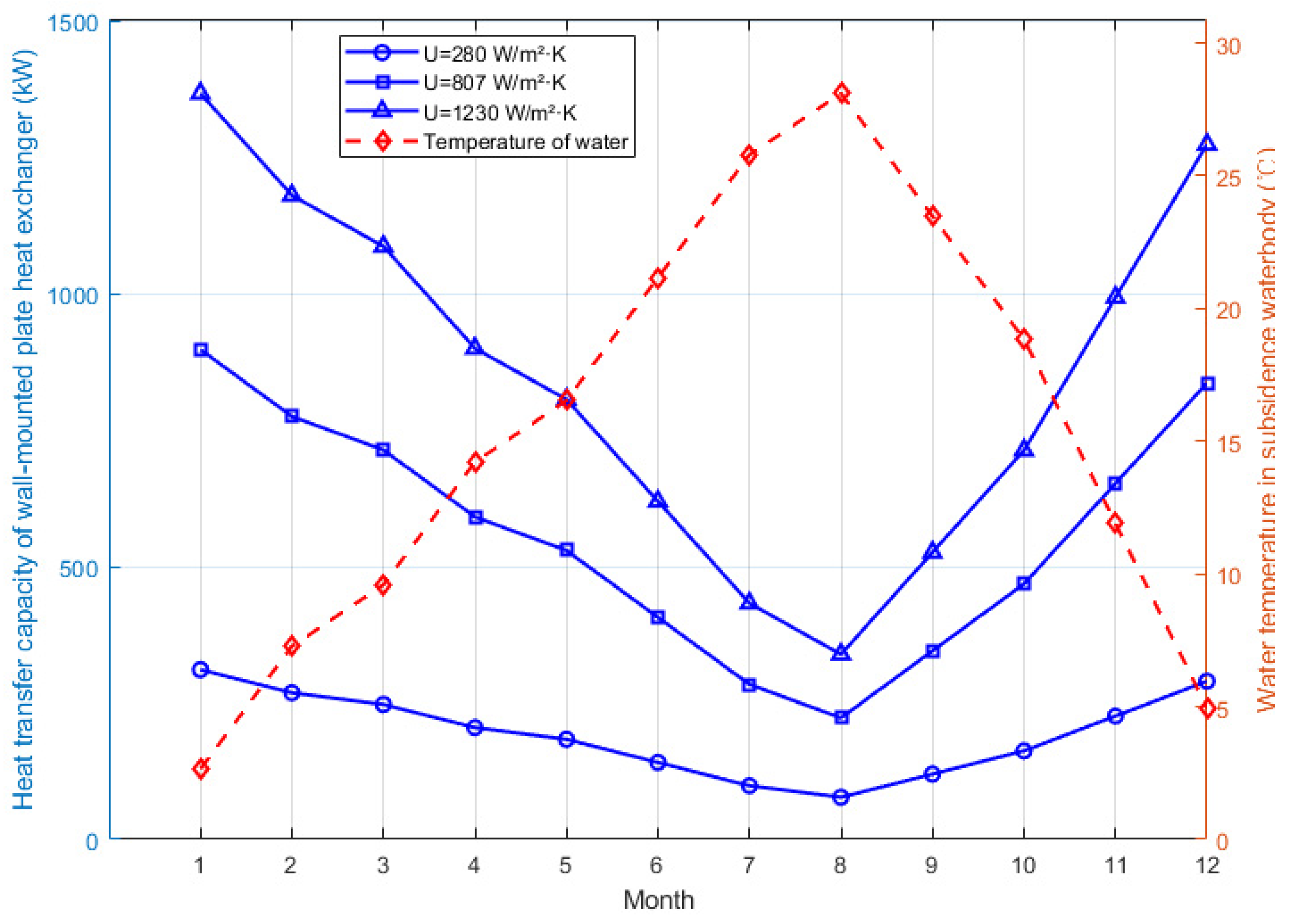

- Heat rejection from the cooling water to the surrounding water body via wall-mounted plate heat exchangers.

- (1)

- Server–coolant heat exchange

- (2)

- Coolant–CDU heat exchange

- (3)

- Cooling water–water body heat exchange

2.5. Model Validation (TRNSYS–MATLAB Comparison)

3. Results and Analysis

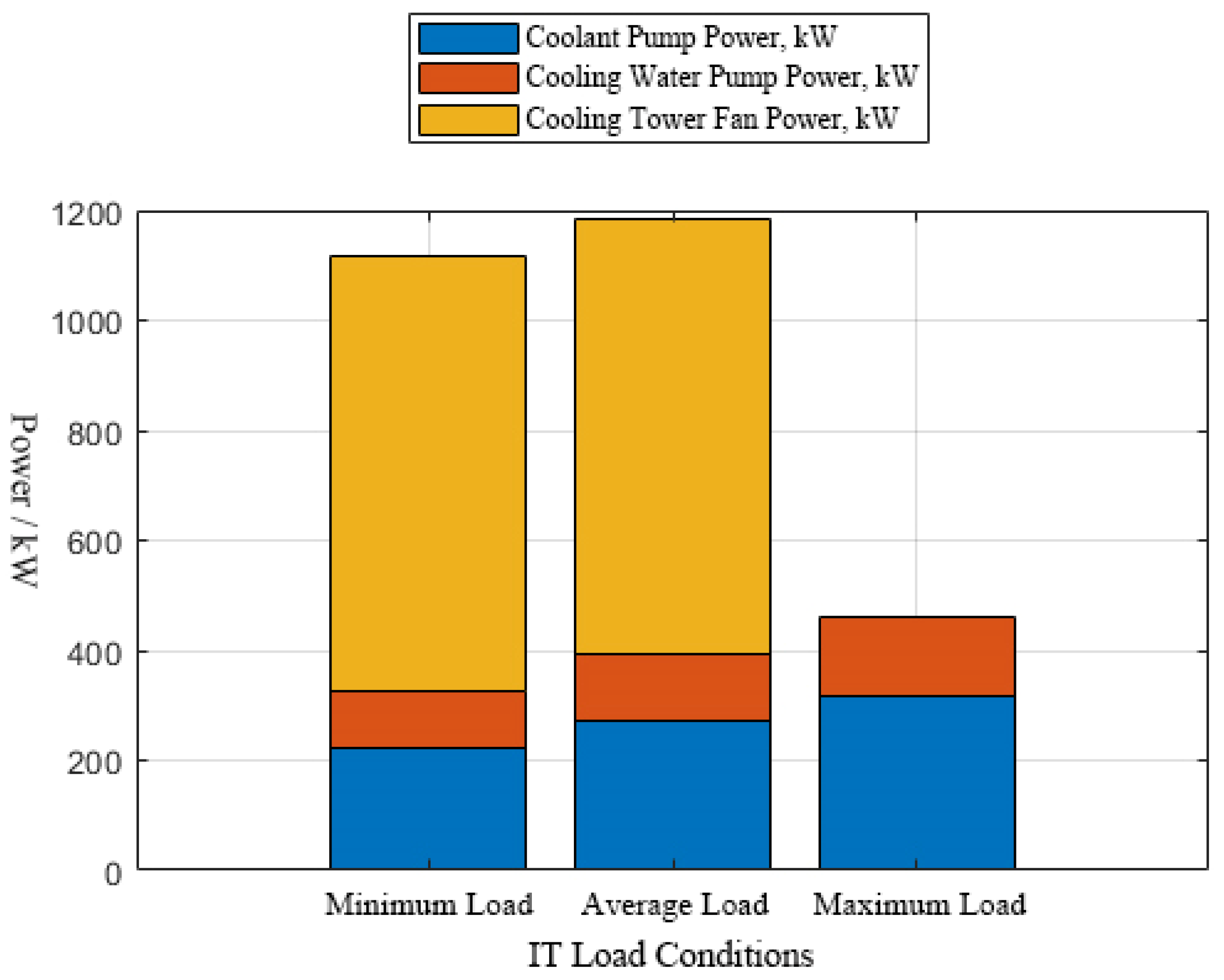

3.1. Cooling Energy Consumption and PUE Analysis

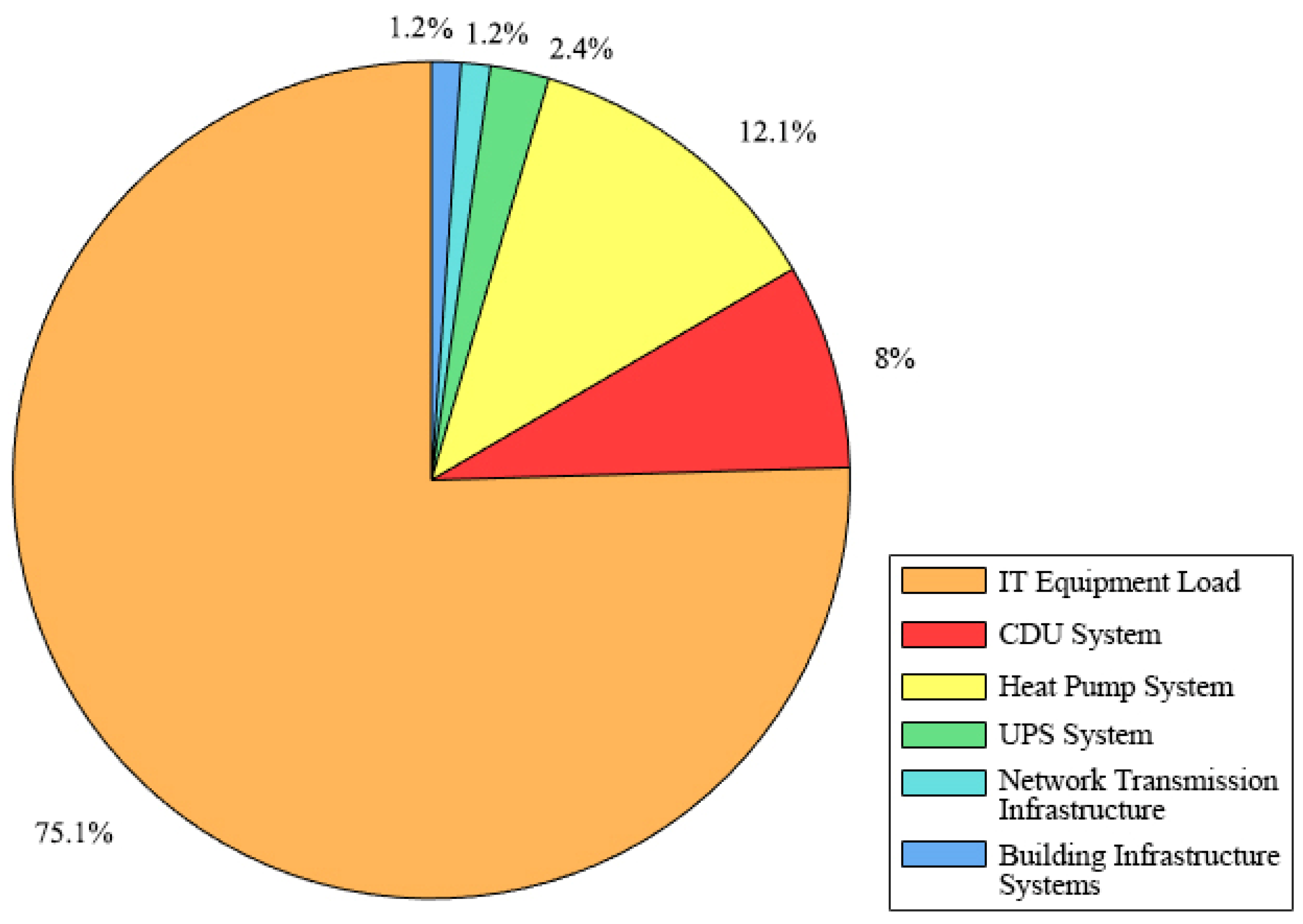

- IT equipment consumption: Estimated based on a median rack-level load of 65 kW;

- Non-cooling system consumption: Including UPS, power conversion, networking, and facility operation loads, estimated at 3%, 1.5%, and 1.5% of the IT load, respectively;

- PUE (Power Usage Effectiveness): Calculated as the ratio of total energy consumption to IT energy consumption.

3.2. Assessment of Energy Savings and Carbon Emissions

- Submerged system: 16,682–41,706 t CO2.

- Conventional system: 33,450–66,901 t CO2.

4. Discussion

4.1. Practical Implications of Energy Efficiency and Carbon Reduction

4.2. Redevelopment Potential in Coal Mining Subsidence Regions

- Spatial compatibility: Subaqueous deployment leverages large-scale idle water surfaces. Where necessary, underwater excavation may reduce the influence of unstable strata on the structure’s performance.

- Structural reusability: The combination of pile foundation and grouting techniques accommodates soft ground conditions and allows later transformation into modular or floating platforms.

- Industrial continuity: As a future-oriented digital infrastructure node (e.g., edge computing, AI training centers, or government cloud hubs), the data center can anchor long-term industrial functions in the area.

4.3. Technical Replicability and Applicability Boundaries

4.4. Research Limitations and Future Work

5. Conclusions

- Under typical IT load conditions, the submerged liquid cooling system reduces cooling energy consumption by 42.5–64.3%, maintaining an annual average PUE of 1.06–1.15, outperforming traditional liquid cooling systems;

- Compared to conventional cooling-tower-based systems, the proposed system achieves a 37.7–75.1% reduction in annual carbon emissions, with peak decarbonization rates reaching 50.1% in optimal operating scenarios;

- The heat exchange model was validated using TRNSYS simulation against MATLAB-calculated data, with a deviation of less than 3% in most operating conditions, demonstrating strong thermal accuracy;

- The spatial configuration supports both submerged deployment and shoreline access, making it suitable for redeveloping post-mining water zones and reactivating underutilized regional infrastructure.

- (1)

- Empirical validation: Close the modeling loop with pilot-scale operational data to verify thermal performance and structural durability under real-world conditions.

- (2)

- Energy integration: Explore coupling with clean energy systems such as photovoltaics, storage, or micro-grids to enhance overall system sustainability.

- (3)

- Life-cycle analysis: Conduct comprehensive life-cycle carbon and economic assessments that include construction, operation, and end-of-life phases.

- (4)

- Environmental assessment: Evaluate potential ecological impacts of continuous heat rejection on aquatic ecosystems and propose mitigation strategies.

- (5)

- Policy alignment: At the policy level, the proposed system demonstrates how China’s dual-carbon strategy can be advanced through both industrial decarbonization and adaptive spatial planning. By reactivating subsidence lakes as productive assets, the approach provides a model for integrating ecological restoration with digital infrastructure, aligning with national targets for energy efficiency and sustainable land use.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PUE | Power Usage Effectiveness |

| ICT | Information and Communication Technology |

| CDU | Coolant Distribution Unit |

| TRNSYS | Transient System Simulation Tool |

| LCA | Life Cycle Assessment |

| CO2 | Carbon Dioxide |

| kW | Kilowatt |

| kWh | Kilowatt-Hour |

| R-1234ze | Refrigerant Type R-1234ze |

| IT | Information Technology |

| Nomenclature | |

| Qrack | The heat dissipation rate of a single server rack (W) |

| ṁcl | The mass flow rate of the coolant (kg/s) |

| ccl | The specific heat capacity of the coolant (J/kg·K) |

| Tcl,out | The outlet temperatures of the coolant (°C) |

| Tcl,in | The inlet temperatures of the coolant (°C) |

| QCDU | The heat transfer rate across the CDU (W) |

| UCDU | The overall heat transfer coefficient (W/m2·K) |

| ACDU | The heat transfer area of the CDU (m2) |

| ΔTlm,CDU | The logarithmic mean temperature difference (LMTD) between the coolant and cooling water |

| Qexchanger | The heat transfer from cooling water to the external subsided water (W) |

| Uplate | The plate exchanger’s heat transfer coefficient (W/m2·k) |

| Aplate | The effective surface area of the plate heat exchanger (m2) |

| ΔTHE | The temperature difference between cooling water and the surrounding water body (K) |

| The total rated power of 32 cooling tower fans (kW) | |

| ηload | A load ratio estimated based on the proportion of thermal load (%) |

References

- An, S.K.; Li, Z.L.; Hu, Z.S. Study on the evolution trend of ecosystem in high groundwater level mining area: A case study of the Panxie mining area in Huainan. China Min. Mag. 2015, 24, 40–44. (In Chinese) [Google Scholar]

- Li, B.J.; Gu, H.H.; Ji, Y.Z. Dynamic changes in fractal characteristics of land use in mining areas. Trans. Chin. Soc. Agric. Eng. 2013, 29, 233–240. (In Chinese) [Google Scholar]

- Yang, R.; Lei, S.; Wang, S. Spatio-temporal analysis of ground subsidence due to underground coal mining in Huainan coalfield, China. Nat. Hazards 2020, 100, 105–123. [Google Scholar] [CrossRef]

- Hao, B.-y.; Kang, L.-x. Mine land reclamation and eco-reconstruction in Shanxi Province I: Mine land reclamation model. Sci. World J. 2014, 2014, 483862. [Google Scholar] [CrossRef] [PubMed]

- Xiao, W.; Hu, Z.; Li, J.; Zhang, H.; Hu, J. A study of land reclamation and ecological restoration in a resource-exhausted city: A case study of Huaibei in China. Int. J. Min. Reclam. Environ. 2011, 25, 332–341. [Google Scholar] [CrossRef]

- Hu, T.; Chang, J.; Liu, X.; Feng, S. Integrated methods for determining restoration priorities of coal mining subsidence areas based on green infrastructure: A case study in the Xuzhou urban area. China. Ecol. Indic. 2018, 94, 164–174. [Google Scholar] [CrossRef]

- Qiu, H.L.; Gui, H.R.; Song, Q.X. Human health risk assessment of trace elements in shallow groundwater of the Linhuan coal-mining district, Northern Anhui Province, China. Hum. Ecol. Risk Assess. 2018, 24, 1342–1351. [Google Scholar] [CrossRef]

- Zipper, C.E.; Skousen, J.G.; Ziemkiewicz, P.F.; Daniels, W.L.; Nolte, B.K.; Schoenholtz, S.H. Restoring forests and associated ecosystem services on Appalachian coal surface mines. J. Environ. Manag. 2011, 47, 751–765. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Wang, L. Comprehensive study on ecological restoration and land exploitation of mining subsidence in suburbs of Chinese mining cities. Int. J. Coal Sci. Technol. 2014, 1, 248–252. [Google Scholar] [CrossRef]

- Li, C.; Chang, J.; Feng, S.; Zhou, S. From a Coal Mining Area to a Wetland Park: How Is the Social Landscape Performance in Pan’ an Lake National Wetland Park? Land 2025, 14, 1305. [Google Scholar] [CrossRef]

- Tan, X.; Peng, Y.; Liu, S.; Liu, P. Landscape pattern and ecotourism carrying capacity of Pan’an Lake Wetland Park in Xuzhou City, China. Desal. Water Treat. 2020, 188, 288–296. [Google Scholar] [CrossRef]

- Kalin, M. Biogeochemical and ecological considerations in designing wetland treatment systems in post-mining landscapes. Waste Manag. 2001, 21, 191–196. [Google Scholar] [CrossRef]

- Li, C.; Yang, S.; Zha, D.; Zhang, Y.; de Boer, W.F. Waterbird communities in subsidence wetlands created by underground coal mining in China: Effects of multi-scale environmental and anthropogenic variables. Environ. Conserv. 2019, 46, 67–75. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Su, X. The spatial distribution and expansion of subsided wetlands induced by underground coal mining in eastern China. Environ. Earth Sci. 2021, 80, 112. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Zha, D.; Yang, S.; de Boer, W.F. Assembly processes of waterbird communities across subsidence wetlands in China: A functional and phylogenetic approach. Divers. Distrib. 2019, 25, 1118–1129. [Google Scholar] [CrossRef]

- Chen, Y.; Zheng, L.; Chen, X.; Hu, J.; Li, C.; Zhang, L.; Cheng, H. Distribution of mercury and methylmercury in aquacultured fish in special waters formed by coal mining subsidence. Ecotoxicol. Environ. Saf. 2024, 280, 116546. [Google Scholar] [CrossRef]

- Tan, M.; Bian, Z.; Dong, J.; Hao, M.; Qu, J. Comparing the variation and influencing factors of CO2 emission from subsidence waterbodies under different restoration modes in coal mining area. Environ. Res. 2023, 237, 116936. [Google Scholar] [CrossRef]

- Xie, K.; Zhang, Y.; Yi, Q.; Yan, J. Optimal resource utilization and ecological restoration of aquatic zones in the coal mining subsidence areas of the Huaibei Plain in Anhui Province, China. Desal. Water Treat. 2013, 51, 4019–4027. [Google Scholar] [CrossRef]

- Yuan, L.; Xu, L.J. Concept and practice of resource-based, energy-based and multifunctional utilization in high groundwater level coal mining subsidence areas. J. China Coal Soc. 2024, 49, 65–74. (In Chinese) [Google Scholar]

- Yuan, L.; Xu, L. Conception and practice of resource utilization, energization and functionalization of coal mining subsidence areas with high groundwater level. J. China Coal Soc. 2024, 49, 65–74. [Google Scholar] [CrossRef]

- Yuan, L.; Peng, S.P.; Wu, Q. Strategic Research on Comprehensive Management and Ecological Restoration of Coal Mining Subsidence Areas in Eastern China; Science Press: Beijing, China, 2020. (In Chinese) [Google Scholar]

- Liu, K.Z. Making the China Data Valley—The National Integrated Big Data Centre System and Local Governance. J. Contemp. Asia 2024, 55, 203–225. [Google Scholar] [CrossRef]

- Dayarathna, M.; Wen, Y.; Fan, R. Data Center Energy Consumption Modeling: A Survey. IEEE Commun. Surv. Tutor. 2016, 18, 732–794. [Google Scholar] [CrossRef]

- Environmental Protection Agency (EPA). Report to Congress on Server and Data Center Energy Efficiency; Public Law 109-431; U.S. Environmental Protection Agency: Washington, DC, USA, 2007.

- Sun, H.S.; Lee, S.E. Case study of data centers’ energy performance. Energy Build. 2006, 38, 522–533. [Google Scholar] [CrossRef]

- Ma, H.; Du, N.; Yu, S.; Lu, W.; Zhang, Z.; Deng, N. Analysis of typical public building energy consumption in northern China. Energy Build. 2017, 136, 139–150. [Google Scholar] [CrossRef]

- Andrae, A.S.G.; Edler, T. On global electricity usage of communication technology: Trends to 2030. Challenges 2015, 6, 117–157. [Google Scholar] [CrossRef]

- Rehman, A.; Nogueira, L.A.H.; Mustafa, M.W. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life cycle primary energy use and carbon emission of an eight-storey wood-framed apartment building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Ren, C.; Wang, D.; Urgaonkar, B.; Sivasubramaniam, A. Carbon-aware energy capacity planning for datacenters. In Proceedings of the 2012 IEEE 20th International Symposium on Modeling, Analysis and Simulation of Computer and Telecommunication Systems (MASCOTS), Washington, DC, USA, 7–9 August 2012; pp. 161–168. [Google Scholar] [CrossRef]

- Stein-Montalvo, M.; Miller, J.; Bou-Zeid, E. Origami-inspired passive ventilation structures for wind capture in urban design. arXiv 2023, arXiv:2310.01577. [Google Scholar]

- Biwole, P.H.; Woloszyn, M.; Pompeo, C. Heat transfer model for a ventilated double skin facade. arXiv 2013, arXiv:1312.1295. [Google Scholar]

- Azeñas, J.; Roldán-Fernández, J.M.; Recio, J.A. Assessment of green roofs as a passive cooling technique in Mediterranean climate. Energies 2018, 11, 2704. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.; Xu, H. Experimental evaluation of green and cool roofs on building energy performance in different seasons. Front. Energy Res. 2023, 11, 1291213. [Google Scholar] [CrossRef]

- Vertiv. Quantifying Data Center PUE When Introducing Liquid Cooling. 2023. Available online: https://www.vertiv.com/en-asia/about/news-and-insights/articles/blog-posts/quantifying-data-center-pue-when-introducing-liquid-cooling/ (accessed on 23 July 2025).

- Jia, N.; Hu, W. Floating Towns: Governance and Reconstruction of Coal Mining Subsidence Water Bodies; China Architecture & Building Press: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Pei, W.M. Remote Sensing Dynamic Monitoring of Water Environment in Coal Mining Subsidence Areas of Panji, Huainan. Ph.D. Thesis, Nanjing University, Nanjing, China, 2012. (In Chinese). [Google Scholar]

- Jia, N.; Hu, W.; Wang, D.Q. New ideas for constructing floating building land in coal mining subsidence water bodies. Mod. Urban Res. 2014, 7, 87–91. (In Chinese) [Google Scholar]

- Wu, X.Q.; Zhou, D.W.; An, S.K. Evolution trend and governance countermeasures of land and water in the Panxie mining area, Huainan. J. China Coal Soc. 2015, 40, 6. (In Chinese) [Google Scholar] [CrossRef]

- Liu, M.; Zeng, Y. Study on geological disasters and prevention strategies of mining subsidence areas. Jiangsu Environ. Sci. Technol. 2005, 18, 29–32. (In Chinese) [Google Scholar]

- Huainan Natural Resources and Planning Bureau. Huainan Territorial Spatial Master Plan (2021–2035)—Draft for Public Comment; Huainan Municipal People’s Government: Huainan, China, 2021. (In Chinese)

- Honeywell Energy and Sustainable Technology Group. Solstice® ze (R-1234ze) [EB/OL]. n.d. Available online: https://www.honeywell.com.cn/ess/products-and-services/advanced-materials/flourine-products/refrigerants/solstice-ze-r-1234ze (accessed on 11 March 2025).

- China Refrigeration Society Data Center Cooling Working Group. Annual Development Report on Cooling Technologies for Data Centers in China 2022; China Architecture & Building Press: Beijing, China, 2023. (In Chinese) [Google Scholar]

- WheatA. V1.6.5b [CP/OL]. 2024. Available online: https://wheata.cn (accessed on 16 August 2024).

- Xfusion. FusionServer XH321 V6 [EB/OL]. Available online: https://www.xfusion.com/en/product/high-density-server/fusionserver-xh321-v6 (accessed on 1 March 2025).

- Danfoss. Installation, Operation, and Maintenance Manual for Gasketed and Semi-Welded Plate Heat Exchangers (AQ3568.45617175zh-000204); Danfoss (Shanghai) Investment Co., Ltd.: Shanghai, China, 2023. (In Chinese) [Google Scholar]

- Anhui Provincial Development and Reform Commission. Analysis report on electricity prices for industrial and commercial users in Anhui Province [R/OL]. 2025. Available online: https://fzggw.ah.gov.cn/jgsz/jgcs/myjjj/hqzc/149826041.html (accessed on 9 March 2025). (In Chinese)

- Li, X. Hydrodynamic Numerical Simulation of Dead Water Zones in Longjing Lake Based on the EFDC Model. Ph.D. Thesis, Chongqing University, Chongqing, China, 2025. (In Chinese). [Google Scholar]

- Wang, J.; Zhang, P. Flood flow field and velocity distribution simulation of Tianjing Lake based on the MIKE21 2D hydrodynamic model. Zhi Huai 2023, 1, 22–24. (In Chinese) [Google Scholar]

| Parameter Type | Value |

|---|---|

| Water depth of subsidence area | 20 m |

| Hydrostatic pressure of subsidence water | 196.5 kPa |

| Server specification | 1U (half-height) |

| Specific heat capacity of coolant | 1402.58 kJ/kg·K |

| Coolant density | 1146.92 kg/m3 |

| Coolant pipe specification | DN80 (inner diameter: 0.080 m) |

| Internal flow path length of CDU heat exchanger | 15 m |

| Dynamic viscosity of coolant | 0.00047 Pa·s |

| Total local resistance coefficient of coolant | 8.7 |

| Heat transfer area of CDU | 17 m2 |

| Specific heat capacity of cooling water | 4180 J/kg·K |

| Cooling water density | 997 kg/m3 |

| Cooling water pipe specification | DN40 (inner diameter: 0.040 m) |

| Heat transfer area of wall-mounted plate heat exchanger | 32.84 m2 |

| Dynamic viscosity of cooling water | 0.000715 Pa·s |

| Thermal conductivity of cooling water | 0.63 W/m·K |

| Carbon emission intensity | 0.6782 kg CO2/kWh [47] |

| Variable Type | Season | Value |

|---|---|---|

| Flow velocity of subsidence water | Annual | 0.1–0.5 m/s [48,49] |

| Mixed-layer water temperature of subsidence area | Annual | 15.91 °C |

| Summer | 26.91 °C | |

| Winter | 3.73 °C | |

| Mixed-layer water temperature range | Summer | 24.38–28.18 °C |

| Winter | 2.65–4.39 °C | |

| Overall-layer average water temperature | Annual | 15.82 °C |

| Summer | 26.65 °C | |

| Winter | 3.74 °C | |

| Overall-layer water temperature range | Summer | 24.24–28.10 °C |

| Winter | 2.65–4.42 °C | |

| Water density of subsidence area | Annual | 1000.024–1000.048 kg/m3 |

| Server power consumption | 600–850 W | |

| Rack-level power consumption | 55.2–78.2 kW | |

| Coolant inlet temperature at CDU side | 40.0–48.0 °C | |

| Coolant outlet temperature at CDU side | 30.0–35.0 °C | |

| Coolant temperature difference (inlet–outlet) | 5.0–18.0 K | |

| Cooling water inlet temperature at CDU side | Summer | 26.24–32.10 °C |

| Winter | 4.65–8.42 °C | |

| Cooling water outlet temperature at CDU side | Annual | 35.0–38.0 °C |

| Cooling water temperature difference (plate HX side) | Summer | 2.9–11.8 K |

| Winter | 26.58–33.35 K | |

| Coolant flow rate | Annual | 34.31–350.01 L/min |

| Coolant velocity range | 0.1138–1.1605 m/s | |

| Coolant total pressure drop | 0.1006–8.8198 kPa | |

| CDU heat transfer coefficient | 2000–3000 W/m2·K | |

| Cooling water temperature rise | 2.9–33.35 K | |

| Cooling water flow rate | 11.8–230.57 L/min | |

| Cooling water velocity range | 0.0122–0.4650 m/s | |

| Heat transfer coefficient (cooling water side of plate HX) | 232.22–5670.88 W/m2·K | |

| Heat transfer coefficient (subsidence water side of plate HX) | 290–1460 W/m2·K | |

| Overall heat transfer coefficient of plate HX | 280–1230 W/m2·K |

| Calculated Heat Load (kW) | Waste Heat Recovery Rate (%) | Heat Exchange Temperature Difference (K) | Coolant Mass Flow Rate (kg/s) | Simulated Heat Load (kW) |

|---|---|---|---|---|

| 55.20000 | 0.00000 | 18.00000 | 2.18645 | 55.20008 |

| 55.20000 | 0.00000 | 5.00000 | 7.87121 | 55.20001 |

| 33.20000 | 40.00000 | 18.00000 | 1.31187 | 33.12005 |

| 33.20000 | 40.00000 | 5.00000 | 4.72273 | 33.12003 |

| 27.20000 | 50.00000 | 18.00000 | 1.09322 | 27.59991 |

| 27.20000 | 50.00000 | 5.00000 | 3.93560 | 27.59996 |

| 16.20000 | 70.00000 | 18.00000 | 0.65593 | 16.55990 |

| 16.20000 | 70.00000 | 5.00000 | 2.36136 | 16.55998 |

| 78.20000 | 0.00000 | 18.00000 | 3.09747 | 78.20009 |

| 78.20000 | 0.00000 | 5.00000 | 11.15088 | 78.20001 |

| 47.20000 | 40.00000 | 18.00000 | 1.85848 | 46.92000 |

| 47.20000 | 40.00000 | 5.00000 | 6.69053 | 46.92002 |

| 39.20000 | 50.00000 | 18.00000 | 1.54873 | 39.09992 |

| 39.20000 | 50.00000 | 5.00000 | 5.57544 | 39.10000 |

| 23.20000 | 70.00000 | 18.00000 | 0.92924 | 23.46000 |

| 23.20000 | 70.00000 | 5.00000 | 3.34526 | 23.45997 |

| System Type | Minimum Estimate | Maximum Estimate |

|---|---|---|

| Submerged Architecture | 24,598,080 | 61,495,200 |

| Conventional Cooling Tower | 49,322,304 | 98,644,608 |

| Scenario | Water Temperature (°C) | IT Load (% of Design) | Submerged System PUE | Cooling Energy Saving vs. Tower (%) | CO2 Reduction vs. Tower (%) |

|---|---|---|---|---|---|

| (A) Low-T water + high load | 5 | 95 | 1.06 | ~66 | ~75 |

| (B) High-T water + low load | 25 | 40 | 1.15–1.18 | ~40–45 | ~46–52 |

| (C) Baseline | 15 | 70 | 1.10–1.12 | ~55 | ~60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Tang, Y.; Ji, X.; Chen, Y. A Submerged Building Strategy for Low-Carbon Data Centers in Coal Mining Subsidence Areas: System Design and Energy–Carbon Performance Assessment. Buildings 2025, 15, 3148. https://doi.org/10.3390/buildings15173148

Hu Y, Tang Y, Ji X, Chen Y. A Submerged Building Strategy for Low-Carbon Data Centers in Coal Mining Subsidence Areas: System Design and Energy–Carbon Performance Assessment. Buildings. 2025; 15(17):3148. https://doi.org/10.3390/buildings15173148

Chicago/Turabian StyleHu, Yixiao, Yuben Tang, Xiang Ji, and Yidong Chen. 2025. "A Submerged Building Strategy for Low-Carbon Data Centers in Coal Mining Subsidence Areas: System Design and Energy–Carbon Performance Assessment" Buildings 15, no. 17: 3148. https://doi.org/10.3390/buildings15173148

APA StyleHu, Y., Tang, Y., Ji, X., & Chen, Y. (2025). A Submerged Building Strategy for Low-Carbon Data Centers in Coal Mining Subsidence Areas: System Design and Energy–Carbon Performance Assessment. Buildings, 15(17), 3148. https://doi.org/10.3390/buildings15173148