1. Introduction

Coal gangue is one of the most generated industrial solid wastes in China [

1], with a stockpiled amount exceeding 7 billion metric tons. Its long-term accumulation has led to severe environmental issues, including occupation of land resources, pollution of water and soil, and geological hazards such as landslides [

2,

3,

4,

5]. To address these challenges, researchers have explored the recycling of coal gangue as a construction material [

6,

7,

8,

9,

10,

11]. Crushing it for use in concrete and cement-based products not only contributes to resource utilization but also reduces reliance on natural aggregates, thereby alleviating the ecological impacts of mining [

12,

13]. Currently, masonry construction continues to dominate in China’s building industry [

14,

15,

16]. The development of coal gangue concrete blocks—which exhibit advantages such as lightweight properties and enhanced thermal insulation [

17,

18,

19,

20]—aligns with the national strategy of promoting green wall materials and contributes to sustainable urbanization under the “dual carbon” goals [

21].

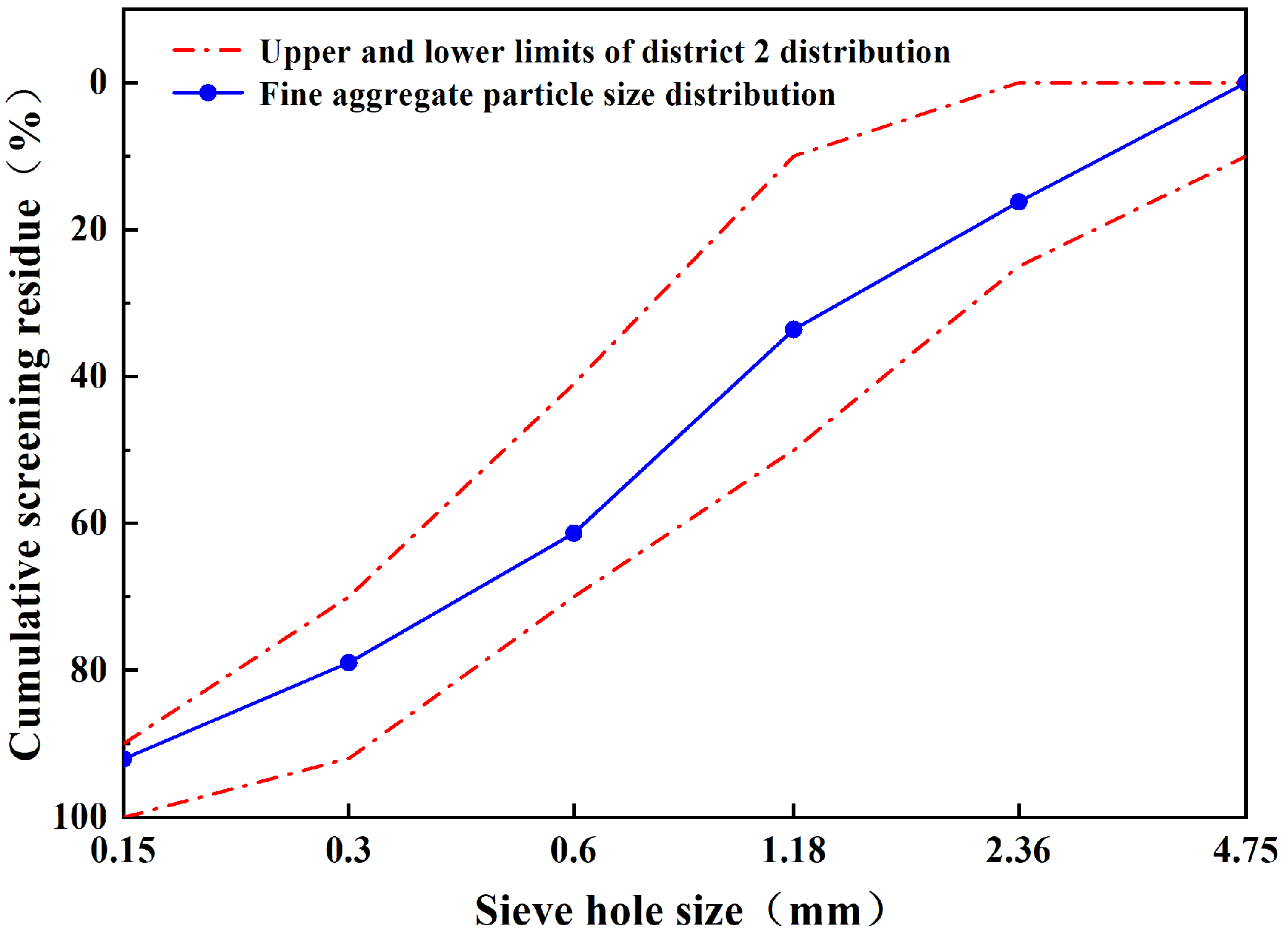

In recent years, coal gangue has made notable progress as a substitute for natural aggregates in the field of construction engineering. For instance, Dong [

22] prepared coal gangue concrete and mortar using raw and calcined coal gangue as coarse and fine aggregates, respectively. The results indicated that calcination significantly upgraded the quality of coal gangue aggregates, thereby improving the performance of the resulting concrete and mortar. Similarly, Zuo [

23] proposed strengthening coal gangue coarse aggregates with cement-based coatings, which effectively optimized the interfacial transition zone and enhanced the mechanical properties of the concrete. Furthermore, Mahmoud Al Khazaleh et al. [

24] utilized coal gangue to replace coarse aggregates in the preparation of structural concrete, enhanced in compressive strength, splitting tensile strength, and flexural strength. In parallel, Shan Gao et al. [

25] developed a predictive model for the compressive strength of coal gangue concrete, further demonstrating that coal gangue, when used as a coarse aggregate, exhibits favorable physical and mechanical performance and stands out as one of the preferred materials for concrete production. However, compared to natural aggregates, coal gangue aggregates exhibit certain drawbacks, such as a high crushing index, elevated porosity, and strong water absorption. These characteristics result in relatively poor mechanical properties of coal gangue concrete and limit its substitution rate. Moreover, the interfacial transition zone (ITZ) between the gangue aggregates and mortar is often weak. As a result, extensive research has been conducted by scholars both in China and abroad to improve aggregate quality and enhance the mechanical performance of coal gangue concrete. Ma et al. [

10] prepared alkali-activated coal gangue-slag concrete using both untreated and 700 °C calcined coal gangue as coarse aggregates. The results indicated that calcined coal gangue exhibited higher compressive strength and better durability when used as coarse aggregate in alkali-activated coal gangue-slag concrete. Moreover, Fan et al. [

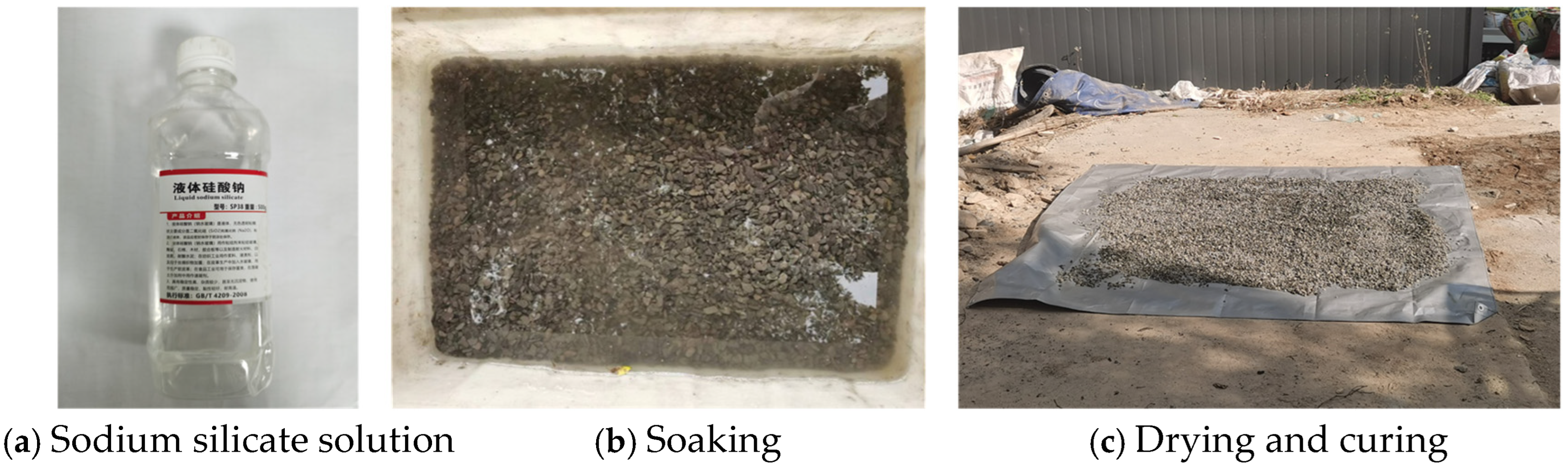

26] demonstrated that soaking recycled aggregates in 5% sodium silicate solution maximized the compressive strength of recycled concrete, a conclusion further supported by Qiu et al. [

27]. These studies collectively suggest that low-cost modification methods can significantly improve coal gangue aggregates, offering a viable pathway for the resource utilization of solid waste in cement-based products.

With the progressive improvement in the performance of coal gangue aggregates, a solid foundation has shown promising potential of coal gangue concrete at the level of structural components. Further processing coal gangue concrete into blocks not only extends the advantages of its resource utilization but also integrates the inherent benefits of masonry structures, such as design flexibility, ease of maintenance, and excellent thermal insulation performance, thereby demonstrating strong application potential. Experimental investigations by Qi et al. [

28] demonstrated that recycled concrete blocks exhibit sufficient mechanical strength and frost resistance, making them suitable in seismic-resistant masonry systems. Izquierdo et al. [

29,

30] developed sisal fiber-reinforced concrete hollow blocks, observing a trade-off between reduced compressive strength and enhanced ductility, accompanied by a transition from brittle to progressive failure modes. In parallel, Gunasekaran et al. [

31] successfully substituted natural aggregates with coconut shells, achieving compliant compressive strength while mitigating shrinkage-induced cracking through the organic material’s internal curing effects. Furthermore, Zheng et al. [

32,

33] investigated the influence of alkali-activated slag mortar strength on the bond performance of hollow block masonry and proposed a shear bond strength formula for design use. J.J. et al. [

34] optimized masonry block geometry via finite element analysis, reducing self-weight while maintaining strength, and proposed a new strategy for lightweight masonry design. These case studies collectively substantiate that through material modification and structural optimization, masonry blocks can achieve multiple performance enhancements. However, research on the application of coal gangue in masonry blocks remains relatively limited, particularly regarding its mechanical performance and the underlying microstructural mechanisms, which still lack systematic investigation and theoretical support.

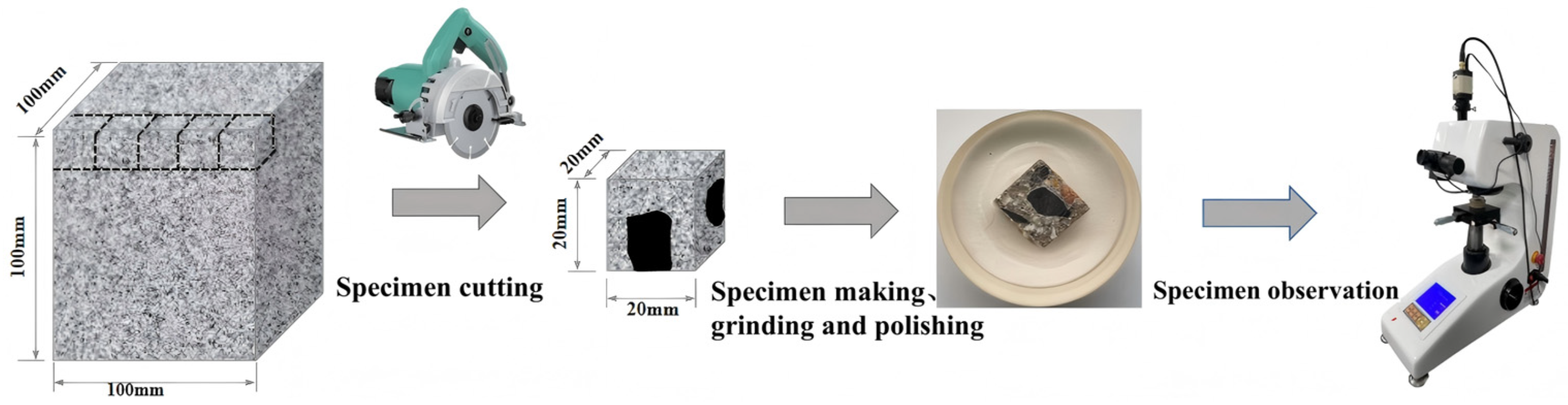

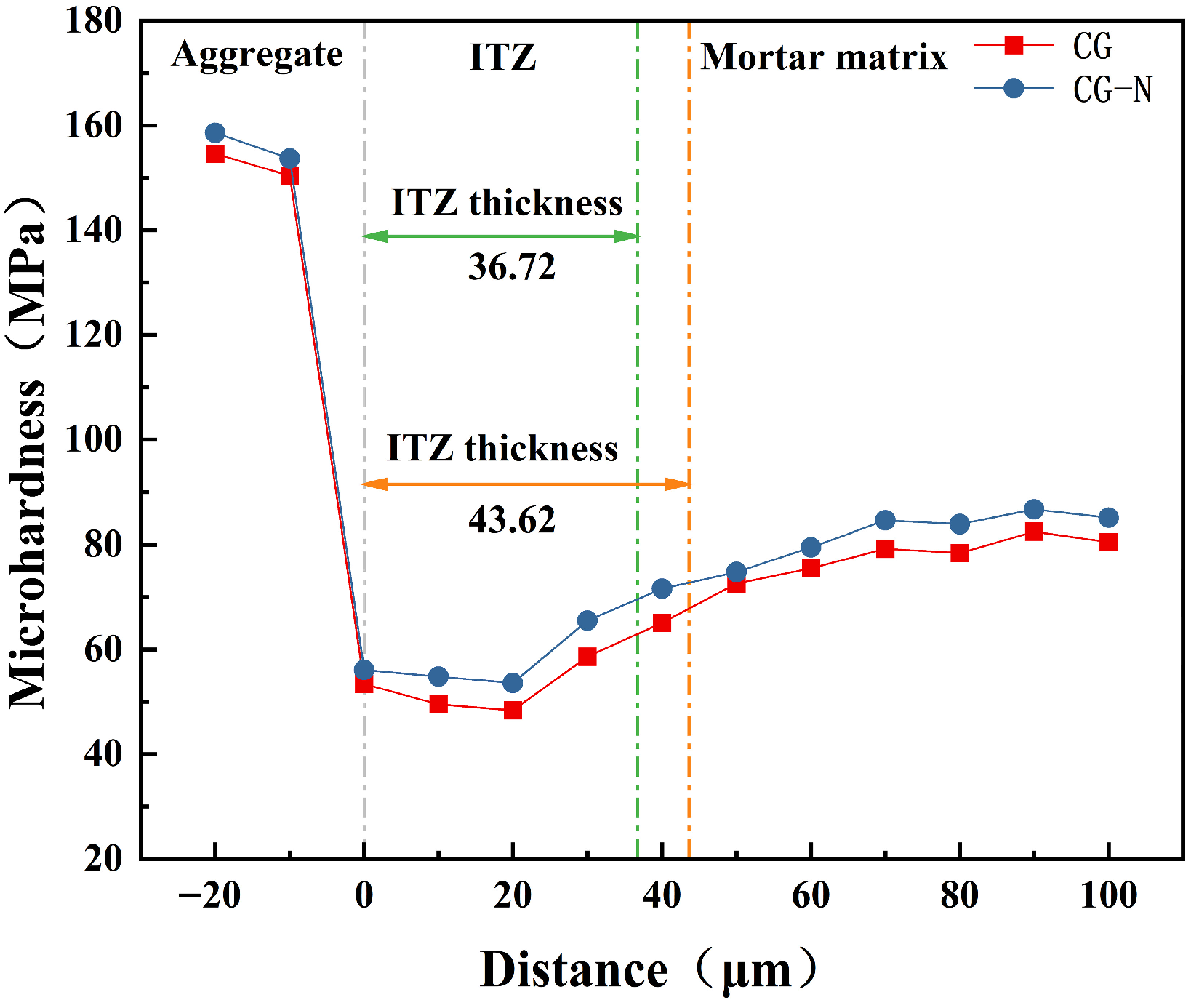

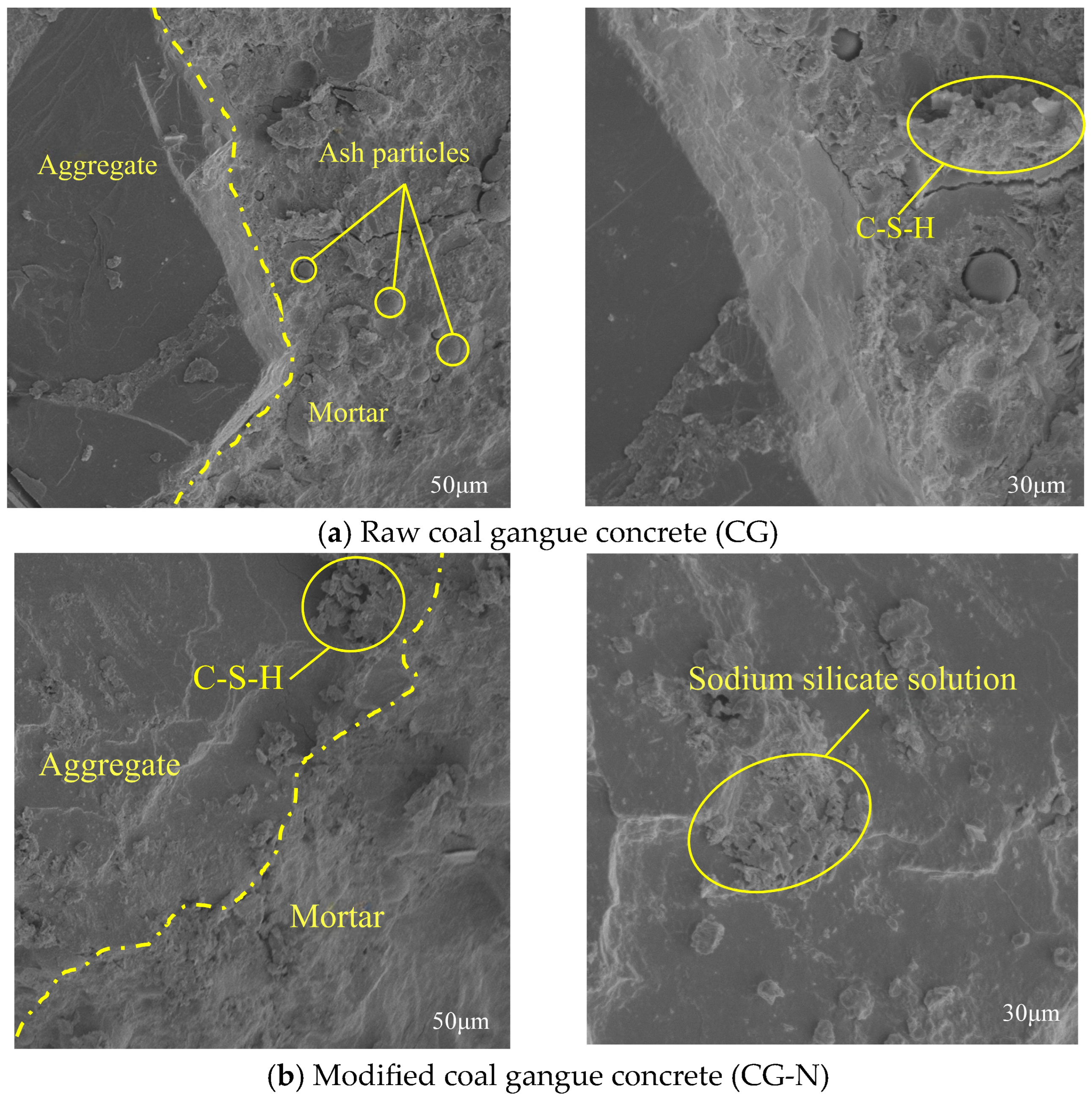

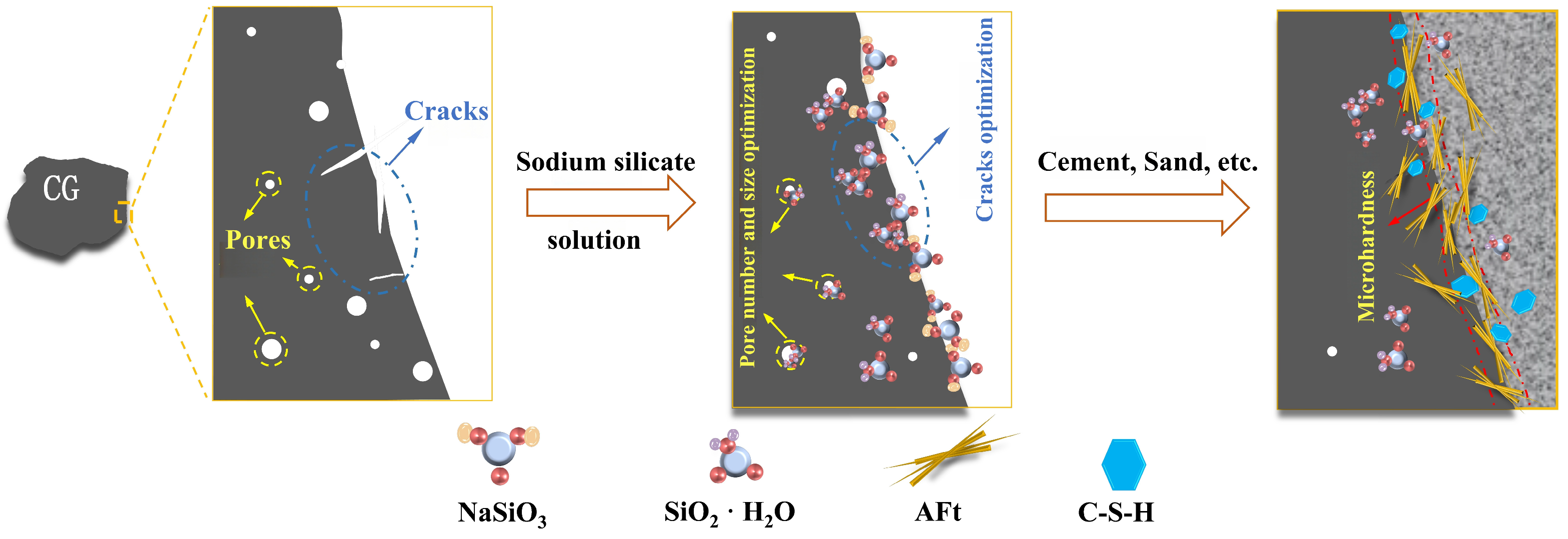

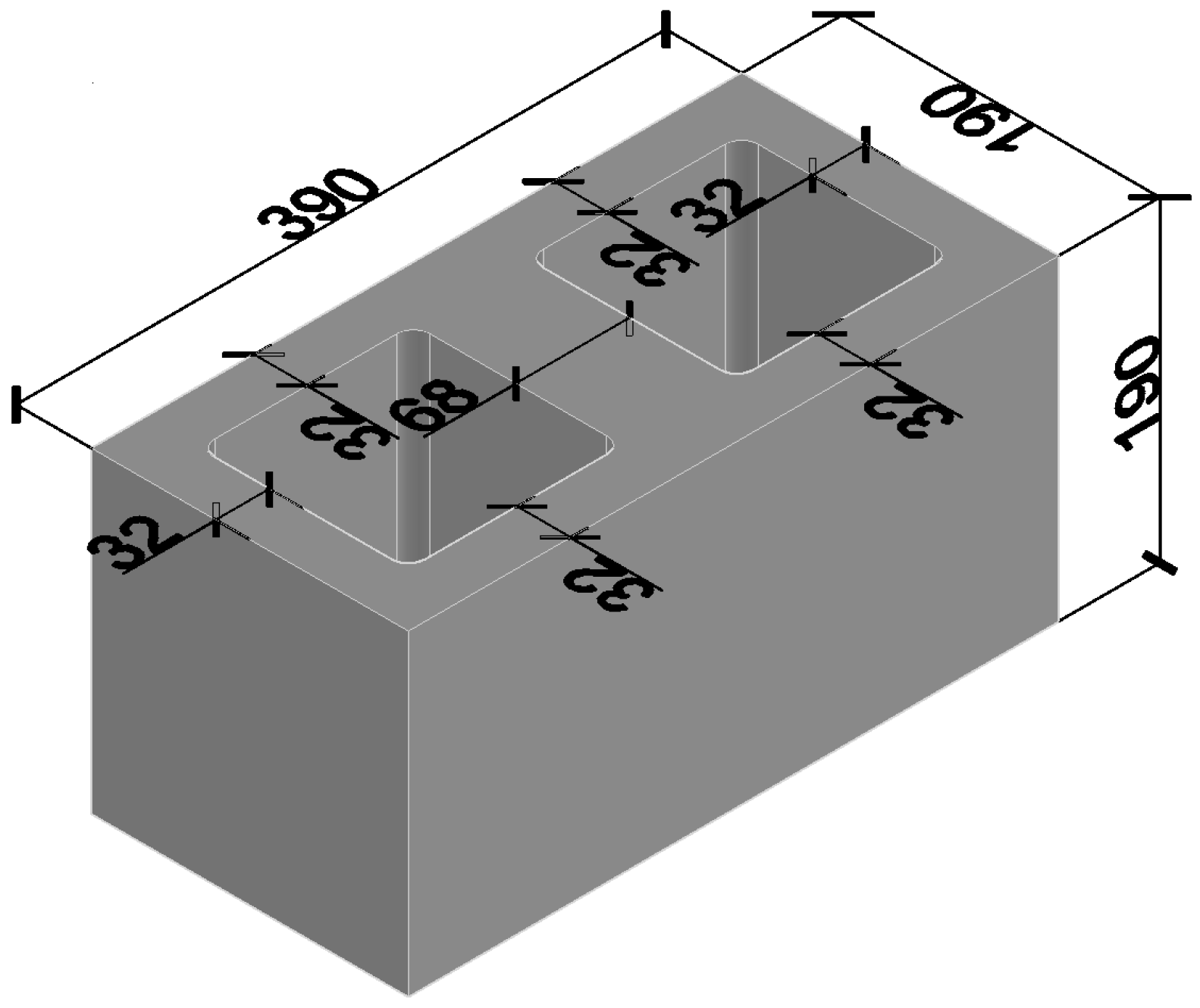

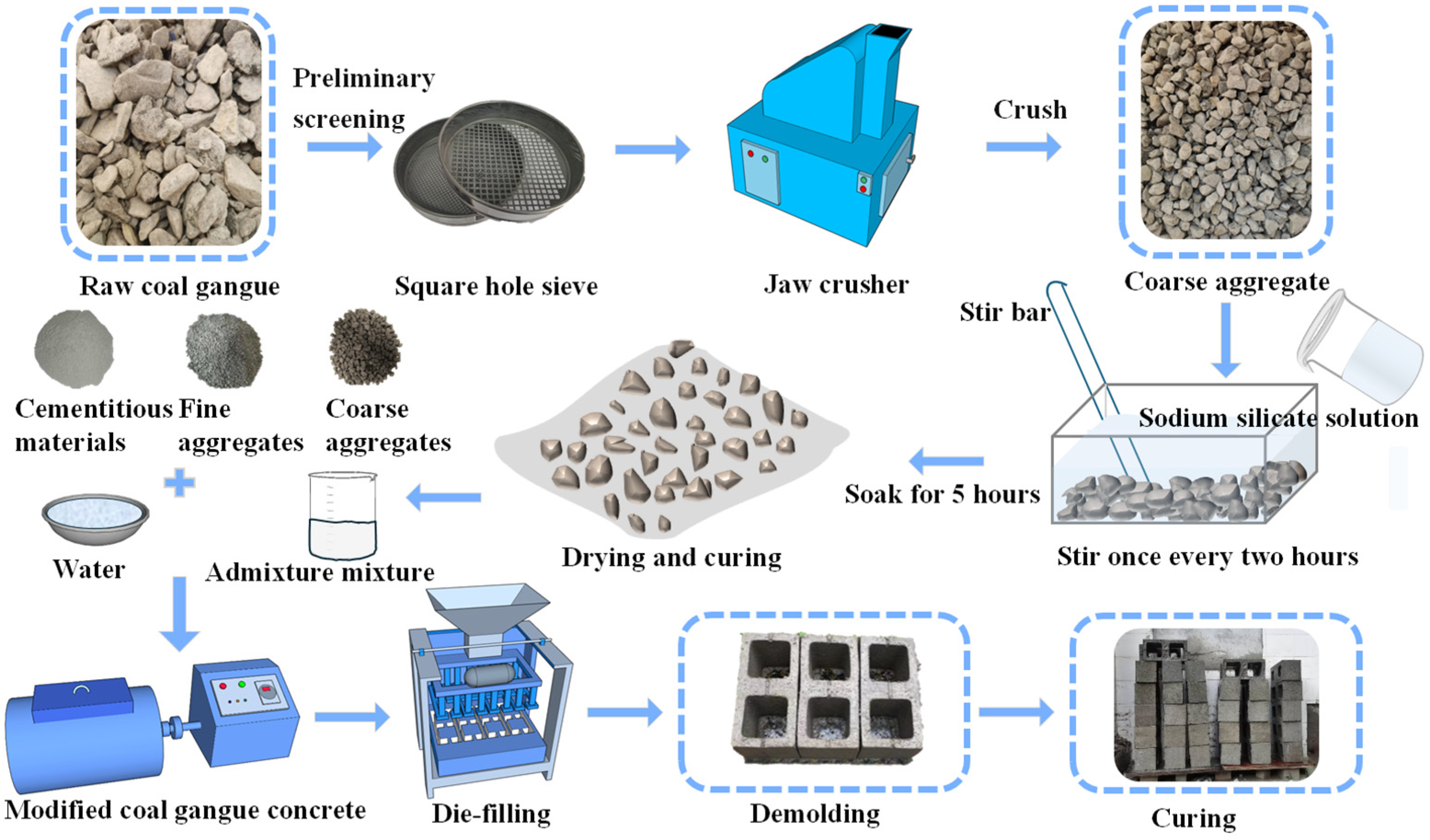

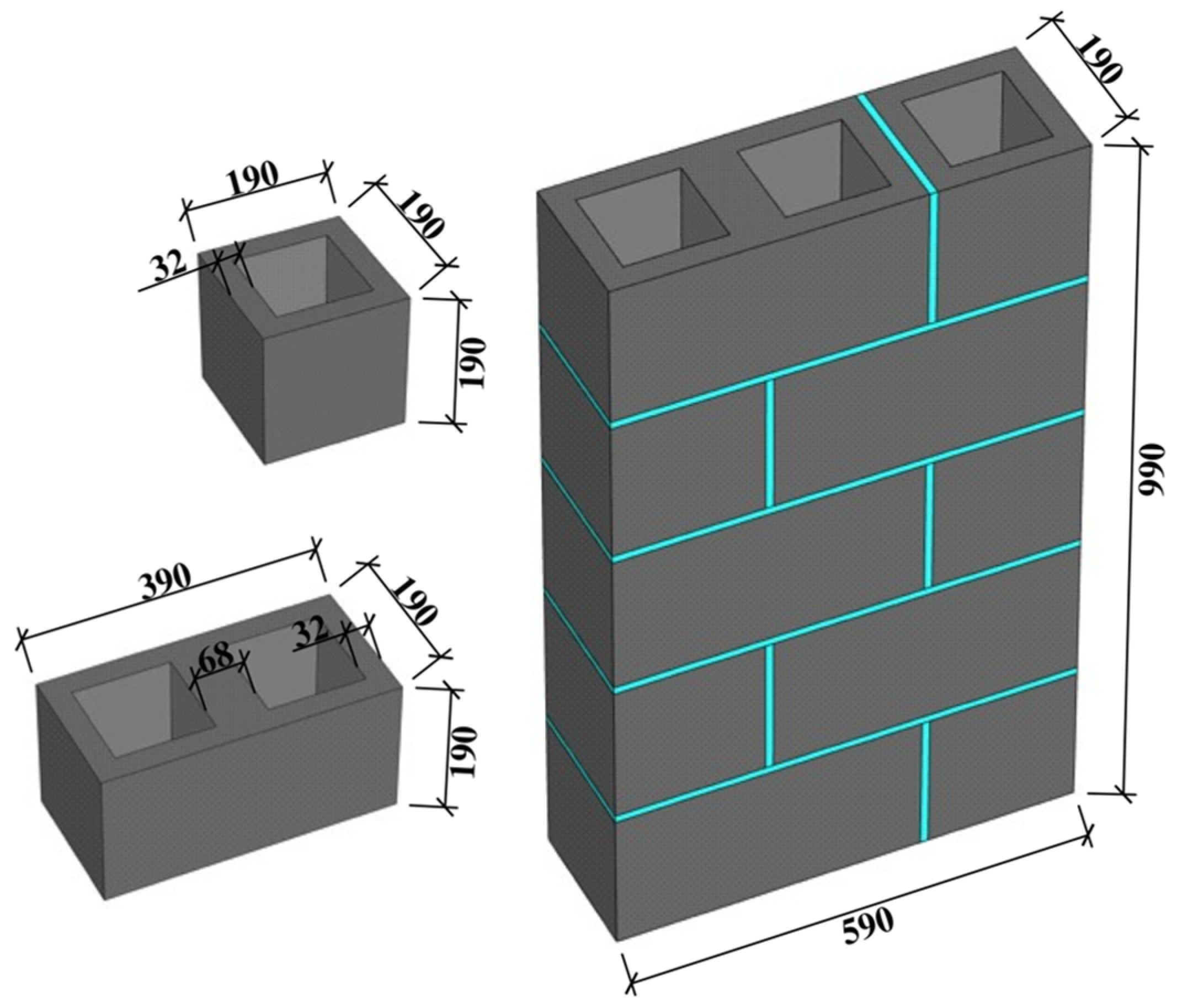

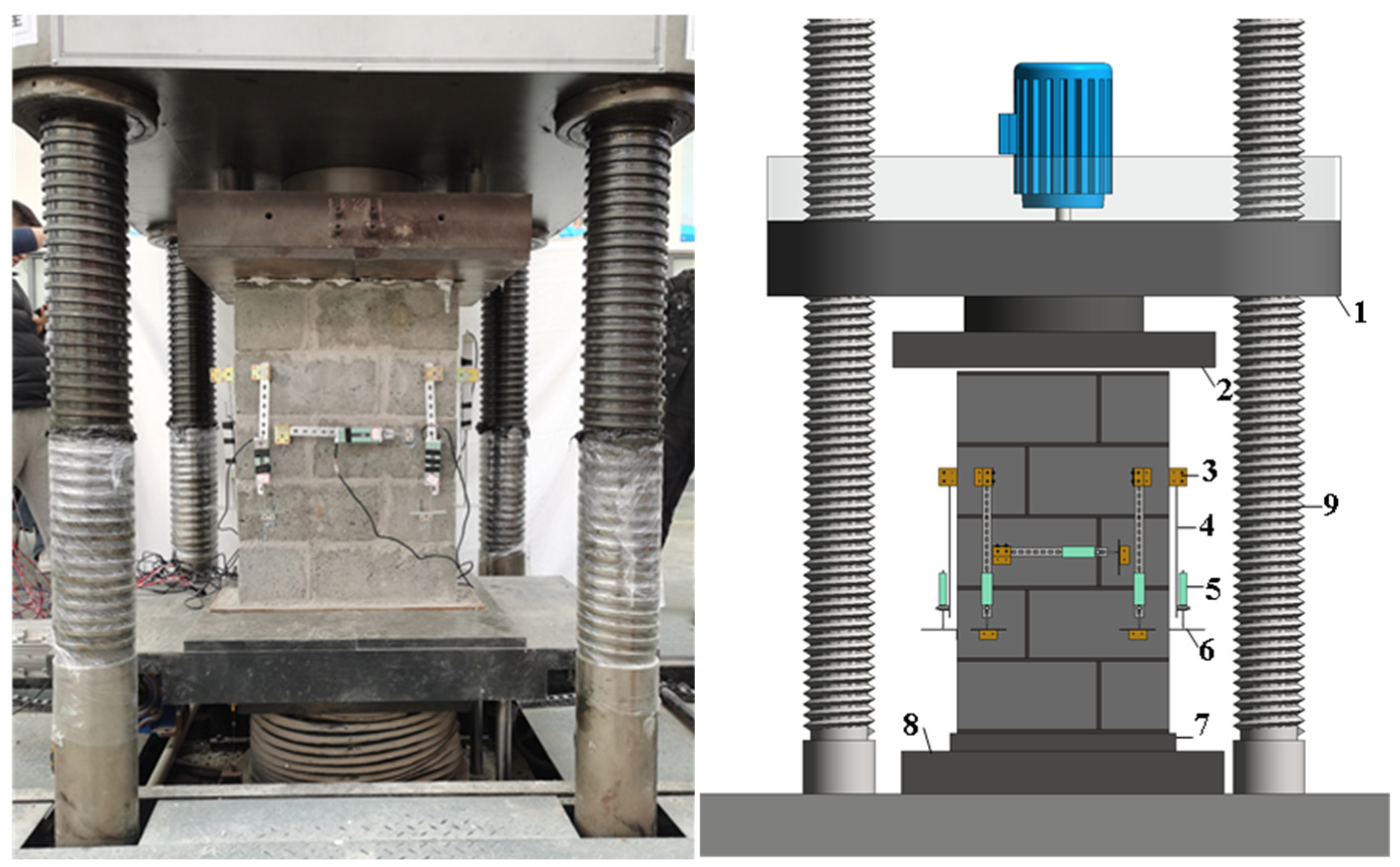

The above research provides valuable insights for the modification of coal gangue aggregates. To enhance the utilization efficiency of coal gangue and promote its high-value applications, while ensuring material cost, operational simplicity, and environmental sustainability, this study employs a 5% sodium silicate solution to modify coal gangue coarse aggregates. The microstructural characteristics of the interfacial transition zone (ITZ) in coal gangue concrete are systematically analyzed using a microhardness tester and scanning electron microscopy (SEM). Additionally, the study investigates the variation patterns in mechanical properties of modified coal gangue concrete blocks under different water-to-cement ratios and substitution rates, aiming to reveal the strengthening mechanism of the modification treatment on coal gangue concrete. At the same time, modified coal gangue concrete is used as the material for hollow blocks, and its physical and mechanical properties as well as engineering applicability are systematically tested. Upon assembling these blocks into masonry, compressive strength tests are conducted, resulting in the formulation of a bearing capacity formula tailored to the modified coal gangue masonry system. This study is conducted from two interconnected perspectives—“material modification” and “structural application”-providing a new pathway and theoretical foundation for the multi-scale and efficient utilization of coal gangue resources.

5. Conclusions

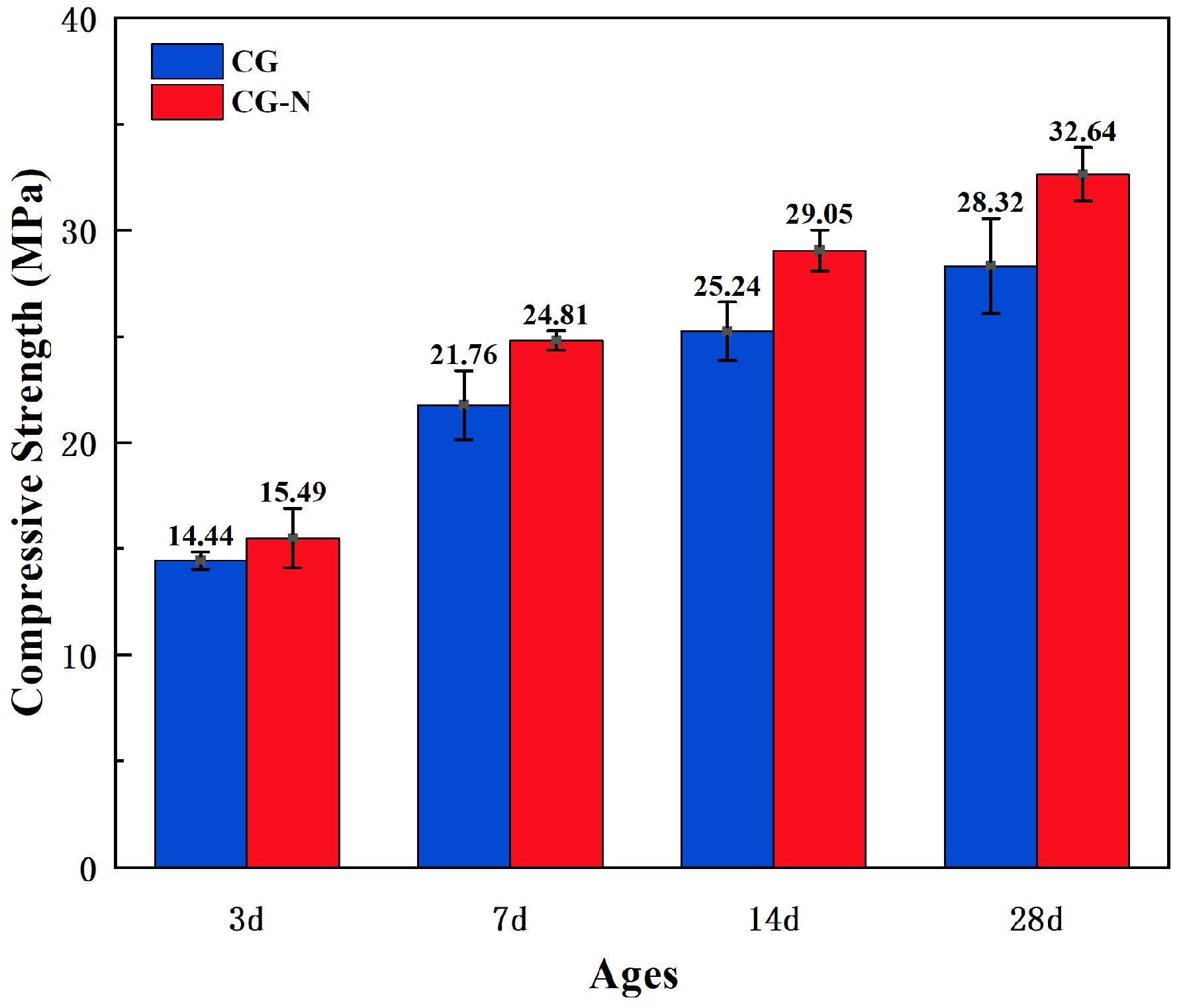

(1) The silicic acid gel formed through sodium silicate hydrolysis effectively filled and bound pores/cracks in coal gangue aggregates, mitigating their inherent defects. This modification improved aggregate quality by increasing apparent density, reducing water absorption, and lowering the crushing index. Consequently, the modified coal gangue significantly enhanced concrete compressive strength. Compared to raw gangue concrete, the modified variant exhibited higher strength at all tested curing ages, with increases of 10.7% (3 d), 12.3% (7 d), 15.1% (14 d), and 15.3% (28 d).

(2) The sodium silicate gel remaining on the surface of modified aggregates reacted with Ca(OH)2 through hydrolysis. This reaction accelerated the hydration of cementitious materials, leading to the formation of additional high-strength, stable flocculent calcium silicate hydrate (C-S-H) and acicular rod-shaped ettringite (AFt) mixtures. These products filled pores and cracks in the interfacial transition zone (ITZ) of concrete and effectively improved the ITZ performance between coal gangue coarse aggregates and cement mortar. Consequently, the compactness of the interfacial transition zone was significantly enhanced.

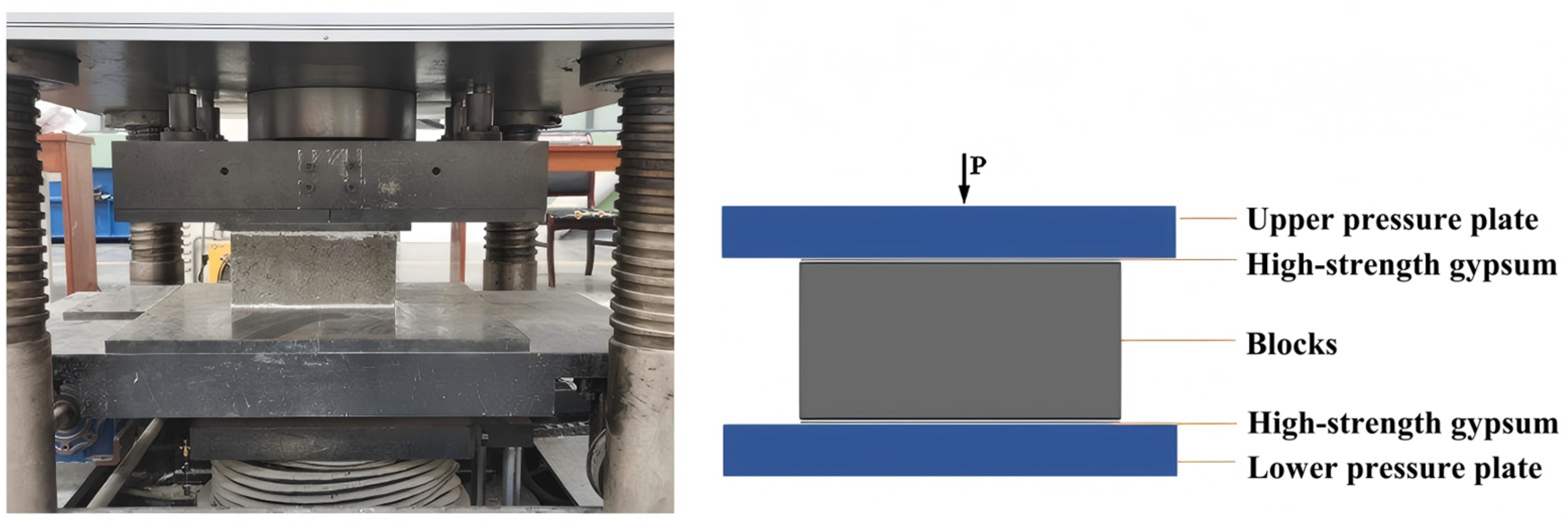

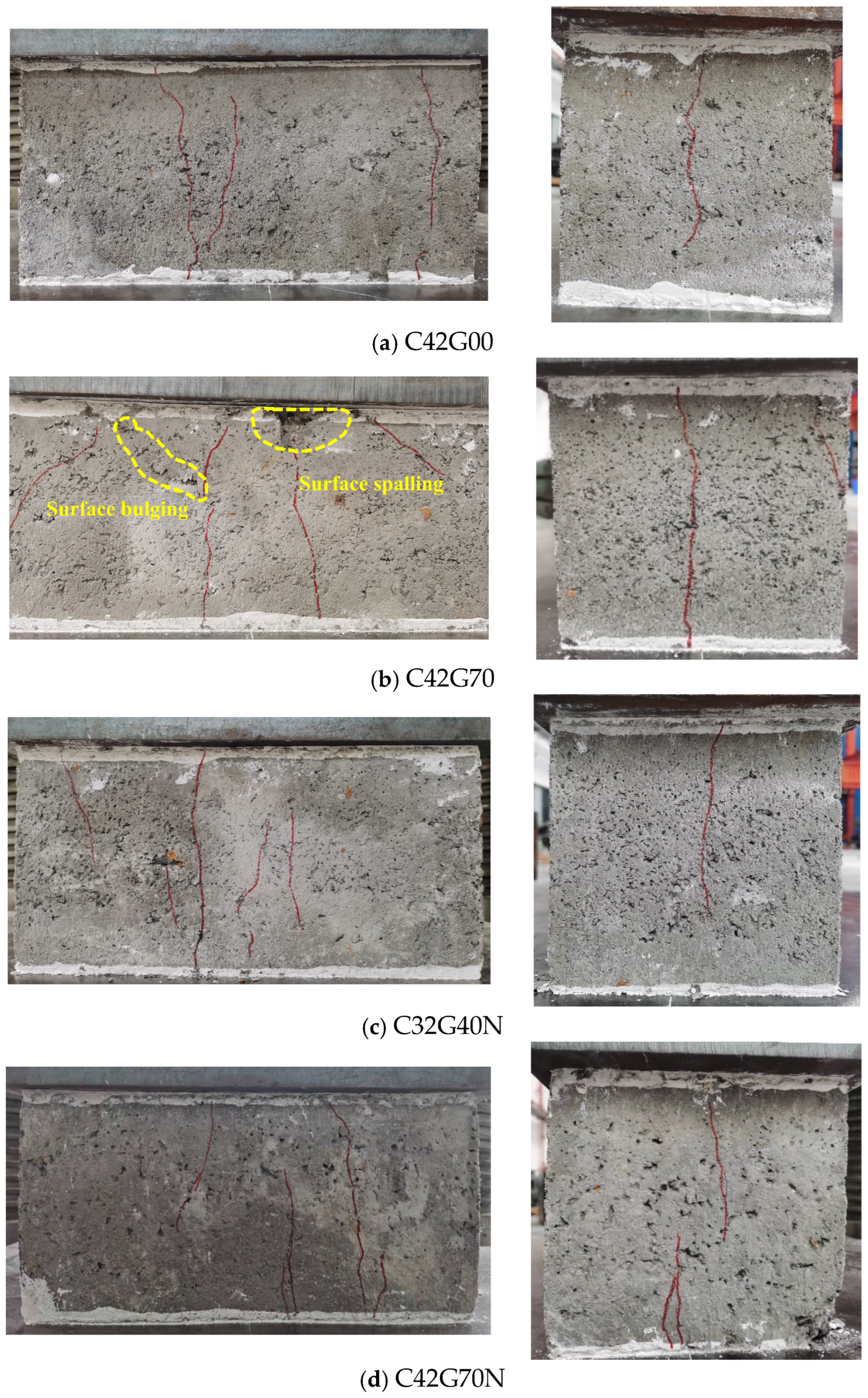

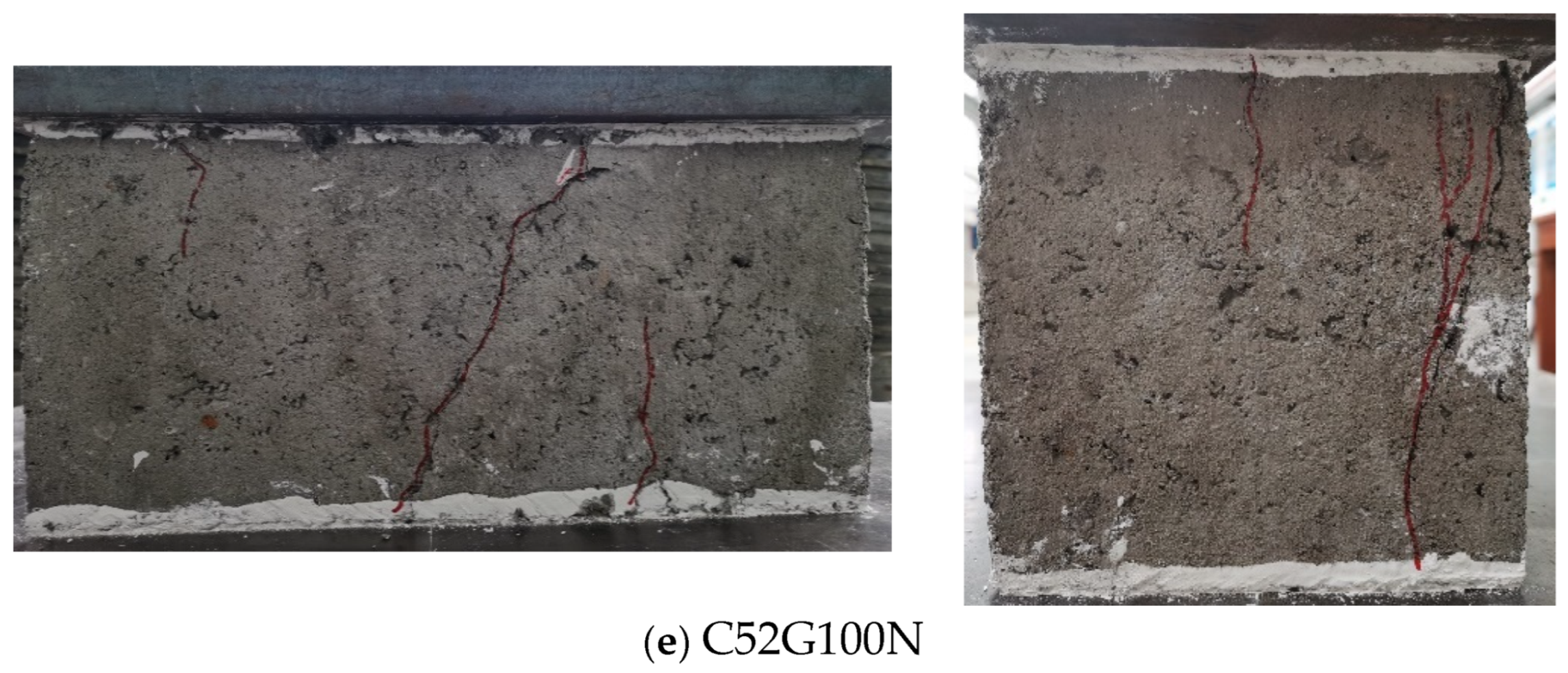

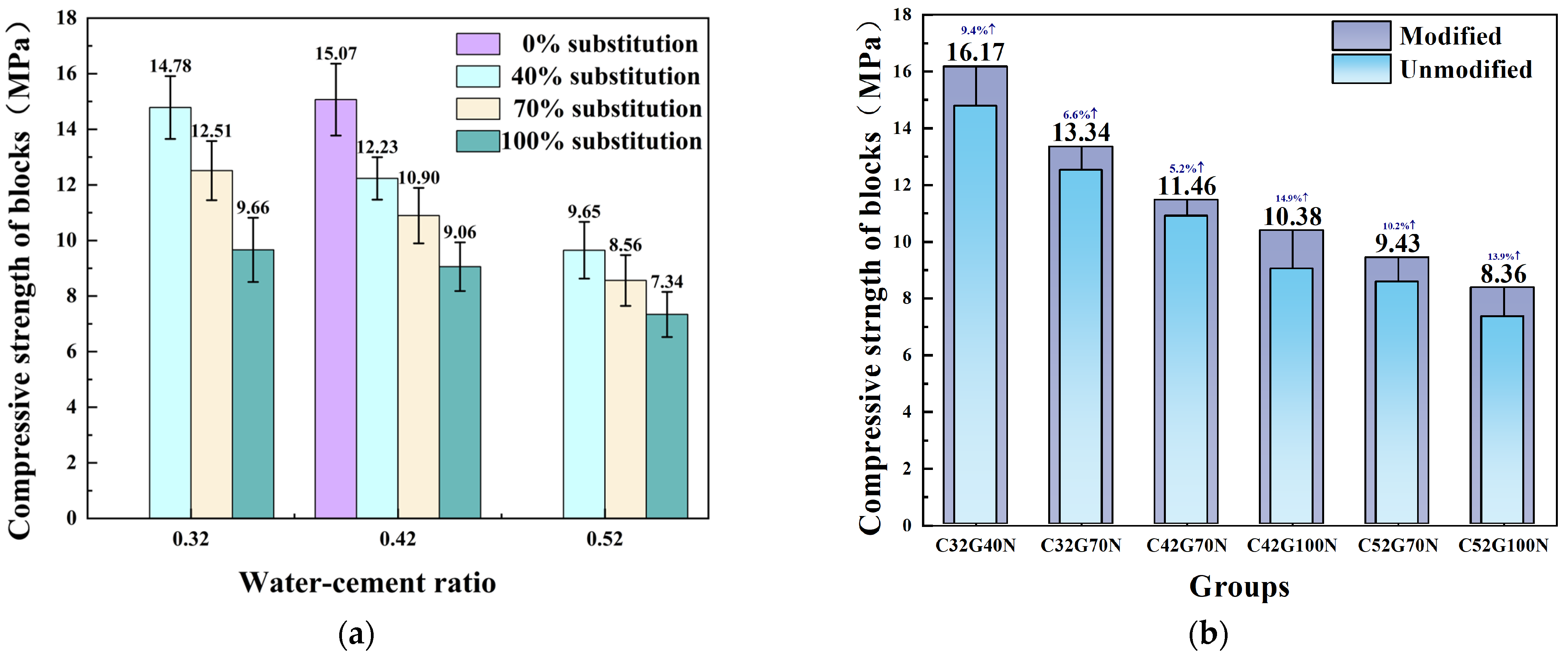

(3) The variation pattern of compressive strength in modified coal gangue concrete blocks was fundamentally similar to that of conventional coal gangue concrete blocks. When the replacement ratio of coal gangue in modified blocks remained constant, their compressive strength gradually decreased with increasing water–cement ratio. Under fixed water–binder ratios, the compressive strength showed a declining trend as the replacement ratio of coal gangue aggregate increased. The average compressive strengths of specimen groups C32G40N, C42G100N, and C52G100N were 16.17 MPa, 10.38 MPa, and 8.36 MPa, respectively, meeting the required strength grades of MU15, MU10, and MU7.5 for experimental validation.

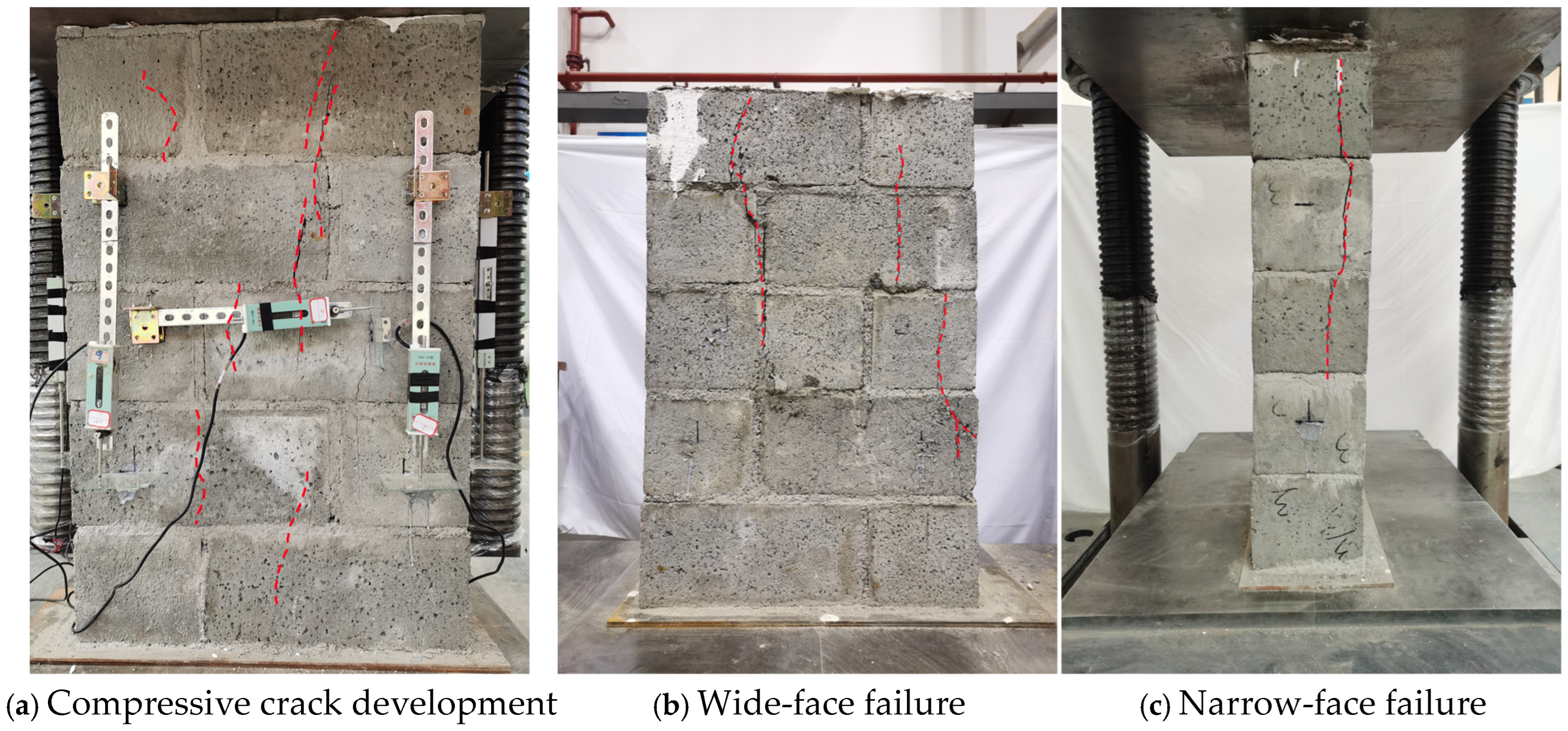

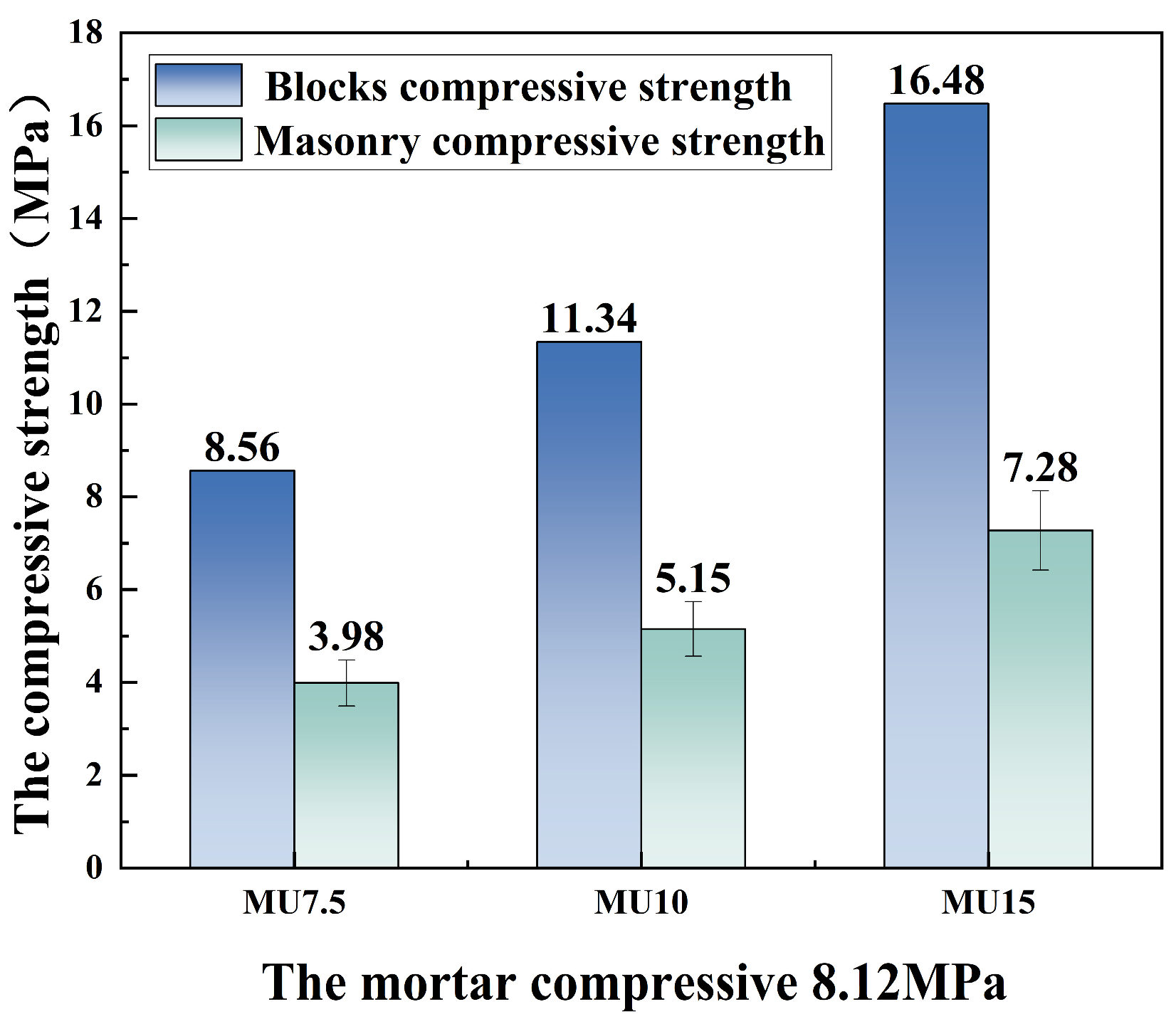

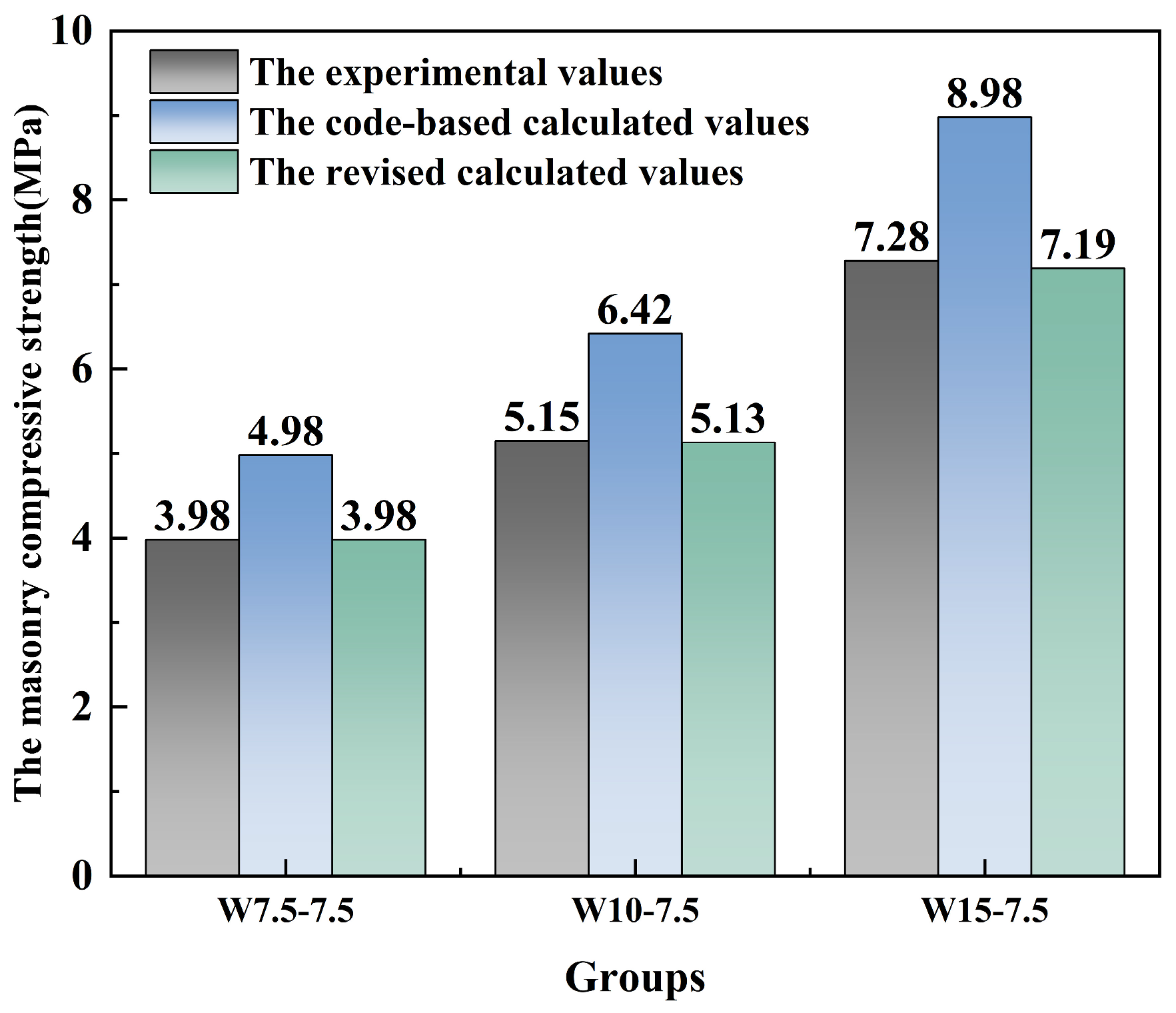

(4) The compressive strength of modified coal gangue concrete hollow block masonry increased significantly with the enhancement of block strength grade, with the average compressive strength of MU15 masonry being approximately 83% higher than that of MU7.5. And a calculation model for the average compressive strength of modified coal gangue concrete masonry was proposed based on compression tests.