Design and Performance of High-RAP-Content Asphalt Mixture: A Case Study in Jianghe Expressway

Abstract

1. Introduction

- (1)

- Mix design of hot mix asphalt with high RAP content. Based on the material composition analysis of recycled mixtures, a 50% RAP incorporation scheme is designed using the Marshall method to evaluate the engineering performance of the recycled mixture.

- (2)

- Evaluation of aggregate gradation and asphalt content in high-RAP-content asphalt mixtures.

- (3)

- Assessment of field performance indicators of the high-RAP-content asphalt test section, including surface smoothness, layer thickness, and permeability coefficient.

2. Materials

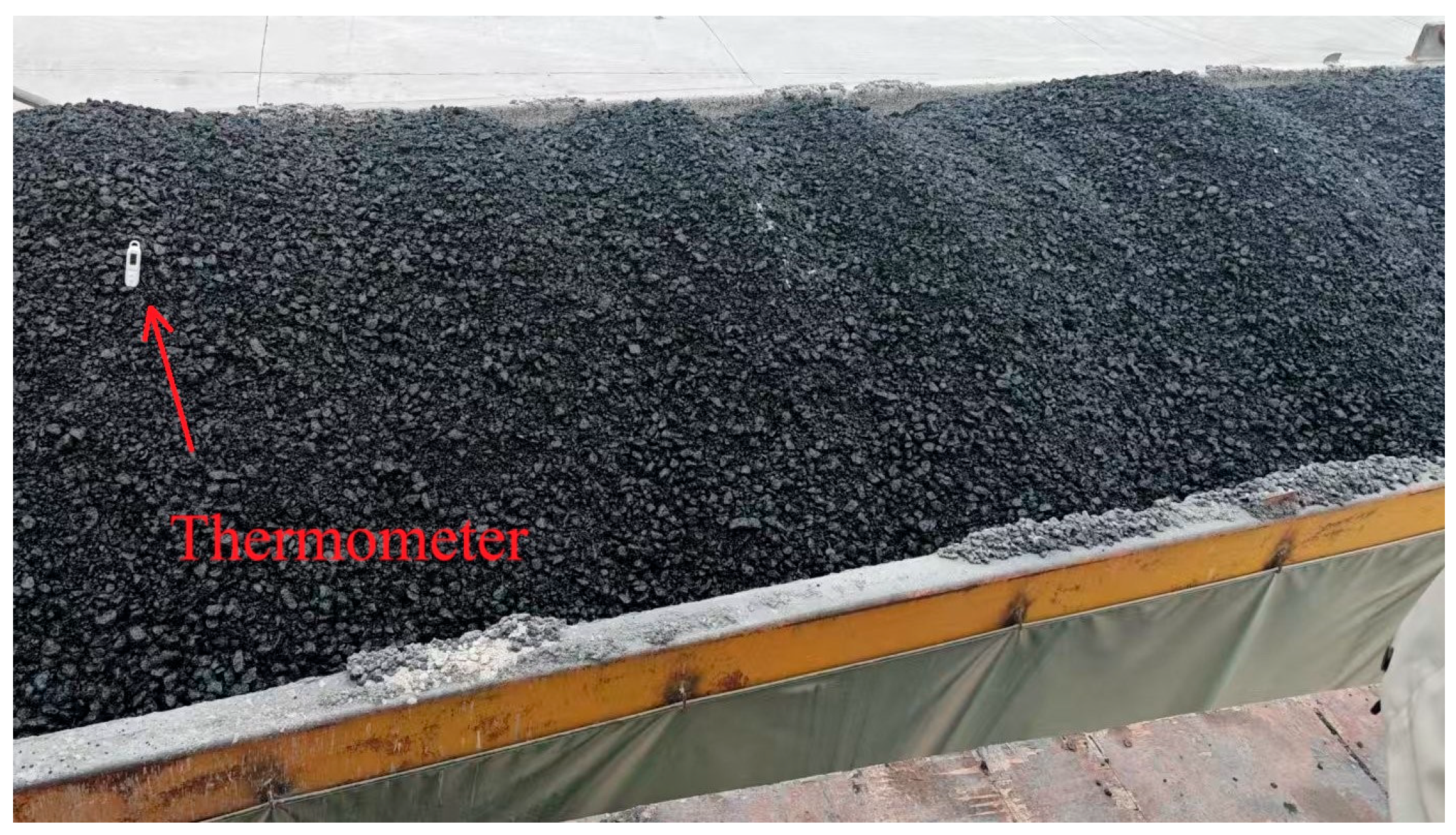

2.1. Reclaimed Asphalt Pavement

2.2. Asphalt

2.3. Aggregate

2.4. Mineral Powder

2.5. Additive

3. Methodology

3.1. Research Plan

3.2. Testing Methods

4. Results and Analysis

4.1. Marshall Mix Design Method

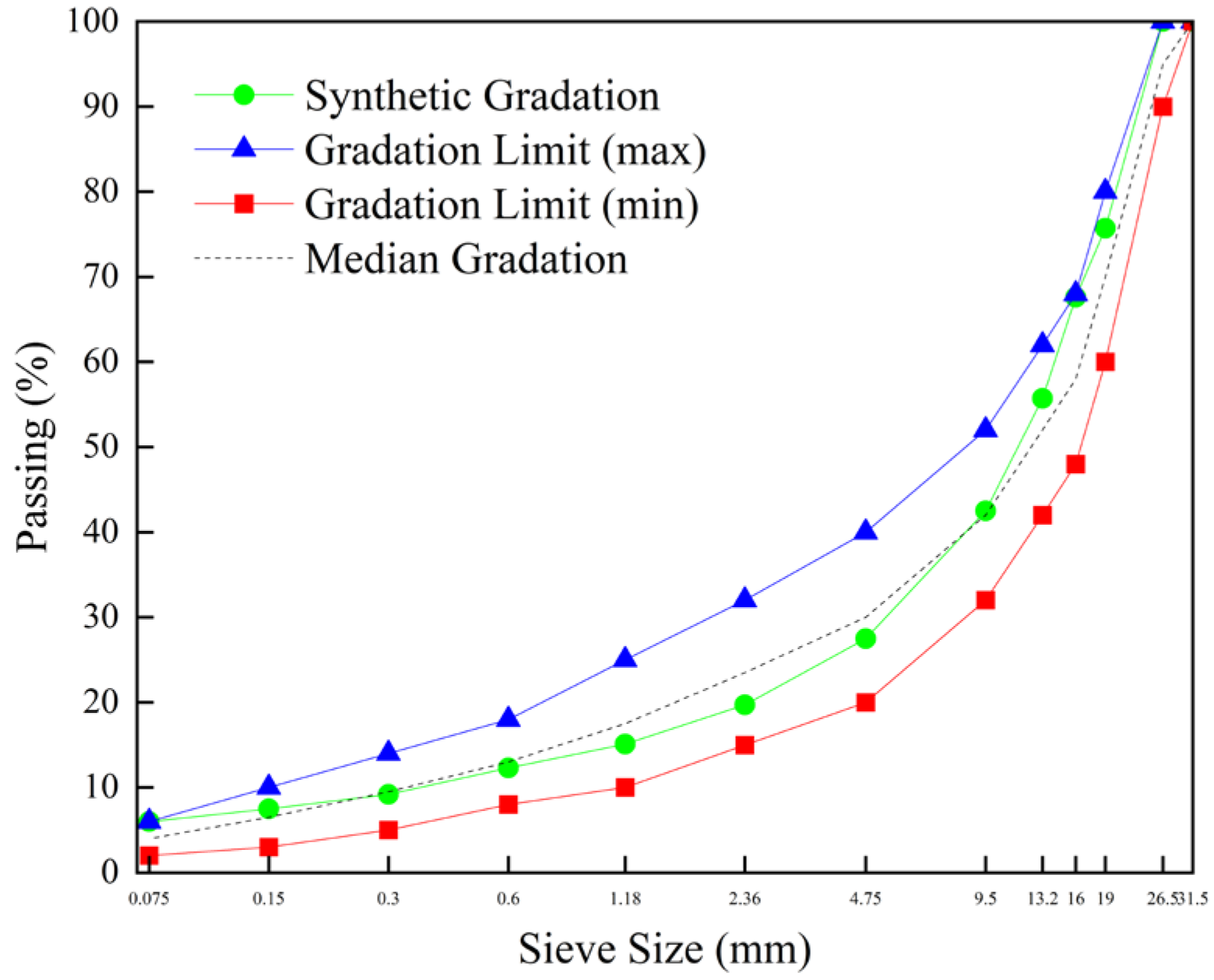

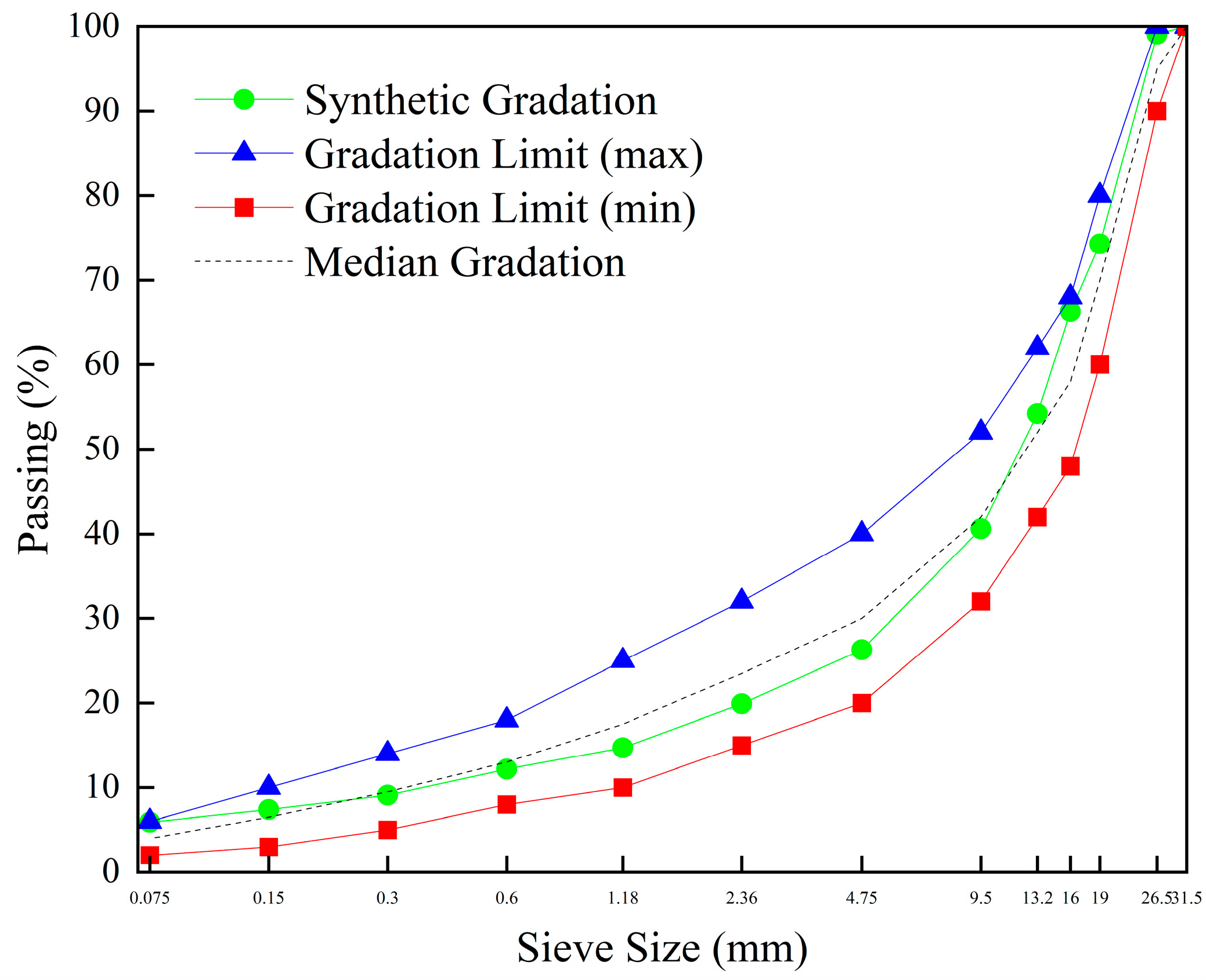

4.1.1. Grading Curve Design

4.1.2. Determination of the Optimal Asphalt Dosage

4.2. Mixture Gradation and Performance Testing

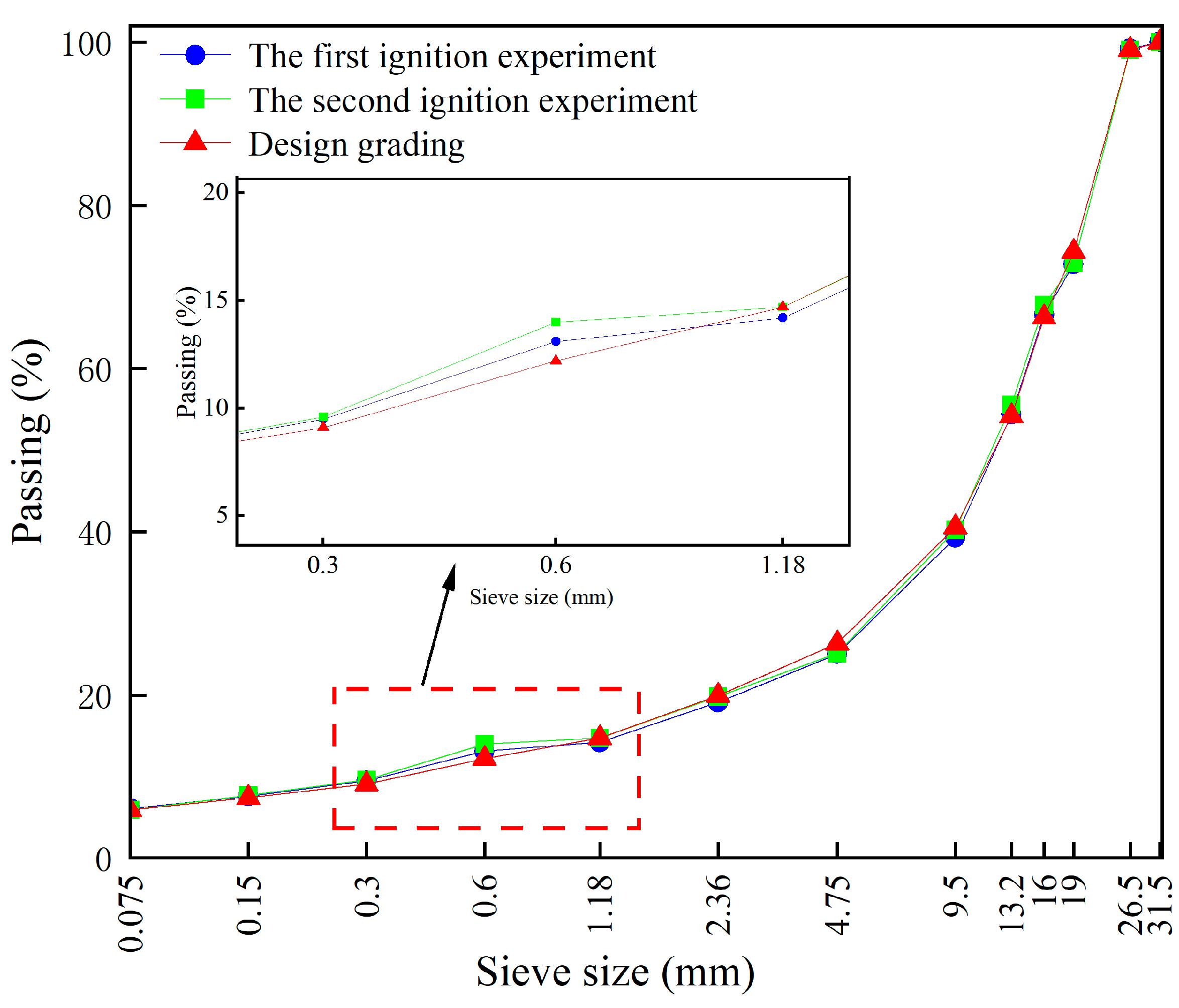

4.2.1. Combustion Test and Screening Test of Asphalt Mixture

4.2.2. Marshall Test

4.3. Road Quality Inspection

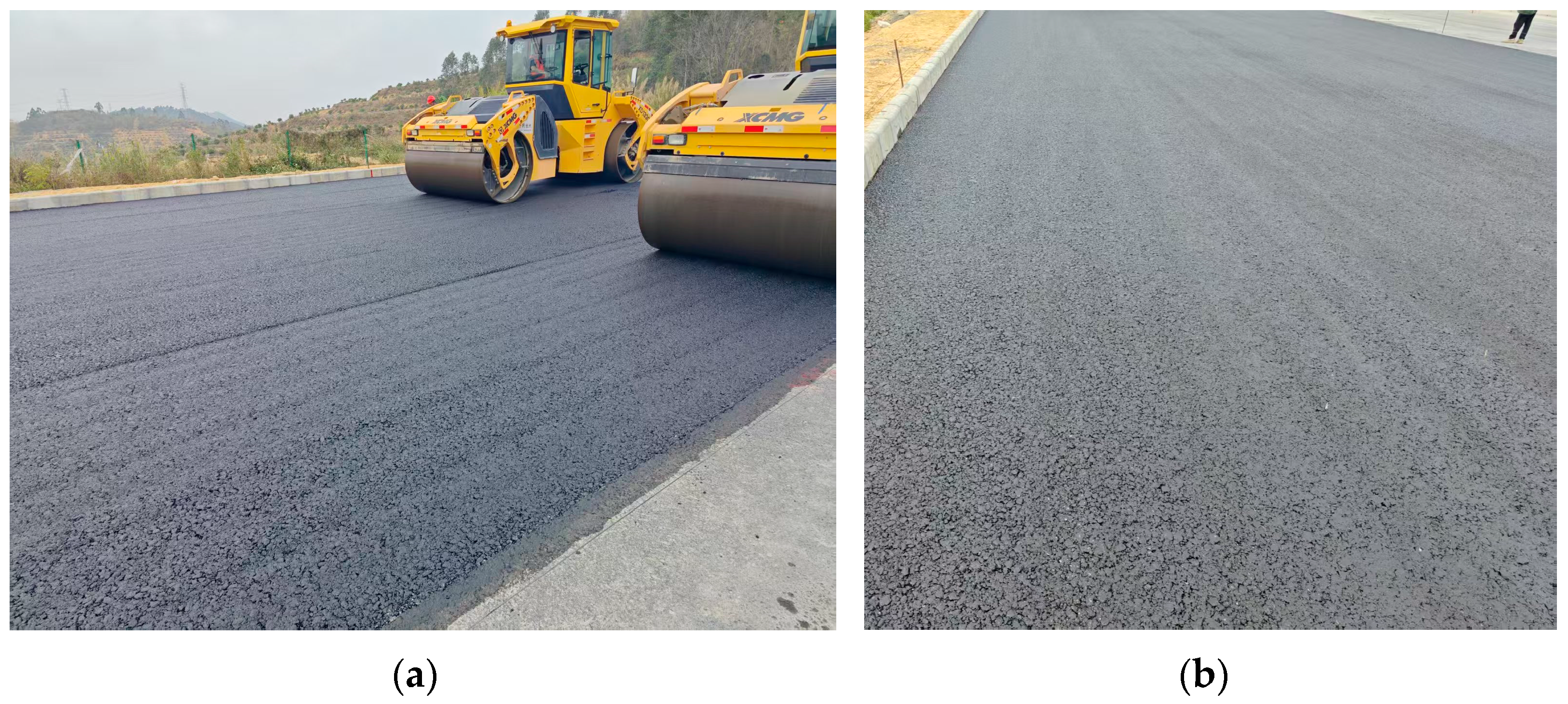

4.3.1. Material Shoving

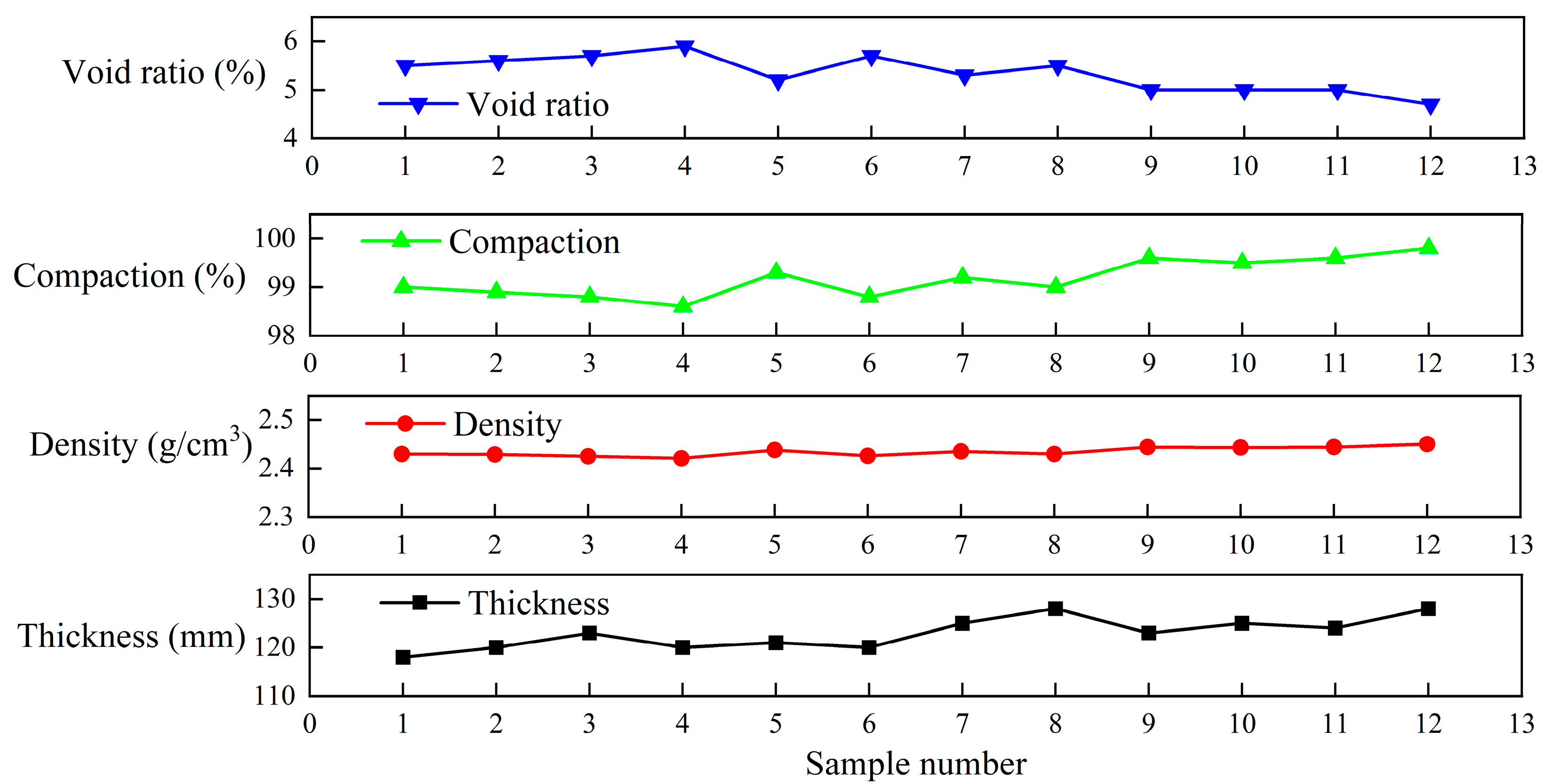

4.3.2. Pavement Thickness Detection

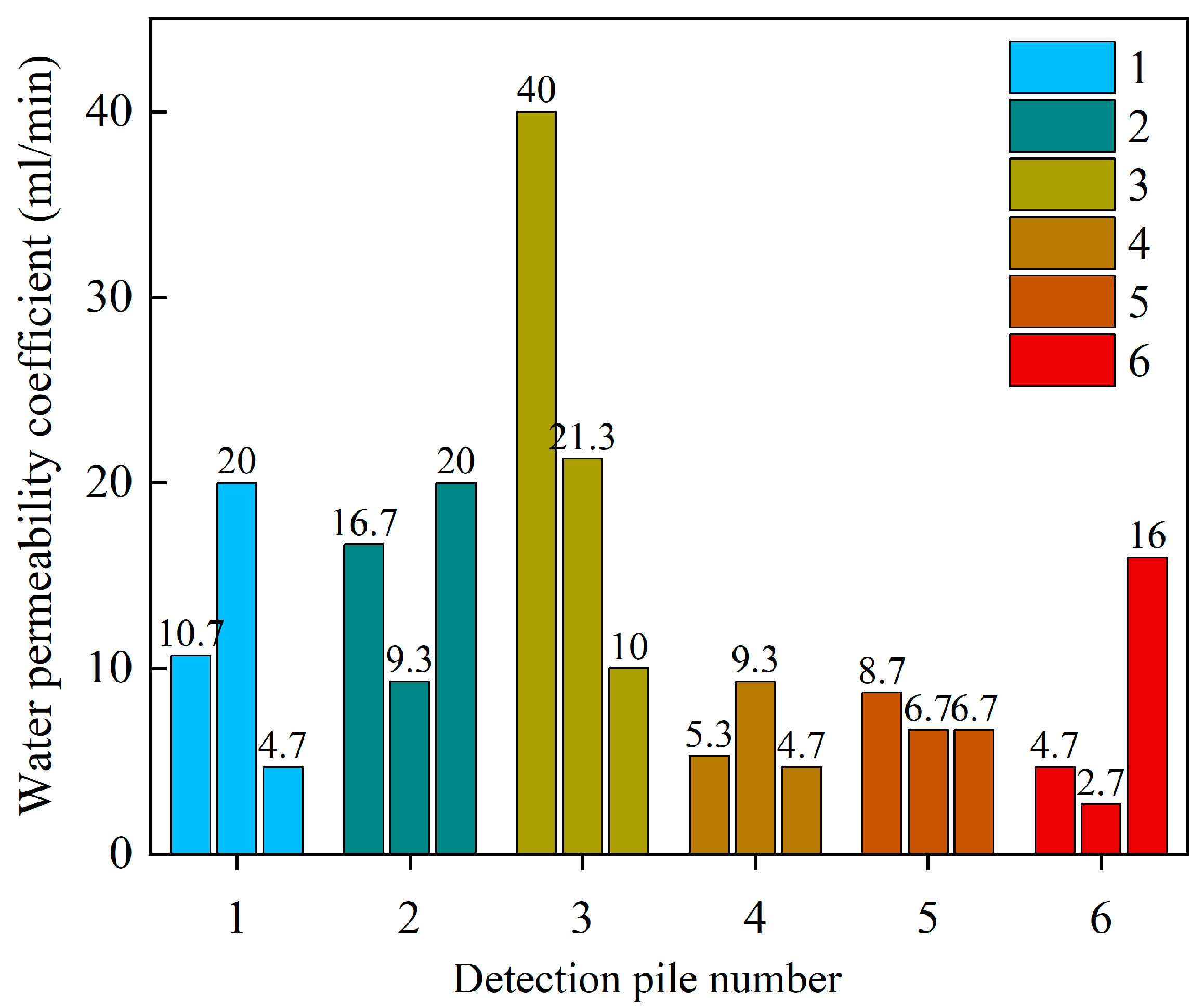

4.3.3. Water Permeability Coefficient

4.3.4. Continuous Flatness Tester

5. Conclusions

- (1)

- The hot central plant recycling ATB-25 asphalt mixture and corresponding engineering indicators met the specification requirements, providing a practical reference for large-scale construction projects.

- (2)

- According to the Marshall mix design, the optimum asphalt–aggregate ratio for the ATB-25 mixture containing 50% RAP was determined to be 3.0%. Burn-off tests on the test section indicated a slight increase in this ratio, although it remained below 4.0%.

- (3)

- A loose paving coefficient of 1.35 with eight passes of compaction resulted in better densification than a coefficient of 1.30 with seven passes. However, the resulting core thickness was relatively large.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Victory, W. A review on the utilization of waste material in asphalt pavements. Environ. Sci. Pollut. Res. 2022, 29, 27279–27282. [Google Scholar] [CrossRef]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The challenges of using reclaimed asphalt pavement for new asphalt mixtures: A review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef]

- Azadgoleh, M.A.; Mohammadi, M.M.; Ghodrati, A.; Sharifi, S.S.; Palizban, S.M.M.; Ahmadi, A.; Vahidi, E.; Ayar, P. Characterization of contaminant leaching from asphalt pavements: A critical review of measurement methods, reclaimed asphalt pavement, porous asphalt, and waste-modified asphalt mixtures. Water Res. 2022, 219, 118584. [Google Scholar] [CrossRef]

- Min, Y.; Zhang, Y.; Qian, Z.; Zhang, H.; Hu, B.; Xie, Y.; Zhang, X. Performance evaluation and feasibility study on reuse of reclaimed epoxy asphalt pavement (REAP). Constr. Build. Mater. 2024, 450, 138653. [Google Scholar] [CrossRef]

- Alkins, A.E.; Lane, B.; Kazmierowski, T. Sustainable Pavements: Environmental, Economic, and Social Benefits of In Situ Pavement Recycling. Transp. Res. Rec. J. Transp. Res. Board 2008, 2084, 100–103. [Google Scholar] [CrossRef]

- Horvath, A. Life-Cycle Environmental and Economic Assessment of Using Recycled Materials for Asphalt Pavements. 2003. Available online: https://escholarship.org/uc/item/5jz3x91z (accessed on 24 May 2025).

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

- Da Costa, L.F.; Mendes, L.P.T.; de Medeiros Melo Neto, O.; de Figueiredo Lopes Lucena, L.C.; de Figueiredo Lopes Lucena, L. Economic and environmental benefits of recycled asphalt mixtures: Impact of reclaimed asphalt pavement and additives throughout the life cycle. Environ. Sci. Pollut. Res. 2025, 32, 11269–11291. [Google Scholar] [CrossRef]

- Wu, J.; Ren, H.; Jin, A. Low-temperature fracture resistance of plant-mixed heat recycled asphalt mixture based on SCB. Mater. Res. Express 2023, 10, 115101. [Google Scholar] [CrossRef]

- McDaniel, R.S.; Shah, A.; Huber, G.A.; Copeland, A. Effects of reclaimed asphalt pavement content and virgin binder grade on properties of plant produced mixtures. Road Mater. Pavement Des. 2012, 13, 161–182. [Google Scholar] [CrossRef]

- Aravind, K.; Das, A. Pavement design with central plant hot-mix recycled asphalt mixes. Constr. Build. Mater. 2007, 21, 928–936. [Google Scholar] [CrossRef]

- McDaniel, R.S.; Anderson, R.M. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method: Technician’s Manual; National Research Council (US): Washington, DC, USA; Transportation Research Board: Washington, DC, USA, 2001. Available online: https://rosap.ntl.bts.gov/view/dot/15417 (accessed on 24 May 2025).

- Edwards, A.C.; Mayhew, H.C. Recycled Asphalt Wearing Courses. 1989. Available online: https://trid.trb.org/View/313917 (accessed on 24 May 2025).

- Servas, V.P.; Ferreira, M.A.; Curtayne, P.C. Fundamental properties of recycled asphalt mixes. In Proceedings of the Sixth International Conference on Structural Design of Asphalt Pavements, Ann Arbor, MI, USA, 13–17 July 1987; pp. 455–465. [Google Scholar]

- Kandhal, P.S. Performance of Recycled Hot Mix Asphalt Mixtures, National Center for Asphalt Technology. 1995. Available online: https://books.google.com/books?hl=zh-CN&lr=&id=kYGhDODQ6ccC&oi=fnd&pg=PA19&dq=Kandhal+PS,+Rao+SS,+Watson+DE,+Young+B.+Performance+of+recycled+hot+mix+asphalt+mixtures.+NCAT+Report+No.+95-1.+National+Center+for+Asphalt+Technology,+Auburn+University,+Alabama%3B+1995.&ots=bCMtvRNW0f&sig=zAP2qE5QaXIt_vt0UmMzlcLfvbY (accessed on 24 May 2025).

- Malpass, G.A. The Use of Reclaimed Asphalt Pavement in New Superpave Asphalt Concrete Mixtures, North Carolina State University. 2003. Available online: https://search.proquest.com/openview/8541e0c12491948bfdbc20ff1fb6a844/1?pq-origsite=gscholar&cbl=18750&diss=y (accessed on 24 May 2025).

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Yang, R.; Kang, S.; Ozer, H.; Al-Qadi, I.L. Environmental and economic analyses of recycled asphalt concrete mixtures based on material production and potential performance, Resources. Conserv. Recycl. 2015, 104, 141–151. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% hot mix asphalt recycling: Challenges and benefits. Transp. Res. Procedia 2016, 14, 3493–3502. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Mariyappan, R.; Palammal, J.S.; Balu, S. Sustainable use of reclaimed asphalt pavement (RAP) in pavement applications—A review. Environ. Sci. Pollut. Res. 2023, 30, 45587–45606. [Google Scholar] [CrossRef]

- Valdés, G.; Pérez-Jiménez, F.; Miró, R.; Martínez, A.; Botella, R. Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2011, 25, 1289–1297. [Google Scholar] [CrossRef]

- Kim, W.; Lim, J.; Labuz, J.F. Cyclic Triaxial Testing of Recycled Asphalt Pavement and Aggregate Base. 2009. Available online: https://trid.trb.org/View/881267 (accessed on 24 May 2025).

- Bueche, N.; Dumont, A.-G.; Vanelstraete, A.; De Visscher, J.; Vansteenkiste, S.; Vervaecke, F.; Gaspar, L.; Thogersen, F. Laboratory and ALT-Evaluation of high stiffness underlayers with high percentage of re-use as developed in the NR2C-project. In Proceedings of the 4th Eurasphalt and Eurobitume Congress, Copenhagen, Denmark, 21–23 May 2008; Available online: https://infoscience.epfl.ch/entities/publication/312a3228-2d69-4f64-9d76-b32369e00917/full (accessed on 24 May 2025).

- West, R.; Kvasnak, A.; Tran, N.; Powell, B.; Turner, P. Testing of Moderate and High Reclaimed Asphalt Pavement Content Mixes: Laboratory and Accelerated Field Performance Testing at the National Center for Asphalt Technology Test Track. Transp. Res. Rec. J. Transp. Res. Board 2009, 2126, 100–108. [Google Scholar] [CrossRef]

- Lee, N.; Chou, C.-P.; Chen, K.-Y. Benefits in Energy Savings and CO2 Reduction by Using Reclaimed Asphalt Pavement. 2012. Available online: https://trid.trb.org/View/1129304 (accessed on 30 July 2025).

- Li, Y.; Zhang, Y.; Zhang, S. A High Proportion Reuse of RAP in Plant-Mixed Cold Recycling Technology and Its Benefits Analysis. Coatings 2022, 12, 1283. [Google Scholar] [CrossRef]

- Ai, X.; Cao, J.; Feng, D.; Gao, L.; Hu, W.; Yi, J. Performance evaluation of recycled asphalt mixtures with various percentages of RAP from the rotary decomposition process. Constr. Build. Mater. 2022, 321, 126406. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.; Yang, F.; Cheng, M.; Wang, Y.; Amirkhanian, S.; Wu, S.; Wei, M.; Xie, J. Multi-scale performance evaluation and correlation analysis of blended asphalt and recycled asphalt mixtures incorporating high RAP content. J. Clean. Prod. 2021, 317, 128278. [Google Scholar] [CrossRef]

- Xiao, F.; Xu, L.; Zhao, Z.; Hou, X. Recent applications and developments of reclaimed asphalt pavement in China, 2010–2021. Sustain. Mater. Technol. 2023, 37, e00697. [Google Scholar] [CrossRef]

- Xu, G.; Shen, Z.; Hao, S.; Du, M.; Hu, J. Mitigating RAP variability through detailed particle size classification: Applications in high RAP content asphalt mixtures. Case Stud. Constr. Mater. 2025, 23, e04993. [Google Scholar] [CrossRef]

- Xing, C.; Chang, Z.; Jiang, W.; Han, Z.; Li, M. Hot central-plant recycling technology: A systematic review on raw materials and performance-influencing factors. J. Traffic Transp. Eng. (Engl. Ed.) 2025, 12, 1040–1063. [Google Scholar] [CrossRef]

- Bowers, B.F.; Powell, R.B. Use of a Hot-Mix Asphalt Plant to Produce a Cold Central Plant Recycled Mix: Production Method and Performance. Transp. Res. Rec. J. Transp. Res. Board 2021, 2675, 451–459. [Google Scholar] [CrossRef]

- Yu, X.; Li, Y. Optimal percentage of reclaimed asphalt pavement in central plant hot recycling mixture. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 2010, 25, 659–662. [Google Scholar] [CrossRef]

- Xu, G.; Du, M.; Shen, Z.; Yang, F.; Han, C. RAP Variability Intelligent Control Framework for Hot in-Plant Recycling of Asphalt Pavement. Results Eng. 2025, 26, 105339. [Google Scholar] [CrossRef]

- Jin, D.; Yin, L.; Malburg, L.; You, Z. Laboratory evaluation and field demonstration of cold in-place recycling asphalt mixture in Michigan low-volume road. Case Stud. Constr. Mater. 2024, 20, e02923. [Google Scholar] [CrossRef]

- Jin, D.; Ge, D.; Chen, S.; Che, T.; Liu, H.; Malburg, L.; You, Z. Cold In-Place Recycling Asphalt Mixtures: Laboratory Performance and Preliminary M-E Design Analysis. Materials 2021, 14, 2036. [Google Scholar] [CrossRef]

- Jiang, Y.; Deng, C.; Xue, J.; Chen, Z. Investigation into the performance of asphalt mixture designed using different methods. Constr. Build. Mater. 2018, 177, 378–387. [Google Scholar] [CrossRef]

- Chakroborty, P.; Das, A.; Ghosh, P. Determining Reliability of an Asphalt Mix Design: Case of Marshall Method. J. Transp. Eng. 2010, 136, 31–37. [Google Scholar] [CrossRef]

- Bui, M.P.; Nguyen, Q.P.; Vo, H.L.; Du Nguyen, V. Marshall and Balanced mix design in determining the asphalt content for hot mix asphalt mixture: A comparative study. Case Stud. Constr. Mater. 2024, 21, e03753. [Google Scholar] [CrossRef]

- Han, D.; Wei, L.; Zhang, J. Experimental study on performance of asphalt mixture designed by different method. Procedia Eng. 2016, 137, 407–414. [Google Scholar] [CrossRef]

- ASTM D6927–15; Materials Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2015.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Communication Press: Beijing, China, 2011.

- Gao, J.; Yao, Y.; Song, L.; Xu, J.; Yang, J. Determining the maximum permissible content of recycled asphalt pavement stockpile in plant hot-mix recycled asphalt mixtures considering homogeneity: A case study in China. Case Stud. Constr. Mater. 2022, 16, e00961. [Google Scholar] [CrossRef]

- Yao, X.; Wang, Y.; Xu, T. Development on recycling, aging simulation and regeneration methods of reclaimed styrene-butadiene-styrene modified asphalt. J. Clean. Prod. 2021, 312, 127767. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. The Industry Standard of the People’s Republic of China: Beijing, China, 2004.

- Asi, I.M. Performance evaluation of SUPERPAVE and Marshall asphalt mix designs to suite Jordan climatic and traffic conditions. Constr. Build. Mater. 2007, 21, 1732–1740. [Google Scholar] [CrossRef]

| Particle Size(mm) | Asphalt–Aggregate Ratio | Screen Size (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 26.5 | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | ||

| 12~22 | 1.59% | 100 | 99.2 | 92.0 | 65.7 | 33.6 | 19.5 | 16.2 | 12.9 | 12.0 | 10.2 | 8.6 | 7.0 |

| 6~12 | 2.81% | 100 | 100 | 100 | 100 | 100 | 65.9 | 45.7 | 31.6 | 28.1 | 21.4 | 16.7 | 12.5 |

| 0~6 | 6.82% | 100 | 100 | 100 | 100 | 100 | 99.0 | 75.0 | 57.4 | 40.1 | 24.4 | 18.2 | 12.8 |

| Parameter | Result |

|---|---|

| Penetration (0.1 mm) | 32 |

| Softening Point (°C) | 56 |

| Ductility (cm) | 10 |

| Parameter | Requirement | Results |

|---|---|---|

| Penetration (0.1 mm) | 60~70 | 62 |

| Softening point (°C) | ≥47 | 47.5 |

| Ductility (cm) | ≥15 | 18 |

| Dynamic viscosity at 60 °C | ≥200 | 216 |

| Relative density (g/cm3) | – | 1.035 |

| Parameter | Requirement | Result | |

|---|---|---|---|

| Crushing Value (%) | ≤22 | 18.0 | |

| Apparent relative density(g/cm3) | 10~25 mm | ≥2.50 | 2.727 |

| 10~20 mm | 2.724 | ||

| 5~10 mm | 2.708 | ||

| 3~5 mm | 2.706 | ||

| Coefficient of water absorption (%) | 10~25 mm | ≤1.5 | 0.50 |

| 10~20 mm | 0.51 | ||

| 5~10 mm | 0.77 | ||

| 3~5 mm | 0.63 | ||

| The needle sheet-gauge tester (%) | 10~25 mm | ≤15 | 4.3 |

| 10~20 mm | 7.1 | ||

| 5~10 mm | ≤18 | 11.2 | |

| Parameter | Result |

|---|---|

| Apparent relative density (g/cm3) | 2.726 |

| Sand equivalent (%) | 78 |

| Methylene blue value (MBV) (g/kg) | 0.6 |

| Parameter | Requirement | Result | |

|---|---|---|---|

| Apparent density (g/cm3) | ≥2.50 | 2.770 | |

| Moisture content (%) | ≤1 | 0.2 | |

| Passing percentage (%) | 0.6 mm | 100 | 100 |

| 0.15 mm | 90~100 | 97.9 | |

| 0.075 mm | 75~100 | 91.0 | |

| Hydrophilic coefficient | <1 | 0.7 | |

| Index of plasticity | <4 | 2.0 | |

| Parameter | Requirement | Result |

|---|---|---|

| Viscosity at 60 (mm2/s) | 176~900 | 540 |

| Flash point (°C) | ≥220 | 238 |

| Saturated phenol content (%) | ≤30 | 15.5 |

| Aromatic phenol content (%) | – | 70.7 |

| Viscosity ratio before and after film oven test (%) | ≤3 | 1.59 |

| Quality change before and after film oven test | ≤4, ≥−4 | −1.51 |

| Density at 25 °C | – | 1.076 |

| Mixing Sequence | Mixing Time (s) |

|---|---|

| RAP and recycling agent | 5 |

| Aggregate and mineral powder addition | 5 |

| Dry mixing | 10 |

| Asphalt addition time | 7 |

| Wet mixing | 30 |

| Discharge time | 5 |

| Total mixing time | 62 |

| Working Procedure | Temperature (°C) |

|---|---|

| Asphalt heating temperature | 155~165 |

| RAP material heating temperature | 110~130 |

| Mineral temperature | 185~195 |

| Mix production temperature | 160~170 |

| Mix waste temperature | Factory temperature > 195 °C waste |

| Paving temperature | ≥145 |

| Road surface temperatures for exposure to traffic restrictions | ≥90 |

| Materials (mm) | Percentage Passed (%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 31.5 | 26.5 | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| 12~22 (RAP) | 100 | 100 | 99.2 | 92 | 65.6 | 33.6 | 19.5 | 16.2 | 12.9 | 12.0 | 10.2 | 8.6 | 7 |

| 6~12 (RAP) | 100 | 100 | 100 | 100 | 100 | 100 | 65.9 | 45.7 | 31.6 | 28.1 | 21.4 | 16.7 | 12.5 |

| 0~6 (RAP) | 100 | 100 | 100 | 100 | 100 | 100 | 99 | 75 | 57.4 | 40.1 | 24.4 | 18.2 | 12.8 |

| 10~25 | 100 | 100 | 22.1 | 6.7 | 2.4 | 0.8 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| 10~20 | 100 | 100 | 84.8 | 61.9 | 33.1 | 4.8 | 0.4 | 0.4 | 0.4 | 0.3 | 0.3 | 0.3 | 0.3 |

| 5~10 | 100 | 100 | 100 | 100 | 100 | 98.9 | 17.8 | 1.7 | 1.1 | 1.0 | 0.9 | 0.9 | 0.8 |

| 3~5 | 100 | 100 | 100 | 100 | 100 | 100 | 43.2 | 3.5 | 2.9 | 2.4 | 1.8 | 1.2 | 0.8 |

| 0~3 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 91.1 | 57.5 | 42.5 | 27.2 | 19.3 | 15 |

| Mineral powder | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.8 | 91.3 |

| Synthetic gradation | 100 | 100 | 75.7 | 67.6 | 55.7 | 42.5 | 27.5 | 19.7 | 15.1 | 12.3 | 9.2 | 7.5 | 6.0 |

| Upper limit | 100 | 100 | 80 | 68 | 62 | 52 | 40 | 32 | 25 | 18.0 | 14.0 | 10.0 | 6.0 |

| Lower limit | 100 | 90 | 60 | 48 | 42 | 32 | 20 | 15 | 10 | 8.0 | 5.0 | 3.0 | 2.0 |

| Parameter | Results | Requirements |

|---|---|---|

| Bulk specific gravity | 2.457 | - |

| Theoretical maximum specific gravity | 2.582 | - |

| Percent air voids | 4.9 | 4~6 |

| Percent voids in mineral aggregate | 13 | ≥12.0 |

| VMA | 62.3 | 55~70 |

| Marshall stability | 8.76 | ≥ |

| Flow value | 3.4 | 15~40 |

| Dynamic stability at 60 °C | 5733 | ≥1800 |

| Parameter | Results | Requirements |

|---|---|---|

| Bulk specific gravity | 2.457 | - |

| Theoretical maximum specific gravity | 2.582 | - |

| Percent air voids | 4.9 | 4~6 |

| Percent voids in mineral aggregate | 13 | ≥12.0 |

| VMA | 62.3 | 55~70 |

| Marshall stability | 8.76 | ≥ |

| Flow value | 3.4 | 15~40 |

| Dynamic stability at 60 °C | 5733 | ≥1800 |

| Designed Asphalt–Aggregate Ratio (%) | Ignition Results (First) | Ignition Results (Second) | Average Value |

|---|---|---|---|

| 3.0 | 3.15 | 3.84 | 3.5 |

| Parameter | Unit | Results | Results (After 48 h) | Requirements |

|---|---|---|---|---|

| Maximum relative theoretical density | g/cm3 | 2.580 | 2.580 | - |

| Bulk specific gravity | g/cm3 | 2.462 | 2.459 | - |

| VV | % | 4.6 | 4.7 | 3~6 |

| VMA | % | 12.8 | 12.9 | ≥12 |

| VFA | % | 64.2 | 63.5 | 55~70 |

| Marshall stability | kN | 9.94 | 9.45 | ≥8.0 |

| Flow value | 0.1 mm | 2.7 | 2.7 | 1.5~4.0 |

| Residual stability | % | 95.1 | ≥80 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Ma, Z.; Huang, Y.; Zhang, Z.; Xiang, X.; Luo, M.; Yu, H. Design and Performance of High-RAP-Content Asphalt Mixture: A Case Study in Jianghe Expressway. Buildings 2025, 15, 3107. https://doi.org/10.3390/buildings15173107

Zhang H, Ma Z, Huang Y, Zhang Z, Xiang X, Luo M, Yu H. Design and Performance of High-RAP-Content Asphalt Mixture: A Case Study in Jianghe Expressway. Buildings. 2025; 15(17):3107. https://doi.org/10.3390/buildings15173107

Chicago/Turabian StyleZhang, Haiqi, Zhiyong Ma, Yimin Huang, Zhengquan Zhang, Xiaomiao Xiang, Mingkun Luo, and Huayang Yu. 2025. "Design and Performance of High-RAP-Content Asphalt Mixture: A Case Study in Jianghe Expressway" Buildings 15, no. 17: 3107. https://doi.org/10.3390/buildings15173107

APA StyleZhang, H., Ma, Z., Huang, Y., Zhang, Z., Xiang, X., Luo, M., & Yu, H. (2025). Design and Performance of High-RAP-Content Asphalt Mixture: A Case Study in Jianghe Expressway. Buildings, 15(17), 3107. https://doi.org/10.3390/buildings15173107