Construction and As-Built Performance of a Miscanthus Straw Bale House

Abstract

1. Introduction

2. Materials and Methods

2.1. Building Description

2.2. Miscanthus Bale Characteristics

2.3. Air Permeability Testing

2.4. In Situ Moisture Monitoring

2.5. In Situ U Value Measurements

3. Results

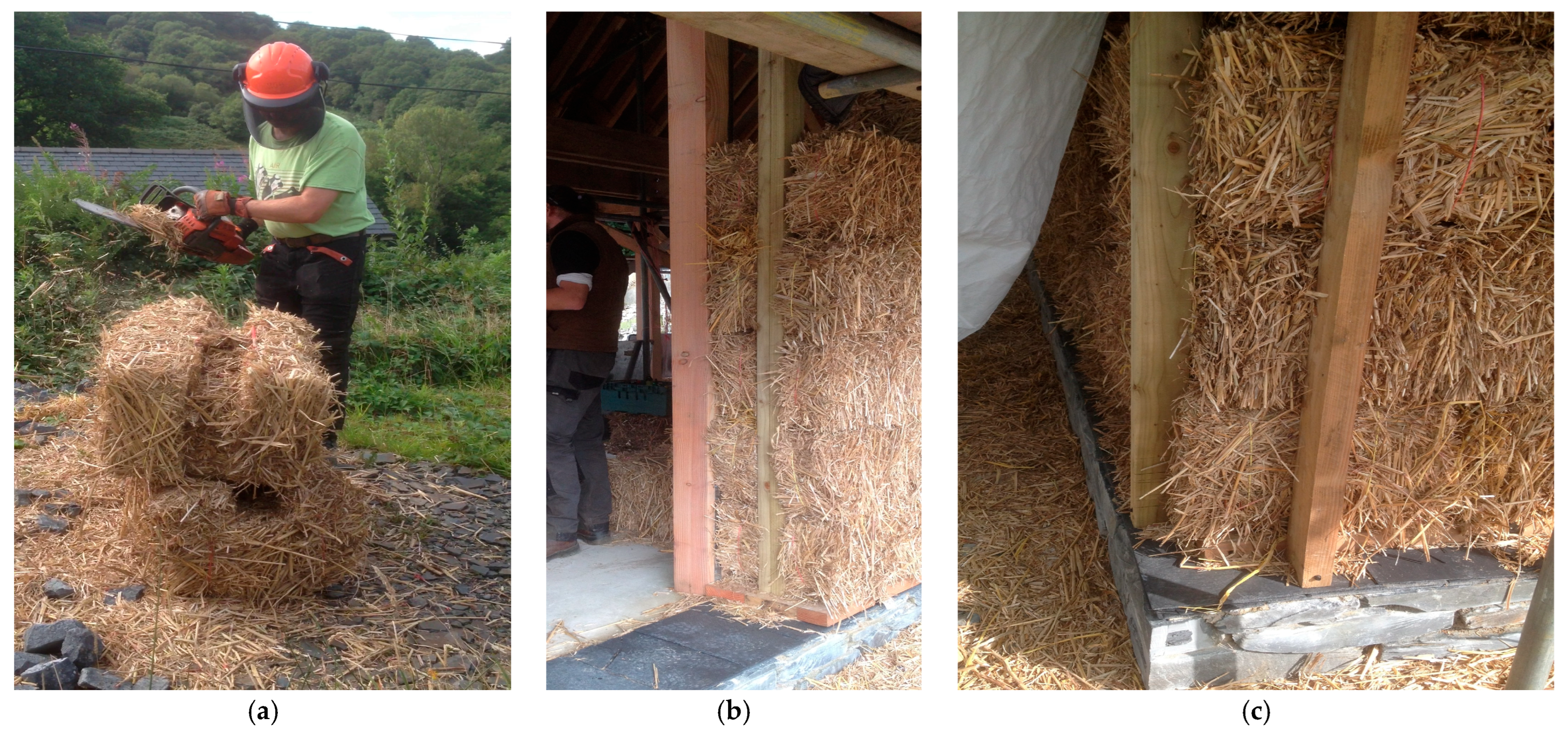

3.1. Construction of the Building

3.2. Comparisons with Using Wheat Straw Bales

3.3. Air Permeability Testing

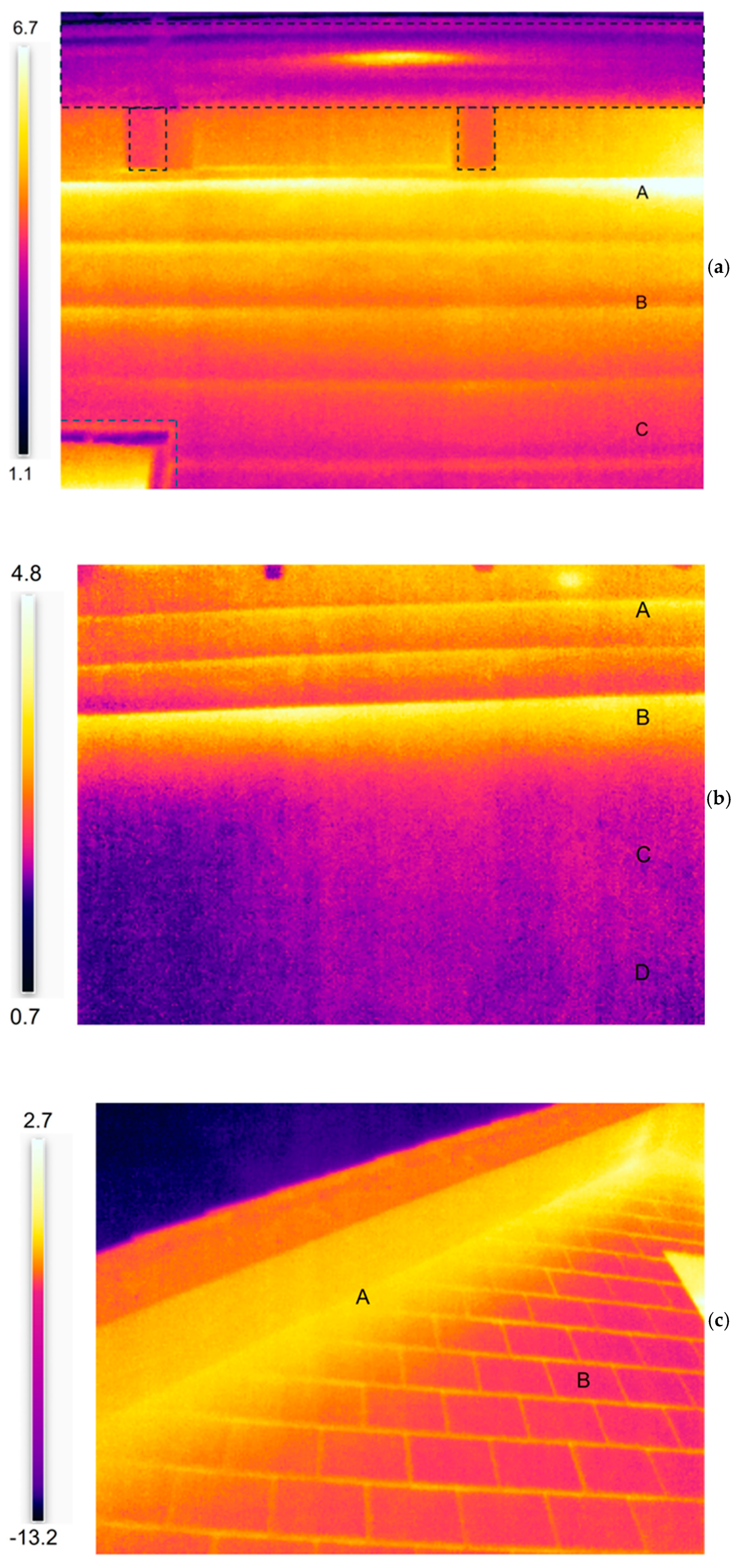

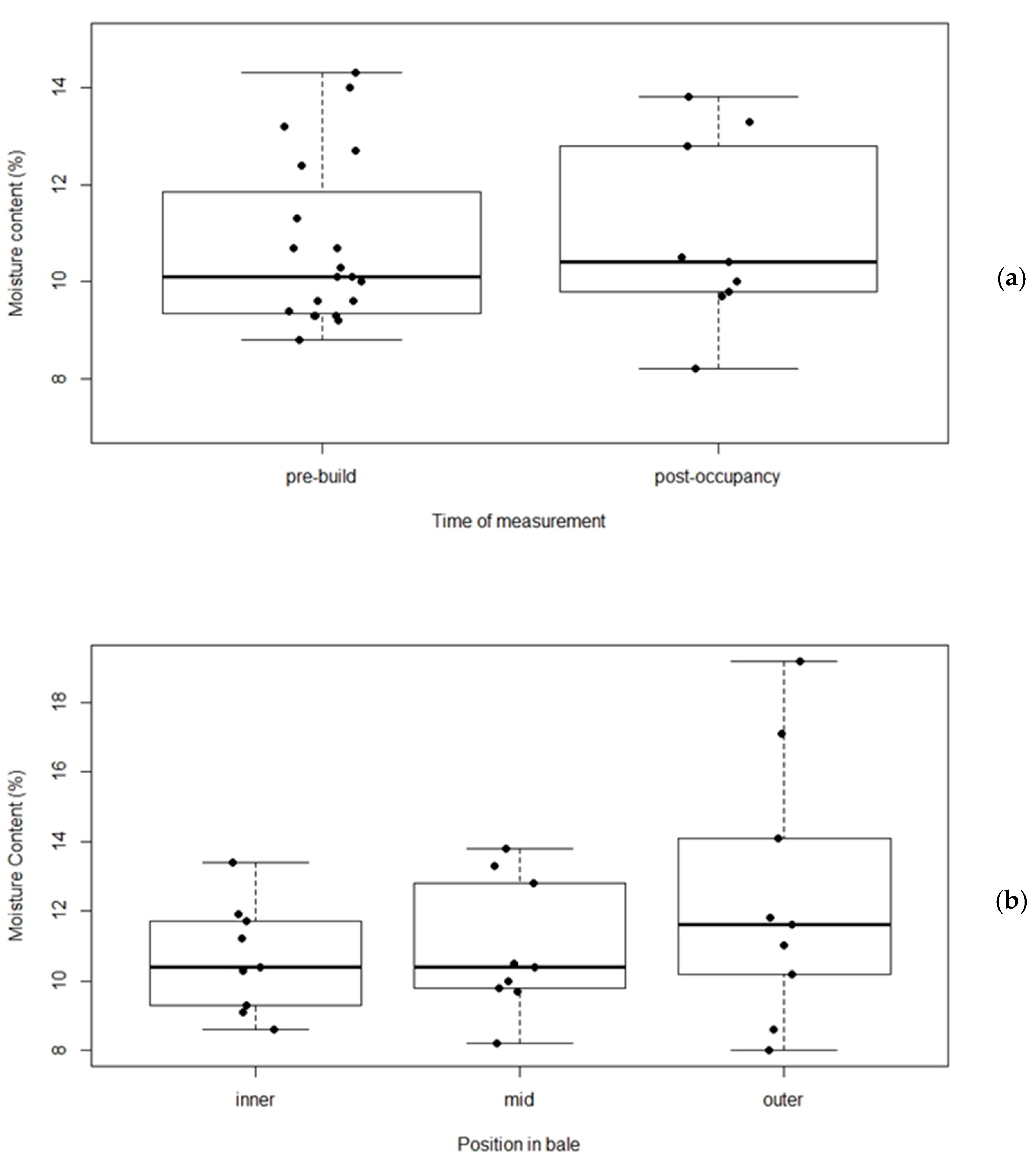

3.4. In Situ Moisture Monitoring

3.5. In Situ U Values

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yahia, A.K.M.; Shahjalal, M. Sustainable Materials Selection in Building Design and Construction. Int. J. Sci. Eng. 2024, 1, 93–105. [Google Scholar] [CrossRef]

- Gottlieb, S.C.; Frederiksen, N.; Mølby, L.F.; Fredslund, L.; Primdahl, M.B.; Rasmussen, T.V. Roadmap for the Transition to Biogenic Building Materials: A Socio-Technical Analysis of Barriers and Drivers in the Danish Construction Industry. J. Clean. Prod. 2023, 414, 137554. [Google Scholar] [CrossRef]

- Bui, T.; Domingo, N.; Le, A. Factors Affecting the Selection of Sustainable Construction Materials: A Study in New Zealand. Buildings 2025, 15, 834. [Google Scholar] [CrossRef]

- Fei, W.; Opoku, A.; Agyekum, K.; Oppon, J.A.; Ahmed, V.; Chen, C.; Lok, K.L. The Critical Role of the Construction Industry in Achieving the Sustainable Development Goals (SDGs): Delivering Projects for the Common Good. Sustainability 2021, 13, 9112. [Google Scholar] [CrossRef]

- United Nations Environment Programme, G.A. for B. and C. Not Just Another Brick in the Wall: The Solutions Exist—Scaling Them Will Build on Progress and Cut Emissions Fast. In Global Status Report for Buildings and Construction 2024/2025; 2025; Available online: https://globalabc.org/resources/publications/global-status-report-buildings-and-construction-20242025-not-just-another (accessed on 19 August 2025).

- European Union. Regulation (EU) 2024/3012 of the European Parliament and of the Council; European Union: Brussels, Belgium, 2024. [Google Scholar]

- Steyn, K.; de Villiers, W.; Babafemi, A.J. A Comprehensive Review of Hempcrete as a Sustainable Building Material. Innov. Infrastruct. Solut. 2025, 10, 97. [Google Scholar] [CrossRef]

- Xu, P.; Tam, V.W.Y.; Li, H.; Zhu, J.; Xu, X. A Critical Review of Bamboo Construction Materials for Sustainability. Renew. Sustain. Energy Rev. 2025, 210, 115230. [Google Scholar] [CrossRef]

- Yadav, M.; Singhal, I. Sustainable Construction: The Use of Cork Material in the Building Industry. Mater. Renew. Sustain. Energy 2024, 13, 375–383. [Google Scholar] [CrossRef]

- Tlaiji, G.; Biwole, P.; Ouldboukhitine, S.; Pennec, F. A Mini-Review on Straw Bale Construction. Energies 2022, 15, 7859. [Google Scholar] [CrossRef]

- Straw Building UK. Straw as Insulation Material—UK. Environmental Product Declaration. Available online: https://www.environdec.com/library/epd3854 (accessed on 23 March 2025).

- Peng, H.; Walker, P.; Maskell, D.; Jones, B. Structural Characteristics of Load Bearing Straw Bale Walls. Constr. Build. Mater. 2021, 287, 122911. [Google Scholar] [CrossRef]

- Wall, K.; Walker, P.; Gross, C.; White, C.; Mander, T. Development and Testing of a Prototype Straw Bale House. Proc. Inst. Civ. Eng. Constr. Mater. 2012, 165, 377–384. [Google Scholar] [CrossRef]

- Ecococon A Construction System Designed by Nature. Available online: https://ecococon.eu/gb (accessed on 23 January 2025).

- Lawrence, M.; Heath, A.; Walker, P. Determining Moisture Levels in Straw Bale Construction. Constr. Build. Mater. 2009, 23, 2763–2768. [Google Scholar] [CrossRef]

- Pierzchalski, M. Straw Bale Building as a Low-Tech Solution: A Case Study in Northern Poland. Sustainability 2022, 14, 16511. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, N.; Chen, J. Straw Characteristics and Mechanical Straw Building Materials: A Review. J. Mater. Sci. 2023, 58, 2361–2380. [Google Scholar] [CrossRef]

- Yin, X.; Lawrence, M.; Maskell, D.; Chang, W.-S. Construction and Monitoring of Experimental Straw Bale Building in Northeast China. Constr. Build. Mater. 2018, 183, 46–57. [Google Scholar] [CrossRef]

- Minke, G.; Krick, B. Straw Bale Construction Manual: Design and Technology of a Sustainable Architecture; Birkhäuser Verlag GmbH: Basel, Switzerland; Boston, MA, USA, 2020; ISBN 978-3-0356-1854-9. [Google Scholar]

- Defra Bioenergy Crops in England and the UK: 2008–2023. Available online: https://www.gov.uk/government/statistics/bioenergy-crops-in-england-and-the-uk-2008-2023/bioenergy-crops-in-england-and-the-uk-2008-2023 (accessed on 8 January 2025).

- Climate Change Committee Sixth Carbon Budget; Climate Change Committee: London, UK, 2020.

- Clifton-Brown, J.; Hastings, A.; Mos, M.; McCalmont, J.P.; Ashman, C.; Awty-Carroll, D.; Cerazy, J.; Chiang, Y.; Cosentino, S.; Cracroft-Eley, W.; et al. Progress in Upscaling Miscanthus Biomass Production for the European Bio-economy with Seed-based Hybrids. GCB Bioenergy 2017, 9, 6–17. [Google Scholar] [CrossRef]

- Iacono, R.; Slavov, G.T.; Davey, C.L.; Clifton-Brown, J.; Allison, G.; Bosch, M. Variability of Cell Wall Recalcitrance and Composition in Genotypes of Miscanthus from Different Genetic Groups and Geographical Origin. Front. Plant Sci. 2023, 14, 1155188. [Google Scholar] [CrossRef] [PubMed]

- van der Cruijsen, K.; Al Hassan, M.; van Erven, G.; Dolstra, O.; Trindade, L.M. Breeding Targets to Improve Biomass Quality in Miscanthus. Molecules 2021, 26, 254. [Google Scholar] [CrossRef]

- Tiwari, R.K.; Goswami, S.K.; Gujjar, R.S.; Kumar, R.; Kumar, R.; Lal, M.K.; Kumari, M. Mechanistic Insights on Lignin-Mediated Plant Defense against Pathogen Infection. Plant Physiol. Biochem. 2025, 228, 110224. [Google Scholar] [CrossRef]

- Dresboll, D.; Magid, J. Structural Changes of Plant Residues during Decomposition in a Compost Environment. Bioresour. Technol. 2006, 97, 973–981. [Google Scholar] [CrossRef]

- Locher, M. Traditional Japanese Architecture: An Exploration of Elements and Forms; Tuttle Publishing: North Clarendon, VT, USA, 2010; ISBN 978-4-8053-0980-3. [Google Scholar]

- Göswein, V.; Arehart, J.; Phan-huy, C.; Pomponi, F.; Habert, G. Barriers and Opportunities of Fast-Growing Biobased Material Use in Buildings. Build. Cities 2022, 3, 745–755. [Google Scholar] [CrossRef]

- Assaf, M.; Brachelet, F.; Tittelein, P.; Defer, D.; Antczak, E. Evaluating Long-Term Durability of a Novel Straw Bale Wall in a Temperate Oceanic Climate. Constr. Build. Mater. 2025, 492, 142876. [Google Scholar] [CrossRef]

- ISO 9869-1; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance. ISO: Geneva, Switzerland, 2014.

- CIBSE Guide A—Environmental Design (7th Edition); The Chartered Institution of Building Services Engineers (CIBSE): London, UK, 2006.

- Anderson, J.; Moncaster, A. Embodied Carbon, Embodied Energy and Renewable Energy: A Review of Environmental Product Declarations. Proc. Inst. Civ. Eng. Struct. Build. 2023, 176, 986–997. [Google Scholar] [CrossRef]

- Bocco Guarneri, A.; Habert, G. New Vernacular Construction: Environmental Awareness and Territorial Inclusivity. IOP Conf. Ser. Earth Environ. Sci. 2024, 1363, 012114. [Google Scholar] [CrossRef]

- Robson, P.; Jensen, E.; Hawkins, S.; White, S.R.; Kenobi, K.; Clifton-Brown, J.; Donnison, I.; Farrar, K. Accelerating the Domestication of a Bioenergy Crop: Identifying and Modelling Morphological Targets for Sustainable Yield Increase in Miscanthus. J. Exp. Bot. 2013, 64, 4143–4155. [Google Scholar] [CrossRef] [PubMed]

- Allison, G.G.; Morris, C.; Clifton-Brown, J.; Lister, S.J.; Donnison, I.S. Genotypic Variation in Cell Wall Composition in a Diverse Set of 244 Accessions of Miscanthus. Biomass Bioenergy 2011, 35, 4740–4747. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, Y.; Wang, X.; Thuy, N.T.D.; Yu, H. A Mechanical Model of Single Wheat Straw with Failure Characteristics Based on Discrete Element Method. Biosyst. Eng. 2023, 230, 1–15. [Google Scholar] [CrossRef]

- Francik, S.; Knapik, P.; Łapczyńska-Kordon, B.; Francik, R.; Ślipek, Z. Values of Selected Strength Parameters of Miscanthus × Giganteus Stalk Depending on Water Content and Internode Number. Materials 2022, 15, 1480. [Google Scholar] [CrossRef]

- Welsh Government. The Building Regulations 2010. Approved Document L. Volume 1—Dwellings. Conservation of Fuel and Power; Welsh Government: Cardiff, UK, 2022. [Google Scholar]

- Smith, D.W. Timber & Straw Passive House Is a World First—Passivehouseplus.Ie. Available online: https://passivehouseplus.ie/magazine/new-build/timber-straw-passive-house-is-a-world-first (accessed on 8 January 2025).

- Smith, D.W. All Bales, No Bills—Passivehouseplus.Co.Uk. Available online: https://passivehouseplus.co.uk/magazine/new-build/all-bales-no-bills (accessed on 8 January 2025).

- Lozinsky, C.H.; Touchie, M.F. Quantifying Suite-Level Airtightness in Newly Constructed Multi-Unit Residential Buildings Using Guarded Suite-Level Air Leakage Testing. Build. Environ. 2023, 236, 110273. [Google Scholar] [CrossRef]

- Jennings, P. Delivering Airtight Buildings: A 12-Step Program; ALDAS: Gloucester, UK, 2022. [Google Scholar]

- Koh, C.H.A.; Kraniotis, D. A Review of Material Properties and Performance of Straw Bale as Building Material. Constr. Build. Mater. 2020, 259, 120385. [Google Scholar] [CrossRef]

- Nicoletti, F.; Cucumo, M.A.; Arcuri, N. Evaluating the Accuracy of In-Situ Methods for Measuring Wall Thermal Conductance: A Comparative Numerical Study. Energy Build. 2023, 290, 113095. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Moyano, J.; Marín, D.; Fresco-Contreras, R. Review of in Situ Methods for Assessing the Thermal Transmittance of Walls. Renew. Sustain. Energy Rev. 2019, 102, 356–371. [Google Scholar] [CrossRef]

| Advantages | Disadvantages |

|---|---|

| Stems seemed stronger. | Risk of skin abrasions, work gloves required. |

| Bale shape easier to manipulate. | Fragility of bale structure resulting from smoothness of stems and high degree of strand alignment. |

| Easier to cut accurate notches for window frames. | Straw too rigid to use for gap stuffing at bale ends. |

| Chainsaw required for shaping of wall surfaces and bale ends. | |

| Uneven bale surface, bale shaping to reduce quantity of render required therefore particularly important. | |

| Difficulty in applying initial key coat of render by hand. |

| Elevation, Location | Location | Spot Temperature (°C) |

|---|---|---|

| North. Junction between timber clad wall and pitched roof (Figure 5a) | A | 7.9 |

| As above | B | 5.2 |

| As above | C | 4.5 |

| South. Junction between lime rendered wall and pitched roof (Figure 5b) | A | 3.5 |

| As above | B | 3.5 |

| As above | C | 2.0 |

| As above | D | 1.9 |

| West. Junction between slate clad wall and pitched roof (Figure 5c) | A | −1.0 |

| As above | B | −3.0 |

| South. Junction between wall and timber frame (indoors, Figure 6b) | A | 13.5 |

| As above | B | 14.7 |

| As above | C | 10.7 |

| As above | D | 12.1 |

| As above | E | 14.4 |

| Location | Inner Wall | Mid Wall | Outer Wall |

|---|---|---|---|

| A | 11.2 | 13.3 | 19.2 |

| B | 8.6 | 8.2 | 8.6 |

| D | 9.1 | 9.8 | 8.0 |

| E | 10.4 | 10.0 | 11.6 |

| F | 9.3 | 10.4 | 11.8 |

| G | 11.7 | 10.5 | 11.0 |

| H | 10.3 | 9.7 | 10.2 |

| I | 13.4 | 13.8 | 17.1 |

| J | 11.9 | 12.8 | 14.1 |

| Mean | 10.7 ± 0.5 | 10.9 ± 0.6 | 12.4 ± 1.3 |

| C (control location) | <8.0 | <8.0 | 8.6 |

| Material | Thickness (m) | λ (W/mK) | R (m2K/W) |

|---|---|---|---|

| External RSE | 0.040 | ||

| Timber cladding | 0.018 | 0.015 | 1.385 |

| Straw bale | 0.450 | 0.097 | 4.592 |

| Clay render | 0.015 | 0.500 | 0.030 |

| Internal RSI | 0.130 | ||

| Total R | = | 6.176 m2K/W | |

| U value | = | 0.162 W/m2K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thornton, J.M.; Rowan, B.; Mos, M.; Donnison, I.S. Construction and As-Built Performance of a Miscanthus Straw Bale House. Buildings 2025, 15, 3075. https://doi.org/10.3390/buildings15173075

Thornton JM, Rowan B, Mos M, Donnison IS. Construction and As-Built Performance of a Miscanthus Straw Bale House. Buildings. 2025; 15(17):3075. https://doi.org/10.3390/buildings15173075

Chicago/Turabian StyleThornton, Judith M., Bee Rowan, Michal Mos, and Iain S. Donnison. 2025. "Construction and As-Built Performance of a Miscanthus Straw Bale House" Buildings 15, no. 17: 3075. https://doi.org/10.3390/buildings15173075

APA StyleThornton, J. M., Rowan, B., Mos, M., & Donnison, I. S. (2025). Construction and As-Built Performance of a Miscanthus Straw Bale House. Buildings, 15(17), 3075. https://doi.org/10.3390/buildings15173075