1. Introduction

Concrete, as the primary and most widely utilised construction material, produces 30 billion tonnes per year worldwide [

1]. Concurrently, the amount of waste concrete produced by the demolition of old buildings and structures annually has reached an extraordinary billion tonnes [

2,

3]. The rational and efficient utilisation of waste concrete to reduce its adverse environmental effects is a significant topic.

Currently, recycled aggregate obtained from the pulverisation of discarded concrete provides an innovative resolution. However, due to the weakened strength of recycled aggregate, recycled aggregate concrete’s mechanical performance is usually inferior to that of natural aggregate concrete [

4,

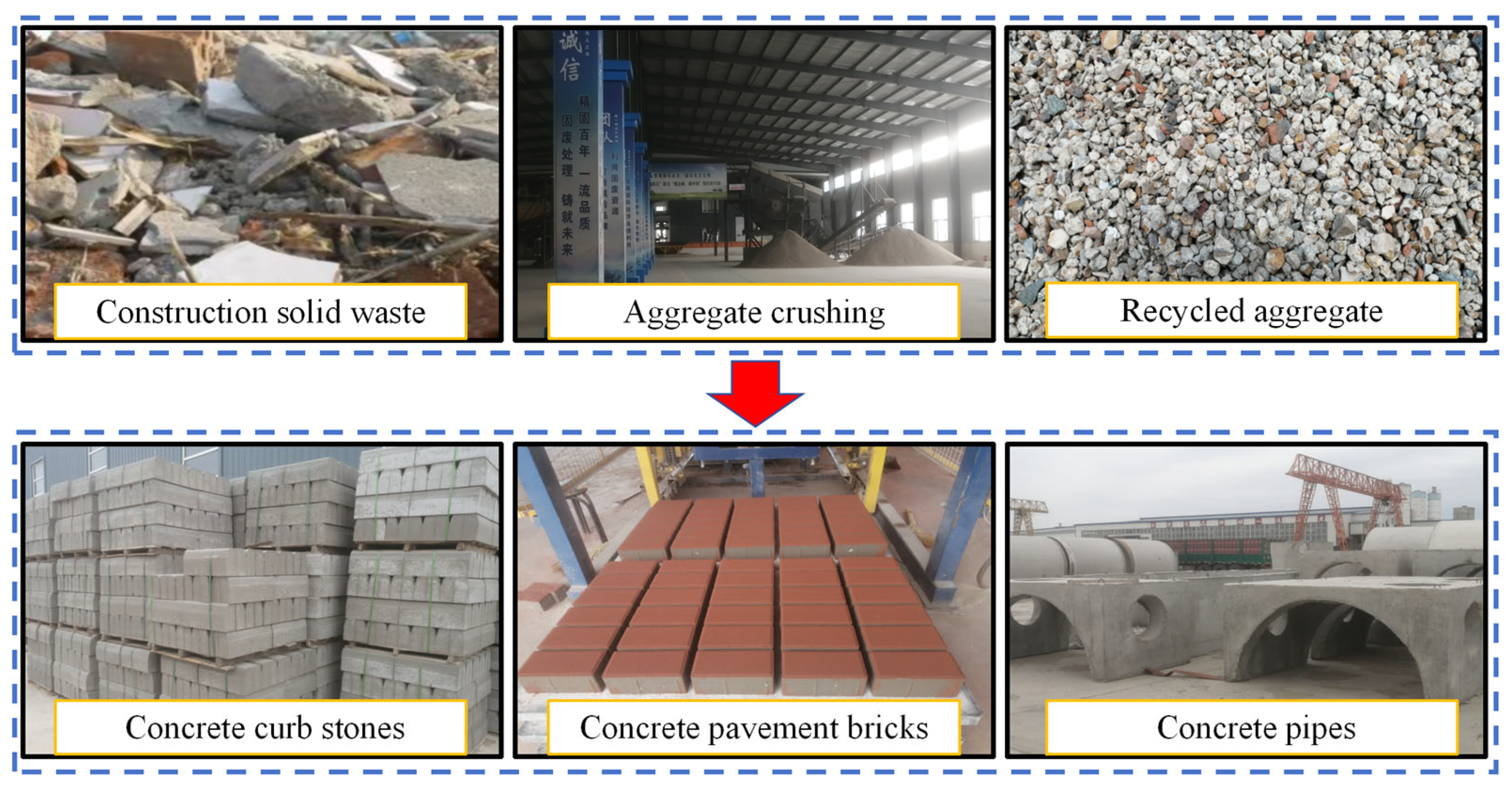

5], hence limiting its use in structural engineering. Unlike structural members, non-structural members (e.g., concrete curbs, concrete pavement bricks) have fewer bearing capacity requirements, hence permitting a broader spectrum of applications for recycled aggregate concrete (RAC).

Figure 1 illustrates the manufacture of RAC products.

The concrete curb, as a non-structural component, is widely employed in municipal road engineering. The market size has exceeded 300 million USD annually on a global scale [

6], and the annual output is substantial. During the manufacturing of concrete curbs, replacing natural aggregate with recycled aggregate can diminish resource consumption and construction expenses. In contrast to natural aggregate concrete curbs, recycled aggregate concrete curbs exhibit issues such as reduced compressive strength, increased cracking, and inadequate durability, requiring immediate intervention by new technology or new material [

7].

Currently, several studies suggest that the strength of RAC curbs can be improved by integrating copper slag, glass fibre-reinforced polymers, rubber, or polyvinyl alcohol fibre [

8,

9,

10,

11,

12,

13,

14]. Nonetheless, considering cost, environmental sustainability, and performance stability, the execution of these techniques necessitates empirical evaluation.

A plethora of experimental investigations have been carried out to reinforce the performance of RAC. The findings indicate that strengthening the intensity of the interfacial transition zone (ITZ) around recycled aggregate is the most common and practical approach. The integration of fibrous materials (e.g., basalt fibre, steel fibre, and polypropylene fibre) and supplementary cementitious materials (e.g., nano-silica, silica fume, fly ash, granulated blast furnace slag powder, and metakaolin) has attracted heightened attention from researchers [

2,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25]. Multiple studies have demonstrated that nanomaterials have the potential to enhance the property of RAC; nevertheless, their elevated cost and challenges in dispersion limit their extensive use in engineering [

26,

27]. Conversely, granulated blast furnace slag powder or fly ash yield only slight enhancements in mechanical performance [

28,

29,

30]. Metakaolin (MK), manufactured by calcining kaolin at temperatures of 650–800 °C and noted for its strong pozzolanic activity, affordability, widespread availability, and low carbon emissions, has recently attracted considerable attention compared to these cementitious materials mentioned above [

31,

32].

Experimental studies have demonstrated that silica in MK will undergo a secondary hydration reaction with CH to generate C-S-H gel, which can reduce the quantity of internal micropores, lower porosity, improve the ITZ, and fill the internal voids and fissures of RAC [

31,

33,

34,

35,

36]. The incorporation of 10% to 20% MK can strengthen the mechanical properties of RAC by 10% to 30%, indicating a considerable enhancement impact [

35,

37,

38,

39,

40]. The RAC strength prediction model utilising the experimental–statistical method effectively forecasts and validates the RAC’s mechanical characteristics, which is crucial for the research and application of RAC [

41,

42]. Despite a number of experimental research on the mechanical characteristics of MK-RAC, investigations into the strength prediction model for MK-RAC based on these results are scarce.

The aforementioned investigations are crucial for elucidating the enhancing mechanism by which MK enhances RAC’s mechanical properties. It may be inferred that most of studies concentrate on the strengthening effects of the sole mixing of MK or its combination with other cementitious materials, whereas fewer investigations address the integration of MK with fibres. Moreover, the recycled aggregates examined in the majority of studies are primarily single-sourced, such as waste concrete derived from the demolition of a particular structure or fabricated in a laboratory environment. However, there exists a scarcity of study about recycled aggregates obtained from construction solid waste recycling companies, characterised by varied origins and significant variations in aggregate strength.

Basalt fibre (BF) is an innovative inorganic fibre with the characteristics of superior tensile strength, remarkable silicate compatibility, great corrosion resistance, and environmental sustainability [

4,

43,

44]. It can markedly improve RAC’s properties. Research shows that adding BF to RAC (at a volumetric proportion of 0.1–0.3%) can increase its mechanical strength by 5–15%. Excessive addition of BF may lead to agglomeration, hence diminishing the strength of RAC [

44,

45,

46,

47,

48,

49]. Orthogonal tests have the benefits of minimising the number of tests and enhancing economic efficiency. They can evaluate multiple variables and have been extensively utilised in the examination of RAC’s mechanical properties. However, limited orthogonal test studies were conducted to investigate the addition of BF to RAC or MK to RAC [

50,

51,

52,

53,

54].

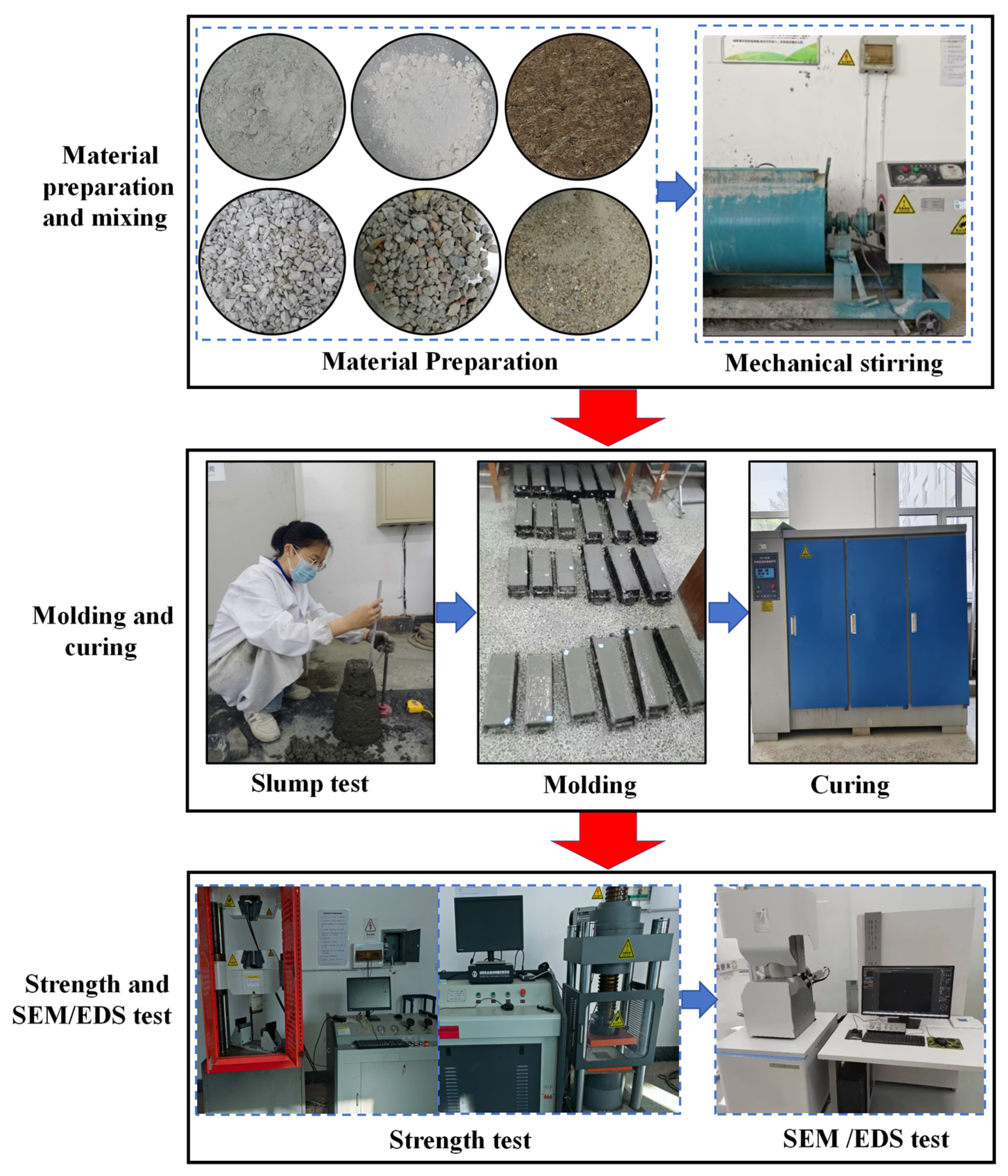

The feasibility of a solitary MK admixture and the combination of MK and BF in RAC products is investigated in this study, utilising recycled aggregate provided by a construction solid waste treatment enterprise in Heilongjiang Province, China. The mechanical properties of RAC with recycled coarse aggregate (RCA) replacement rates of 30%, 45%, and 60% were evaluated at various MK contents (5%, 10%, 15%, and 20% cement substitution by mass). An orthogonal test was performed to investigate the mechanical behaviour of RAC incorporating MK and BF, concentrating on the variables: the RCA replacement rate, the MK content, and the BF volume content (0.1%, 0.2%, and 0.3%). A model test of metakaolin recycled aggregate concrete curbs was undertaken to validate the feasibility of the optimal mix ratio scheme proposed by the single mixing of MK and the combination of MK and BF in the orthogonal test.

4. Microstructure Analysis

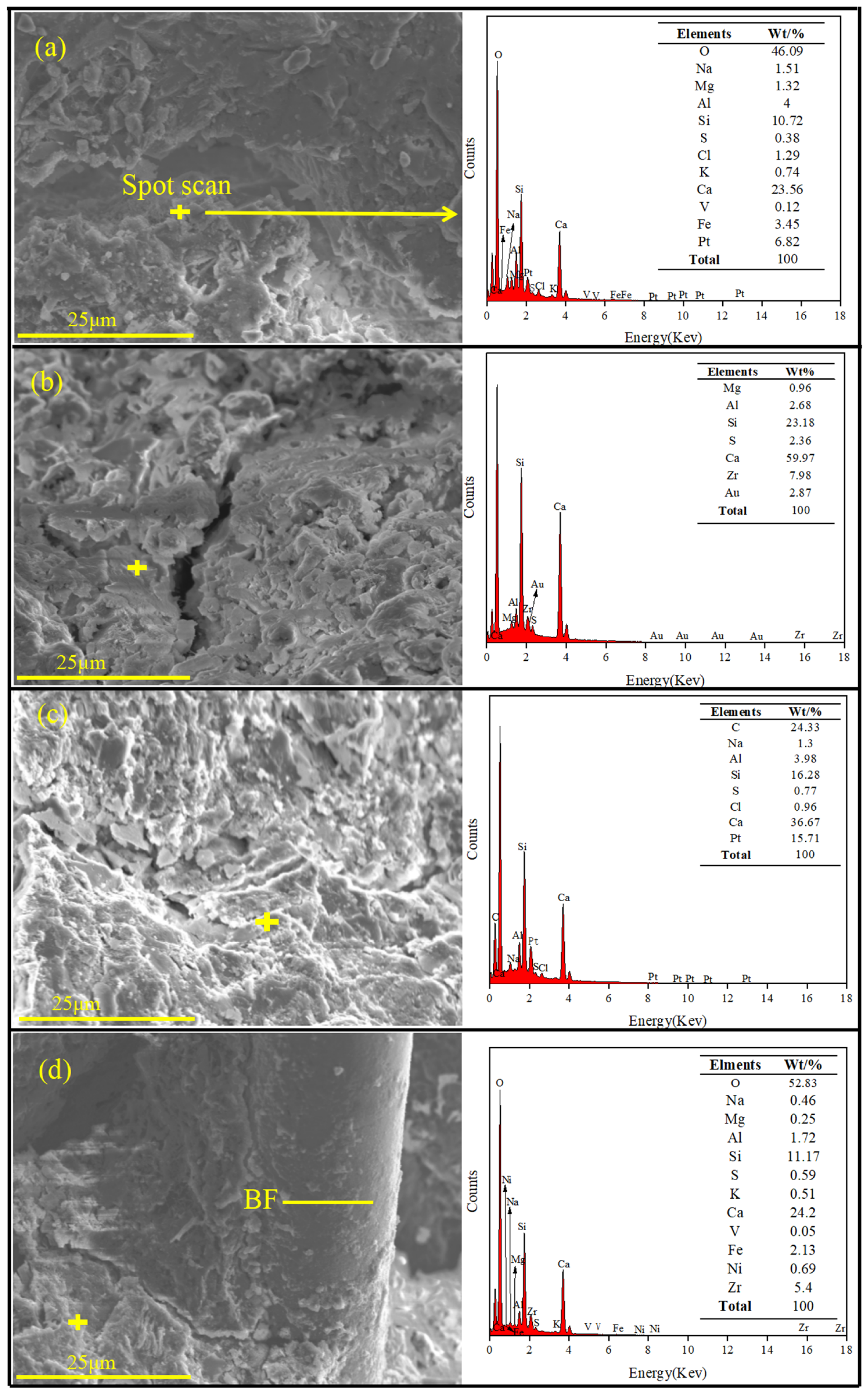

According to the test results presented in

Section 3, concrete specimens (NAC, R30M0, R30M15, A-2) were chosen for microstructure analysis by SEM and energy dispersive spectroscopy (EDS), as illustrated in

Figure 12,

Figure 13 and

Figure 14.

Figure 12 illustrates the dense microstructure in specimen NAC. Natural aggregates displayed an abundance of C-S-H gel, CH, and acicular AFt on their surfaces. Nevertheless, the specimen R30M0 has very substantial apertures and fissures. The recycled aggregate displays increased defects, such as cracks, and the cement hydration seems insufficient, resulting in less hydrated products being formed to fill the RAC’s pores and fractures, thus weakening its strength. In R30M15, the amount of reticulated C-S-H gel is abundant, whereas CH and AFt are significantly reduced, resulting in a denser structure that indicates the elevated pozzolanic activity of MK [

65]. The incorporation of MK enhances the secondary hydration reaction, lowers the hydrated product’s CH, and yields a more cohesively interconnected C-S-H gel [

31,

39]. In specimen A-2, the adhesion between the BF and the matrix is enhanced by the presence of hydrated products on the BF surface. The fibres alleviate and redistribute energy when the RAC encounters external pressure, therefore limiting micro-cracks and enhancing RAC strength [

3,

7,

39].

The EDS analysis was performed on specimens of NAC, R30M0, R30M15, and A-2 (A

1B

2C

2D

2), as illustrated in

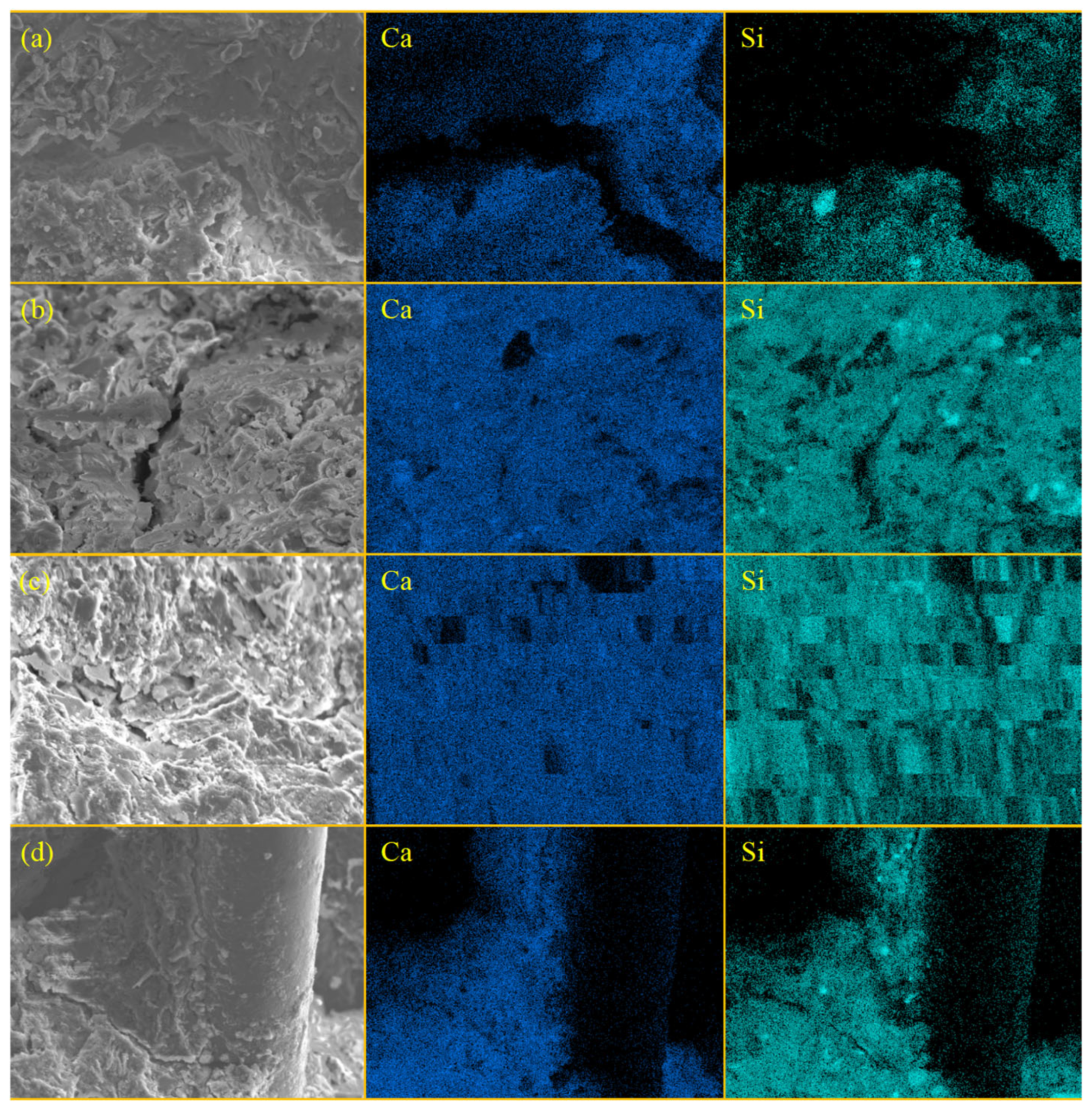

Figure 13 and

Figure 14.

Figure 13 demonstrates that R30M0 predominantly comprises the elements Ca, Si, Zr, Al, S, Au, and Mg. The ratios of Ca to Si for NAC, R30M0, R30M15, and A-2 are 2.20, 2.59, 2.25, and 2.17, respectively; the (Al + Fe)/Ca ratios are 0.32, 0.04, 0.11, and 0.16, respectively. Taylor et al. found that C-S-H gel is the primary hydrated product in the condition where the value of Ca/Si is between 0.8 and 2.5 and the value of (Al + Fe)/Ca is no more than 0.2 [

66]. The quantity of C-S-H gel diminishes when the value of Ca/Si rises. In comparison to NAC, the Ca/Si ratio of R30M0 increased by 0.39, signifying that the internal microstructure of RAC became less dense after replacing 30% of NCA with RCA. Compared to R30M0, R30M15’s Ca/Si ratio fell by 0.34, while the Ca/Si ratio of A-2 decreased by 0.42, demonstrating that adding MK significantly enhances the formation of C-S-H gel [

67,

68]. Simultaneously, the microstructure of RAC becomes denser with the addition of BF.

The hydration degree of cement in concrete can be clarified through the distribution of Ca and Si elements observed in the EDS mapping analysis. The concentrations of Ca and Si in specimens R30M15 have increased, possibly related to the increased development of C-S-H gel [

67]. This discovery aligns with the performance of macroscopic mechanical properties.

5. Model Test of RAC Curbs

Based on the optimal mix ratio derived from single-factor analysis and orthogonal test analysis, three mix ratios designated as R30M0, R30M15, and A-2 have been selected for the fabrication of RAC curbs, with external dimensions of 500 × 150 × 120 mm [

69]. The RAC curb mould employs a custom mould with interior dimensions of 500 × 150 × 140 mm.

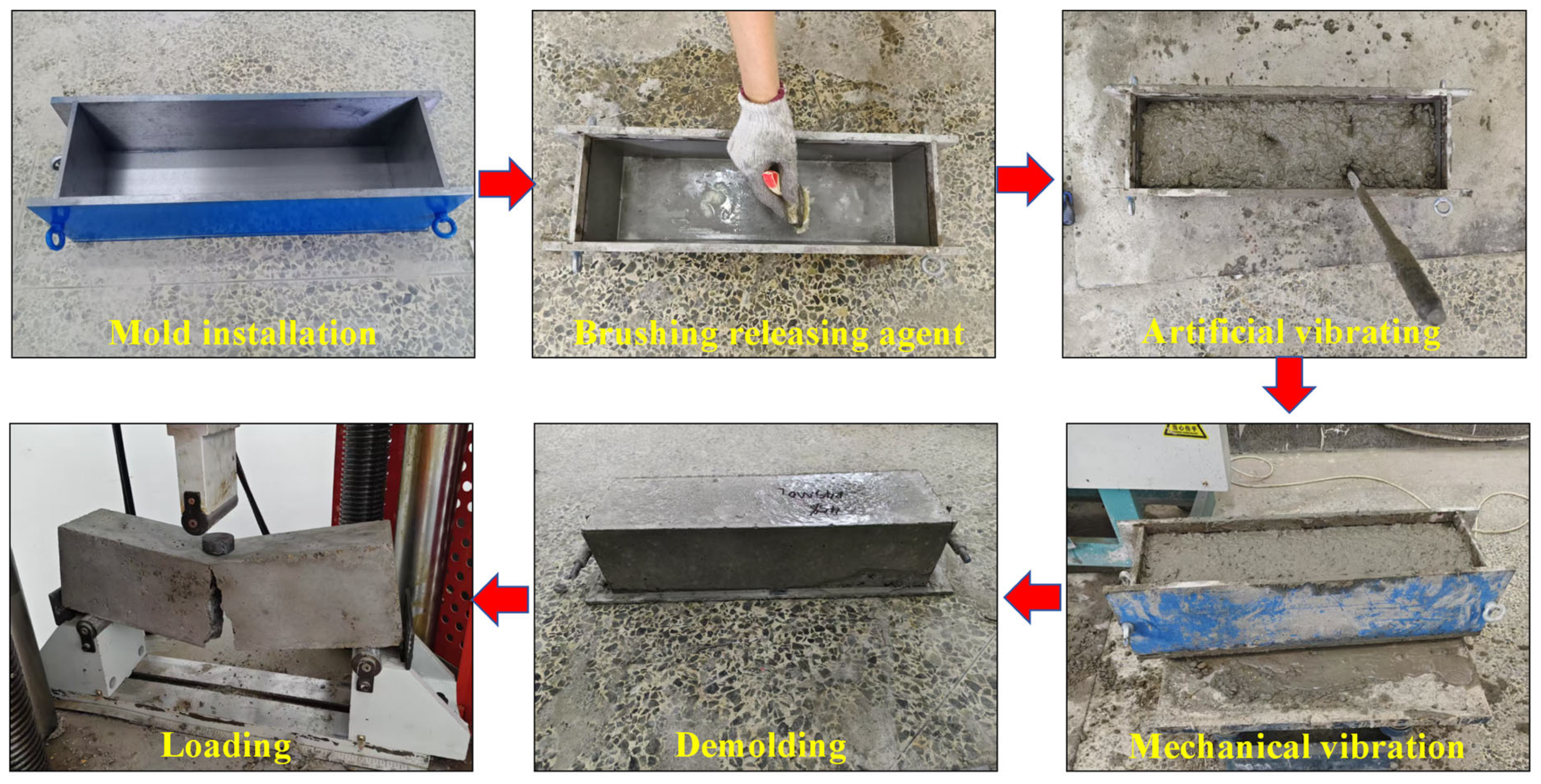

Figure 15 shows the manufacturing process of recycled concrete curbs. Initially, the mould assembly and the application of the internal release agent coating are completed first. Thereafter, the agitated filler is introduced into the mould and vibrated on the vibrating table for 30 s. An iron plate with a thickness of 20 mm is placed on top of the mould. The pressure testing machine (Model YAW–2000) is utilised to compact at a pressure of 15 MPa to enable moulding and perform indoor and standard condition curing [

7]. The designated curing parameters correspond with those of the previously referenced RAC.

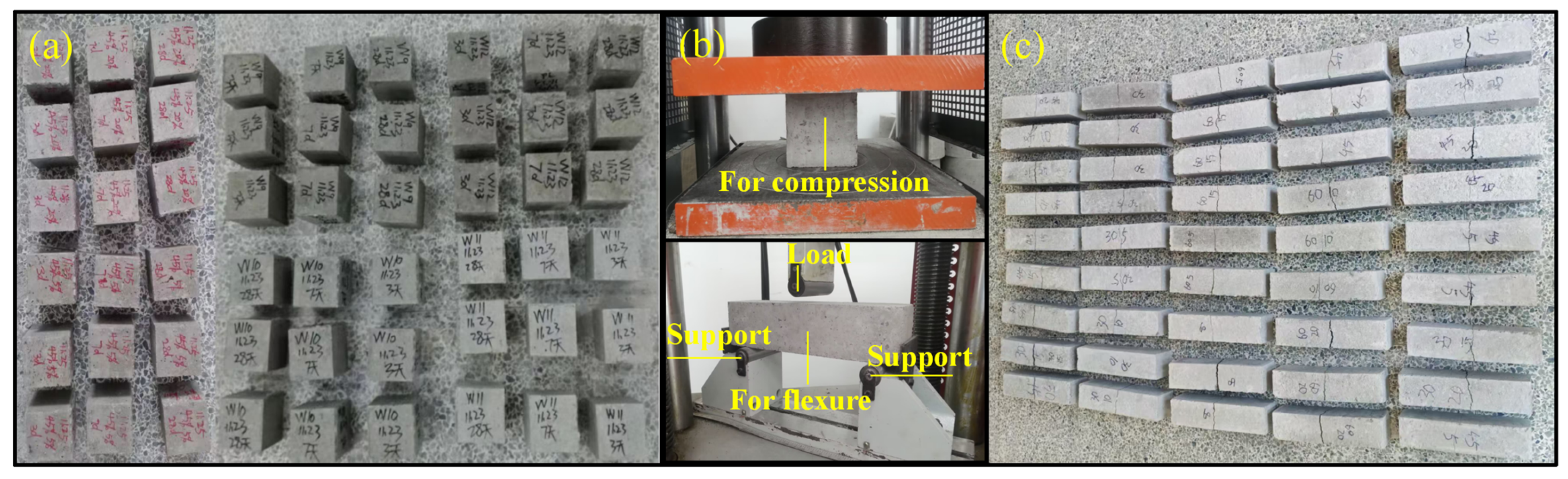

Mechanical property tests of RAC curb models (with a recycled aggregate replacement rate of 30%) were undertaken per the standards of JC/T 899-2016 and GB/T 50081-2019 [

62,

69]. The results show that the 28-day compressive and flexural strengths for the RAC curb models (per the R30M0 mixing ratio) are 36.4 and 5.61 MPa, respectively. When 15% MK was added (corresponding to the R30M15 mix ratio), the RAC curb model exhibits an increase in compressive strength at 23.08% and flexural strength at 10.52%, respectively, yielding values of 44.8 and 6.20 MPa. Adding 15% MK and 0.2% BF (according to the mix ratio of A-2), the RAC curb model performs better in compressive and flexural strength, achieving values of 49.6 and 6.65 MPa, respectively.

The integration of MK and BF can strengthen the mechanical qualities of RAC and RAC products. The primary cause is that the silica in MK and the hydrated product CH produce hydrated calcium silicate, hence augmenting the matrix’s compactness. The incorporation of BF can concurrently hinder fracture initiation and propagation while enhancing the recycled aggregate’s strength. The mechanical property growth law exhibited in the model test of the RAC curb aligns with the law outlined in the RAC specimens test in this study. An increase in RAC strength was observed when MK and BF were combined, and this composite mixing methodology is more effective than using MK alone.

Utilising the cost platform, a cost analysis of the raw materials for RAC curb was conducted, exemplified by Heilongjiang Province of China as illustrated in

Table 14 [

70,

71]. It is evident that the cost of materials per cubic meter of conventional RAC curb (specimen R30M0) is elevated further when MK or a combination of MK and BF is incorporated. Nonetheless, taking into account the mechanical performance of RAC curbs, particularly compressive strength, the ratio of the material cost per cubic meter to compressive strength is employed for thorough assessment. The calculated material cost per cubic meter related to the RAC curbs’ unit compressive strength, based on the specimens of R30M0, R30M15, and A-2, is 9.74, 9.64, and 9.42 RMB/MPa, respectively. It is obvious that the RAC curb (mixed with MK and BF) demonstrates the most favourable economics, succeeded by the RAC curb mixed solely with MK, and lastly, the conventional RAC curb.

6. Conclusions

This study utilised single-factor analysis and orthogonal tests to investigate the mechanical performance of RAC alone and incorporated with MK, as well as the combined inclusion of MK and BF. The effect of RCA replacement rate, MK content, and BF volume content on RAC’s mechanical properties was discussed. Model tests for RAC curbs were conducted based on the optimal mix ratios determined by single-factor analysis and orthogonal test. The primary conclusions are as follows:

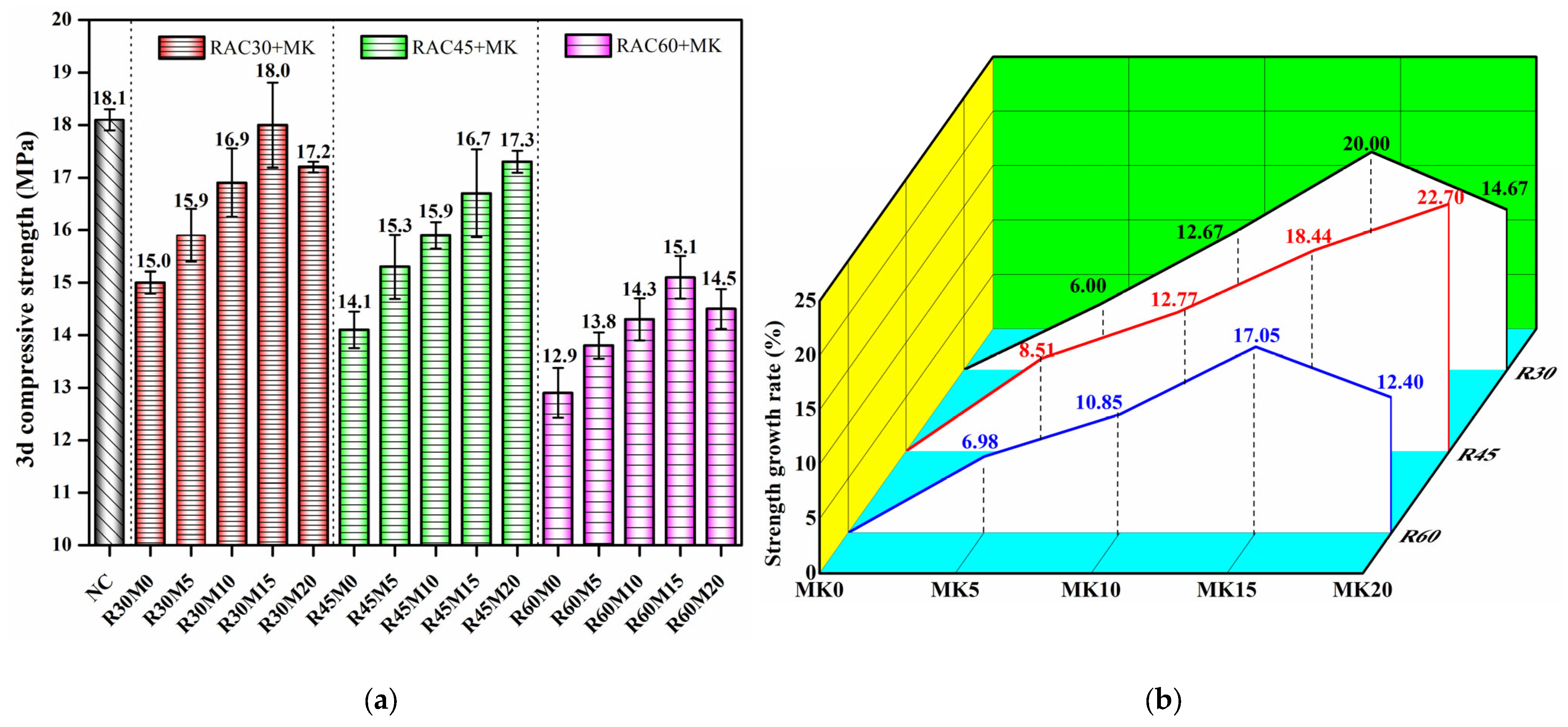

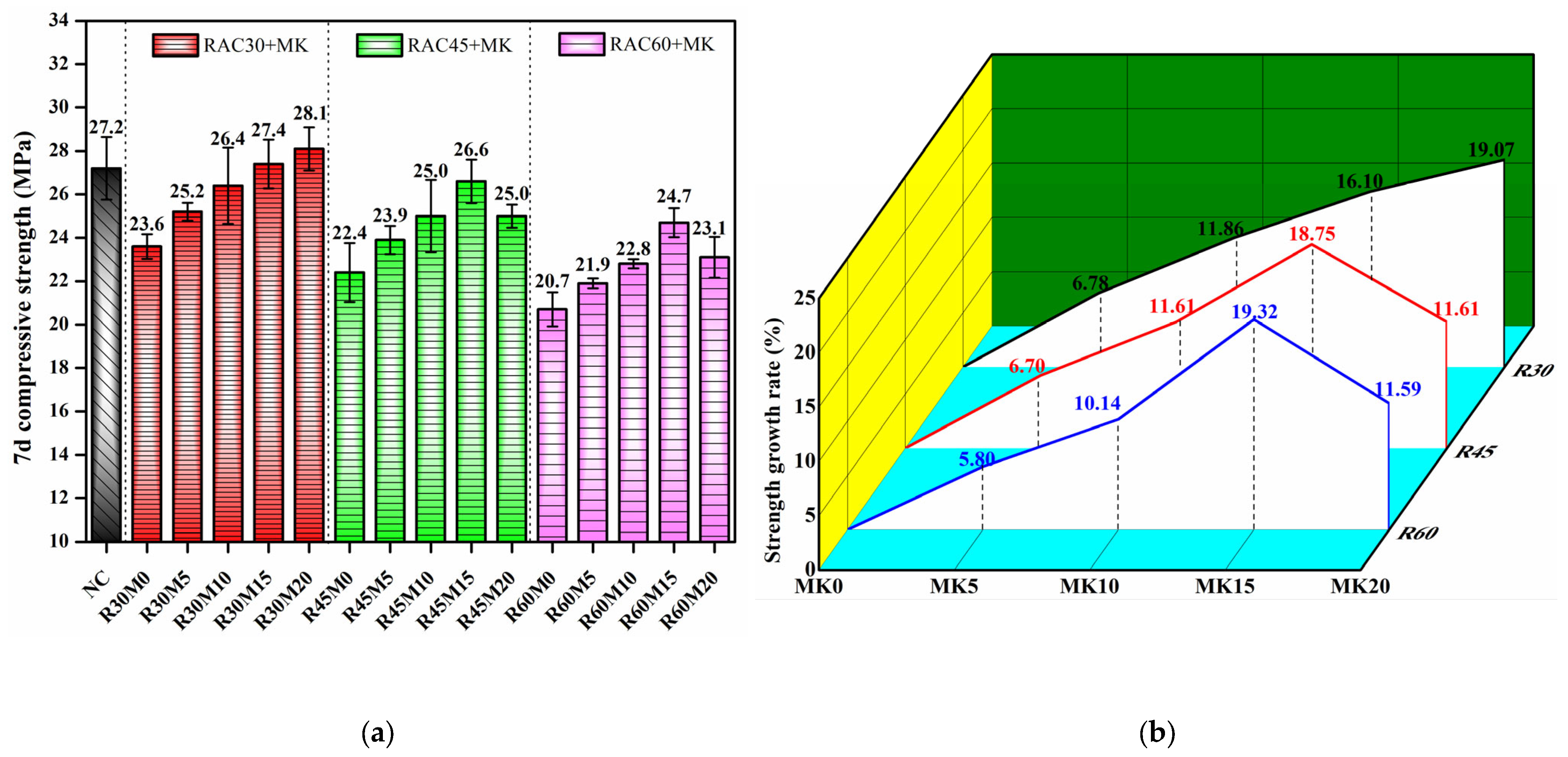

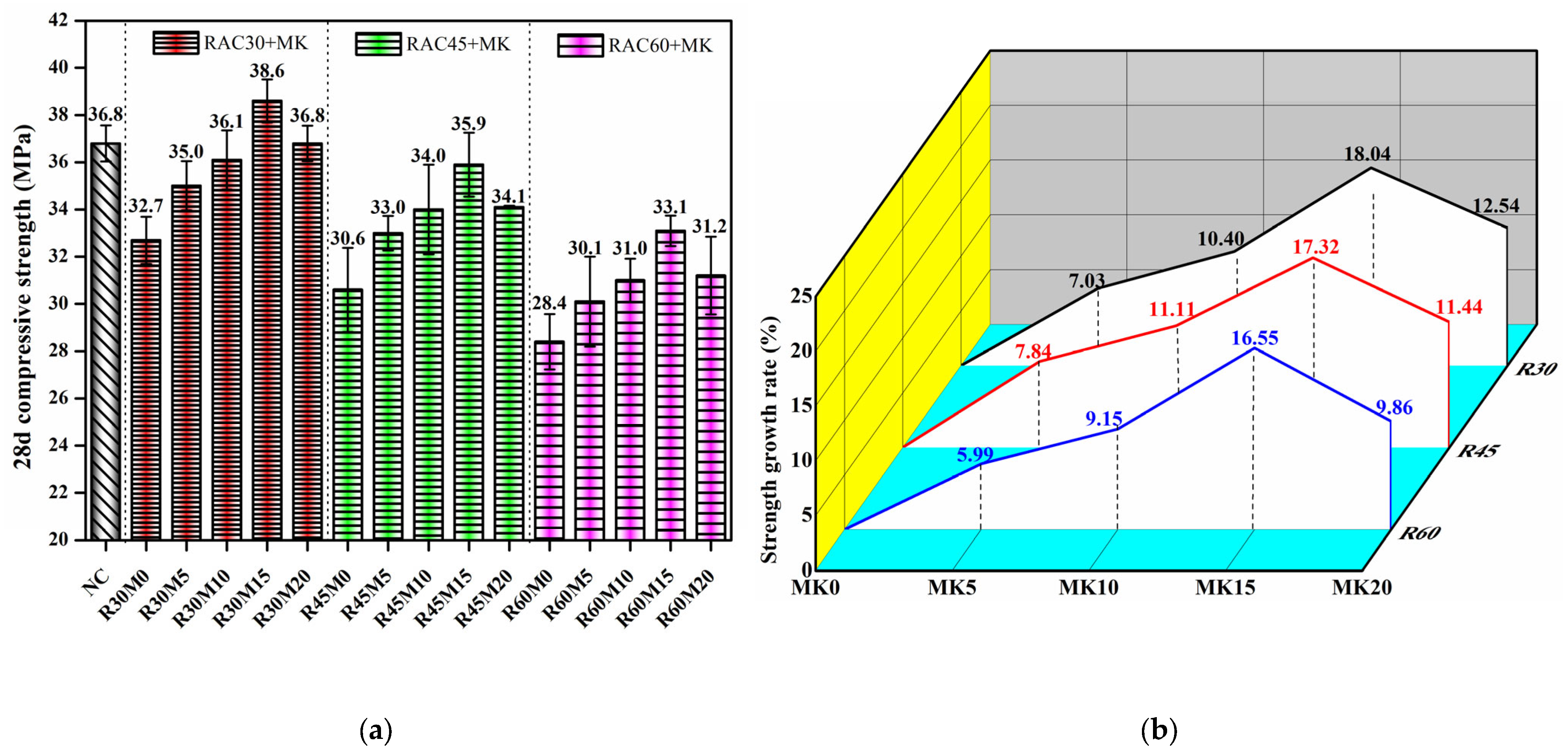

As the MK content increased, MK-RAC’s mechanical properties initially rose and then declined. The best concentration of MK is 15%. The compressive and flexural strength of MK-RAC with RCA replacement rates of 30%, 45%, and 60% at 28 d are 18.04%, 17.32%, and 16.55%, and 19.44%, 17.65%, and 16.13%, superior to those of RAC without MK incorporation, respectively.

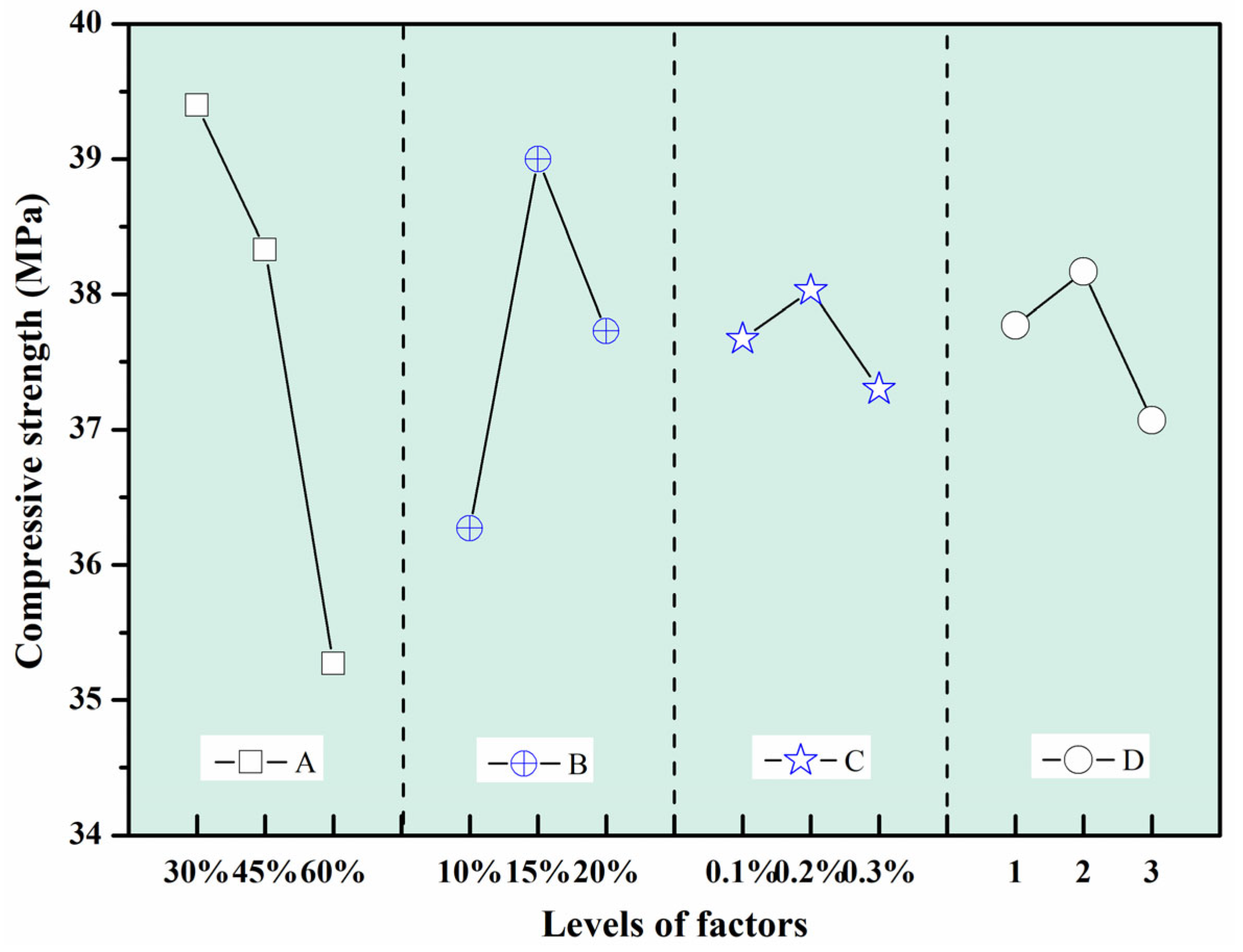

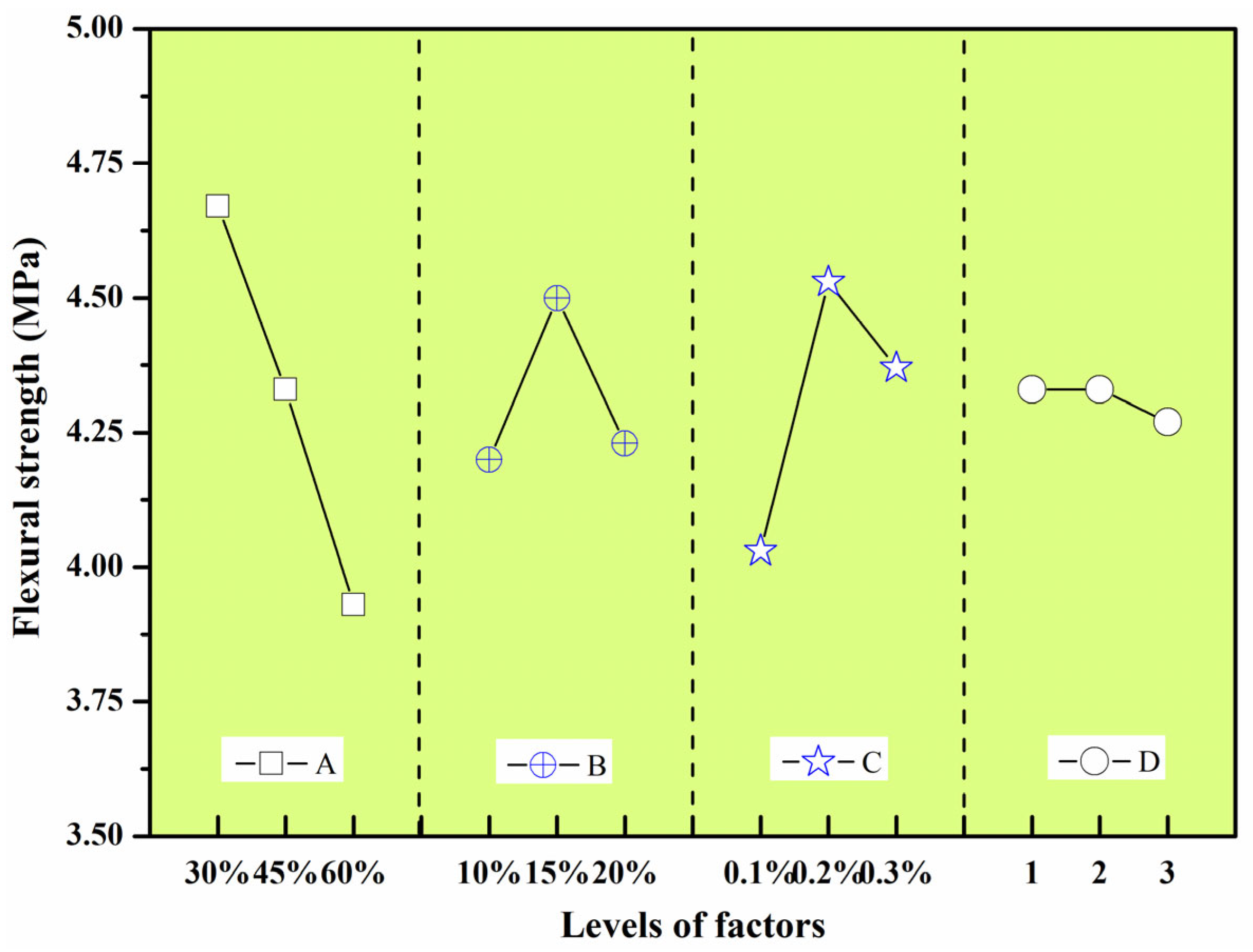

The orthogonal test indicates that the MK content significantly influences the RAC’s compressive strength more than the volume of BF does. The influence of BF on flexural strength is more significant than that of MK content. Introducing BF notably enhances MK-RAC’s mechanical properties compared to studies that focus on a single variable. The mechanical performance of MK-BF RAC is optimised at an RCA replacement rate of 30%, an MK content of 15%, and a BF volume content of 0.2%. Compressive and flexural strength increase by 27.22% and 41.67%, compared to samples devoid of MK and BF, and by 7.77% and 18.60%, compared to specimens containing only 15% MK, respectively.

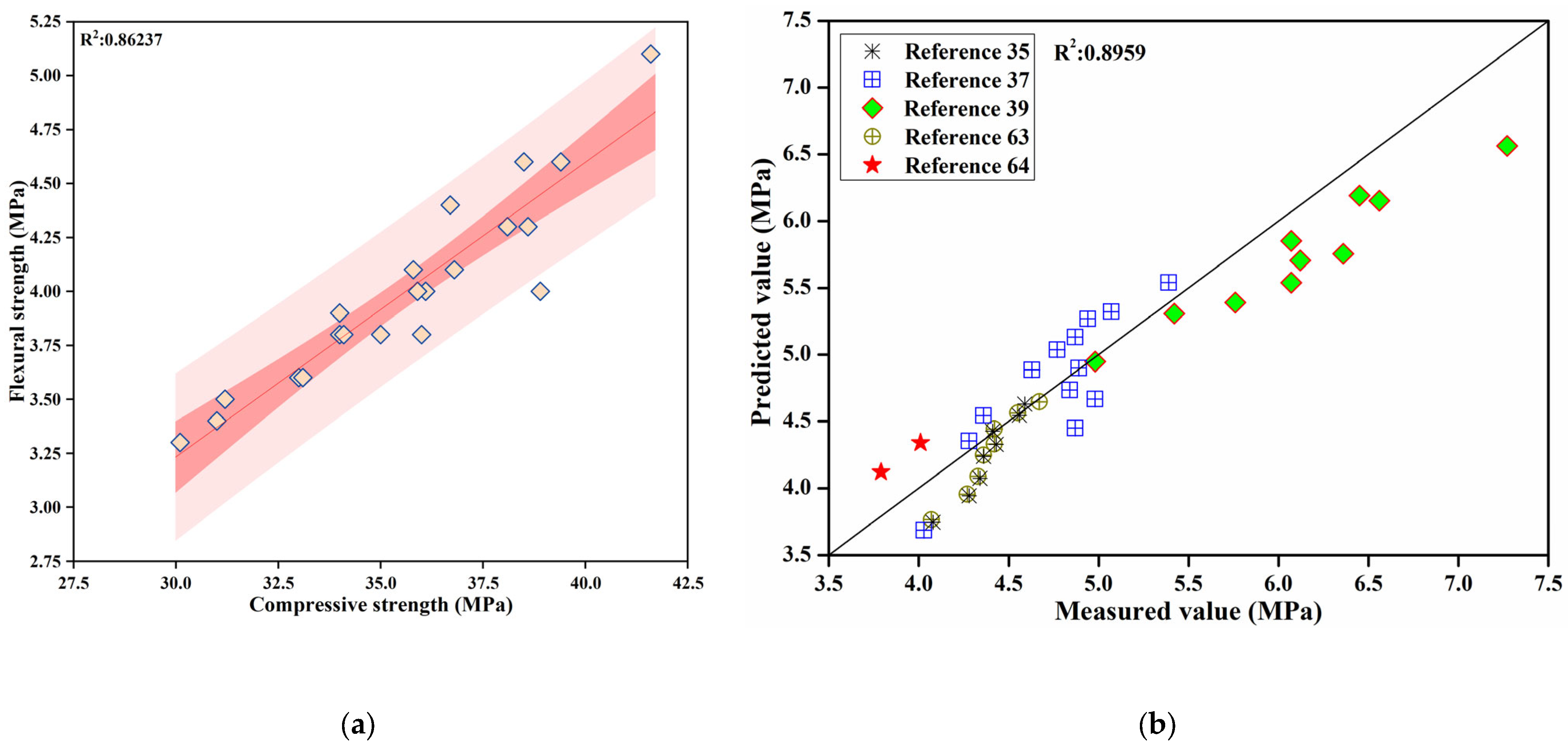

The model test of RAC curbs demonstrates that MK single mixing and MK combined with BF mixing increase the RAC curbs’ mechanical properties. From the perspective of engineering applications, it is recommended to utilise either 15% MK only or 15% MK in conjunction with 0.2% BF (length of 6 mm) to increase the RAC products’ mechanical properties. A predictive model for MK-RAC‘s flexural strength was established based on test results and thoroughly validated by literature data.

Most research on MK-RAC focuses on incorporating MK alone or in conjunction with other extra cementitious materials, with limited studies addressing the combination of MK and fibres. This work investigates the mechanical performance of RAC added with MK and BF. Additional research is recommended in the following areas: (1) The mechanical performance of RAC incorporating MK and BF at a high recycled aggregate substitution rate may encompass impact resistance, compressive strength, and flexural capabilities. (2) The investigation of the long-term performance and durability characteristics of RAC incorporated with MK and BF, including resistance to freezing, cracking, and surface erosion. (3) Investigate RAC products employing single-mixed MK and the synergistic incorporation of MK and BF, encompassing non-load-bearing components such as pavement bricks and concrete curbs, as well as structural components such as concrete beams, slabs, and columns. For instance, evaluate the durability performance of RAC curbs subjected to severe environmental conditions, such as freeze–thaw cycles.