Abstract

Quantifying the environmental benefits of designing buildings for disassembly and flexibility (DfD/DfF) remains challenging within current life cycle assessment (LCA) frameworks. This study assesses the climate impact of a two-story Swedish timber multifamily building (377 m2) designed for future transformation and reuse. An LCA covering modules A–D was performed for one linear scenario (S0: demolition without reuse) and three circular scenarios (S1: layout change, S2: relocation, S3: vertical extension), applying three allocation methods: 100:0, 50:50, and system expansion. All circular scenarios reduced climate impact compared to the linear reference, though to varying degrees. Reductions ranged from 8–50% within the system boundary (A–C), depending on scenario and allocation method. While the 50:50 approach attributed significant reductions within A–C, the 100:0 method emphasized benefits primarily in module D. The 50:50 method yielded the lowest impacts within the system boundary, whereas system expansion showed the largest overall reductions but relied on uncertain assumptions. The study concludes that including future scenarios in LCA is more effective in promoting circularity than the specific choice of allocation method. It emphasizes the need for standardized frameworks that account for multiple use cycles and support fair comparisons in policy and procurement.

1. Introduction

In the transition towards a sustainable society with mitigated greenhouse gas emissions, the building sector plays a critical role [1]. The built environment accounts for approximately 50% of the global material consumption [2] and generates nearly 40% of the global energy and process-related climate impact [1].

Life cycle assessment (LCA) is increasingly used in the building sector to define and reduce climate impact. In the European Union (EU), LCA is implemented in the Level(s) framework for sustainable buildings, focusing on environmental impact [3]. LCA for new buildings is also currently being implemented in the updated version of the Energy Performance of Building Directive (EPBD) which entered into force 28 May 2024 [4]. In addition, several Nordic countries (Norway, Finland, Sweden, and Denmark) have already implemented or are in the process of implementing LCA in building legislation.

LCA is a widely recognized method to assess the environmental impact of products and services. However, applying LCA to buildings is more complex than to single products, as buildings have long lifespans, consist of numerous materials and components, and serve multiple functions [5]. Prior studies have shown that results from building LCAs are highly sensitive to methodological choices, such as end-of-life (EoL) scenarios [6], assumed lifespans [7,8], as well as allocation choices [8].

When accounting for the effect of circularity in the construction sector LCA is the most commonly used method [9]. However, several articles point out that current LCA standards are primarily suited for linear material flows and do not adequately account for circular economy (CE) principles [7,10,11]. Roberts et al. (2023) [12] also emphasize the lack of consensus on how to conduct LCA for circular strategies such as design for disassembly (DfD). Joensuu et al. (2022) [10] further argue that the LCA standards have shortcomings when it comes to CE principles.

The CE concept challenges the traditional linear economy of “take–make–use–dispose” by promoting principles such as reduce, reuse, recycling, and resource efficiency. CE aims to reduce material consumption, extend the life of products and materials, and close resource loops to create a more regenerative system [13,14]. Applied to the building sector, CE means maintaining the value of buildings, sites, and building products for as long as possible through strategies such as design for longevity, durability, flexibility (DfF), and DfD [5].

The European Green Deal has a strong focus on CE [15], and the construction sector is no exception. Circularity in buildings is seen as a key strategy to reduce greenhouse gas emissions and the European Environmental Agency (EEA) (2020) [16] estimates that circular strategies could lead to 61% minimized climate impact from materials in buildings.

Despite the increased number of published LCA studies there is no consensus regarding which method is to be used for assessing circular construction [8]. Previous work has identified several allocation approaches that can be applied within existing standards to evaluate circularity [8,17,18,19] as well as how an LCA can be complemented with a circularity index [11].

When LCA is applied to buildings in the EU and Nordic countries, the potential benefits of DfD and DfF are typically accounted for in module D (beyond the system boundary), in accordance with EN 15978:2011 [20]. However, module D is not always mandatory in practice. Even when included, assumptions often follow linear pathways due to difficulties verifying reuse outcomes, meaning that materials are commonly assumed to go to recycling, energy recovery, or landfill.

With an increasing demand on LCA both from national legislation and the EU and in procurement it is the authors’ opinion that there is a risk of suboptimization where the most climate-efficient building is chosen only considering a linear flow.

The purpose of this study is therefore to examine how different future scenarios and allocation methods influence LCA outcomes for a building designed according to CE principles. The specific objectives are:

- To evaluate the consequences of different scenarios and allocation methods in the context of promoting more circular construction practices.

- To quantify the environmental impact of a building designed for disassembly and flexibility.

1.1. Life Cycle Assessment for Construction in the EU and Nordic Countries

There is a growing demand for LCA in both the EU and Nordic countries, where national regulations increasingly require life cycle assessment for new buildings. In the EU, building LCA is also included in the latest update of the Energy Performance of Building Directive (EPBD) which is to be put in force in 2028 for new buildings over 1000 m2 and 2030 for all new buildings [21].

Both the EU and the Nordic countries refer to the EN 15978:2011 standard for LCA methodology. However, system boundaries and other specific calculation rules differ between countries. The interpretation of the EPBD’s system boundary is based on its definition of the whole life cycle: “… the whole life cycle of a building, including the production and transport of construction products, construction-site activities, the use of energy in the building and replacement of construction products, as well as demolition, transport and management of waste materials and their reuse, recycling and final disposal” [21] (p. 16). More detailed methodology for EPBD implementation is not yet in place and a delegated act defining harmonized methods for calculating life cycle global warming potential (GWP), under Annex III, is to be adopted by 31 December 2025 [22].

To support harmonization of LCA methodology across the Nordic region, a report by Erlandsson et al. (2024) [23], developed within the Nordic Sustainable Construction program, proposes shared scenarios and calculation rules. The report emphasizes the need for comparable results and thus the importance of applying a consistent methodology and scenario framework. The recommended rules follow the 100:0 cut-off approach, where all impacts from building materials are allocated to the first use cycle. It is also assumed that the EPBD will not make calculation of module D mandatory, allowing it to be excluded from national LCA frameworks. The report further recommends that scenarios for module C should be based on current practices in the EU or respective country, meaning that reuse, recycling, and recovery assumptions reflect today’s reality [23].

1.2. Allocation Methods

According to the LCA standard ISO 14044:2006 [24], allocation should primarily be avoided. This can be achieved by (1) dividing the process into sub-processes and “cutting off” the sub-processes that provides the secondary function, (2) applying system expansion where the process providing the secondary function is included in the system boundary. If allocation cannot be avoided it should be applied using (a) physical properties such as mass or (b) other relations such as economic value.

In a literature review by Allacker et al. (2014) [25] eleven different allocation methods for secondary material production and EoL recovery were identified. These were grouped into three different approaches: 0:100, 100:0, and 50:50. The review also identifies other alternatives, such as the circular footprint formula (CFF), used in the product environmental footprint (PEF) methodology [26]. These allocation approaches are used in several articles such as Nygaard Rasmussen et al. (2019) [27], Kjær Zimmerman et al. (2022) [28], and De Wolf et al. (2020) [29]. The different allocation approaches together with system expansion are presented below:

- System expansion: System expansion includes the impact from the secondary function within the system boundary. For a building designed for disassembly and flexibility, this means including the impacts from reuse, use, and EoL across all anticipated use cycles of the building [10].

- The 100:0 approach: The 100:0 approach is sometimes referred to as avoided burden [28] or the cut-off approach [19] and allocates the burden to the use cycle in which it occurs. This is the approach found in the European standards such as EN 15978:2011 and EN 15804:2012 [30] and is aligned with the “polluter pays” principle. For a building designed for disassembly and flexibility this means the burden of reuse or recycling is allocated to the use cycle in which those processes occur. Thus, the initial use bears the full impact of, for example, material production, while subsequent uses are considered free of that impact. The burden from EoL is attributed to the final use cycle. The 100:0 approach promotes the use of reused and recycled materials rather than the system that provides the reused or recycled materials [27]. Potential benefits from future reuse and recycling are instead presented as benefits beyond the system boundaries in module D.

- The 0:100 approach: Sometimes referred to the EoL method [29], this approach is conceptually the opposite to the 100:0 approach. It allocates the impact of production and EoL to the last use cycle. While this encourages the design of reusable components, it does not incentivize the actual reuse of materials [17].

- The 50:50 approach: The 50:50 approach divides the impact from production, use, and EoL equally between the use cycles. This approach encourages both reuse of materials as well as design for reuse. However, interpretations vary. For instance, Lausselet et al. (2023) [17] allocates between the first and the second use cycle, while Eberhardt et al. (2019) [8] distribute the impacts across several (all assumed) use cycles.

2. Materials and Methods

LCA was used to quantify the environmental impact of a Swedish multifamily building designed for disassembly and flexibility, with different future scenarios in a second use cycle. The methodology followed the EN 15978:2011 standard, with the addition of system expansion and the two allocation methods 100:0 and 50:50, as described in later sections. An attributional LCA approach was adopted, meaning the assessment seeks to quantify the potential environmental impacts that can be attributed to the product system [13]. Attributional LCA is also used in current practice of legislation in the Nordic countries [23] as well as in the recast of the EPBD [21].

The system boundary in this study included the following life cycle stages: production (A1–A3), construction (A4–A5), refurbishment (B5, when applicable), EoL (C1–C4), and the next construction system (D), as shown in Table 1. The focus of this study is on how the choice of future scenario and allocation approach affects the outcome of the LCA. Consequently, the rest of the use stage (B1–B7) is not included in the assessment. As module B6 (operational energy) may be influenced by changes in layout or occupancy density, a bounding estimate was performed to check the potential influence of this exclusion (see Section 3).

Table 1.

Life cycle stages included in this study as well as in legislation in the Nordic countries and interpretation of the recast of the EPBD.

Table 1 also presents the life cycle modules currently included in national legislation across the Nordic countries, as well as an interpretation of the recast EPBD. Finland and Iceland have not yet adopted the legal proposal and are therefore excluded from the table.

The building included in the assessment is designed to be adaptable over time, so no specific reference study period is applied to the functional unit. This is based on the assumption that changes to the building are driven not by material lifespans but by evolving user needs. This is also motivated by Huuka and Lahdensivu (2014) [31], concluding that the general reason for demolition is not age, rather, it is commonly carried out to make way for new construction. Such changes could thus occur at any point during the building’s lifetime. Accordingly, the functional unit is defined as one square meter (m2) of the gross floor area. The environmental impact category used in this study is global warming potential (GWP) excluding the biogenic carbon, in line with Swedish legislations [32].

The life cycle inventory (LCI) data for this study is based on publicly available datasets from the national board of housing in Sweden [32], Byggsektorns Miljöberäkingsplattform (BM, 3.2; IVL Swedish Environmental Research Institute, Stockholm, Sweden) and the public database CO2Data.fi (accessed on 09 November 2023) from Finland. Primary inventory data was gathered directly from the architectural design team in collaboration with the construction company, including material quantities and specifications. Where such data was incomplete, additional information was retrieved from technical datasheets, environmental product declarations (EPDs), and manufacturer or supplier documentation. Data for technical installations, interior surfaces, and furnishings (e.g., kitchens, built-in wardrobes) were not available in detail, these components were instead represented using template data from Malmqvist et al. (2023) [33], based on typical Swedish multifamily buildings with timber frames. Also, certain construction elements, such as rainwater collection systems, nails, bolts, fasteners, and other small fittings, were not included in the material inventory.

Calculations were performed using BM, with inventory modeling based on standardized databases (national board of housing in Sweden, BM 3.2, CO2data.fi).

2.1. The Case Study: A Multifamily House

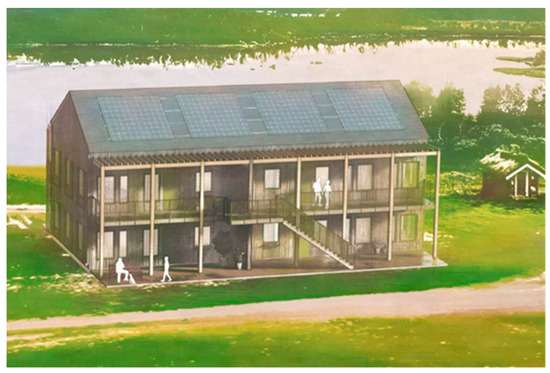

The case study was a multifamily house unit with two floors and a gross floor area of 377 m2. It is structurally designed to support the load of up to four floors. The exterior wall elements consist of wood and are constructed of standing wooden latches with milled channels where stagnant air creates insulation. The interior walls are designed to be easily moved or taken apart to accommodate changes in building function or layout. The load-bearing structure includes lightweight wooden beams, capable of spanning long distances and supporting up to eight floors. The foundation is made of foam glass and steel latches and is designed to manage a load of four floors. An illustration of the building is presented in Figure 1 and the materials used in its construction are presented in Table 2.

Figure 1.

Case study: a two-story multifamily timber house designed for disassembly and flexibility. Illustration: ETTELVA Architects AB, Stockholm, Sweden.

Table 2.

Construction materials for the case study.

2.2. Scenarios

This study evaluates three different allocation approaches across four future scenarios representing the building’s second use cycle. The future scenarios are divided into one linear scenario and three circular scenarios. In the circular scenarios, the building is adapted to future conditions through transformation or relocation, enabling analysis of multiple possible outcomes. The scenarios are as follows:

- Scenario 0 (S0): EoL with no reuse (linear scenario).

- Scenario 1 (S1): Change of layout (circular scenario).

- Scenario 2 (S2): Change of location (circular scenario).

- Scenario 3 (S3): Adding floors (circular scenario).

The scenarios are described in more detail below.

2.2.1. Scenario 0 (S0): EoL with No Reuse (Linear Scenario)

This scenario does not take DfD and DfF into account. As a result, no reuse of the building is considered after EoL. This represents a conventional linear approach.

2.2.2. Scenario 1 (S1): Change of Layout (Circular Scenario)

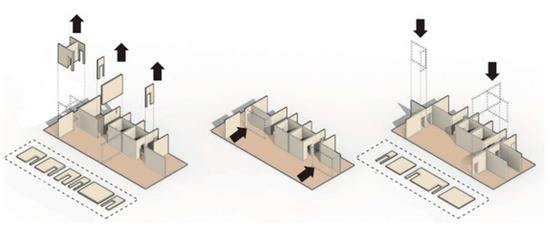

In S1 the function of the building changes from one family per apartment to co-housing. In this scenario walls are removed, moved, and added to change the layout from four rooms and a kitchen in one apartment and two rooms and a kitchen in the other apartment to a co-housing floor of six smaller bedrooms and a large joint kitchen, dining area, and living room, see illustration in Figure 2.

Figure 2.

Scenario 1 (S1): Walls removed, walls moved, and walls added in case study building design. Illustration: ETTELVA Architects.

The activities occurring in the second use cycle are deconstruction and reconstruction of existing wall elements, production of new materials for new wall elements, transport to the construction site and energy use for construction as well as handling and transport of construction waste.

Although deconstruction and reconstruction of wall elements occur in this scenario, their environmental impacts were not included in the LCA due to insufficient data. As a sensitivity check, literature-based factors for selective demolition were applied. Malella et al. (2021) [34] report values of 1.42–2.16 kg CO2e/m2 GFA, although these figures cover a broader set of building components. Moreover, since only a fraction of the floor area is affected by layout changes in S1, the resulting contribution is expected to be negligible relative to the total impacts and does not influence the comparative conclusions.

See Table 3 for added materials in the second use cycle.

Table 3.

New material use (kg) in S1.

2.2.3. Scenario 2 (S2): Change of Location (Circular Scenario)

In S2 the entire building is moved to a new location. Activities occurring in the second use cycle are deconstruction, transport of the building to the new location, reassembly of the reused building parts, production of new materials needed, transport and energy use at the construction site as well as handling and transport of construction waste. For simplicity, the building is assumed to be moved directly to the new location without intermediate storage. It is further assumed that all installations, interior surfaces, and built-in furniture are replaced after the building is moved and therefore included as new additions in the second use cycle. Template data for the added technical installations, interior surfaces, and built-in furniture is presented in Table 4.

Table 4.

Use of template data for S2 in GWP-GHG per gross floor area (GFA).

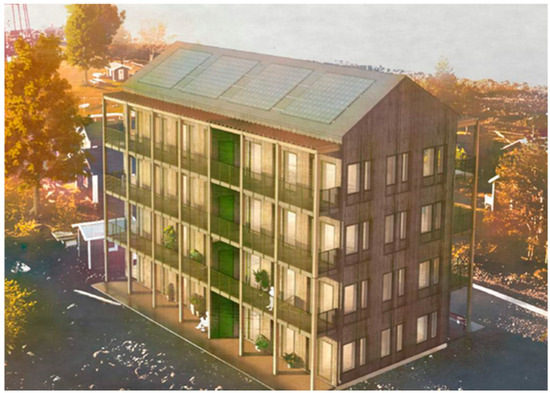

2.2.4. Scenario 3 (S3): Adding Floors (Circular Scenario)

In S3, a two-story extension is constructed, see illustration in Figure 3. To enable this, the existing roof is disassembled and then reassembled once the extension is complete. As a result, the second use cycle includes the disassembly and reassembly of the roof, the production of new materials and products required for the extension, as well as the installation of an elevator, transport, and energy use at the construction site. The extension adds a new frame, ceiling, façade, interior walls, windows, doors, technical installations (incl. elevator), interior surfaces, and built-in furniture. A detailed overview of the materials added in the second use cycle is provided in Table 5. Template data for the additional materials used in technical installations, interior surfaces, and built-in furniture is presented in Table 6.

Figure 3.

Scenario 3 (S3): two floors are added. Solar roof is not part of the assessment. Illustration: ETTELVA Architects.

Table 5.

New material use (kg) in S3.

Table 6.

Use of template data for S3 in GWP-GHG per gross floor area (GFA).

2.3. Application of Allocation Methods on Chosen Scenarios

The allocation methods tested in this study are the 100:0 approach used in EN 15978:2011/EN 15804:2012 and the 50:50 approach. Although system expansion is technically a method to avoid allocation, it is also applied in this study and will be referred to as an allocation approach for simplicity.

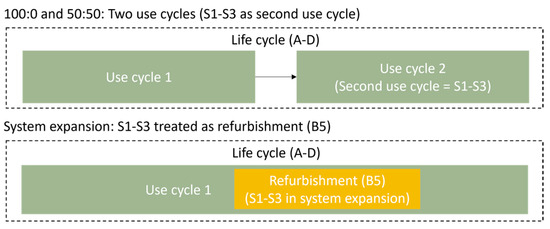

The future scenarios (S1–S3) are modeled as a second use cycle under the 100:0 and 50:50 approaches but as a refurbishment (B5) within the first use cycle under the system expansion approach. In the case of system expansion, a key challenge arises in interpreting the standard. According to EN 15978:2011, refurbishment can either be considered part of the initial building use cycle or attributed to a separate second life cycle assessment. However, the standard does not clearly define how this distinction should be made. EN 15978:2011 states that scenarios for refurbishment shall be developed where details of planned refurbishment are known to the assessor, including if the refurbishment is performed or planned in conjunction with a change of use. This raises the question of whether scenarios based on DfD and DfF should be classified as planned refurbishment or if they should be treated as independent future use cycles. In this study, they are considered as planned refurbishment.

The application of the different allocation approaches on each scenario is described below.

2.3.1. System Expansion

The system expansion approach includes the first and the second use cycle of the building within the system boundary. For scenario 0 (S0), EoL with no reuse, this covers the impacts from production as well as the EoL of an entirely new building replacing the first. This assumes that the original building is demolished and no components are reused. For scenario 1 (S1), change of layout, scenario 2 (S2), change of location, and scenario 3 (S3), adding floors, system expansion also includes impacts associated with the corresponding refurbishment activities. These impacts cover the production, transport, installation, and EoL treatment of the materials and components involved in the refurbishment.

Alternative S0 (major refurbishment) for sensitivity: In addition to the main S0 (full demolition and new construction), a sensitivity case was modeled in which the initial building undergoes a major refurbishment instead of full replacement. B5 impacts were approximated as ~90 kg CO2e/m2, drawing on Rasmussen and Birgisdóttir (2016) [35], who reported embodied impacts of 87.5 kg CO2e/m2 for a refurbishment including measures on the building envelope, interiors, and technical installations. End-of-life (C) was treated in two ways: (i) kept equal to S0 (63 kg CO2e/m2, upper bound; no credit for reduced demolition waste) and (ii) aligned with a limited-waste refurbishment (~32 kg CO2e/m2, consistent with S1–S3).

2.3.2. The 100:0 Allocation

The 100:0 approach only includes the first use cycle of the building for all scenarios. The benefit from reuse is reported outside the system boundary in module D. For S0, no reuse is assumed and hence the benefits shown in module D are benefits from material recycling and incineration with energy recovery, based on current Swedish recycling statistics. For S1–S3 the benefits shown in module D are from the materials being reused in the second use cycle assuming they replace primary materials. Materials and products meeting EoL in the first use cycle in S1–S3 are handled in the same way as in S0.

2.3.3. The 50:50 Allocation

Since there will be parts of the building in each scenario that are only used in one use cycle the application of the 50:50 approach is combined with the 100:0 approach. Only impacts from activities related to reused materials are therefore divided equally by the two use cycles. This applies, for instance, to the production stage of materials that are reused. For materials and components without a second use, the full environmental impact is allocated entirely to the first use cycle. Table 7 provides an overview of how the impacts are allocated to the first use cycle.

Table 7.

Division of impact between use cycles using the 50:50 approach.

2.4. Terminology and Conceptual Framework

For clarity, the following terminology is used consistently throughout this paper: “use cycle” denotes one complete service period of the building; “life cycle” refers to the full cradle-to-grave assessment; “refurbishment (B5)” refers to interventions within the initial use cycle; and “second use cycle” denotes scenarios S1–S3. See Figure 4 for conceptual terminology.

Figure 4.

Conceptual illustration of terminology.

2.5. Reuse in Each Allocation Approach

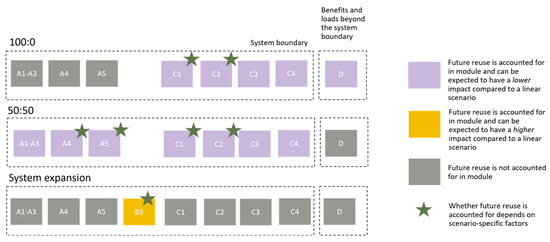

The effects of reuse are distributed across different life cycle modules depending on the chosen allocation approach. Figure 5 illustrates how reuse is accounted for in the different allocation approaches.

Figure 5.

Overview of life cycle modules where reuse is accounted for under different allocation approaches (100:0, 50:50, system expansion). Purple boxes indicate lower climate impact compared to the linear scenario; orange boxes indicate higher impact. The star symbol highlights modules where results depend on scenario-specific factors (e.g., on-site vs. off-site reuse, transport, or disassembly/reassembly processes).

When applying the 100:0 approach, reuse is reflected in the EoL phase, as less material is treated as waste in module C and in module D for the next construction system.

When applying the 50:50 approach reuse is accounted for in all modules within the system boundary, as the impacts of reusable products are shared equally between the two use cycles. Since reuse is already included within the system boundary, only benefits from material recycling and energy recovery are reported in the next construction system (module D). This follows the principles of EN 15978:2011/EN 15805:2012, which state that all input flows of secondary materials must be subtracted from module D to avoid double counting of benefits.

The distribution of shared burdens from transport (modules A4, C1) and energy use during construction or deconstruction (modules A5, C2) varies by scenario:

- In S1 reuse occurs on-site, so all the accounted for burden is shared. Energy use from deconstruction and construction of wall elements is not included in the LCA due to insufficient data.

- In S2 reuse involves additional transport and energy use; therefore, this burden is not shared, as these processes occur twice.

- In S3 reuse also occurs on-site, so the burden is shared. However, additional energy is required for disassembling and reassembling of the roof, meaning this energy burden is not shared.

For the system expansion approach, it is less clear where reuse is accounted for. Since the impact from the transformation is categorized as a refurbishment (module B5), and thus expected to occur during the same use cycle as the initial building, the added impacts are included, but no reuse benefits are explicitly accounted for. This means reuse is treated as an additional impact rather than as a source of avoided burdens.

3. Results

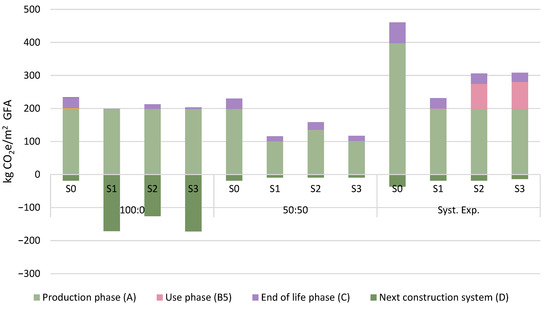

The full result of this study is presented in Table 8 as well as in Figure 6, enabling a comparative overview across scenarios (S0–S3) and allocation approaches (100:0, 50:50, and system expansion).

Table 8.

Impact per life cycle stage in GWP per gross floor area (kg CO2e/m2 GFA) for each scenario and allocation approach.

Figure 6.

Climate impact per life cycle stage in GWP per gross floor area (kg CO2e/m2 GFA) across scenarios (S0–S3) and allocation approaches (100:0, 50:50, system expansion).

Beyond absolute values, the results highlight consistent patterns. Scenario S1 (layout change) performs best across all allocation methods due to maximum reuse of original elements, whereas S2 and S3 involve more replacements and therefore slightly higher impacts. Across all approaches, the main driver of reductions is avoided production of new materials, which outweighs additional burdens from transport, demolition, or energy use. These findings confirm that the design for adaptability yields benefits under varied methodological assumptions.

Alternative S0 (major refurbishment) under system expansion: If the second use cycle of the reference case S0 is modeled as a major refurbishment instead of full demolition and new construction, the total impacts are reduced. Assuming refurbishment impacts of ~90 kg CO2e/m2, the alternative S0 results in 352 kg CO2e/m2 when end-of-life (C) is kept equal to the original S0 (63 kg CO2e/m2) and 320 kg CO2e/m2 when C is aligned with the limited-waste assumption used for S1–S3 (32 kg CO2e/m2). For comparison, the system expansion results for the circular scenarios are S1 = 232, S2 = 306, and S3 = 308 kg CO2e/m2 (Table 8). Thus, modeling S0 as a major refurbishment narrows the gap with S1–S3. Nevertheless, S1 (layout change) consistently remains the lowest-impact option.

3.1. Results for Reuse in Each Allocation Approach

As shown in Table 8 and Figure 6, all three circular scenarios (S1–S3) result in lower climate impact compared to S0, regardless of allocation approach. This demonstrates a clear advantage of circular construction over linear alternatives. The findings are consistent with previous studies [7,8,10,12].

The primary reason for the higher impact of S0 compared to S1–S3 lies in the extent of material reuse in the second use cycle. In the circular scenarios, extensive reuse leads to reduced waste in the 100:0 approach, halved impacts for many materials and products in the 50:50 approach, and minimal new material input in the system expansion approach. In contrast, S0 assumes that all materials reach end-of-life in the 100:0 approach, no impact is shared in the 50:50 approach, and a completely new building is constructed under system expansion.

It is also worth noting that scenario S0, EoL with no reuse, has the same impact for all modules using the 100:0 cut-off approach and the 50:50 approach. This is because only one use cycle is assumed, and 100% of the impact is allocated to that use cycle in both cases. Applying system expansion, however, an entire new building is assumed to replace the first one upon demolition, resulting in a doubled impact. If no replacement were assumed, the impact would be identical across all allocation methods for S0.

Furthermore, Table 8 and Figure 6 show that S1, change of layout, results in the lowest climate impact regardless of allocation approach. This is because the building receives a new use cycle while nearly all materials from the original structure are reused. Hence, the most climate-beneficial scenario, according to this study, is the one where the building never gets demolished or deconstructed and where renovations are kept to a minimum.

The second lowest impact from the building system boundary (modules A, B5, and C) is observed for S3, adding floors. This is true for all allocation approaches except for the system expansion where S2, change of location, shows a slightly lower impact than S3. Both S2 and S3 involve more materials reaching EoL compared to in S1. This means that fewer materials are assumed to be reused in the second use cycle for S2 and S3 compared to S1. Consequently, fewer materials are reused in the second use cycle in S2 and S3, leading to a smaller share of impact being allocated to the second cycle in the 50:50 approach. For system expansion, this also means more new materials are added during the use stage (module B5) in S2 and S3 than in S1.

However, the differences in impact between S1–S3 within each allocation approach are relatively small. This is largely due to the significant avoidance of new material production, which has a far greater climate impact than transport, demolition, and energy use at the construction site. The substantial impact from material production also explains why relocating a building can be environmentally beneficial despite the additional emissions from deconstruction and transport, as seen in the results for S2.

The finding that circular scenarios show lower impacts than the linear baseline is consistent with previous LCAs of DfD/DfF buildings (e.g., [7,8,12]), which similarly reported substantial reductions in embodied emissions when reuse was enabled.

3.2. Comparison of Allocation Approaches

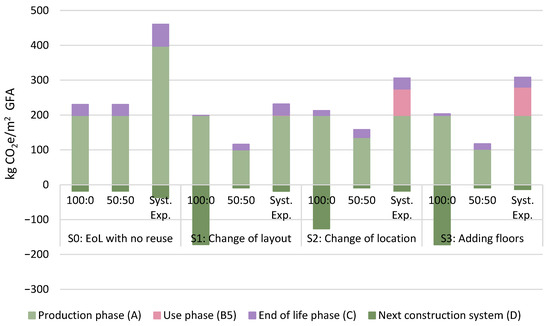

As shown in Figure 7, the choice of allocation approach has a significant effect on the total climate impact.

Figure 7.

Comparison of total climate impact (kg CO2e/m2 GFA) across allocation approaches for all scenarios (S0–S3).

The result clearly indicates that system expansion yields the highest total impact across all scenarios. Within the system boundary (modules A–C) system expansion ranges from 232 kg CO2e/m2 for S1, change of layout, and 308 kg CO2e/m2 for S3, adding floors. This is expected since the activities in the next use cycle are seen as a renovation in the use phase of the first use cycle.

In contrast, the 50:50 approach results in the lowest total impact for scenarios S1–S3, ranging from 116 kg CO2e/m2 for S1 to 158 kg CO2e/m2 for S2, change of location, within the system boundary (modules A–C). The lower impact is explained by the fact that the emissions associated with materials and products reused in the second use cycle are shared equally between both use cycles, effectively halving their impact.

Figure 7 also reveals that the reuse benefits in the 100:0 approach are not visible within modules A–C but appear clearly in module D. For S1–S3, the impact within the system boundary (modules A–C) ranges between 199 kg CO2e/m2 for S3 and 230 kg CO2e/m2 for S2. However, in module D, substantial benefits are evident: −172 kg CO2e/m2 for both S1 and S3 and −126 kg CO2e/m2 for S2. If module D is included in the total assessment, the 100:0 approach would yield the lowest overall climate impact among the three allocation methods.

Similar to findings by Lausselet et al. (2023) [17] and Malabi Eberhardt et al. (2020) [19], the results demonstrate that the allocation method strongly influences how reuse benefits are represented. In particular, the visibility of avoided burdens differs substantially between approaches, confirming that methodological choices remain a key source of variability in building LCAs.

3.3. Relative Differences Compared to the Linear Scenario

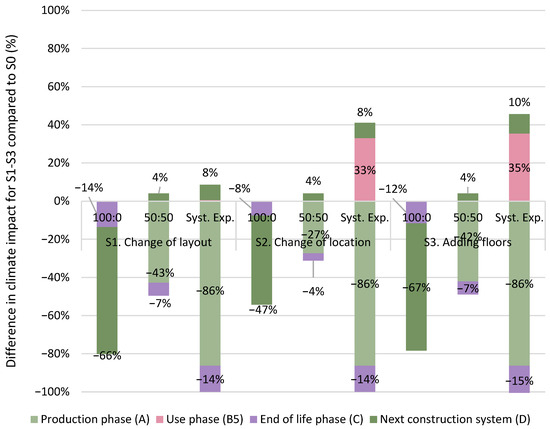

Table 9 and Figure 8 present the difference in climate impact for the circular scenarios (S1–S3) compared to the linear one (S0).

Table 9.

Increase or decrease in GWP per gross floor area (kg CO2e/m2 GFA) for S1–S3 compared to S0 per allocation approach. Negative values indicate a decrease (improvement), and positive values represent an increase.

Figure 8.

Relative differences in climate impact between S1–S3 (circular) and S0 (linear). Negative values indicate a reduction (improvement) and positive values indicate an increase.

When considering only the system boundary (modules A, B5, and C), the 100:0 approach results in the smallest impact reduction for S1–S3 compared to S0. The reduction ranges from 8% for S2, change of location, to 14% for S1, change of layout. In this approach, future reuse is only reflected as a reduction in the EoL phase (module C) within the building system boundary. As the production phase (module A) is identical for all scenarios under 100:0, it contributes to no difference (0% change).

In contrast, system expansion yields the largest reduction for S1–S3 compared to S0. Even though impacts from the second use cycle are allocated to the use phase (module B5), the total impact in the production (module A) and EoL (module C) phases is significantly lower for S1–S3 than for S0, which assumes a full new building. Specifically, the reduction is about 50% for S1 and around 33% for S2–S3.

However, the results for system expansion are highly sensitive to assumptions made for the linear reference scenario (S0). For example, if S0 assumes extensive renovation instead of demolition and reconstruction, the relative advantage of S1–S3 would diminish. This adds uncertainty to the comparison.

The 50:50 approach also shows considerable impact reductions for S1–S3. This is mainly because the large impact from the production phase (module A) is split between the two use cycles. As shown in Figure 6 and Figure 7, this stage accounts for the largest share of emissions. More specifically, the reduction from modules A and C combined is about 50% for S1, 31% for S2, and 49% for S3.

Comparing S1–S3 to S0, there are fewer benefits in module D when applying the 50:50 and system expansion approaches, compared to the 100:0 method. In fact, only the 100:0 approach shows a reduction in module D for S1–S3 relative to S0. This is because module D accounts only for benefits from recycling and energy recovery in the 50:50 and system expansion approaches, whereas the 100:0 approach also includes reuse benefits. More specifically, in the 50:50 approach, module D shows an increase of 4% for all S1–S3 scenarios. Under system expansion, the values increase by 8% for S1 and S2 and by 10% for S3. In contrast, under 100:0, module D shows substantial reductions of 47% for S2 and 67% for S3.

3.4. Operational Energy (B6)

Although module B6 was excluded, a bounding estimate was made to test its potential influence. An estimate based on typical Swedish multifamily energy use of 90 kWh/m2 per year for buildings constructed after 2010 [36], equivalent to 90–135 kg CO2e/m2 over 50 years (using Swedish electricity intensity of ~20–30 g CO2e/kWh), suggests that even a ±10% variation would shift totals by only 9–14 kg CO2e/m2. Compared to the embodied results of 116–460 kg CO2e/m2 (Table 8 and Table 9), this represents a difference of ~2–12%. Thus, operational energy may shift absolute totals slightly, but the relative ranking of scenarios is not expected to change.

4. Discussion

This section discusses and evaluates the result of the study to explore how different future scenarios and allocation methods can support more circular construction practices within current LCA legislation.

All three allocation approaches tested in this study can be used to promote circular construction. This is evident, as all circular scenarios (S1–S3) show lower climate impact compared to the linear scenario (S0), regardless of allocation method. However, the allocation approaches differ in complexity and promote circularity in different ways.

4.1. Uncertainty in Future Scenarios

Despite the benefits from circular construction demonstrated in this study, projecting outcomes for future scenarios highlights the inherent challenge of assessing events that have yet to occur. There is no guarantee how a building will be treated after its initial use. Factors such as economic incentives, regulatory frameworks, and even sentimental or aesthetic preferences can influence whether reuse occurs, even when the building is designed for flexibility and disassembly. Thus, as seen in S0, EoL with no reuse, a building may still be demolished and not reused.

This uncertainty is one of the primary reasons why future scenarios are difficult to implement in legislation and procurement. Nonetheless, if circular construction is to be prioritized over linear alternatives, a means to quantify its potential benefits is essential. It is therefore the authors’ opinion that a clear set of rules and methodological guidance are needed to be able to include future scenarios that takes circularity into account, ensuring fair comparisons between buildings designed for circularity and those designed for conventional use.

4.2. Sensitivity to Allocation Method

While the choice of circular scenario (S1–S3) has a relatively smaller influence within each allocation method, the choice of allocation approach significantly affects the outcome of the LCA. The choice of allocation approach has an especially large impact on how the reuse is depicted. For instance, the benefit from reuse in the 100:0 approach results in a lower value at the EoL, whereas in the 50:50 approach and system expansion the benefits are mainly visible as reductions in the production stage.

Further, the result varies depending on if module D is included or not. If only including the system boundary (modules A–C), the 50:50 approach results in the lowest total climate impact. However, if module D is included, and not reported outside the system boundary, the 100:0 approach shows the overall lowest impact. System expansion shows the greatest reduction compared to the linear scenario, S0, but this depends on the assumption that the original building is replaced with a new one in the second use cycle, which introduces added uncertainty.

4.3. System Boundaries and Legislative Implications

The findings show that LCA results are sensitive to the chosen system boundary, which raises issues for current legislation in countries that exclude certain life cycle stages (see Table 1). The consequences of such exclusions depend on the allocation approach:

- The exclusion of modules C and D would be the least beneficial for the 100:0 approach if circular construction such as DfD and DfF is to be promoted, as most reuse benefits are captured in these stages.

- In contrast, the 50:50 or the system expansion approaches show most of their benefit in module A and are therefore less affected by the exclusion of later life cycle stages.

Therefore, excluding parts of the building’s life cycle is problematic when promoting circular construction. This issue is especially relevant today, as legislation often fails to account for these later use cycle stages.

4.4. Method-Specific Challenges

This study also highlights challenges of each allocation approach. It includes several scenarios that can result from designing for disassembly and flexibility, demonstrating that no single method is equally suitable for all cases. This is particularly evident in S2, change of location, which proved to be the most challenging to model. This might be one reason why the literature includes many different methods for handling circularity and why it is hard to gather around one unified method. Further research is needed to test allocation approaches across a broader set of circular scenarios to understand their generalizability and limits.

4.4.1. The 50:50 Approach: Lowest Impact, Highest Complexity

The 50:50 allocation approach was the most complex to apply and proves to be difficult to analyze on a building level. For example, its effectiveness depends on the assumption that materials and products are reused for a consistent number of use cycles, something that may vary in practice. Furthermore, the 50:50 method can be difficult to apply depending on future scenario. For example, it proved most difficult to apply to S2, change of location, due to the need to allocate impacts from transport, deconstruction, and reassembly across two use cycles.

Because of this complexity, the 50:50 approach may not be well suited for widespread application—particularly in contexts where non-experts are responsible for interpreting LCA results. Another concern is accountability: splitting impacts evenly across use cycles could mean no one takes responsibility for the impacts that are allocated to the second use cycle [8].

Since the 50:50 approach greatly depends on the number of use cycles assumed, the more use cycles assumed, the lower the impact assigned to each one. Nevertheless, assuming only one more use cycle as in this study, the 50:50 approach still showed the lowest impact within the defined system boundary.

4.4.2. The 100:0 Approach: Easiest to Apply, Least Reflective of Reuse

The more common allocation method 100:0 was the least beneficial allocation approach for promoting DfD and DfF if only considering the impact within the system boundary. However, 100:0 is the most used method for the climate calculations of buildings today, in Nordic countries and in EU harmonization efforts.

Including module D, where reuse benefits are captured, significantly improves results for S1–S3 under this approach. However, since EN 15978:2011 defines module D as beyond the system boundary, it is typically reported separately from the core life cycle stages (modules A–C). As a result, the benefits of reuse may be overlooked. Without module D, the 100:0 approach only shows limited benefits in EoL (module C) due to less material going to waste.

The 100:0 allocation approach was the easiest to apply since it clearly defines the system boundary and allocates all material impacts to the first use cycle. However, like the other methods, 100:0 also depends heavily on assumptions regarding which materials will be reused in the second use cycle.

4.4.3. System Expansion: Most Reduction, Most Uncertainty

The system expansion approach shows the largest impact reduction for the circular scenarios (S1–S3) compared to the linear scenario (S0), as it assumes that the initial construction is demolished and replaced with an identical new building, thus counting the impact from the initial construction twice. However, the magnitude of this benefit depends strongly on how the linear baseline is defined, which introduces considerable uncertainty.

As a result, system expansion yields both the highest absolute impacts within the system boundary and the largest relative reductions compared to S0. While S0 is amplified by the assumption of full replacement, the circular scenarios benefit from avoiding the burden of constructing a new building. This makes the method effective in highlighting the value of reuse but also highly sensitive to baseline assumptions.

These results need to be interpreted considering current practice and the role of refurbishment versus demolition. The sensitivity analysis with an alternative S0 (major refurbishment instead of full replacement) shows that the gap between S0 and the circular scenarios narrows substantially, clearly showing that results depend on the chosen baseline. At the same time, since demolition and full replacement are still common outcomes in practice, the original S0 represents a realistic reference. The key point is that DfD and DfF strategies reduce the need for such heavy interventions in the first place, by enabling transformations with minimal material turnover.

Furthermore, applying system expansion requires specific methodological choices regarding whether it is reasonable to account for the second use cycle as refurbishment (module B5) or not. EN 15978:2011 states that refurbishment can be included if it is planned from the outset, but this may not always be clear with DfD and DfF. Similar to the 50:50 approach, system expansion was less suited to S2, as relocating a building does not easily fit within standard definitions of refurbishment.

4.5. Challenges in Applying EN Standards to Circular Design

For allocation methods to fairly represent circularity in LCA outcomes, design for disassembly and flexibility must be treated as valid and realistic EoL scenarios. Otherwise, buildings will be assessed as if they have no reuse potential and thus treated the same as conventional ones.

Currently, no standardized method exists for verifying circular construction practices such as DfD and DfF. As a result, prevailing practice and standardization efforts like those from the Nordic construction program rely on assumptions based on today’s linear systems. While it is true that the benefits of future reuse are uncertain in their nature it is contradictory that strategies that hold such large impact reduction potential, as this study has shown, should not be accounted for.

While EN 15978:2011 and EN 15804:2012 do allow accounting for reuse or future reusability, they provide limited guidance on how to model multiple reuse or recycling cycles, which are central to circular thinking. Allocation is a way to handle multiple cycle systems. However, EN standards primarily support a cut-off model (100:0), which effectively means that only one use cycle is included in the assessment. According to these standards, any secondary material input must be subtracted from module D to avoid double counting, making it difficult to model long-term circular loops.

This clashes with the concept of circular economy, where materials are intended to remain in use for as long as possible [14]. While this study only considered one reuse or recycling cycle, it is likely that more would be realistic if material value is maintained over time.

4.6. Limitations

This analysis was limited to modeling a single secondary use cycle. While this captures the most immediate and policy-relevant effects of DfD and DfF, allocation rules may become more influential when multiple reuse cycles are considered. Extending the assessment to two or more cycles could therefore provide valuable additional insights. However, such modeling would require further assumptions on reuse rates, substitution quality, and long-term material performance, which were beyond the scope of this study.

The analysis of module D further assumed a 1:1 substitution of reused components for primary materials. This simplifying assumption was necessary due to insufficient data on reuse quality classes, yield rates, and substitution factors in the case study. While this approach ensures transparency and avoids speculative assumptions, it may overestimate substitution benefits. Future studies should therefore explore sensitivity analyses with varying substitution factors to improve robustness and reproducibility.

5. Conclusions

This study investigated how different future scenarios and allocation approaches influence the life cycle assessment (LCA) of a building designed for disassembly and flexibility, with the aim of supporting more circular construction practices in legislation and policy.

The result shows that DfD and DfF, such as enabling layout changes or structural modifications, can lead to substantial environmental benefits. The main reason is the avoidance of production of new materials and products. Preparing for multiple possible future uses further increases the resilience and environmental value of such buildings.

A key finding is that the inclusion of circular scenarios in LCA is more critical for promoting circular construction than the choice of allocation method alone. However, the complexity of predicting future scenarios complicates LCA modeling and can lead to widely different results, particularly when applying system expansion. This complexity often discourages the inclusion of such future scenarios altogether, due to the uncertainty involved. This challenge emphasizes the need for standardized guidelines that quantify the benefits of circularity for fairer comparisons to more traditional construction in legislation and procurement.

While the differences between scenarios (S1–S3) within a given allocation approach were relatively small, the differences between allocation approaches themselves were significant. Each method influences how reuse is represented, with implications for both practice and policy.

5.1. Key Findings Regarding Allocation Approaches

- The allocation approaches 50:50 and system expansion showed the benefits of DfD and DfF more clearly than the 100:0 approach.

- The 50:50 approach showed the largest benefit from DfD and DfF and in most parts of the life cycle. However, it was also the most complex to apply.

- System expansion also showed significant reductions, at least compared to the initial construction being built twice. However, it introduces methodological complexity and scenario sensitivity, particularly in deciding whether to classify second-life activities as refurbishment (B5).

- The 100:0 approach was the simplest to apply and aligns with existing standards and legislation in the EU and Nordic countries. However, the benefits of DfD and DfF appear primarily in module D, which is often excluded in regulatory LCAs, limiting its effectiveness in promoting circularity.

The choice of allocation method is especially important when only partial life cycle stages are assessed. Excluding key modules like the use stage (module B), EoL (module C), and benefits beyond the system boundary (module D) reduces the visibility of reuse benefits, particularly under the 100:0 approach. In contrast, the 50:50 method remains relatively robust even when some modules are excluded.

The study also reveals challenges in applying existing European standards (EN 15978:2011, EN 15804:2012) to circular scenarios, particularly in handling multiple use cycles and calculating benefits beyond system boundary.

For practitioners applying EN 15978 today, three pragmatic steps can help reflect circularity: (i) report module D with transparent reuse assumptions, (ii) include sensitivity runs with alternative allocation methods (e.g., 50:50 alongside 100:0), and (iii) describe transformation scenarios as planned refurbishments (B5) when relevant. These measures enhance comparability and ensure that circular design benefits are not overlooked in practice.

5.2. Recommendations for Further Research

In order to highlight the value of circular construction practices in LCA the following research is needed:

- Investigate how the environmental impacts of circular building design, such as DfD and DfF, are influenced by building type and material composition and extend the analysis to a wider range of future scenarios.

- Assess whether circular design can be integrated into current LCA frameworks or whether complementary methods or indicators are needed.

- Develop robust methods for verifying circular building design, such as DfD and DfF, in practice, to enable credible and consistent assessment of circular design in legislation and procurement.

Author Contributions

Conceptualization, S.M. and F.G.; methodology, S.M. and F.G.; software, S.M. and F.G.; validation, S.M. and F.G.; formal analysis, S.M. and F.G.; investigation, S.M. and F.G.; resources, S.M. and F.G.; data curation, F.G.; writing—original draft preparation, S.M. and F.G.; writing—review and editing, S.M.; visualization, S.M. and F.G.; supervision, S.M. and F.G.; project administration, S.M. and F.G.; funding acquisition, S.M. and F.G. Both authors contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Sweden’s Innovation Agency (Vinnova), grant number 2020-03668.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

We would like to thank the project members that have provided valuable input in the creation of this work: Karin Sandberg at RISE Research Institutes of Sweden, Janina Östling at IsoTimber, Henrietta Borseman at ETTELVA Architects, Anna Söderholm at IVL Swedish Environmental Research Institute. This article is a revised and expanded version of a paper entitled “Design for the Future—Versatile, Relocated and Vertically Extended Timber Buildings for a Circular Economy,” originally presented at the Circular Building Sector Conference (CBSC 2025), Lund, Sweden, 1–3 June 2025, and published in the conference proceedings [37].

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- IEA; UNEP. 2019 Global Status Report for Buildings and Construction; IEA: Paris, France, 2019. [Google Scholar]

- European Commission. Buildings and Construction. 2022. Available online: https://single-market-economy.ec.europa.eu/industry/sustainability/buildings-and-construction_en (accessed on 16 March 2023).

- Dodd, N.; Cordella, M.; Traverso, M.; Donatello, S. Level(s)—A Common EU Framework of Core Sustainability Indicators for Office and Residential Buildings: Parts 1 and 2: Introduction to Level(s) and How It Works (Beta v1.0); Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Dulian, M. Revision of the Energy Performance of Buildings Directive; European Parliament Research Service (EPRS): Brussels, Belgium, 2024. [Google Scholar]

- Dos Santos Gervasio, H.; Dimova, S. Model for Life Cycle Assessment; EUR 29123 EN; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Morris, F.; Allen, S.; Hawkins, W. On the embodied carbon of structural timber versus steel, and influence of LCA methodology. Build. Environ. 2021, 206, 108285. [Google Scholar] [CrossRef]

- Kröhnert, H.; Itten, R.; Stucki, M. Comparing flexible and conventional monolithic building design: Life cycle environmental impact and potential for material circulation. Build. Environ. 2022, 222, 109409. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life cycle assessment of a Danish office building designed for disassembly. Build. Res. Inf. 2019, 47, 666–680. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector—A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Joensuu, T.; Leino, R.; Heinonen, J.; Saari, A. Developing Buildings’ Life Cycle Assessment in Circular Economy-Comparing methods for assessing carbon footprint of reusable components. Sustain. Cities Soc. 2022, 77, 103499. [Google Scholar] [CrossRef]

- Lam, W.C.; Claes, S.; Ritzen, M. Exploring the Missing Link between Life Cycle Assessment and Circularity Assessment in the Built Environment. Buildings 2022, 12, 2152. [Google Scholar] [CrossRef]

- Roberts, M.; Allen, S.; Clarke, J.; Searle, J.; Coley, D. Understanding the global warming potential of circular design strategies: Life cycle assessment of a design-for-disassembly building. Sustain. Prod. Consum. 2023, 37, 331–334. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdóttir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2022, 18, 93–113. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circular Economy Introduction. Available online: https://www.ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed on 10 June 2025).

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Environment Agency (EEA). Cutting Greenhouse Gas Emissions Through Circular Economy Actions in the Buildings Sector. 2020. Available online: https://www.eea.europa.eu/publications/cutting-greenhouse-gas-emissions-through (accessed on 21 August 2023).

- Lausselet, C.; Dahlstrøm, O.A.; Thyholt, M.; Eghbali, A.; Schneider-Marin, P. Methods to Account for Design for Disassembly: Status of the Building Sector. Buildings 2023, 13, 1012. [Google Scholar] [CrossRef]

- van Stijn, A.; Malabi Eberhardt, L.C.; Wouterszoon Jansen, B.; Meijer, A. A circular Economy Life Cycle Assessment (CE-LCA) model for building components. Resour. Conserv. Recycl. 2021, 174, 105683. [Google Scholar] [CrossRef]

- Malabi Eberhardt, L.C.; van Stijn, A.; Rasmussen, F.N.; Birkved, M.; Birgisdóttir, H. Towards circular life cycle assessment for the built environment: A comparison of allocation approaches. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 032026. [Google Scholar] [CrossRef]

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- European Union. Directive (EU) 2024/1275 of the European Parliament and of the Council on the Energy Performance of Buildings (Recast); Official Journal of the European Union: Luxembourg, 2024. [Google Scholar]

- European Commission. Life-Cycle Global Warming Potential of New Buildings (Article 7(2) and (5))—Annex 13; European Commission: Brussels, Belgium, 2024. [Google Scholar]

- Erlandsson, M.; Görman, F.; Thrysin, Å.; Häkkinen, T.; Eckerberg, K.; Pesu, J.; Dalborg, M.; Asplund, J. Nordic View on Data Need and Scenario Settings for Full Life Cycle Building Environmental Assessment; Nordic Sustainable Construction: Copenhagen, Denmark, 2024. [Google Scholar]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Allacker, K.; Mathieux, F.; Manfredi, S.; Pelletier, N.; De Camillis, C.; Ardente, F.; Pant, R. Allocation solutions for secondary material production and end of life recovery: Proposals for product policy initiatives. Resour. Conserv. Recycl. 2014, 88, 137–144. [Google Scholar] [CrossRef]

- European Commission. Commission Recommendation on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organizations; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Rasmussen, F.N.; Birkved, M.; Birgisdóttir, H. Upcycling and Design for Disassembly–LCA of buildings employing circular design strategies. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012050. [Google Scholar] [CrossRef]

- Zimmermann, R.K.; Rasmussen, F.N.; Kanafani, K.; Eberhardt, L.C.M.; Birgisdóttir, H. Reviewing allocation approaches and modelling in LCA for building refurbishment. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012095. [Google Scholar] [CrossRef]

- De Wolf, C.; Hoxa, E.; Fivet, C. Comparison of environmental assessment methods when reusing building components: A case study. Sustain. Cities Soc. 2020, 61, 102322. [Google Scholar] [CrossRef]

- EN 15804:2012; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Huuhka, S.; Lahdensivu, J. Statistical and geographical study on demolished buildings. Build. Res. Inf. 2014, 44, 73–96. [Google Scholar] [CrossRef]

- Boverket. Boverkets Klimatdatabas. 11 May 2023. Available online: https://www.boverket.se/sv/klimatdeklaration/klimatdatabas/ (accessed on 20 December 2024).

- Malmqvist, T.; Borgström, S.; Brismark, J.; Erlandsson, M. Referensvärden för Klimatpåverkan Vid Uppförande av Byggnader. Version 2, 2023; KTH, School of Architecture and the Built Environment: Stockholm, Sweden, 2023. [Google Scholar]

- Melella, R.; Di Ruocco, G.; Sorvillo, A. Circular construction process: Method for developing a selective, low CO2eq disassembly and demolition plan. Sustainability 2021, 13, 11824. [Google Scholar] [CrossRef]

- Rasmussen, F.N.; Birgisdóttir, H. Life cycle environmental impacts from refurbishment projects—A case study. Energy Procedia 2016, 96, 818–829. [Google Scholar] [CrossRef][Green Version]

- Energimyndigheten. Energy Statistics for Multi-Dwelling Buildings in 2016; Swedish Energy Agency: Eskilstuna, Sweden, 2017. [Google Scholar]

- Sandberg, K.; Görman, F.; Östling, J.; Just, A.; Sandin, Y. Design for the future—Versatile, relocated and vertically extended timber buildings for a circular economy. In Proceedings of the Circular Building Sector Conference 2025, Lund, Sweden, 1–3 June 2025; pp. 185–196. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).