Research on Flexural Performance of Low-Strength Foamed Concrete Cold-Formed Steel Framing Composite Enclosure Wall Panels

Abstract

1. Introduction

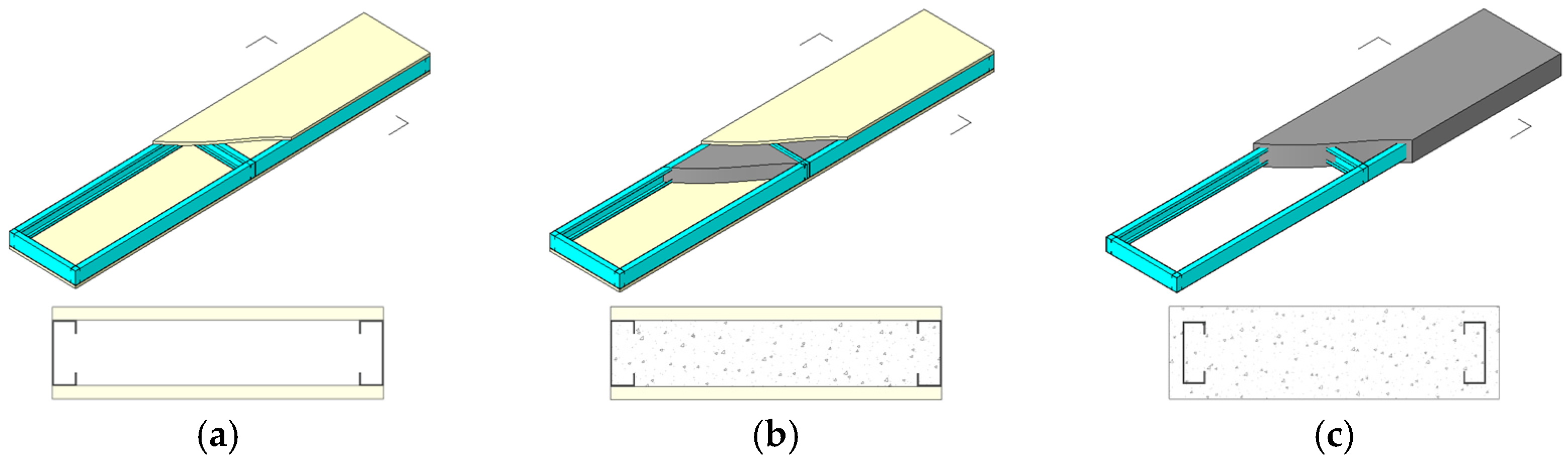

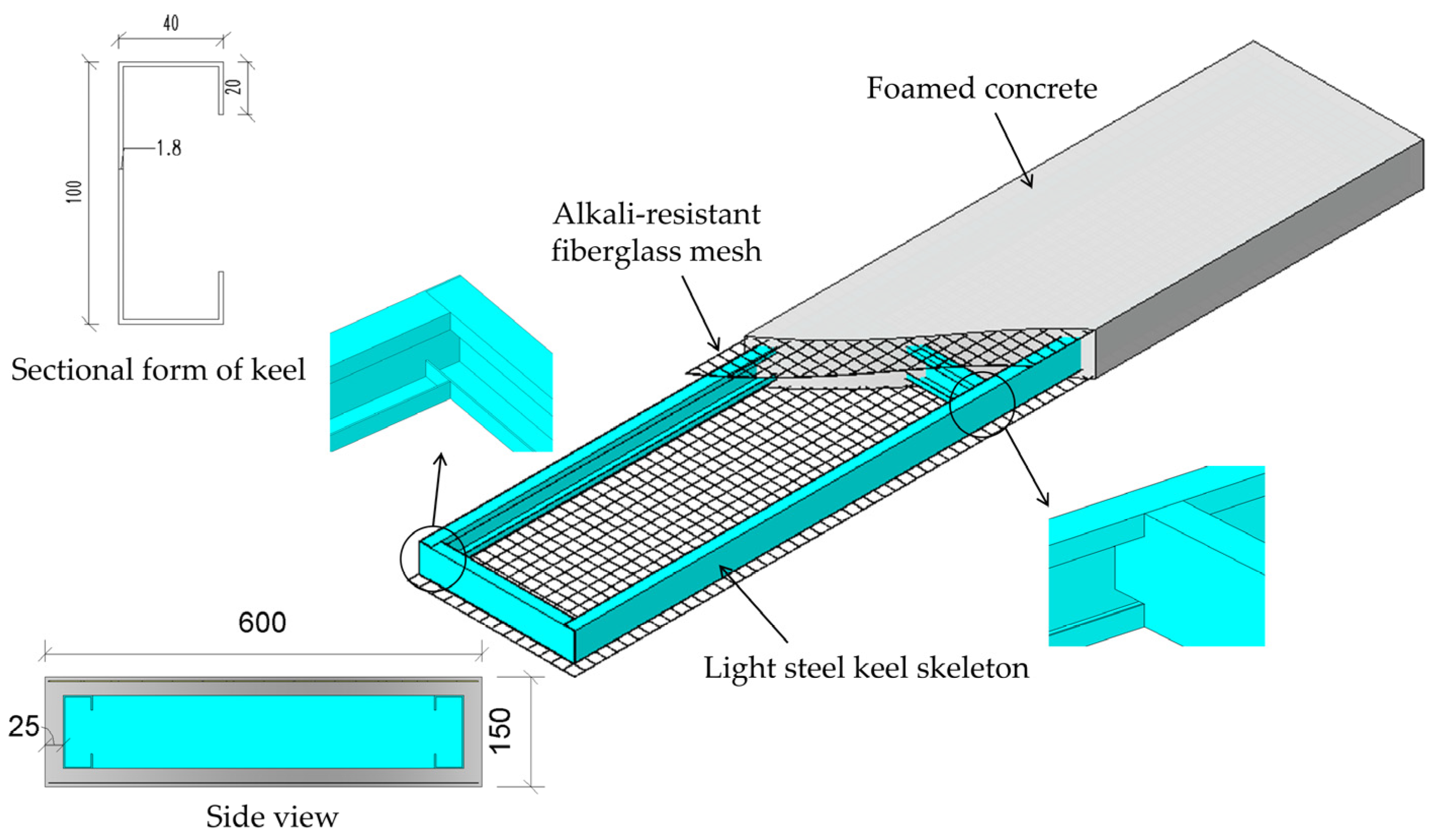

2. Composite Wall Panel Design

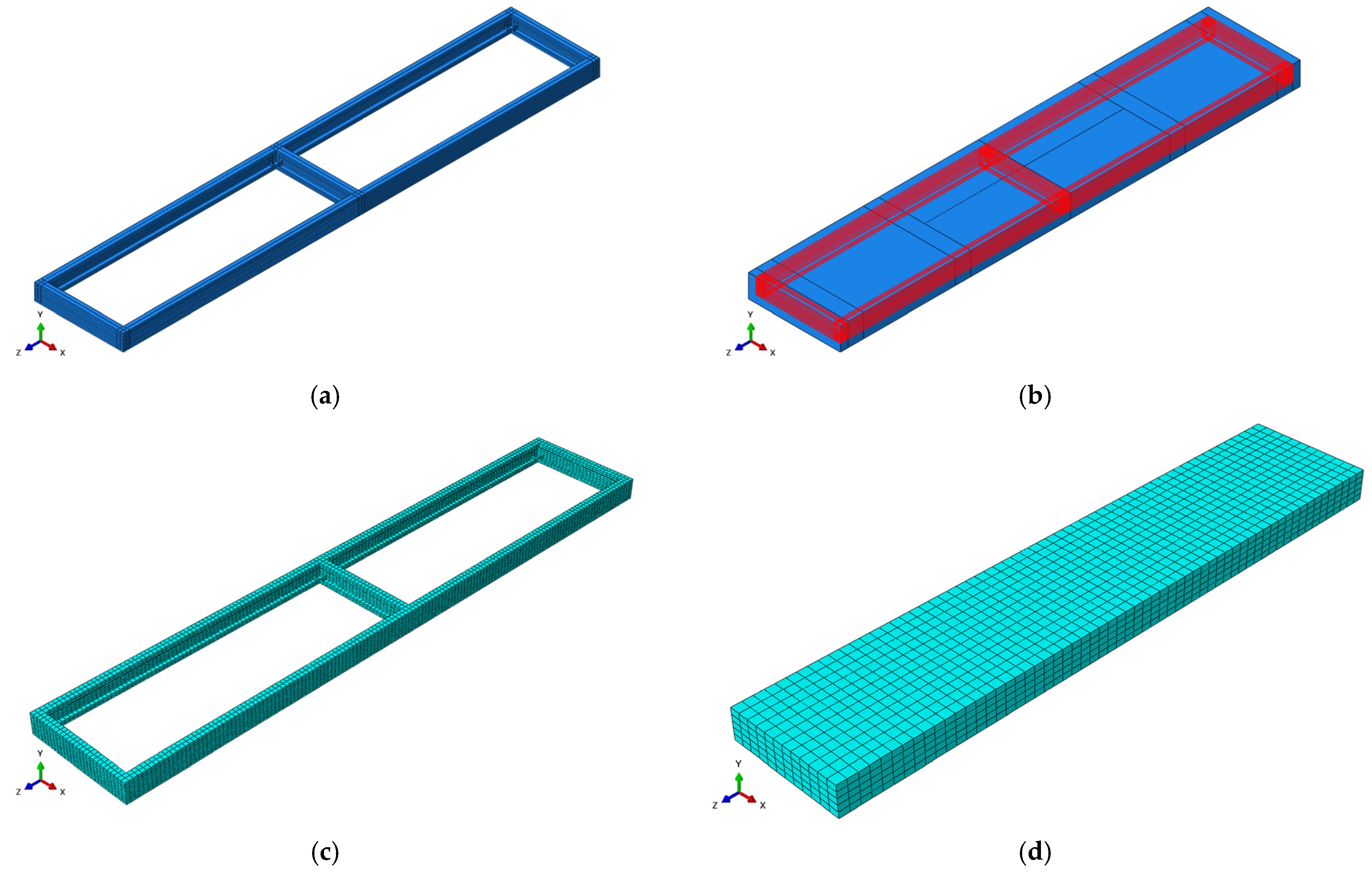

3. Finite Element Simulation Analysis

3.1. Analysis Assumptions

- (1)

- Literature review reveals two distinct scenarios regarding the concrete–steel interface: consideration of interface slip versus neglect of interface slip. Based on flexural tests of CFS-foamed concrete specimens [42,43,45], the CFS framing serves as the primary load-bearing component. Negligible interfacial slip occurs between the CFS framing and foamed concrete, with minimal impact on the global structural behavior.

- (2)

- Due to the minimal impact of alkali-resistant fiberglass mesh on the model’s flexural performance (owing to its low strength), this component is omitted from the model.

- (3)

- Given that the bending radius of CFS framing is very small, its influence on flexural performance is deemed negligible and thus excluded from the analysis.

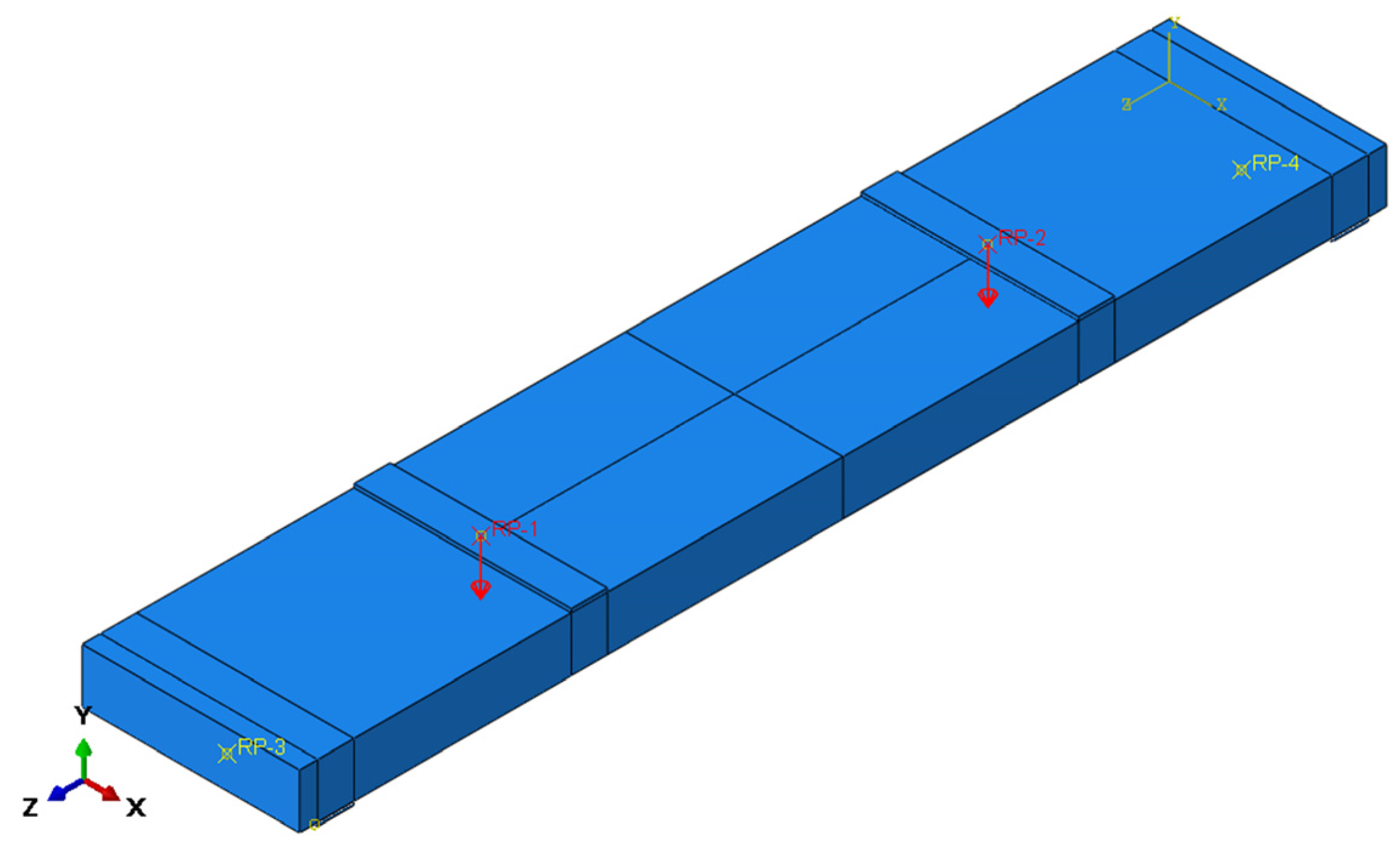

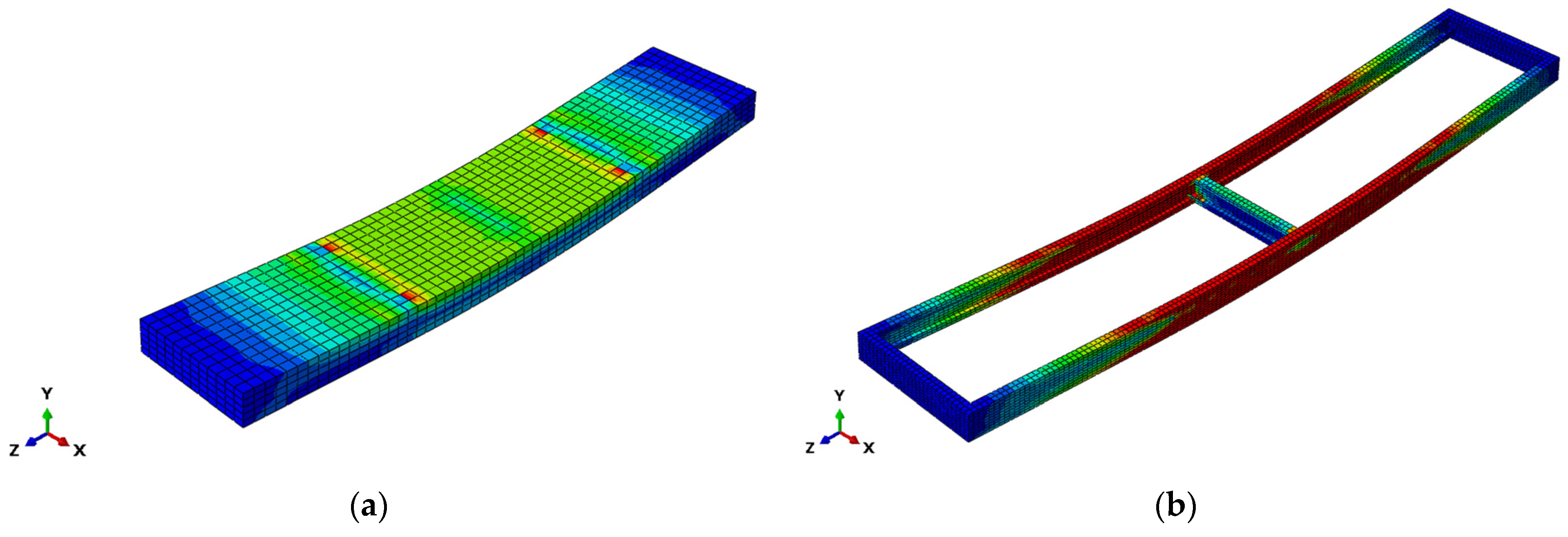

3.2. Wall Panel Model Establishment

3.3. Calculation of Parameter Settings

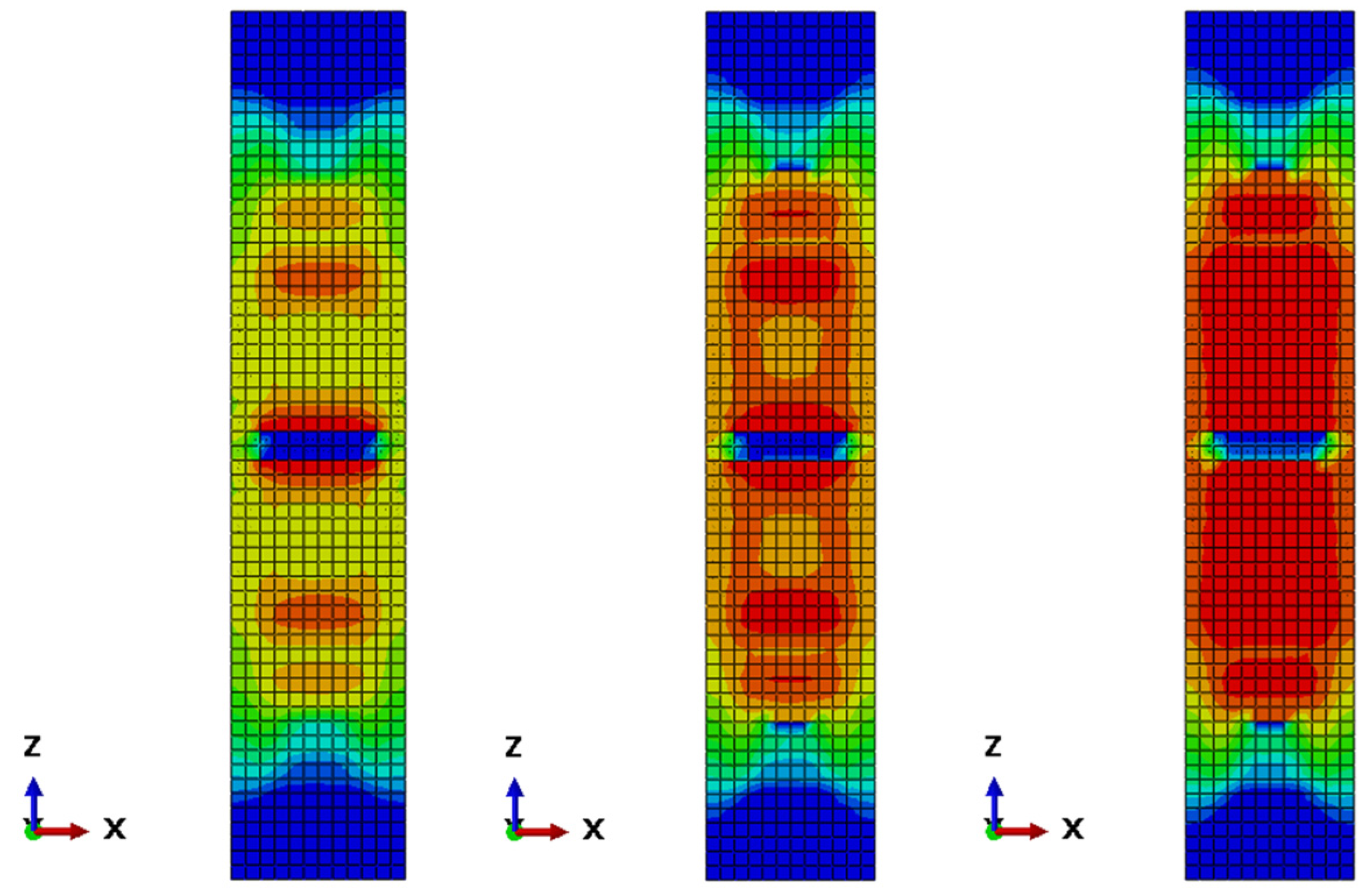

3.4. Analysis of Finite Element Simulation Results

4. Applicability Analysis of Wall Panels

5. Research on the Bending Resistance Test of Wall Panels

5.1. Test Wall Panel Specimen Parameters

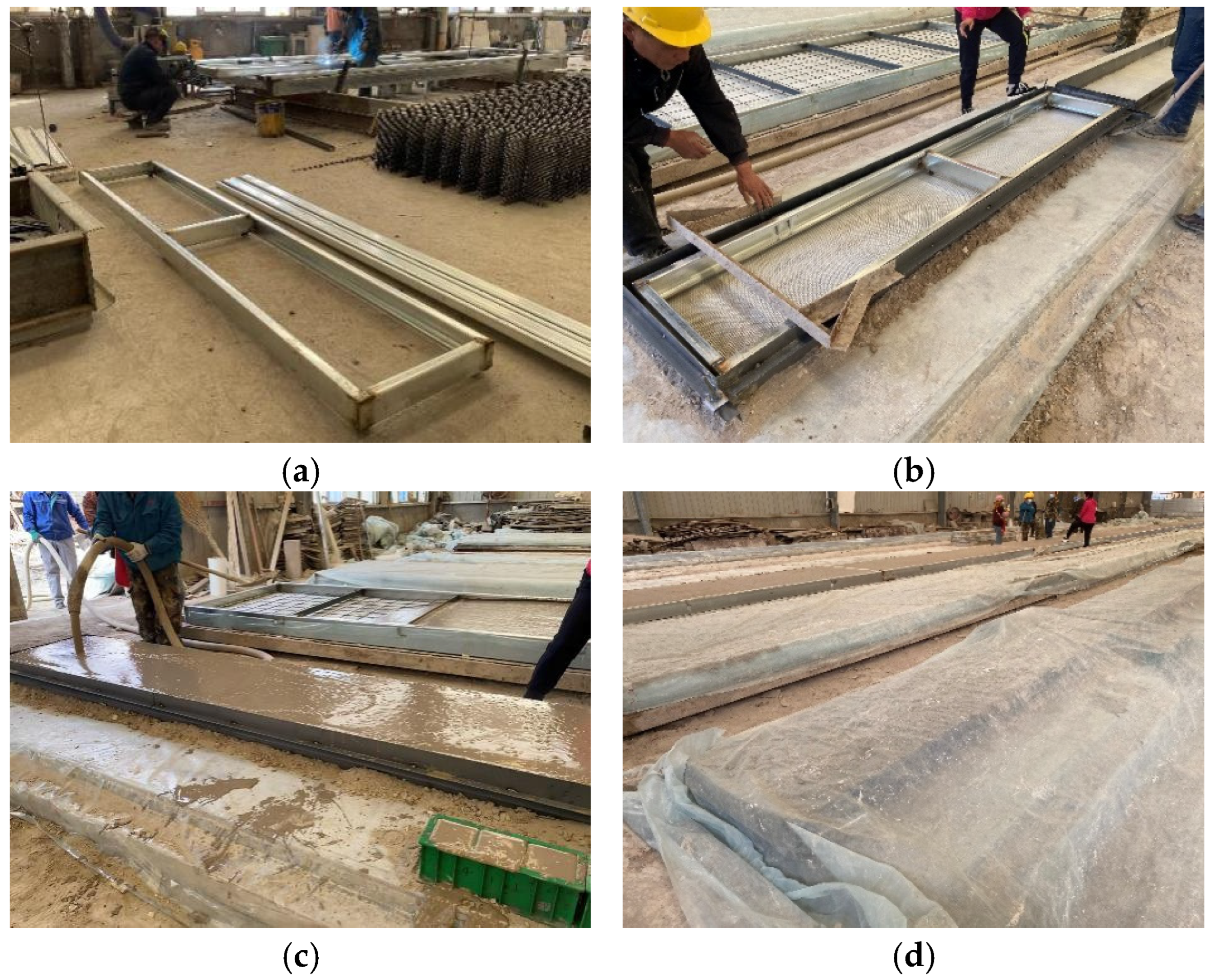

5.2. Specimen Fabrication

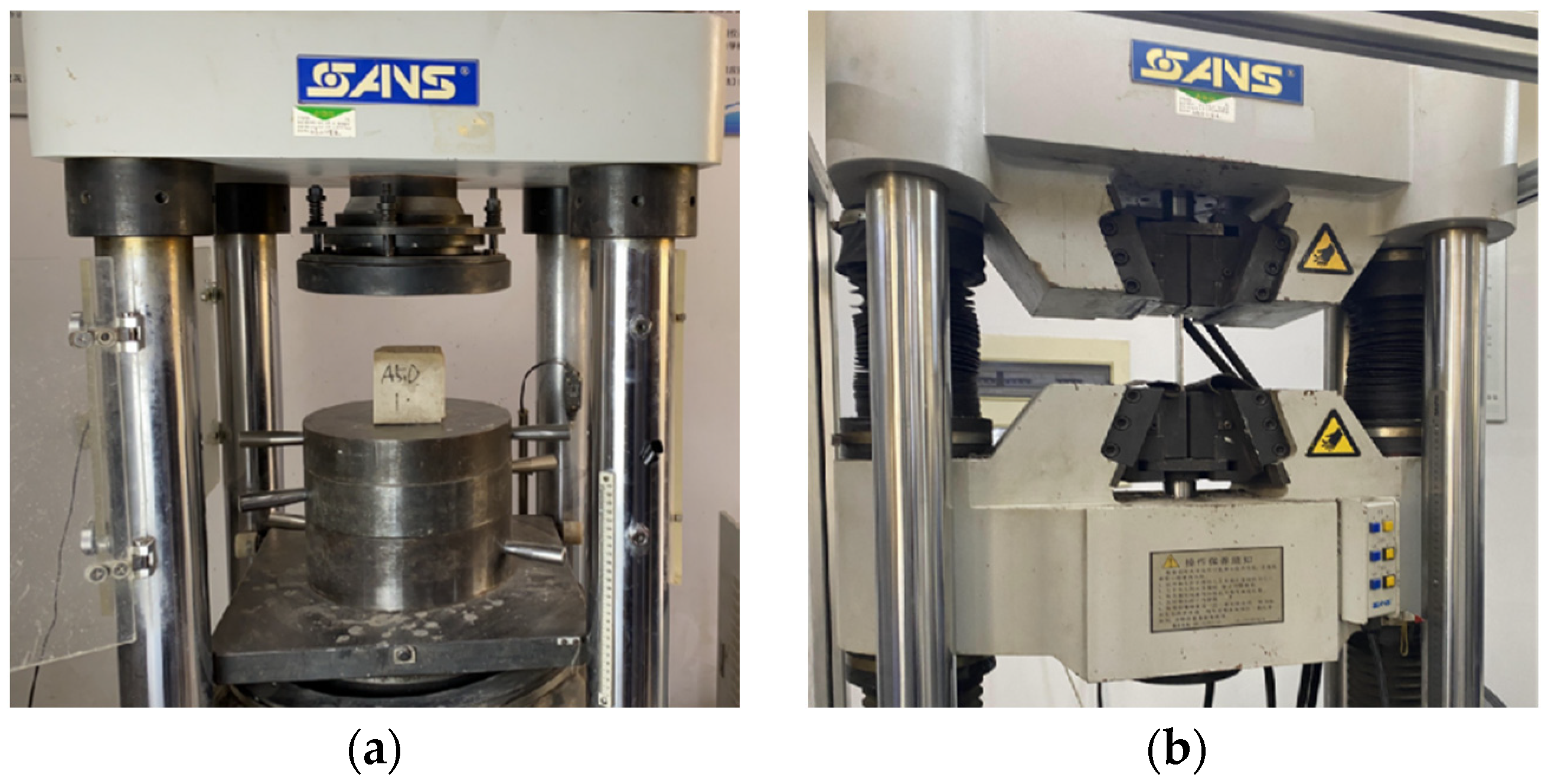

5.3. Material Performance Test

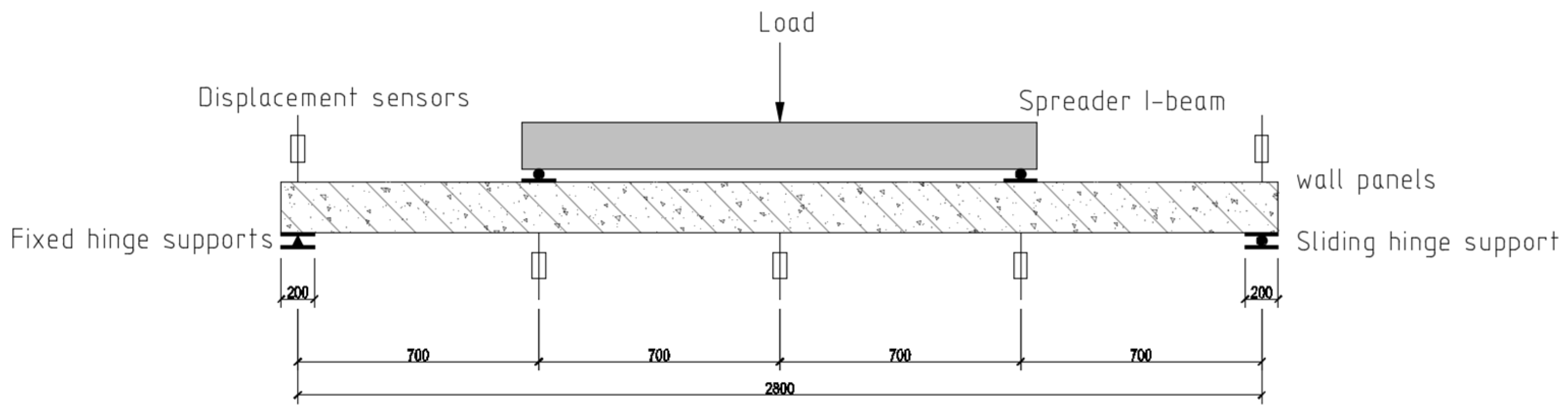

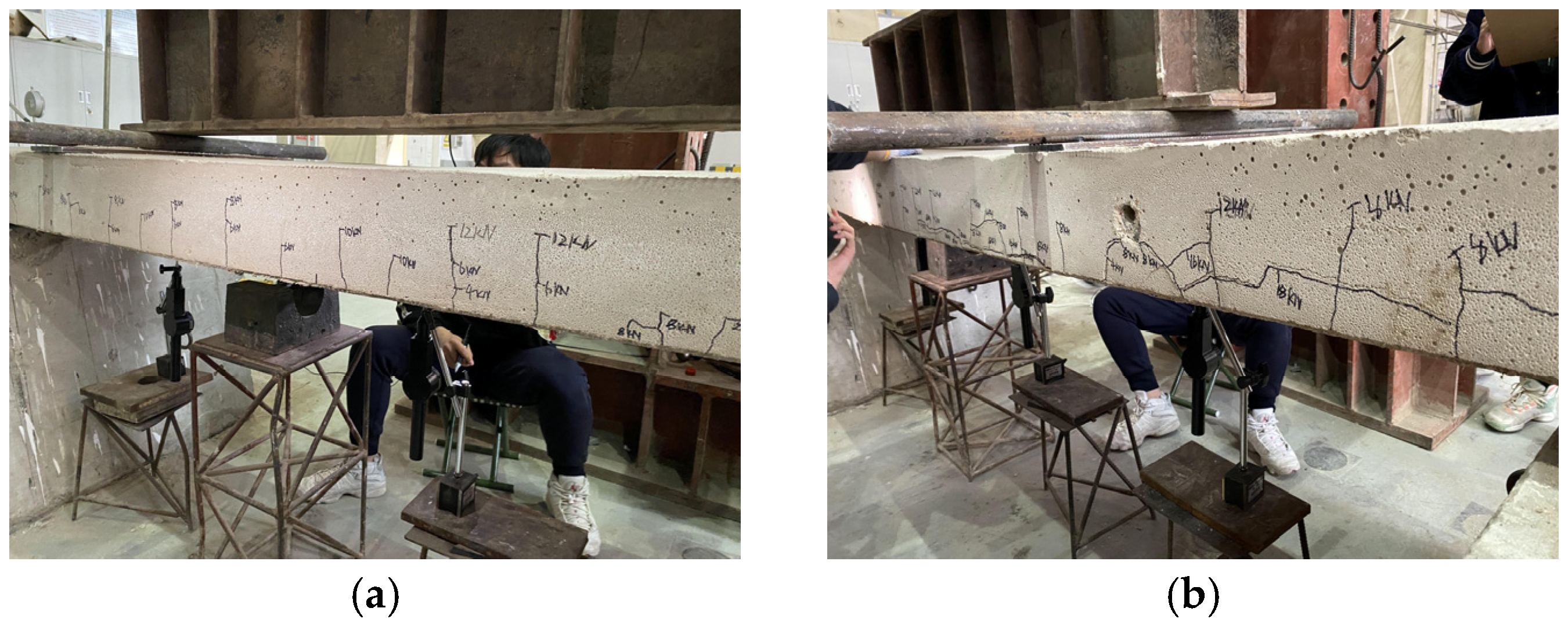

5.4. Experimental Apparatus and Data Acquisition

5.5. Loading Method

6. Test Results and Analysis

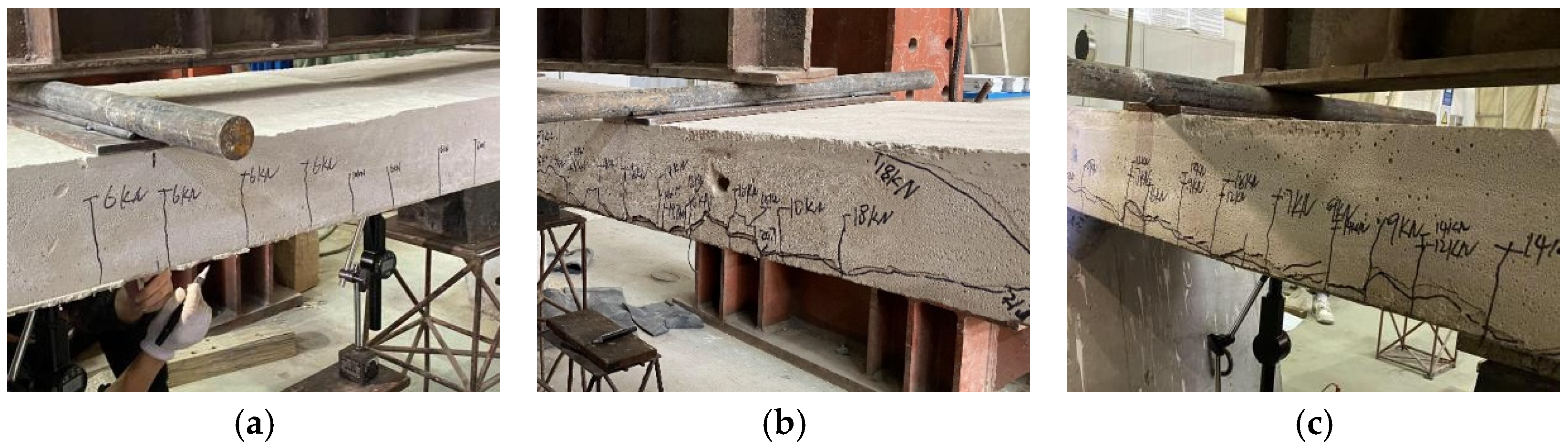

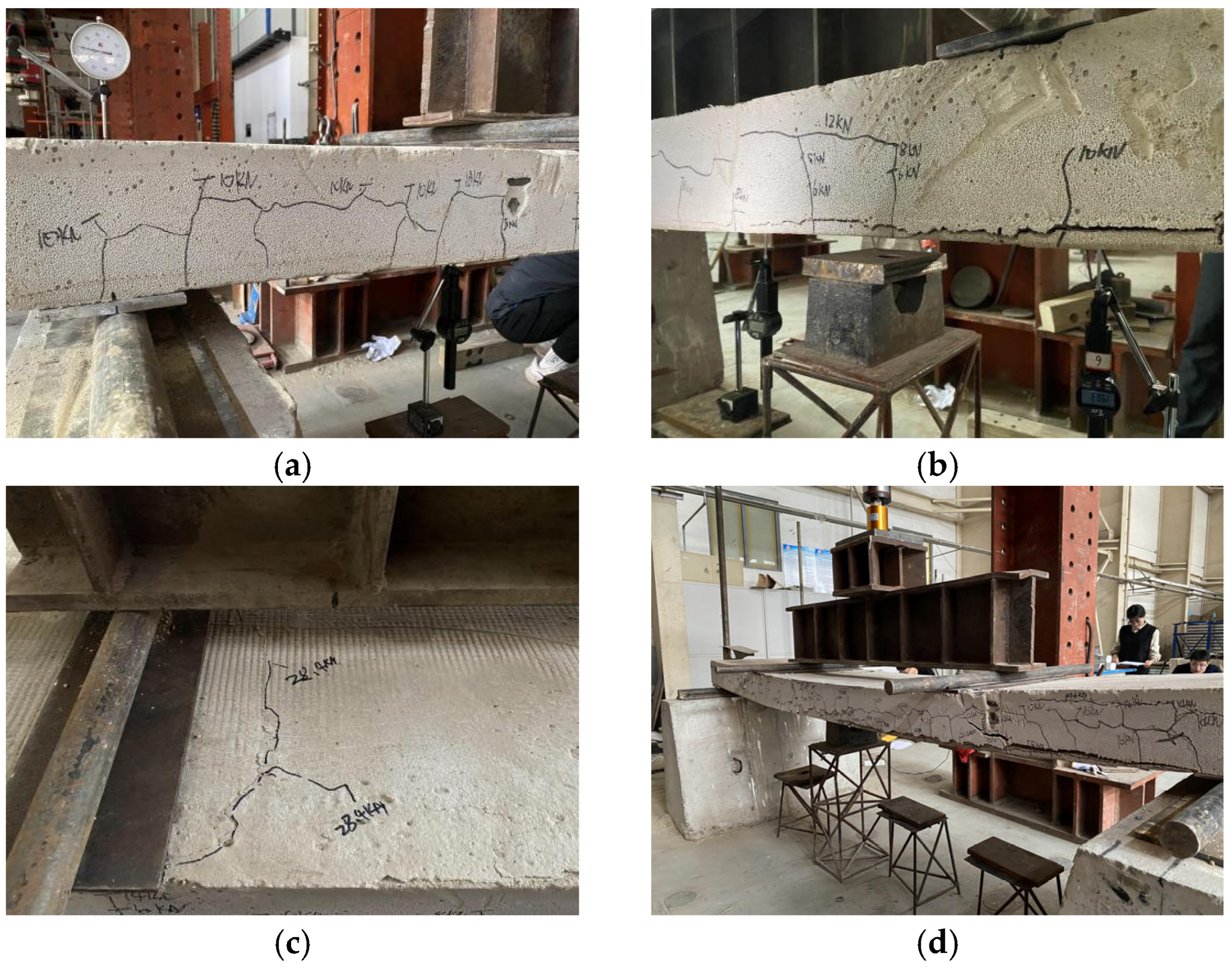

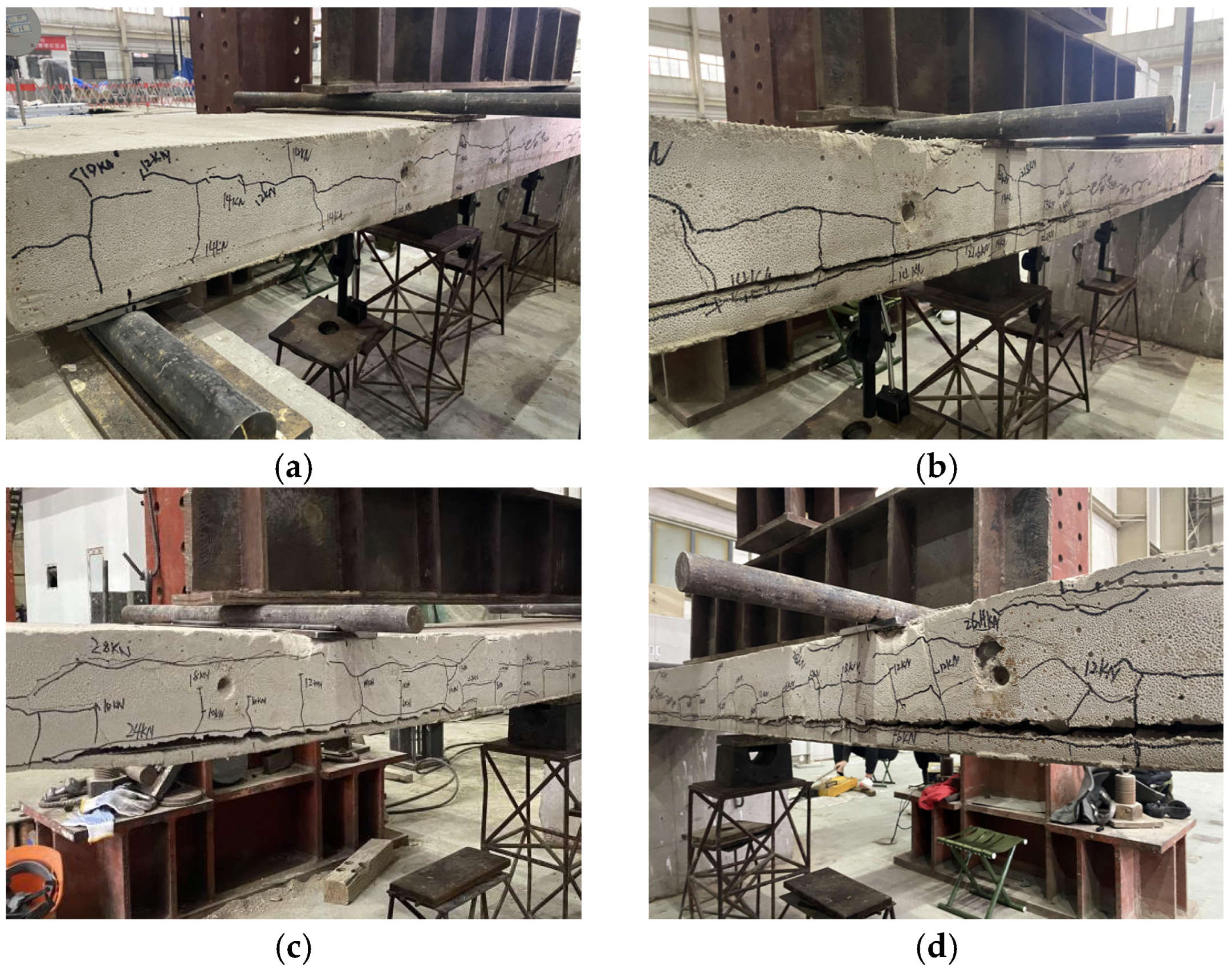

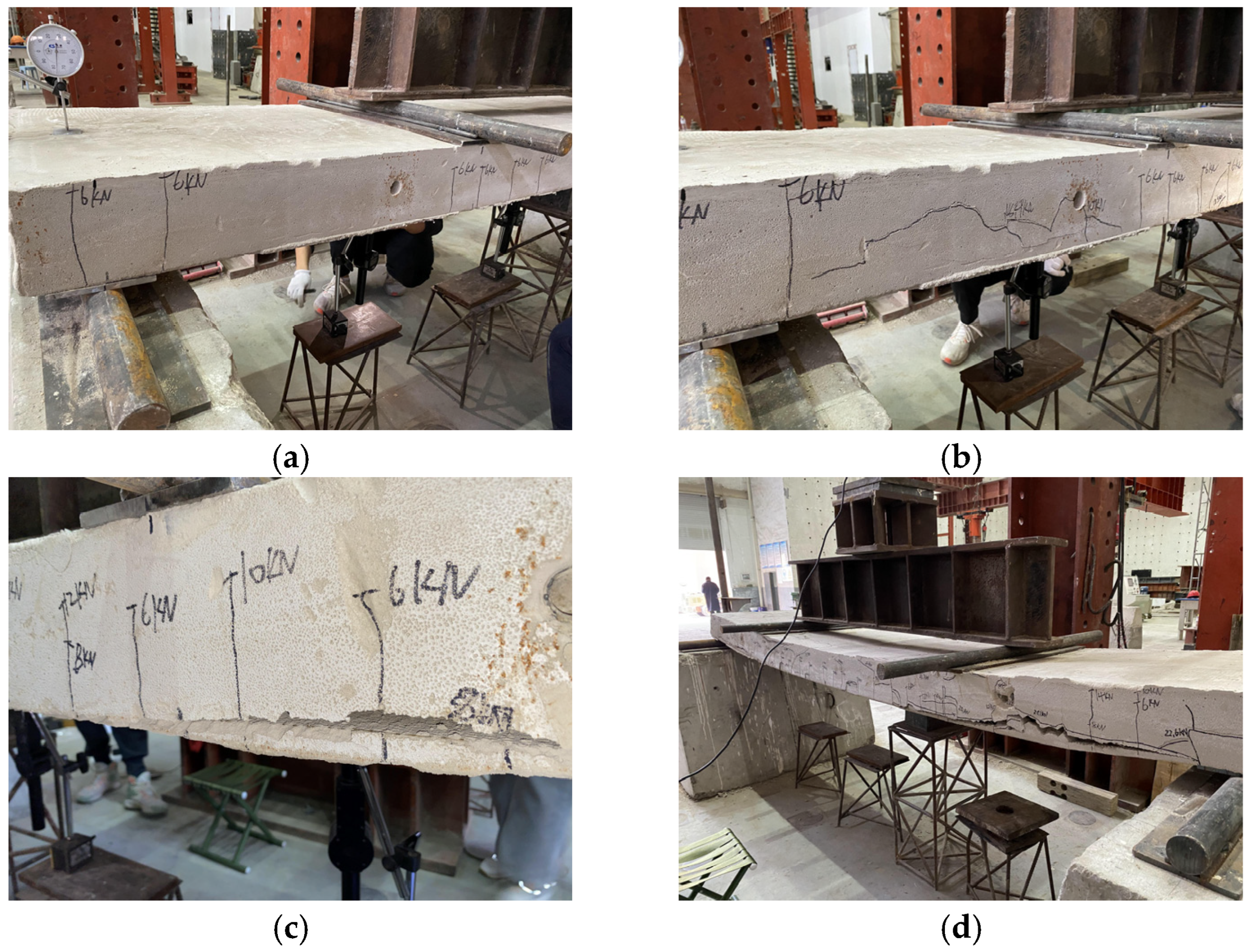

6.1. Destructive Phenomenon

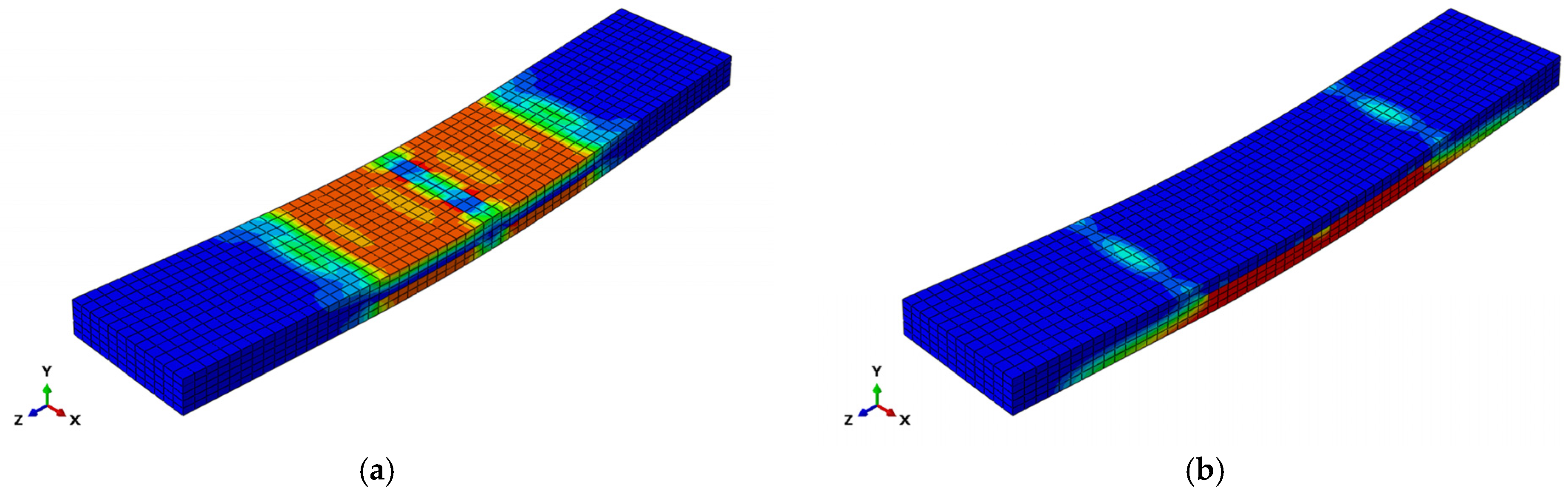

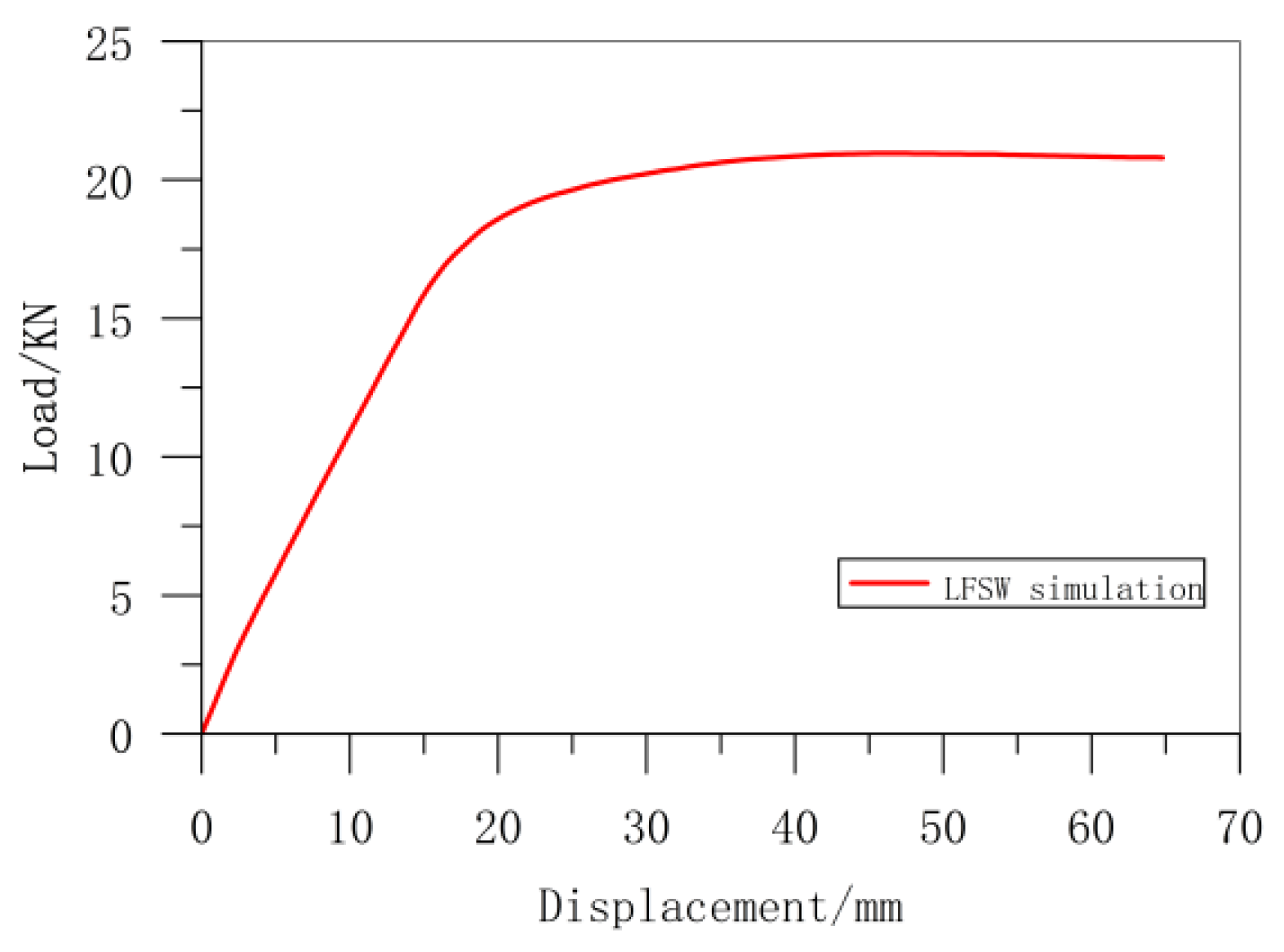

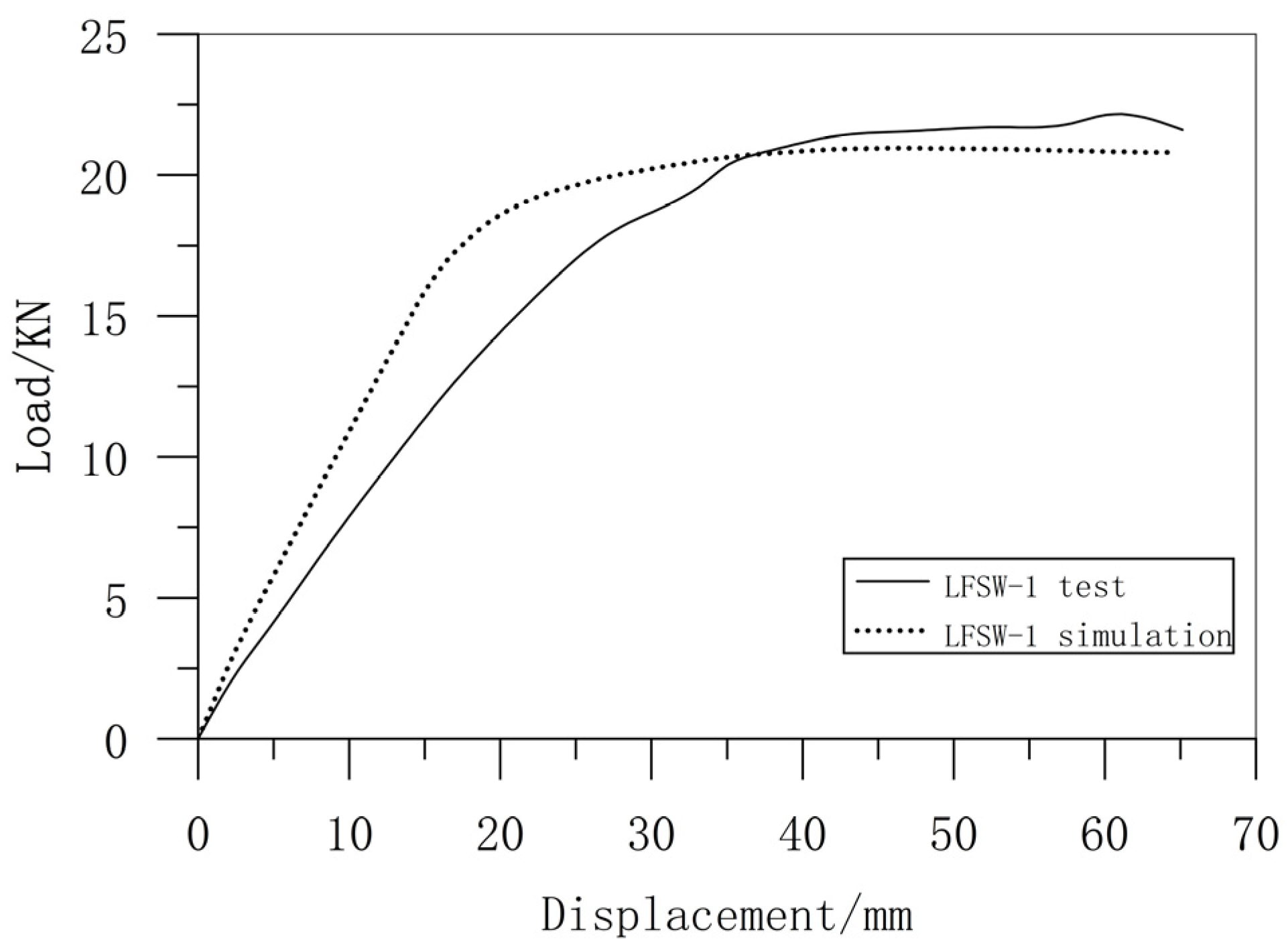

6.2. Comparison Between LFSW-1 Test and Simulation of Test Piece

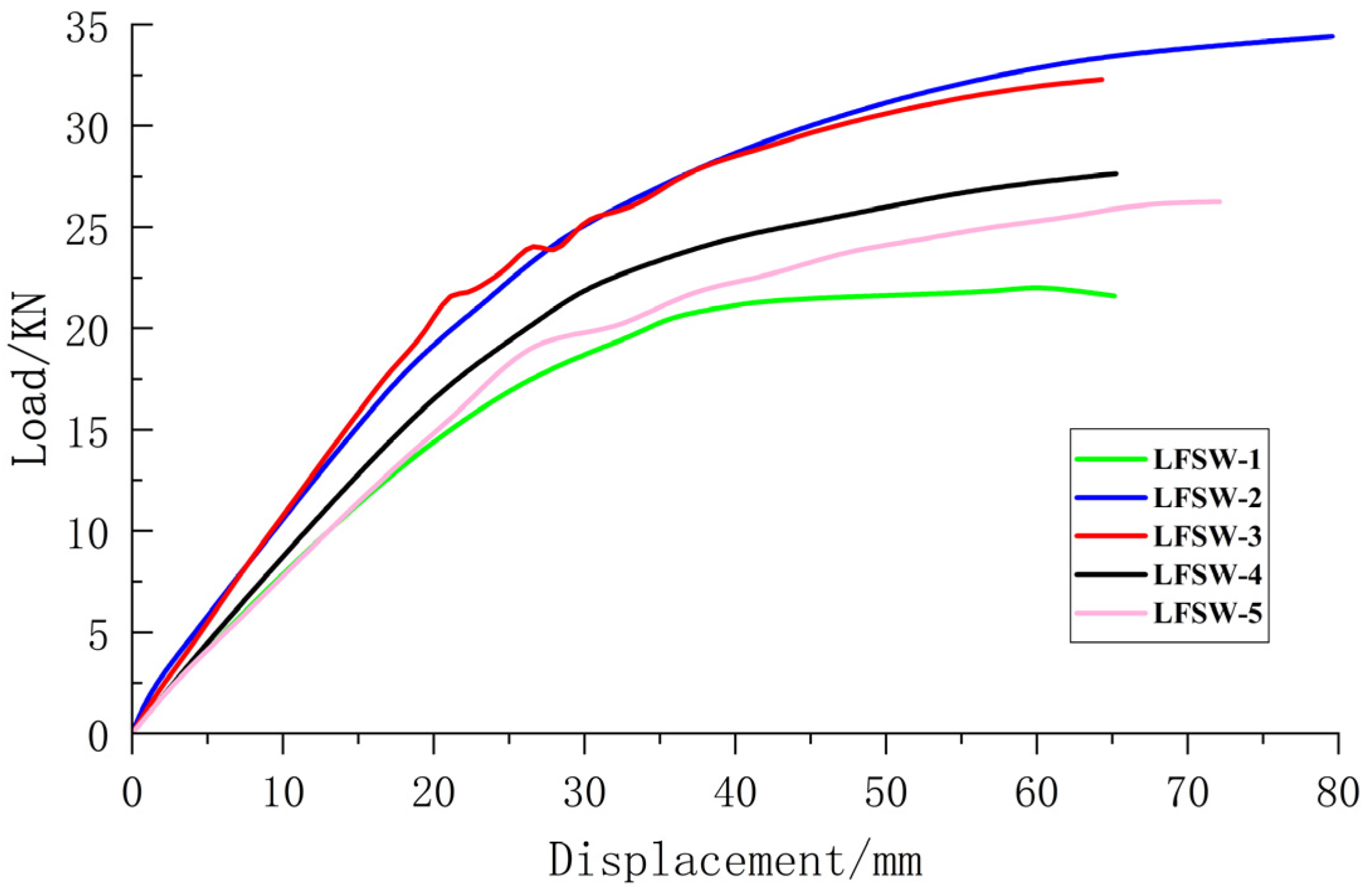

6.3. Test Load-Displacement Curves and Key Test Data for Each Specimen

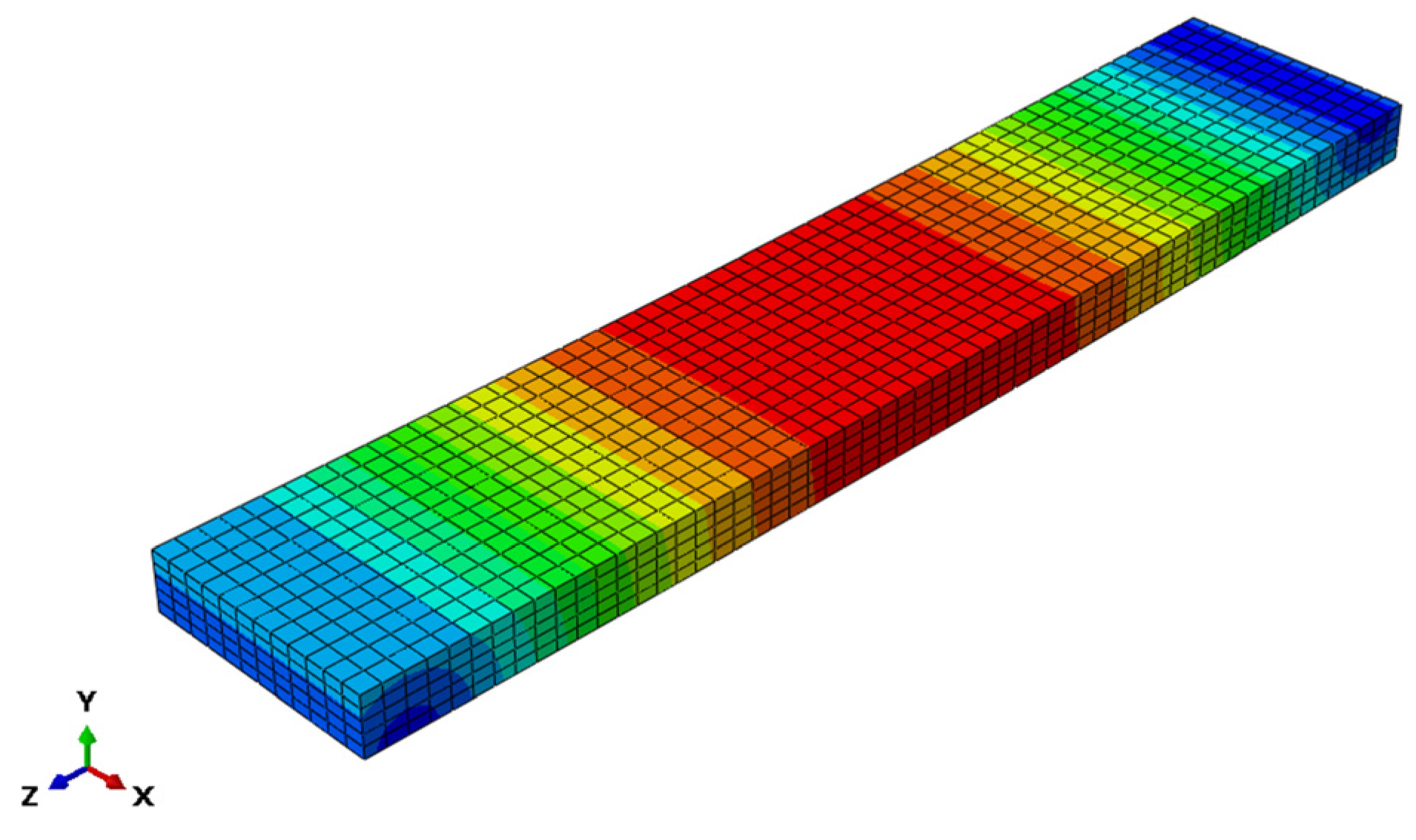

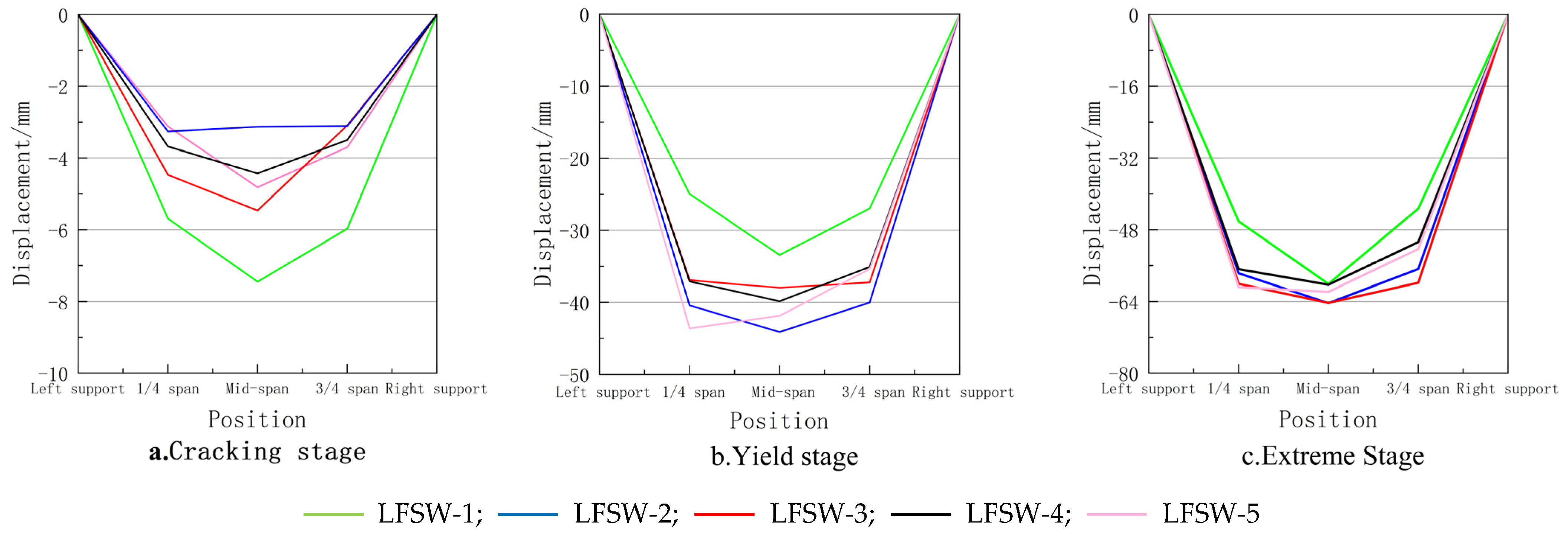

6.4. Bending Deformation of Test Piece

6.5. Analysis of Influencing Factors

6.5.1. Strength of Foam Concrete

6.5.2. CFS Framing Wall Thickness

6.5.3. CFS Framing Section Height

6.5.4. Protection Layer Thickness

7. Conclusions and Prospect

- (1)

- CFS-foamed concrete composite wall panels exhibit distinct failure characteristics at each loading stage, demonstrating typical flexural failure modes.

- (2)

- Comparative tests demonstrate that when LFSW framing wall thickness increased from 1.8 mm to 2.5 mm, ultimate load capacity improved by 46.15% and when section height enlarged from 80 mm to 100 mm, capacity increased by 26.67%. Foamed concrete strength enhancement from 0.5 MPa to 1.0 MPa raised wall panel cracking load by 50% while altering ultimate load capacity by less than 5%. Increasing concrete cover thickness from 25 mm to 35 mm enhanced ultimate capacity by 7%. Both parameters (foamed concrete strength and cover thickness) exert limited influence on LFSW flexural capacity. Elevating the cross-sectional height and wall thickness of steel framing effectively enhances flexural behavior and ultimate load-bearing performance of this wall panel.

- (3)

- The ABAQUS finite element analysis combined with experimental validation elucidate parameter influence mechanisms on flexural behavior, establishing foundations for subsequent research on flexural capacity equations, optimal panel design, and engineering implementation.

- (1)

- While this study examined foamed concrete strength, concrete cover thickness, CFS section height, and thickness, future work should investigate additional parameters (panel width, CFS material grade, length, stiffener configuration) through FEA or experimentation on four supplementary specimens.

- (2)

- Experimental observations revealed significant bond degradation between low-strength foamed concrete and plastically deformed CFS framing during failure stages, causing severe concrete spalling at the base. Current FEA models show limited accuracy in ultimate failure prediction. Design optimization should address interfacial failure mechanisms to mitigate concrete spalling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Manfredi, V.; Santarsiero, G.; Masi, A.; Ventura, G. The High-Performance Dissipating Frame (HPDF) System for the Seismic Strengthening of RC Existing Buildings. Sustainability 2021, 13, 1864. [Google Scholar] [CrossRef]

- Li, B.Z.; Yao, R.M. Building energy efficiency for sustainable development in China: Challenges and opportunities. Build. Res. Inf. 2012, 40, 417–431. [Google Scholar] [CrossRef]

- Alkaff, S.A.; Sim, S.; Efzan, M.E. A review of underground building towards thermal energy efficiency and sustainable development. Renew. Sustain. Energy Rev. 2016, 60, 692–713. [Google Scholar] [CrossRef]

- Androutsopoulos, V.; Spanou, A. Energy Efficiency Actions to Uptake Energy Retrofitting Measures in Buildings. In Proceedings of the International Conference on Sustainable Synergies from Buildings to the Urban Scale (SBE), Thessaloniki, Greece, 16–19 October 2016; pp. 875–881. [Google Scholar]

- Lawson, P.M.; Byfield, M.P.; Popo-Ola, S.O.; Grubb, P.J. Robustness of light steel frames and modular construction. Proc. Inst. Civ. Eng. Struct. Build. 2008, 161, 3–16. [Google Scholar] [CrossRef]

- Yang, N.; Bai, F. Damage Analysis and Evaluation of Light Steel Structures Exposed to Wind Hazards. Appl. Sci. 2017, 7, 239. [Google Scholar] [CrossRef]

- Uang, C.M.; Bruneau, M. State-of-the-Art Review on Seismic Design of Steel Structures. J. Struct. Eng. 2018, 144, 03118002. [Google Scholar] [CrossRef]

- Zhang, J.-F.; Zhao, J.-J.; Yang, D.-Y.; Deng, E.-F.; Wang, H.; Pang, S.-Y.; Cai, L.-M.; Gao, S.-C. Mechanical-property tests on assembled-type light steel modular house. J. Constr. Steel Res. 2020, 168, 105981. [Google Scholar] [CrossRef]

- Tao, C.; Yun, Z.; Deng, B.F. Study on seismic behavior of double leg C-type cold-formed thin-walled steel frame. J. Constr. Steel Res. 2023, 209, 108035. [Google Scholar] [CrossRef]

- Shi, Y.; Gao, C.; Xu, Y.; Zeng, L.; Peng, X. Study on the shear resistance of CFS walls with built-up side columns. J. Constr. Steel Res. 2024, 213, 108435. [Google Scholar] [CrossRef]

- Yang, J.; Zou, J.; Yang, W. Analytical Research on the Impact Test of Light Steel Keel and Lightweight Concrete of Composite Wall. Appl. Sci. 2022, 12, 2957. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, Z.; Liang, J. Experimental investigations on the lateral performance of foam concrete light steel keel composite wall. J. Build. Eng. 2023, 72, 106551. [Google Scholar] [CrossRef]

- Nithyadharan, M.; Kalyanaraman, V. Behaviour of cold-formed steel shear wall panels under monotonic and reversed cyclic loading. Thin-Walled Struct. 2012, 60, 12–23. [Google Scholar] [CrossRef]

- Selvaraj, S.; Madhavan, M. Investigation on sheathing effect and failure modes of gypsum sheathed cold-formed steel wall panels subjected to bending. Structures 2019, 17, 87–101. [Google Scholar] [CrossRef]

- Selvaraj, S.; Madhavan, M. Studies on Cold-Formed Steel Stud Panels with Gypsum Sheathing Subjected to Out-of-Plane Bending. J. Struct. Eng. 2018, 144, 04018136. [Google Scholar] [CrossRef]

- Selvaraj, S.; Madhavan, M. Structural behaviour and design of plywood sheathed cold-formed steel wall systems subjected to out of plane loading. J. Constr. Steel Res. 2020, 166, 105723. [Google Scholar] [CrossRef]

- AISIS100–16C; North American Cold-Formed Steel Specification for the Design of Cold-Formed Steel Structural Members. American Iron and Steel Institute: Washington, DC, USA, 2016.

- Yilmaz, F.; Becque, J.; Mojtabaei, S.M.; Hajirasouliha, I. Experimental investigation of the behaviour and capacity of sheathed cold-formed steel stud walls under inward flexural loading. Thin-Walled Struct. 2023, 192, 111048. [Google Scholar] [CrossRef]

- Gao, W.C.; Xiao, Y. Seismic behavior of cold-formed steel frame shear walls sheathed with ply-bamboo panels. J. Constr. Steel Res. 2017, 132, 217–229. [Google Scholar] [CrossRef]

- Cai, W.; Fang, H.; Qi, Y.J.; Liu, W.Q.; Zhu, X.X. Bending Performance Test of Prefabricated Light Steel Concrete External Wall Panel. Ind. Build. 2021, 51, 50–57. [Google Scholar] [CrossRef]

- Li, Y.M.; Zhao, D.P.; Li, K.; Wang, H. Calculation and experimental study on bending skin effect of light steel keel fireproof board composite wall. Prog. Build. Steel Struct. 2023, 25, 10–15. [Google Scholar] [CrossRef]

- Wu, K.K.; Qi, Y.J. Bending Performance of Light Steel Keel Aluminum Honeycomb Sandwich Plate Composite Wall Panel. J. Nanjing Univ. Technol. (Nat. Sci. Ed.) 2022, 44, 214–219. [Google Scholar]

- Accorti, M.; Baldassino, N.; Zandonini, R.; Scavazza, F.; Rogers, C.A. Reprint of Response of CFS Sheathed Shear Walls. Structures 2016, 8, 318–330. [Google Scholar] [CrossRef]

- Mowrtage, W.; Yel, N.H.; Pekmezci, B.; Atahan, H.N. Load carrying capacity enhancement of cold formed steel walls using shotcreted steel sheets. Thin-Walled Struct. 2012, 60, 145–153. [Google Scholar] [CrossRef]

- Ye, J.; Wang, X.; Jia, H.; Zhao, M. Cyclic performance of cold-formed steel shear walls sheathed with double-layer wallboards on both sides. Thin-Walled Struct. 2015, 92, 146–159. [Google Scholar] [CrossRef]

- Yilmaz, F.; Mojtabaei, S.M.; Hajirasouliha, I.; Becque, J. Behaviour and performance of OSB-sheathed cold-formed steel stud wall panels under combined vertical and seismic loading. Thin-Walled Struct. 2023, 183, 110419. [Google Scholar] [CrossRef]

- Zhang, W.; Mahdavian, M.; Yu, C. Lateral strength and deflection of cold-formed steel shear walls using corrugated sheathing. J. Constr. Steel Res. 2018, 148, 399–408. [Google Scholar] [CrossRef]

- Selvaraj, S.; Madhavan, M. Flexural Behaviour and Design of Cold-Formed Steel Wall Panels Sheathed with Particle Cement Board. J. Constr. Steel Res. 2019, 162, 105723. [Google Scholar] [CrossRef]

- Xie, Z.; Yan, W.; Yu, C.; Mu, T.; Song, L. Experimental investigation of cold-formed steel shear walls with self-piercing riveted connections. Thin-Walled Struct. 2018, 131, 1–15. [Google Scholar] [CrossRef]

- Liu, C.; Mao, X.; He, L.; Chen, X.; Yang, Y.; Yuan, J. A new demountable light-gauge steel framed wall: Flexural behavior, thermal performance and life cycle assessment. J. Build. Eng. 2022, 47, 103856. [Google Scholar] [CrossRef]

- Qian, Z.X.; Pan, J.L.; Zhang, L.A.; Wang, L. Study on the flexural performance of light steel keel concrete composite wall panels. Ind. Build. 2020, 50, 32–37+4. [Google Scholar] [CrossRef]

- DaBreo, J.; Balh, N.; Ong-Tone, C.; Rogers, C. Steel sheathed cold-formed steel framed shear walls subjected to lateral and gravity loading. Thin-Walled Struct. 2014, 74, 232–245. [Google Scholar] [CrossRef]

- Nan, B.; Chi, Y.; Yang, Z. Study on flexural performance of light steel keel composite wall with web openings. J. Constr. Steel Res. 2025, 228, 109376. [Google Scholar] [CrossRef]

- Tan, C.L.; Wan, H.Y.; Chen, A.Y. Parametric Numerical Analysis of Bending Performance of Light Steel Keel Sandwich Composite External Wall Panel. J. Taiyuan Univ. Technol. 2020, 51, 19–25. [Google Scholar] [CrossRef]

- Yao, B.; Fang, H.; Qian, Z.; Wang, Q.; Sun, J.; Wang, W. Experimental and Numerical Study on Axial Compression Cold-Formed Steel Composite Wall under Concentrated Loads. Buildings 2023, 13, 1232. [Google Scholar] [CrossRef]

- Wang, J.; Liang, J.; Hou, W.; Lu, L. Experimental investigation on the compressive behaviour of foam concrete light steel keel composite wall. J. Asian Archit. Build. Eng. 2024, 1–14. [Google Scholar] [CrossRef]

- Fang, H.; Qian, Z.; Yao, B.; Wang, W. Experimental studies on the mechanical behaviors of cold-formed thin-walled steel-foam concrete composite walls. Adv. Struct. Eng. 2024, 27, 1477–1489. [Google Scholar] [CrossRef]

- Shi, Y.; Sun, C.; Gao, C.; Liu, J.; Peng, X. Study on lateral resistance of cold-formed corrugated steel plates with lightweight foam concrete composite walls. Thin-Walled Struct. 2025, 210, 112964. [Google Scholar] [CrossRef]

- Yu, F.; Kuang, G.; Bu, S.; Chen, L. Flexural performance tests and numerical analysis of fabricated light-gauge steel reinforced foam concrete filled steel mesh formwork wallboards. Structures 2024, 66, 106813. [Google Scholar] [CrossRef]

- Amran, Y.M.; Rashid, R.S.; Hejazi, F.; Safiee, N.A.; Ali, A.A. Response of precast foamed concrete sandwich panels to flexural loading. J. Build. Eng. 2016, 7, 143–158. [Google Scholar] [CrossRef]

- Qiao, W.; Yan, X.; Zhu, R.; Wang, F.; Wang, D. Flexural properties of new cold -formed thin -walled steel and concrete composite slabs. J. Build. Eng. 2020, 31, 101441. [Google Scholar] [CrossRef]

- Liu, D.; Fu, F.; Liu, W. Structural Behavior of Composite Floor System Using Cold-Formed Thin-Walled C Steel Channel Embedded Foam Concrete. Appl. Sci. 2021, 11, 9888. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, L.; Yuan, L.; Wu, G.; Zheng, R.; Mu, Y. Research on Flexural Performance of Basalt Fiber-Reinforced Steel-Expanded Polystyrene Foam Concrete Composite Wall Panels. Buildings 2025, 15, 285. [Google Scholar] [CrossRef]

- GB/T 700—2006; Carbon Structural Steel. China Standard Press: Beijing, China, 2007.

- Hu, X.B.; Zhang, Z.W.; Huang, J.Y.; Mao, Q.S.; Li, Q.S.; Yuan, Z.S. Research on flexural performance of light steel keel foam concrete lightweight wallboard. Prog. Build. Steel Struct. 2022, 24, 67–75. [Google Scholar] [CrossRef]

- Soares, N.; Santos, P.; Gervásio, H.; Costa, J.J.; da Silva, L.S. Energy efficiency and thermal performance of lightweight steel-framed (LSF) construction: A review. Renew. Sustain. Energy Rev. 2017, 78, 194–209. [Google Scholar] [CrossRef]

- Xiong, Y.Q. Research on the Damage Evolution Law and Damage Model of Multi Ribbed Composite Walls. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2008. [Google Scholar]

- GB 50009-2012; Code for Load of Building Structures. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2012.

- JG/T 266-2011; Foam Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2011.

- GB/T 50081-2019; Standard for Test Methods of Physical and Mechanical Properties of Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2019.

- GB/T 50152-2012; Standard for Test Methods of Concrete Structures. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2012.

- JG/T 544-2018; Light steel keel composite wall. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2018.

- Feng, P.; Qiang, H.L.; Ye, L.P. Definition and Discussion of the “Yield Point” of Materials, Components, and Structures. Eng. Mech. 2017, 34, 36–46. [Google Scholar]

| Wall Panel Type | Weight Range Per Unit Area (kg/m2) | Key Technical Features | Thermal Bridge | Construction Method |

|---|---|---|---|---|

| CFS framing with overlay panels | 30–60 | CFS framing with screw-connected cladding panels (cement fiber/gypsum boards, etc.) and cavity insulation | Significant | Dry construction |

| CFS framing with grout-filled cavities | 70–120 | CFS framing with cladding panels and screw-connected on-site grouting (concrete/mortar) | Moderate | Semi-wet/semi-dry construction |

| CFS framing with foam concrete composites | 90–160 | CFS framing with factory-precast lightweight concrete | Low | Dry construction |

| Traditional reinforced concrete enclosure wall panel | 410–450 | Steel reinforcement with cast-in-place ordinary concrete | Low | Semi-wet/semi-dry construction |

| Material | Tensile Strength (MPa) | Compressive Strength (MPa) | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|---|

| Foamed concrete | 0.085 | 0.85 | 500 | 0.2 |

| C-shaped steel | 310 | 310 | 2.06 × 105 | 0.3 |

| Height Above Ground/m | Pressure Height Coefficient | Gust Coefficient | Wind Load Standard Value/KN/m2 | ||

|---|---|---|---|---|---|

| = 0.45 | = 0.60 | ||||

| 10 | 1.00 | 1.70 | 1.22 | 1.63 | 1.90 |

| 20 | 1.23 | 1.63 | 1.44 | 1.92 | 2.25 |

| 30 | 1.39 | 1.59 | 1.59 | 2.12 | 2.48 |

| 40 | 1.52 | 1.57 | 1.72 | 2.29 | 2.67 |

| 50 | 1.62 | 1.55 | 1.81 | 2.41 | 2.81 |

| 60 | 1.71 | 1.54 | 1.90 | 2.53 | 2.95 |

| 70 | 1.79 | 1.52 | 1.96 | 2.61 | 3.05 |

| 80 | 1.87 | 1.51 | 2.03 | 2.71 | 3.16 |

| 90 | 1.93 | 1.50 | 2.08 | 2.78 | 3.24 |

| 100 | 2.00 | 1.50 | 2.16 | 2.88 | 3.36 |

| Test Piece Number | Dimensions of C-Shaped Steel/mm | Protection Layer Thickness/mm | Strength of Foam Concrete/MPa |

|---|---|---|---|

| LFSW-1 | C100 × 40 × 20 × 1.8 | 25 | 1.0 |

| LFSW-2 | C100 × 40 × 20 × 2.5 | 25 | 0.5 |

| LFSW-3 | C100 × 40 × 20 × 2.5 | 25 | 1.0 |

| LFSW-4 | C80 × 40 × 15 × 2.5 | 35 | 1.0 |

| LFSW-5 | C80 × 40 × 15 × 2.5 | 25 | 1.0 |

| Test Block Number | Measured Density/kg/m3 | Failure Load/kN | Compressive Strength/MPa | Mean Value/MPa |

|---|---|---|---|---|

| A1.0-1 | 495 | 7.92 | 0.79 | 0.85 |

| A1.0-2 | 493 | 9.42 | 0.94 | |

| A1.0-3 | 488 | 8.28 | 0.83 | |

| A2.0-1 | 506 | 14.12 | 1.4 | 1.48 |

| A2.0-2 | 516 | 16.91 | 1.69 | |

| A2.0-3 | 526 | 13.44 | 1.34 |

| Specimen Number | Yield Strength (MPa) | Mean Value (MPa) | Tensile Strength (MPa) | Mean Value (MPa) |

|---|---|---|---|---|

| F-1 | 219.4 | 221.3 | 310.4 | 312.2 |

| F-2 | 220.6 | 311.8 | ||

| Y-1 | 223.7 | 314.2 | ||

| Y-2 | 221.5 | 312.4 |

| Test Piece | Type | Cracked Node | Peak Node | ||||

|---|---|---|---|---|---|---|---|

| Load /KN | Displacement /mm | Stiffness /kN/mm | Load /KN | Displacement /mm | Stiffness /kN/mm | ||

| LFSW-1 | Test | 6.00 | 7.45 | 0.81 | 22.13 | 60.08 | 0.37 |

| Simulate | 5.76 | 4.95 | 1.16 | 20.84 | 60.23 | 0.35 | |

| Parameter | LFSW-2 | LFSW-3 | |

|---|---|---|---|

| Strength of foam concrete/MPa | 0.5 | 1.0 | |

| Cracking state | Load/KN | 4.0 | 6.0 |

| Displacement/mm | 3.13 | 5.46 | |

| Yielding state | Load/KN | 29.8 | 28.0 |

| Displacement/mm | 44.11 | 37.99 | |

| Limit state | Load/KN | 33.4 | 32.3 |

| Displacement/mm | 64.35 | 64.30 | |

| Elastic stiffness | 1.28 | 1.10 | |

| Parameter | LFSW-1 | LFSW-3 | |

|---|---|---|---|

| CFS framing wall thickness/mm | 1.8 | 2.5 | |

| Cracking state | Load/KN | 6.0 | 6.0 |

| Displacement/mm | 7.45 | 5.46 | |

| Yielding state | Load/KN | 19.7 | 28.0 |

| Displacement/mm | 33.44 | 37.99 | |

| Limit state | Load/KN | 22.1 | 32.3 |

| Displacement/mm | 60.08 | 64.30 | |

| Elastic stiffness | 0.81 | 1.10 | |

| Parameter | LFSW-5 | LFSW-3 | |

|---|---|---|---|

| CFS framing section height/mm | 80 | 100 | |

| Cracking state | Load/KN | 4.0 | 6.0 |

| Displacement/mm | 4.82 | 5.46 | |

| Yielding state | Load/KN | 22.6 | 28.0 |

| Displacement/mm | 41.88 | 37.99 | |

| Displacement/mm | 61.85 | 64.30 | |

| Elastic stiffness | 0.83 | 1.10 | |

| Parameter | LFSW-5 | LFSW-4 | |

|---|---|---|---|

| Concrete cover/mm | 25 | 35 | |

| Cracking state | Load/KN | 4.0 | 4.0 |

| Displacement/mm | 4.82 | 4.43 | |

| Yielding state | Load/KN | 22.6 | 24.5 |

| Displacement/mm | 41.88 | 39.86 | |

| Limit state | Load/KN | 25.5 | 27.3 |

| Displacement/mm | 61.85 | 60.26 | |

| Elastic stiffness | 0.83 | 0.90 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wang, K.; Zhao, Q.; Luo, C. Research on Flexural Performance of Low-Strength Foamed Concrete Cold-Formed Steel Framing Composite Enclosure Wall Panels. Buildings 2025, 15, 3018. https://doi.org/10.3390/buildings15173018

Liu X, Wang K, Zhao Q, Luo C. Research on Flexural Performance of Low-Strength Foamed Concrete Cold-Formed Steel Framing Composite Enclosure Wall Panels. Buildings. 2025; 15(17):3018. https://doi.org/10.3390/buildings15173018

Chicago/Turabian StyleLiu, Xinliang, Kunpeng Wang, Quanbin Zhao, and Chenyuan Luo. 2025. "Research on Flexural Performance of Low-Strength Foamed Concrete Cold-Formed Steel Framing Composite Enclosure Wall Panels" Buildings 15, no. 17: 3018. https://doi.org/10.3390/buildings15173018

APA StyleLiu, X., Wang, K., Zhao, Q., & Luo, C. (2025). Research on Flexural Performance of Low-Strength Foamed Concrete Cold-Formed Steel Framing Composite Enclosure Wall Panels. Buildings, 15(17), 3018. https://doi.org/10.3390/buildings15173018