A Rubberized-Aerogel Composite Binder Modifier for Durable and Sustainable Asphalt Pavements

Abstract

1. Introduction

2. Materials and Methodology

2.1. Materials

2.1.1. Rubberized-Aerogel Composite for Construction Materials (RaC)

- Warm Method (WM): Pre-swelled crumb rubber is mixed with the hot asphalt binder (160 °C) using a high-speed mixer, followed by aerogel addition. The binder acts as the encapsulating agent.

- Cold Method (CM): Pre-swelled crumb rubber and the aerogel are mixed at room temperature with an emulsified asphalt encapsulator, forming a dry particulate composite.

2.1.2. Asphalt Binder

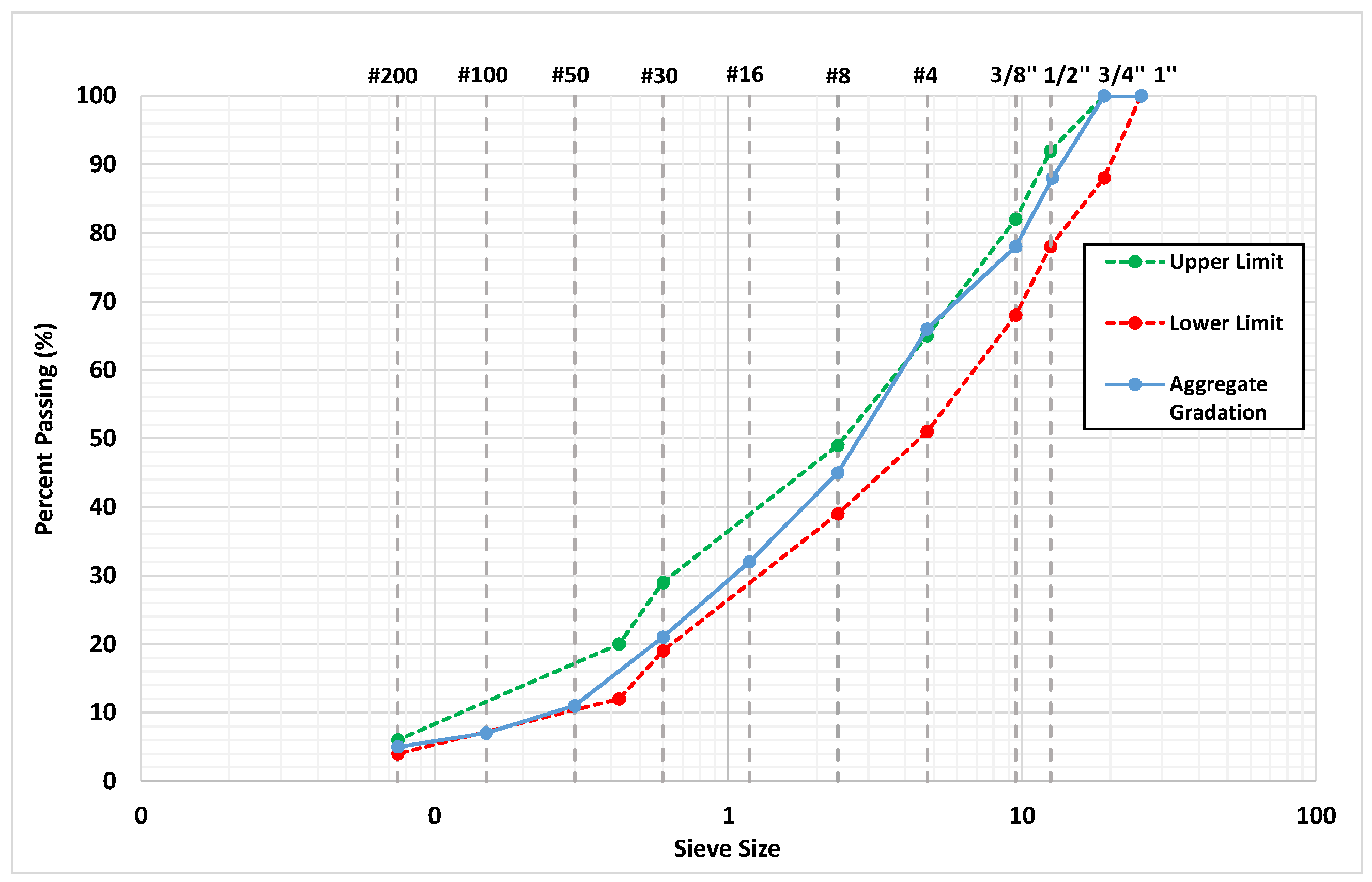

2.1.3. Aggregates

2.2. Methodology

2.2.1. Preparation of Asphalt Binder Samples

- -

- Preheat the PG70-10 binder to 160 °C in an oven.

- -

- Calculate the required RaC amount (5:1 ratio) based on test needs.

- -

- Add the RaC to the binder using a metallic spoon and mix manually with a wooden stick for 1 min to ensure uniform dispersion.

- -

- Pour samples into molds for specific tests.

2.2.2. Asphalt Mixture Characteristics

- -

- Mixing aggregates with 20% of the RaC (by binder weight) for 30 s.

- -

- Adding the PG70-10 binder and mixing to achieve homogeneity.

- -

- Compacting mixtures to a target air void content of 4%.

2.2.3. Performance Testing

- Asphalt Binder Testing was carried out following the standards and procedures below:

- -

- Temperature susceptibility of asphalt binders: This analysis involves penetration, viscosity, and softening data. The softening point was determined based on ASTM D36/D36M-14 [29]. The penetration test at 25 °C was conducted based on ASTM D5-97 [30]. Rotational viscosity at different temperatures was determined according to ASTM D4402-02 [31].

- -

- Rheology of the binders using a Dynamic Shear Rheometer (DSR): ASTM D7175-08 [32].

- -

- -

- Asphalt Binder Bond Strength (BBS): The pull-off tensile strength of the asphalt binder from a siliceous surface was measured and determined via the bitumen bond strength test according to AASHTO T 361 [35].

- -

- Thermal Conductivity (TC) of Asphalt Binders: This test was developed in The National Center of Excellence for SMART Innovations at ASU with the patent number US20220252532A1 [36]. To perform the test, samples were poured into a cylindrical silicon mold with a height of 25 mm, a half-height indent of 2 mm in the center, and a total radius of 20 mm. After being demolded, thermocouples were placed on the sample to track the temperature change between the sample’s inner and outer layers [11].

- -

- Specific Heat Capacity (Cp): The method used in this study was developed at The National Center of Excellence for SMART Innovations at ASU. It consists of heating the specimens in the oven for 1 h and then submerging them into water at room temperature. The system is placed in a completely insulated container, minimizing the energy exchange with the exterior environment. To perform the test, asphalt binder samples were poured into a cylindrical silicon mold with a height of 25 mm and a radius of 20 mm [20].

- -

- Flexural Creep Stiffness of the Asphalt Binder Using the Bending Beam Rheometer (BBR): AASHTO T 313-19 [27]. Based on the results the low-temperature performance grading of the binders was determined.

- -

- Toughness and Tenacity of Asphalt Materials: ASTM D5801 [37]. The total work required to separate the material from the tension head and the post-peak behavior, known as tenacity, were determined.

- Asphalt Mixture Testing and Analysis was carried out following the standards and procedures below:

- -

- Modified Witczak Model (NCHRP 1-40D) for Dynamic Modulus (E*) Prediction: The modified Witczak model, developed under NCHRP Project 1-40D [38], represents an evolution of the earlier Witczak E* predictive model (NCHRP 1-37A [39]). This version was primarily developed to improve the characterization of asphalt binders within the model and enhance the accuracy of E∗ predictions for hot-mix asphalt (HMA) mixtures. A key difference in the NCHRP 1-40D model is its incorporation of the asphalt binder complex shear modulus (G*) and phase angle (δ) as inputs, rather than relying on binder viscosity as in the 1-37A version. In addition to binder properties, the model also considers mixture volumetric properties and aggregate gradation [40]. The predicted dynamic modulus values obtained from the Witczak model would serve as a critical tool for evaluating and comparing the temperature-dependent performance of the control and RaC asphalt mixtures. As E* is a direct measure of mixture stiffness and is highly sensitive to temperature, the model’s predictions across a range of temperatures provide insight into how each mixture will behave under varying thermal conditions encountered in a pavement structure. It is calculated according to the following equation:where is the aggregate contact volume calculated from the following equation:

- -

- Hamburg Wheel-Tracking Test (HWTT): The Hamburg Wheel-Tracking Test (AASHTO T 324) [41] is a widely used performance test designed to evaluate the rutting and moisture susceptibility of asphalt mixtures. It simulates traffic loading under submerged conditions to replicate real-world environmental and loading stresses, making it especially valuable for identifying stripping-prone or rut-susceptible mixes [42,43]. In the HWTT, a slab or cylindrical specimens of the compacted asphalt mixture are submerged in a water bath—typically maintained at 50 °C (though other temperatures may be used depending on climate or agency requirements). A steel wheel (usually 705 N or ~158 lb) repeatedly rolls back and forth across the surface of the specimen. The total number of passes is limited to 20,000. Two replicates were tested for each sample, the control and the 20% RaC modified.

- -

- Indirect Tensile Strength (IDT): The indirect tensile strength (IDT) following ASTM D6931 [44] and the tensile strength ratio (TSR) following AASHTO T 283 [45] are fundamental tests for evaluating the moisture susceptibility and cracking resistance of asphalt mixtures. When these tests are combined with freeze–thaw conditioning, they provide a more comprehensive understanding of how the mixture will perform under real-world climatic conditions. The IDT test measures the tensile strength of an asphalt mixture by applying a diametral compressive load to a cylindrical disk of 65 mm. The load induces tensile stress perpendicular to the loading plane, mimicking the cracking behavior that occurs in the field. Both mixtures were subjected to freeze–thaw cycles. The IDT test was conducted on two sets of samples for each mixture: before (under dry conditions) and after conditioning the specimens under wet–freeze conditions (e.g., soaked in water and then frozen at sub-zero temperatures). This conditioning simulates the effect of repeated freeze–thaw cycles in field environments, which can exacerbate moisture damage and lead to cracking or rutting.After conditioning, the specimens undergo the standard IDT procedure at a typical field temperature (e.g., 25 °C). The tensile strength for dry and wet conditions is calculated as follows:where P is the maximum load (N), t is the specimen thickness (mm), and D is the diameter of the specimen (mm).The TSR compares the tensile strength of conditioned (moisture-damaged) specimens to the unconditioned (dry) specimens, after freeze–thaw conditioning. After vacuum saturation, specimens undergo a freeze–thaw cycle (16 h of freezing at −18 °C, followed by 24 h of thawing at 60 °C). The TSR formula is as follows:

- -

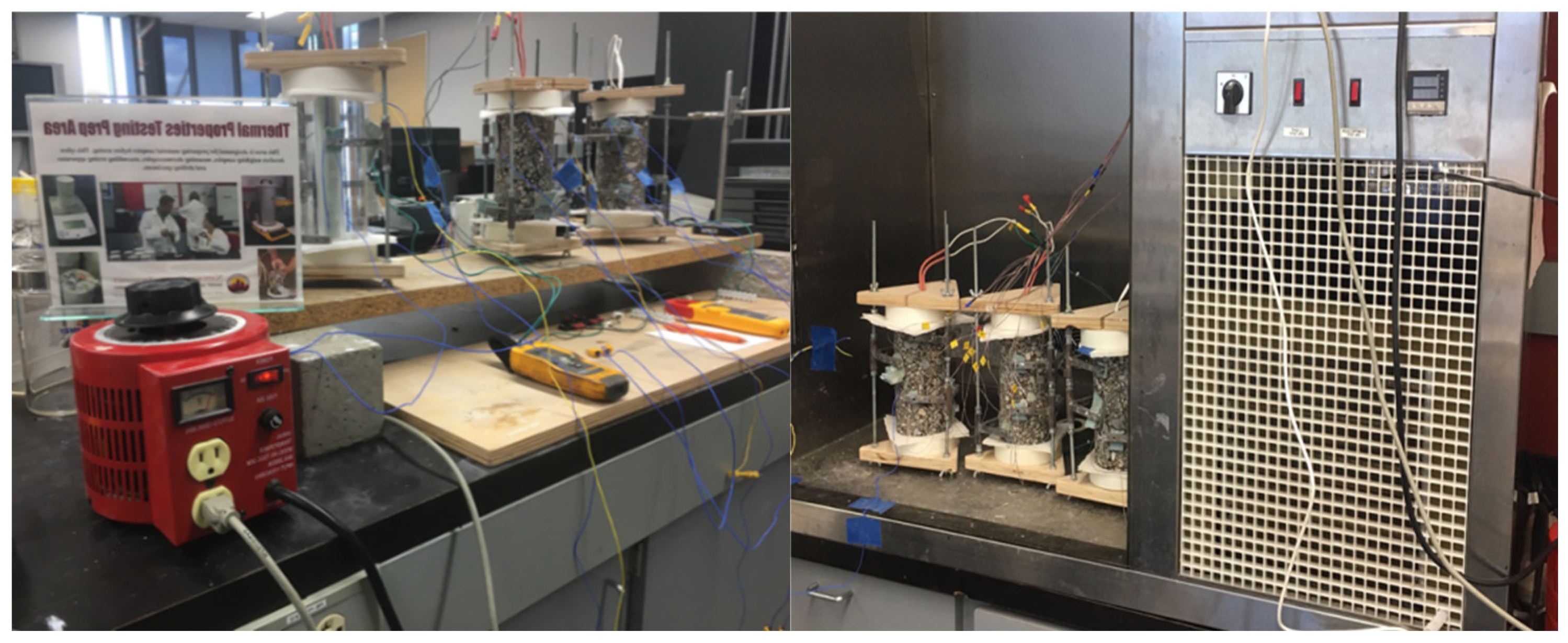

- Thermal Conductivity: The thermal conductivity and the specific heat capacity for the mixtures considered are to be determined. The thermal conductivity of the samples was determined in a closed and conditioned chamber to minimize the effect of the ambient air on the samples. A cylindrical heating probe is inserted inside each of the asphalt mixture cylinders. Six thermocouples were used to measure the temperatures: three inside the specimen and three outside. The experiment ended when the steady-state temperature was reached. Figure 3 show the setup for this experiment. The thermal conductivity is calculated according to Equation (5) [46].where k = the thermal conductivity (W/m K) = the power into the heating probe (W); , where V is the voltage and A is the current; = the outer radius (m); = the inner radius (m); = the average of the outer temperatures (°C); and = the average of the inner temperatures (°C).

- -

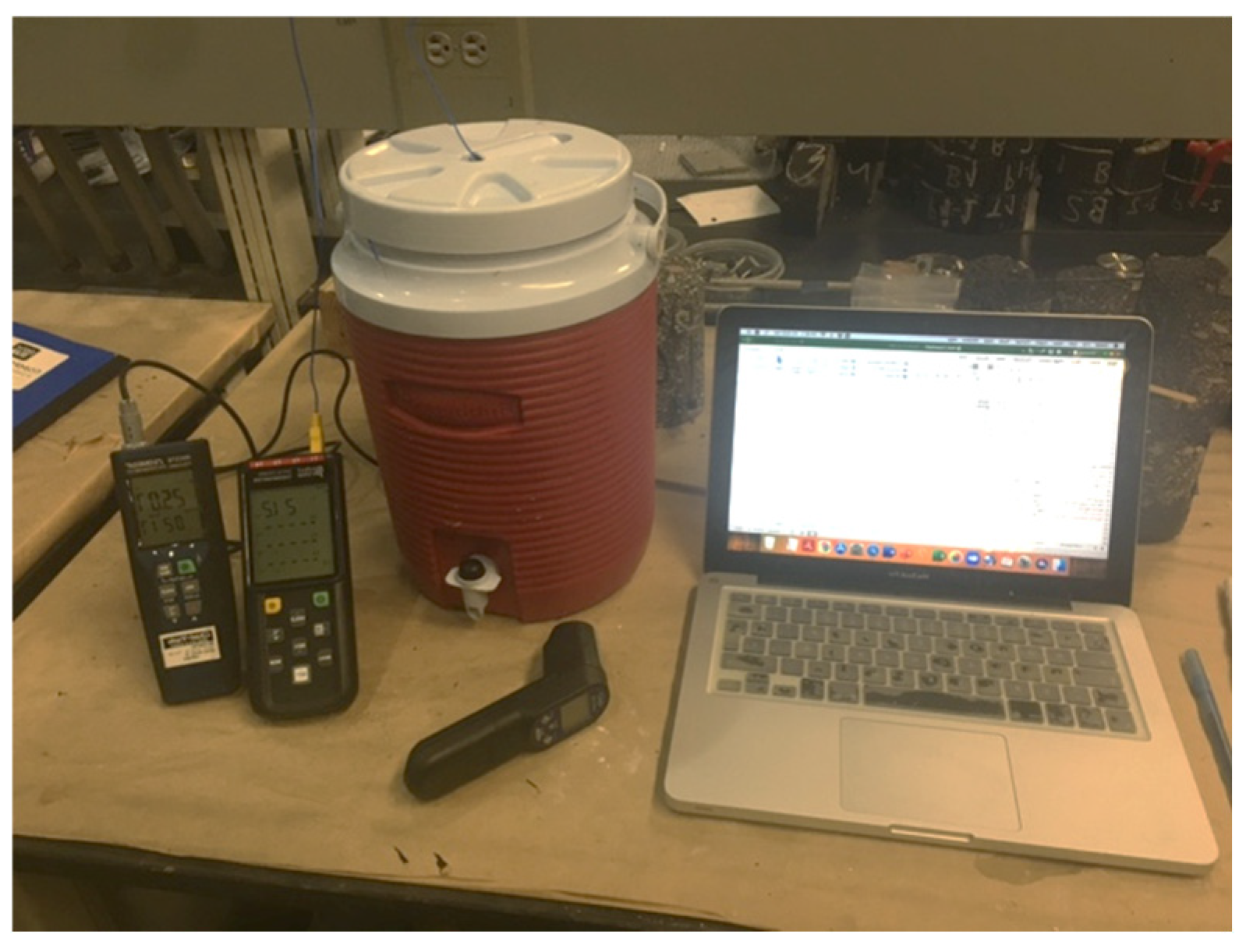

- Specific Heat Capacity: As asphalt mixtures are anisotropic and heterogeneous materials, capturing the change in specific heat capacity is challenging. The method used in this study gave the most consistent results. It consists of heating the specimens in the oven for 8 h and then submerging them into water at room temperature. The system is placed in a completely insulated container, minimizing the energy exchange with the exterior. The change in temperature of the sample and water was recorded with respect to time until the water temperature is constant (around 30 min), leading to the calculation of the specific heat capacity using Equation (6). Figure 4 shows the setup used for this procedure [47].where m = the mass (Kg), T = the temperature (°C), C = the specific heat capacity (J/°C/Kg). And W is for water; f is for flask, and S is for specimen.

- -

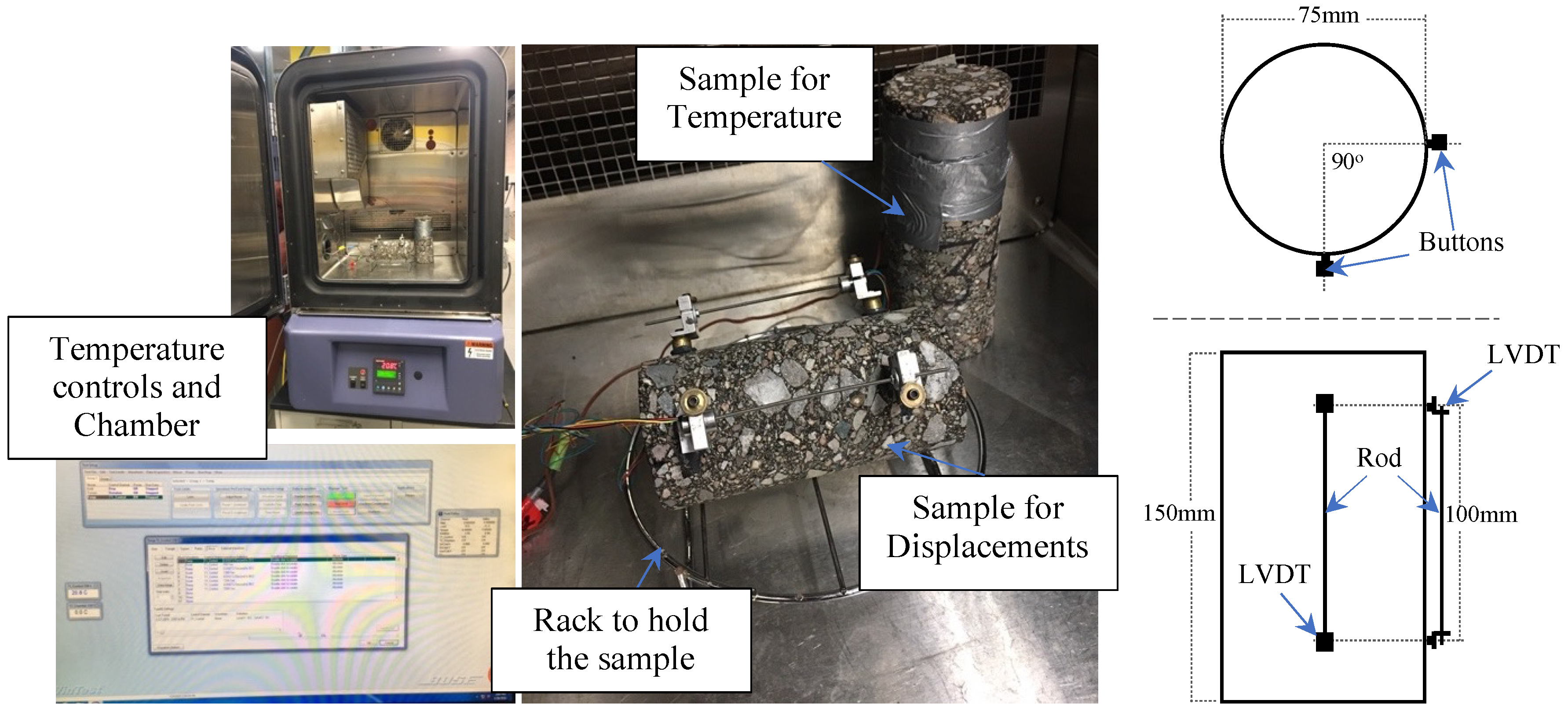

- Expansion and Contraction: The expansion and contraction test was used to evaluate the thermal behavior of asphalt mixtures by measuring the strain induced in the specimen as it undergoes temperature changes. In this test, two linear variable differential transducers (LVDTs) were mounted on a cylindrical asphalt mixture sample to accurately measure strain due to temperature fluctuations. The specimen was subjected to temperature cycling, where the temperature inside a conditioning chamber was varied from 25 °C to 45 °C, simulating real-world temperature variations [20].

- During the cycling process, the specimen expanded as the temperature increased and contracted as the temperature decreased. The strain was measured for each temperature, and the coefficient of thermal expansion and contraction was calculated according to Equation (7):where is the measured strain difference at two different temperatures in °C.This coefficient quantifies the ability of the material to expand and contract per unit of temperature change, providing insight into the thermal stability of the asphalt mixture. The importance of this test lies in its ability to predict how the asphalt will respond to temperature fluctuations in the field. By understanding the thermal expansion and contraction behavior, the risk of cracking due to temperature-induced stress can be assessed. Below, Figure 5 presents the setup of the test [20].

- -

- AASHTOWare Pavement ME Predictions: To evaluate the potential field performance of the asphalt mixtures under realistic traffic and environmental conditions, Pavement ME Design simulations were conducted. The Pavement ME Design software (v2.6.2.1) is a sophisticated tool that utilizes mechanistic–empirical principles to predict pavement distresses based on material properties, traffic loading, and climate data [48]. Using the laboratory-determined material parameters for both the control and RaC mixtures, including dynamic modulus (E*) and thermal properties, simulations were performed for a matrix of scenarios designed to represent varying environmental and structural conditions. A constant average daily truck traffic volume of 2000 was selected across all scenarios for a 20-year analysis period. The simulation matrix included two distinct climate locations: Phoenix, Arizona, representing a hot desert climate, and Chicago, Illinois, representing a temperate climate with significant freeze–thaw cycling. For each climate, two typical flexible pavement structural sections were modeled: a thin section consisting of 76 mm of asphalt concrete (AC) over the subgrade and a thick section consisting of 153 mm of AC over the subgrade. This approach allowed for an assessment of how the material properties of the control and RaC mixtures influence predicted performance under different thermal regimes and structural demands.

3. Results and Discussion

- A.

- Binders

- -

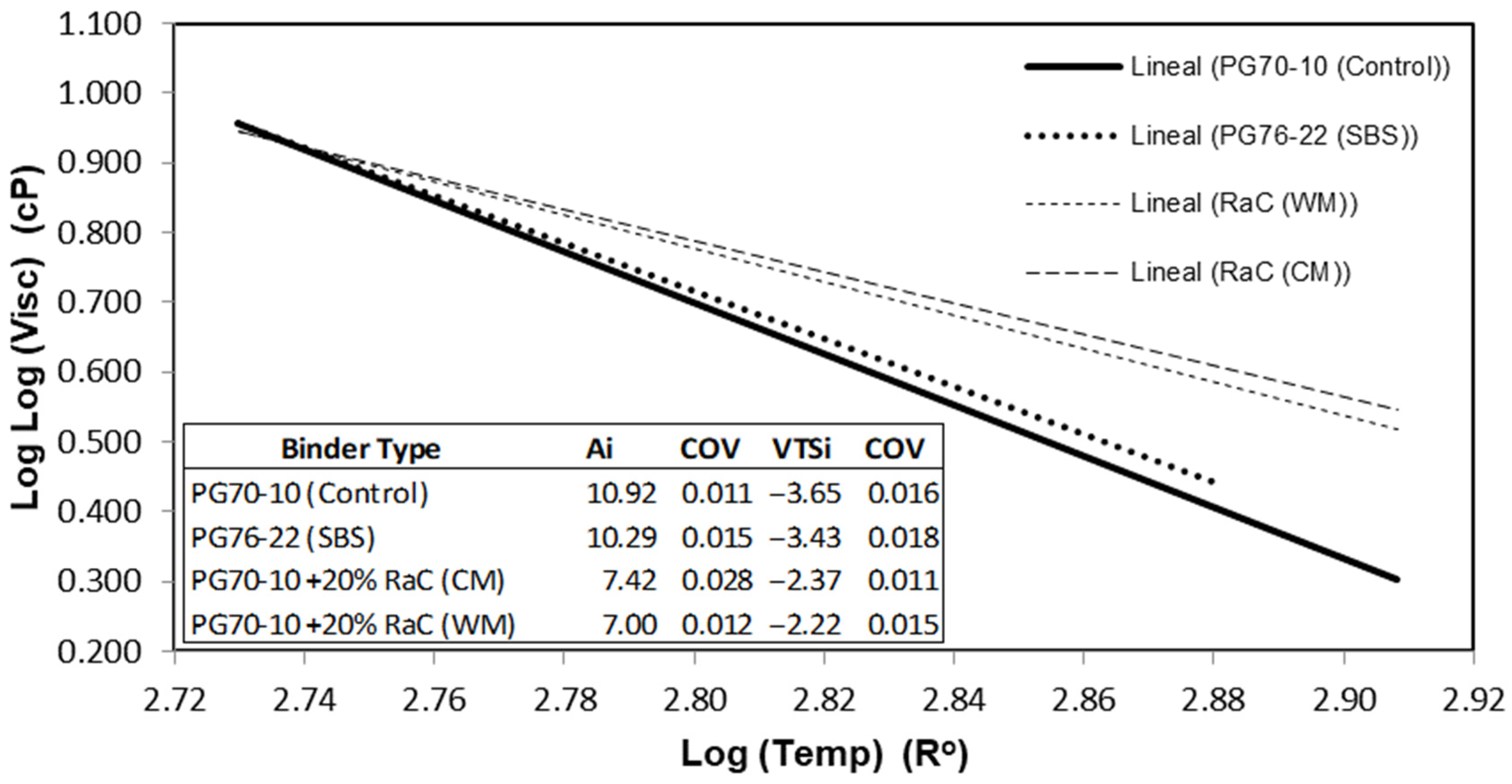

- Temperature Susceptibility of Asphalt Binders: The incorporation of the RaC significantly reduced the temperature susceptibility of PG70-10 binders due to the elastic properties of crumb rubber [49] and the insulating effect of the aerogel. Viscosity–temperature susceptibility parameters (Ai and VTSi) showed that RaC-modified binders (WM and CM) had a 40% lower VTSi (slope) compared to the control (VTSi: −3.7 vs. −2.2) and a 36% lower Ai (y-intercept), indicating reduced viscosity at low temperatures. Compared to SBS-modified PG76-22 (VTSi: −3.4), RaC binders exhibited superior temperature stability (Refer Figure 6). These results align with those by Wang et al. (2017), who reported a 20% reduction in VTSi for crumb rubber and SBS blends, though the RaC’s aerogel component further enhances thermal stability by reducing heat transfer [17].

- -

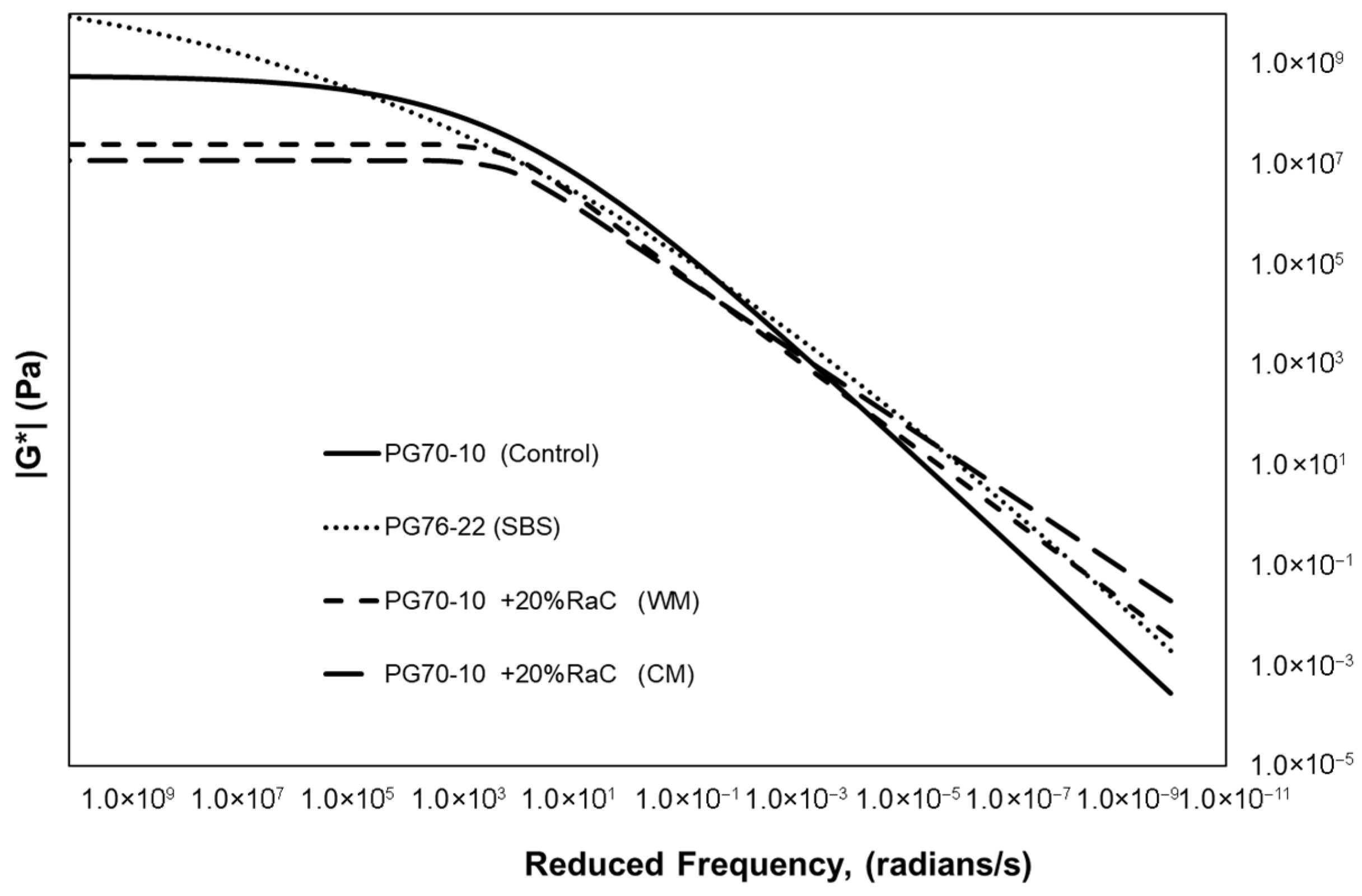

- Rheology of the binders using the Dynamic Shear Rheometer (DSR): Dynamic Shear Rheometer (DSR) testing revealed that the RaC’s additives improved binder stiffness and flexibility. The complex shear modulus (|G*|) of RaC-modified binders increased by 40% at high temperatures (70 °C) compared to the control, enhancing rutting resistance due to crumb rubber’s elastic network. At low temperatures (−10 °C), |G*| decreased by 30%, improving crack resistance due to the waste oil’s rejuvenating effect. Compared to SBS-modified binders, RaC binders showed a 10% higher |G*| at high temperatures and comparable flexibility at low temperatures (Refer Figure 7). These findings are consistent with those by Shen et al. (2009) [7], where crumb rubber increased high-temperature stiffness, but the RaC’s aerogel component uniquely broadens the effective temperature range.

- -

- High-Temperature Performance Grading: The RaC’s additives elevated the high-temperature Performance Grade (PG) of PG70-10 by 30°C (to PG100), surpassing SBS-modified PG76-22 by 24°C, as determined by G*/sin(δ) ≥ 1.1 kPa. The multiple stress creep recovery (MSCR) test showed that RaC-modified binders had higher percent recovery (15% vs. 0.0% for control) and a 30% lower non-recoverable creep compliance (Jnr: 4.2 vs. 7.1), indicating superior rutting resistance due to crumb rubber’s elasticity and the aerogel’s thermal stability [50]. Compared to Zhang et al. (2018) [18], who reported a 40% recovery increase with crumb rubber and rejuvenators, the RaC’s performance is enhanced by the aerogel’s thermal insulation, reducing heat-induced deformation [38]. Table 3 presents the PG grading results for binders tested with a 2 mm gap between the DSR plates to prevent frictional interference caused by RaC particles. These results demonstrate the RaC’s strong potential for enhancing high-temperature rutting resistance [33].

- -

- Asphalt Binder Bond Strength (BBS): The RaC’s components maintained effective binder–aggregate adhesion, with cohesive failure modes similar to the control and SBS binders. The pull-off tensile strength of the RaC-modified binders was 332 kPa and 298 kPa, for the WM and CM, respectively, comparable to 409 kPa for the control and 415 kPa for SBS (refer Table 4), indicating that crumb rubber and waste oil do not compromise bonding dramatically, while the aerogel’s encapsulation ensures compatibility. These results align with those by Bhasin and Little (2007), who found that crumb rubber-modified binders maintain cohesive strength, suggesting that the RaC’s additives preserve adhesion critical for pavement durability [40].

- -

- Thermal Conductivity (TC) and Specific Heat Capacity (Cp) of Asphalt Binders: Table 5 shows that the RaC’s aerogel component significantly reduced thermal conductivity [11,51] by 14% (0.19 W/m·K vs. 0.22 W/m·K for the control) and increased the specific heat capacity by 7% (1000 J/g·K vs. 946 J/g·K) due to the aerogel’s insulating properties and crumb rubber’s thermal inertia [52]. These changes enhance thermal stability, slowing heat transfer and buffering temperature fluctuations. Compared to Li et al. (2025) [19], who reported a 25% reduction in thermal conductivity with the aerogel alone, the RaC’s combination with crumb rubber and waste oil provides additional flexibility, mitigating stiffness concerns noted in aerogel-only modifications [46]

- -

- Low-Temperature Performance Grading: This test characterizes the stress–strain response of binders at low temperatures using the Bending Beam Rheometer (BBR). Binders must be sufficiently soft and responsive at low temperatures to dissipate accumulated thermal stresses before they result in fractures [27,53]. Table 6 summarizes the test results, where binders modified with the RaC exhibited increased m-values (51%, −16.1 vs. −10.28) and reduced stiffness. The inclusion of the RaC improved the low-temperature PG of PG70-10 by 13 °C, indicating enhanced flexibility and reduced cracking potential. This performance matches SBS-modified binders, which is attributed to waste oil’s rejuvenation and crumb rubber’s elasticity. Zaumanis et al. (2014) [9] reported a 15% reduction in stiffness with rejuvenators, but the RaC’s aerogel further stabilizes the thermal behavior, reducing the cracking potential.

- -

- Toughness and Tenacity of Asphalt Binders: Tenacity is the binder’s elongation capacity beyond the peak load, indicating elasticity and flexibility [54]. Results in Table 7 show a significant increase in both toughness and tenacity for RaC-modified binders. The RaC’s additives enhanced binder ductility, with toughness increasing by 100% (5395 vs. 2715 for control) and tenacity by five times due to crumb rubber’s elastic properties [52] and waste oil’s softening effect. These improvements indicate better crack resistance under tensile loads, surpassing SBS binders. Airey and Rahman (2003) [54] noted about a 30% increase in toughness with crumb rubber, but the RaC’s synergistic additives provide superior energy absorption, enhancing fatigue resistance.

- B.

- Mixtures

- -

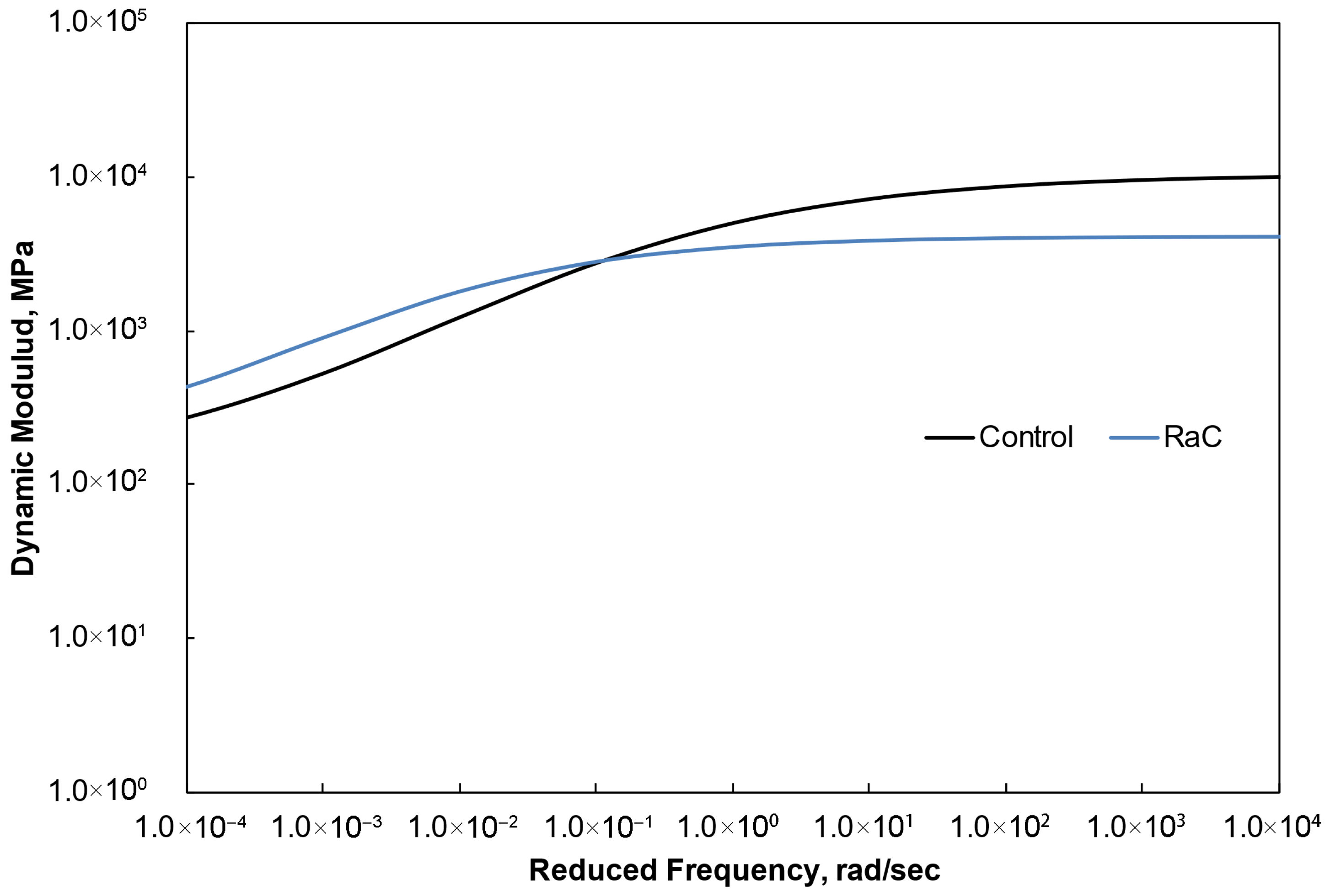

- E* Prediction Model: The modified Witczak model predicted that the RaC’s additives altered mixture stiffness. RaC-modified mixtures showed a 20% lower E* at low temperatures (5 °C: 8 GPa vs. 10 GPa for the control), enhancing flexibility due to crumb rubber and waste oil, and a 25% higher E* at high temperatures (40 °C: 2.5 GPa vs. 2.0 GPa), improving rutting resistance due to the aerogel’s thermal stability. These results align with those by Wang et al. (2017) [17], who reported a 15–20% increase in E* at high temperatures for crumb rubber–SBS blends, but the RaC’s aerogel provides additional thermal buffering. The Witczak model, by incorporating mixture composition and binder properties, appears to effectively capture these temperature-dependent modifications introduced by the recycled aerogel and crumb rubber, indicating the potential for the RaC mixture to offer improved thermal susceptibility performance [38]. The master curves obtained for both mixtures are presented below in Figure 8.

- -

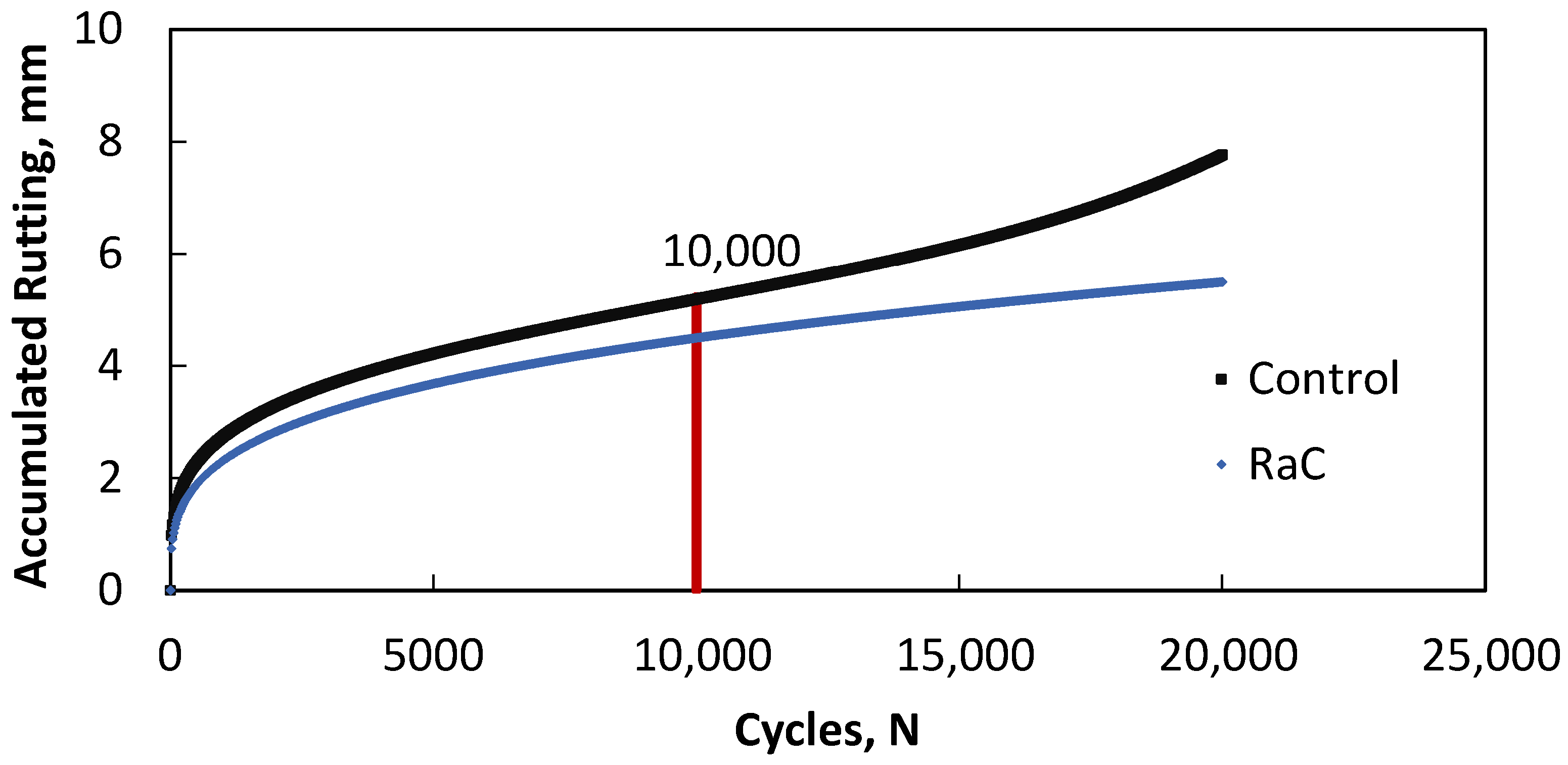

- Hamburg Wheel Tester (HWTT): HWTT results revealed a significant difference in rutting performance between the RaC and control asphalt mixtures (Figure 9a,b). RaC-modified mixtures are showing a 50% reduction in rut depth (2 mm vs. 4 mm for the control after 20,000 passes at 55 °C) and no tertiary flow, unlike the control, which failed at 10,000 passes (refer to Figure 10). This is attributed to crumb rubber’s elastic recovery and the aerogel’s thermal insulation, reducing deformation under heat.

- -

- Indirect Tensile Test (IDT): The RaC’s additives slightly improved moisture resistance, with a tensile strength ratio (TSR) of 90% compared to 87% for the control, which is attributed to the hydrophobic aerogel surface and crumb rubber’s elasticity (refer Table 8). Bhasin et al. (2007) [55] found similar TSR improvements with crumb rubber, but the RaC’s aerogel encapsulation minimizes moisture absorption concerns, enhancing durability. A higher TSR indicates greater resistance to moisture-induced damage, which is crucial for pavements exposed to wet or freeze–thaw conditions [45,55].

- -

- Thermal Conductivity and Specific Heat Capacity of Mixtures: Table 9 shows that RaC-modified mixtures exhibited a 11% lower thermal conductivity (0.98 W/m·K vs. 0.88 W/m·K for control) and a 26% higher specific heat capacity (1192 J/g·K vs. 951 J/g·K), which were driven by the aerogel’s insulating properties and crumb rubber’s thermal inertia. These properties reduce temperature fluctuations, mitigating thermal cracking and rutting. Proper thermal balance can reduce premature distresses such as thermal cracking, rutting, and binder aging [11]. The results are summarized in the table below.

- -

- Expansion and Contraction: With respect to the thermal dimensional response, the RaC mixture had a lower coefficient of expansion and a slightly higher coefficient of contraction than the control. These coefficients quantify the rate of linear deformation of the mixture due to temperature increase or decrease. A lower expansion rate implies that the RaC mixture will deform less when exposed to heat, while a modest contraction allows it to relieve cold-induced stresses without inducing fractures [54]. This behavior is crucial for minimizing low-temperature cracking, especially in cold climates where contraction stresses accumulate rapidly [20,56].

- -

- AASHTOWare Pavement ME Analysis: The Pavement ME Design simulation results, using material parameters obtained from laboratory testing of the control and 20% RaC mixtures, are summarized in Table 10. Across all simulated scenarios, thin and thick pavements in both Chicago and Phoenix, the RaC mixture consistently predicted approximately 8% lower total permanent deformation (Total PD) and 30% lower asphalt concrete permanent deformation (AC PD) compared to the control mixture. These findings strongly corroborate the laboratory-based Hamburg Wheel-Tracking Test (HWTT) results, which indicated superior rutting resistance in the RaC mix. Additionally, Pavement ME predictions revealed significant reductions in thermal cracking, with values approximately eight times lower in cold climates and three times lower in hot climates.

- C.

- Correlation Between Binder and Mixture Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smart Growth America & Taxpayers for Common Sense. Repair Priorities 2021: Spending More to Fix Less. [Internet]. 2021. Available online: https://www.smartgrowthamerica.org/knowledge-hub/resources/repair-priorities-transportation-spending-strategies-to-save-taxpayer-dollars-and-improve-roads/ (accessed on 4 August 2025).

- Huang, Y.H. Pavement Analysis and Design, 2nd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Federal Highway Administration. User Guidelines for Waste and Byproduct Materials in Pavement Construction–Scrap Tires; U.S. Department of Transportation: Washington, DC, USA, 2014.

- USDE. Used Oil Management Program: Annual Progress Report; U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy: Washington, DC, USA, 2020.

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2004, 42, 265–274. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled rubber in asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Xiao, F.; Tang, B. Influence of surface area and size of crumb rubber on high temperature properties of crumb rubber modified binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Wang, H.; Hao, P. High-temperature performance of crumb rubber modified asphalt binder containing waste oil. Constr. Build. Mater. 2018, 173, 316–324. [Google Scholar]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Valuation of rejuvenator’s effectiveness with conventional mix testing for 100% RAP mixtures. Transp. Res. Record. 2014, 2370, 17–25. [Google Scholar] [CrossRef]

- D’Angelo, J. The relationship of the MSCR test to rutting. J. Assoc. Asph. Paving Technol. 2009, 78, 555–588. [Google Scholar]

- Obando, C.J.; Kaloush, K.E. Estimating the Thermal Conductivity of Asphalt Binders. J. Test. Eval. 2021, 50, 13. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Reim, M.; Hüsing, N.; Schwertfeger, F. Advanced applications of aerogels in thermal insulation. J. Mater. Chem. 2020, 8, 7374–7383. [Google Scholar]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Rheological properties of asphalt binders modified with crumb rubber and styrene-butadiene-styrene polymer. Constr. Build. Mater. 2017, 151, 183–194. [Google Scholar]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Physical, rheological and chemical characterization of aging behaviors of thermochromic asphalt binder. Fuel 2018, 211, 850–858. [Google Scholar] [CrossRef]

- Li, Q.; Shen, A.; Wang, C.; Guo, Y.; Wu, J. Performance of aerogel-modified asphalt binders under high and low temperatures. Constr. Build. Mater. 2025, 468, 140434. [Google Scholar] [CrossRef]

- Obando, C.J. Development of a Novel Aerogel-Based Modified Bituminous Materials. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2022. [Google Scholar]

- Sousa, J.B.; Pais, J.; Saim, R. Moisture damage evaluation of rubber-modified asphalt mixtures. Constr. Build. Mater. 2012, 26, 60–68. [Google Scholar]

- Obando, G.C.J.; Kaloush, K.E.; Karam, J.J.; Medina, J.R. Recycled-Aerogel Composite for Construction Materials (rac). WO2024173729A2. 2024. Available online: https://patents.google.com/patent/WO2024173729A2/en (accessed on 4 August 2025).

- Bahia, H.U.; Anderson, D.A. The Development of the Binder Selection Criteria in the Superpave PG Asphalt Binder Specification. J. Assoc. Asph. Paving Technol. 1995, 64, 437–475. [Google Scholar]

- AASHTO T 48-06 (2015); Standard Method of Test for Flash and Fire Points by Cleveland Open Cup. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- AASHTO T 316-22; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T315-08; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2008.

- AASHTO T313-19; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- City of Phoenix. Standard Specifications and Details for Public Works. Phoenix 2012. Available online: https://www.phoenix.gov/content/dam/phoenix/streetssite/documents/2012CoPSupplementto2012MAGSpecifications.pdf (accessed on 4 August 2025).

- ASTM D36/D36M-14; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D5-97; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2008.

- AASHTO M320-17; Standard Specifications for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017.

- AASHTO M332-19; Standard Specification for Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- AASHTO T 361-22; Standard Method of Test for Determining Asphalt Binder Bond Strength by Means of the Binder Bond Strength (BBS) Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Obando, J.; Kaloush, K.E. Thermal Conductivity of Viscoelastic Materials. US11927556B2, 12 March 2024. Available online: https://patents.google.com/patent/US11927556B2/en (accessed on 12 March 2024).

- ASTM D5801-95 (2015); Standard Test Method for Toughness and Tenacity of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- Witczak, M.W.; El-Basyouny, M. Development of the E* predictive model for use in MEPDG. In National Cooperative Highway Research Program (NCHRP) 1-40D Final Report; National Academy of Sciences: Washington, DC, USA, 2005. [Google Scholar]

- NCHRP. Development of the 2002 Guide for the Design of New and Rehabilitated Pavement Structures. [Internet]. 2004. Available online: https://apps.trb.org/cmsfeed/TRBNetProjectDisplay.asp?ProjectID=218 (accessed on 20 January 2025).

- Bhasin, A.; Little, D.N. Characterization of aggregate surface energy using the universal sorption device. J. Mater. Civ. Eng. 2007, 19, 634–641. [Google Scholar] [CrossRef]

- AASHTO T324-21; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2021.

- Mogawer, W.S.; Bennert, T.; Daniel, J.S.; Bonaquist, R. Performance characteristics of asphalt mixtures using a performance-related specification approach. Road Mater. Pavement Des. 2012, 13, 1–20. [Google Scholar]

- Zhou, F.; Scullion, T.; Hu, S. Investigation of the relationship between rutting performance and moisture susceptibility of asphalt mixtures. J. Assoc. Asph. Paving Technol. 2006, 75, 771–796. [Google Scholar]

- ASTM D6931; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- AASHTO T283-14 (2019); Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage (TSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- Carlson, J.D.; Bhardwaj, R.; Phelan, P.E.; Kaloush, K.E.; Golden, J.S. Determining thermal conductivity of paving materials using cylindrical sample geometry. J. Mater. Civ. Eng. 2010, 22, 186–195. [Google Scholar] [CrossRef]

- Obando, C.J.; Karam, J.; Medina, J.R.; Kaloush, K.E. Thermal Properties of Asphalt Pavements Modified. J. Mater. Civ. Eng. 2023, 35, 04023218. [Google Scholar] [CrossRef]

- AASHTO. AASHTOWare Pavement ME Design: Pavement Structural Design Software. National Cooperative Highway Research Program; 2015. Available online: https://www.aashtoware.org/products/pavement/pavement-me-design/ (accessed on 4 August 2025).

- Anderson, D.A.; Christensen, D.W.; Bahia, H.U.; Dongré, R.; Sharma, M.G.; Antle, C.E. Binder Characterization and Evaluation, Volume 3: Physical Characterization. SHRP-A-369; Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Fricke, J. Aerogels: Highly tenuous solids with fascinating propertie. J. Non-Cryst. Solids 1988, 100, 169–173. [Google Scholar] [CrossRef]

- Fricke, J.; Tillotson, T. Aerogels: Production, characterization, and applications. Thin Solid Film. 1997, 297, 212–223. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C. Mechanical performance of asphalt mixtures containing crumb rubber. J. Assoc. Asph. Paving Technol. 2003, 72, 243–273. [Google Scholar]

- Lu, X.; Isacsson, U. Effect of polymer modification on low temperature behavior of bitumen. Mater. Struct. 2002, 35, 127–130. [Google Scholar]

- Airey, G.D.; Rahman, M.M. The mechanical properties of polymer modified bitumen using waste rubber. J. Inst. Asph. Technol. 2003, 67, 32–42. [Google Scholar]

- Bhasin, A.; Bommavaram, R.; Little, D.N. Influence of mineralogy and surface free energy on the moisture susceptibility of HMA mixtures. J. Mater. Civ. Eng. 2007, 19, 190–197. [Google Scholar]

- Zeng, M.; Luo, R.; Wang, W.; Qian, Z. Mechanical and thermal properties of asphalt mixtures incorporating aerogel-based modifiers. Mater. Struct. 2016, 49, 4877–4889. [Google Scholar]

| Test | Test Temperature | Test Result | Specification | |

|---|---|---|---|---|

| Tests on the Original Binder | Flash Point, AASHTO T48 [24] | >230 °C | Min. 230 °C | |

| Apparent Viscosity, AASHTO T316 [25] | 135 °C | 0.565 Pa-s | Max. 3 Pa-s | |

| 175 °C | 0.101 Pa-s | |||

| Dynamic Shear, AASHTO T315 [26], G*/sin δ | 70 °C | 1.19 kPa | Min. 1.00 kPa | |

| Tests on Residue from RTFO | Mass Change | −0.143 | Max 1.0 | |

| Dynamic Shear, AASHTO T315 [26], G*/sin δ | 70 °C | 3.05 kPa | Min. 2.20 kPa | |

| Tests on Residue from PAV | PAV Aging Temperature | 110 °C | ||

| Dynamic Shear, AASHTO T315 [26], G*sin δ | 34 °C | 3840 kPa | Max. 5000 kPa | |

| Creep Stiffness, AASHTO T313 [27] | 0 °C | 93.0 Mpa | Max. 300 Mpa | |

| m-value, AASHTO T313 [27] | 0 °C | 0.312 | Min. 0.300 |

| Properties | 0% RaC (Control) | 20% RaC |

|---|---|---|

| % Total Binder Content | 5.1 | 5.5 |

| Number of Gyrations | 125 | 125 |

| % Air Voids | 4.00 | 4.00 |

| % VMA | 14.4 | 16.73 |

| % Air Voids Filled | 70.7 | 76.75 |

| % Eff Asphalt Total Mix | 4.44 | 4.85 |

| Max. Theoretical Specific Gravity | 2.47 | 2.41 |

| High Temperature PG (°C) | Sample | Rec % (0.1) | COV | Jnr (0.1) | COV |

|---|---|---|---|---|---|

| 70 | PG70-10 (Control) | 0.0 | 0.018 | 7.3 | 0.012 |

| 76 | PG76-22 (SBS) | 20.5 | 0.020 | 5.2 | 0.015 |

| 88 | PG70-10 + 20% RaC WM | 15.8 | 0.021 | 4.6 | 0.016 |

| 100 | PG70-10 + 20% RaC CM | 15.2 | 0.019 | 6.2 | 0.013 |

| BBS | Failure Mode | Average (kPa) | COV |

|---|---|---|---|

| PG70-10 (Control) | Cohesive | 409 | 0.043 |

| PG76-22 (SBS) | Adhesive | 415 | 0.025 |

| PG70-10 + 20% RaC WM | Cohesive | 332 | 0.051 |

| PG70-10 + 25% RaC CM | Cohesive | 298 | 0.067 |

| Binder Type | Cp (J/kg K) | COV | k (W/m K) | COV |

|---|---|---|---|---|

| PG70-10 (Control) | 946 | 0.09 | 0.221 | 0.08 |

| PG76-22 (SBS) | 1121 | 0.10 | 0.192 | 0.09 |

| PG70-10 + 20% RaC WM | 986 | 0.11 | 0.187 | 0.07 |

| PG70-10 + 20% RaC CM | 1008 | 0.12 | 0.185 | 0.08 |

| Stiffness Evaluation | Minimum m-Value 0.300 | COV | Maximum Stiffness 300 Mpa | COV |

|---|---|---|---|---|

| PG | PG | |||

| Control PG70-10 | −10.28 | 0.11 | −13.10 | 0.09 |

| PG76-22 (SBS) | −21.78 | 0.09 | −27.91 | 0.08 |

| PG70-10 + 20% RaC WM | −16.05 | 0.09 | −26.12 | 0.12 |

| PG70-10 + 20% RaC CM | −14.98 | 0.08 | −21.15 | 0.11 |

| Binder Type | Toughness (N/mm) | COV | Tenacity (N/mm) | COV |

|---|---|---|---|---|

| PG70-10 (Control) | 2715 | 0.09 | 1501 | 0.13 |

| PG76-22 (SBS) | 4501 | 0.08 | 3285 | 0.12 |

| PG70-10 + 20% RaC WM | 3891 | 0.12 | 7852 | 0.09 |

| PG70-10 + 20% RaC CM | 5395 | 0.08 | 6052 | 0.05 |

| Measured Strength | Control | COV | 20% RaC | COV |

|---|---|---|---|---|

| Dry (Pa) | 218 | 0.032 | 209 | 0.051 |

| Wet (Pa) | 190 | 0.058 | 189 | 0.062 |

| TSR | 87% | 90% |

| Tested Thermal Property | Control | COV | 20% RaC | COV |

|---|---|---|---|---|

| Thermal Conductivity (W/m K) | 0.98 | 0.08 | 0.88 | 0.09 |

| Specific Heat Capacity (J/kg K) | 951 | 0.12 | 1192 | 0.15 |

| Coefficient of Expansion/Contraction (mm/mm/°C) | Expansion: 4.13 × 10−5 | 0.21 | Expansion: 2.53 × 10−5 | 0.25 |

| Contraction: 2.83 × 10−5 | 0.18 | Contraction: 2.05 × 10−5 | 0.17 |

| Design Type | Climate | Mixture | IRI (m/km) | Total PD (mm) | Fatigue (%Lane) | Thermal Cracking (m/km) | TD Fatigue (%) | AC PD (mm) |

|---|---|---|---|---|---|---|---|---|

| Thin | Chicago | Control | 2.67 | 14.99 | 36.70 | 323.08 | 16.32 | 4.06 |

| 20% RaC | 2.38 | 13.97 | 26.09 | 40.98 | 16.54 | 3.05 | ||

| Thin | Phoenix | Control | 2.50 | 14.99 | 28.68 | 605.58 | 16.02 | 6.60 |

| 20% RaC | 2.40 | 12.95 | 21.98 | 271.63 | 16.29 | 4.57 | ||

| Thick | Chicago | Control | 2.37 | 10.16 | 2.66 | 220.30 | 13.95 | 2.54 |

| 20% RaC | 2.24 | 9.40 | 1.68 | 40.97 | 13.98 | 1.78 | ||

| Thick | Phoenix | Control | 2.35 | 11.18 | 3.86 | 585.58 | 11.12 | 5.08 |

| 20% RaC | 2.17 | 9.40 | 1.77 | 228.71 | 11.15 | 3.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obando, C.J.; Karam, J.J.; Medina, J.R.; Kaloush, K.E. A Rubberized-Aerogel Composite Binder Modifier for Durable and Sustainable Asphalt Pavements. Buildings 2025, 15, 2998. https://doi.org/10.3390/buildings15172998

Obando CJ, Karam JJ, Medina JR, Kaloush KE. A Rubberized-Aerogel Composite Binder Modifier for Durable and Sustainable Asphalt Pavements. Buildings. 2025; 15(17):2998. https://doi.org/10.3390/buildings15172998

Chicago/Turabian StyleObando, Carlos J., Jolina J. Karam, Jose R. Medina, and Kamil E. Kaloush. 2025. "A Rubberized-Aerogel Composite Binder Modifier for Durable and Sustainable Asphalt Pavements" Buildings 15, no. 17: 2998. https://doi.org/10.3390/buildings15172998

APA StyleObando, C. J., Karam, J. J., Medina, J. R., & Kaloush, K. E. (2025). A Rubberized-Aerogel Composite Binder Modifier for Durable and Sustainable Asphalt Pavements. Buildings, 15(17), 2998. https://doi.org/10.3390/buildings15172998