4.1. Scientometric Analysis Results

According to

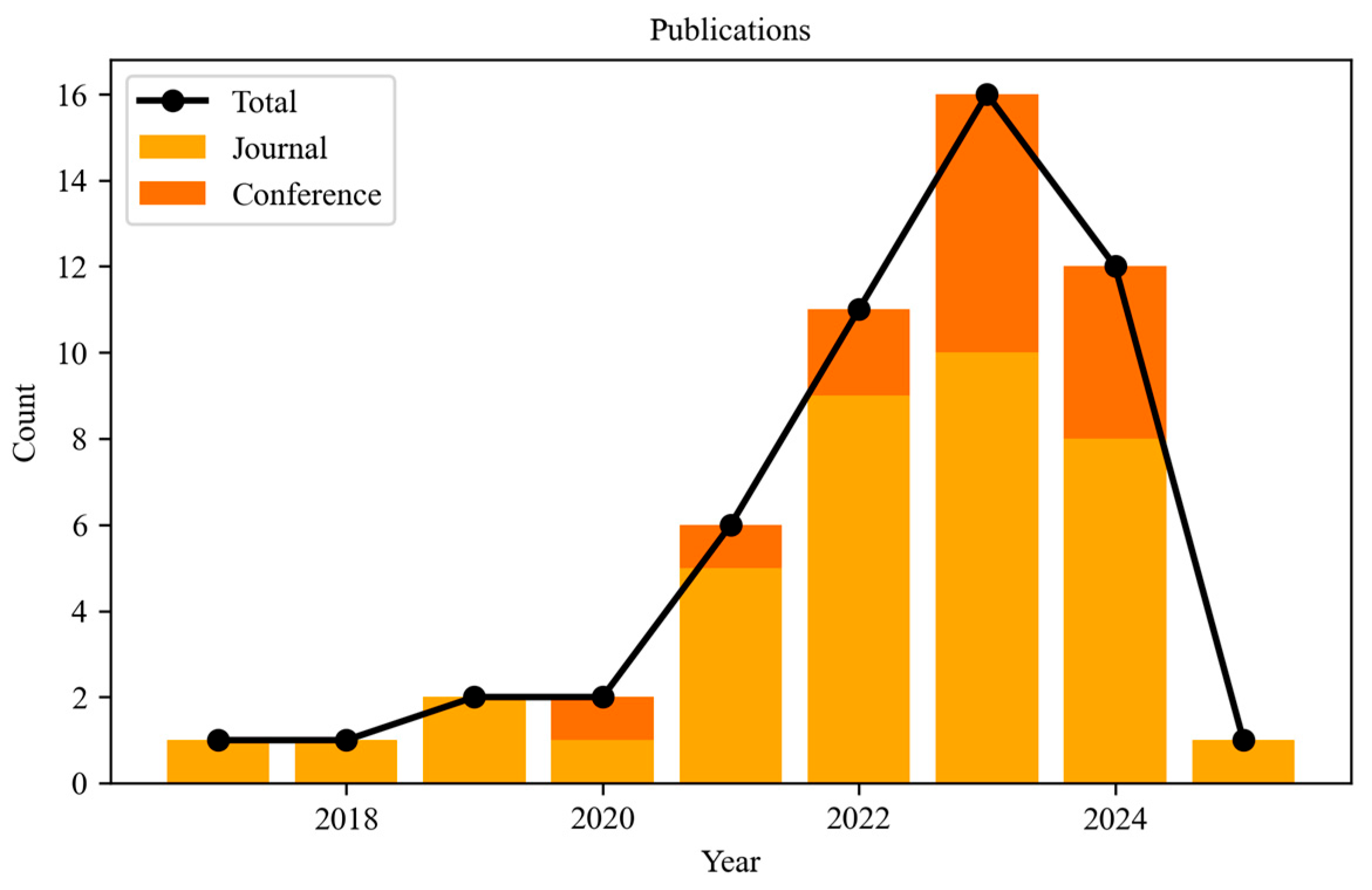

Figure 4, there was a modest emergence of scholarly interest in DTs in IOC in 2017, followed by a formative period through 2020 with only 1–2 publications per year. This limited output can be attributed to the early developmental stage of DTs, often explored under adjacent terms such as IoT-enabled BIM [

57]. While DTs were already being examined in other areas of the construction industry during this time, their application to IOC was only beginning to emerge. From 2021 onward, research activity increased markedly, reaching a peak of 16 publications in 2023. This growth reflects the transition from foundational investigations toward more applied studies, supported by clearer conceptual frameworks established during the earlier phase. Publications from 2021 began to target well-defined use cases—such as quality assessment and supply chain coordination [

15,

58]—demonstrating growing maturity in the field. Journal articles represent the predominant type, likely due to the complex and interdisciplinary nature of DTs and IOC, which often require the depth and rigor afforded by long-form journal formats. Conference proceedings also gained visibility in 2023 (6 publications), suggesting growing interest among research communities. A slight decline was observed in 2024 (12 publications), which may reflect publication lag or saturation following the 2023 peak. The 2025 count (1) includes only outputs indexed through February and is thus expected to rise as the year progresses.

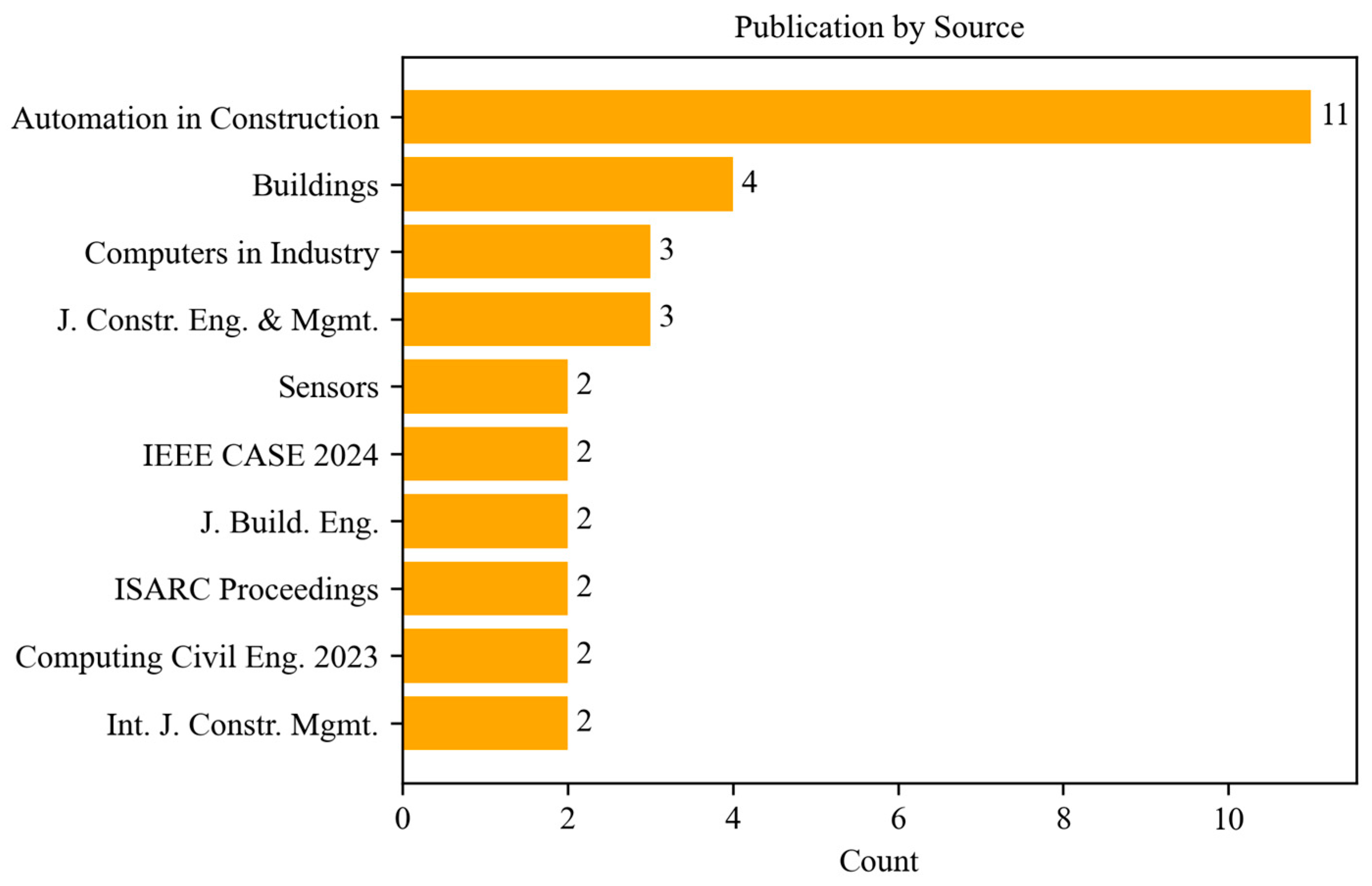

The bibliometric analysis identified 29 sources—18 journals and 11 conference proceedings—that have shaped research on DTs in IOC. As shown in

Figure 5, and applying a minimum threshold of two publications,

Automation in Construction emerges as the most influential journal, contributing 11 articles. Its prominence reflects the journal’s established focus on digital transformation and automation in the construction domain [

6]. Other notable journals, such as

Advanced Engineering Informatics,

Computers in Industry, and

Journal of Building Engineering, highlight the interdisciplinary scope of the field, spanning construction informatics, project management, and digital innovation. The inclusion of

Sensors points to the growing integration of IoT and real-time monitoring technologies—core components in dynamic DT systems.

Conference proceedings serve as key outlets for disseminating emerging research. Noteworthy venues include the 2024 IEEE 20th International Conference on Automation Science and Engineering and the International Symposium on Automation and Robotics in Construction, both of which emphasize advancements in robotics, automation, and smart construction systems. Collectively, the diversity of these sources underscores the multidisciplinary nature of DT research in IOC.

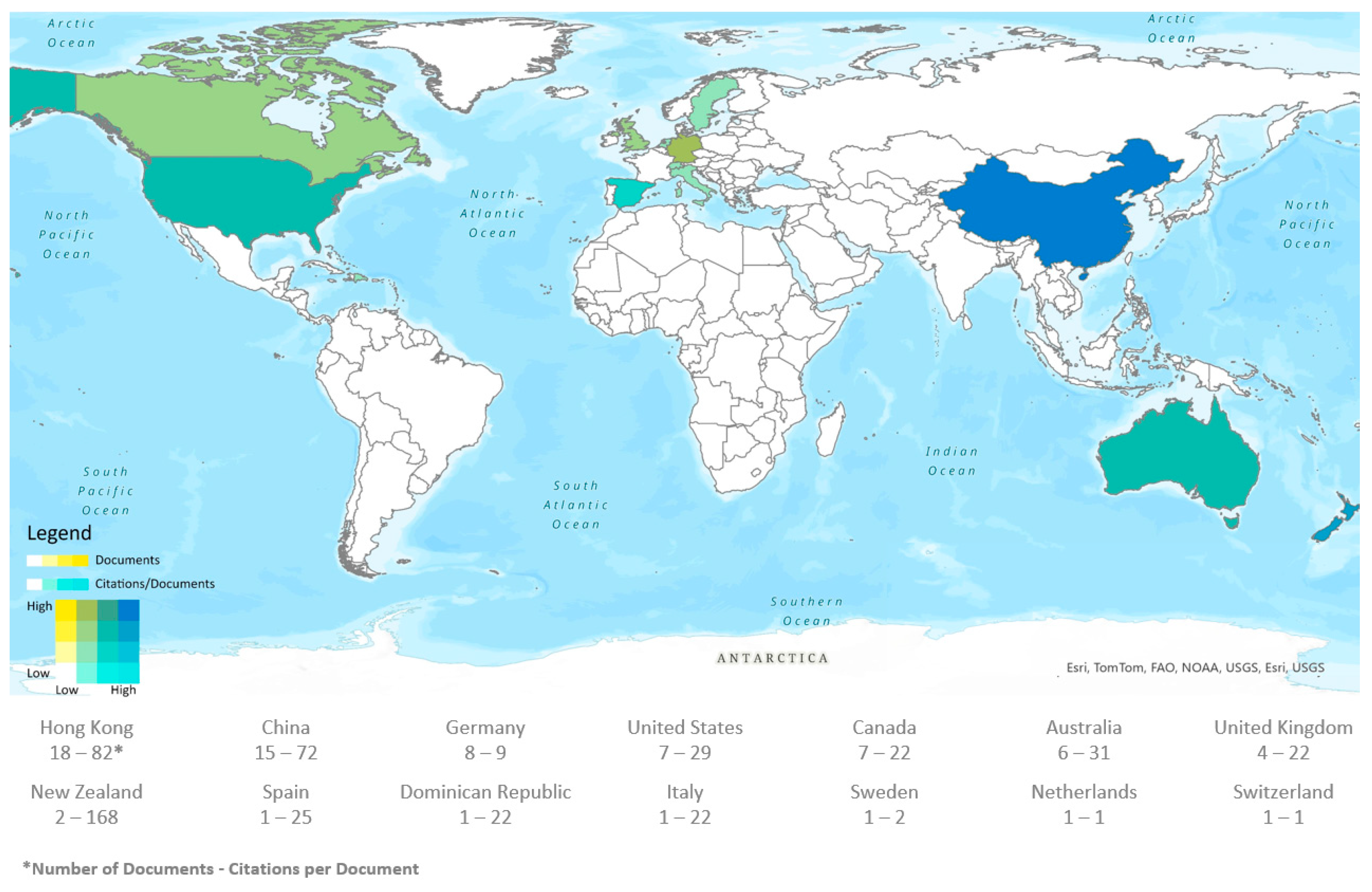

The geographical distribution of publications, as illustrated in

Figure 6, reveals Hong Kong and China as the most prolific contributors to DT research in IOC. Notably, both regions played pivotal roles during the early conceptualization of DTs in this context, contributing foundational frameworks and initial adoption models. While this early involvement has driven scholarly momentum, it may have also introduced a geographical favor into the research landscape. Many of the developed models and case applications appear tailored to the construction ecosystems of these two regions, potentially limiting their generalizability across diverse global contexts. As such, broader international engagement is essential to ensure that DT implementations in IOC are adaptable to varying regulatory, technological, and industrial environments. When analyzed in terms of citation impact—measured by average citations per publication—a different pattern emerges. New Zealand, despite producing only two papers, leads with a remarkable average of 168 citations per publication, followed by Hong Kong and China. This elevated impact can be attributed to New Zealand’s early and substantive contributions, particularly those offering pioneering implementation models and case studies. These foundational works have likely served as critical reference points, either as frameworks for refinement or as subjects of critique, thereby amplifying their academic influence.

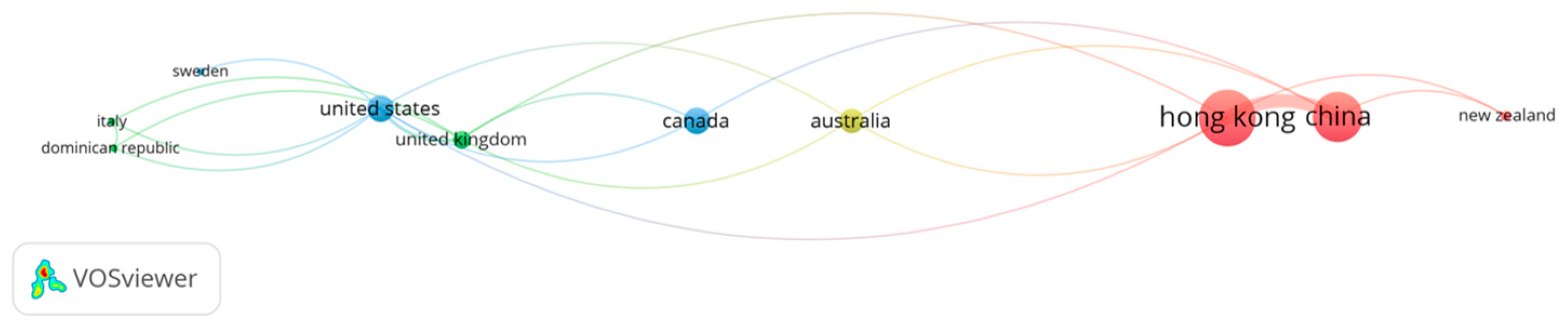

As shown in

Figure 7, the United States is the most interconnected node in the international collaboration network, engaging with seven countries—including the United Kingdom, Canada, and Australia—highlighting its role as a central research intermediary. The strongest bilateral link is between China and Hong Kong, reflecting close regional collaboration. While Australia, Canada, and the UK are also prominent, their international ties are less extensive. Additionally, the absence of high-performing countries—such as New Zealand—from major collaboration clusters suggests their contributions, while academically substantive, may be more specialized or independent.

Table 1 summarizes the top contributing authors in the field, detailing each author’s number of publications (NP), total citations (TC), domain-specific h-index, year of first contribution (FC), most cited publication, its publication year (Y), total citations for that publication (TC), and normalized citations per year (NTC) to account for differences in publication timing. The author contribution analysis identified 171 researchers actively publishing on DTs in IOC. The analysis shows Huang George Q. as the most prolific author, followed by Zhong Ray Y. and Xue Fan. It is clear that these pioneer authors often collaborate closely, frequently within the same research labs. Their most impactful publications bridge foundational studies with recent highly cited works, highlighting the crucial role of early adoption models and frameworks. These pioneering contributions have fundamentally shaped the field’s direction, establishing conceptual foundations that continue to guide and inspire subsequent research and practical applications.

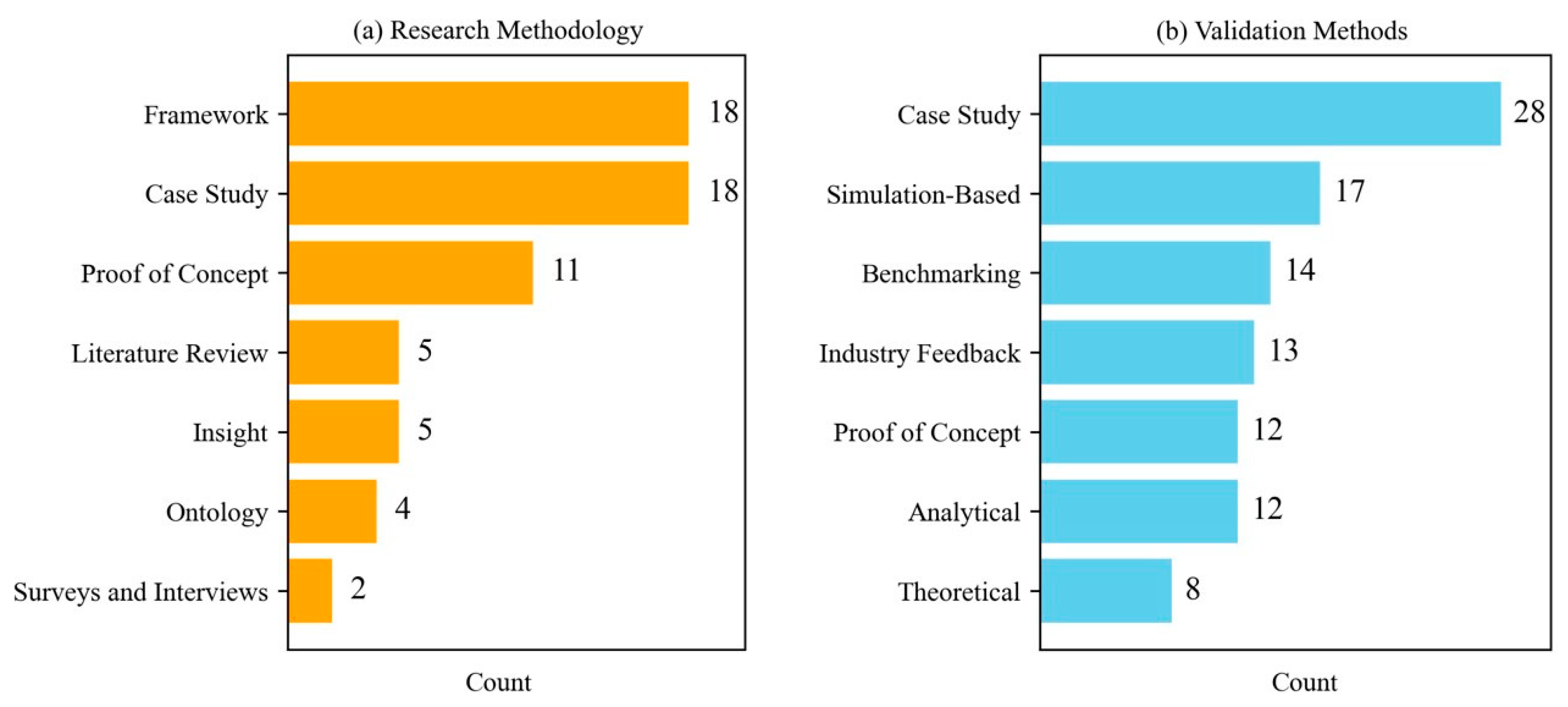

The research landscape is largely shaped by framework development and case studies. This dual focus directly reflects IOC’s critical need for a conceptual backbone to integrate complex DT functionalities (e.g., BIM, IoT, logistics) across its distinct manufacturing, transportation, and assembly phases [

26]. Frameworks define these integration processes, while case studies provide the essential empirical testbed, applying and validating these models directly in IOC factory or project environments using real operational data. Bridging this gap, proof-of-concept implementations explore technical feasibility. Often conducted in simulations or lab settings that mirror IOC’s controlled production lines, these studies de-risk larger DT deployments by verifying specific components or strategies [

17]. Beyond these applied methods, literature reviews and insight papers offer vital theoretical contributions, synthesizing existing knowledge and proposing new conceptual directions. Crucially for IOC, ontology development studies directly tackle the pervasive data interoperability challenge across its multi-stakeholder supply chains by creating structured semantic models [

49]. Though less common, qualitative interview-based research provides essential human-centric insights from IOC practitioners on DT adoption and usability. This methodological mix highlights the field’s balance between foundational theory and the practical implementation challenges unique to IOC.

The sophistication of these methodologies is further reflected in their diverse, often complementary validation approaches; studies used an average of 1.8 methods. This multi-layered validation directly addresses the multifaceted nature of DT implementation in IOC, where technical performance, practical utility, and industry acceptance are all paramount [

66]. Case study validation dominates, reflecting the critical need to test DT systems in active IOC projects for their real-world impact and scalability within prefabricated workflows. Simulation-based validation offers a crucial alternative for optimizing complex IOC processes (e.g., factory assembly lines, module logistics) where physical testing is prohibitive. Benchmarking compares DT system performance against IOC industry standards, gauging competitive advantage. Moreover, proof-of-concept validation and analytical methods collectively ensure the technical integrity of IOC-specific DT components, such as data models for modular elements. Crucially, industry feedback validation bridges the research–practice gap by involving IOC practitioners and ensuring that solutions are operationally viable. Finally, theoretical validation confirms the conceptual rigor of new DT frameworks for IOC before extensive empirical testing.

Figure 8 summarizes the validation strategies and research methods.

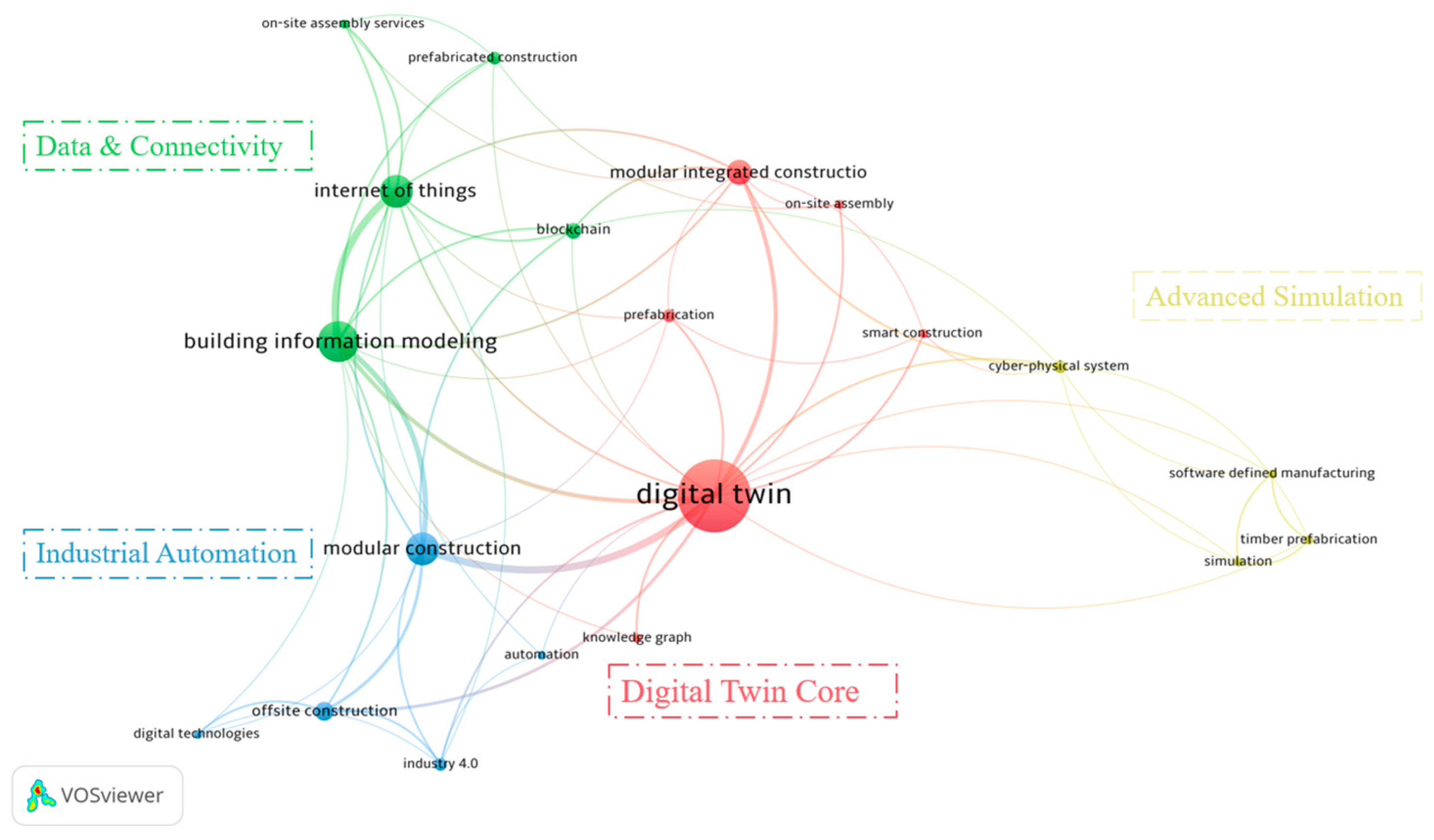

Figure 9 displays the resulting keyword co-occurrence network: node size indicates keyword frequency, while link thickness denotes the strength of co-occurrence. Prominent keywords such as “digital twin” (central node), “building information modeling”, and “modular construction” exhibit the highest frequency and strongest interconnections, underscoring their foundational role in the field. Notably, “digital twin” shows strong linkages with “Internet of Things” and “cyber-physical systems” [

67]. The network resolves into four thematic clusters: The red cluster (Digital Twin Core) represents the central research axis, emphasizing practical implementation frameworks that integrate DTs with modular integrated construction, on-site assembly, and smart construction. The green cluster (Data & Connectivity) underpins the infrastructure supporting DTs, encompassing BIM, IoT, and blockchain technologies, which enable secure data exchange and interoperability. The blue cluster (Industrial Automation) reflects the industry’s shift toward smart manufacturing, encompassing automation, digital industrialization, and offsite construction models. The yellow cluster (Advanced Simulation) focuses on predictive capabilities enabled by cyber–physical systems, advanced simulation techniques, and material-specific innovations such as timber prefabrication. These approaches support enhanced decision-making, system validation, and performance optimization across IOC.

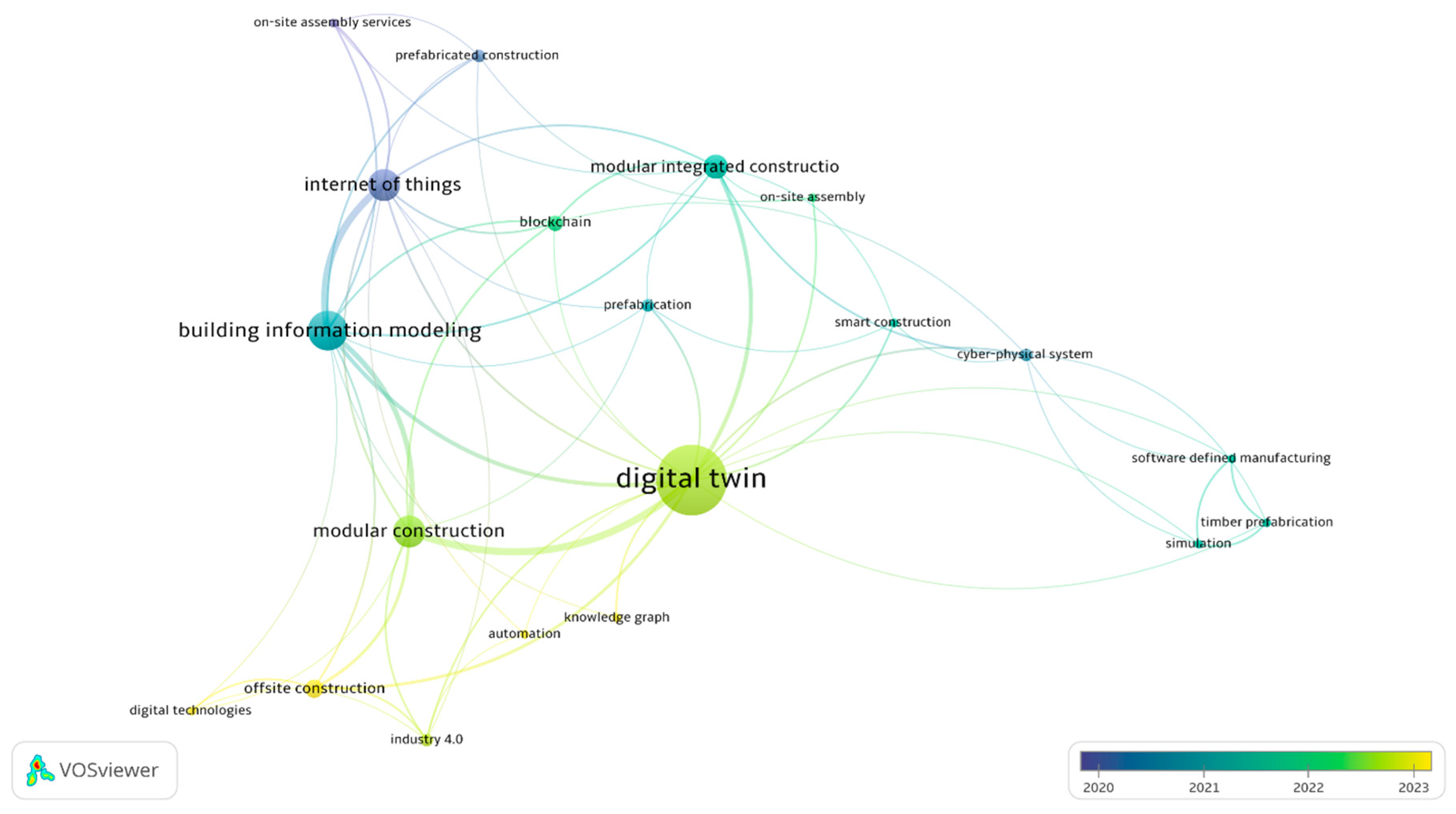

Temporal keyword analysis reveals a clear progression, as depicted in

Figure 10. The color gradient from blue to yellow visualizes this trajectory, demonstrating how research priorities have shifted over time. In the initial phase (2020–2021, blue to green tones), studies often focused on foundational enabling technologies such as BIM and IoT, which frequently co-occurred in the literature. These efforts reflect early attempts to digitally integrate construction workflows. Keywords like “prefabricated construction” and “on-site assembly services” appeared prominently, indicating interest in leveraging real-time data and prefabrication to enhance efficiency. Although the concept of DT had not yet fully emerged, its constituent technologies were actively explored. By 2021–2022 (green tones), DT gained visibility as a central research theme. Keywords such as “modular construction”, “blockchain”, and “cyber-physical systems” signaled increased attention to automation, data interoperability, and system integration. The rising presence of terms like “simulation” and “Industry 4.0” highlighted a move toward smart manufacturing. In the most recent phase (2022–2023, yellow tones), the literature reflects more advanced DT applications. Emerging terms such as “knowledge graph”, “software-defined manufacturing”, and “timber prefabrication” point to growing interest in AI-driven decision support and sustainable construction. The increased emphasis on “smart construction” and “automation” suggests a continued trajectory toward intelligent, adaptive, and integrated construction environments driven by DT frameworks. This temporal progression reflects the field’s shift from foundational digitization—characterized by the adoption of BIM and IoT—to the operational integration of DTs and modular construction methods. It culminates in advanced applications such as AI-driven automation and sustainable manufacturing.

4.2. Themes and Application Areas

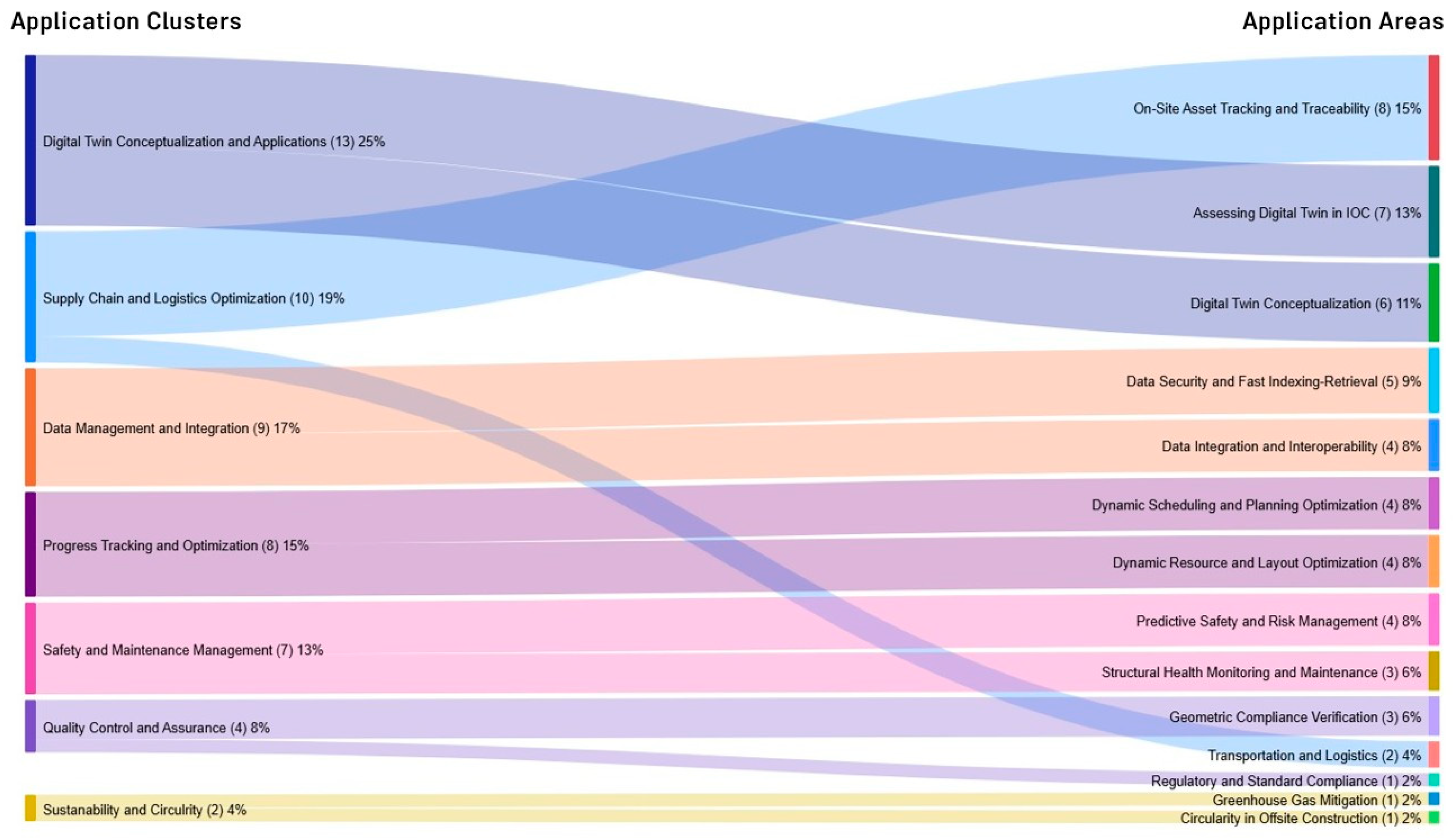

This analysis identified 14 distinct themes related to the application of DT in IOC, which were further consolidated into seven overarching thematic clusters as depicted in

Figure 11.

Theme 1.1: Assessing Digital Twin in IOC: As anticipated, studies assessing DT in IOC emerged as a prominent research focus, driven by the need to evaluate DT’s strengths, weaknesses, opportunities, and threats during the pre-adoption stage, and to assess whether adopted models aligned with intended objectives. Most studies in this theme employed qualitative methods, such as literature reviews and interviews. In some cases, DT was analyzed within the broader context of Industry 4.0 technologies in IOC. For instance, Xu et al. [

16] conducted a systematic literature review on automation technologies in the manufacturing and assembly stages of IOC, analyzing 53 articles and identifying 22 tools, including AI, DT, and BIM. Their findings showed that DT supported seven key benefits in IC: interoperability, scheduling optimization, production traceability, production safety, manufacturability, quality assurance, and constructability—with its core contribution in enhancing assembly planning. These outcomes aligned with Cheng and Oconnell et al. [

3,

46], although Oconnell et al. [

46] emphasized critical barriers such as lack of standardization, poor interoperability, cybersecurity risks, and limited real-world validation, which hindered DT’s full adoption.

Other papers in this cluster focused solely on DT in IOC. For example, Xie et al. [

48] performed a three-step systematic review on DT in modular integrated construction (MiC), identifying opportunities such as real-time logistics coordination, progress monitoring, and AI-driven site management. However, they also reported challenges including sensor integration issues, cybersecurity and data privacy risks from cloud reliance, and regulatory barriers linked to unclear implementation guidelines. The study’s generalizability remained limited due to its small sample size (10 publications) and regional focus on Hong Kong. Consistently, Jaryani et al. [

68] conducted a case study on a wood panelized construction firm, using interviews with professionals to define information needs for off-site construction management. The findings revealed challenges such as fragmented data integration due to multiple ERP systems, limited logistics and site tracking because of inadequate real-time monitoring, and inefficiencies arising from manual data collection through spreadsheets—challenges that DT integration could directly address [

69].

Although the literature confirms growing attention to DT in IOC, Zhai et al. [

60] examined modular housing perceptions in Australia using a focus group of 81 construction professionals. The findings showed that only 52% were aware of modular construction, with many perceiving modular housing as container-like boxes. Initially, 88% were neutral or unwilling to invest, but after a DT demonstration, 90% expressed a willingness to invest. These results highlighted persistent misconceptions about IOC, often shaped by regional context. Similar insights were reported by Lei et al. [

70], who applied game theory to analyze stakeholder decision-making in DT adoption. Their findings demonstrated that addressing misunderstandings and lack of awareness could substantially increase the likelihood of financing IOC projects. Moreover, DT adoption depended heavily on economic factors. The analysis revealed equilibrium strategies where some stakeholders adopted DT while others delayed; however, government interventions—such as subsidies and incentives—could shift the equilibrium toward broader adoption.

Theme 1.2: Digital Twin Conceptualization: This theme focuses on conceptual frameworks and early-stage proofs of concept, primarily addressing theoretical rather than practical implementation aspects of DT in IOC. For instance, Čustović et al. [

41] proposed a three-layered DT model integrating objectives, processes, and data/tools to improve coordination between prefabrication and on-site activities. Using hypothetical scenarios, the study demonstrated how DTs supported conflict resolution, resource optimization, and enhanced decision-making through bi-directional information flow. Similarly, Cole et al. [

71] developed a DT architecture for precast concrete manufacturing, targeting temperature and moisture control during curing. The framework, applied in a small case from NVC Precast (Melbourne), combined IoT sensors, machine learning, and simulation across four layers—data acquisition, analytics, visualization, and feedback—to enable real-time monitoring and proactive control. The model enhanced sustainability, quality, and operational efficiency.

However, these models remained largely theoretical and lacked real-world validation. A more critical issue lay in their limited scalability—a gap addressed by Kosse et al. [

72], who explored modularity in DTs across four dimensions: technical, process, spatial, and life cycle. Through a literature review, the study identified “information containers” as a practical approach to modular DT implementation, comparing Asset Administration Shell and Information Container for Linked Document Delivery as complementary solutions for semantic interoperability and machine-readability. To further bridge the implementation gap, Jaryani et al. [

68] investigated the integration of knowledge graphs (KGs) into cognitive modular production. The study highlighted how KGs enhanced decision-making, interoperability, and automation in modular environments by supporting real-time analytics, predictive maintenance, and process optimization. An online-based survey of professionals from modular production, construction, and IT consultancy confirmed that KGs improved system interconnectivity and intelligent automation, reinforcing the potential of Cognitive DTs in advancing modular production. However, challenges in standardizing KGs across different modular production systems remained a critical issue the study failed to address.

Theme 2.1: On-Site Asset Tracking and Traceability: Since the initial implementation of DT applications in IOC in 2017, on-site component tracking and traceability has remained the most prominent research domain. Early work by Zhong et al. [

32] introduced a multidimensional IoT-enabled BIM platform that established a three-phase process: RFID-based tracking during prefabrication, real-time monitoring during logistics, and automated verification during on-site assembly, with a special focus on the on-site assembly phase. This approach enhanced real-time visibility and inter-organizational coordination, producing quantifiable outcomes such as a 48.3% reduction in production paperwork, 40% shorter prefabrication lifecycles, 40% reduction in order picking time, and a 99.8% on-time delivery rate. These benefits underscored DT’s potential to streamline workflows and reduce errors in component handling and site installation. Comparable frameworks proposed by Li et al. [

57], Zhou et al. [

64], and Wang et al. [

73] employed similar technological configurations—including RFID for component tracking, GPS for logistics data acquisition, and BIM for real-time visualization—and consistently reported gains in efficiency, decision-making, supply chain integration, and cost/time savings. However, these studies largely underdeveloped the service layer of DT systems, particularly in leveraging data analytics for predictive and adaptive decision-making—an area that gained traction in post-2020 research. For instance, Fischer et al. [

74] advanced the analytical dimension by integrating extended value stream mapping, RFID-based tracking and tracing, and discrete-event simulation within a modular housing production context. By implementing this framework at Maxmodul (a subsidiary of Max Bögl Group, Sengenthal, Germany), the study identified critical production bottlenecks, reduced inventory by 64%, and accelerated lead times by 20%. This work illustrated the importance of data-driven simulation for system optimization, yet it also highlighted the complexity of translating RFID data into actionable intelligence, particularly in dynamic factory settings.

In the domain of robotics-integrated construction, Jiang et al. [

61] proposed a DT-enabled Smart MiC System to enhance robotic on-site assembly via UWB positioning and real-time digital modeling. The system demonstrated improvements in control, navigation, and human–robot collaboration, with acceptable positioning accuracy (average deviation of 16.04 cm). However, the study highlighted key challenges: UWB’s inability to track module orientation, unstable outdoor positioning, limited scalability of robots due to environmental factors and workforce skills, and the need for AI autonomy to enable safer, adaptive automation through further machine learning research. Furthermore, Yang et al. [

8] developed a 5D DT platform integrating IoT, BIM, complex event processing (CEP), and hierarchical finite-state machines (HFSM) for real-time material tracking in on-site fit-out construction. Using Automation Markup Language (AML) and OPC UA (Open Platform Communications Unified Architecture), it ensured smooth digital–physical data exchange, while CEP enabled automated, rule-based responses and HFSMs prioritized actions by urgency. Tested on a water pump house project, the platform enhanced coordination, reduced construction time, and improved traceability—demonstrating the effectiveness of combining real-time monitoring with intelligent control to address on-site communication challenges.

Collectively, while early DT models provided foundational benefits in traceability and monitoring, their limited analytic depth restricted predictive and autonomous decision-making capabilities. Later studies began to address these limitations through simulation, event logic, and robotic integration. Nevertheless, challenges persist around environmental variability, interoperability, and AI autonomy, indicating that while traceability is well-advanced in DT research, its full integration with intelligent decision support systems has remained a critical area for continued development.

Theme 2.2: Transportation and Logistics: This cluster examines DT applications aimed at enhancing tracking and traceability during the transportation and logistics phases of IOC. Lee et al. [

15] proposed an integrated DT framework combining BIM and geographic information system (GIS) to improve supply chain coordination in modular construction. The approach leverages BIM for detailed module specifications (geometry, weight, delivery schedules) alongside GIS data on road networks, traffic conditions, and regulations. Real-time GPS data from in-transit modules dynamically updates the virtual model, enabling logistics scenario simulations via the Unity engine and route optimization using the Bing Maps API. A case study of a six-story modular apartment project in Seattle reported a significant reduction of 157.5 hours of idle time over 80 deliveries, primarily attributed to enhanced estimated time of arrival (ETA) accuracy and dynamic rerouting capabilities. This demonstrates the framework’s effectiveness in mitigating delivery delays and optimizing logistics operations. In comparison, Zhai et al. [

60] developed an IoT-enabled BIM platform incorporating RFID, NFC, and GPS-based “smart trinity tags” for real-time asset tracking, complemented by a rule-based control system automating alerts, emergency responses, and progress updates. The cloud-based environment facilitated automated data collection, scheduling, and stakeholder coordination, reducing manual interventions and improving workflow integration. Practical application in a subsidized housing project confirmed notable gains in construction efficiency and collaboration. While Lee et al.’s [

15] approach excels in leveraging spatial and traffic data for route optimization, Zhai et al.’s [

60] platform emphasizes automation and real-time process control, illustrating complementary strengths. Together, these solutions highlight how diverse DT architectures address distinct logistics challenges, with their effectiveness contingent upon project scale, data availability, and stakeholder integration.

Theme 3.1: Data Security and Fast Indexing-Retrieval: Ensuring data security and integration is fundamental in DT applications, especially as DT evolved into a comprehensive framework for managing the entire lifecycle of IOC. Several studies explored blockchain as a key enabler of secure, transparent, and verifiable DT ecosystems. For example, Wu et al. [

62] developed a Blockchain-Integrated IoT-BIM Platform (BIBP) to enhance off-site production management by addressing key IoT-BIM limitations, including data inconsistency, lack of trust, and version control. By integrating RFID sensors with Hyperledger Fabric and smart contracts coded in JavaScript, the system secured data provenance and automated verification tasks. Comparative analysis with conventional platforms showed improvements in data accuracy, traceability, and operational efficiency. Similarly, Li et al. [

59] proposed a blockchain-enabled platform to tackle supply chain fragmentation in modular construction. The authors introduced a data–information–knowledge (DIK)-driven supply chain management (SCM) model within a three-layer system architecture (infrastructure, blockchain BIM, and software-as-a-service). Their prototype, validated on a modular student residence, demonstrated enhanced traceability, reduced latency, and lowered storage costs—confirming blockchain’s value in streamlining SCM processes.

Echoing these findings, Jiang et al. [

75] and Dong et al. [

76] advanced similar blockchain-integrated frameworks. Notably, Dong et al. [

76] focused on real-time asset tracking and 4D change visualization. Their system automated data transfer between BIM and blockchain, used QR codes for physical tracking, and deployed smart contracts to detect schedule dependencies. A Navisworks plugin enabled 4D visualization, supporting transparent and collaborative project execution. The prototype validation confirmed the approach’s potential to increase trust and reduce manual inefficiencies. However, while these studies highlighted blockchain’s strengths in enhancing transparency and automation, they also shared limitations, namely network speed and the lack of offline communication capabilities. Addressing these gaps, Zhao et al. [

4] introduced ChainPM, a Blockchain 3.0 framework optimized for DT-based construction project management. ChainPM improved on earlier blockchain models by enabling fast synchronization, offline functionality, advanced indexing, and complex querying. Validated through a modular construction case, ChainPM demonstrated superior performance in responsiveness and data integrity. Overall, while the reviewed solutions showcase significant advancements in securing and streamlining DT ecosystems in IOC, their comparative performance highlights a progression from foundational blockchain integration to sophisticated, high-performance frameworks; however, real-world scalability and network limitations remain areas for further research.

Theme 3.2: Data Integration and Interoperability: The challenge of information fragmentation and discontinuity remains critical in IOC, particularly when coordinating diverse technologies and multiple stakeholders. A key factor influencing interoperability in construction digital environments is the adoption of industry standards and platforms such as the Industry Foundation Classes (IFC), an open, international standard. IFC provides a widely accepted, open data schema designed to facilitate seamless information exchange across heterogeneous software tools in AEC projects. However, despite its foundational role, IFC’s complex data model and inconsistent implementation across platforms often hinder efficient integration of emerging technologies like AI-driven DTs especially in handling dynamic, real-time data streams that were not originally considered in the standard’s static design.

To address this, Jiang et al. [

63] proposed a blockchain-enabled cyber–physical platform aimed at enhancing cross-enterprise information exchange. Using a user-centered design methodology, the framework integrated blockchain, IoT, and cyber–physical systems to support traceability, transparency, and real-time decision-making in modular integrated construction. The study demonstrated the full lifecycle of platform development and validated its impact on improving information continuity.

Focusing on production environments, Wen et al. [

12] designed a four-layer DT framework to manage the prefabrication information of ultra-large, immersed tunnels. Applied in the Shenzhen–Zhongshan Link Project, the system integrated IoT, AI, BIM, and data management to optimize key operations such as concrete casting and section handling. The results showed improvements in process efficiency and intelligent monitoring, although the solution was highly specialized for factory-based tunnel fabrication. At the design-fabrication interface, Skoury et al. [

13] developed a digital thread-based framework to improve data consistency and interoperability in robotic fabrication. By incorporating DTs, cyber–physical systems, and modular data schemas within a service-oriented architecture, the approach enhanced collaboration and reduced errors across design and fabrication domains. Its validation on the livMats Biomimetic Shell demonstrated effective support for co-design and automation in complex AEC projects.

Broadening the scope of interoperability, Ramonell et al. [

77] proposed a knowledge graph-based DT system that integrated BIM, IoT, and other heterogeneous data sources. Built on cloud-based microservice architecture, the system enabled dynamic updates, efficient querying, and semantic interoperability. The framework was validated through several real-world demonstrators and was positioned as a versatile and scalable solution for DT development in built asset environments. While each study targeted distinct stages and contexts, a shared emphasis on real-time data integration and intelligent decision support was evident.

Theme 4.1: Dynamic Scheduling and Planning Optimization: Traditional scheduling in IOC often relied on fixed average production rates, which overlooked real-time variability and led to inaccurate estimates and inefficiencies. To address this, Alsakka et al. [

18] developed DiTES, a DT system that integrated computer vision, ultrasonic sensors, machine learning, and 3D simulation to dynamically estimate cycle times and adjust production schedules in real-time. A case study at a wood-wall framing workstation showed an 81% reduction in scheduling deviations compared to conventional methods, highlighting DTs’ capacity to improve planning precision and operational responsiveness.

Expanding on real-time synchronization, Jiang et al. [

17] proposed DT-SYNC, a DT-enabled model for planning, scheduling, and execution in precast on-site assembly. Using a hybrid validation approach—including numerical experiments and robotic testbeds—the study demonstrated improved coordination, reduced delays, and greater resilience to disruptions. Unlike DiTES, which focused on factory-level control, DT-SYNC emphasized on-site assembly synchronization.

Further advancing this concept, Jiang et al. [

25] introduced an out-of-order (OoO) scheduling model inspired by CPU task sequencing. Leveraging DTs with IoT, computer vision, and real-time tracking, the model reordered tasks dynamically based on field conditions. Its rolling-horizon and forward heuristic mechanisms enabled adaptability to uncertainties such as material delays and labor fluctuations. The model reduced makespan by up to 15%, improved material handling efficiency, and outperformed both MILP and heuristic-based scheduling methods under real-time constraints. Collectively, these studies moved beyond static scheduling by leveraging DTs for real-time, adaptive planning.

Theme 4.2: Dynamic Resource and Layout Optimization: A core strength of DTs in IOC is their capacity to simulate, validate, and optimize production systems prior to physical deployment. Addressing high prefabrication costs, Wang et al. [

78] used a DT-enabled 3D virtual environment to optimize facility layout through a modified genetic algorithm. By solving a mathematical model, the study improved workload balance, reduced transport distances, and minimized operational costs. This proactive optimization illustrated a pragmatic approach to improving prefabrication line efficiency.

Extending into robotics, Kaiser et al. [

79] developed an automated method to generate DT models for simulating reconfigurable timber construction systems. Utilizing AML, the framework encoded geometry, kinematics, behavior, and interfaces, while simulations via ROS (

www.ros.org, accessed on 11 August 2025) and Gazebo (

www.gazebosim.org, accessed on 11 August 2025) supported rapid reconfiguration and integrity checks. Applied within the IntCDC system, this method enabled fast design iteration and adaptability—both vital for robotics-integrated construction workflows.

Building on these setup-focused strategies, Barkokebas et al. [

80] investigated real-time optimization during fabrication by simulating multiskilled labor configurations. Using DTs as a surrogate for full-scale trials, the study employed discrete-event and continuous simulation to assess labor efficiency. The findings showed significant reductions in worker waiting times and enhanced labor flexibility. While multiskilling posed risks of diminished individual productivity, the DT-managed system offset these limitations, improving overall efficiency and reducing lean waste—underscoring DTs’ value in refining dynamic labor strategies.

Theme 5.1: Predictive Safety and Risk Management: While DTs in IOC are widely recognized for improving cost, time, and efficiency performance, their expanding role in predictive safety and risk management is becoming increasingly vital [

81,

82]. Zhao et al. [

83] developed a DT framework for managing prefabricated component hoisting by integrating BIM, IoT sensors, and LoRa communication. The five-dimensional model—encompassing physical and virtual environments, data systems, service platforms, and interconnections—facilitated real-time tracking using IMU, GPS, and RFID sensors. Hoisting paths were optimized through Dijkstra’s algorithm, significantly reducing manual errors, collisions, and operation times. A case study validated its effectiveness in enhancing both safety and efficiency.

Extending this, Liu et al. [

84] introduced a DT-based risk control framework that combined real-time monitoring, Bayesian networks, and a hierarchical safety model structured via DEMATEL-ISM methods. This framework enabled dynamic risk prediction, identified critical risk factors such as worker skill, equipment condition, and environmental variables, and supported proactive safety decisions. Case study outcomes indicated improved visualization, enhanced risk mitigation, and lower accident probabilities.

Reinforcing these developments, Li et al. [

14] presented a DT platform for crane operations, showing that real-time localization significantly improved on-site safety. Addressing the limitations of vision-based methods—such as sensitivity to lighting and high deployment costs—Han et al. [

85] integrated transformer-based pose estimation (PoseFormer) with UWB and IMU sensors. This hybrid system continuously updated the DT with precise position and orientation data, reducing average and final displacement errors by up to 87.29% and 56.95%, respectively. The result was improved stacking accuracy, real-time responsiveness, and enhanced installation safety.

Theme 5.2: Structural Health Monitoring and Maintenance: Structural health monitoring and maintenance remains a significant challenge in IOC due to installation inaccuracies, inefficient data transmission among stakeholders, and the limitations of traditional load rating methods, which tend to be costly, time-intensive, and disruptive. To address these challenges, Zhao et al. [

67] proposed a DT framework that integrated RFID for component localization, a wireless sensor network for strain monitoring during installation, and LoRa communication for reliable data transmission to an on-site server. The collected data were visualized within a cloud-based BIM environment. Validated through a real-world application, the system enabled precise component tracking and satisfactory structural monitoring, thereby enhancing overall project performance by automating real-time data acquisition and analysis.

Complementing this, Ai et al. [

86] and Rojas-Mercedes et al. [

87] focused on improving load rating accuracy and structural risk assessment through DTs. Notably, Rojas-Mercedes et al. [

87] developed seismic fragility curves for a precast reinforced concrete bridge in the Dominican Republic by integrating a structural health monitoring system with a DT. Real-time sensor data fed into a computational model to perform nonlinear incremental dynamic analyses, allowing probabilistic assessment of damage under varying seismic intensities. The study identified a 62% probability of extensive damage at peak ground acceleration (0.8 g) and a 30% probability of moderate damage at 0.6 g. The DT significantly enhanced fragility curve accuracy over traditional approaches, offering critical insights for disaster preparedness and post-earthquake recovery strategies.

Theme 6.1: Geometric Compliance Verification: DTs are transforming geometric quality control in IOC by embedding high-resolution 3D scanning into dimensional verification processes. In this regard, Tran et al. [

65] proposed a DT framework for assessing the geometric fidelity of as-built prefabricated façades by comparing a 3D as-designed model against a 3D as-built semantic model derived from LiDAR point clouds. Automated correspondence identification enabled evaluation of completeness, correctness, and accuracy, facilitating rapid error detection and localization. Tests on both synthetic and real façade samples revealed that deviation visualization enhanced timely construction adjustments and supported rigorous quality assurance. Expanding this application into offsite manufacturing, Rausch et al. [

88] presented a framework for geometric DTs during fabrication and assembly. The study evaluated three approaches—Scan-vs-BIM, Scan-to-BIM, and Parametric BIM Updating—using a commercial case study. Scan-vs-BIM demonstrated the highest accuracy, Parametric BIM Updating yielded semantically rich models, and Scan-to-BIM offered a balanced outcome. The authors advocated for hybrid implementations and advanced scanning technologies to optimize precision within offsite workflows. Advancing compliance and automation in prefabrication, Kirner et al. [

89] introduced a semantic DT ontology tailored to robotic steel manufacturing. By incorporating process data, tolerances, and deviation metrics through semantic web standards (e.g., DSTV-NC), the model strengthened automation and resilience in production systems. A case study on robotic plasma cutting validated this approach, showing improved adaptability and consistent compliance with manufacturing tolerances.

Theme 6.2 Regulatory and Standard Compliance: Studies in this theme predominantly focus on automating rule-checking against codes and standards but often overlook the socio-technical challenges of operationalizing such automation across fragmented offsite workflows. Maturity frameworks for DT adoption—such as the Off-site Construction DT Assessment Model—provided a structured pathway for transitioning from manual documentation to automated compliance in panelized wood construction [

90]. Case studies showed that about 78% of building code provisions could be translated into machine-readable formats, supporting real-time compliance during fabrication. However, the assumption that rule formalization alone ensured compliance omitted the variability in interpretation and exceptions embedded in many codes. The framework rightly stressed the need for phased digitalization, but broader institutional alignment, standard ontology development, and interoperability remained underexplored barriers to full automation.

Theme 7.1 Greenhouse Gas Mitigation: Integrating DTs into the prefabrication supply chain enhances smart construction by enabling real-time monitoring of carbon emissions and resource consumption across production, transportation, and on-site assembly according to Yevu et al. [

5] Technologies such as RFID, AI, IoT sensors, and GPS supported accurate emissions tracking and carbon footprint estimation, improving logistics and operational efficiency. While real-time data acquisition enabled informed decision-making and sustainability optimization, assuming it automatically delivered environmental benefits overlooked challenges in data quality, granularity, and integration into planning. Greater focus is needed on how DTs support trade-offs between efficiency and embodied emissions, particularly in resource-constrained contexts.

Theme 7.2 Circularity in Offsite Construction: The potential of DTs to operationalize circular economy (CE) principles in offsite construction remains promising but conceptually underdeveloped. O’grady et al. [

91] proposed a BIM-VR-DT framework via the Legacy Living Lab (L3), focusing on documentation, visualization, and education. While their findings indicated that 58% of materials were reusable and that the VR interface supported stakeholder learning, the study largely equated visibility with implementation. It underexamined how DTs could address deeper CE challenges, such as lifecycle traceability, material certification, or value chain coordination. The identified limitations—including the absence of robust material banks and the BIM model’s poor modularity representation—highlighted systemic gaps. The work pointed to the need for rethinking DTs not just as visual tools but as integrated platforms for circular SCM orchestration.

4.3. Digital Twin in IOC Phases, Sectors, Components, and Materials

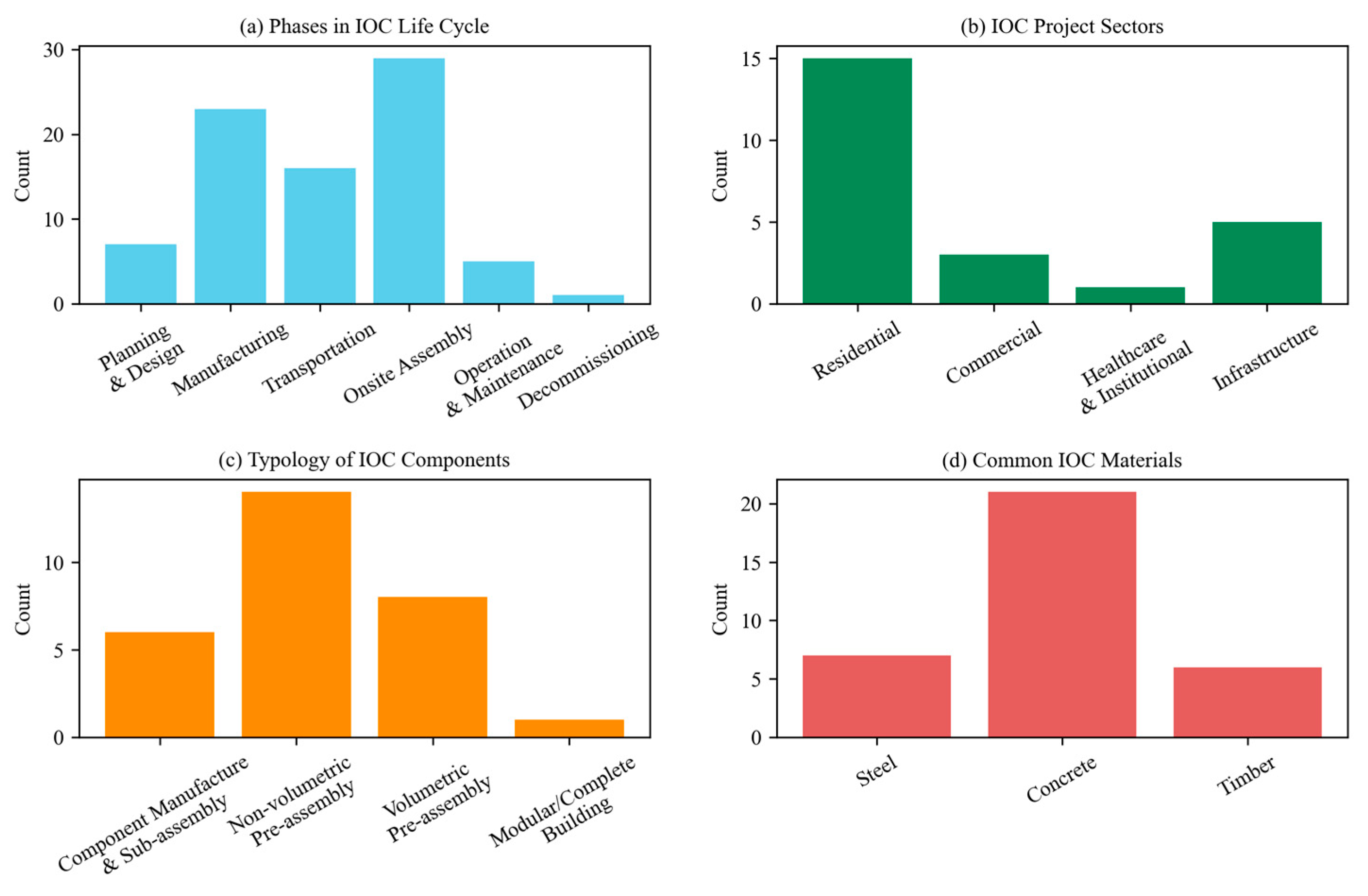

The literature has addressed various phases of the IOC project lifecycle, including planning and design, manufacturing, transportation, onsite assembly, operation and maintenance, and decommissioning.

The planning and design phase serves as a critical foundation in construction projects, defining the technical and organizational frameworks that guide all subsequent activities. A growing body of research (seven studies) emphasizes the role of advanced digital technologies, particularly BIM and DTs, in enhancing this phase [

85]. These technologies are increasingly leveraged to improve design precision, simulate construction scenarios, and facilitate early coordination among stakeholders, ultimately reducing downstream errors and delays [

13,

92]. A relevant example can be seen in the work of Kaiser et al. [

79], who developed a method for automatically generating DT models to simulate reconfigurable robotic fabrication systems in timber prefabrication. This approach enabled efficient layout validation and task simulation, addressing the limitations of manual DT adjustments. The study exemplifies how simulation-driven planning methods can significantly enhance the flexibility and responsiveness of design workflows, particularly in industrialized and off-site construction contexts.

The manufacturing phase has attracted considerable scholarly interest, with 23 studies underscoring its central role in ensuring the quality, efficiency, and reliability of prefabricated construction components. Research in this domain frequently explores automation, production process optimization, and real-time monitoring—highlighting the integration of IoT technologies and DTs as a core strategy to enhance traceability, safety, and quality assurance throughout manufacturing operations [

16,

93]. This emphasis is reflected in the work of Li et al. [

59], who developed a Blockchain-Enabled IoT-BIM Platform to address supply chain fragmentation and trust issues in modular construction. Their platform integrates blockchain, IoT, and BIM within a data-information-knowledge framework, successfully improving information transparency and traceability in a modular student housing project. This example illustrates how advanced digital integration can streamline manufacturing workflows while enhancing the overall performance and reliability of modular construction supply chains.

Transportation represents a critical phase within the lifecycle of IOC, with 16 studies identifying the logistical complexities inherent in transferring prefabricated components from manufacturing sites to installation locations. These complexities often lead to schedule delays and increased costs, particularly when coordination and tracking mechanisms are insufficient [

73]. In response, the literature highlights the adoption of IoT technologies and GIS-based routing systems as effective tools to optimize delivery schedules and minimize site-level disruptions [

15]. A notable example is provided by Yang et al. [

8], who developed a DT-enabled platform that integrates IoT, neural networks, and hierarchical finite state machines to enhance real-time monitoring and supply chain coordination. Although the study is applied to on-site fit-out construction, its focus on improving material visibility and traceability addresses core transportation challenges in prefabricated systems, reinforcing the importance of smart technologies in streamlining logistics across construction phases.

On-site assembly is the most extensively examined phase within the IOC process, with 29 studies dedicated to addressing its inherent complexities. The literature explores a range of strategies aimed at enhancing on-site operations, including real-time monitoring, automated tracking, and the optimization of hoisting and installation workflows [

16,

76]. Central to these advancements is the integration of DTs and IoT technologies, which are consistently highlighted for their ability to improve operational visibility, component traceability, and data-driven decision-making during assembly [

61]. For instance, Zhou et al. [

64] developed an IoT-enabled BIM platform to support on-site assembly services in prefabricated housing projects in Hong Kong. By incorporating technologies such as RFID, GPS, and smart sensors into the BIM environment, the platform demonstrated improved tracking, monitoring, and process integration. This example illustrates how digital platforms can streamline on-site operations and enhance the overall efficiency and reliability of prefabricated construction projects.

The operation and maintenance phase remains significantly underrepresented within the IOC literature, with only five studies addressing this critical stage. This gap reflects the sector’s traditional emphasis on earlier phases such as planning, manufacturing, and assembly, where the majority of interventions are typically concentrated. However, the limited existing research underscores the transformative potential of DTs and IoT technologies in post-construction contexts, particularly for real-time monitoring, condition assessment, and predictive maintenance [

87]. A notable example is provided by Rojas-Mercedes et al. [

87], who utilized a DT and structural health monitoring system to assess the seismic vulnerability of a precast reinforced concrete bridge in the Dominican Republic. By integrating sensor data with a computational model, the study developed seismic fragility curves to inform disaster mitigation and recovery planning. This case highlights how digital technologies can extend the value of prefabricated systems beyond construction, supporting long-term performance monitoring and resilience in infrastructure applications.

Decommissioning is the least explored phase in the IOC lifecycle, with only one study addressing its potential. This limited attention reflects a broader gap in lifecycle-oriented research, despite growing sustainability and circular economy imperatives. The existing study highlights the integration of DTs and BIM to facilitate the disassembly and reuse of building components [

91]. By enabling detailed documentation and accurate tracking of elements throughout the building’s life, these technologies support systematic deconstruction, reduce construction waste, and minimize environmental impact [

91]. This approach demonstrates the emerging role of digital tools in extending the value chain of prefabricated systems beyond their initial service life, aligning decommissioning practices with sustainable development goals.

Research on DTs in IOC spans a range of sectors, component typologies, and structural materials. Residential construction emerges as the most studied sector (15 studies), with a strong emphasis on improving design accuracy, real-time monitoring, and quality control through DT integration [

57,

65]. Infrastructure applications (five studies) primarily focus on logistics optimization and structural health monitoring [

8,

77], while commercial projects (three studies) concentrate on space utilization and facility management [

88,

91]. In contrast, healthcare and institutional settings remain underrepresented, with only one study addressing the use of DTs for enhancing operational efficiency and safety performance [

25]. Regarding component typologies, non-volumetric pre-assembly—such as beams and slabs—dominates the literature (14 studies), followed by volumetric modules (8) and sub-assemblies or manufactured components (6). Modular buildings have received minimal scholarly attention, with only one study specifically addressing them. In terms of structural materials, concrete is the most frequently investigated (21 studies), followed by steel (7) and timber (6). Among multi-material strategies, hybrid systems combining steel and concrete are the most commonly explored, reflecting their prevalence in contemporary off-site construction practices.

Figure 12 summarizes these findings.

4.4. Digital Twin Tools and Technologies

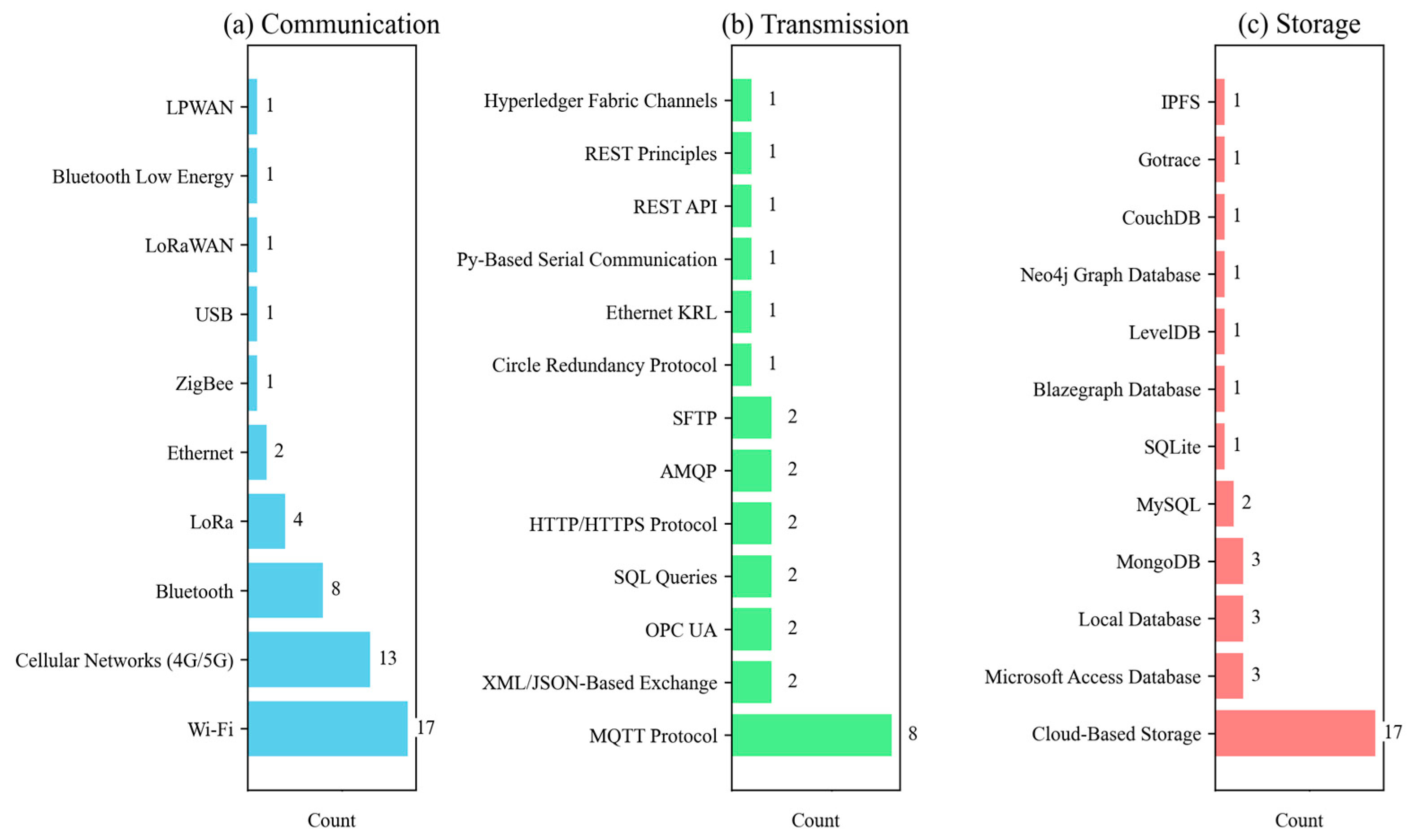

Sensing Layer: The sensing layer, also known as the data acquisition or perception layer, forms the primary interface between physical construction environments and the DT system. It collects real-time data from machines, components, and environments to ensure the virtual model remains synchronized with the physical system—supporting dynamic simulation, performance analysis, and informed decision-making [

94]. As the foundation for communication, storage, and processing layers, it delivers high-fidelity data essential for analytics and integration, directly influencing the reliability of DT operations. According to the studies of DT in IOC, and as illustrated in

Figure 13, this layer comprises five functional clusters. (1) Geometric and spatial sensing, using GPS, LiDAR, ultra-wideband, inertial measurement units, and accelerometers, captures dimensions and motion. (2) Identification and tracking, including RFID, near-field communication, and production sensors, focuses on real-time inventory and logistics visibility. (3) Environmental monitoring employs sensors like thermocouples, barometers, and humidity detectors to assess ambient conditions. (4) Visual and wearable sensing involves cameras and industrial wearables for image capture and worker monitoring. (5) Structural and mechanical monitoring uses strain sensors, fiber optics, and load cells to evaluate asset integrity and performance.

Different functional clusters within the sensing layer serve distinct application areas in IOC, with technology preferences shaped by their specific capabilities. Geometric and spatial sensing, primarily using GPS, is central to progress tracking and site coordination due to its effectiveness in asset localization and movement monitoring. Identification and tracking tools, particularly RFID, dominate supply chain and logistics optimization, offering cost-effective, real-time visibility of components and materials. Visual and wearable sensors, such as cameras, are mainly employed in safety and maintenance management for their versatility in monitoring worker activity and site conditions. Structural sensors, especially strain sensors, support quality control by detecting potential component failures and measuring load performance. Environmental sensors, including temperature and humidity monitors, are widely used in sustainability and circularity initiatives, tracking ambient conditions to ensure compliance and operational integrity.

A recurring trend in the reviewed studies is the integration of hybrid sensing systems, with 78% adopting two or more sensing technologies. The combination of GPS and RFID is particularly common, providing spatial tracking and identification simultaneously. However, challenges such as data synchronization in multi-sensor configurations and visual occlusions remain prevalent [

18,

48]. Timestamping and the addition of inertial measurement units are frequent strategies used to address these gaps [

84,

90]. In a study for managing on-site assembly services in prefabricated construction, Li et al. [

57] suggest Edge computing to reduce latency in real-time processing [

25]. Additionally, Ramonell et al. [

77] reported RFID performance degradation due to material interference, which researchers mitigated by integrating vision-based methods and optimizing workspace layouts. The design and selection of sensing technologies directly influence DT accuracy. Multi-cluster systems demonstrate superior spatial fidelity compared to single-cluster setups. Even limited sensor integration shows substantial benefits. For instance, Rojas-Mercedes et al. [

87], employing strain sensors for bridge structural health monitoring, reported a 40% improvement in failure prediction and an 87% reduction in displacement errors compared to human data records. However, several studies caution against excessive sensor deployment, as the complexity of data fusion may outweigh marginal accuracy gains.

The sensing layer’s data serve distinct but complementary roles: spatial and geometric data—such as point clouds and kinematic metrics—form the foundational digital scaffold, enabling precise tracking of assets, workers, and equipment across dynamic construction environments [

14,

65]. Production process data, particularly high-frequency metrics like task status and machine health, reveal bottlenecks and efficiency gaps in prefabrication workflows [

90,

95]. Inventory and material tracking data—the most extensively logged category—provide detailed visibility into supply chain states, which is critical for just-in-time delivery in modular construction [

76]. Environmental and quality data act as compliance safeguards. Ambient condition tracking helps mitigate weather-related risks, while inspection records ensure regulatory adherence [

62,

83]. Structural performance data (e.g., strain and vibration) offer predictive insights into component durability [

87]. The prevalence of worker-related metrics, including location and movements, reflects an industry shift toward safety-centric IoT integration [

25].

Figure 14 presents the data types captured by the sensing layer in IOC.

Communication Layer: The communication layer plays a pivotal role in DT systems by enabling real-time data exchange between the physical and digital domains, thereby ensuring synchronization, responsiveness, and system scalability [

96]. Rather than being a passive conduit, this layer actively shapes the reliability, latency, and interoperability of DT architectures across construction settings.

Across the reviewed studies, communication technologies are selected based on application-specific criteria such as transmission range, data volume, energy efficiency, and environmental conditions. Wi-Fi and cellular networks (4G/5G) are the most widely adopted technologies due to their high data throughput, scalability, and suitability for dynamic, mobile environments such as construction sites and modular factories [

21]. Their support for wide-area coverage and ease of deployment make them ideal for real-time progress monitoring, remote control, and mobile worker tracking.

Short-range communication technologies, such as Bluetooth and Bluetooth Low Energy (BLE), are typically deployed in sensor-dense environments where proximity-based monitoring is critical—for example, in worker safety wearables or equipment status detection. BLE, in particular, is favored for its low power consumption, enabling long-term operation in battery-powered devices [

22]. In contrast, long-range, low-power solutions like LoRa and LoRaWAN are leveraged in applications where centralized connectivity is impractical—such as monitoring prefabricated component movements or tracking environmental data over large construction sites [

83]. These technologies strike a balance between energy efficiency and signal reach, although their limited bandwidth constrains them to transmitting small, periodic data packets.

In more controlled environments such as robotics labs or modular factories, wired networks like Ethernet and USB are preferred for their stability, low latency, and immunity to wireless interference. For instance, Ethernet is often integrated into robotic DTs, enabling high-frequency data transmission between physical and simulated models during control tasks or training cycles [

13].

Communication protocols further determine how effectively data is structured, transmitted, and integrated across DT systems. MQTT is the most commonly adopted protocol due to its lightweight publish–subscribe architecture, which minimizes overhead and suits bandwidth-constrained applications with frequent sensor updates [

21]. For secure, real-time data exchange in industrial settings, protocols like OPC UA, HTTP/HTTPS, and REST are employed to maintain interoperability across heterogeneous devices. AMQP and SFTP provide reliability and security in message queuing and file transfers, particularly for regulatory-compliant or multi-stakeholder environments [

22].

At the data formatting level, XML and JSON facilitate interoperability by supporting structured and semi-structured data exchange. Specialized communication protocols are used to meet unique operational needs: Circle Redundancy supports fault-tolerant industrial automation; Ethernet KRL enables precise robotic control; and Python-based serial communication offers scripting flexibility in custom or modular DT applications [

12,

13,

18]. Furthermore, the inclusion of Hyperledger Fabric Channels in one study signals growing interest in blockchain-enabled DTs, where secure, traceable, and decentralized communication is essential for collaborative construction project management [

59]. Overall, communication in DTs is not a one-size-fits-all solution—it is a multi-layered, adaptive system where technology selection must align with spatial scale, energy constraints, latency tolerance, and data fidelity requirements

Storage Layer: The storage layer forms a critical backbone of DT architectures by managing the lifecycle of data—from initial capture to long-term archival and real-time analytics. Its structure and capabilities significantly influence the responsiveness, scalability, and interoperability of DT systems in IOC environments [

21].

Cloud-based storage solutions from different technology providers such as Microsoft and Google dominate most implementations, reflecting the industry’s shift toward centralized, scalable infrastructures capable of supporting multi-user access, real-time processing, and integration with advanced analytics and visualization platforms [

21]. These systems offer high availability and elasticity, which are particularly valuable in large-scale applications such as modular production coordination or cross-site monitoring. Cloud-native platforms also support seamless integration with machine learning pipelines, enabling predictive analytics for tasks like structural health monitoring or schedule optimization.

Despite the prominence of cloud systems, local storage solutions remain relevant in contexts where network connectivity is intermittent, data latency must be minimized, or systems are in prototype or experimental phases. Databases such as Microsoft Access, MySQL, and SQLite are often employed for such scenarios, providing lightweight and easily deployable alternatives for pilot-scale or localized DTs [

77].

As DT implementations increasingly deal with heterogeneous and unstructured data, there is a growing reliance on NoSQL and non-relational database models. Document-based databases such as MongoDB [

77] and CouchDB [

59] support flexible data schemas, making them well-suited to dynamic construction environments where new data types (e.g., sensor metadata, component status, BIM annotations) are frequently introduced. Graph-based systems like Neo4j [

77] allow for the modeling of complex relationships, such as interdependencies between prefabricated elements, supply chain actors, and construction phases—enhancing semantic query capabilities and data traceability.

Some studies have introduced semantic and ontology-driven storage frameworks to promote data interoperability and reasoning across distributed DT platforms. For example, Blazegraph enables ontology-based data management, which supports intelligent querying and integration with Linked Data sources [

89]. Similarly, InterPlanetary File System (IPFS) has been explored as a decentralized, peer-to-peer file storage system, offering immutability and provenance—capabilities that are particularly beneficial in blockchain-integrated DTs or regulatory-compliant documentation workflows [

63]. Collectively, these developments reflect a maturing DT ecosystem in IOC, where storage layer design is increasingly context-sensitive, tailored to factors such as project scale, collaboration intensity, data heterogeneity, and system resilience requirements. While MQTT-based transmission remains a common precursor to storage, the convergence of semantic modeling, cloud-native services, and distributed ledger technologies suggests a move toward more intelligent, decentralized, and interoperable architectures.

Figure 15 summarizes the tools and technologies applied in DT-enabled IOC.

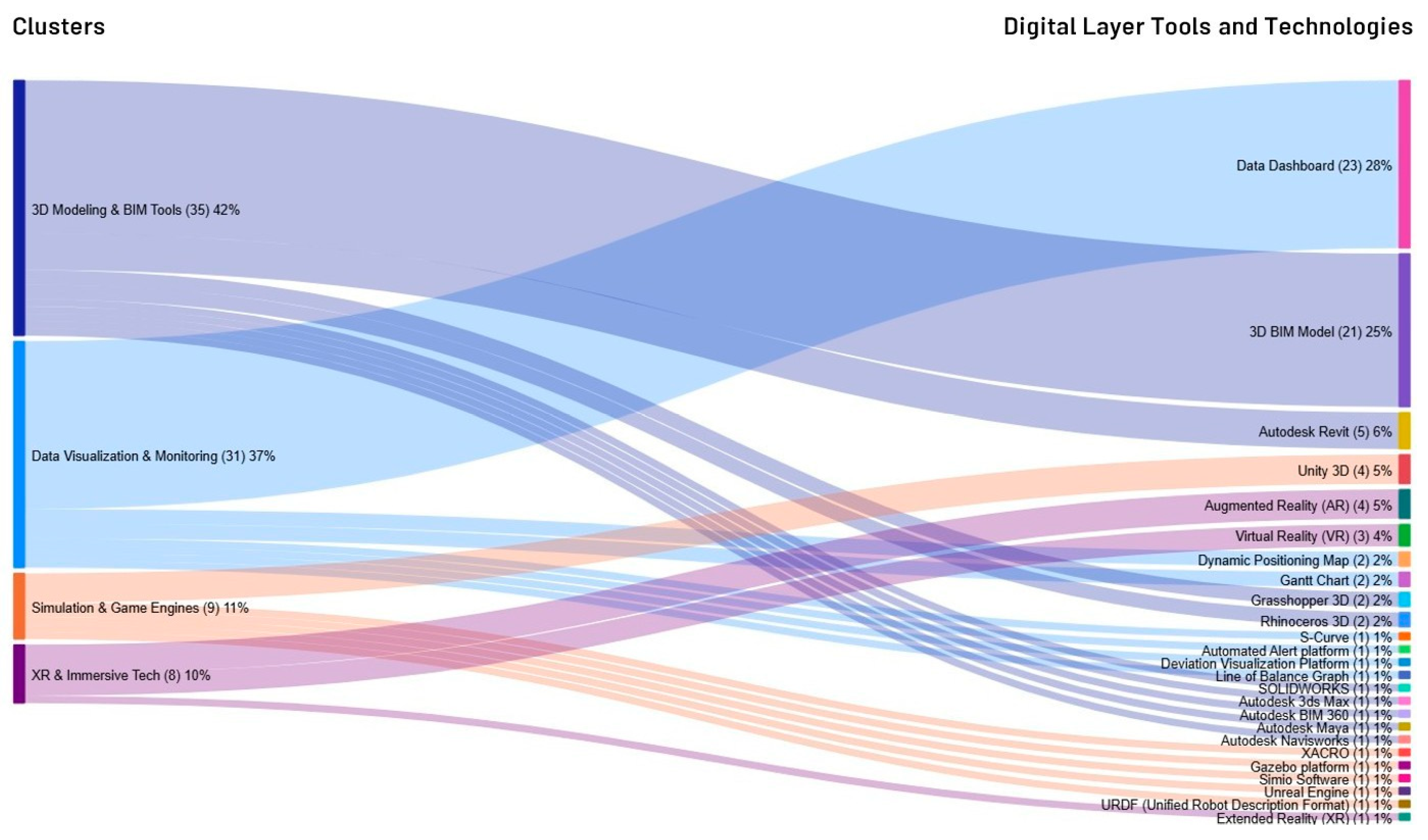

Digital Layer: The digital layer of DTs in IOC forms the foundation for establishing, visualizing, and maintaining the virtual counterpart of physical assets and processes [

97]. This layer encompasses technologies that enable 3D modeling, geometric updates, immersive visualization, and simulation environments, ensuring accurate and dynamic synchronization between digital and physical domains throughout the project lifecycle [

21]. Distinct from the service layer—which focuses on analytical interpretation and optimization—the digital layer is dedicated to the fidelity, continuity, and responsiveness of the virtual representation [

35]. As depicted in

Figure 16, we could identify four groups of the technologies supporting this layer: (1) 3D Modeling and BIM Tools, (2) Simulation and Game Engines, (3) Data Visualization and Monitoring, and (4) Extended Reality and Immersive Technologies.

Three-dimensional modeling and BIM tools constitute the foundation of digital model development, facilitating detailed virtual representations, parametric control, and the integration of geometric and semantic data [

88]. The 3D BIM model has been the most frequently referenced concept, underscoring its central role in capturing both design intent and as-built conditions. Autodesk Revit (

www.autodesk.com, accessed on 11 August 2025) is commonly employed for semantic modeling and parametric operations, often in combination with complementary tools. Rhinoceros 3D and Grasshopper 3D are primarily used in robotic prefabrication workflows, supporting complex geometry handling and automated modeling [

89]. Additional platforms—including Autodesk Maya [

63], SOLIDWORKS [

61] (

www.solidworks.com, accessed on 11 August 2025), Autodesk 3ds Max [

91], BIM 360 [

25] (

www.autodesk.com, accessed on 11 August 2025), and Navisworks (

www.autodesk.com, accessed on 11 August 2025) [

67]—enable high-resolution modeling, visual simulation, and coordination within BIM-based project environments.

Simulation and game engines serve as powerful platforms for visualizing and modeling construction processes, particularly in robotic and offsite manufacturing contexts [

12]. These tools enable the simulation of system configurations, motion sequences, and operational logic within immersive, interactive environments. Unity 3D (

www.unity.com, accessed on 11 August 2025) is frequently utilized to model interactions among human operators, robotic systems, and prefabricated building components [

15], while Unreal Engine (

www.unrealengine.com, accessed on 11 August 2025) supports high-fidelity visualization of large-scale infrastructure scenarios [

12]. Domain-specific platforms such as Gazebo, URDF, and XACRO facilitate the simulation of robotic kinematics and validation of motion planning strategies [

95]. Additionally, Simio Software (

www.simio.com, accessed on 11 August 2025) is employed to model factory layouts and workflow logic, supporting spatial planning and process visualization without engaging in detailed computational analysis [

18].

Data visualization and monitoring comprises tools that translate complex datasets into intuitive visual formats to support human interpretation and operational decision-making [

71]. Among these, data dashboards are most frequently cited, particularly for real-time monitoring of key performance indicators, construction progress, and sensor-derived feedback [

71]. Visualization tools such as Gantt charts and dynamic location maps are commonly applied to schedule and logistics management [

93], while deviation mapping platforms [

89], automated alert systems [

71], line-of-balance graphs [

80], and S-curve charts [

95] facilitate quality assurance and progress tracking. Collectively, these tools enhance both strategic oversight and real-time operational transparency.

Extended reality and immersive technologies refer to platforms that enable users to interact with DT environments through spatially immersive interfaces. Augmented reality (AR) and virtual reality (VR) have been employed to support applications such as assembly simulation, ergonomic analysis, and virtual construction walkthroughs [

64]. Several studies [

59,

91] conceptualize XR as the integration of AR and VR to facilitate collaborative visualization and spatial decision-making. These technologies have proven particularly valuable in modular and prefabricated construction workflows, enhancing real-time alignment, stakeholder communication, and on-site validation [

91].

Several studies highlight the integration of tools across software clusters to enable real-time visualization and simulation in construction robotics. For instance, Unity 3D is frequently coupled with Revit- or Rhino-based (

www.rhino3d.com, accessed on 11 August 2025) BIM models to facilitate real-time visualization of robotic processes [

17,

89]. Autodesk BIM 360 serves both as a modeling environment and as a conduit for linking design models to real-time dashboards [

67]. In robotic system simulations, formats such as URDF and XACRO are commonly integrated with platforms like Gazebo and Unity to model system behavior prior to physical deployment [

95]. The literature also distinguishes between real-time and periodic visualization methods. Real-time visualization—enabled by platforms such as BIM 360, Unity, and interactive dashboards—is used for live monitoring of operations including module placement and deviation tracking [

25,

65]. In contrast, periodic visualization techniques, such as S-curves, line-of-balance charts, and post-scan deviation analyses, support retrospective evaluation and quality assurance [

95]. This combination of real-time and periodic methods enables DTs to meet the varying feedback and responsiveness requirements of diverse construction activities.

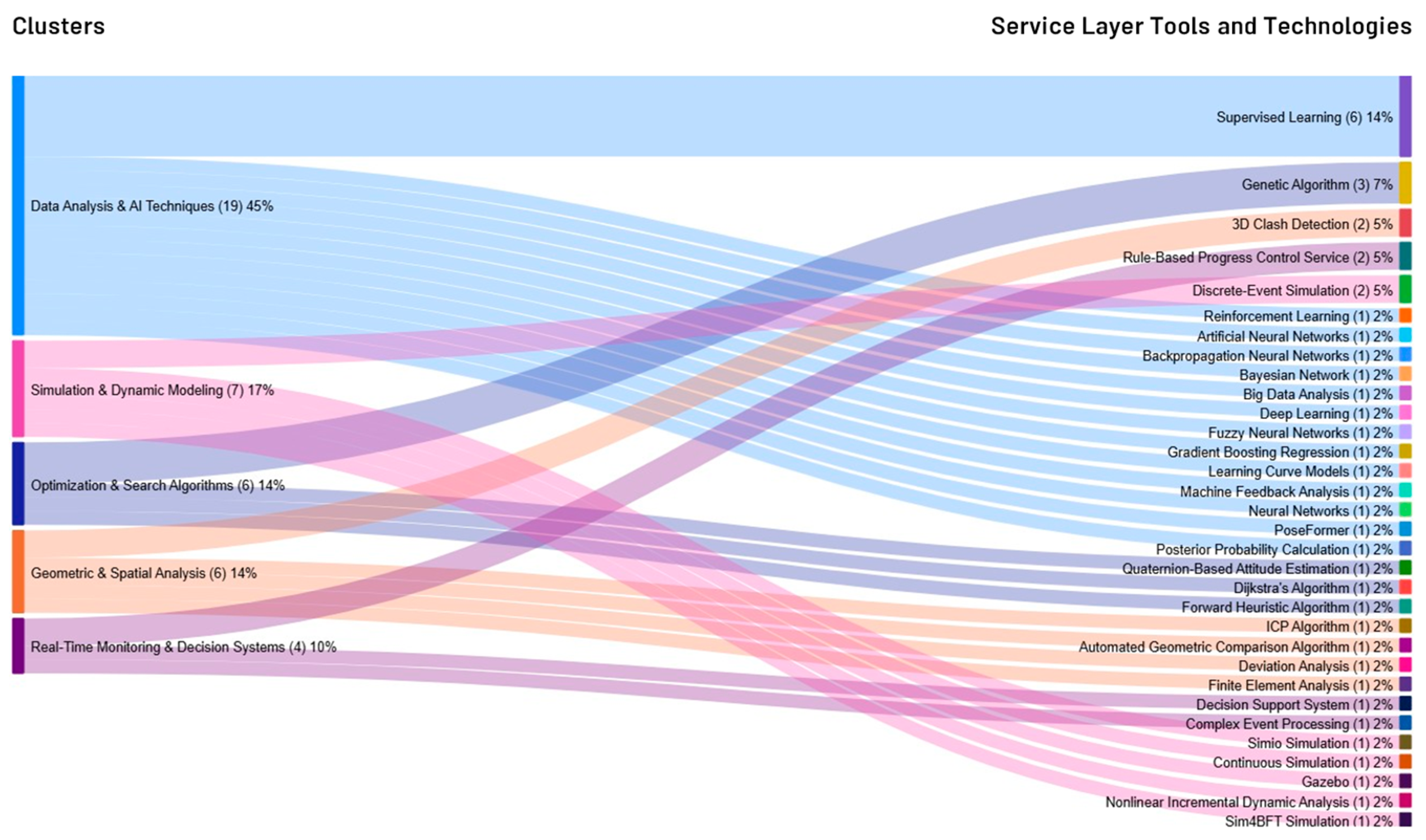

Service Layer: This layer represents the analytical and cognitive engine of the DT framework in IOC. It operates beyond data visualization and static model handling, instead translating real-time data streams and historical records into actionable insights, predictive logic, and system optimizations [

98]. This transformation hinges on a spectrum of algorithmic tools spanning machine learning, optimization, simulation, geometric validation, and decision support mechanisms. According to

Figure 17, At the heart of this layer lies AI, particularly supervised learning techniques, which dominate in applications such as progress estimation, defect classification, and activity recognition from sensor or vision data. While neural networks—including deep learning architectures and fuzzy logic systems—offer the capacity to extract nonlinear patterns from complex datasets, their dependency on large volumes of annotated data and their limited interpretability raise concerns regarding their robustness and transparency in critical decision-making contexts [

71]. Tools like PoseFormer (

www.github.com/zczcwh/PoseFormer, accessed on 11 August 2025) have extended AI’s capabilities into spatial behavior tracking and pose estimation, supporting tasks such as ergonomic evaluation or equipment alignment [

85]. However, such models often face practical limitations when confronted with noisy construction environments or occlusions in vision-based monitoring, pointing to a gap between algorithmic accuracy in controlled datasets and field applicability.

In optimization-intensive contexts such as layout configuration, resource sequencing, and robotic workflow planning, evolutionary algorithms—particularly genetic algorithms—have become prevalent due to their flexibility in handling multi-objective trade-offs and constraint-laden environments [

16]. Yet, their convergence times and sensitivity to problem formulation can limit their suitability for real-time applications. Heuristic-based algorithms like Dijkstra’s and forward search strategies have proven more efficient for deterministic tasks such as path planning in robotic systems or connectivity analysis in modular assembly, though their capacity to handle uncertainty or dynamically changing environments remains restricted [

83]. Meanwhile, quaternion-based estimation provides more precise modeling of spatial orientation for robotic joints and module alignment; however, it often requires integration with external simulation tools to validate mechanical feasibility [

83].

Simulation and dynamic modeling form another critical dimension of the service layer, serving to forecast performance, test alternate scenarios, and evaluate the systemic impact of design or operational changes. Discrete-event simulation enables temporal modeling of prefabrication workflows, capturing dependencies and bottlenecks with granularity suitable for factory process optimization [

74]. Continuous simulations and hybrid approaches—often supported by platforms such as Simio and Gazebo—offer more holistic insights into continuous system behavior, including robotic movements or structural responses under load [

95]. However, such simulations remain heavily reliant on accurate input data and parameter tuning, and many studies neglect the incorporation of feedback loops from real-world sensors, undermining the representational fidelity and adaptability of these models over time. Despite the increasing availability of dynamic modeling platforms, integration challenges persist, particularly when linking process simulations with geometric or AI-driven components in real-time.

Geometric and spatial analytics underpin many quality assurance and assembly validation tasks within the DT ecosystem. Algorithms like Iterative Closest Point (ICP) and deviation analysis are routinely deployed for comparing as-designed and as-built geometries, providing dimensional feedback essential for ensuring fabrication precision and detecting installation errors [

65]. While effective in capturing static discrepancies, these tools often function in isolation, lacking integration with predictive models that could foresee deviations based on preceding process trends. Finite Element Analysis (FEA), where integrated, contributes a performance-based layer to the DT, enabling structural behavior simulation under various load scenarios [

86]. However, FEA integration is often limited to isolated studies in IOC, and its computational intensity and lack of real-time operability hinder its full deployment in dynamic assembly environments. This reflects a broader limitation: many advanced tools in the service layer operate as point solutions rather than being embedded in a coherent, interoperable ecosystem.

Perhaps most critically, the service layer serves as the gateway to real-time responsiveness and autonomous decision-making. Rule-based systems and complex event processing architectures enable DTs to respond to unplanned deviations, safety events, or resource shortages with conditional logic in IOC [

8]. These are complemented by decision support systems that incorporate both historical data and predictive analytics to refine project strategies dynamically. Machine feedback systems, which interpret data streams from sensors and equipment during fabrication or robotic assembly, further enhance adaptability. Yet, the intelligence of these systems is still often constrained by pre-defined rules or black-box AI models, rather than by truly context-aware reasoning [

35]. Moreover, while real-time systems are increasingly deployed during assembly and production, planning-phase applications remain dominated by static optimization and simulation tools, creating a temporal disconnect in DT intelligence across the project lifecycle.

Interoperability remains the linchpin of the service layer’s effectiveness. Emerging research indicates a move toward hybridization, where geometric analytics inform machine learning models, or where simulation outputs are looped into optimization routines to refine parameters iteratively. For instance, AI classifiers trained on geometric deviation data can inform tolerance-aware sequencing, and resource allocation algorithms can be dynamically adjusted based on simulation feedback [

88]. These integrated workflows begin to shift the DT from a passive representation to an adaptive, learning system. However, the lack of standardized frameworks for cross-domain tool integration—especially across proprietary platforms—continues to limit scalability and robustness [

18]. The service layer’s promise lies not simply in its computational strength, but in its capacity to orchestrate diverse forms of reasoning—geometric, temporal, statistical, and heuristic—into cohesive, context-aware intelligence that can evolve with the system it mirrors.