Development and Engineering Evaluation of Interlocking Hollow Blocks Made of Recycled Plastic for Mortar-Free Housing

Abstract

1. Introduction

House Construction Concept Using Novel IHBs Made of Recycled Plastic

2. Materials and Methods

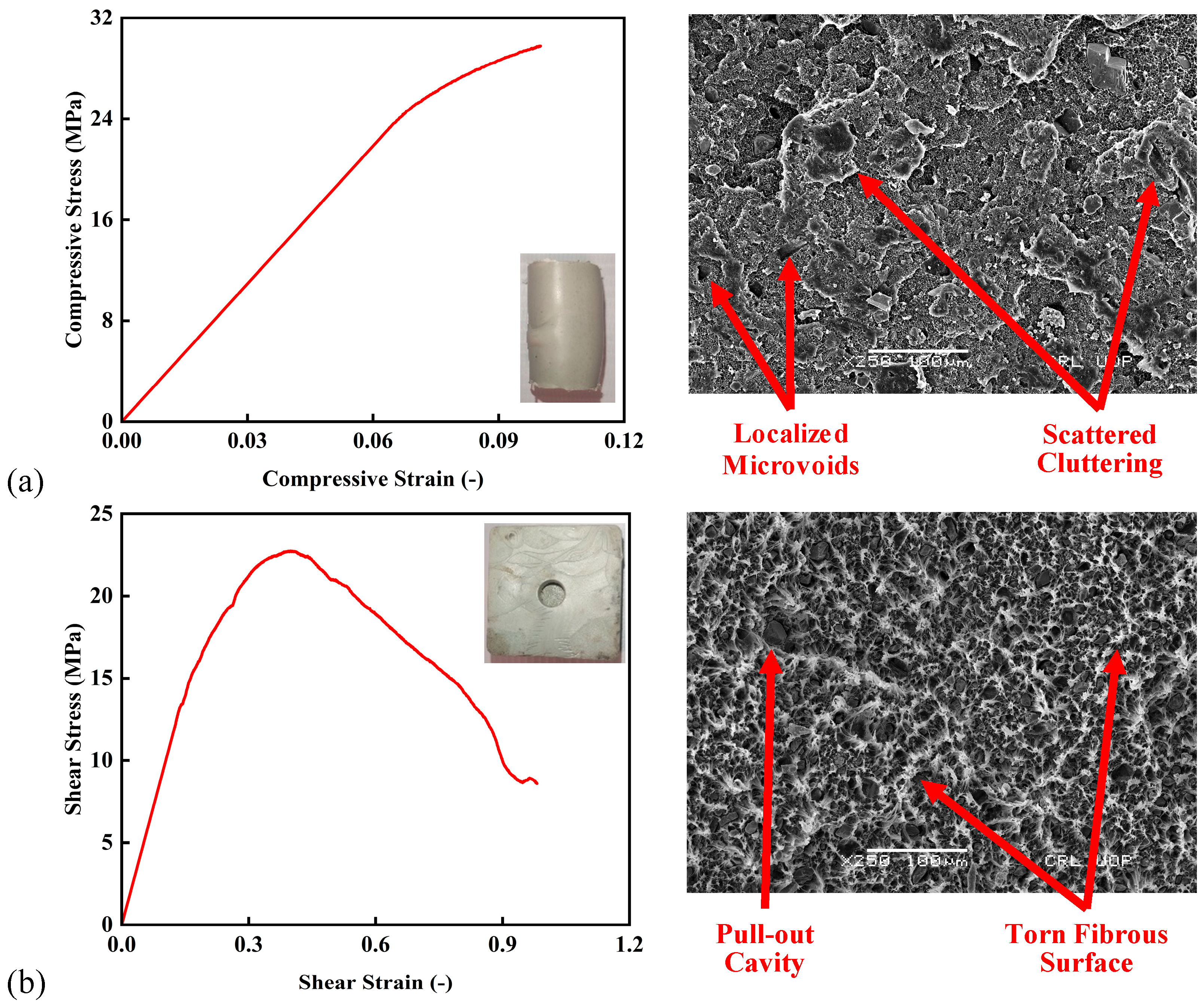

2.1. Waste Plastic Recycling and Material Properties

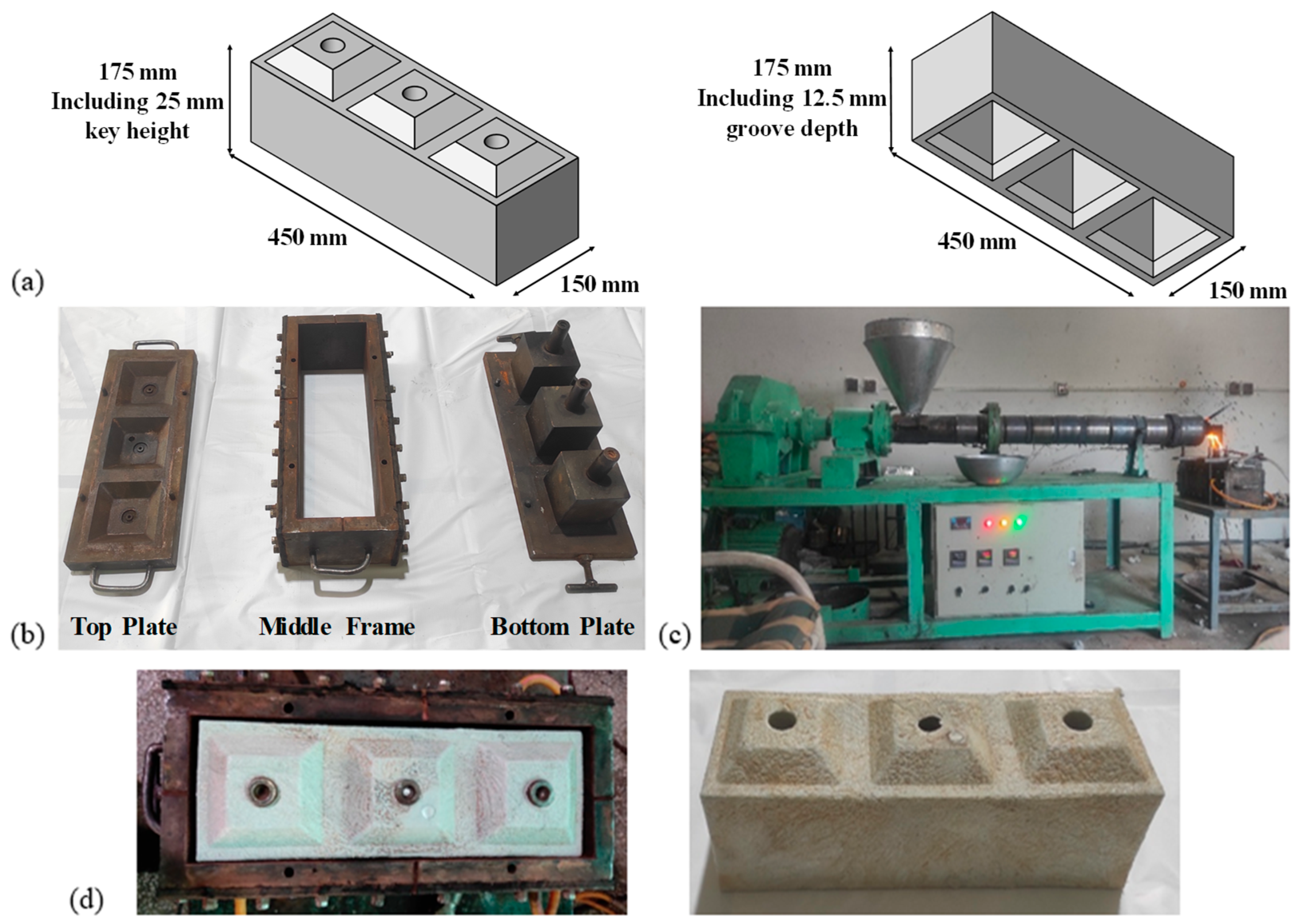

2.2. Design and Manufacturing of IHBs

2.3. Dynamic Testing of IHBs

2.4. Mechanical Testing of IHBs

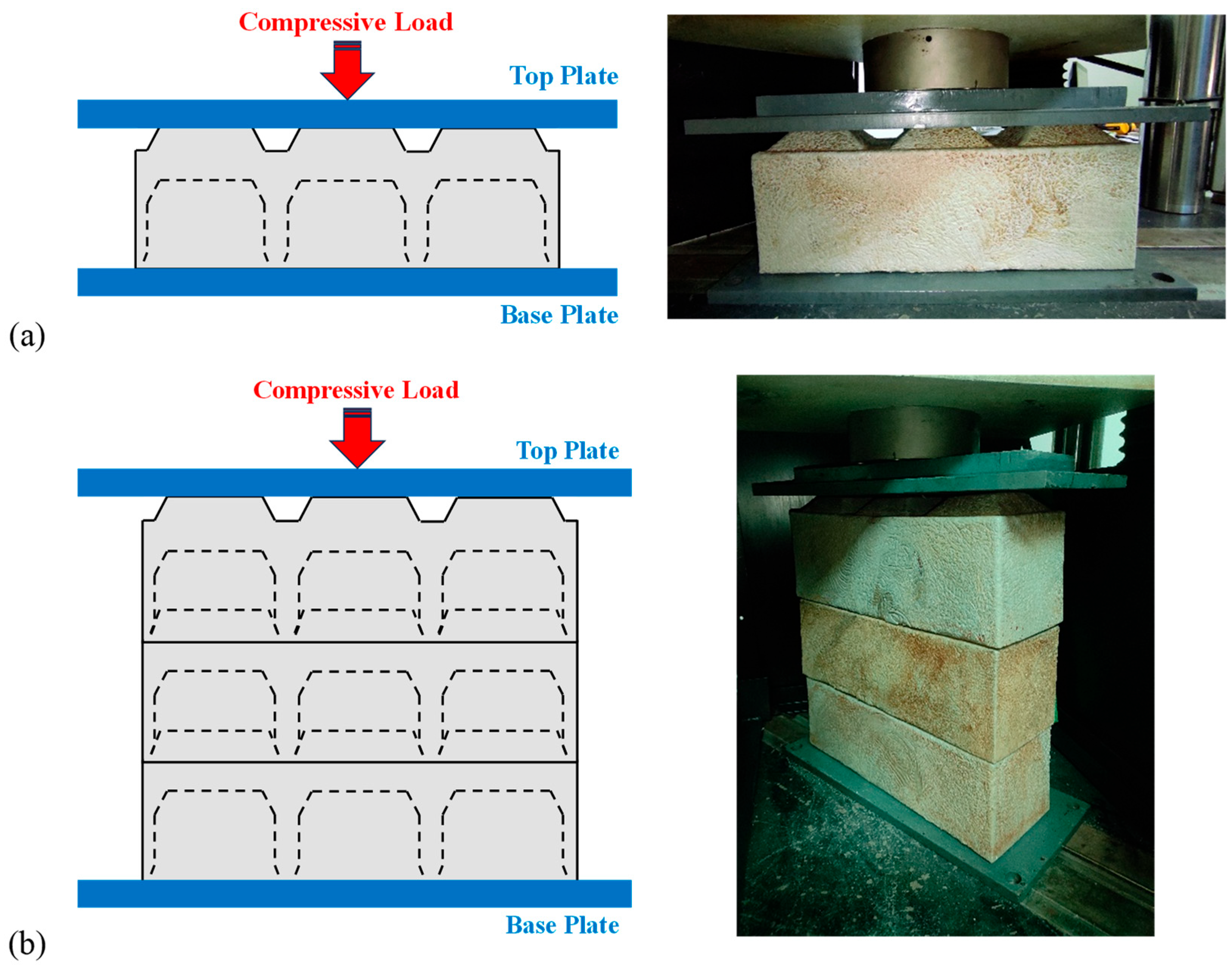

2.4.1. Compressive Testing of IHBs

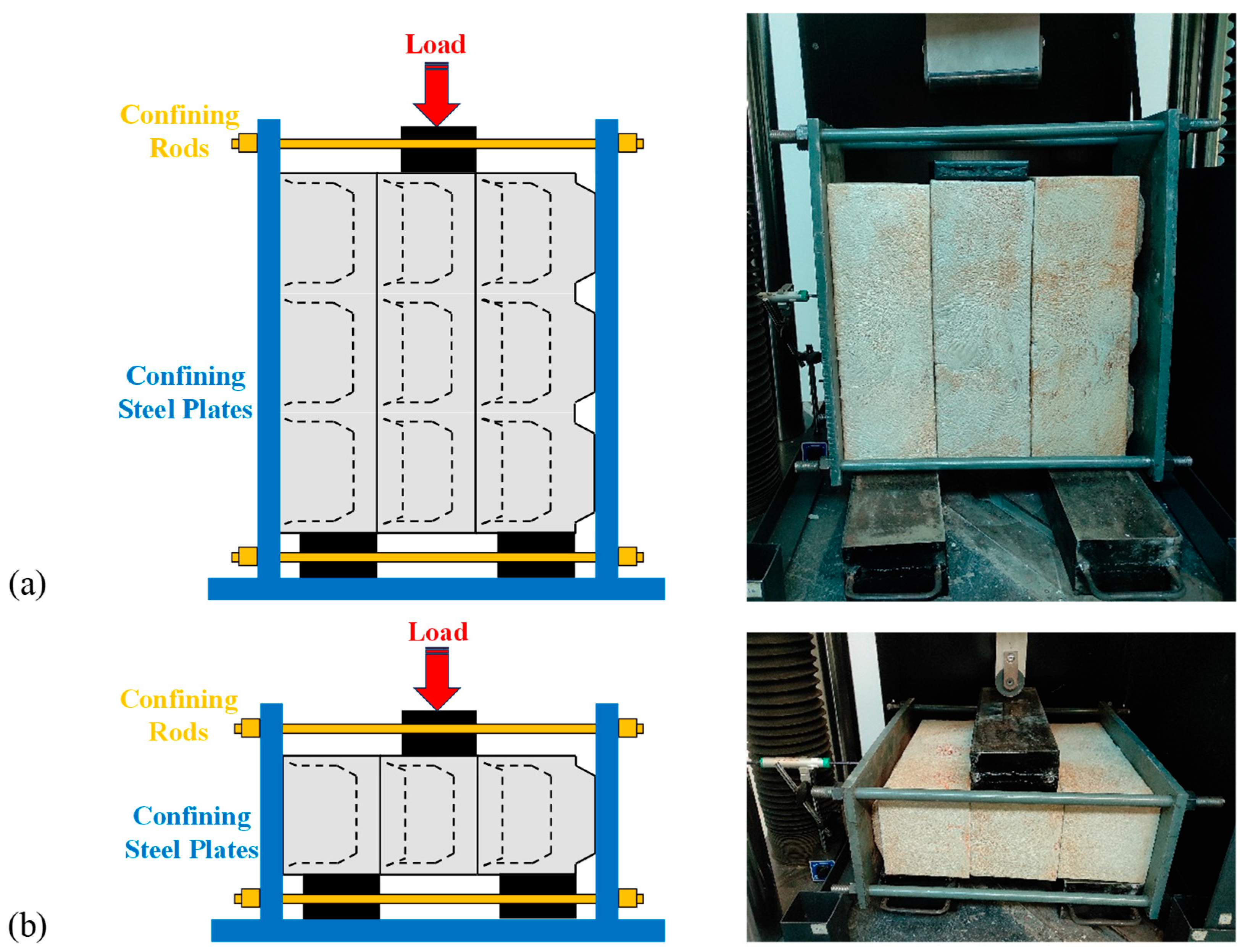

2.4.2. Shear Testing of IHBs

2.4.3. Empirical Modeling for Prediction of Shear Strength Using Pre-Compressive Stress

2.5. Microstructural and Compositional Evaluation

2.6. Chemical and Thermal Evaluations

3. Results and Analysis

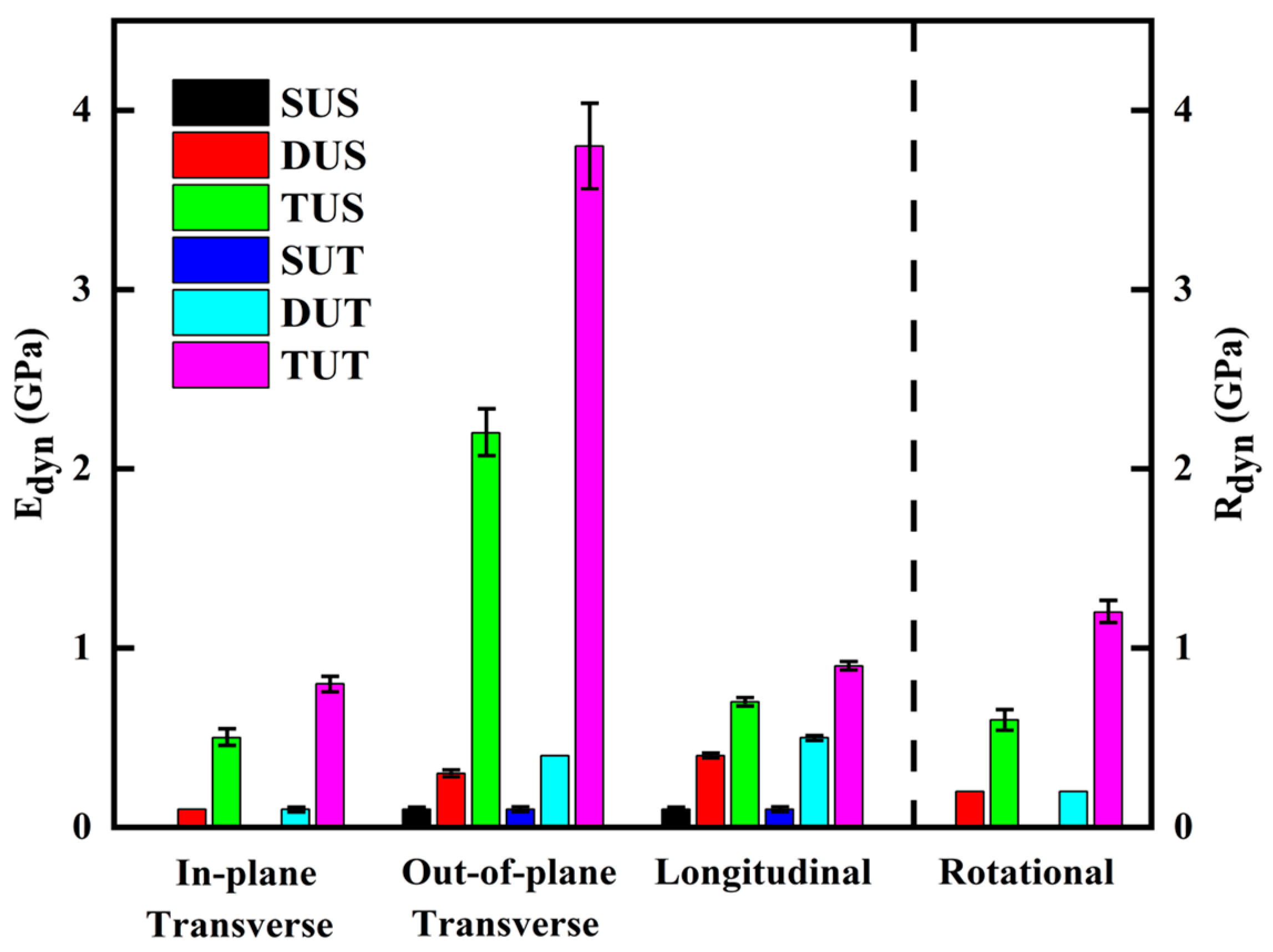

3.1. Dynamic Properties of IHBs

3.2. Mechanical Properties of IHBs

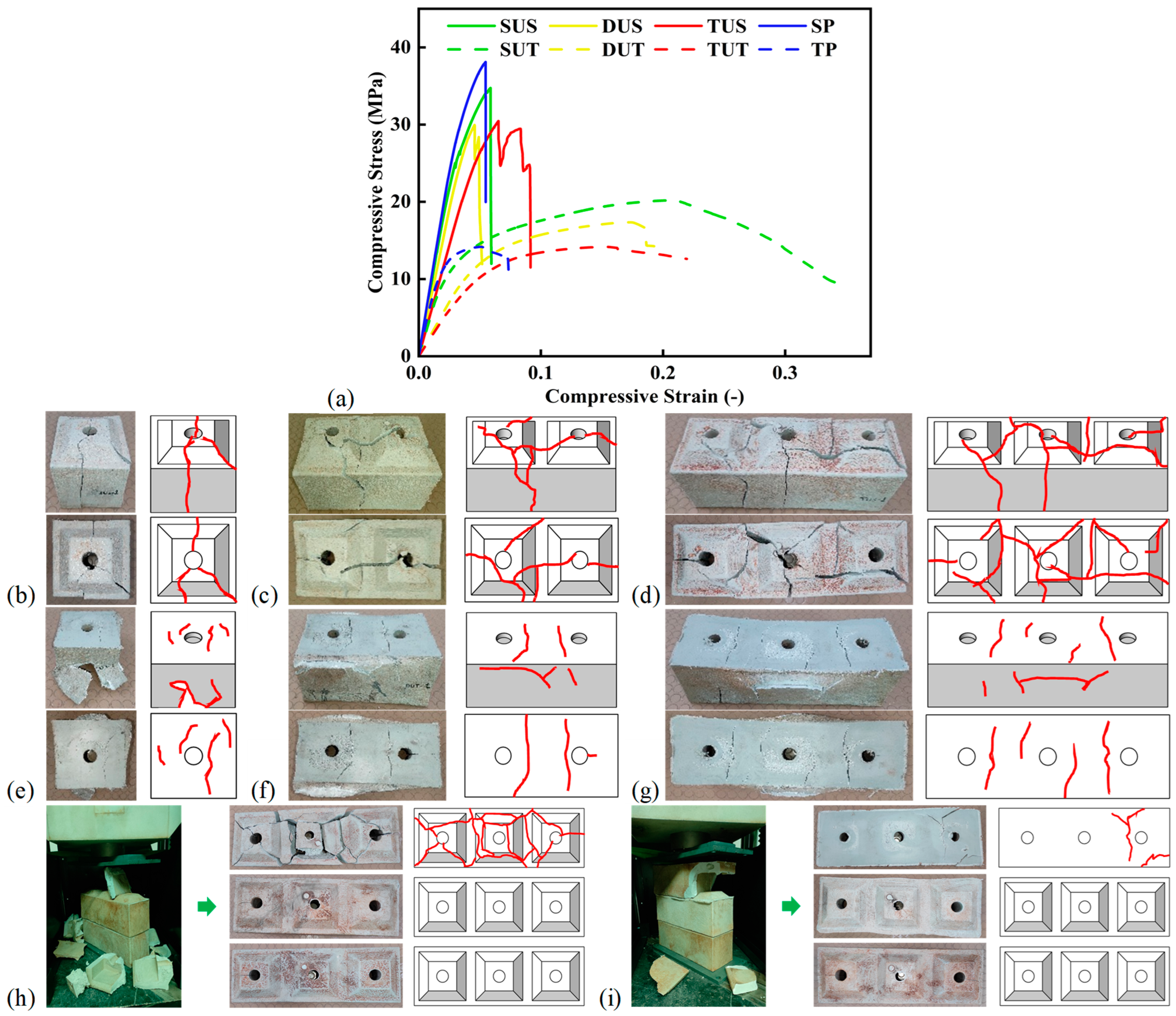

3.2.1. Compressive Strength and Related Parameters of IHBs

3.2.2. Shear Strength and Related Parameters of IHBs

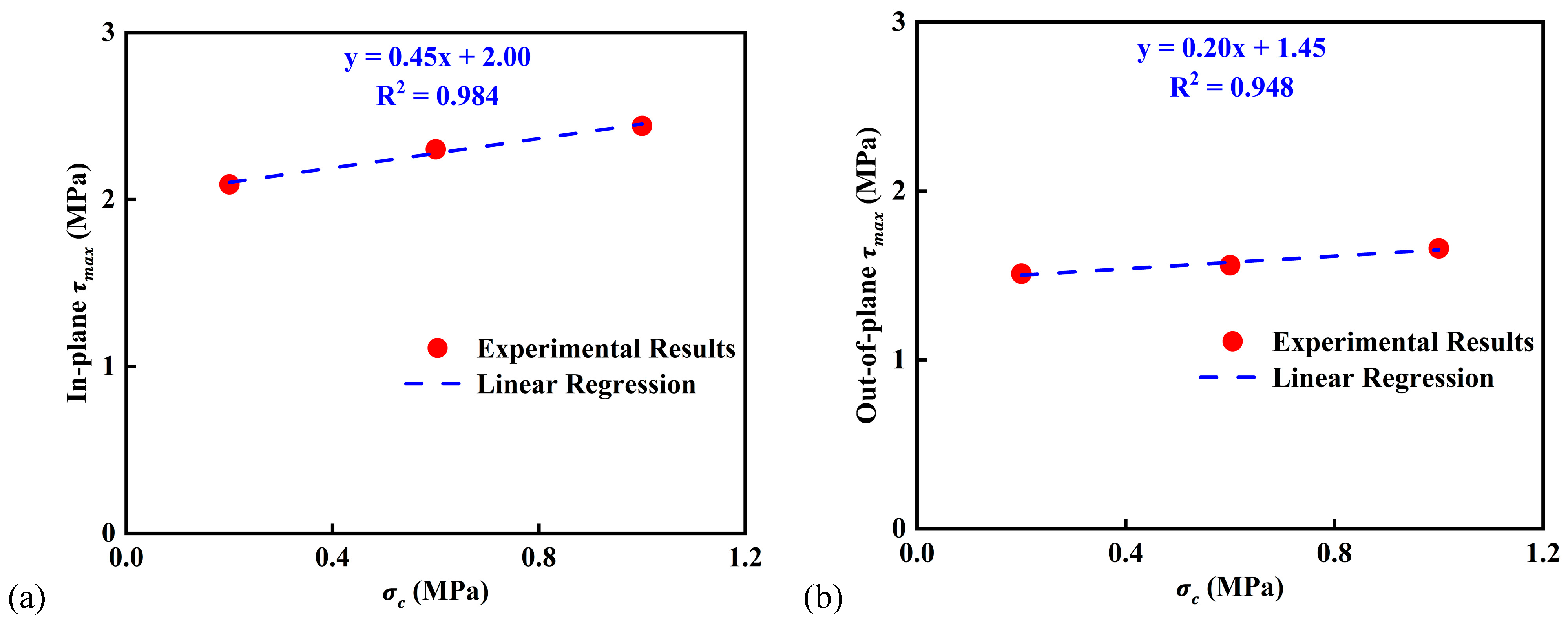

3.2.3. Correlation Between Shear Strength and Pre-Compressive Stress

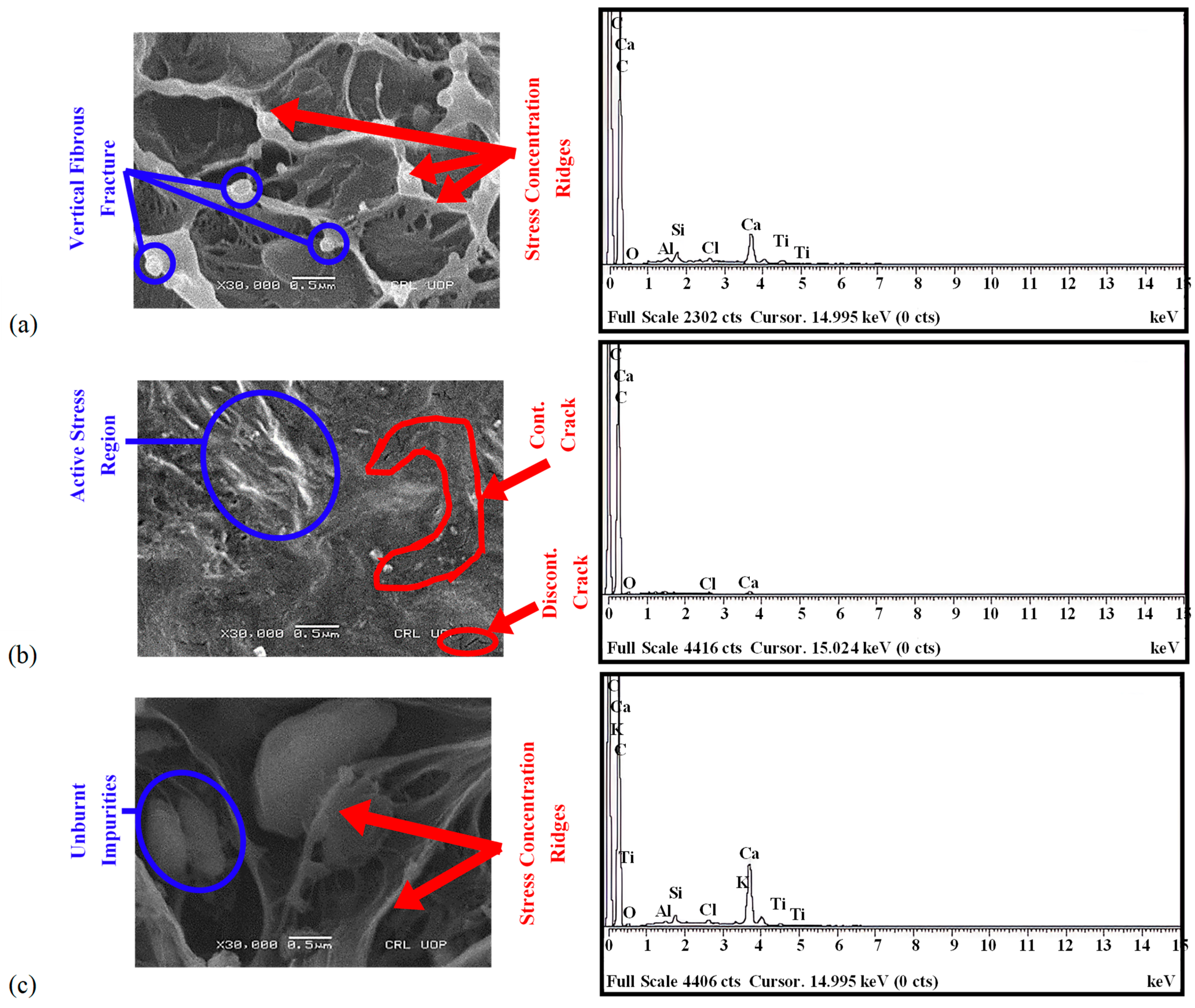

3.3. Microstructural Analysis and Distribution of Elemental Composition

3.4. Chemical Characterization and Thermal Analysis

4. Potential Challenges in Construction of Mortar-Free Interlocking Hollow Block House Made of Recycled Plastic

5. Conclusions

- The damping capacities in the in-plane transverse, longitudinal, and rotational directions increase with an increase in the longitudinal dimension. The highest damping value of 29.9% was observed in the SUT block in the in-plane transverse direction, and the lowest damping value of 3.3% was observed in the TUS block in the out-of-plane transverse direction. The novel shape of the IHBs, with hollow sections within the blocks, helps dissipate energy.

- The compressive and shear strengths are directly influenced by the shapes of the IHBs. The blocks and prisms with shear keys at the top exhibited greater compressive strength compared to the blocks with plain top surfaces. The shear strengths for different pre-compressive stresses revealed greater strength in the in-plane direction ranging from 2.09 MPa to 2.44 MPa, compared to the strength in the out-of-plane direction ranging from 1.51 MPa to 1.66 MPa.

- The microstructural analysis revealed strong resistance of fibrous polymer chains against stresses, which resulted in active stress regions. Also, the cracks propagated over continuous fiber paths, leading to splitting of the IHB surface. The presence of unburnt particles confirmed the presence of impurities, as witnessed in the elemental composition, which was attributed to the recycled nature of waste plastic.

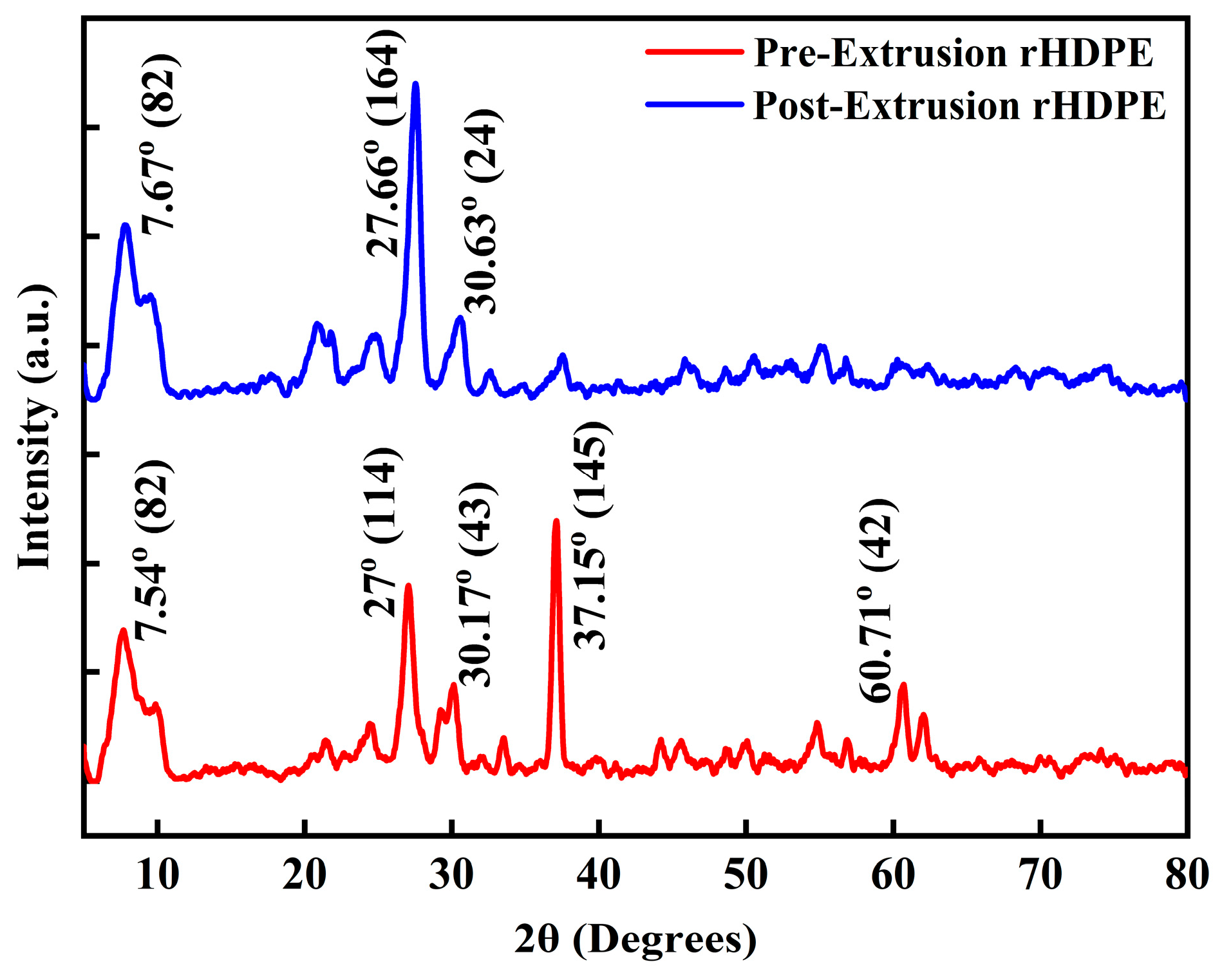

- The chemical characterization revealed omission of peaks of impurities, variation in crystallinity, and degradation of crystalline regions due to the extrusion process. The thermal behavior of rHDPE shows a slight stability reduction in post-extrusion rHDPE. However, there seems to be no abrupt mass loss behavior, which makes it thermally stable. The heat flow behavior suggests strong endothermic and exothermic reactions at high temperatures with limited deviations in pre-extrusion and post-extrusion behavior.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DSC | Differential Scanning Calorimetry |

| DUS | Double-Unit Standard |

| DUT | Double-Unit Top |

| EDX | Energy-Dispersive X-ray Spectroscopy |

| HDPE | High-Density Polyethylene |

| IHB | Interlocking Hollow Block |

| IP | In-Plane |

| NSL | Natural Surface Level |

| OOP | Out-Of-Plane |

| rHDPE | Recycled High-Density Polyethylene |

| rpm | Rotations Per Minute |

| SEM | Scanning Electron Microscopy |

| SP | Standard Prism |

| STA | Simultaneous Thermal Analysis |

| SUS | Single-Unit Standard |

| SUT | Single-Unit Top |

| TGA | Thermogravimetric Analysis |

| TP | Top Prism |

| TUS | Triple-Unit Standard |

| TUT | Triple-Unit Top |

| XRD | X-ray Diffraction |

References

- Santos, A.K.; Ferreira, V.M.; Dias, A.C. Promoting decarbonisation in the construction of new buildings: A strategy to calculate the embodied carbon footprint. J. Build. Eng. 2025, 103, 112037. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Wang, X.; Tu, S.; Song, Y.; Shi, T.; Wang, L.; Zhou, H. A comprehensive benefit evaluation of recycled carbon fiber reinforced cement mortar based on combined weighting. Constr. Build. Mater. 2025, 489, 142196. [Google Scholar] [CrossRef]

- Wei, M.; Chen, L.; Lei, N.; Li, H.; Huang, L. Mechanical properties and microstructures of thermally activated ultrafine recycled fine powder cementitious materials. Constr. Build. Mater. 2025, 475, 141195. [Google Scholar] [CrossRef]

- Marrero, M.; Rivero-Camacho, C.; Martínez-Rocamora, A.; Alba-Rodríguez, D.; Lucas-Ruiz, V. Holistic assessment of the economic, environmental, and social impact of building construction. Application to housing construction in Andalusia. J. Clean. Prod. 2024, 434, 140170. [Google Scholar] [CrossRef]

- Alam, Z.; Ahmed, S.; Fiaz, M.; Noroozinejad Farsangi, E. An Insight into the Characteristics of the September 24, 2019, MW 5.8 Mirpur, Pakistan, Earthquake and Reconnaissance of the Induced-Failure Modes in Buildings and Civil Infrastructure Facilities. Pract. Period. Struct. Des. Constr. 2023, 28, 05023005. [Google Scholar] [CrossRef]

- Álvarez-Pérez, J.; Mesa-Lavista, M.; Chávez-Gómez, J.H.; Fajardo-San Miguel, G.; Carpio-Santamaría, F.A.; García-Cedeño, R. Analysis of behavior and uniaxial compression failure modes in ungrouted hollow concrete block masonry and their implication in design expressions. J. Build. Eng. 2024, 98, 111048. [Google Scholar] [CrossRef]

- Debnath, P.; Dutta, S.C.; Mandal, P. Lateral behaviour of masonry walls with different types of brick bonds, aspect ratio and strengthening measures by polypropylene bands and wire mesh. In Structures; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Maheri, M.R.; Moslemi, A.; Najafgholipour, M. The effects of brick wall and RC tie variables on the seismic performance of low-rise confined masonry buildings. J. Build. Eng. 2024, 95, 110289. [Google Scholar] [CrossRef]

- Borah, B.; Kaushik, H.B.; Singhal, V. Lateral load-deformation models for seismic analysis and performance-based design of confined masonry walls. J. Build. Eng. 2022, 48, 103978. [Google Scholar] [CrossRef]

- Vargas, L.; Aguilar, V.; Calderón, S.; Araya-Letelier, G.; Sandoval, C. Design of partially grouted reinforced masonry shear walls in an earthquake-prone area: Proposal based on the LRFD approach. Eng. Struct. 2025, 330, 119915. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, Y.; Sun, H.; Yang, H.; Sun, M.; Wang, R.; Jia, Y.; Wang, S. Seismic behavior and repairability of new composite concrete block wall with distributed slipping damage. In Structures; Elsevier: Amsterdam, The Netherlands, 2025. [Google Scholar]

- Dorji, S.; Derakhshan, H.; Thambiratnam, D.P.; Zahra, T.; Mohyeddin, A. Behaviour and material properties of versaloc semi-interlocking mortarless masonry. Mater. Struct. 2023, 56, 17. [Google Scholar] [CrossRef]

- Xin, R.; Jia, F.; Hamid, M.; Ma, R.; Lu, Z. Experimental study on the in-plane seismic performance of fully grouted interlocking block walls. J. Build. Eng. 2024, 97, 110851. [Google Scholar] [CrossRef]

- Gallegos, H. Mortarless masonry: The Mecano system. Int. J. Hous. Sci. Its Appl. 1988, 12, 145–157. [Google Scholar]

- Thanoon, W.A.; Jaafar, M.S.; Kadir, M.R.A.; Ali, A.A.A.; Trikha, D.; Najm, A.M. Development of an innovative interlocking load bearing hollow block system in Malaysia. Constr. Build. Mater. 2004, 18, 445–454. [Google Scholar] [CrossRef]

- Qamar, F.; Thomas, T.; Ali, M. Improvement in lateral resistance of mortar-free interlocking wall with plaster having natural fibres. Constr. Build. Mater. 2020, 234, 117387. [Google Scholar] [CrossRef]

- Tan, S.K.; Ma, H.; Ma, Q. A Review of Interlocking Earth Block: Material Modification, Block Structural System, and Seismic Performance. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 3275–3291. [Google Scholar] [CrossRef]

- El-Azizy, O.A.; Ezzeldin, M.; El-Dakhakhni, W. Comparative analyses of reinforced masonry and reinforced concrete shear walls with different end configurations: Seismic performance and economic assessment. Eng. Struct. 2023, 296, 116852. [Google Scholar] [CrossRef]

- Li, J.; Zhou, H.; Chen, W.; Chen, Z. Shear properties of a new type recycled aggregate concrete interlocking hollow block masonry with axial load. Adv. Struct. Eng. 2021, 24, 2735–2747. [Google Scholar] [CrossRef]

- Gul, A.; Alam, B.; Khan, I.U.; Shah, S.A.A.; Khan, S.W.; Shahzada, K. Improving seismic capacity of dry stacked interlocking masonry structure through confinement at corners. Soil Dyn. Earthq. Eng. 2023, 165, 107710. [Google Scholar] [CrossRef]

- Ali, M.; Briet, R.; Chouw, N. Dynamic response of mortar-free interlocking structures. Constr. Build. Mater. 2013, 42, 168–189. [Google Scholar] [CrossRef]

- Shuai, L.; Zhang, J.; Wu, T.; Zhang, Z.; Liu, S.; Liu, B. Seismic behavior of load-bearing horizontal-hole interlocking concrete block masonry walls: An experimental investigation of variable configurations. Eng. Struct. 2024, 307, 117939. [Google Scholar] [CrossRef]

- Sathurshan, M.; Derakhshan, H.; Thamboo, J.; Gill, J.; Inglis, C.; Zahra, T. Compressive strength in grouted dry-stack concrete block masonry: Experimental and analytical predictions. Constr. Build. Mater. 2025, 467, 140411. [Google Scholar] [CrossRef]

- Mohamed, N.A.G.; Moustafa, A.; Darwish, E. Structural, acoustical, and thermal evaluation of an experimental house built with reinforced/hollow interlocking compressed stabilized earth brick-masonry. J. Build. Eng. 2024, 86, 108790. [Google Scholar] [CrossRef]

- Anuar, S.Z.K.; Nordin, A.H.; Husna, S.M.N.; Yusoff, A.H.; Paiman, S.H.; Noor, S.F.M.; Nordin, M.L.; Ali, S.N.; Ismail, Y.M.N.S. Recent advances in recycling and upcycling of hazardous plastic waste: A review. J. Environ. Manag. 2025, 380, 124867. [Google Scholar] [CrossRef]

- Xu, T.; Lv, Q.; Sheng, G.; Zhang, Y.; Liu, Y.; Shi, L. Evolving patterns and drivers of waste plastic trade in key global economies. Resources, Conservation and Recycling 2024, 206, 107606. [Google Scholar] [CrossRef]

- Pobłocki, K.; Pawlak, M.; Drzeżdżon, J.; Jacewicz, D. Catalytic materials based on metals (ions) used in the upcycling of plastics and polymers into fuels and valuable chemicals as part of sustainable development. Mater. Sci. Eng. R Rep. 2025, 162, 100881. [Google Scholar] [CrossRef]

- Yusuf, B.O.; Abdalla, T.A.; Alahmari, T.S.; Hassan, R. Adaptive reuse of waste plastic as binders in composites for sustainable construction. Clean. Eng. Technol. 2024, 22, 100812. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Mohammed, A.A. Engineering properties of geopolymer concrete composites incorporated recycled plastic aggregates modified with nano-silica. J. Build. Eng. 2023, 75, 106942. [Google Scholar] [CrossRef]

- Titone, V.; Botta, L.; La Mantia, F.P. Mechanical recycling of new and challenging polymer systems: A brief overview. Macromol. Mater. Eng. 2025, 310, 2400275. [Google Scholar] [CrossRef]

- Russo, C.; Wiszumirska, K.; Wojciechowska, P.; Cappelletti, G.M.; Nicoletti, G.M.; Klamecki, H.; Pawlicka, A. Assessing the sustainability of an innovative closed-loop process of mechanical recycling of agricultural stretch film from a life cycle perspective. Environ. Impact Assess. Rev. 2025, 112, 107800. [Google Scholar] [CrossRef]

- Nováková, K.; Šeps, K.; Achten, H. Experimental development of a plastic bottle usable as a construction building block created out of polyethylene terephthalate: Testing PET (b) rick 1.0. J. Build. Eng. 2017, 12, 239–247. [Google Scholar] [CrossRef]

- Babaremu, K.; Adediji, A.; Olumba, N.; Okoya, S.; Akinlabi, E.; Oyinlola, M. Technological advances in mechanical recycling innovations and corresponding impacts on the circular economy of plastics. Environments 2024, 11, 38. [Google Scholar] [CrossRef]

- Bharadwaaj, S.K.; Jaudan, M.; Kushwaha, P.; Saxena, A.; Saha, B. Exploring cutting-edge approaches in plastic recycling for a greener future. Results Eng. 2024, 23, 102704. [Google Scholar] [CrossRef]

- Tian, L.; Zhang, P.; Li, C.; Xian, G. In-situ pultrusion of thermoplastic acrylate-based FRP bars with mechanical properties comparable to industrial thermoset profiles. J. Build. Eng. 2025, 106, 112622. [Google Scholar] [CrossRef]

- Ahmed, S.; Ali, M. Potential Applications of Different Forms of Recycled Plastics as Construction Materials—A Review. Eng. Proc. 2023, 53, 5. [Google Scholar]

- Taghavi, N.; Udugama, I.A.; Zhuang, W.-Q.; Baroutian, S. Challenges in biodegradation of non-degradable thermoplastic waste: From environmental impact to operational readiness. Biotechnol. Adv. 2021, 49, 107731. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Huang, Z.; Qin, Y.; Zhi, W. Industrialized fine physical regeneration process and economic benefit assessment for recycling waste HDPE containers. J. Clean. Prod. 2024, 447, 141477. [Google Scholar] [CrossRef]

- Zhang, J.; Hirschberg, V.; Goecke, A.; Wilhelm, M.; Yu, W.; Orfgen, M.; Rodrigue, D. Effect of mechanical recycling on molecular structure and rheological properties of high-density polyethylene (HDPE). Polymer 2024, 297, 126866. [Google Scholar] [CrossRef]

- Gnoffo, C.; Arrigo, R.; Frache, A. Mechanical recycling of HDPE-based packaging: Interplay between cross contamination, aging and reprocessing. Polym. Degrad. Stab. 2025, 236, 111290. [Google Scholar] [CrossRef]

- López-Malest, A.; Gabor, M.R.; Panait, M.; Brezoi, A.; Veres, C. Green Innovation for Carbon Footprint Reduction in Construction Industry. Buildings 2024, 14, 374. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Abed, F.; Beddu, S.; Humada, A.M.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Enhancing sustainability in concrete construction: A comprehensive review of plastic waste as an aggregate material. Sustain. Mater. Technol. 2024, 40, e00877. [Google Scholar] [CrossRef]

- Liu, L.; Barlaz, M.A.; Johnson, J.X. Economic and environmental comparison of emerging plastic waste management technologies. Resour. Conserv. Recycl. 2024, 205, 107531. [Google Scholar] [CrossRef]

- García-Gutiérrez, P.; Amadei, A.M.; Klenert, D.; Nessi, S.; Tonini, D.; Tosches, D.; Ardente, F.; Saveyn, H.G. Environmental and economic assessment of plastic waste recycling and energy recovery pathways in the EU. Resour. Conserv. Recycl. 2025, 215, 108099. [Google Scholar] [CrossRef]

- Al-Kerttani, O.M.G.; Hilal, N.; Hama, S.M.; Sor, N.H.; Banyhussan, Q.S.; Tawfik, T.A. Durability and hardened characteristics of cement mortar incorporating waste plastic and Polypropylene exposed to MgSO4 attack. Results Eng. 2024, 24, 103310. [Google Scholar] [CrossRef]

- Olsen, K.; Ulus, H.; Head, M.H.; Advani, S.G. Effect of particle size and replacement ratio on mechanical performance of cementitious mortar containing ground recycled acrylonitrile butadiene styrene (GRABS) waste plastics. Compos. Part B Eng. 2025, 289, 111914. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, Q.; Zhou, L.; Jiang, T.; Dong, C.; Zhang, Q. Mechanical properties, durability and life-cycle assessment of waste plastic fiber reinforced sustainable recycled aggregate self-compacting concrete. J. Build. Eng. 2024, 91, 109683. [Google Scholar] [CrossRef]

- Jin, D.; Park, J.H.; Nam, J.; Kim, S. Repurposing recycled plastic banners for the development and creation of innovative high-performance building insulation materials. Case Stud. Constr. Mater. 2025, 22, e04521. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Farina, A.; Yang, B.; Ceylan, H.; Kim, S.; Tutumluer, E.; Cetin, B. The utilization of recycled plastics in the transportation infrastructure systems: A comprehensive review. Constr. Build. Mater. 2024, 411, 134448. [Google Scholar] [CrossRef]

- Zeiada, W.; Al-Khateeb, G.; Hajj, E.Y.; Ezzat, H. Rheological properties of plastic-modified asphalt binders using diverse plastic wastes for enhanced pavement performance in the UAE. Constr. Build. Mater. 2024, 452, 138922. [Google Scholar] [CrossRef]

- Musa, A.E.; Ahmed, A.; Ahmed, S.; Mohamed, K.; Al-Fakih, A.; Al-Osta, M.A. Properties of concrete incorporating plastic wastes and its applications: A comprehensive review. J. Build. Eng. 2025, 101, 111843. [Google Scholar] [CrossRef]

- Sau, D.; Shiuly, A.; Hazra, T. Utilization of plastic waste as replacement of natural aggregates in sustainable concrete: Effects on mechanical and durability properties. Int. J. Environ. Sci. Technol. 2024, 21, 2085–2120. [Google Scholar] [CrossRef] [PubMed]

- Callejas, I.J.A.; da Guarda, E.L.A.; Durante, L.C.; Krüger, E. Cement roof tiles manufactured with PET waste: Experimental tests and thermal building simulations. J. Clean. Prod. 2025, 495, 145063. [Google Scholar] [CrossRef]

- Chen, H.; Qin, R.; Chow, C.L.; Lau, D. Recycling thermoset plastic waste for manufacturing green cement mortar. Cem. Concr. Compos. 2023, 137, 104922. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Yusuf, M.; Kamyab, H.; Chelliapan, S. Development of sand-plastic composites as floor tiles using silica sand and recycled thermoplastics: A sustainable approach for cleaner production. Sci. Rep. 2022, 12, 18921. [Google Scholar] [CrossRef] [PubMed]

- Sudheer, M.; Ali, M. Dynamic response of an interlocking plastic-block wall with opening. J. Mech. Mater. Struct. 2024, 19, 595–613. [Google Scholar] [CrossRef]

- Das, A.J.; Ali, M. Prospective Use and Assessment of Recycled Plastic in Construction Industry. Recycling 2025, 10, 41. [Google Scholar] [CrossRef]

- Das, A.J.; Ali, M. Sustainable Development and Assessment of Low-Strength/High-Toughness Recycled Plastic Rebars for Structural Elements Under Light Loads. Sustainability 2025, 17, 4997. [Google Scholar] [CrossRef]

- Das, A.J.; Ali, M. Multiscale Evaluation of Recycled Plastic Corrugated Panels for Sustainable Construction. Buildings 2025, 15, 2423. [Google Scholar] [CrossRef]

- ASTM D695-23; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D732-17; Standard Test Method for Shear Strength of Plastics by Punch Tool. ASTM International: West Conshohcken, PA, USA, 2017.

- ASTM D570-22; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM E1876-22; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 2022.

- BS EN 1052-1; Methods of Test for Masonry—Determination of Compressive Strength. British Standards Institution: London, UK, 1999.

- BS EN 1052-3; Methods of Test for Masonry—Determination of Initial Shear Strength. British Standards Institution: London, UK, 2002.

- Nadeem, M.; Gul, A.; Bahrami, A.; Azab, M.; Khan, S.W.; Shahzada, K. Evaluation of mechanical properties of cored interlocking blocks–A step toward affordable masonry material. Results Eng. 2023, 18, 101128. [Google Scholar] [CrossRef]

- Lin, K.; Totoev, Y.Z.; Liu, H.; Wei, C. Experimental characteristics of dry stack masonry under compression and shear loading. Materials 2015, 8, 8731–8744. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Yong, C.L.; Tan, T.H.; Onn, C.C.; Sinoh, S.S.; Hung, C.-C.; Mo, K.H. Innovative valorization of basic oxygen furnace slag in gypsum-based sustainable building blocks. J. Build. Eng. 2025, 105, 112489. [Google Scholar] [CrossRef]

- Kuoribo, E.; Shokry, H.; Mahmoud, H. Attaining material circularity in recycled construction waste to produce sustainable concrete blocks for residential building applications. J. Build. Eng. 2024, 96, 110503. [Google Scholar] [CrossRef]

- Irfan-ul-Hassan, M.; Daud, M.; Rashid, K.; Alqahtani, F.K.; Zafar, I.; Batool, U. Development and sustainability assessment of red mud-based green bricks: Techno-economic and environmental performance. J. Build. Eng. 2024, 95, 110350. [Google Scholar] [CrossRef]

- Sarhat, S.R.; Sherwood, E.G. The prediction of compressive strength of ungrouted hollow concrete block masonry. Constr. Build. Mater. 2014, 58, 111–121. [Google Scholar] [CrossRef]

- BS EN 771-1; Specification for Masonry Units-Part 1: Clay Masonry Units. British Standards Institution: London, UK, 2003.

- BE 5628-1; Code of Practice for the Structural Use of Masonry—Part 1: Unreinforced Masonry. British Standards Institution: London, UK, 2005.

| Test | (MPa) | (—) | (MJ/m3) | (MJ/m3) | (MJ/m3) | T. I. (—) |

|---|---|---|---|---|---|---|

| Compression | 29.92 ± 0.94 | 0.10 ± 0.00 | 1.83 ± 0.26 | 0.00 ± 0.00 | 1.83 ± 0.26 | 1.00 ± 0.00 |

| Shear | 21.77 ± 0.98 | 0.41 ± 0.01 | 5.88 ± 0.04 | 9.80 ± 0.34 | 15.67 ± 0.30 | 2.67 ± 0.06 |

| Block Configurations | Label | Properties | ||||

|---|---|---|---|---|---|---|

| Dynamic | Compressive | In-Plane Shear | Out-of-Plane Shear | |||

| Single-Unit Standard IHB | SUS | ✓ | ✓ | - | - |

| Double-Unit Standard IHB | DUS | ✓ | ✓ | - | - |

| Triple-Unit Standard IHB | TUS | ✓ | ✓ | - | - |

| Single-Unit Top IHB | SUT | ✓ | ✓ | - | - |

| Double-Unit Top IHB | DUT | ✓ | ✓ | - | - |

| Triple-Unit Top IHB | TUT | ✓ | ✓ | - | - |

| Three Standard IHBs (Standard Prism) | SP | - | ✓ | ✓ | ✓ |

| Top + Two Standard IHBs (Top Prism) | TP | - | ✓ | - | - |

| Parameter | Units | Samples | |||||

|---|---|---|---|---|---|---|---|

| SUS | DUS | TUS | SUT | DUT | TUT | ||

| Hz | 352.5 ± 19.6 | 443.9 ± 0.0 | 676.9 ± 33.3 | 221.9 ± 0.0 | 413.6 ± 30.3 | 676.9 ± 11.1 | |

| Hz | 1243.5 ± 45.5 | 921.5 ± 33.7 | 1369.9 ± 50.2 | 1264.5 ± 22.5 | 932.2 ± 0.0 | 1469.9 ± 49.9 | |

| Hz | 1187.4 ± 78.4 | 1341.3 ± 10.3 | 1287.0 ± 0.0 | 1153.5 ± 44.5 | 1442.0 ± 22.0 | 1309.0 ± 22.0 | |

| Hz | 621.4 ± 0.0 | 859.4 ± 16.0 | 1045.6 ± 69.1 | 799.0 ± 0.0 | 932.2 ± 0.0 | 1398.0 ± 22.0 | |

| % | 14.1 ± 1.5 | 10.9 ± 2.3 | 9.1 ± 1.2 | 29.9 ± 2.3 | 14.4 ± 1.8 | 10.8 ± 1.2 | |

| % | 4.2 ± 1.1 | 5.0 ± 0.3 | 3.3 ± 0.7 | 4.8 ± 1.8 | 6.1 ± 0.0 | 3.8 ± 0.9 | |

| % | 5.1 ± 0.0 | 3.3 ± 0.9 | 3.8 ± 0.1 | 7.5 ± 1.1 | 3.6 ± 0.9 | 4.0 ± 0.3 | |

| % | 9.7 ± 0.5 | 5.4 ± 0.4 | 4.3 ± 0.0 | 11.3 ± 1.8 | 5.6 ± 0.5 | 4.7 ± 0.0 | |

| Samples | EMstatic | T. I. | |||||

|---|---|---|---|---|---|---|---|

| (MPa) | (—) | (MPa) | (MJ/m3) | (MJ/m3) | (MJ/m3) | (—) | |

| SUS | 35.75 ± 1.01 | 0.058 ± 0.00 | 616.38 ± 17.41 | 1.29 ± 0.02 | 0.13 ± 0.11 | 1.42 ± 0.13 | 1.10 ± 0.08 |

| DUS | 33.61 ± 3.65 | 0.062 ± 0.02 | 542.10 ± 58.87 | 1.32 ± 0.56 | 0.24 ± 0.10 | 1.56 ± 0.66 | 1.18 ± 0.00 |

| TUS | 30.99 ± 0.53 | 0.072 ± 0.01 | 430.42 ± 7.36 | 1.04 ± 0.10 | 0.23 ± 0.04 | 1.27 ± 0.05 | 1.23 ± 0.06 |

| SUT | 18.74 ± 1.46 | 0.168 ± 0.04 | 111.55 ± 8.69 | 2.49 ± 0.88 | 1.09 ± 0.00 | 3.58 ± 1.97 | 1.32 ± 0.32 |

| DUT | 17.82 ± 0.48 | 0.189 ± 0.02 | 94.29 ± 2.54 | 2.61 ± 0.36 | 0.78 ± 0.38 | 3.39 ± 0.73 | 1.29 ± 0.11 |

| TUT | 12.23 ± 1.94 | 0.146 ± 0.01 | 83.77 ± 13.29 | 1.32 ± 0.31 | 0.56 ± 0.34 | 1.87 ± 0.65 | 1.38 ± 0.17 |

| SP | 34.23 ± 3.88 | 0.046 ± 0.01 | 744.13 ± 84.35 | 0.92 ± 0.35 | 0.01 ± 0.00 | 0.92 ± 0.35 | 1.01 ± 0.01 |

| TP | 12.34 ± 1.83 | 0.053 ± 0.00 | 232.83 ± 34.53 | 0.44 ± 0.11 | 0.18 ± 0.12 | 0.62 ± 0.23 | 1.36 ± 0.20 |

| Loading Direction | T. I. | ||||||

|---|---|---|---|---|---|---|---|

| (MPa) | (MPa) | (—) | (MJ/m3) | (MJ/m3) | (MJ/m3) | (—) | |

| In plane | 0.2 | 2.09 ± 0.12 | 0.054 ± 0.00 | 0.07 ± 0.01 | 0.01 ± 0.00 | 0.08 ± 0.00 | 1.17 ± 0.04 |

| 0.6 | 2.30 ± 0.05 | 0.071 ± 0.00 | 0.10 ± 0.01 | 0.01 ± 0.00 | 0.11 ± 0.01 | 1.12 ± 0.01 | |

| 1.0 | 2.44 ± 0.00 | 0.066 ± 0.00 | 0.12 ± 0.01 | 0.01 ± 0.00 | 0.12 ± 0.01 | 1.07 ± 0.01 | |

| Out of plane | 0.2 | 1.51 ± 0.05 | 0.099 ± 0.01 | 0.10 ± 0.00 | 0.03 ± 0.00 | 0.13 ± 0.00 | 1.30 ± 0.04 |

| 0.6 | 1.56 ± 0.01 | 0.110 ± 0.00 | 0.11 ± 0.00 | 0.04 ± 0.00 | 0.14 ± 0.01 | 1.32 ± 0.01 | |

| 1.0 | 1.66 ± 0.03 | 0.103 ± 0.01 | 0.11 ± 0.00 | 0.04 ± 0.00 | 0.15 ± 0.01 | 1.35 ± 0.01 |

| Loading Direction | Actual | Predicted | Absolute Difference | |

|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | (%) | |

| In plane | 0.2 | 2.09 | 2.09 | 0.00 |

| 0.6 | 2.30 | 2.27 | 1.30 | |

| 1.0 | 2.44 | 2.45 | 0.41 | |

| Out of plane | 0.2 | 1.51 | 1.49 | 1.32 |

| 0.6 | 1.56 | 1.57 | 0.64 | |

| 1.0 | 1.66 | 1.65 | 0.60 |

| Sr. No. | Sample | Element | Weight (%) | Atomic (%) | Compound |

|---|---|---|---|---|---|

| 1. | Compression-tested block | C | 87.95 | 94.32 | CaCO3 |

| O | 3.44 | 2.77 | SiO2 | ||

| Al | 0.31 | 0.15 | Al2O3 | ||

| Si | 0.89 | 0.41 | SiO2 | ||

| Cl | 0.44 | 0.16 | KCl | ||

| Ca | 6.11 | 1.97 | CaSiO3 | ||

| Ti | 0.86 | 0.23 | Ti | ||

| 2. | In-plane shear-tested block | C | 94.36 | 96.13 | CaCO3 |

| O | 4.64 | 3.55 | SiO2 | ||

| Cl | 0.26 | 0.09 | KCl | ||

| Ca | 0.73 | 0.22 | CaSiO3 | ||

| 3. | Out-of-plane shear-tested block | C | 79.05 | 89.54 | CaCO3 |

| O | 6.28 | 5.34 | SiO2 | ||

| Al | 0.22 | 0.11 | Al2O3 | ||

| Si | 0.74 | 0.36 | SiO2 | ||

| Cl | 0.56 | 0.22 | KCl | ||

| K | 0.32 | 0.11 | KAlSi3O8 | ||

| Ca | 12.26 | 4.16 | CaSiO3 | ||

| Ti | 0.55 | 0.16 | Ti |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, S.; Ali, M. Development and Engineering Evaluation of Interlocking Hollow Blocks Made of Recycled Plastic for Mortar-Free Housing. Buildings 2025, 15, 2996. https://doi.org/10.3390/buildings15172996

Ahmed S, Ali M. Development and Engineering Evaluation of Interlocking Hollow Blocks Made of Recycled Plastic for Mortar-Free Housing. Buildings. 2025; 15(17):2996. https://doi.org/10.3390/buildings15172996

Chicago/Turabian StyleAhmed, Shehryar, and Majid Ali. 2025. "Development and Engineering Evaluation of Interlocking Hollow Blocks Made of Recycled Plastic for Mortar-Free Housing" Buildings 15, no. 17: 2996. https://doi.org/10.3390/buildings15172996

APA StyleAhmed, S., & Ali, M. (2025). Development and Engineering Evaluation of Interlocking Hollow Blocks Made of Recycled Plastic for Mortar-Free Housing. Buildings, 15(17), 2996. https://doi.org/10.3390/buildings15172996