Bond–Slip Properties and Acoustic Emission Characterization Between Steel Rebar and Manufactured Sand Concrete

Abstract

1. Introduction

2. Test Program

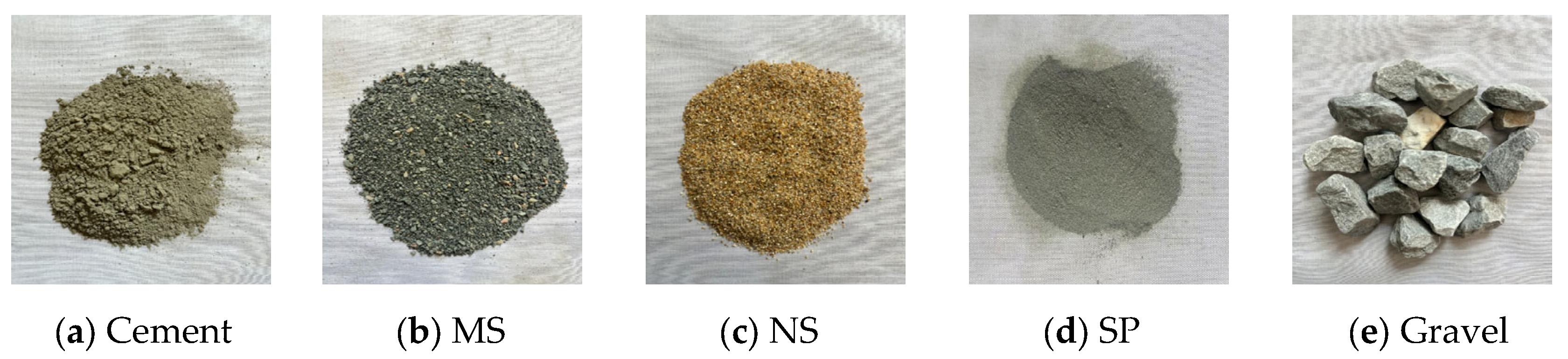

2.1. Materials

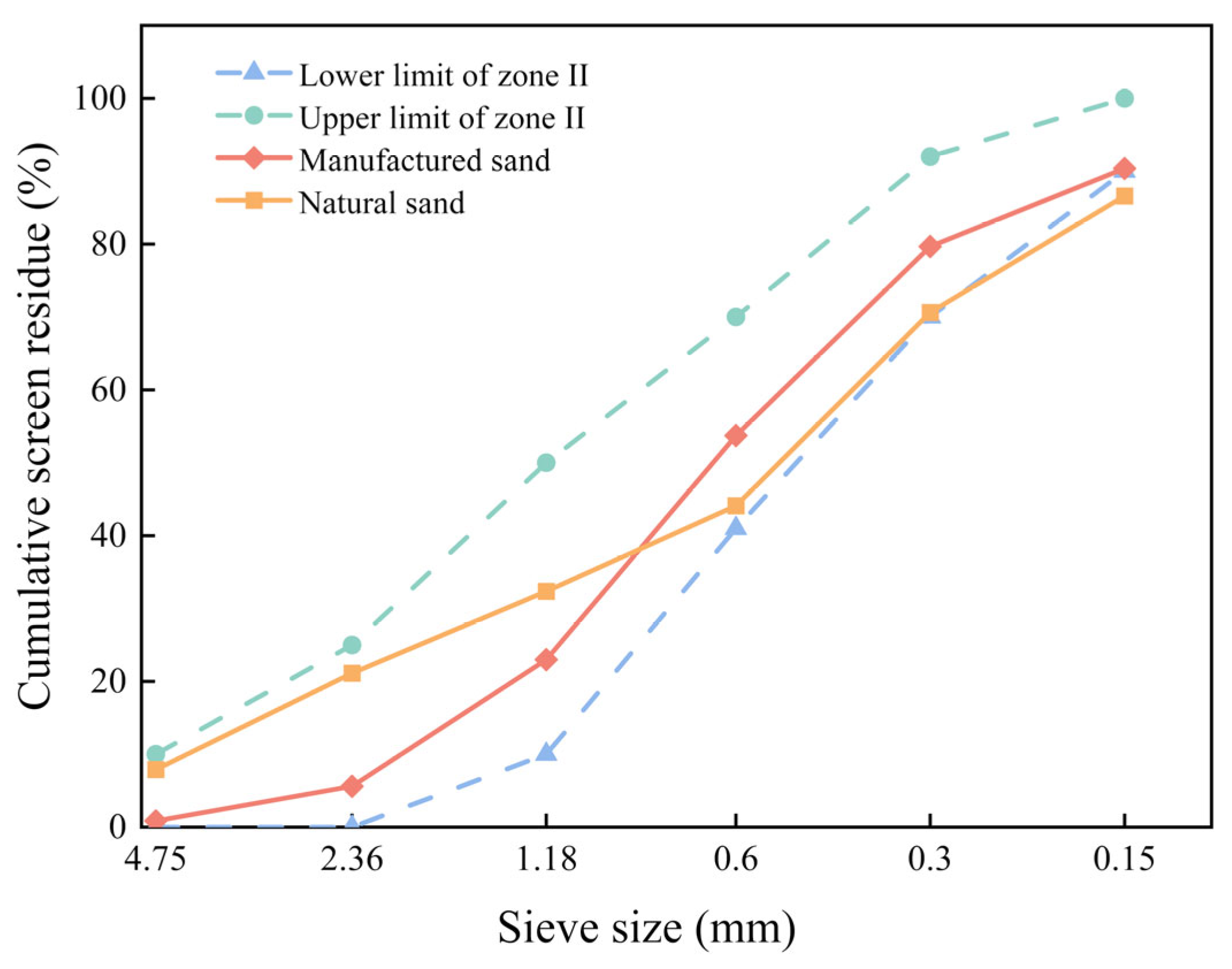

2.1.1. MSC

2.1.2. Steel Rebar

| Performance Indicators | Numerical or Descriptive |

|---|---|

| Rebar grade | HRB400 |

| Standard | GB/T 1499.2-2018 [40] |

| Yielding strength | ≥400 MPa |

| Tensile strength | ≥540 MPa |

| Elongation rate | ≥16% |

| Bending properties | Bend 180° without cracks |

| Weldability | Good welding properties |

2.2. Specimen Setting

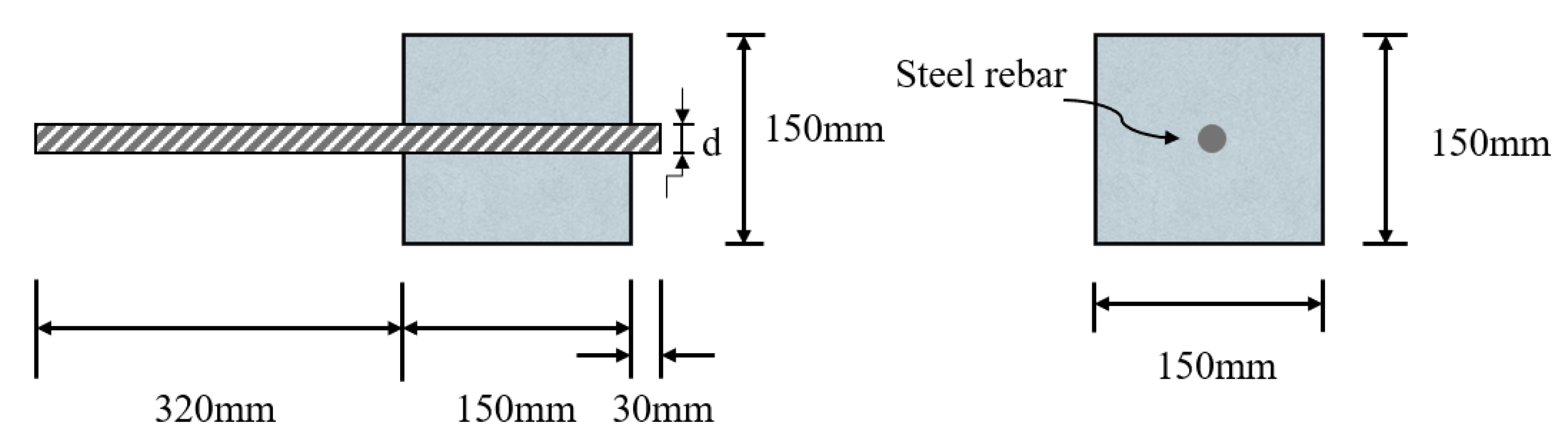

2.2.1. Specimen Details

2.2.2. Proportion of Mixes

2.2.3. Specimen Preparation

2.3. Test Methods

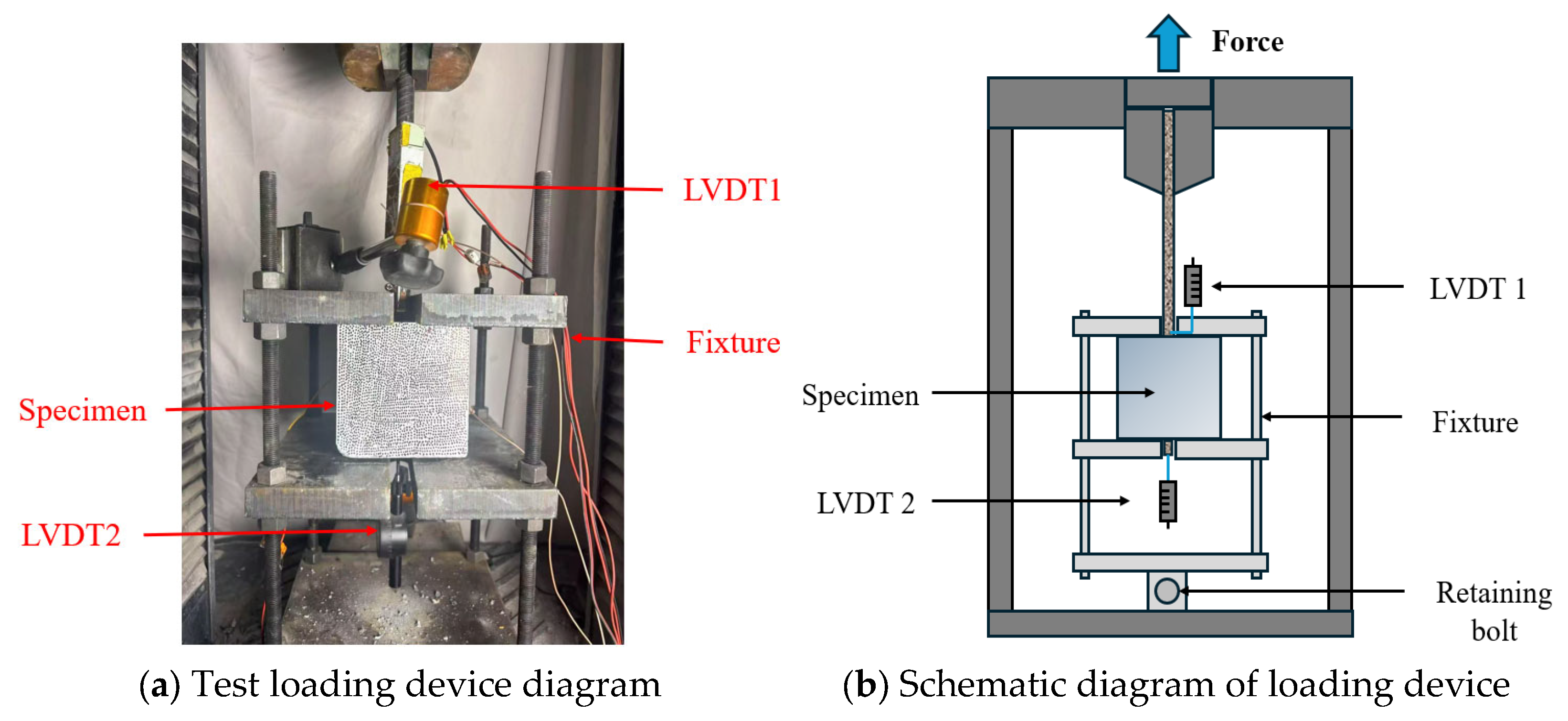

2.3.1. Center Pull-Out Test

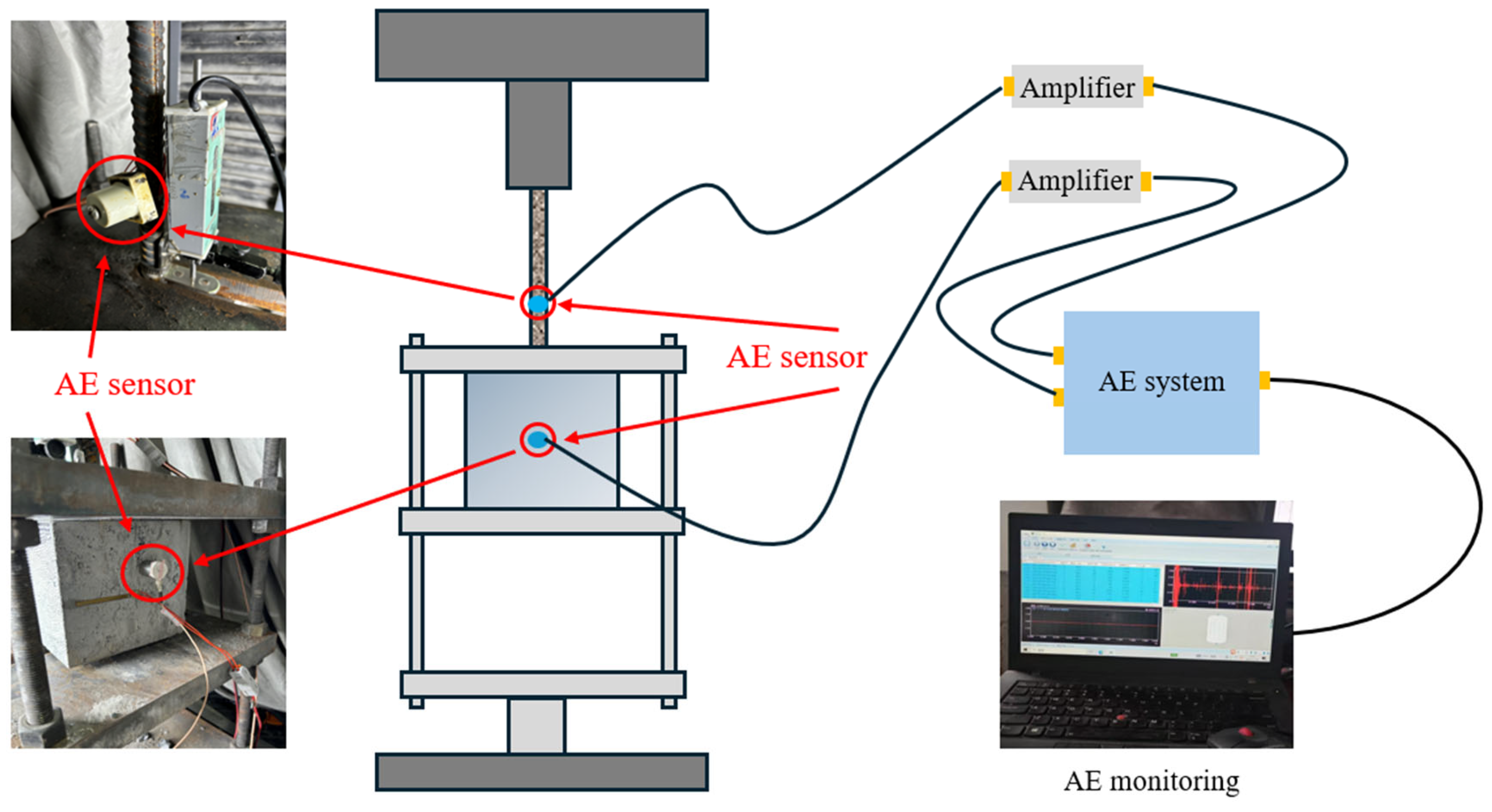

2.3.2. AE Test

3. Results and Analysis

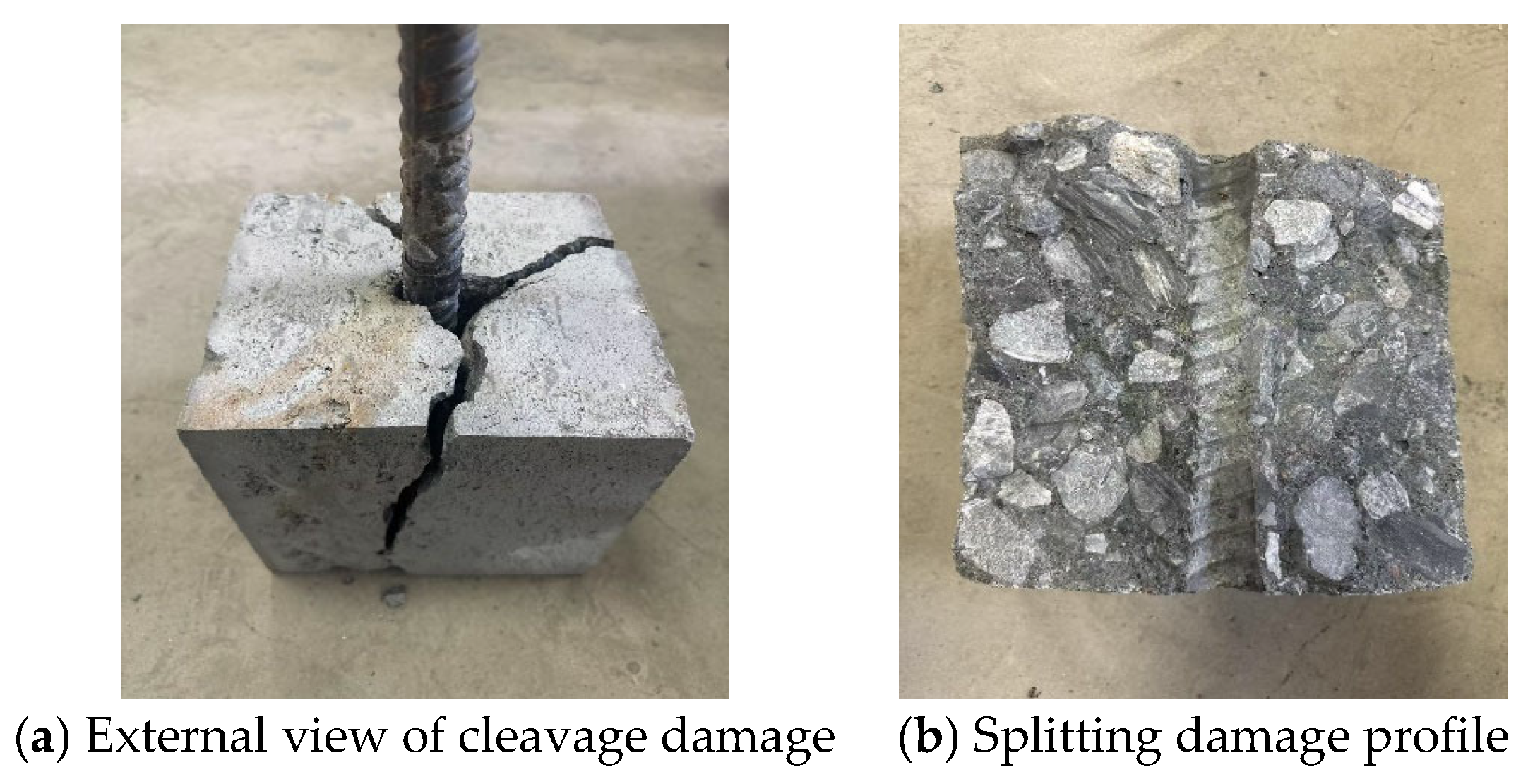

3.1. Destruction Mode

3.2. Bond Strength Analysis of Rebar with MSCs

3.2.1. Bond Stress–Slip Curve Analysis

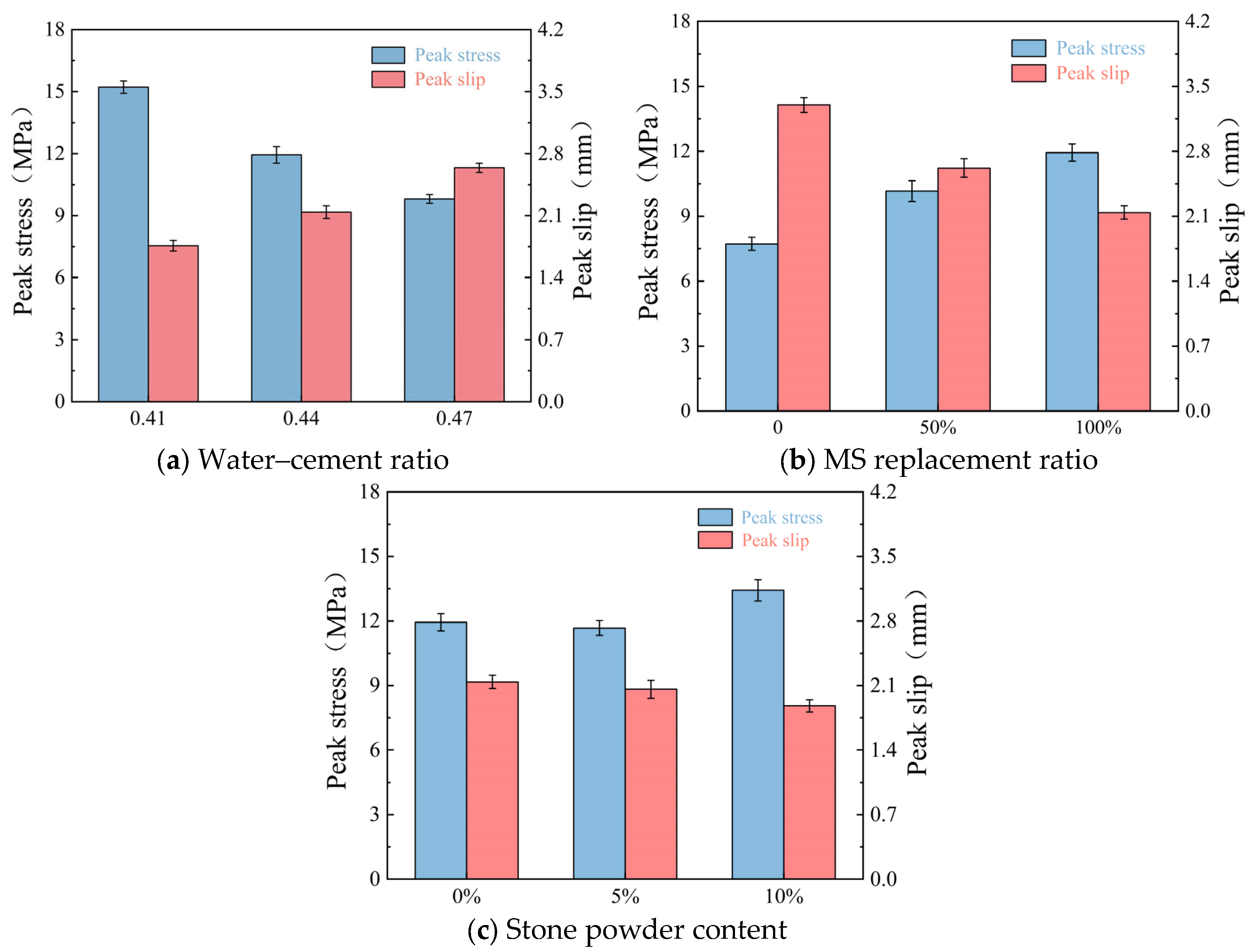

3.2.2. Peak Bond Stress and Peak Slip Analysis

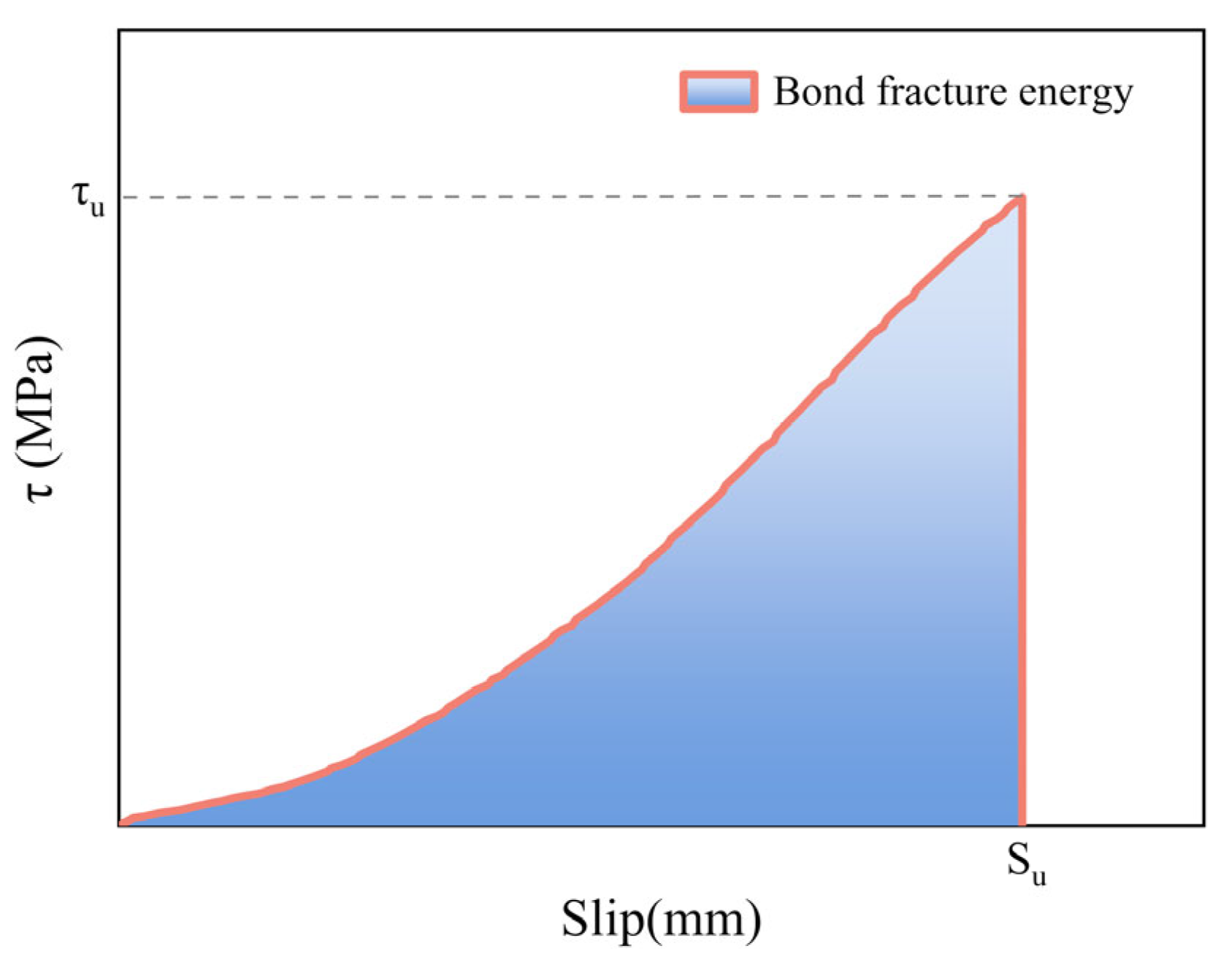

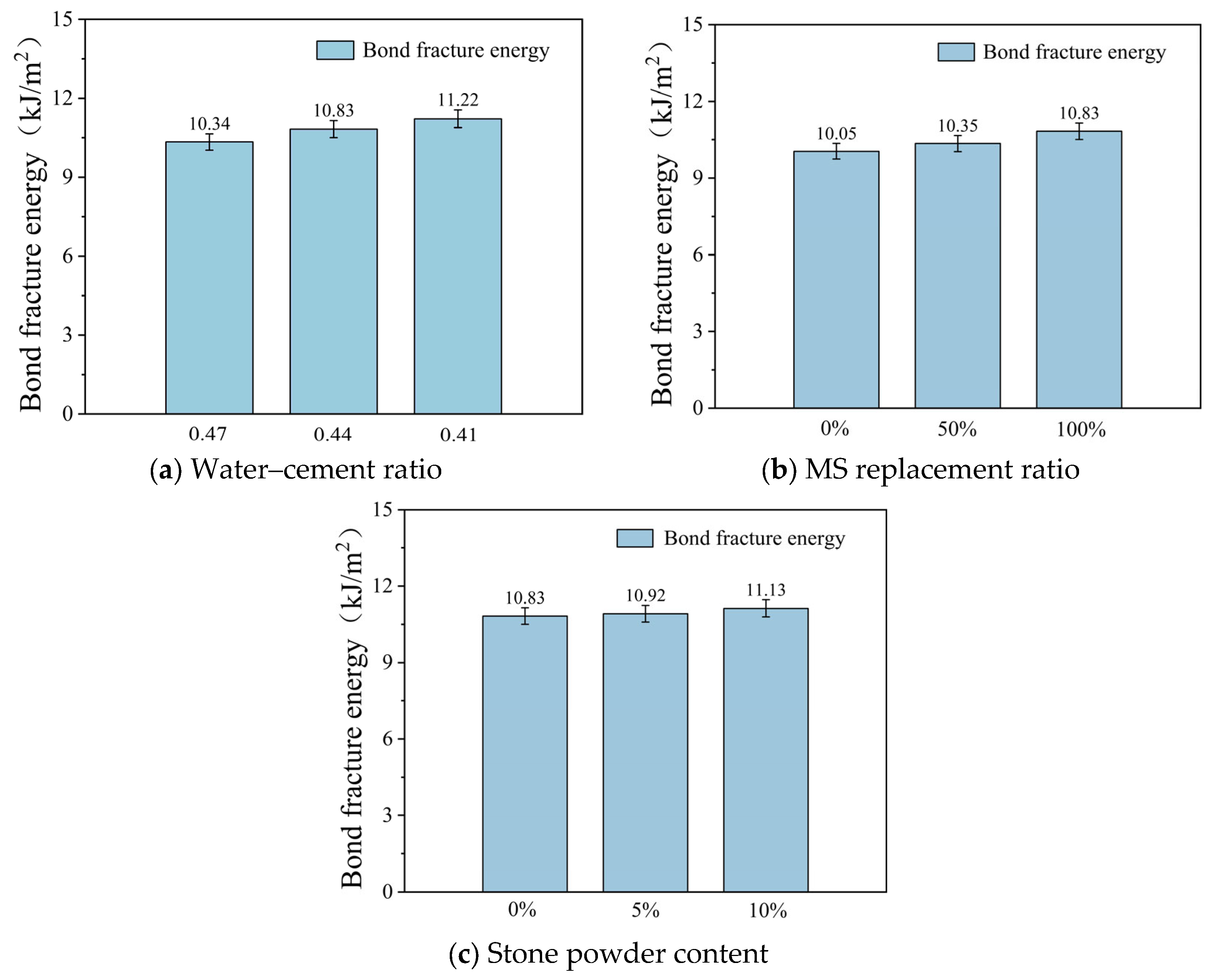

3.2.3. Bond Fracture Energy Analysis

3.3. MSC Damage Analysis Based on Acoustic Emission Parameters

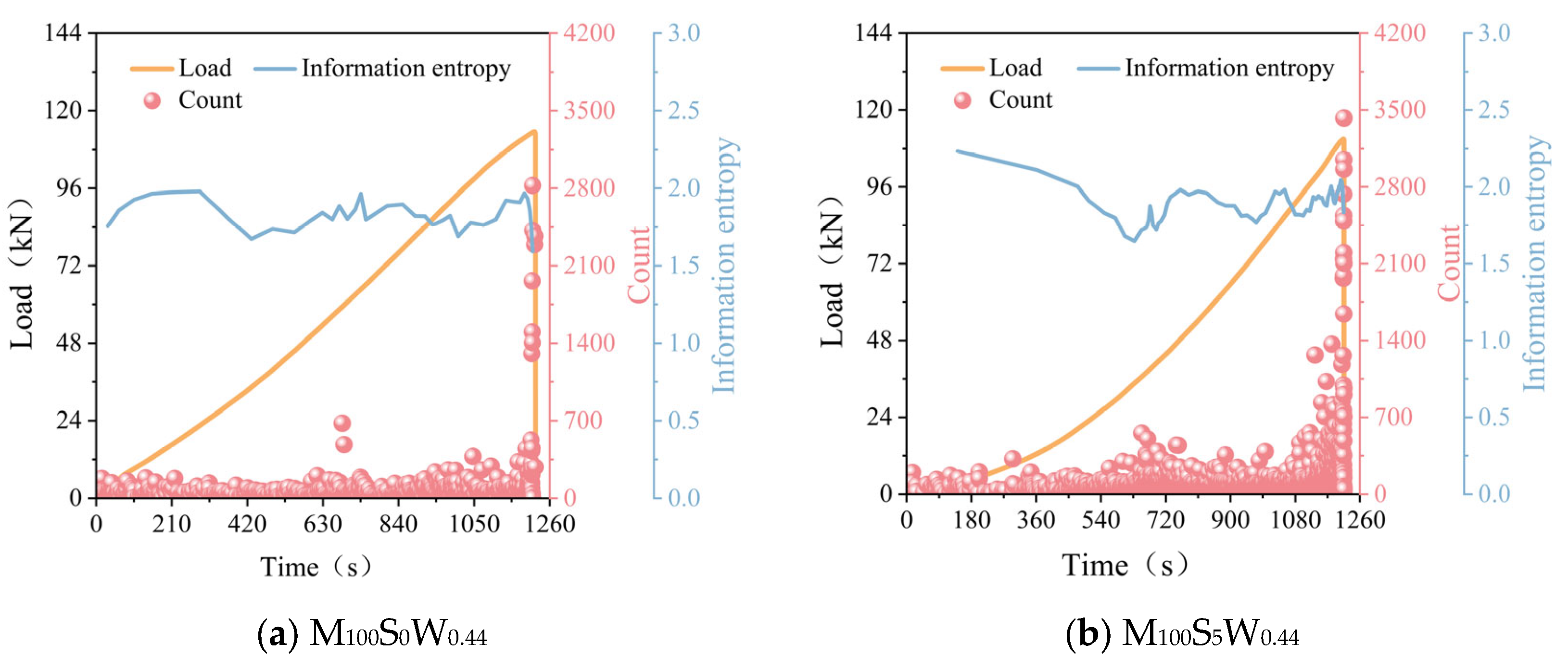

3.3.1. Acoustic Emission Counting and Information Entropy Analysis

- (1)

- MSC with different water–cement ratios

- (2)

- MSC with different replacement rates of MS

- (3)

- MSC with different stone powder contents

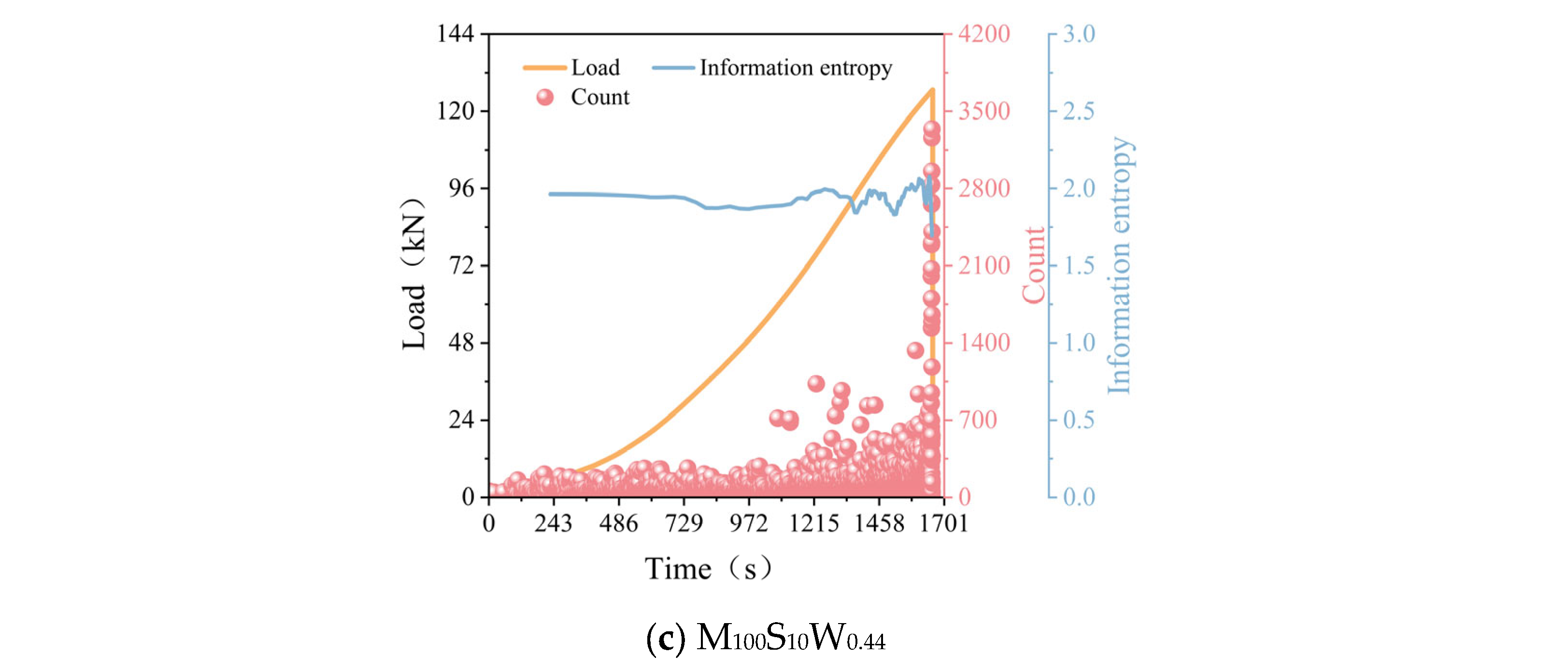

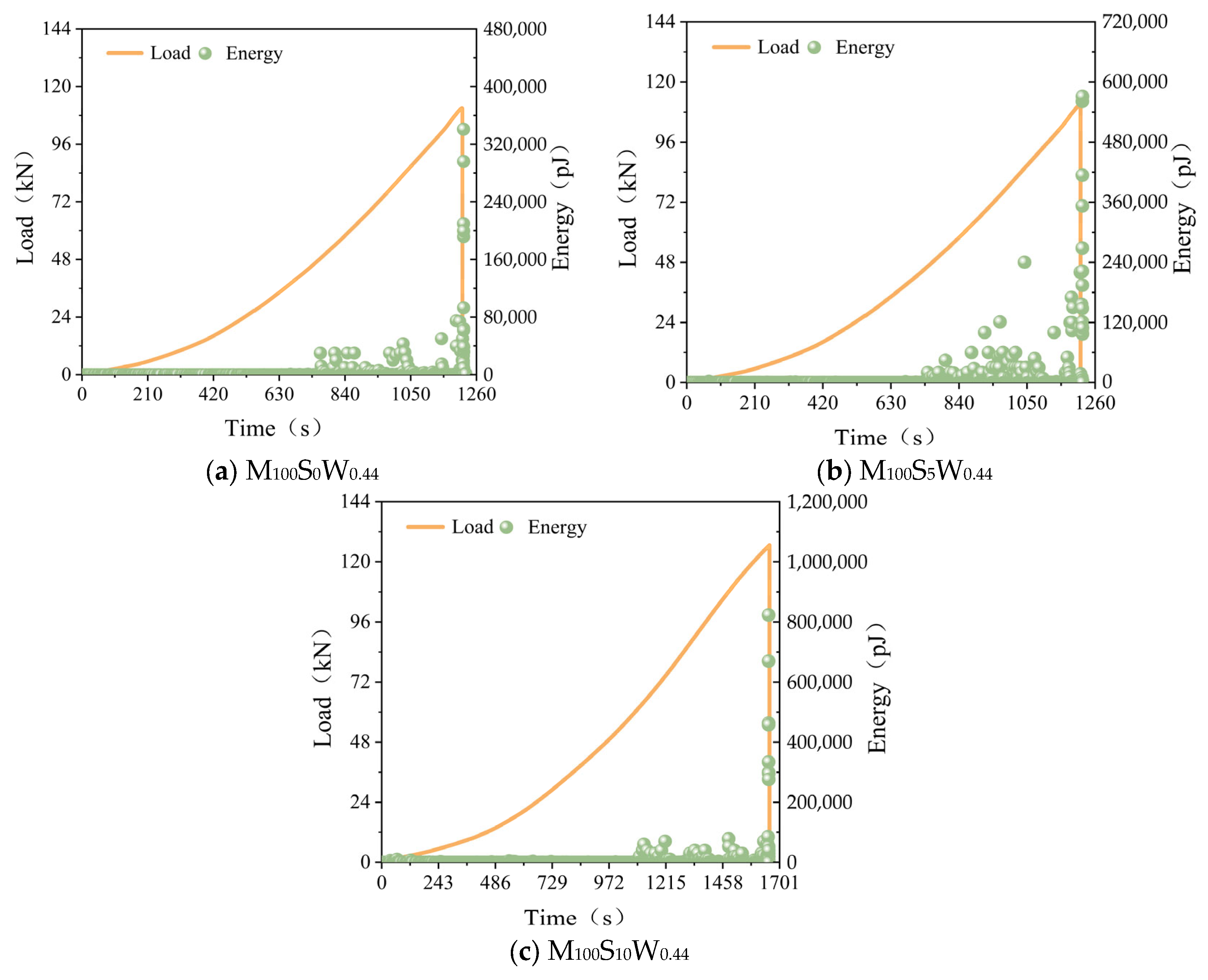

3.3.2. Acoustic Emission Energy Analysis

- (1)

- MSC with different water–cement ratios

- (2)

- MSC with different replacement rates of MS

- (3)

- MSC with different stone powder contents

4. Conclusions

- (1)

- When the water–cement ratio decreased from 0.47 to 0.41, the peak bond stress and bond fracture energy increased by 56.8% and 8.5%, respectively, while the peak slip decreased by 30.5%, indicating a significant enhancement in the bond strength of the reinforced concrete specimens.

- (2)

- As the manufactured sand replacement ratio increased from 0% to 100%, the peak bond stress and bond fracture energy rose by 54.7% and 7.8%, respectively, while the peak slip decreased by 22.7%, demonstrating a significant improvement in the bond strength of the reinforced concrete specimens.

- (3)

- The improvement effect of stone powder incorporation on bond properties was small. When the content of stone powder was increased from 0% to 10%, the peak bond stress was elevated by 12.6%, and the bond fracture energy was slightly increased by 2.8%. Further, the amount of steel rebar slip was reduced by 9.5%, which was weaker than the first two factors, but still reflected a positive regulatory effect.

- (4)

- The damage process was characterized using AE parameters (counts, information entropy, energy). At the beginning of the test, counts and energy were kept at the lowest level and information entropy did not fluctuate significantly. As the test progressed, the specimen produced small cracks, the counts and energy became larger, and the information entropy fluctuated. Finally, the count and energy increased dramatically to reach the maximum value, the information entropy fluctuated dramatically, and the specimen was damaged by splitting.

- (5)

- The damage process was quantified using AE parameters (counts, information entropy, energy). Thresholds for each parameter to reach the three damage stages (no damage at the beginning of the test, appearance and expansion of microcracks, brittle damage) were analyzed. A three-stage warning theory was proposed.

- (6)

- As the water–cement ratio decreases (0.47–0.41), the replacement ratio of mechanism sand increases (0–100%), and the content of stone dust increases (0–10%), the acoustic emission parameters become more and more active, and the threshold increases accordingly.

- (7)

- Based on the experimental results of this paper, it is concluded that in the actual MSC project, it is recommended to use a water–cement ratio greater than 0.44, replace all NS with MS, and keep the content of stone powder in the range of 5–10% as a way to enhance the strength of the material.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alwaeli, M.; Gołaszewski, J.; Niesler, M.; Pizoń, J.; Gołaszewska, M. Recycle option for metallurgical sludge waste as a partial replacement for natural sand in mortars containing CSA cement to save the environment and natural resources. J. Hazard. Mater. 2020, 398, 123101. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K.; Chourasia, A. Alternative fine aggregates in production of sustainable concrete—A review. J. Clean. Prod. 2020, 268, 122089. [Google Scholar]

- Jiang, Z. Green High-Performance Concrete with Manufactured Sand; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Cheng, Y.-H.; Yang, S.-H.; Zhang, J.-Y.; Sun, X.H. Test research on hydration process of cement-iron tailings powder composite cementitious materials. Powder Technol. 2022, 399, 117215. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, Y.; Liu, Z.; Qiao, H.; Ye, F.; Lei, Z. Research on carbon emission reduction of manufactured sand concrete based on compressive strength. Constr. Build. Mater. 2023, 403, 133101. [Google Scholar] [CrossRef]

- Zhang, L.; Song, Y.; Shi, T.; Zhao, Z.; Zhang, X.; Liu, Y.; Li, Q.; Wang, P.; Zhang, F.; Qian, X.; et al. A correlation study between the properties of manufactured sand and tunnel muck. Case Stud. Constr. Mater. 2024, 21, e03684. [Google Scholar] [CrossRef]

- Chandrasekhar, C.; Ransinchung, G.D. Assessment of interface characteristics and durability aspects of manufactured sand (M-sand) in engineered cementitious composites. J. Build. Eng. 2024, 91, 109705. [Google Scholar] [CrossRef]

- Kavya, A.; Rao, A.V. Experimental investigation on mechanical properties of concrete with M-sand. Mater. Today Proc. 2020, 33, 663–667. [Google Scholar] [CrossRef]

- Zhang, J.; Li, D.; Wang, Y. Toward intelligent construction: Prediction of mechanical properties of manufactured-sand concrete using tree-based models. J. Clean. Prod. 2020, 258, 120665. [Google Scholar] [CrossRef]

- Ding, X.; Li, C.; Xu, Y.; Li, F.; Zhao, S. Experimental study on long-term compressive strength of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Shen, W.; Wu, J.; Du, X.; Li, Z.; Wu, D.; Sun, J.; Wang, Z.; Huo, X.; Zhao, D. Cleaner production of high-quality manufactured sand and ecological utilization of recycled stone powder in concrete. J. Clean. Prod. 2022, 375, 134146. [Google Scholar] [CrossRef]

- Zhou, A.; Miao, G.; Zhang, Y.; Qian, R.; Zhang, Y.; Shi, J.; Yang, Y. Effects of stone powder on microstructure of manufactured-sand concrete and its gas permeability. J. Build. Eng. 2024, 91, 109539. [Google Scholar] [CrossRef]

- Yang, X.; Pan, M.; Zheng, S.; Liang, J.; Tan, M.; Rong, H. Influence of stone powder content on carbonation performance of manufactured sand concrete (MSC). J. Build. Eng. 2023, 76, 107341. [Google Scholar] [CrossRef]

- Ren, Q.; Ding, L.; Dai, X.; Li, C.; Li, C.; Jiang, Z. Optimizing mix design of concrete with manufactured sand for low embodied carbon and desired strength using machine learning. Constr. Build. Mater. 2024, 457, 139407. [Google Scholar] [CrossRef]

- Meng, Q.; Jing, X.; Wang, H.; Guo, X.; Song, J.; Du, J. Flexural fatigue properties of concrete based on different replacement percentage of natural sand with manufactured sand. J. Build. Eng. 2024, 87, 108987. [Google Scholar] [CrossRef]

- Jin, K.; Li, Y.; Shen, J.; Lin, H.; Fan, M.; Shi, J. Investigation on compressive strength and splitting tensile strength of manufactured sand concrete: Machine learning prediction and experimental verification. J. Build. Eng. 2024, 97, 110852. [Google Scholar] [CrossRef]

- Zhen, H.; Xiong, Z.; Song, Y.; Li, L.; Qiu, Y.; Zou, X.; Chen, B.; Chen, D.; Liu, F.; Ji, Y. Early mechanical performance of glass fibre-reinforced manufactured sand concrete. J. Build. Eng. 2024, 83, 108440. [Google Scholar] [CrossRef]

- Li, F.; Yao, T.; Luo, J.; Song, Q.; Yang, T.; Zhang, R.; Cao, X.; Li, M. Experimental investigation on the performance of ultra-high performance concrete (UHPC) prepared by manufactured sand: Mechanical strength and micro structure. Constr. Build. Mater. 2024, 452, 139001. [Google Scholar] [CrossRef]

- Xia, J.; Chen, K.; Wu, Y.; Xiao, W.; Jin, W.; Zhang, J. Shear fatigue behavior of reinforced concrete beams produced with manufactured sand as alternatives for natural sand. J. Build. Eng. 2022, 62, 105412. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Huang, F.; Yang, Z.; Wen, J.; Yi, Z. Bond properties between railway high-strength manufactured sand concrete and steel bars. Constr. Build. Mater. 2024, 416, 135179. [Google Scholar] [CrossRef]

- Shi, H.; Li, H.; Wang, Z.; Huang, F.; Yang, Z.; Wen, J.; Dong, H.; Yi, Z. Bond-slip behaviour between recycled sand concrete and steel bars. J. Build. Eng. 2024, 86, 108980. [Google Scholar] [CrossRef]

- Jiang, K.; Wang, X.; Ben, Q.; Ding, L.; Chen, Z.; Liew, J.R.; Du, H.; Wu, Z. Bond behavior of BFRP bars in ultra-high performance seawater sea-sand concrete reinforced by non-metallic fibers. Eng. Struct. 2024, 318, 118699. [Google Scholar] [CrossRef]

- He, S.; Li, L.; Lin, J.; Chen, X.; Weng, C.; Xiao, H.; Liu, P.; Qiao, S.; Xiong, Z. Bond Performance Between Ribbed BFRP bar and Seawater Sea-Sand Concrete: Influences of rib Geometry. Structures 2024, 65, 106660. [Google Scholar] [CrossRef]

- Xu, Q.; Jiang, X.; Lv, H.; Xu, C. Experimental investigation on bond-slip performance and damage evolution mechanism of deformed reinforcing bar embedded in steel polyvinyl-alcohol hybrid fiber high performance concrete after high temperature. Constr. Build. Mater. 2024, 436, 136951. [Google Scholar] [CrossRef]

- Kuang, Y.; Tang, F.; Li, G.; Lin, W.; Lin, Z. Bond characteristics of quartz sand modified enamel coated steel bars with concrete. Constr. Build. Mater. 2023, 408, 133699. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; Barris, C.; Joyklad, P.; Hussain, Q.; Benmokrane, B. Bond performance of fiber reinforced polymer bars in normal-and high-strength concrete. Constr. Build. Mater. 2023, 393, 131957. [Google Scholar] [CrossRef]

- Liao, J.; Zeng, J.J.; Bai, Y.L.; Zhang, L. Bond strength of GFRP bars to high strength and ultra-high strength fiber reinforced seawater sea-sand concrete (SSC). Compos. Struct. 2022, 281, 115013. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, M.; Zhang, M.; Zhang, W.; Liu, J. Bond Behavior Between Highly Ductile Fiber-Reinforced Concrete (HDC) and Deformed Rebar Under Repeated and Post-Repeated Monotonic Loading. Structures 2024, 67, 106933. [Google Scholar] [CrossRef]

- Liu, C.; Liu, X.; Yan, L.; Zheng, C. Experimental study on bond behavior of corroded reinforced concrete under coupling effect of fatigue load and elevated temperature. Eng. Fail. Anal. 2024, 166, 108862. [Google Scholar] [CrossRef]

- Hua, J.; Yang, Z.; Xue, X.; Huang, L.; Wang, N.; Chen, Z. Bond properties of bimetallic steel bar in seawater sea-sand concrete at different ages. Constr. Build. Mater. 2022, 323, 126539. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, W.; Tang, W.; Wang, Y. Bond performance in reinforced concrete exposed to moderately-high sustained temperatures. Eng. Struct. 2025, 331, 120007. [Google Scholar] [CrossRef]

- Liu, C.; Li, W.; Zhang, S.; Li, J.; Miao, J.; Zhang, R. Bond Behavior of Reinforced Concrete Structures Under Different Cooling Methods Based on Pull-Out Tests. Structures 2025, 72, 108189. [Google Scholar] [CrossRef]

- Huang, T.; Wan, C.; Liu, T.; Ou, J.; Ai, Y.; Ren, Z.; Miao, C. Data-Driven Prediction of High-Temperature Bond Strength in Corroded Reinforced Concrete. Structures 2025, 71, 107973. [Google Scholar] [CrossRef]

- Li, X.; Miao, T.; Liu, T.; Chen, R.; Yu, A. Acoustic Emission Evaluation and Localization Correction of Concrete Damage Considering Stress Levels. Case Stud. Constr. Mater. 2025, 22, e04281. [Google Scholar] [CrossRef]

- Van Steen, C.; Pahlavan, L.; Wevers, M.; Verstrynge, E. Localisation and characterisation of corrosion damage in reinforced concrete by means of acoustic emission and X-ray computed tomography. Constr. Build. Mater. 2019, 197, 21–29. [Google Scholar] [CrossRef]

- Boniface, A.; Saliba, J.; Sbartaï, Z.M.; Ranaivomanana, N.; Balayssac, J.-P. Evaluation of the acoustic emission 3D localisation accuracy for the mechanical damage monitoring in concrete. Eng. Fract. Mech. 2020, 223, 106742. [Google Scholar] [CrossRef]

- Tsangouri, E.; Karaiskos, G.; Deraemaeker, A.; Van Hemelrijck, D.; Aggelis, D. Assessment of acoustic emission localization accuracy on damaged and healed concrete. Constr. Build. Mater. 2016, 129, 163–171. [Google Scholar] [CrossRef]

- Li, P.; Ren, X.; Li, J. Damage assessment of concrete via acoustic emission and mesoscopic damage constitutive model. Eng. Fract. Mech. 2024, 303, 110133. [Google Scholar] [CrossRef]

- GB/T 1499.2-2018; Steel for the Reinforcement of Concrete—Part 2: Hot Rolled Ribbed Bars. Ministry of Housing and Urban-Rural Development People’s Republic China (MOHURD): Beijing, China, 2018.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban-Rural Development People’s Republic China (MOHURD): Beijing, China, 2016.

- Chang, Y.; Qin, S.; Huang, M.; Hu, D.; Yang, H.; Li, S. Analytical model of the bond stress-slip relationship for reinforced concrete due to splitting failure. Constr. Build. Mater. 2021, 287, 123025. [Google Scholar] [CrossRef]

- Eligehausen, R.; Popov, E.P.; Bertero, V.V. Local Bond Stress-Slip Relationships of Deformed Bars Under Generalized Excitations; NTIS: Springfield, VA, USA, 1983. Available online: https://nehrpsearch.nist.gov/static/files/NSF/PB84192848.pdf (accessed on 18 August 2025).

- Wang, X.; Saifullah, H.A.; Nishikawa, H.; Nakarai, K. Effect of water–cement ratio, aggregate type, and curing temperature on the fracture energy of concrete. Constr. Build. Mater. 2020, 259, 119646. [Google Scholar] [CrossRef]

- Zhang, M.H.; Islam, J. Use of nano-silica to reduce setting time and increase early strength of concretes with high volumes of fly ash or slag. Constr. Build. Mater. 2012, 29, 573–580. [Google Scholar] [CrossRef]

- Zhou, S.; Jiang, Z.; Ou, Q.; Liu, J.; Wang, C. Analysis on flexural toughness of steel fiber reinforced concrete based on acoustic emission and digital image correlation techniques. Constr. Build. Mater. 2025, 492, 143039. [Google Scholar] [CrossRef]

- Holsamudrkar, N.; Banerjee, S. B-value based damage source localization and classification using acoustic emission (AE) data for concrete cylinders wrapped with hybrid FRCM composites. Compos. Part C Open Access 2025, 17, 100624. [Google Scholar] [CrossRef]

| Ingredient | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 | MgO | Loss |

| Content/% | 20.47 | 5.90 | 59.64 | 4.80 | 2.08 | 3.74 | 2.44 |

| Group | MS | NS | Cement | SP | Gravel | Water | WRA |

|---|---|---|---|---|---|---|---|

| M0S0W0.44 | 0 | 757 | 386 | 0 | 1135 | 170 | 4 |

| M50S0W0.44 | 378.5 | 378.5 | 386 | 0 | 1135 | 170 | 4 |

| M100S0W0.44 | 757 | 0 | 386 | 0 | 1135 | 170 | 4 |

| M100S5W0.44 | 720.952 | 0 | 386 | 36.048 | 1135 | 170 | 4 |

| M100S10W0.44 | 688.182 | 0 | 386 | 68.818 | 1135 | 170 | 4 |

| M100S0W0.41 | 746 | 0 | 413 | 0 | 1119 | 170 | 4 |

| M100S0W0.47 | 766 | 0 | 362 | 0 | 1150 | 170 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, L.; Yang, H.; Wu, Q.; Jiao, Y. Bond–Slip Properties and Acoustic Emission Characterization Between Steel Rebar and Manufactured Sand Concrete. Buildings 2025, 15, 2959. https://doi.org/10.3390/buildings15162959

Han L, Yang H, Wu Q, Jiao Y. Bond–Slip Properties and Acoustic Emission Characterization Between Steel Rebar and Manufactured Sand Concrete. Buildings. 2025; 15(16):2959. https://doi.org/10.3390/buildings15162959

Chicago/Turabian StyleHan, Lei, Hua Yang, Qifan Wu, and Yubo Jiao. 2025. "Bond–Slip Properties and Acoustic Emission Characterization Between Steel Rebar and Manufactured Sand Concrete" Buildings 15, no. 16: 2959. https://doi.org/10.3390/buildings15162959

APA StyleHan, L., Yang, H., Wu, Q., & Jiao, Y. (2025). Bond–Slip Properties and Acoustic Emission Characterization Between Steel Rebar and Manufactured Sand Concrete. Buildings, 15(16), 2959. https://doi.org/10.3390/buildings15162959