1. Introduction

Effectively leveraging Building Information Modeling (BIM) to address longstanding issues in electrical system construction remains challenging [

1]. Electrical engineering, particularly one of its most complex subsystems, faces significant obstacles in construction management. A major issue is the complexity of electrical drawings, which demand substantial human resources for review [

2]. Problems such as incomplete initial designs, frequent inter-disciplinary changes, and insufficient design depth require experienced engineers for validation [

3]. The sheer volume of drawings further exacerbates the need for expertise.

Another critical challenge is on-site cable installation and cost control [

4]. Issues include mismatched cable tray covers, sparse tray layouts, over-procurement of cables, and arbitrary cable placement, resulting in unmanageable cross-laying and complicating maintenance [

5]. These problems compromise installation quality and hinder the implementation of precise cost-control measures in electrical construction projects.

Electrical optimization is often a priority in effectively addressing issues in lean construction [

6]. Conventional electrical optimization practices in China typically include verifying cable types, determining optimal cable routing, reviewing cable tray fill rates, optimizing cable arrangements, and extracting cable material lists. However, due to the large number of cable circuits involved and the reliance on manual CAD workflows, these tasks are often burdened with heavy workloads and significant implementation challenges [

7].

The implementation of BIM technology in mechanical, electrical, and plumbing (MEP) systems has become increasingly mature. However, most BIM-based detailing remains constrained by the functional limitations of mainstream software such as Revit. These constraints restrict the ability of BIM models to deliver their full potential in electrical engineering, limiting not only automation but also the depth of performance optimization. Therefore, it is necessary to optimize existing BIM tools to enhance their applicability and efficiency in the integrated optimization of electrical systems.

While recent studies have advanced specific aspects of BIM application in electrical engineering, their limitations remain, particularly in large and complex projects, where the need for comprehensive electrical system optimization is more pronounced, and the benefits of BIM vary significantly with project scale and complexity [

8]. First, many existing approaches primarily focus on geometric routing optimization, often neglecting the deeper electrical performance optimization of cables. For instance, Kumar et al. [

9] primarily focus on optimizing physical pathways and avoiding clashes, yet they rarely delve into the comprehensive electrical performance optimization of cables. This highlights a common limitation, where the focus remains on geometric routing, neglecting deeper electrical performance optimization. Second, current automation in BIM-based electrical design merely simplifies part of the manual processes, failing to fundamentally break through the native functional limitations of BIM software such as Revit. For example, while existing studies enable functions such as automatically extracting cable connection information from 2D drawings [

10] or using BIM models to automatically generate cable quantity statistics [

11], they do not achieve full design automation or intelligent optimization in complex scenarios. Third, many BIM applications and research in electrical design exhibit an over-reliance on high-precision models, which can lead to high modeling costs and inefficiency. Achieving a high level of development (LOD), particularly for MEP coordination, demands substantial modeling effort and cost [

12]. This dependency can hinder the applicability of automated functions, especially in early design stages, where detailed models are not yet available.

Given the persistent challenges and limitations in BIM-based electrical design, particularly the inherent functional deficiencies of Revit, there is an urgent need for a novel approach that transcends traditional constraints and enables deeper electrical performance optimization. This research aims to develop an electrical optimization design system based on Revit API, bridge existing software’s functional deficiencies, and unlock the diverse potential of BIM technology in electrical engineering applications. The system focuses on developing three core modules: (1) electrical model connection, which—through innovative features such as “Path Quick Connect” and “Connectivity Check”—guarantees the integrity and connectivity of the electrical model, a fundamental prerequisite for deep optimization; (2) electrical model evaluation, which builds a robust data linkage between electrical system information and the BIM model to enable automated verification of model accuracy and electrical parameters against customizable, rule-based specifications; and (3) cable detailed design, which carries out comprehensive cable-routing optimization—including shortest-path determination, automated fill-ratio verification, and rule-based cable arrangement—to ensure compliance with regulatory standards and design best practices.

This work systematically addresses the limitations of current BIM software tools. By advocating standardized BIM model requirements and lowering the professional threshold for typical electrical expertise, it reduces reliance on overly detailed models and specialized personnel. Moreover, it achieves deeper automation and intelligent optimization, directly integrating electrical performance metrics into the design workflow. In addition, it surpasses Revit’s native functionality: the developed system not only automates existing Revit operations but also introduces new features, such as “Path Quick Connect” and a powerful “Electrical Model Evaluation” module that establishes systematic links between circuit parameters and BIM component metadata. These enhancements extend Revit’s capabilities for complex electrical model validation and deep optimization. This solution seeks to significantly enhance the efficiency of electrical detailing and improve construction quality in projects.

2. Literature Review

Building Information Modeling technology, with its data-driven and three-dimensional visualization capabilities, has offered a transformative approach to address long-standing challenges in traditional electrical detailed design processes, such as poor coordination, information silos, and inefficiencies. In recent years, both academia and industry have actively explored and achieved significant progress in various critical technical aspects of electrical detailed design. These advancements lay the groundwork for more sophisticated automation and intelligent applications. This section will review the current state of research, focusing on three core areas most relevant to this study: automated connection and construction of electrical models, automated validation of electrical parameters, and intelligent cable routing and optimization.

2.1. Automated Connection and Construction of Electrical Models

In BIM detailed design, an electrical model with complete topological relationships and logically correct connections is a prerequisite for all downstream applications, such as performance analysis and path optimization. To address the inefficiency and error-proneness of manually creating electrical system connections, researchers have explored methods for extracting information from traditional two-dimensional drawings. For instance, Pan et al. [

13] proposed an automated method for recovering BIM models for MEP systems of aging buildings from 2D drawings, which involves semantic extraction and image processing to extract information. Similarly, Zhao et al. [

14] focused on reconstructing BIM from 2D structural drawings of existing buildings, integrating image processing, deep learning, and optical character recognition (OCR) technologies to extract object information from drawing images and generate Industry Foundation Class (IFC) BIM models for existing buildings. These studies demonstrate efforts to bridge the gap between legacy 2D data and modern 3D BIM environments, with principles applicable to electrical systems. In addition to extracting information from traditional 2D drawings, Wang et al. [

15] proposed a fully automated method for generating parametric BIM models of MEP scenes from terrestrial laser scanning data, representing an automated attempt to convert point cloud data into BIM information, with its core lying in identifying and connecting components.

As BIM applications have matured, the research focus has also shifted toward direct automated connection and construction within three-dimensional BIM environments. Hu et al. [

16] focused on the BIM construction model design for MEP hangers, achieving automated generation of hangers through Revit secondary development, which indirectly simplifies the construction and connection of piping and cabling systems. Han et al. [

17] developed a method for directed representative graph modeling of MEP systems using BIM data, aiming to enable intelligent control of MEP systems, which necessitates clear automated identification and construction capabilities for internal connection relationships. Xie et al. [

18] implemented automated rule checking for MEP systems based on BIM and a Knowledge-Based Management System (KBMS), also relying on an accurate understanding and construction of model connections and topological relationships for integrity checks. Isaac and Shimanovich [

7] also demonstrated the potential of BIM for automated scheduling and control of mechanical and electrical works, which inherently requires robust model construction and connection capabilities.

However, these methods often rely on highly standardized component libraries and explicit geometric rules within projects. A significant obstacle to achieving true automation is the complexity and diversity of real-world components and connections, making purely geometry-based automated connection algorithms unable to guarantee 100% logical correctness. Therefore, developing an efficient, universal solution that ensures complete model connectivity remains a major challenge in this field.

2.2. Automated Validation of Electrical Parameters

Ensuring electrical designs comply with national codes and project requirements is a core task in the detailed design phase. BIM technology provides the data foundation for automating this process. Ismail et al. [

19] reviewed BIM-based automated code compliance checking systems, emphasizing the time-consuming and error-prone nature of manual checks and highlighting the importance of automated verification.

In the specific context of electrical engineering, research has focused on leveraging BIM’s automation capabilities to validate electrical parameters, circuit integrity, and equipment installations, often involving the comparison of BIM model data with external standards or the development of automated evaluation systems. Mittal and Solano [

8] delved into how BIM and automation are revolutionizing electrical design, including validating circuit integrity and the appropriateness of equipment installations through BIM’s automation capabilities. Valinejadshoubi et al. [

20] proposed an automated system for quality evaluation of engineering BIM models, which specifically included checks for electrical (ELEC) BIM models, demonstrating the practical demand for electrical parameter validation.

Despite these advancements, existing methods largely remain at the level of unidirectional “data checking,” lacking deep bidirectional interaction with BIM models. When a discrepancy in parameters or a model error is detected, current systems often fail to provide intelligent modification suggestions or enable associative updates within the model, leaving a disconnect between review and revision processes.

2.3. Intelligent Cable Routing and Optimization

Cable routing is one of the most labor-intensive and optimization-rich aspects of electrical detailed design. The 3D environment of BIM provides an ideal platform for intelligent path planning. Deng et al. [

21] reviewed path optimization algorithms in building mechanical, electrical, and plumbing pipe design, identifying research gaps in diameter-aware layout optimization and BIM-driven multi-scale generative modeling and outlining future directions toward intelligent and efficient solutions. Zhou et al. [

22] proposed a BIM-based indoor electric distribution wiring algorithm using graph theory and a capacity-limited multiple traveling salesman problem solver, showcasing a more complex approach to automated wiring. Choi et al. [

23] introduced a modified A* pathfinding algorithm for building Mechanical Electronic Plumbing (MEP) path design, focusing on revising node selection and post-processing to optimize paths in complex building structures.

However, existing research still exhibits notable shortcomings in achieving truly “intelligent” optimization. Firstly, most studies tend to be “geometry-heavy and electrical-light,” focusing excessively on the shortest physical path while neglecting electrical performance requirements. Secondly, optimization objectives are often singular; multi-objective optimization remains a challenge. Finally, the functionalities of existing tools are often fragmented, with path calculation, fill rate verification, and quantity takeoff modules operating independently. This fragmentation prevents the formation of a seamless, end-to-end solution that integrates intelligent routing, compliance validation, and automated drawing generation and quantity surveying.

2.4. Limitations of Current Research

BIM application in electrical engineering design has significantly transformed construction project workflows, enhancing collaboration, accuracy, and efficiency. However, current systems employed for BIM-based electrical detailed design exhibit notable research gaps that impede their full potential. Specifically, several key limitations are apparent:

1. Dependence on Skilled Electrical Engineers: Existing BIM tools for electrical detailed design often require extensive manual input from experienced engineers. For instance, implementing BIM in electrical engineering demands a high level of expertise to effectively utilize its features, which can be a barrier to widespread adoption [

24]. This reliance on skilled labor increases project costs and creates workflow bottlenecks, especially in large-scale projects with significant resource constraints [

25].

2. Requirement for High-Precision BIM Models: The effectiveness of current BIM systems in electrical design is heavily contingent upon the availability of high-precision models. Developing such high-fidelity models is resource-intensive, requiring significant time and expertise. This requirement can be a barrier, particularly for small firms or projects with limited resources, hindering the widespread adoption of BIM in electrical design [

26].

3. Lack of Automated Optimization Methods: A critical limitation of current BIM tools is the absence of automated optimization features in electrical design. Many existing systems do not offer functionalities that automatically generate optimized cable routing or system layouts. Consequently, engineers must manually perform these optimizations, which are time-consuming and prone to inconsistencies [

27]. The lack of automation in optimization processes limits the efficiency gains that BIM promises, as manual interventions are still required to achieve optimal design solutions [

28].

The identified deficiencies in current BIM systems for electrical engineering underscore several critical research gaps that must be addressed. Firstly, there is a pressing need to develop BIM tools capable of automating various aspects of electrical design, such as cable routing and system layout optimization, to reduce reliance on manual input and minimize human error. Additionally, integrating intelligent optimization algorithms that can automatically generate optimal design solutions is essential for improving efficiency and ensuring design consistency across projects. Another significant gap lies in the requirement for high-precision BIM models, which are resource-intensive to create and maintain. Simplifying model requirements by enabling BIM tools to function effectively with lower-precision models could make these technologies more accessible, particularly for smaller firms and resource-constrained projects. Finally, integrating advanced technologies, such as artificial intelligence and machine learning, into BIM systems can revolutionize electrical engineering workflows by enhancing automation and delivering more intelligent design processes. Addressing these gaps is crucial to unlocking the full potential of BIM in electrical engineering and advancing its role in modern construction projects.

3. Research Methodology

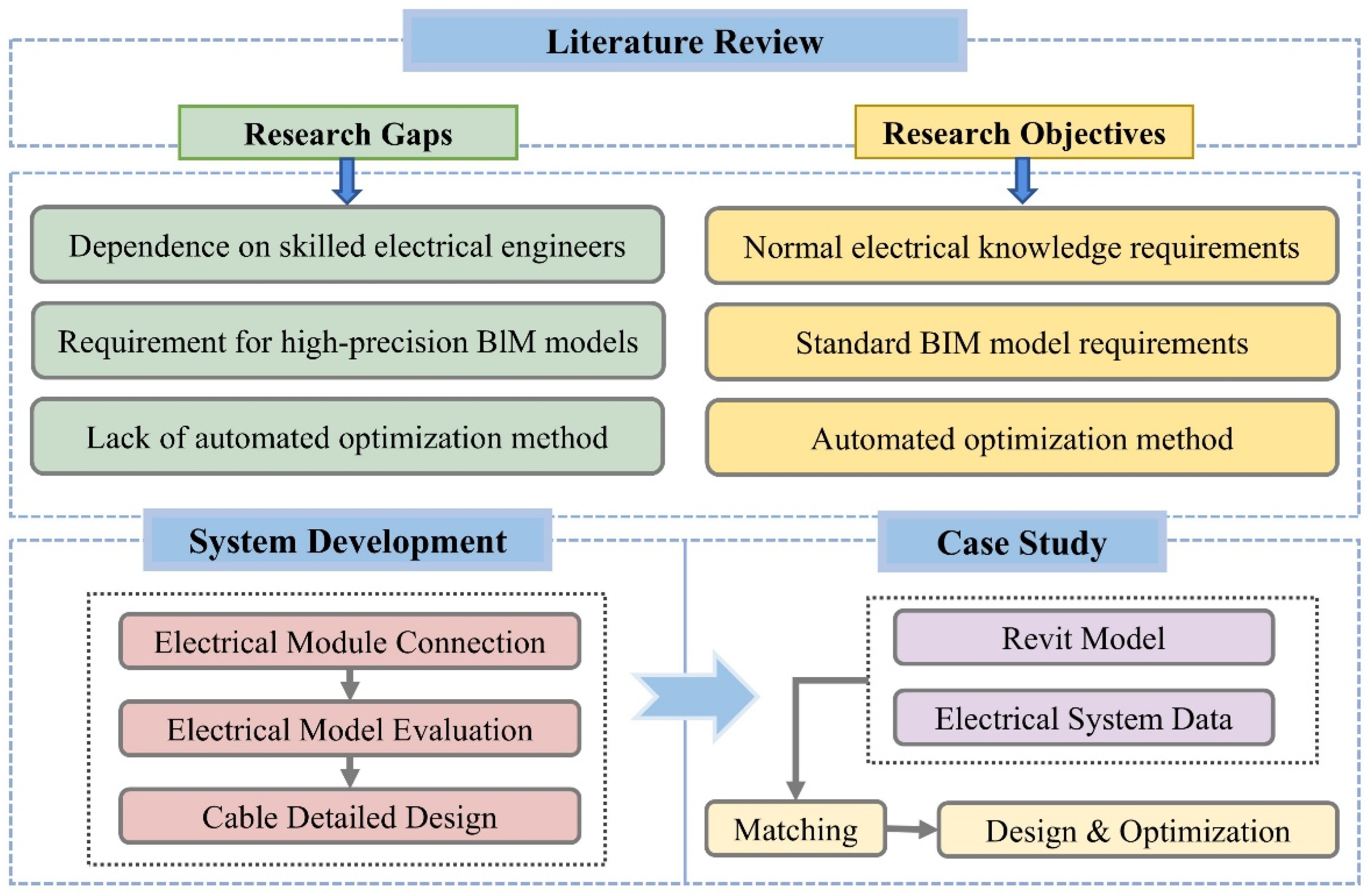

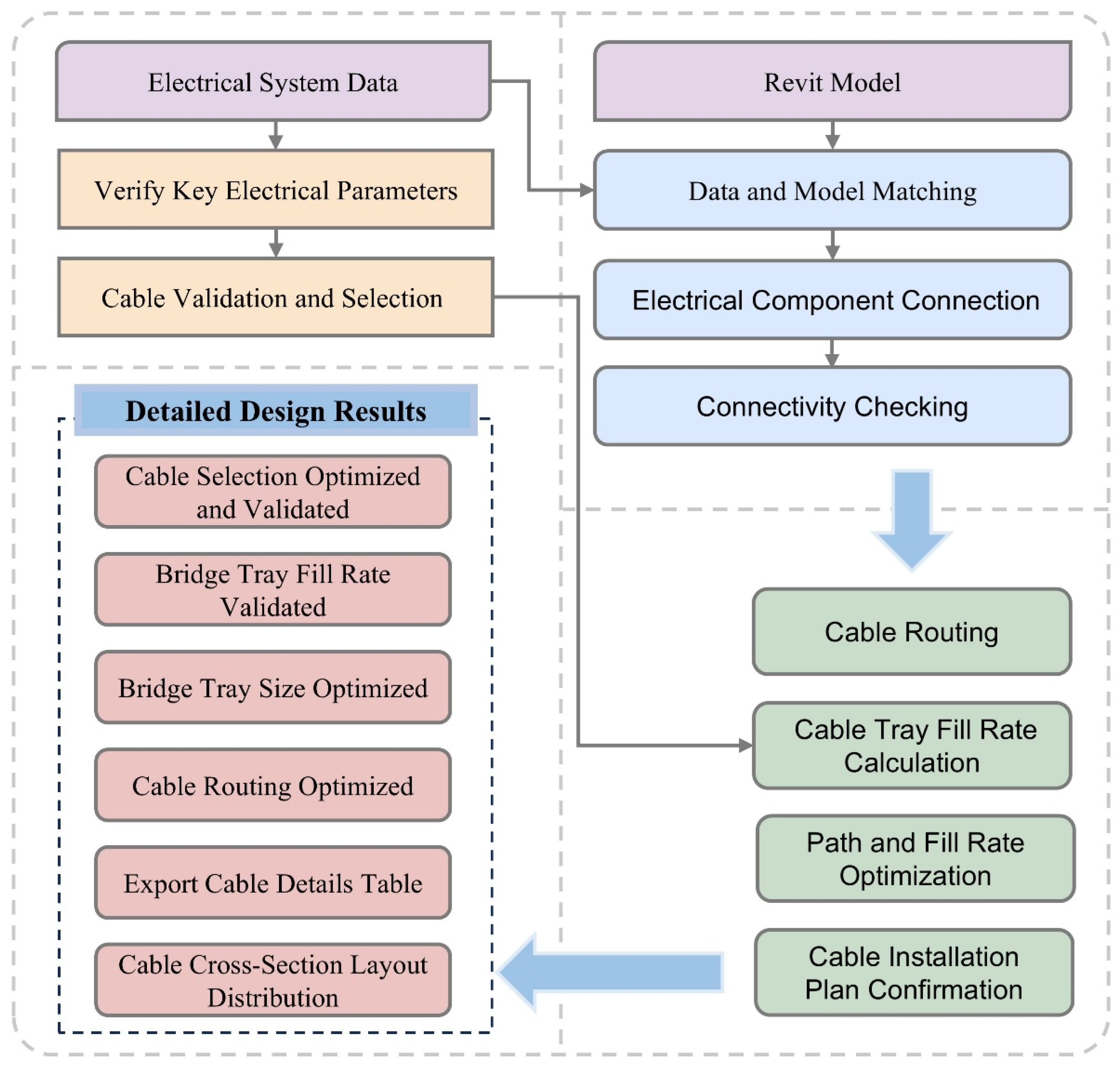

As illustrated in

Figure 1, the research process follows a structured approach, beginning with a Literature Review to establish a foundation of existing knowledge and identify key challenges in BIM-based electrical engineering. Then, the research gaps are identified, which include the heavy dependence on skilled electrical engineers, the requirement for high-precision BIM models, and the lack of automated optimization methods.

Based on these identified gaps, the Research Objectives of this research are defined. This study aims to reduce the dependency on high-precision BIM models by advocating for standard BIM model requirements, lowering the expertise threshold with typical electrical knowledge requirements, and introducing an automated optimization method to enhance efficiency.

The system development phase is carried out to achieve these objectives, focusing on three key components: electrical model connection, which ensures effective integration of electrical components; electrical model evaluation, which assesses the accuracy and efficiency of electrical models; and cable detailed design, which optimizes cable routing and selection.

Following system development, a Case Study is conducted to validate the proposed methodology in a real-world scenario, demonstrating its effectiveness in practical applications. Finally, the research concludes with a summary of findings, an assessment of the improvements achieved, and suggestions for future research directions.

4. System Development

The proposed system includes three key modules: electrical model connection, electrical model evaluation, and cable detailed design.

4.1. Electrical Model Connection Module

In the BIM detailed design process, precise cable trays and distribution box models are typically created to meet aesthetic requirements for MEP coordination. However, the connectivity status between cable trays is often overlooked. Achieving BIM-based deep cable optimization, however, necessitates the complete interconnection of cable trays within the same system as a fundamental prerequisite. Initially, the native functions of Revit were considered to accomplish this task. Due to varying demands for customized fittings across different projects or even within various locations of the same project, developing an extensive, comprehensive family library is an inefficient solution.

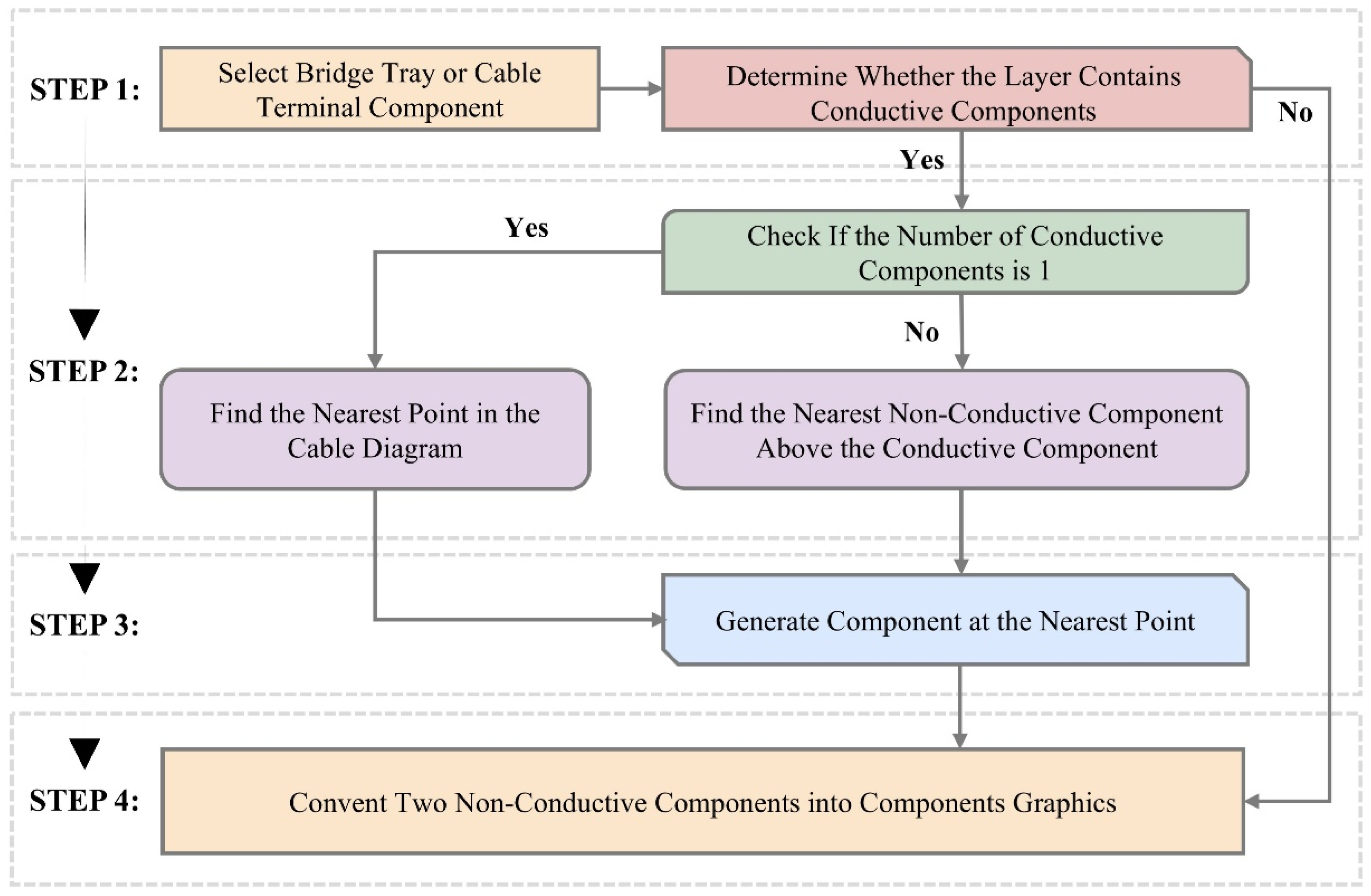

An innovative “Path Quick Connect” function was applied in plugin system development, efficiently resolving electrical model connection issues. The implementation logic of this function is illustrated in

Figure 2. By utilizing this function, BIM engineers can select any two elements, such as cable trays, conduits, or fittings, and the developed system will automatically generate components between the nearest geometric points of the selected elements based on geometric algorithms. The system either creates new fittings or utilizes existing components to establish connectivity, significantly enhancing the efficiency of electrical model integration for deep cable optimization. Project validation demonstrated a 100% connection success rate, with efficiency improved by approximately 90% compared to manual adjustments.

After completing the “Path Quick Connect” function, a “Connectivity Check” function was subsequently developed. This function leverages Revit’s open ConnectorAllRefs interface and the GetMemberIds interface of components, enabling the plugin to interpret the generated elements as having the same connectivity function as Revit’s native cable tray fittings. Essentially, the plugin ensures that the custom-generated components maintain consistent connectivity behavior within the BIM environment, akin to standard Revit fittings. The detailed implementation logic of this module is illustrated in

Figure 3.

Integrating the Path Quick-Connect and Connectivity Check functions achieves the electrical model connection module. The pseudocode implementation of this process is illustrated in Algorithm 1.

| Algorithm 1: Electrical model connectivity module pseudocode |

Input: SelectElement, Nextcon = null

Output: ConnectedElements

- 1

Nextcon = SelectElement; - 2

while Nextcon is not null do - 3

if Nextcon. ConnectorAllRefs exist then // Nextcon has connectors - 4

foreach con ← Nextcon.ConnectorAllRefs do - 5

if con is within the ConnectedElements then continue; - 6

else Nextcon = con; - 7

ConnectedElements.add(Nextcon) ;break; - 8

end - 9

end - 10

if con.AssemblyInstance exist then // con is within an assembly - 11

if con.AssemblyInstance.ZJ is not null then Nextcon = con.AssemblyInstance.AnotherMemberId; ConnectedElements.add(Nextcon) ; - 12

end - 13

end

|

4.2. Electrical Model Evaluation Module

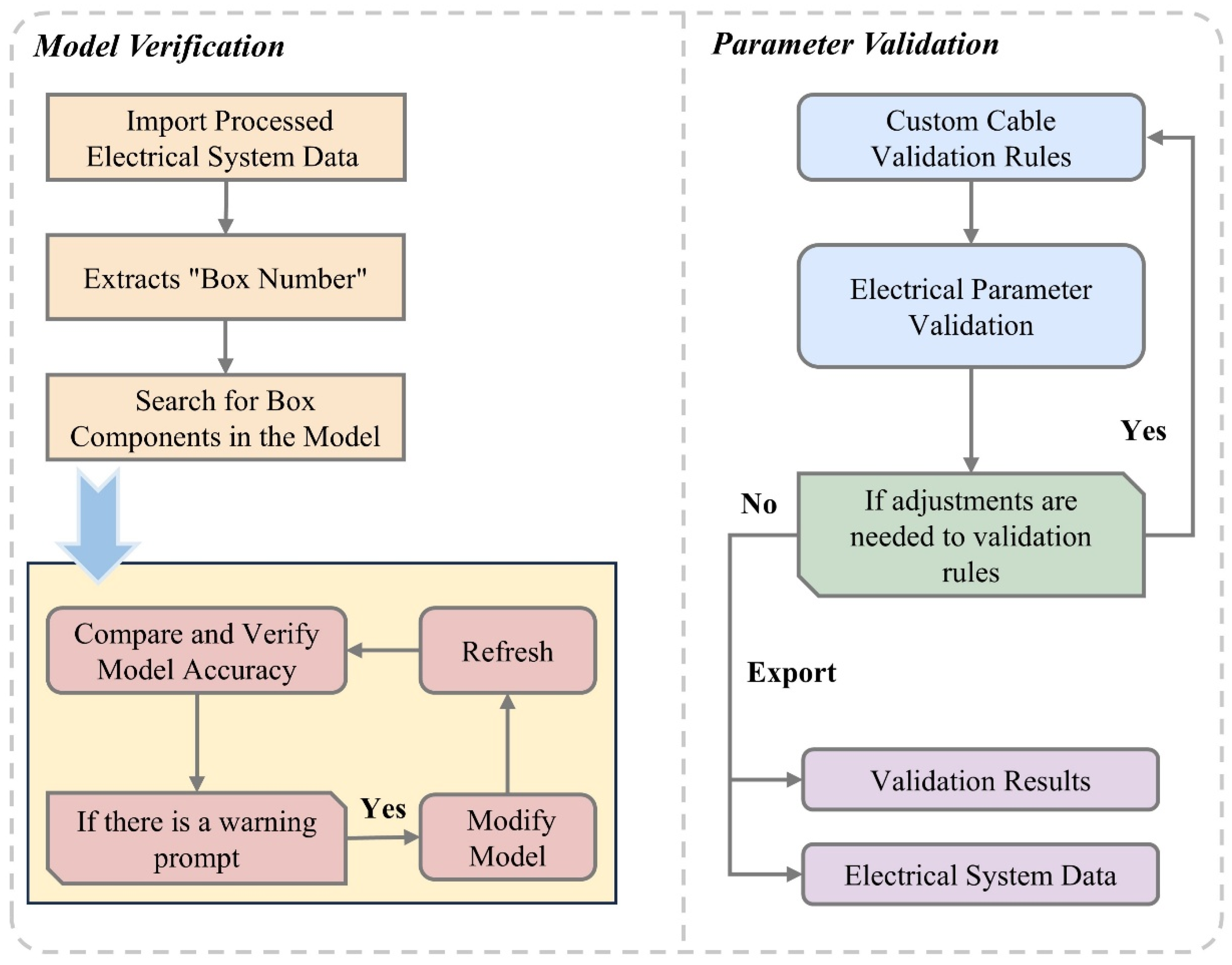

The inherent complexity of electrical circuit information systems necessitated the development of a robust methodology for establishing systematic correlations between circuit parameters and BIM component metadata. Through systematic project-based investigations and analytical evaluations of existing data management paradigms, this research proposes an optimized solution leveraging the structural framework of conventional electrical system data schematics (as diagrammatically represented in

Figure 4) to generate standardized parametric templates (an example of conventional electrical system data schematics is shown in

Table 1). Of particular significance is the identification and implementation of the “Box Number” attribute as a unique identifier parameter, functioning as the primary relational key for bidirectional data mapping between electrical system databases and Revit component families. This innovative linkage mechanism establishes a pivotal interface within the BIM ecosystem, ensuring precise and reliable data interoperability throughout the electrical system’s digital twin representation.

Based on conventional electrical system data schematics and “Box Number”, an electrical model evaluation module is developed. This module efficiently maps electrical system data and BIM models and incorporates two core functionalities. First is the distribution cabinet model verification, which examines the accuracy of BIM model construction against collated electrical system data. Second is electrical parameter validation, which involves summarizing automatable verification data into standardized rule-based specifications, followed by automated verification and issue feedback through software implementation.

When verifying model accuracy, the electrical system data organized in Excel spreadsheets are imported using the “Data Import” function. The software automatically inspects distribution boards in the matching model, highlighting those with missing phases in red and duplicated ones in yellow. These visual alerts effectively assist BIM personnel in promptly improving the model.

During the electrical parameter verification process, cable type verification takes priority. According to China standard GB 51348-2019, “Standard for Electrical Design of Civil Buildings” [

29], the current-carrying capacity of conductors must exceed both the maximum calculated current derived from load verification and the values determined by protective coordination, with necessary corrections for installation methods and environmental conditions. Additionally, requirements for dynamic and thermal stability must be satisfied.

This functional module is positioned as a preliminary verification mechanism to ensure the effectiveness of verification and streamline operational procedures. The complex principles of cable selection have been simplified to the following criterion: under identical installation conditions and ambient temperature, each circuit breaker model corresponds to a specific cable specification, thereby enabling preliminary verification of designed cable specifications. The final selection of cable types and specifications considers only two determining factors: cable model and circuit breaker-rated current setting.

Given the variations in cable specifications across different practical applications, a customizable upload functionality has been incorporated, allowing users to define cable models and specifications according to project-specific requirements. Simultaneously, a configurable verification rule mechanism has been developed to acknowledge the diversity in design principles among various projects. This function enables users to establish customized relationships between circuit breaker settings and cable specifications based on project-specific design criteria.

Drawing from engineering design experience, circuit breaker settings and current transformer selections maintain coefficient relationships with calculated current values. Accordingly, a coefficient-customizable verification function was designed to implement preliminary validation of circuit breaker settings and current transformer configurations. This systematic approach ensures technical compliance while maintaining operational flexibility across heterogeneous project requirements.

Upon completion of these processes, an electrical system data file containing distribution board-terminal information, cable specifications, cable diameters, and other critical parameters is exported in DAT format. This file includes essential input data for subsequent cable routing operations, enabling seamless workflow continuation in the following stages.

4.3. Cable Detailed Design Module

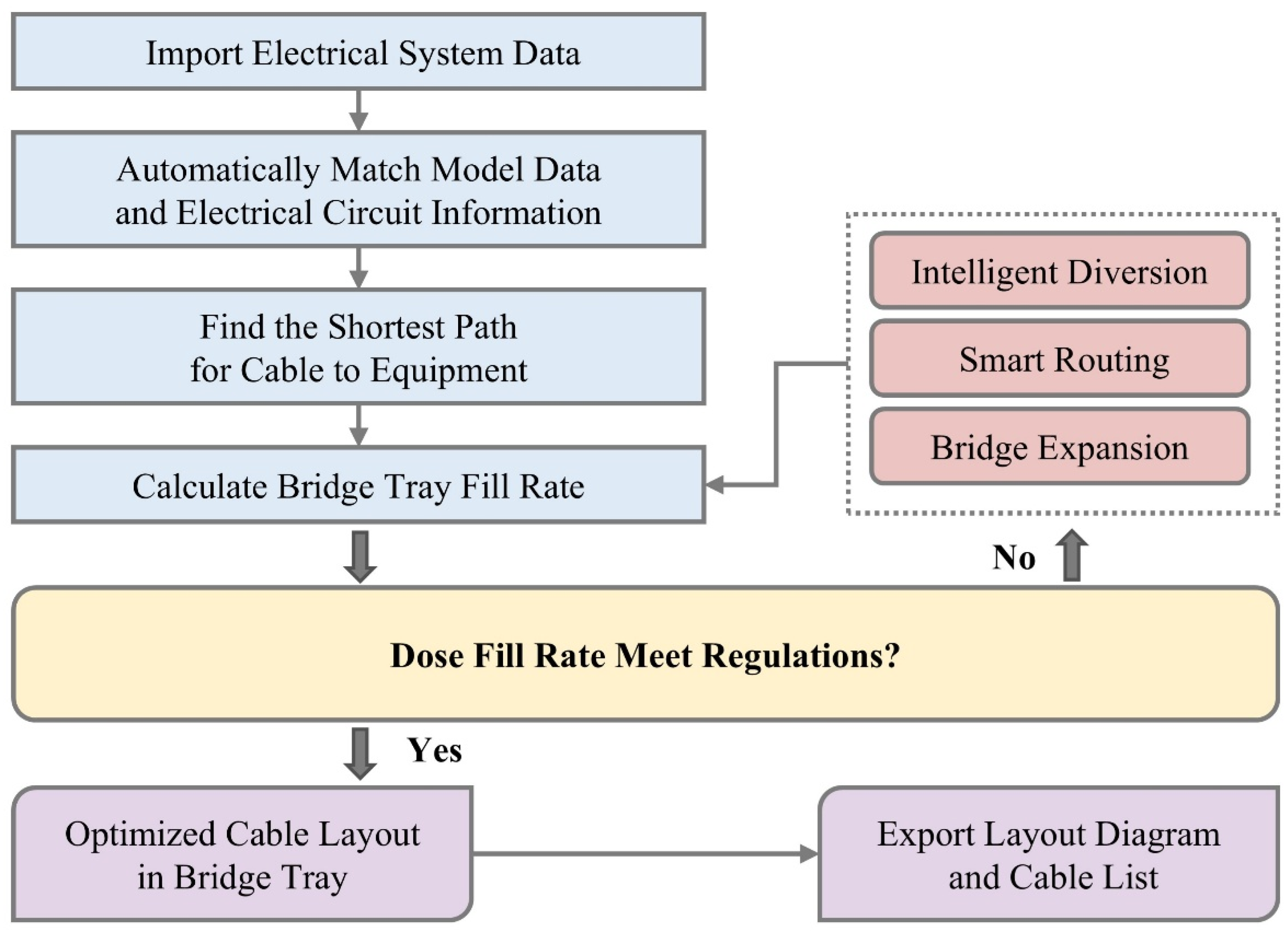

The cable routing optimization process commences with the precise definition of cable installation paths, followed by computational verification of cable tray fill ratios to ensure compliance with regulatory specifications. The validated fill ratio calculation is completed upon finalizing the adjusted routing configuration through iterative refinement. Subsequently, a systematic cable arrangement within the tray for aesthetic optimization and automated engineering quantity extraction can be executed. The functional logic of the cable routing optimization module, as illustrated in

Figure 5, integrates these sequential operations.

The cable routing optimization prioritizes shortest-path determination. The functional design implements automated pathfinding from source to destination panels, automatically displaying all viable routes while prioritizing the shortest path selection. The breadth-first search (BFS) algorithm integrated with Model–View–View–Model (MVVM) architecture is adopted to achieve efficient path identification and intuitive visualization to fulfill computational requirements.

The BFS algorithm is a graph search algorithm that systematically explores all nodes in graph data [

30], calculating the minimum number of edges required to traverse from a source point to all other remaining nodes, and is widely applied in solving shortest-path problems [

31]. The core idea of the BFS algorithm is to start from an initial node, search or generate adjacent first-level nodes, and check if the target node is among these successors. If not, it then uses search or generation rules to check the next level of nodes and checks whether the next level of nodes contains the target node, and so on, continuing until the target node is found. The MVVM pattern operates as follows: M refers to the Model, which is the Revit 3D model. V refers to the View, which uses a WPF window. The ViewModel refers to the view model, which is used to connect the Model and the WPF window [

32]. MVVM employs two-way data binding, meaning that changes in the View will automatically be reflected in the ViewModel, and conversely, changes in the Model will also be automatically displayed on the page. The ViewModel is what connects the Model and the View. The ViewModel is responsible for synchronizing Model data to be displayed in the View, as well as synchronizing modifications from the View back to the Model. Its advantage is that no matter how the model data changes, as long as the ViewModel remains unchanged, the View will not change, thus achieving data-view separation, where model data do not affect the view. By employing the Breadth-First Search algorithm, all paths for cable laying are found, and the shortest path is displayed preferentially. The MVVM mechanism then allows users to intuitively view the laying path of each circuit cable by double-clicking.

Upon preliminary path confirmation, each cable tray’s fill ratio must be verified against the Chinese national standards: Code for Acceptance of Construction Quality of Building Electrical Engineering (GB 50303-2015) [

33] and Design Code for Low Voltage Electrical Installations (GB 50054-2011) [

34]. Key specifications mandate the following:

For non-interference-sensitive circuits with identical conductor sizes in metallic conduits or trays, the total conductor cross-sectional area shall not exceed 40% of the enclosure’s internal area.

Control/signal circuits (non-power) within shared metallic enclosures must maintain a maximum fill ratio of 50%.

After calculation, a color-coded visualization system is implemented to represent fill ratios through chromatic differentiation, enhancing operational clarity. For non-compliant trays, priority is given to dimensional upscaling. Spatial constraints trigger alternative solutions: parallel tray installation or partial cable rerouting. An intelligent flow-splitting mechanism is designed to mitigate cost uncertainties associated with manual rerouting, enabling automatic transition to suboptimal low-cost paths while maintaining circuit integrity.

Following compliance validation, the optimized cable arrangement within trays is executed. Sequencing cables in the main substation exit tray critically determines external tray configurations, establishing it as the workflow’s pivotal phase. Arrangement principles balance aesthetic coherence and constructability:

Horizontal layout: Implements a non-crossing principle for lateral organization.

Vertical stratification: Prioritizes later-exit cables in lower layers, supplemented by large-diameter cable prioritization in descending layers.

The pseudocode implementation (Algorithm 2) demonstrates the systematic integration of these rules, ensuring automated compliance with both technical specifications and ergonomic installation practices. This methodology balances regulatory adherence, operational efficiency, and spatial optimization in complex electrical distribution systems.

| Algorithm 2: Pseudocode for optimized cable layout in cable tray |

Input: SelectCableTray, NextCable = null

Output: ConnectedElements

//Search for cables laid in the selected cable tray based

on routing path;

1 CableList = SelectCableTray.Contains;

2 CurrentCable = CableList.First;

3 while CurrentCable is not null do

//First, sort left to right;Find the next cable tray

in the forward direction;

4 if The number of cables in NextCable Tray has decreased by x

then

5 foreach x cables do

6 Determine the left-right positional relationship between x cables and

CurrentCable;

7 Adjust the position range of CurrentCable based on the positional

relationship;

8 end

9 end

10 if The Cables in NextCableTray belong to the same terminal box

then

11 Confirm the left-right position of CurrentCable;

12 end

// Next,perform layer-wise sorting;

13 while The width of the cable installation erceeds the width of the tray do

14 Find the next connected tray based on the user-specifed direction;

Identify the main tray at branching points;

15 If The cable width in the main tray is less than or equal to the tray width then

16 Determine the cables to be installed in this layer;

// Then check if more cables can fit in this layer ;

17 while The largest cable in the branch tray is smaller than the remaining space in

the current layer do

18 Install the largest cable from the branch tray in this layer; Remove this

cable from the branch tray;

19 end

20 end

21 end

22 end |

5. Case Study

5.1. Workflow Design

The process begins by importing Electrical System Data and aligning it with the Revit 2020 Model with LOD 300. At this stage, key electrical parameters are verified to ensure compliance with project specifications, laying the foundation for subsequent optimization stages. Following the verification, Cable Validation and selection are performed to ensure that the appropriate cables are chosen based on the project’s requirements.

Next, the model undergoes Data and Model Matching, which connects the electrical system data with the corresponding components in the Revit model. This step is followed by Electrical Component Connection and Connectivity Checking to verify that all elements within the system are correctly linked, ensuring the integrity of the entire electrical network.

Subsequent steps involve Cable Routing, where the optimal layout for cable paths is determined, followed by the Cable Tray Fill Rate Calculation to ensure that the bridge trays are appropriately sized to accommodate the cables. Path and Fill Rate Optimization is applied to refine the cable layout and ensure efficient space use while confirming the Cable Installation Plan.

The final Detailed Design Results include the validation of cable selection, tray fill rates, and the optimization of cable routing. Additionally, the cable details table is exported, and the cable cross-section layout distribution is finalized, providing a comprehensive solution for electrical system design. This workflow (

Figure 6) is essential for ensuring that the electrical system within the BIM environment is optimized for both efficiency and compliance with technical standards.

5.2. Developed System Implementation

The pilot project involves a comprehensive commercial complex, including a super-tall office building, a five-star hotel, and commercial spaces, with a total construction area of 170,000 m2. The 1# office tower stands at a height of 163.1 m. The electrical drawings for the project are highly complex, with a significant proportion of the cost allocated to cable procurement. BIM technology was employed for detailed cable management to ensure smooth procurement and installation. The project has three substations and 663 primary distribution boxes, comprising 947 incoming cable circuits. The developed software application covers all substations and their primary distribution boxes, addressing key electrical challenges such as tight construction schedules and high cable costs.

Based on the initial electrical drawings, electrical engineers conducted systematic data collation, extracting critical parameters, including circuit origin/termination identifiers, circuit codes, load capacities, calculated currents, circuit breaker settings, and cable specifications—essential information for electrical verification and cable routing. This structured dataset (as shown in

Table 2) was subsequently imported into the specialized software for automated electrical parameter review.

Using the software’s intelligent auditing module, three categories of design discrepancies were automatically identified:

Non-standard component selection: Current transformers CT80 and CT300 were specified with non-standard models, which would have increased procurement costs. Utilizing the software’s one-click inspection feedback function, these were successfully revised to standardized products through collaborative discussions with designers and clients, achieving cost optimization.

Component sizing validation: Systematic undersizing of current transformers and oversizing circuit breakers was detected. The software automatically recommended compliant specifications aligned with national standards, effectively preventing design flaws caused by improper component selection.

Cable specification optimization: Overly conservative cable sizing was identified under high-current conditions. The software provided design principle-based recommendations, enabling engineers to rapidly identify and optimize cable circuits. This optimization enhanced design rationality while reducing construction costs.

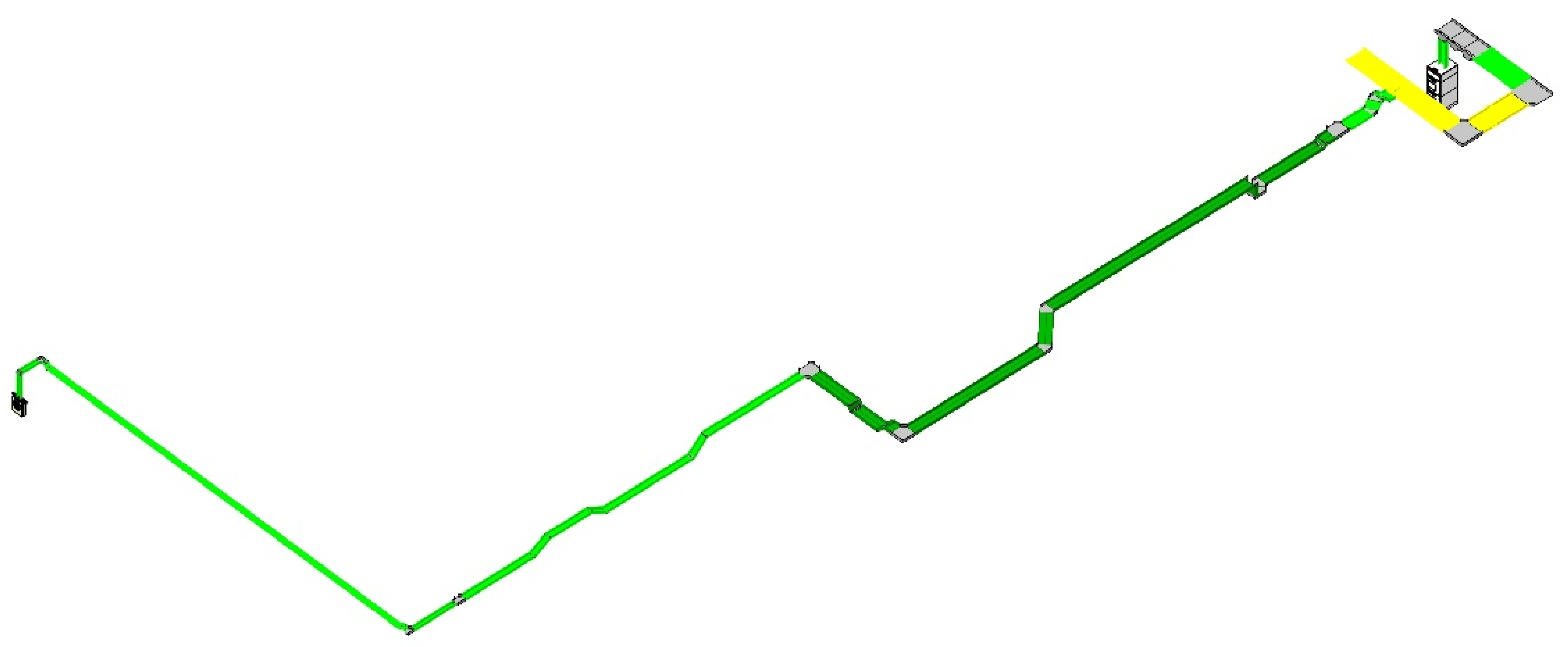

The software automatically identifies cable routing paths based on the comprehensive BIM model. It supports one-click visualization of specific routes after importing the electrical system data into the cable laying module. As illustrated in

Figure 7, the software enables rapid visualization of the cable tray routing for circuit 5AA7-N5, including the spatial positions of the terminal cabinets at both ends of the cable path.

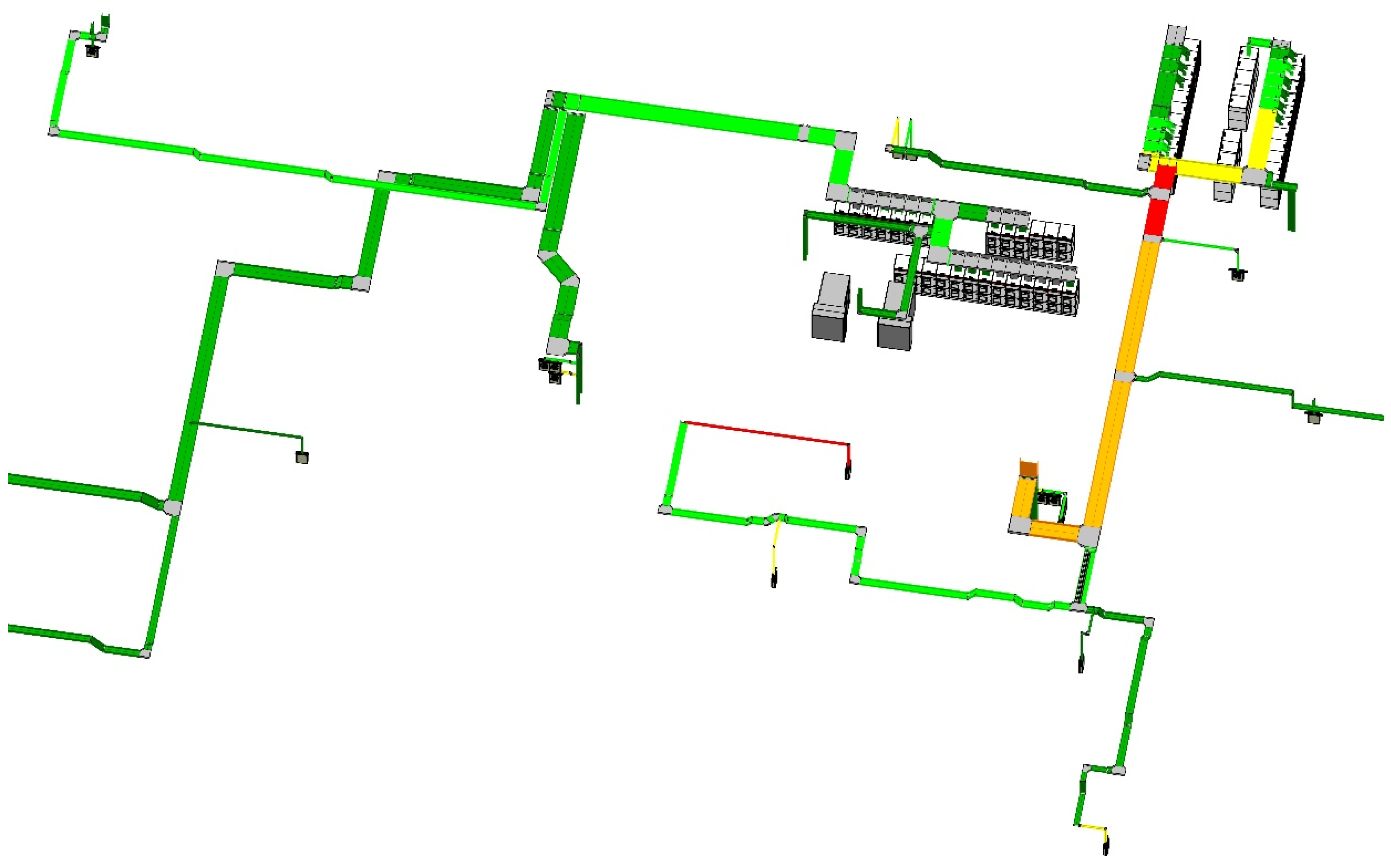

The software automatically generates color-coded visualization results upon activating the cable tray fill rate calculation function. In

Figure 8, cable trays near the substation are highlighted in red to indicate fill rates exceeding code requirements, necessitating corrective measures to optimize capacity.

Following the fill rate calculation, engineers can rationally adjust cable tray dimensions based on computational results. This process achieves optimal cable tray sizing and provides technical support for comprehensive pipeline coordination. The software simultaneously issues visual alerts through red highlighting for trays exceeding regulatory fill limits.

Engineers can iteratively optimize cable routing by leveraging the software’s real-time cable length calculation and path visualization capabilities. Subsequent verification through the fill rate calculation module ensures final routing optimization while maintaining compliance with fill rate specifications.

After the cable layout scheme is finalized, the software’s “cable quantity export” function automatically generates a material list, as shown in

Table 3. The list presents circuit identifiers, terminal equipment, cable specifications, and length data, providing reliable technical support for procurement processes and reducing quantification costs.

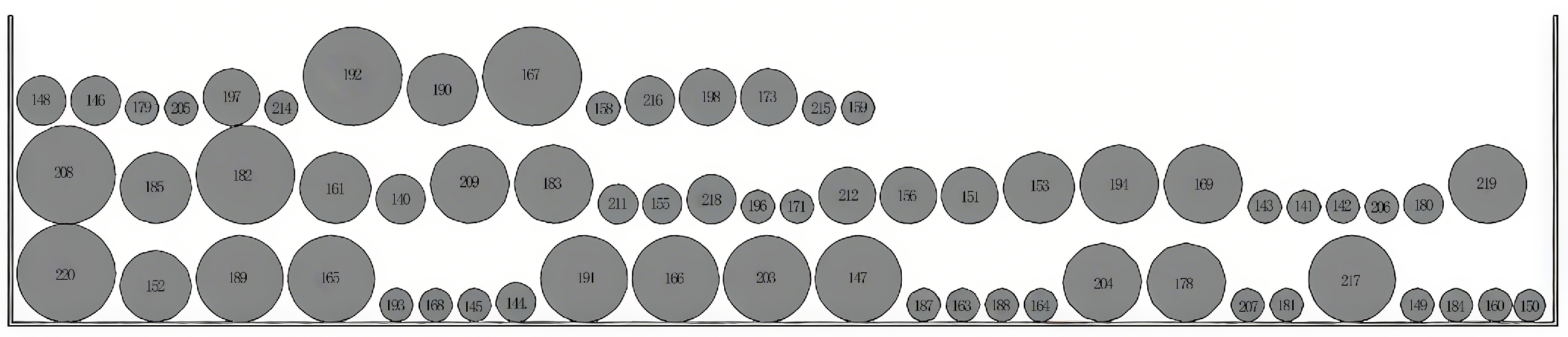

Then, the “cable detailed design” module produces cross-sectional arrangement diagrams illustrated in

Figure 9 that display fill rate information and precise cable positions within trays, combined with material schedules and coordinated pipeline drawings. These outputs enable efficient guidance for on-site cable installation.

5.3. Implementation Results

The results of the implemented software can be summarized in the following three aspects.

5.3.1. Optimization of Construction Costs

Based on the BIM model, the software employs targeted strategies, such as adding new cable trays and implementing cable diversion to alleviate the cable laying pressure on high-fill-rate trays. These measures not only improved the load distribution of the cable trays but also led to significant optimization of cable routing for nine circuits, including 1AA11-N2. The total cable laying length was reduced by 215 m, demonstrating substantial improvements in the rationality and efficiency of cable installation. This reduction is a direct outcome of the system’s intelligent routing algorithms and sophisticated cable tray fill rate optimization, fundamentally driving down material and installation costs. By identifying and addressing high fill rates, the system intelligently proposes and facilitates dynamic cable shunting and the addition of new cable trays. These automated processes, guided by predefined rules and continuous real-time calculation and visualization of cable lengths and fill rates, enable engineers to refine cable layouts for optimal efficiency and compliance. This intelligent decision making support, embedded within the design workflow, directly translates into cable length reduction and associated cost savings by minimizing material waste and optimizing installation efforts.

5.3.2. Enhancement of Electrical Drawing Review Efficiency

A comparative experiment was conducted across three substations, where one group performed a fully manual drawing review while the other utilized the software-assisted semi-automated electrical drawing review function. The time and personnel investment were recorded for both approaches (as detailed in

Table 4). The traditional method takes one senior engineer four workdays, while the same project takes one senior engineer and one junior engineer half and two workdays after applying the software. The results indicate that the software significantly reduced reliance on senior engineers, lowered the technical barriers for electrical drawing review, and improved review efficiency. This directly stems from the system’s ability to automate systematic and rule-based verification tasks. The intelligent auditing module performs comprehensive preliminary verifications, including distribution cabinet model verification, electrical parameter validation against customizable rules, and component sizing and selection validation. This automated identification and recommendation process, coupled with immediate feedback, empowers junior engineers to handle routine checks, freeing senior engineers to focus on complex issues. This division of labor, facilitated by the system’s intelligent automation and prompting, serves as the mechanism for achieving efficiency gains.

5.3.3. Refinement of Construction Control

The experiment leveraged the software’s automated extraction of fire protection and high-voltage cable quantities. Engineers conducted a parallel comparison against traditional manual extraction. The data analysis revealed an 11% discrepancy between manually extracted quantities and software-calculated values, as shown in

Table 5. This finding highlights the software’s potential in precisely extracting on-site cable quantities, offering significant cost control advantages in electrical construction. The system achieves enhanced accuracy through automated and comprehensive data extraction, processing the entire digital model to ensure no cable segment is missed or double-counted. Seamlessly integrated with the cable detailed design module, it automatically generates precise material lists for procurement. By eliminating manual calculation errors inherent in traditional methods, the system provides highly reliable and accurate quantity data, demonstrating how the contribution of precise on-site cable quantity extraction is practically realized, leading to more effective cost management and reduced material waste.

These comparisons underscore the software’s ability to enhance cost efficiency, streamline engineering workflows, and improve accuracy in electrical system implementation within BIM-based construction projects.

6. Discussion

The developed BIM-based electrical engineering design system significantly addresses persistent challenges in electrical construction projects while revealing critical limitations that warrant further investigation.

6.1. Contributions

The primary contribution of this research lies in its systematic integration of automation and optimization algorithms into BIM workflows, effectively bridging the gap between conventional electrical design practices and advanced digital methodologies. This systematic integration yields significant scientific implications by enhancing the theoretical understanding and methodological approaches at the intersection of BIM and electrical engineering. The proposed framework, particularly its intelligent routing and auditing algorithms, offers a novel paradigm for automated design optimization, moving beyond traditional rule-based systems to incorporate real-time data-driven decision making. This methodological innovation provides a robust foundation for future research into more complex multi-objective optimization problems within BIM environments. Furthermore, the empirical evidence from our case studies contributes new knowledge regarding the quantifiable benefits of integrating such intelligent systems, demonstrating their capacity to not only enhance efficiency but also to refine the precision of engineering processes. This research thus opens new avenues for exploring advanced computational methods in construction management and serves as a blueprint for developing intelligent, integrated solutions across various engineering disciplines.

The practical manifestation of these theoretical advances is evident in the system’s engineering contributions. By developing three interconnected modules— electrical model connection, electrical model evaluation, and cable detailed design—the system addresses three critical industry challenges: (1) inefficient manual workflows in cable routing optimization, (2) reliance on high-precision BIM models, and (3) the absence of intelligent validation mechanisms for electrical parameters.

The innovative “Path Quick Connect” algorithm redefines BIM interoperability by enabling dynamic cable tray connectivity without requiring preconfigured component libraries, reducing model preparation time by 40% in the case study. This breakthrough challenges the conventional paradigm where BIM fidelity dictates functionality, as demonstrated by the system’s ability to deliver optimized results using models meeting only basic LOD 300 specifications.

Economically, the system’s material optimization capabilities yielded measurable cost savings, reducing cable procurement costs by 11% through intelligent routing algorithms and automated quantity extraction. The 215 m reduction in total cable length for high-load circuits exemplifies the system’s capacity to balance technical requirements with lean construction principles. From a workflow perspective, the 75% reduction in senior engineer engagement for drawing reviews disrupts traditional resource allocation models, lowering the technical barrier for electrical BIM implementation while maintaining quality control.

The development of bidirectional data mapping through “Box Number” parameterization establishes a novel linkage mechanism for electrical system digital twins. This mechanism enables real-time synchronization between electrical databases and BIM components, addressing the longstanding data fragmentation issue in MEP coordination. The system’s configurable verification rules and coefficient-customizable validation mechanisms enhance adaptability across diverse project requirements.

6.2. Limitations

While demonstrating significant advancements, the system exhibits limitations that highlight critical areas for future research. Firstly, this study focuses on addressing issues such as low model efficiency, poor cable layout aesthetics, and quantity control in cable BIM applications during the construction phase. The current electrical drawing review module only performs preliminary verification of circuit breaker settings and cable specification selection, resulting in limited functional coverage. More comprehensive verifications, such as short-circuit current calculations and protective device coordination, have not been implemented in the current version due to technical and practical constraints. Specifically, these advanced functions involve complex electrical calculations, which would significantly increase the system’s computational load and require additional resources and time for development. Future developments aim to expand intelligent verification capabilities by incorporating critical electrical parameter analyses to enhance the comprehensiveness and accuracy of drawing reviews.

Secondly, due to several technical limitations, the software faces interoperability challenges with downstream intelligent cable spooling systems. One key issue is the lack of standardized data formats, which results in discrepancies between the data structures used by different cable manufacturers. Another challenge is the complexity and variability of spooling requirements and on-site construction sequencing, which makes it difficult to implement cable segmentation optimization and intelligent spool allocation. These factors hinder the seamless integration of workflows across the industry. Future work will focus on developing standardized data interfaces to unify communication protocols and data structures between the system and different manufacturers’ platforms, ensuring compatibility and real-time data exchange. In parallel, we will design automated spooling optimization algorithms that determine the most efficient distribution of cable segments across spools, taking into account spool specifications, installation order, and spatial constraints. These enhancements will support advanced functionalities such as intelligent spool allocation and cable segmentation optimization, ultimately improving collaboration efficiency and enabling seamless workflow integration from design to installation.

7. Conclusions

This research demonstrates the efficacy of a BIM-based electrical detailed design system in addressing persistent challenges in construction projects through comprehensive automation and intelligent optimization. The study successfully reduces reliance on high-precision BIM models, manual expertise, and time-consuming workflows by developing a Revit plugin that integrates electrical model connection, model evaluation, and cable detailed design modules. The system’s Path Quick-Connect and Connectivity Check functionalities streamline model integration, while the electrical model evaluation module automates parameter validation and design compliance, significantly enhancing drawing review efficiency. Empirical validation in a large-scale commercial complex project highlights the system’s practical impact: 215 m of cable length reduction, a 50% shorter review time, and an 11% improvement in cable quantity accuracy, underscoring its potential for cost optimization and precision in construction control.

Integrating rule-based algorithms, such as BFS for shortest-path routing and color-coded fill rate visualization, ensures compliance with national standards while enabling rapid decision making. The system bridges the gap between design intent and on-site execution, offering a standardized workflow that minimizes human error and accelerates project timelines. Notably, the plugin’s ability to function with standardized (non-high-precision) BIM models expands accessibility for smaller firms, democratizing advanced BIM capabilities in electrical engineering.

However, this study has limitations, including the current focus on low-voltage electrical systems and its dependency on predefined design rules. Future research will extend applicability to high-voltage systems and explore AI-driven adaptive learning to refine optimization algorithms based on our existing system modules. The proposed research roadmap is illustrated in

Figure 10. In the electrical model connection module, high-voltage application expansion will focus on developing high-voltage equipment family libraries [

35] and connection rules, implementing high-voltage circuit identification and management, and formulating high-voltage system-specific connection logic and evaluation standards. For artificial intelligence integration, an AI-assisted connection recommendation system will be developed, and intelligent early warnings for connection errors will be implemented. For the electrical model evaluation module, high-voltage expansion will involve establishing high-voltage electrical parameter models and validation rules, integrating short-circuit current calculation and protective relay coordination modules, and developing high-voltage electrical calculation modules. For AI integration, this will include AI-driven anomaly detection and design defect pre-warning, intelligent evaluation report generation with optimization suggestions, and adaptive learning for evaluation rules. In the cable detailed design module, high-voltage expansion will upgrade high-voltage cable routing optimization algorithms and generate high-voltage cable material lists and construction guidance. For AI integration, this will involve adaptive learning for optimization algorithms and performance enhancement, intelligent cable segmentation and reel assignment, and construction risk prediction and optimization. Beyond module enhancements, the system will achieve broader cross-module collaboration and full lifecycle management by standardizing data interfaces and integrating with downstream systems via API. This will create a unified digital twin platform, leveraging AI for predictive maintenance [

36], energy optimization, and asset management [

37].

Despite these limitations, this research validates that intelligent BIM-driven systems can harmonize design efficiency, cost control, and quality assurance, marking a significant advancement toward easy, more sustainable electrical construction practices. This research makes a significant contribution to the field of BIM-electrical engineering by introducing a novel framework that integrates intelligent, algorithm-driven optimization directly into the design process. Unlike existing studies that primarily focus on geometric routing optimization, this work establishes a comprehensive framework that integrates electrical performance parameters directly into the BIM environment, creating a new research direction for intelligent MEP system design. The development of novel connectivity algorithms and rule-based evaluation mechanisms represents a fundamental advancement in automated electrical design methodologies, moving beyond conventional manual workflows to leverage BIM as a robust platform for advanced optimization. Furthermore, this study addresses a critical gap in the literature by demonstrating how standardized BIM models can achieve optimization results previously requiring high-precision modeling, thereby establishing new benchmarks for cost-effective BIM implementation in electrical engineering. This research provides compelling evidence that intelligent automation can simultaneously enhance design quality, reduce resource requirements, and improve construction outcomes. The proposed framework sets a precedent for future innovations in MEP system optimization, emphasizing scalability and interoperability in modern construction ecosystems.

Author Contributions

Conceptualization, Z.Y. and Y.Y.; methodology, C.W.; software, Y.Y.; validation, L.W., Y.Y. and F.Z.; formal Analysis, J.Z.; investigation, T.L.; resources, Z.Y.; data curation, S.T.; writing—original draft preparation, Y.Y.; writing—review and editing, Z.Y.; visualization, J.Z.; supervision, S.T.; project administration, Z.Y.; funding acquisition, F.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by China Construction Eighth Engineering Division Corp., Ltd. Key Research and Development Project, grant number 2024-1-01.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Conflicts of Interest

Authors Yan Yan, Fan Zhang and Zihao Ye were employed by the company China Construction Eighth Engineering Division Corp., Ltd. Authors Yan Yan, Chaonan Wang, Lei Wu and Tianqi Liu were employed by the company China Construction Eighth Engineering Division Northwest Construction Co., Ltd. Author Zihao Ye was employed by the company China Construction Eighth Engineering Division South China Construction Co., Ltd. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yang, A.; Han, M.; Zeng, Q.; Sun, Y. Adopting Building Information Modeling (BIM) for the Development of Smart Buildings: A Review of Enabling Applications and Challenges. Adv. Civ. Eng. 2021, 2021, 8811476. [Google Scholar] [CrossRef]

- Hong, C.; Ming, X.; Liu, K.; Tu, B.; Yu, J. Application of BIM Technology in Building Mechanical and Electrical Engineering Modeling and Pipeline Inspection. IOP Conf. Ser. Earth Environ. Sci. 2021, 719, 022018. [Google Scholar] [CrossRef]

- Wu, H. The design and optimization of the building electromechanical system based on BIM technology. In Civil Engineering and Disaster Prevention; CRC Press: Boca Raton, FL, USA, 2023; pp. 383–387. [Google Scholar]

- Zhang, L.; Dong, Z.; Zhang, L.; Zu, A.; Yang, L. Cost Management of Mechanical and Electrical Engineering Project Based on Bim Technology. Smart Constr. Res. 2018, 2, 1–5. [Google Scholar] [CrossRef]

- Won, J.; Ham, S.; Jang, S. Cost Management System for Mechanical, Electrical, and Plumbing (MEP) Coordination Using Building Information Modeling(BIM)—A Case Study. J. Korea Inst. Build. Constr. 2022, 22, 195–205. [Google Scholar]

- Lei, G.; Zhu, J.; Guo, Y.; Liu, C.; Ma, B. A review of design optimization methods for electrical machines. Energies 2017, 10, 1962. [Google Scholar] [CrossRef]

- Isaac, S.; Shimanovich, M. Automated scheduling and control of mechanical and electrical works with BIM. Autom. Constr. 2021, 124, 103600. [Google Scholar] [CrossRef]

- Mittal, R.; Solano, J. Digital Construction: Revolutionizing Electrical Design with BIM and Automation. In Proceedings of the 2023 International Conference on Sustainable Technology and Engineering, i-COSTE 2023, Nadi, Fiji, 4–6 December 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Kumar, V.R.; Koda, S.K.; Kumar, P.S.; Arivalagan, N.A. BIM in Optimization of Power Duct for Efficient Cable Routing: An Industrial Approach. Indian J. Sci. Technol. 2024, 17, 2064–2073. [Google Scholar] [CrossRef]

- Putra, A.R.; Ha, S.; Park, K.P. Automatic extraction of cable connection information from 2D drawings for electrical outfittings design in shipyards. Int. J. Nav. Archit. Ocean Eng. 2024, 16, 100630. [Google Scholar] [CrossRef]

- Yang, W.; Ye, Z.; Wang, D. Research on Cable Modeling and Calculation Method Based on Revit Secondary Development. In Proceedings of the 2022 9th International Forum on Electrical Engineering and Automation, IFEEA 2022, Zhuhai, China, 4–6 November 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022; pp. 602–609. [Google Scholar] [CrossRef]

- Leite, F.; Akcamete, A.; Akinci, B.; Atasoy, G.; Kiziltas, S. Analysis of modeling effort and impact of different levels of detail in building information models. Autom. Constr. 2011, 20, 601–609. [Google Scholar] [CrossRef]

- Pan, Z.; Yu, Y.; Xiao, F.; Zhang, J. Recovering building information model from 2D drawings for mechanical, electrical and plumbing systems of ageing buildings. Autom. Constr. 2023, 152, 104914. [Google Scholar] [CrossRef]

- Zhao, Y.; Deng, X.; Lai, H. Reconstructing BIM from 2D structural drawings for existing buildings. Autom. Constr. 2021, 128, 103750. [Google Scholar] [CrossRef]

- Wang, B.; Yin, C.; Luo, H.; Cheng, J.C.P.; Wang, Q. Fully automated generation of parametric BIM for MEP scenes based on terrestrial laser scanning data. Autom. Constr. 2021, 125, 103615. [Google Scholar] [CrossRef]

- Hu, J.; Bao, Q.; Zhou, T.; Li, K.; Shang, L.; Zhang, J.; Fu, X. Automatic Generation Construction Shop Design Model of the MEP Hanger Based on BIM. Buildings 2023, 13, 867. [Google Scholar] [CrossRef]

- Han, J.; Zhou, X.; Zhang, W.; Guo, Q.; Wang, J.; Lu, Y. Directed Representative Graph Modeling of MEP Systems Using BIM Data. Buildings 2022, 12, 834. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, J.; Fu, X.; Zhang, R.; Zhu, H.; Bao, Q. Automated Rule Checking for MEP Systems Based on BIM and KBMS. Buildings 2022, 12, 934. [Google Scholar] [CrossRef]

- Ismail, A.S.; Ali, K.N.; Iahad, N.A. A Review on BIM-based automated code compliance checking system. In Proceedings of the 2017 International Conference on Research and Innovation in Information Systems (ICRIIS), Langkawi, Malaysia, 16–17 July 2017; IEEE: Washington, DC, USA, 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Moselhi, O.; Iordanova, I.; Valdivieso, F.; Shakibabarough, A.; Bagchi, A. The Development of an Automated System for a Quality Evaluation of Engineering BIM Models: A Case Study. Appl. Sci. 2024, 14, 3244. [Google Scholar] [CrossRef]

- Deng, R.; Li, X.; Tian, Y. A Review: The Application of Path Optimization Algorithms in Building Mechanical, Electrical, and Plumbing Pipe Design. Buildings 2025, 15, 2093. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, K.; Wang, Q.; Wang, J.; Huang, X.; Zhou, W. IEDW: A BIM-based indoor electric distribution wiring algorithm using graph theory and capacity-limited multiple traveling salesman problem solver. Adv. Eng. Inform. 2023, 56, 101999. [Google Scholar] [CrossRef]

- Choi, W.; Kim, C.; Heo, S.; Na, S. The Modification of A* Pathfinding Algorithm for Building Mechanical, Electronic and Plumbing (MEP) Path. IEEE Access 2022, 10, 65784–65800. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons: New York, NY, USA, 2018. [Google Scholar]

- Godager, B.; Onstein, E.; Huang, L. The Concept of Enterprise BIM: Current Research Practice and Future Trends. IEEE Access 2021, 9, 42265–42290. [Google Scholar] [CrossRef]

- Teo, Y.H.; Yap, J.H.; An, H.; Yu, S.C.M.; Zhang, L.; Chang, J.; Cheong, K.H. Enhancing the MEP Coordination Process with BIM Technology and Management Strategies. Sensors 2022, 22, 4936. [Google Scholar] [CrossRef]

- Pogorelskiy, S.; Kocsis, I. Automation for structured cabling system in data centers using Building Information Modelling. Int. Rev. Appl. Sci. Eng. 2022, 13, 335–345. [Google Scholar] [CrossRef]

- Lu, Q.; Wong, Y.H. A BIM-based approach to automate the design and coordination process of mechanical, electrical, and plumbing systems. HKIE Trans. Hong Kong Inst. Eng. 2018, 25, 273–280. [Google Scholar] [CrossRef]

- GB 51348-2019; Design Standard for Electrical Systems of Civil Buildings. China Architecture & Building Press: Beijing, China, 2019.

- Silvela, J.; Portillo, J. Breadth-First Search and Its Application to Image Processing Problems. In Proceedings of the IEEE Transactions on Image Processing, Anchorage, AK, USA, 31 August 2001; Volume 10. No. 8. [Google Scholar]

- Li, Q.; Xie, F.; Zhao, J.; Xu, B.; Yang, J.; Liu, X.; Suo, H. FPS: Fast Path Planner Algorithm Based on Sparse Visibility Graph and Bidirectional Breadth-First Search. Remote Sens. 2022, 14, 3720. [Google Scholar] [CrossRef]

- Madiniyeti, J.; Zhou, Q.; Qi, H.; Chao, Y.; Zhang, Y. Research on Automated Modeling Technology of Sluice Gate Project Based on BIM Technology. Sensors 2024, 24, 5114. [Google Scholar] [CrossRef]

- GB 50303-2015; Acceptance Specification for Construction Quality of Building Electrical Installations. China Planning Press: Beijing, China, 2015.

- GB 50054-2011; Code for Design of Low Voltage Electrical Installations. China Planning Press: Beijing, China, 2011.

- Dong, T.; Zhang, Y.; Li, G.; Li, B. The research and development of parts library system oriented to high voltage switchgear. In Proceedings of the 2009 IEEE 10th International Conference on Computer-Aided Industrial Design & Conceptual Design, Wenzhou, China, 26–29 November 2009; pp. 781–785. [Google Scholar] [CrossRef]

- Falekas, G.; Karlis, A. Digital twin in electrical machine control and predictive maintenance: State-of-the-art and future prospects. Energies 2021, 14, 5933. [Google Scholar] [CrossRef]

- Rajora, G.L.; Sanz-Bobi, M.A.; Tjernberg, L.B.; Cabus, J.E.U. A review of asset management using artificial intelligence-based machine learning models: Applications for the electric power and energy system. IET Gener. Transm. Distrib. 2024, 18, 2155–2170. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).