Real-Time Hybrid Test Development and Application in Soil–Structure Interaction Systems

Abstract

1. Introduction

2. Review of RTHT

2.1. RTHT Application

2.1.1. Vibration-Isolated Structures and Non-Vibration-Controlled Structures

2.1.2. Electrical and Non-Structural Coupled Systems

2.1.3. SSI Systems

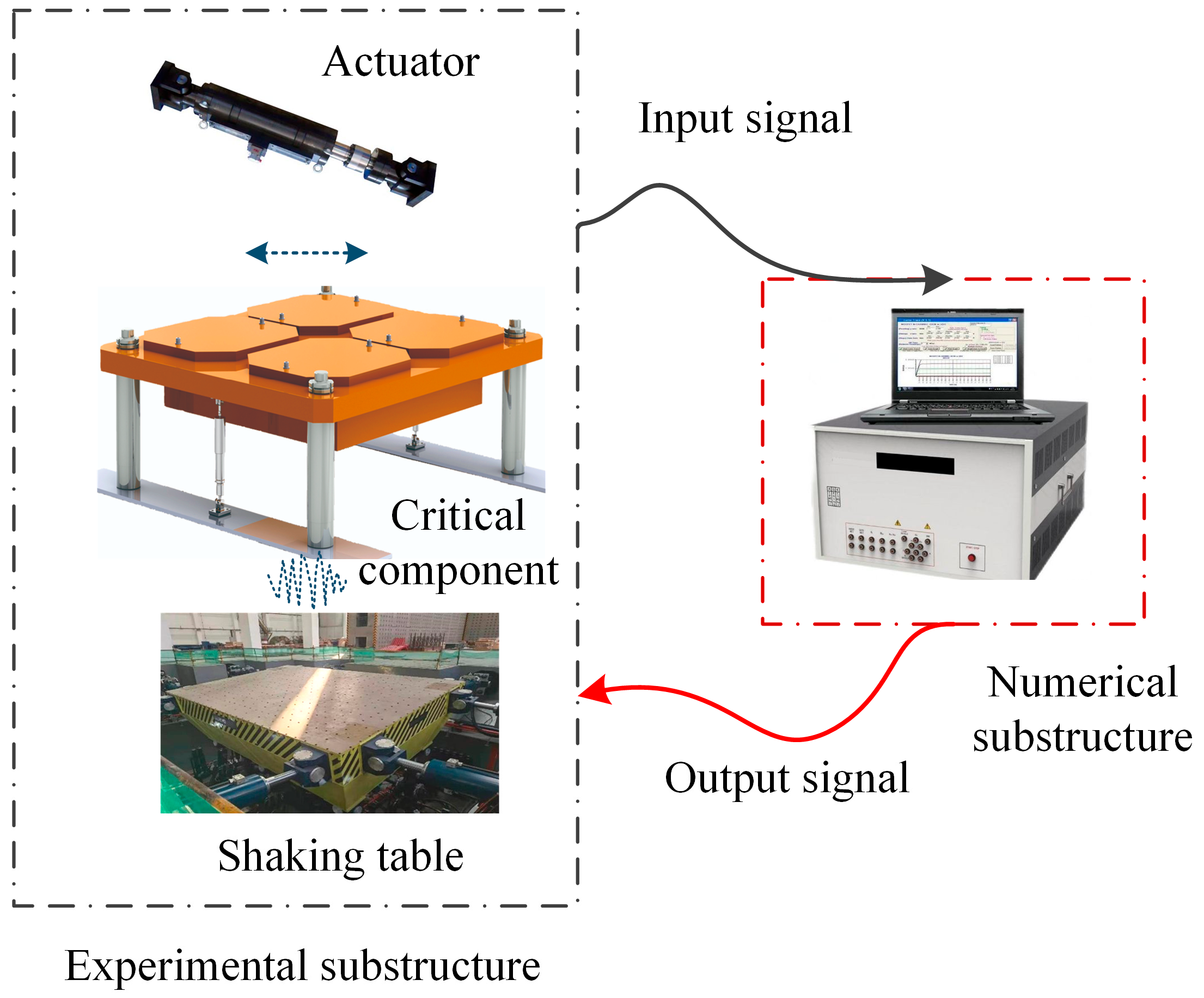

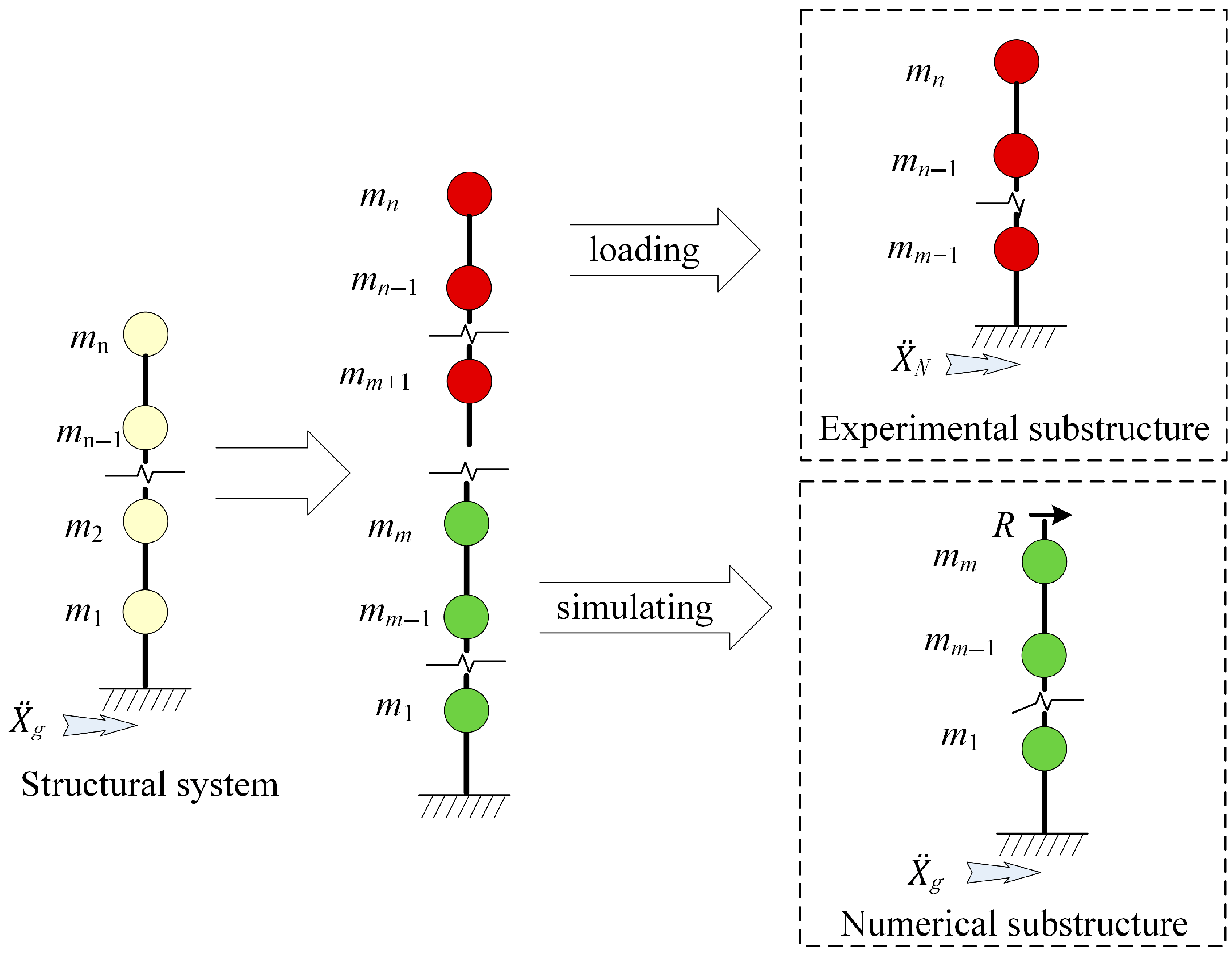

2.2. Experimental Substructure Loading

2.2.1. Load Device Control and Time-Delay Compensation

2.2.2. Experimental Substructure Interface Load

2.3. Numerical Substructure Calculation

2.4. Data Exchange

2.4.1. Derivation of Multi-DOF Systems [5,20]

2.4.2. Derivation of Individual Numerical Substructure Motion Equation [15,111]

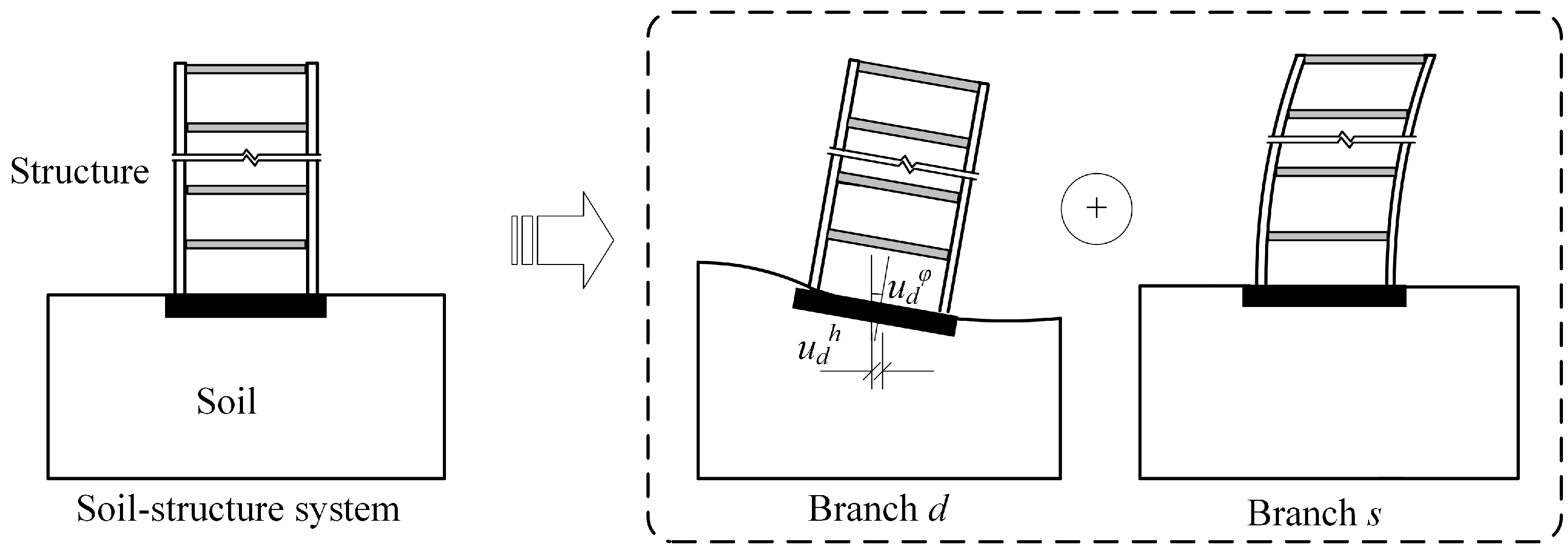

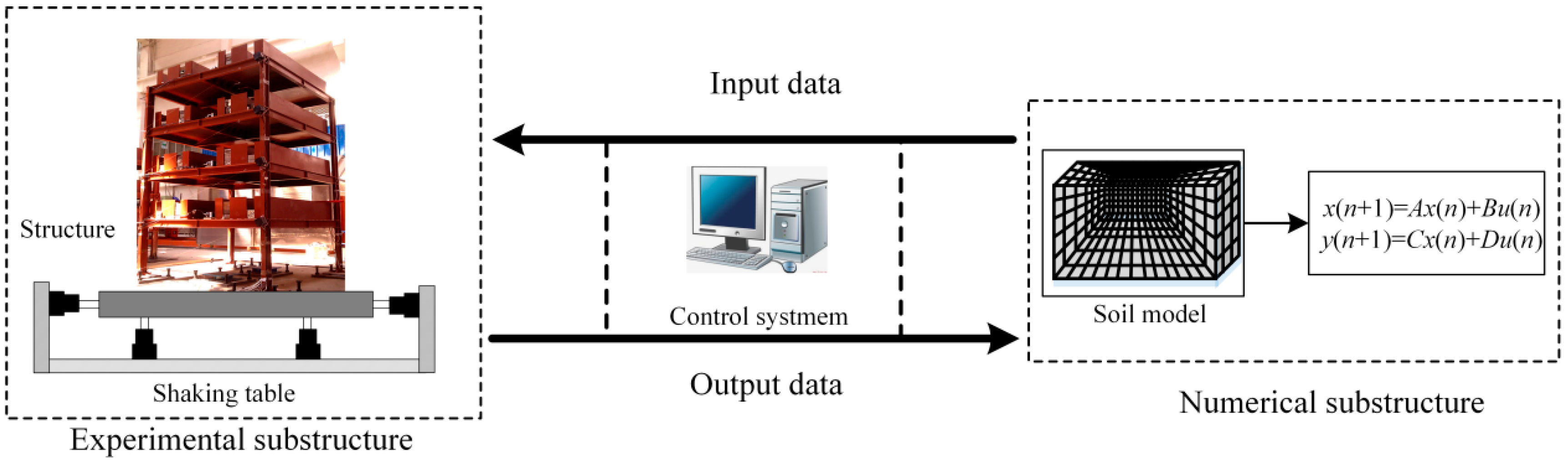

3. Soil–Structure System RTHT

3.1. Review of Numerical Substructure Models and Date Exchanging Methods in Existing SSI-RTHT Studies

3.2. RTHT Method of SSI Based on Branch Modal Method

4. Discussion

4.1. Main Findings

4.2. Key Obstacles

- Limited numerical substructure modeling capacity: Existing studies rarely improve computational efficiency for large-scale finite element models, which severely restricts RTHT deployment in complex systems.

- Restricted delay-compensation accuracy: Current algorithms struggle to maintain high fidelity for heavy specimens or low-frequency structures.

- Poor generality of interface equations: Over 90% of existing RTHT implementations adopt lumped mass assumptions, making it difficult to couple three-dimensional continuum finite element models with experimental substructures.

4.3. Future Directions

- Model condensation: Modal synthesis strategies offer DOF reductions exceeding two orders of magnitude while safeguarding key modes within 5% deviation.

- Shared resources: Open-access, parameterized soil libraries integrated into real-time platforms can cut the model setup time and accelerate RTHT adoption for large-scale seismic assessment.

5. Conclusions

- A quantitative review of 120 RTHT papers (1992–2025) revealed that SSI applications account for only 8% of all test applications, indicating a significant research gap in this complex area.

- The primary research obstacles were identified and quantified. Less than 3% of studies use numerical models with over 10,000 DOFs; large-mass specimens still struggle with delay compensation accuracy; and over 90% of interface equations rely on lumped mass assumptions.

- A branch modal RTHT framework is proposed, which compresses the DOFs of a soil model from thousands to one hundred DOFs, with a verified peak acceleration error of less than 7%, providing a viable pathway for large-scale SSI-RTHT.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nakashima, M.; Kato, H.; Takaoka, E. Development of real-time pseudo dynamic Testing. Earthq. Eng. Struct. Dyn. 1992, 21, 79–92. [Google Scholar] [CrossRef]

- Horiuchi, T.; Inoue, M.; Konno, T.; Yamagishi, W. Development of a real-Time hybrid experimental system using shaking tables: Proposal of experiment concept and feasibility study with rigid secondary system. JSME. Int. J. Ser. C 1999, 42, 255–264. [Google Scholar] [CrossRef]

- Igarashi, A.; Iemura, H.; Suwa, T. Development of substructured shaking table test method. In Proceedings of the 12th World Conference on Earthquake Engineering, Auckland, New Zealand, 30 January–4 February 2000. [Google Scholar]

- Lee, S.K.; Park, E.C.; Min, K.W.; Park, J.H. Real-time substructuring technique for the shaking table test of upper substructures. Eng. Struct. 2007, 29, 2219–2232. [Google Scholar] [CrossRef]

- Lee, S.K.; Park, E.C.; Min, K.W.; Lee, S.H.; Chung, L.; Park, J.H. Real-time hybrid shaking table testing method for the performance evaluation of a tuned liquid damper controlling seismic response of building structures. J. Sound. Vib. 2007, 302, 596–612. [Google Scholar] [CrossRef]

- Reinhorn, A.; Sivaselvan, M.V.; Liang, Z.; Shao, X. Real-time dynamic hybrid testing of structural systems. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, Canada, 1–6 August 2004. [Google Scholar]

- Zhu, F.; Wang, J.T.; Jin, F.; Lu, L.Q. Control performance comparison between tuned liquid damper and tuned liquid column damper using real-time hybrid simulation. Earthq. Eng. Eng. Vib. 2019, 18, 695–701. [Google Scholar] [CrossRef]

- Wu, B.; Zhou, H.M. Equivalent force control method with sliding mode controller for real-time substructure test. J. Vib. Shock. 2012, 31, 27–33. [Google Scholar]

- Yang, G.; Wu, B.; Ou, G.; Wang, Z.; Dyke, S. HyTest: Platform for structural hybrid simulation with finite element model updating. Adv. Eng. Softw. 2017, 112, 200–210. [Google Scholar] [CrossRef]

- Wu, B.; Ning, X.Z.; Xu, G.S.; Wang, Z.; Mei, G.; Yang, G.; Wang, T. Online numerical simulation: A hybrid simulation method for incomplete boundary conditions. Earthq. Eng. Struct. Dyn. 2018, 47, 889–905. [Google Scholar] [CrossRef]

- Zhou, H.M.; Wu, B.; Tan, X.J.; Dai, J.W. Shaking table substructure test of tuned liquid damper. Chin. Civ. Eng. J. 2014, 47, 70–75. [Google Scholar]

- Wang, X. Performance Based Implementation of Seismic Protective Devices for Structures. Ph.D. Thesis, University of California, Los Angeles, CA, USA, 2014. [Google Scholar]

- Riascos, C.; Casas, J.M.; Thomson, P. Semi-active tuned liquid column damper implementation with real-time hybrid simulations. In Proceedings of the Active and Passive Smart Structures and Integrated Systems 2016, Las Vegas, NV, USA, 20–24 March 2016. [Google Scholar]

- Chu, S.Y.; Lu, L.Y.; Yeh, S.W. Real-time hybrid testing of a structure with a piezoelectric friction controllable mass damper by using a shake table. J. Struct. Control Health Monit. 2018, 25, e2124. [Google Scholar] [CrossRef]

- Schellenberg, A.H.; Becker, T.C.; Mahin, S.A. Hybrid shake table testing method: Theory, implementation and application to midlevel isolation. J. Struct. Control Health Monit. 2018, 24, e1915. [Google Scholar] [CrossRef]

- Zhang, R.Y.; Phillips, B.M.; Taniguchi, M.; Ikenaga, K. Shake table real-time hybrid simulation techniques for the performance evaluation of buildings with inter-story isolation. J. Struct. Control Health Monit. 2017, 24, e1971. [Google Scholar] [CrossRef]

- Park, J.; Chae, Y.; Chin, W.J.; Cho, C.B. Real-time hybrid simulation for investigating the seismic response of a bridge isolated with lead rubber bearings. Earthq. Eng. Struct. Dyn. 2017, 54, 548–561. [Google Scholar] [CrossRef]

- Shen, J.; Igarashi, A.; Dang, J.; Hamada, Y.; Himeno, T. Seismic Performance Evaluation of Lead High-Damping Rubber Bearings Tested by Real-Time Hybrid Simulations at Low Temperatures. Earthq. Eng. Struct. Dyn. 2025, 54, 2805–2823. [Google Scholar] [CrossRef]

- Chi, F.D.; Wang, J.T.; Jin, F. Delay-dependent stability and added damping of SDOF real-time dynamic hybrid testing. Earthq. Eng. Eng. Vib. 2010, 9, 425–438. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.T.; Jin, F.; Zhang, C.H. Real-Time dynamic hybrid testing based on shaking-table and its application to a two storey rigid frame. Eng. Mech. 2010, 27, 57–64. [Google Scholar]

- Wang, X.Y.; Tian, S.Z. Principle and implementation of the hybrid testing method based on substructure techniques by using shaking table. J. Earthq. Eng. Eng. Vib. 2009, 29, 46–52. [Google Scholar]

- Cai, X.J.; Tian, S.Z.; Wang, D.P.; Xiao, Y. Networked collaborative pseudo-dynamic testing of a multi-span bridge based on NetSLab. Earthq. Eng. Eng. Vib. 2009, 8, 387–397. [Google Scholar] [CrossRef]

- Mosalam, K.M.; Moustafa, M.A.; Günay, S.; Takhirov, S. Experimental investigation of the seismic performance of substation porcelain insulator posts in high voltage disconnect switches. In Proceedings of the 15WCEE, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Mosalam, K.M.; Günay, S. Seismic performance evaluation of high voltage disconnect switches using real-time hybrid simulation: I. System development and validation. Eng. Struct. Dyn. 2014, 43, 1205–1222. [Google Scholar] [CrossRef]

- Günay, S.; Mosalam, K.M. Seismic performance evaluation of high-voltage disconnect switches using real-time hybrid simulation: II. Parametric study. Earthq. Eng. Struct. Dyn. 2014, 43, 1223–1237. [Google Scholar] [CrossRef]

- Bi, J.H.; Luo, L.F.; Jiang, N. Seismic energy response analysis of equipment-structure system via real-time dynamic substructuring shaking table testing. Adv. Struct. Eng. 2020, 23, 37–50. [Google Scholar] [CrossRef]

- Xu, G.S.; Zheng, L.C.; Wu, Z.; Wang, G.L.; Sun, X.Z.; Zhang, D.J.; Li, G.; Yang, G.; Wang, T. A real-time hybrid testing based on shaking table and actuator for cable tray systems. Eng. Struct. 2023, 284, 115977. [Google Scholar] [CrossRef]

- Guo, W.; Zeng, C.; Gou, H.; Gu, Q.; Wang, T.; Zhou, H.M.; Zhang, J.L.; Wu, J. Real-time hybrid simulation of high-speed train-track-bridge interactions using the moving load convolution integral method. Eng. Struct. 2021, 228, 111537. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Liang, R.Q.; Huang, X.; He, Z.P.; Rao, B. Boundary coordination algorithm for real-time hybrid test of high-speed maglev train-guideway coupling vibration. Eng. Struct. 2024, 314, 118355. [Google Scholar] [CrossRef]

- Wang, Z.; Xiao, J.J.; Zhang, B.A.; Yang, G.; Wu, B.; Jia, X.J. Performance of Real-Time Hybrid Simulation for Hunting Dampers of High-Speed Trains. Struct. Control Health Monit. 2024, 2024, 4984025. [Google Scholar] [CrossRef]

- Xu, G.S.; Jiang, Y.T.; Ning, X.Z.; Liu, Z.P.; Wang, T. A Real-Time Hybrid Simulation Method for Vehicle-Bridge Interaction Systems Considering Vehicle Jumping. Int. J. Struct. Stab. Dyn. 2024, 24, 2450129. [Google Scholar] [CrossRef]

- Al-Subaihawi, S.; Kolay, C.; Marullo, T.; Ricles, J.M.; Quiel, S.E. Assessment of wind-induced vibration mitigation in a tall building with damped outriggers using real-time hybrid simulations. Eng. Struct. 2019, 205, 110044. [Google Scholar] [CrossRef]

- Dong, J.; Wojtkiewicz, S.F.; LoboAguilar, J.; Yuan, Y.; Christenson, R.E. Aeroelastic Real-Time Hybrid Simulation. I: Validation. J. Eng. Mech. 2020, 150, 04020058. [Google Scholar] [CrossRef]

- Zhou, H.M.; Shao, X.Y.; Zhang, J.W.; Yao, H.C.; Liu, Y.H.; Tan, P.; Chen, L.; Xu, Y.; Zhang, W.; Gong, R. Real-time hybrid model test to replicate high-rise building resonant vibration under wind loads. Thin. Wall. Struct. 2024, 197, 111559. [Google Scholar]

- Wang, J.L.; Fu, J.Y.; Wu, J.R.; Liu, Y.H.; Zhou, H.M.; Ng, C.T.; Liu, Q.X. Evaluation of wind-induced response of high-rise structure with TMD system by real-time hybrid simulation test with motor-driven shaking table. Eng. Struct. 2024, 322, 119097. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Zhang, D.; Zhang, Y.F.; Li, N.; Gao, S.L.; Yue, Y.N. Real-time hybrid simulation incorporating machine learning for deep-water bridges subjected to seismic ground motion with fluid-structure dynamic interaction. Soil Dyn. Earthq. Eng. 2023, 175, 108263. [Google Scholar] [CrossRef]

- Lin, G.L.; Lu, L.Y.; Lei, K.T.; Yeh, S.W.; Liu, K.Y. Accuracy assessment of real-time hybrid testing for seismic control of an offshore wind turbine supporting structure with a TMD. Smart Struct. Syst. 2023, 31, 601–619. [Google Scholar]

- Shi, W.; Fu, J.; Cao, L.Y.; Han, X.; Wan, L.; Karimirad, M.; Wang, W.H. Multi-rotor-based real-time hybrid model tank testing of a 10-MW semi-submersible offshore floating wind turbine. Mar. Struct. 2025, 104, 103888. [Google Scholar] [CrossRef]

- Bagheri, M.; Ebadi Jamkhaneh, M.; Samali, B. Effect of seismic soil–pile–structure interaction on midand high-rise steel buildings resting on a group of pile foundations. Int. J. Geomech. 2018, 18, 04018103. [Google Scholar] [CrossRef]

- Konagai, K.; Nogami, T. Analog circuit to simulate dynamic soil-structure interaction in shake table test. Soil Dyn. Earthq. Eng. 1999, 17, 279–287. [Google Scholar] [CrossRef]

- Kobayashi, H.; Tamura, K.; Tanimoto, S. Hybrid vibration experiments with a bridge foundation system model. Soil Dyn. Earthq. Eng. 2003, 22, 1135–1141. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.T.; Jin, F. Soil-structure interaction analysis by real-time dynamic hybrid hybrid testing. Eng. Mech. 2011, 31, 3765–3770. [Google Scholar] [CrossRef]

- Chi, F.D.; Wang, J.T.; Jin, F.; Wang, Q. Real-time dynamic hybrid testing for soil-structure-fluid interaction analysis. Rock. Soil Mech. 2010, 31, 3765–3770. [Google Scholar]

- Zhou, M.X.; Wang, J.T.; Jin, F.; Gui, Y.; Zhou, F. Real-Time Dynamic Hybrid Testing Coupling Finite Element and Shaking Table. J. Earthq. Eng. 2014, 18, 637–653. [Google Scholar] [CrossRef]

- Fu, X.Q.; Pan, D.G.; Huang, Y.; Huang, T.L. Real-time dynamic hybrid testing method for the dynamic characteristics of soil-structure interaction system. Soil Dyn. Earthq. Eng. 2022, 166, 107742. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.T.; Jin, F.; Chi, F.D.; Zhang, C.H. Real-time dynamic hybrid testing for soil-structure interaction analysis. Soil Dyn. Earthq. Eng. 2011, 31, 1690–1702. [Google Scholar] [CrossRef]

- Li, Z.B.; Tang, Z.Y.; Ji, J.B.; Li, X.L.; Zhou, D.X.; Yan, W.M. Research on the Dynamic Sub-Structuring Testing Method for SSI Based on Shaking Table Array. Struct. Eng. 2011, 27, 76–81. [Google Scholar]

- Dietz, M.; Tang, Z.Y.; Taylor, C.; Li, Z.B. Substructuring for Soil Structure Interaction Using a Shaking Table. In Experimental Research in Earthquake Engineering. Geotechnical, Geological and Earthquake Engineering; Taucer, F., Apostolska, R., Eds.; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Chen, Y.J.; Zhou, D.X.; Yan, W.M.; Zhen, T.Y. Shaking Table Test of a Long-span Continuous Girder Bridge. Adv. Mater. Res. 2012, 446–449, 242–246. [Google Scholar] [CrossRef]

- Yan, X.Y.; Li, Z.X.; Li, Y.; Du, X.L. Shaking tables test on a long-span continuous girder bridge considering soil-structure interaction. China Civ. Eng. J. 2013, 46, 98–104. [Google Scholar]

- Yan, X.Y.; Cao, S.S.; Zhao, Z. Shaking Tables Test on Seismic Responses of a Long-Span Rigid-Framed Bridge Considering Traveling Wave Effect and Soil-Structure Interaction. Buildings 2024, 14, 1432. [Google Scholar] [CrossRef]

- Xu, G.S.; Xu, J.F.; Wang, Z.; Zhou, H.M.; Wu, B.; Zhou, L.J.; Wang, X.Y. Substructure Testing Method and Numerical Simulation of Storage Tank Considering Interaction between Soil and Structure. J. Disaster Prev. Mitig. Eng. 2014, 4, 347–352. [Google Scholar]

- Li, H.; Maghareh, A.; Condori, J.; Montoya, J.S.; Dyke, Z.D.; Xu, H. Advancing real-time hybrid simulation for coupled nonlinear soil-isolator-structure system. Smart Struct. Syst. 2021, 28, 105–119. [Google Scholar]

- Tao, J.J.; Mercan, O.; Calayir, M. Multi-rate real-time hybrid simulation with adaptive discrete feedforward controller-based compensation strategy. Earthq. Eng. Struct. Dyn. 2024, 53, 1260–1284. [Google Scholar] [CrossRef]

- Cho, C.B.; Chae, Y.; Park, M. Improved real-time force control for applying axial force to axially stiff members. Earthq. Eng. Struct. Dyn. 2024, 53, 331–347. [Google Scholar] [CrossRef]

- Horiuchi, T.; Inoue, M.; Konno, T.; Namita, Y. Real-time hybrid experimental system with actuator delay compensation and its application to a piping system with energy absorber. Earthq. Eng. Struct. Dyn. 1999, 28, 1121–1141. [Google Scholar] [CrossRef]

- Neild, S.A.; Stoten, D.P.; Drury, D.J.; Wagg, D. Control issues relating to real-time substructuring experiments using shaking tables. Earthq. Eng. Struct. Dyn. 2005, 34, 1171–1192. [Google Scholar] [CrossRef]

- Wallace, M.I.; Sieber, J.; Neild, S.A.; Wagg, D.J.; Krauskopf, B. Stability analysis of real-time dynamic substructuring using delay differential model. Earthq. Eng. Struct. Dyn. 2005, 34, 1817–1832. [Google Scholar] [CrossRef]

- Zakersalehi, M.; Tasnimi, A.A.; Ahmadizadeh, M. Reliable nonlinear hybrid simulation using modified operator splitting technique. J. Struct. Control Health Monit. 2018, 26, e2283. [Google Scholar] [CrossRef]

- Carrion, J.E.; Spencer, B.F.; Phillips, B.M. Real-time hybrid testing of a semi-actively controlled structure with an MR damper. In Proceedings of the American Control Conference, St. Louis, MO, USA, 10–12 June 2009. [Google Scholar]

- Chen, C.; Ricles, J.M. Analysis of actuator delay compensation methods for real-time testing. Eng. Struct. 2009, 31, 2643–2655. [Google Scholar] [CrossRef]

- Chen, P.C.; Tsai, K.C. Dual compensation strategy for real-time hybrid testing. Earthq. Eng. Struct. Dyn. 2013, 42, 1–23. [Google Scholar] [CrossRef]

- Chen, P.C.; Chang, C.-M.; Spencer, B.F.; Tsai, K.-C. Adaptive model-based tracking control for real-time hybrid simulation. Bull. Earthq. Eng. 2015, 13, 1633–1653. [Google Scholar] [CrossRef]

- Günay, S.; Mosalam, K.M. Enhancement of real-time hybrid simulation on shaking tables configuration with implementation of an advanced control method. Earthq. Eng. Struct. Dyn. 2015, 44, 657–675. [Google Scholar] [CrossRef]

- Gao, X.Y.; Castaneda, S.J.; Dyke, S.J. Real time hybrid simulation: From dynamic system, motion control to experimental error. Earthq. Eng. Struct. Dyn. 2013, 42, 815–832. [Google Scholar] [CrossRef]

- Stefanaki, A.; Sivaselvan, M.V. A simple strategy for dynamic substructuring: I. Concept and development. Earthq. Eng. Struct. Dyn. 2018, 47, 1801–1822. [Google Scholar] [CrossRef]

- Chae, Y.; Rabiee, R.; Dursun, A.; Kim, C.Y. Real-time force control for servo-hydraulic actuator systems using adaptive time series compensator and compliance springs. Earthq. Eng. Struct. Dyn. 2018, 47, 854–871. [Google Scholar] [CrossRef]

- Zhang, R.Y.; Lauenstein, P.V.; Phillips, B.M. Real-time hybrid simulation of a shear building with a uni-axial shake table. Eng. Struct. 2016, 119, 217–229. [Google Scholar] [CrossRef]

- Nasiri, M.; Safi, A. Stability analysis of real-time hybrid simulation in consideration of time delays of actuator and shake table using delay differential equations. J. Mech. Sci. Technol. 2019, 33, 1489–1499. [Google Scholar] [CrossRef]

- Wu, B.; Xu, G.S.; Li, Y.; Shing, P.B.; Ou, J.P. Performance and Application of Equivalent Force Control Method for Real-Time Substructure Testing. J. Eng. Mech. 2012, 138, 1303–1316. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Z.; Bursi, O.S. Actuator dynamics compensation based on upper bound delay for real-time hybrid simulation. Earthq. Eng. Struct. Dyn. 2013, 42, 1749–1765. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, B.; Bursi, O.S.; Xu, G.S.; Ding, Y. An effective online delay estimation method based on a simplified physical system model for Real-Time Hybrid Simulation. Smart Struct. Syst. 2014, 14, 1247–1267. [Google Scholar] [CrossRef]

- Shi, P.F.; Wu, B.; Spencer, B.F.; Phillips, B.M.; Chang, C.M. Real-time hybrid testing with equivalent force control method incorporating Kalman filter. J. Struct. Control Health Monit. 2016, 23, 735–748. [Google Scholar] [CrossRef]

- Chi, F.D.; Wang, J.T.; Jin, F. Delay-dependent stability analysis of mode real-time dynamic hybrid testing considering compensation. Eng. Mech. 2011, 28, 200–207. [Google Scholar]

- Zhu, F.; Wang, J.T.; Jin, F.; Gui, Y.; Zhou, M.X. Analysis of delay compensation in real-time dynamic hybrid testing with large integration time-step. Smart Struct. Syst. 2014, 14, 1269–1289. [Google Scholar] [CrossRef]

- Wang, J.T.; Lu, L.; Zhu, F. Efficiency analysis of numerical integrations for finite element substructure in real-time hybrid simulation. Earthq. Eng. Eng. Vib. 2018, 17, 73–86. [Google Scholar] [CrossRef]

- Maghareh, A.; Dyke, S.J.; Silva, C.E. A Self-tuning Robust Control System for nonlinear real-time hybrid simulation. Earthq. Eng. Struct. Dyn. 2018, 49, 695–715. [Google Scholar] [CrossRef]

- Guo, J.; Tang, Z.Y.; Chen, S.C.; Li, Z.B. Control strategy for the substructuring testing systems to simulate soil-structure interaction. Smart Struct. Syst. 2016, 18, 1169–1188. [Google Scholar] [CrossRef]

- Tang, Z.Y.; Dietz, M.; Li, Z.B. Substructuring stability analysis in light of comprehensive transfer system dynamics. Bull. Earthq. Eng. 2018, 16, 129–154. [Google Scholar] [CrossRef]

- Liu, H.; Tang, Z.Y. Stability prediction method for real-time hybrid test system based on the measured dynamics of physical test system. Soil Dyn. Earthq. Eng. 2023, 176, 108305. [Google Scholar] [CrossRef]

- Huang, L.; Chen, C.; Pu, Y.F.; Wang, J.F.; Guo, T. Stability analysis of real time hybrid simulation under coupled actuator delay and nonlinear behavior. Earthq. Eng. Struct. Dyn. 2022, 51, 2357–2377. [Google Scholar] [CrossRef]

- Liu, M.; Gu, W.; Guo, W.; Zhou, H.M.; Wang, T.; Chang, R.J. Numerical simulation for real-time hybrid testing of high-speed maglev train-track-bridge systems under complex loads. Structures 2025, 73, 108337. [Google Scholar] [CrossRef]

- Liu, H.; Tang, Z.Y.; Enokida, R. Stability prediction method of time-varying real-time hybrid testing system on vehicle-bridge coupled system. Mech. Syst. Signal Process. 2024, 216, 111463. [Google Scholar] [CrossRef]

- Zhao, P.F.; Wang, Y.Y.; Cheng, S.G. A new method of structure seismic test. Earthq. Resist. Eng. Retrof. 2005, 27, 41–44. [Google Scholar]

- Jia, H.X.; Tian, S.Z.; Li, S.J.; Wu, W.Y.; Cai, X.J. seismic Application of Multi-Scale Finite Element Model for Hybrid simulation. Int. J. Struct. Integrity 2018, 9, 548–559. [Google Scholar] [CrossRef]

- Jia, H.X.; Tian, S.Z.; Lin, Y.Z. Hybrid simulation based on finite element analysis of a continuous gird bridge with fiber reinforced polymer composition. In Proceedings of the 6th International Conference on Advance in Experimental Structural Engineering, 11th International Workshop on Advanced Smart Materials and Smart Structures Technology, Champaign, IL, USA, 1–2 August 2015. [Google Scholar]

- Tian, S.J.; Jia, H.X.; Lin, Y.Z. Hybrid simulation of a carbon fibre-reinforced polymer-strengthened continuous reinforced concrete girder bridge. Adv. Struct. Eng. 2017, 20, 1658–1670. [Google Scholar] [CrossRef]

- Cai, X.J.; Wang, B.; Tian, S.Z. Approximate simulation method for Long-period seismic response of tall buildings based on substructure test. J. Disaster Prev. Mitig. Eng. 2015, 35, 536–542. [Google Scholar]

- Aguila, A.J.; Li, H.L.; Palacio-Betancur, A.; Ahmed, K.A.; Kovalenko, M.; Soto, G. Conditional adaptive time series compensation and control design for multi-axial real-time hybrid simulation. Earthq. Eng. 2024, 10, 1384235. [Google Scholar] [CrossRef]

- Amirali, N.; Spencer, F.B. Multiaxial Real-Time Hybrid Simulation for Substructuring with Multiple Boundary Points. J. Struct. Eng. 2021, 147, 5021007. [Google Scholar] [CrossRef]

- Lin, Y.Z.; Xu, Y.; Wang, Y.H.; Chai, W.C.; Xu, W.J.; Zong, Z.H. Implementation of real-time hybrid simulation using a large shake table with onboard actuators. Eng. Struct. 2024, 305, 117724. [Google Scholar] [CrossRef]

- Wang, T.; Mosqueda, G.; Jacobsen, A.; Cortes-Delgado, M. Performance evaluation of a distributed hybrid test framework to reproduce the collapse behavior of a structure. Earthq. Eng. Struct. Dyn. 2012, 41, 295–313. [Google Scholar] [CrossRef]

- Verma, M.; Rajasankar, J.; Iyer, N.R. Numerical assessment of step-by-step integration methods in the paradigm of real-time hybrid testing. Earthq. Struct. 2015, 8, 1325–1348. [Google Scholar] [CrossRef]

- Andersen, S.; Poulsen, P.N. A Taylor basis for kinematic nonlinear real-time simulations. Part I: The complete modal derivatives. Earthq. Eng. Struct. Dyn. 2019, 48, 989–1006. [Google Scholar] [CrossRef]

- Asgari, A.; Ranjbar, F.; Bagheri, M. Seismic resilience of pile groups to lateral spreading in liquefiable soils: 3D parallel finite element modeling. Structures 2025, 74, 108578. [Google Scholar] [CrossRef]

- Asgari, A.; Bagheri, M.; Hadizadeh, M. Advanced seismic analysis of soil-foundation-structure interaction for shallow and pile foundations in saturated and dry deposits: Insights from 3D parallel finite element modeling. Structures 2024, 69, 107503. [Google Scholar] [CrossRef]

- Bonnet, P.A.; Lim, C.N.; Williams, M.S.; Neild, S.A.; Stoten, D.P.; Taylor, C.A. Real-time hybrid experiments with Newmark integration, MCSmd outer-loop control and multi-tasking strategies. Earthq. Eng. Struct. Dyn. 2007, 36, 119–141. [Google Scholar] [CrossRef]

- Chen, P.C.; Hsu, S.C.; Ma, C.C. Development and verification of real-time hybrid simulation with deep learning-based nonlinear numerical substructure. Earthq. Eng. Struct. Dyn. 2024, 53, 2141–2161. [Google Scholar] [CrossRef]

- Tao, J.J.; Mercan, O.; Calayir, M. Improved implementation of concentrated plasticity models in real-time hybrid simulation. Structures 2024, 64, 106525. [Google Scholar] [CrossRef]

- Zhu, F.; Wang, J.T.; Jin, F.; Zhou, M.X.; Gui, Y. Simulation of large-scale numerical substructure in real-time, dynamic hybrid testing. Earthq. Eng. Eng. Vib. 2014, 13, 599–609. [Google Scholar] [CrossRef]

- Tang, Z.Y.; Liu, H.; Dietz, M.; Chatzigogos, T.C.; Du, X.L. Nonlinear behavior simulation of soil-structure interaction system via real-time hybrid testing. Bull. Earthq. Eng. 2022, 20, 6109–6128. [Google Scholar] [CrossRef]

- Saouma, V.; Kang, D.H.; Haussmann, G. A computational finite-element program for hybrid simulation. Earthq. Eng. Struct. Dyn. 2012, 41, 375–389. [Google Scholar] [CrossRef]

- Aguilar, N.E.C. Development and Validation of a Real-Time Computational Framework for Hybrid Simulation of Dynamically-Excited Steel Frame Structures. Bachelor’s Thesis, Purdue University, West Lafayette, IN, USA, 2012. [Google Scholar]

- McCrum, D.P.; Broderick, B.M. Evaluation of a substructured soft Real-time Hybrid Test for performing Seismic analysis of complex structural systems. Comput. Struct. 2013, 129, 111–119. [Google Scholar] [CrossRef]

- Lu, L.Q.; Wang, J.T.; Zhu, F. Improvement of Real-Time Hybrid Simulation Using Parallel Finite-Element Program. J. Earthq. Eng. 2020, 24, 1547–1565. [Google Scholar] [CrossRef]

- Tang, Z.Y.; Dong, X.H.; Li, Z.B.; Du, X.L. Implementation of real-time hybrid simulation based on GPU computing. Struct. Des. Tall Spec. Build. 2022, 31, e1942. [Google Scholar]

- Maghareh, A.; Waldbjørn, J.P.; Dyke, S.J.; Prakash, A.I.; Ozdagli, A. Adaptive multi-rate interface: Development and experimental verification for real-time hybrid simulation. Earthq. Eng. Struct. Dyn. 2016, 45, 1411–1425. [Google Scholar] [CrossRef]

- Waldbjoern, J.P.; Maghareh, A.; Ge, O.; Dyke, H.; Stang, J.S. Multi-rate Real Time Hybrid Simulation operated on a flexible LabVIEW real-time platform. Eng. Struct. 2021, 239, 112308. [Google Scholar] [CrossRef]

- Gao, F.K.; Tang, Z.Y.; Du, X.L. Implementation of offline iterative hybrid simulation based on neural networks. Earthq. Eng. Resil. 2021, 2, 383–402. [Google Scholar] [CrossRef]

- Wang, T.; Zheng, H.; Xu, G.S.; Wang, Z.; Meng, L.Y. Novel offline iterative hybrid testing method based on model identification and correction. Smart Struct. Syst. 2025, 35, 15–28. [Google Scholar]

- Xu, G.S.; Zheng, K.B.; Yang, K.; Tan, X.J.; Wu, B. Application of equivalent force control method to shaking table substructure testing of structure with TLD. Earthq. Eng. Struct. Dyn. 2006, 35, 113–119. [Google Scholar]

- Konagai, K.; Ahsan, R. Simulation of Nonlinear Soil-Structure Interaction on a Shaking Table. J. Earthq. Eng. 2002, 6, 31–51. [Google Scholar] [CrossRef]

- Zhu, F.; Wang, J.T.; Jin, F.; Lu, L.Q.; Zhou, M.X.; Gui, Y. Real-time hybrid simulation of the size effect of tuned liquid dampers. Struct. Control Health Monit. 2017, 24, e1962. [Google Scholar] [CrossRef]

- Li, Z.B.; Li, X.L.; Tang, Z.Y.; Jiang, H. Research on the methods of evaluating reaction force for dynamic sub-structure experiments using shaking table. Earthq. Eng. Eng. Dyn. 2011, 31, 65–70. [Google Scholar]

- Ding, H.; Wang, J.T.; Zhang, J. Discussion on the accuracy of methods for determining interface force between numerical and physical substructures in shaking table-based real-time hybrid simulation. Mech. Syst. Signal. Process. 2024, 223, 111865. [Google Scholar] [CrossRef]

- Luo, L.F.; Jiang, N. Constrained Mode–Damping Solvent Extraction Combined Method for the Soil Incorporation into a Real-Time Hybrid Test of the Soil–Structure System. Buildings 2022, 12, 1468. [Google Scholar] [CrossRef]

| Researchers | Research Object | Experimental Substructure | Numerical Substructure |

|---|---|---|---|

| Zhu et al. [7], Wu et al. [8,9,10,11], Wang et al. [12], Riascos et al. [13], Chu et al. [14] | Vibration-isolated structures | Various dampers (TLD, MR, Piezoelectric) | Various systems (Single-DOF, Three-DOF, Lumped mass model) |

| Schellenberg et al. [15], Zhang et al. [16] | Interstory isolation structures | Various isolation bearings | Various frame structures (Single-story, Three-story), Lumped mass model |

| Park et al. [17], Shen et al. [18] | Vibration-isolated bridge structures | Bridge isolation bearings, High-damping rubber bearings | Bridge structure |

| Chi et al. [19,20], Tian et al. [21,22] | Non-vibration-controlled structures | Specific floors of the frame structure | Remaining floors |

| Researchers | Research Object |

|---|---|

| Wang et al. [42,43], Zhou et al. [44], Fu et al. [45] | Frame structure–soil interaction system |

| Wang et al. [46] | Soil–structure–fluid dynamic interaction system |

| Li et al. [47,48], Chen et al. [49], Yan et al. [50,51] | Bridge structure–soil interaction |

| Xu et al. [52] | Storage tanks–soil interaction system |

| Li et al. [53] | Seismic isolation structures–soil interaction system |

| Researchers | Experimental Substructure | Date Exchanging Methods |

|---|---|---|

| Wang et al. [42,43], Xu et al. [52] | Lumped parameter model for soil | Few existing studies have focused on the derivation of data interaction formulas. References [42,43] simplified the superstructure into a two-DOF concentrated mass system model to derive the method for RTHT |

| Wang et al. [46], Li et al. [53] | ||

| Zhou et al. [44] | Finite element analysis module with 132 DOFs | |

| Li et al. [47] | Time-domain recursive model | |

| Fu et al. [45] | 200 quadrilateral plane elements |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, L.; Jiang, N.; Zhang, C.; Sun, Y.; Zhang, J. Real-Time Hybrid Test Development and Application in Soil–Structure Interaction Systems. Buildings 2025, 15, 2930. https://doi.org/10.3390/buildings15162930

Luo L, Jiang N, Zhang C, Sun Y, Zhang J. Real-Time Hybrid Test Development and Application in Soil–Structure Interaction Systems. Buildings. 2025; 15(16):2930. https://doi.org/10.3390/buildings15162930

Chicago/Turabian StyleLuo, Lanfang, Nan Jiang, Chongxiang Zhang, Yaoting Sun, and Jinyuan Zhang. 2025. "Real-Time Hybrid Test Development and Application in Soil–Structure Interaction Systems" Buildings 15, no. 16: 2930. https://doi.org/10.3390/buildings15162930

APA StyleLuo, L., Jiang, N., Zhang, C., Sun, Y., & Zhang, J. (2025). Real-Time Hybrid Test Development and Application in Soil–Structure Interaction Systems. Buildings, 15(16), 2930. https://doi.org/10.3390/buildings15162930