Seismic Performance of Steel Structures with Base-Hinged Columns Under Rigidly and Flexibly Braced Systems

Abstract

1. Introduction

2. Materials and Methods

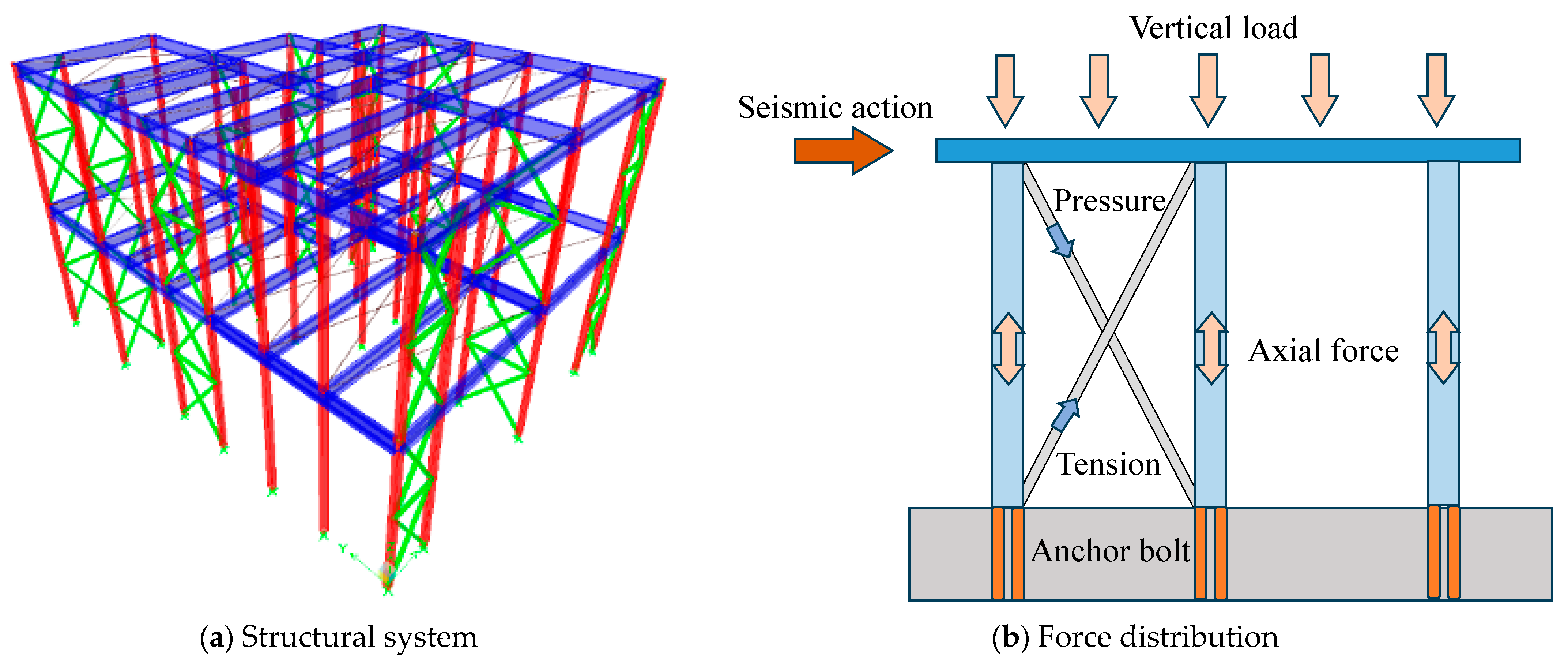

2.1. Steel Structures with Base-Hinged Columns

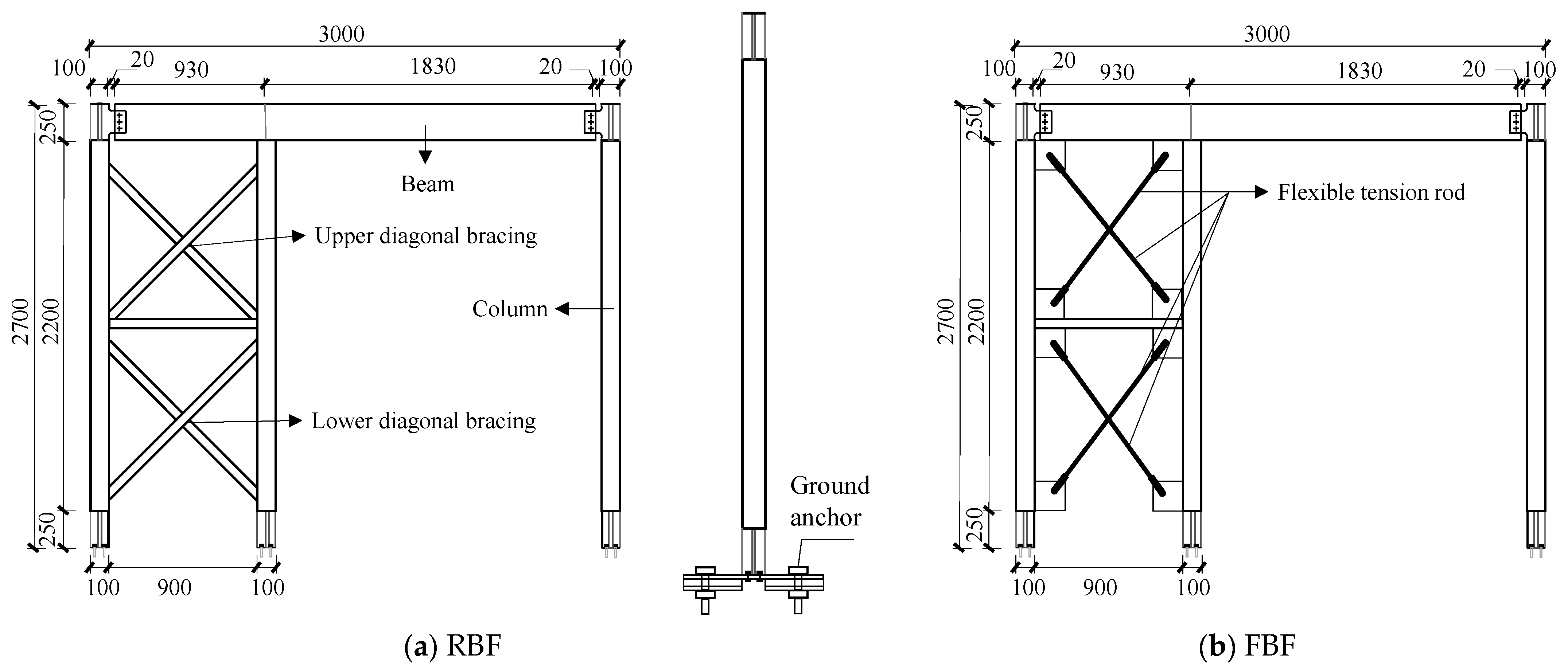

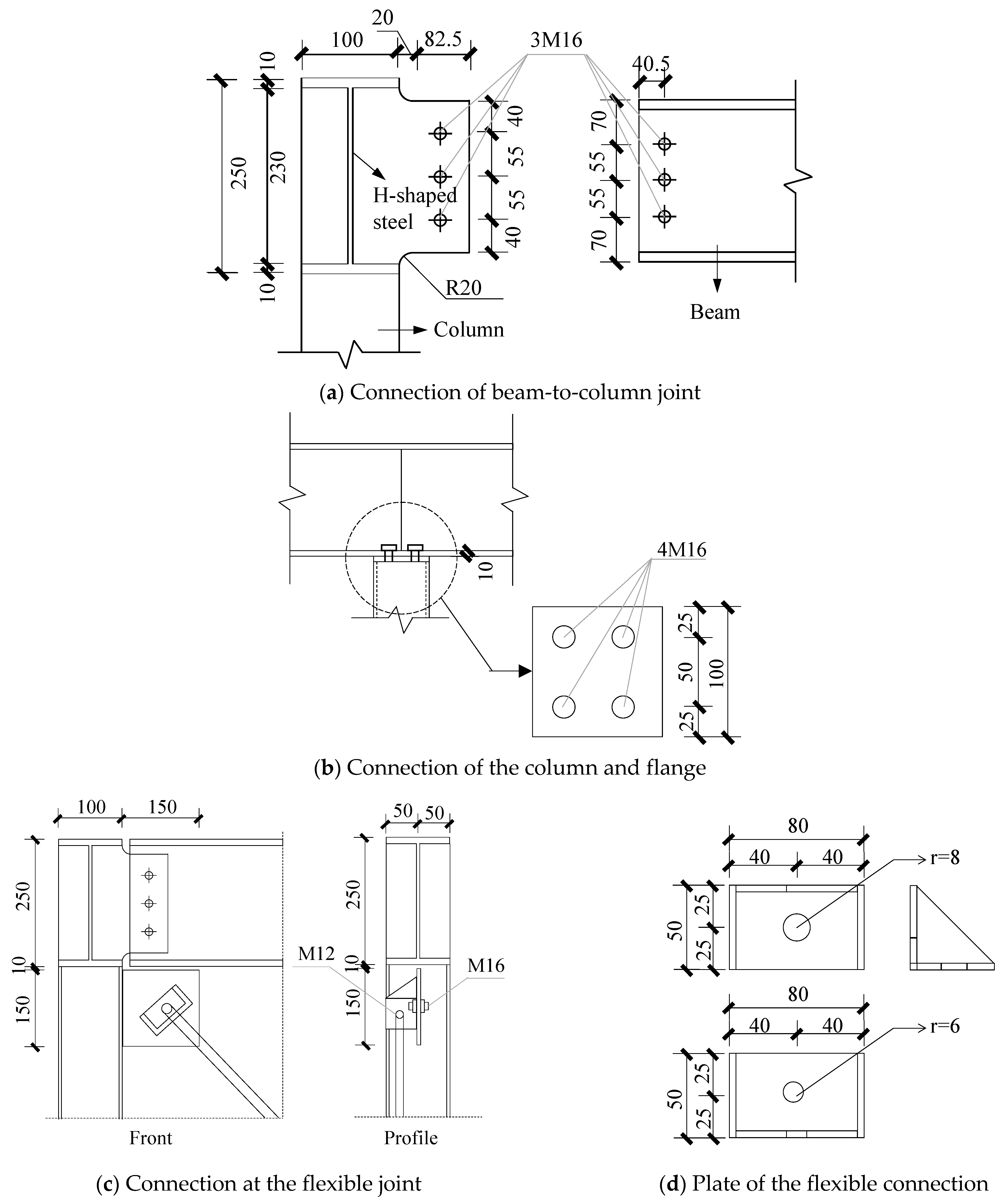

2.2. Specimen Design

2.3. Material Properties

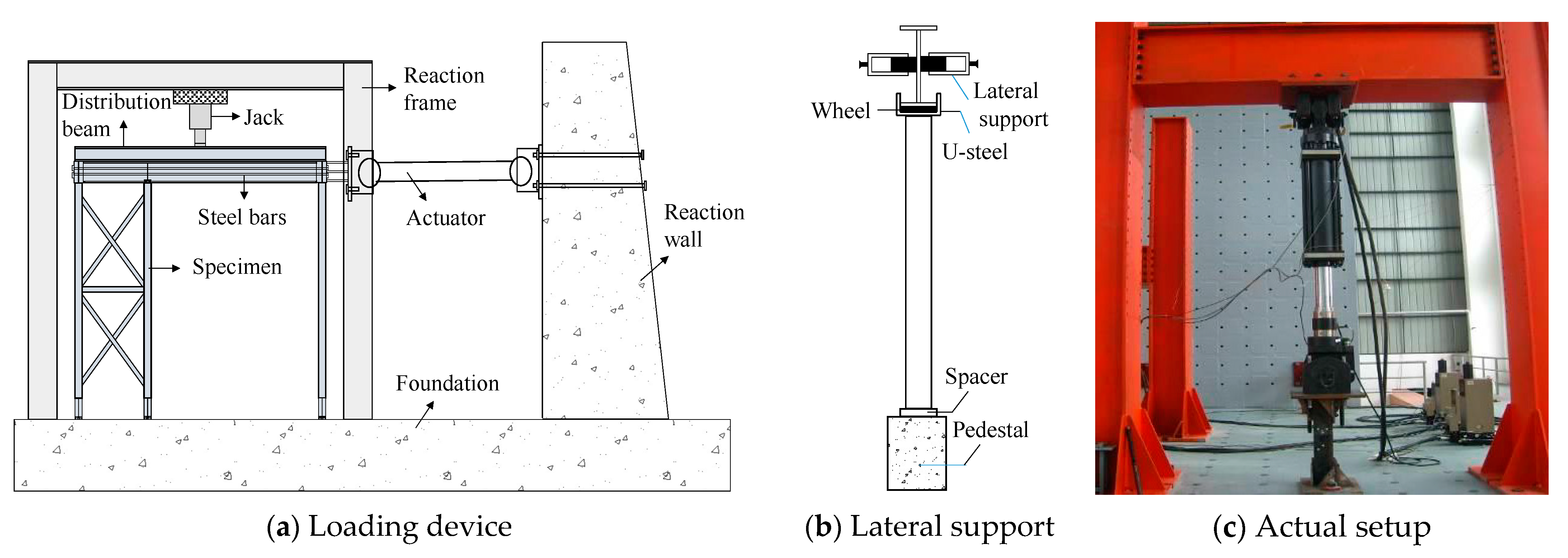

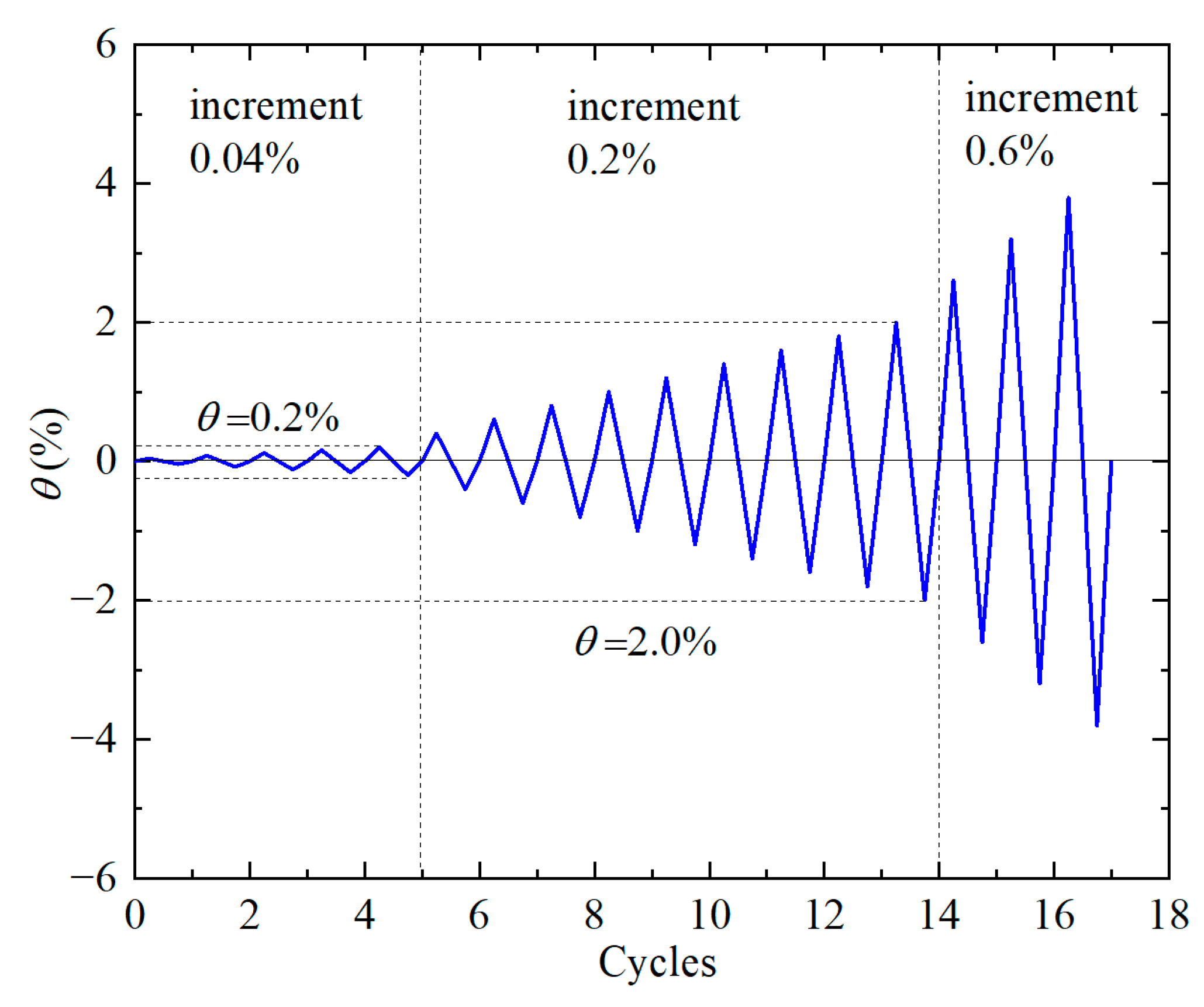

2.4. Test Procedures

3. Test Results

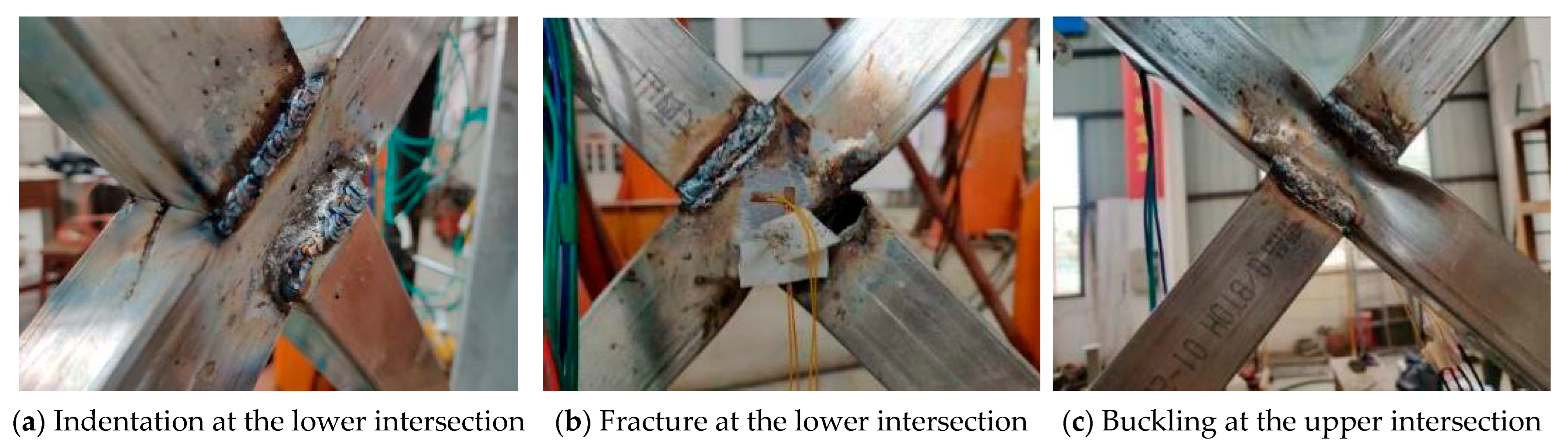

3.1. Experimental Phenomena

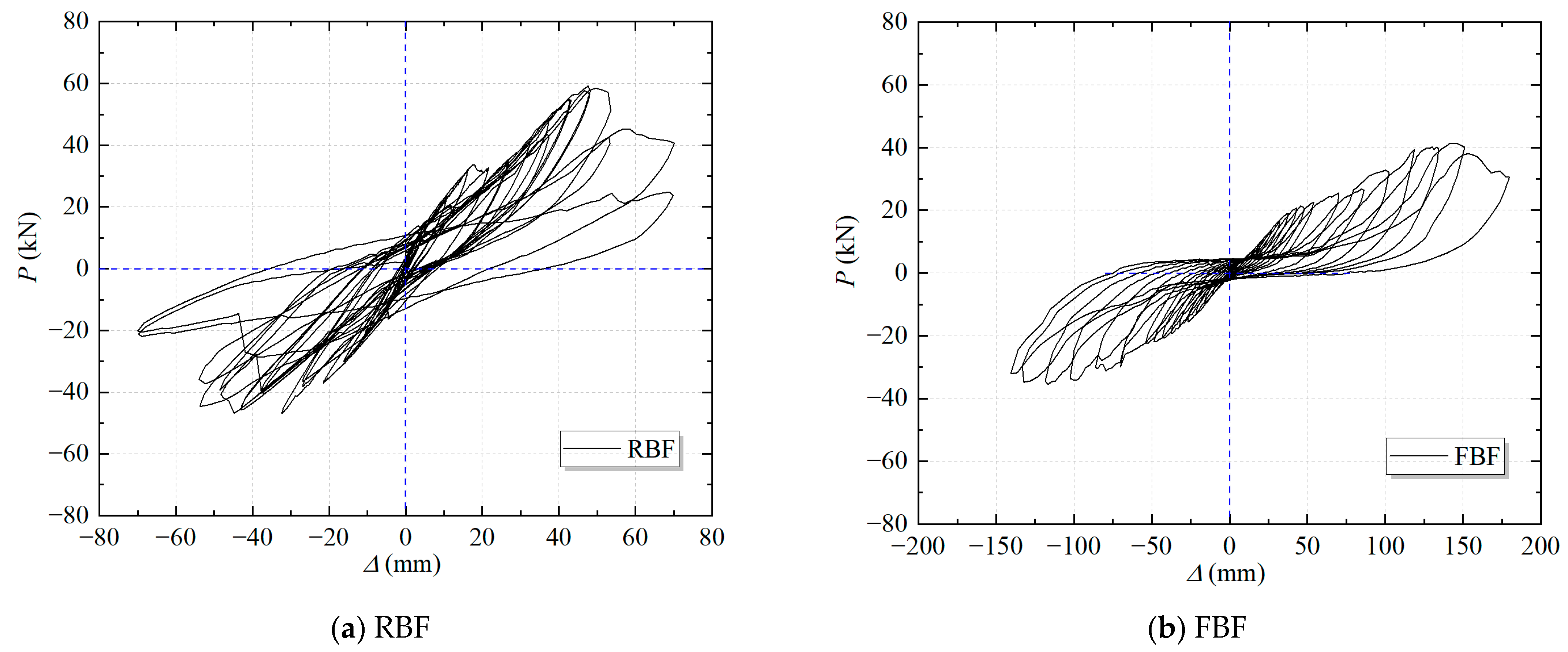

3.2. Hysteresis Curve

3.3. Skeleton Curve

3.4. Strength

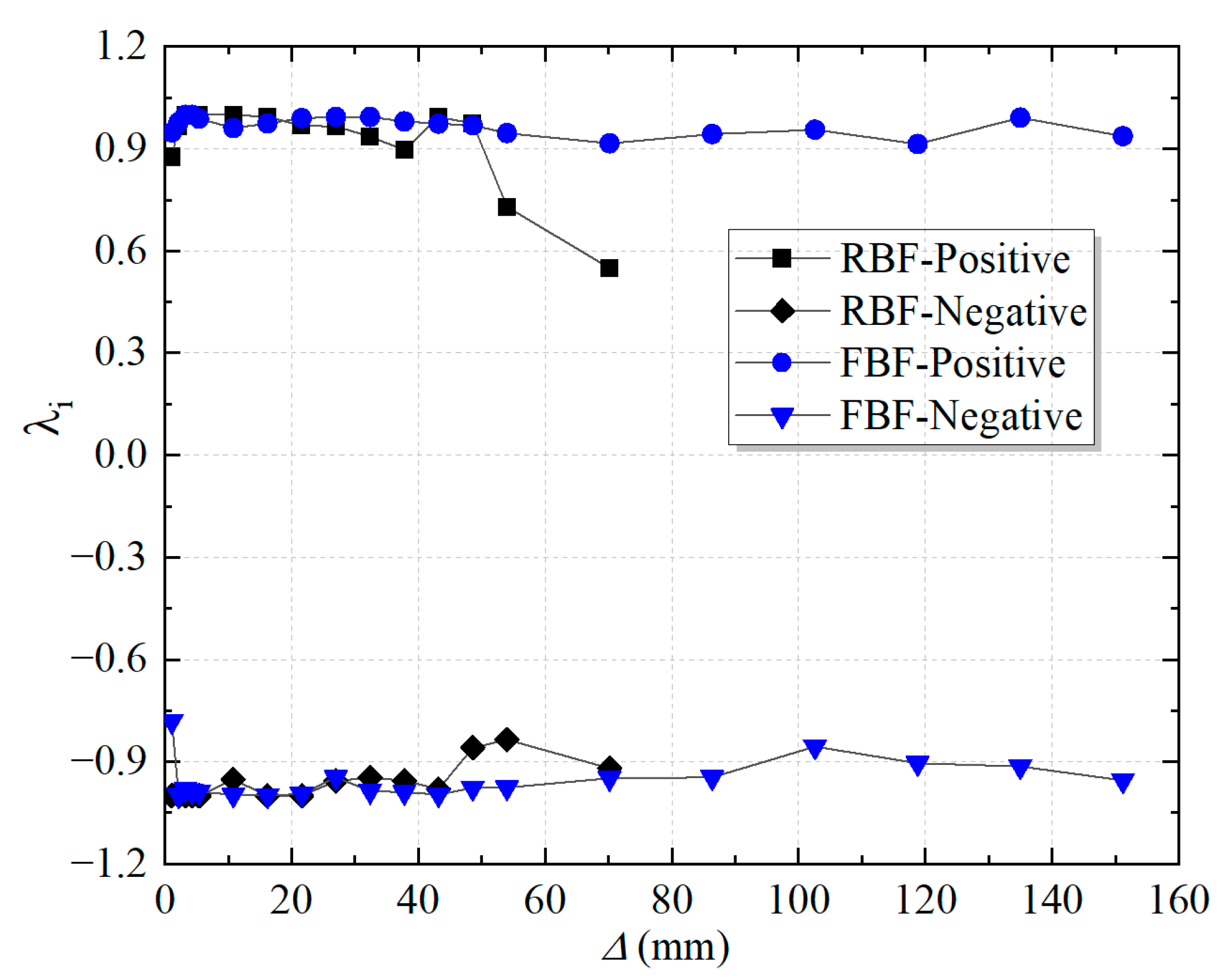

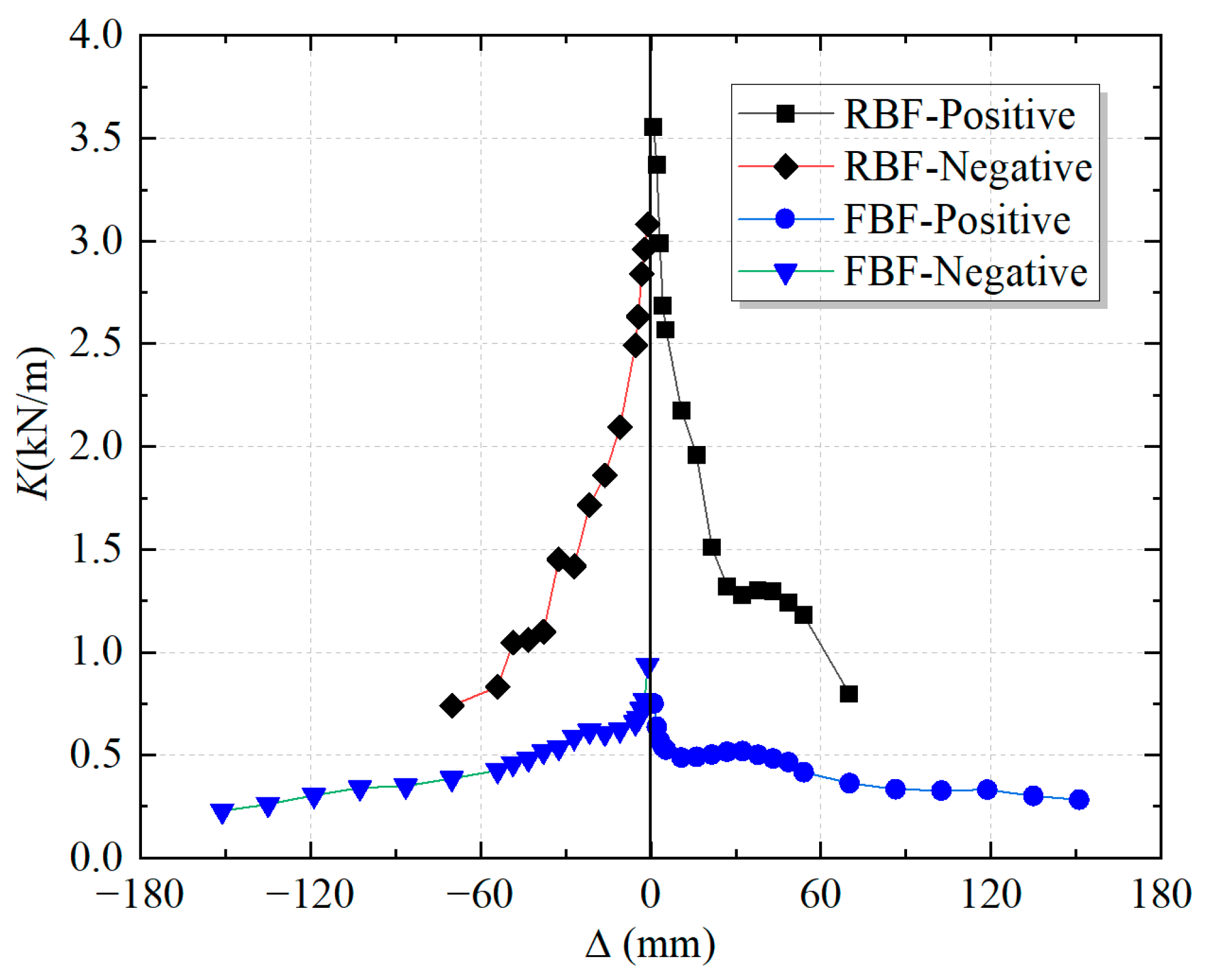

3.5. Stiffness

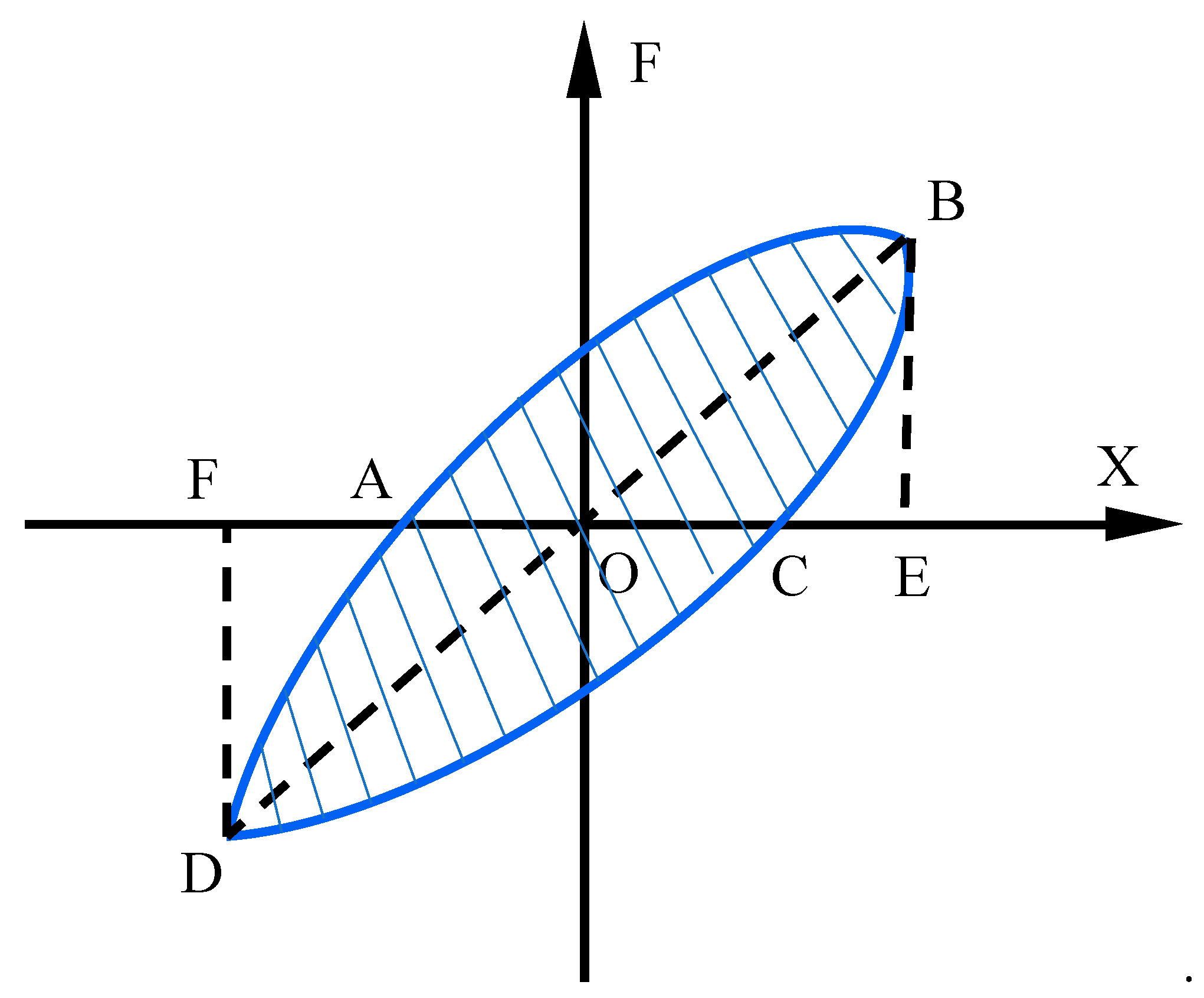

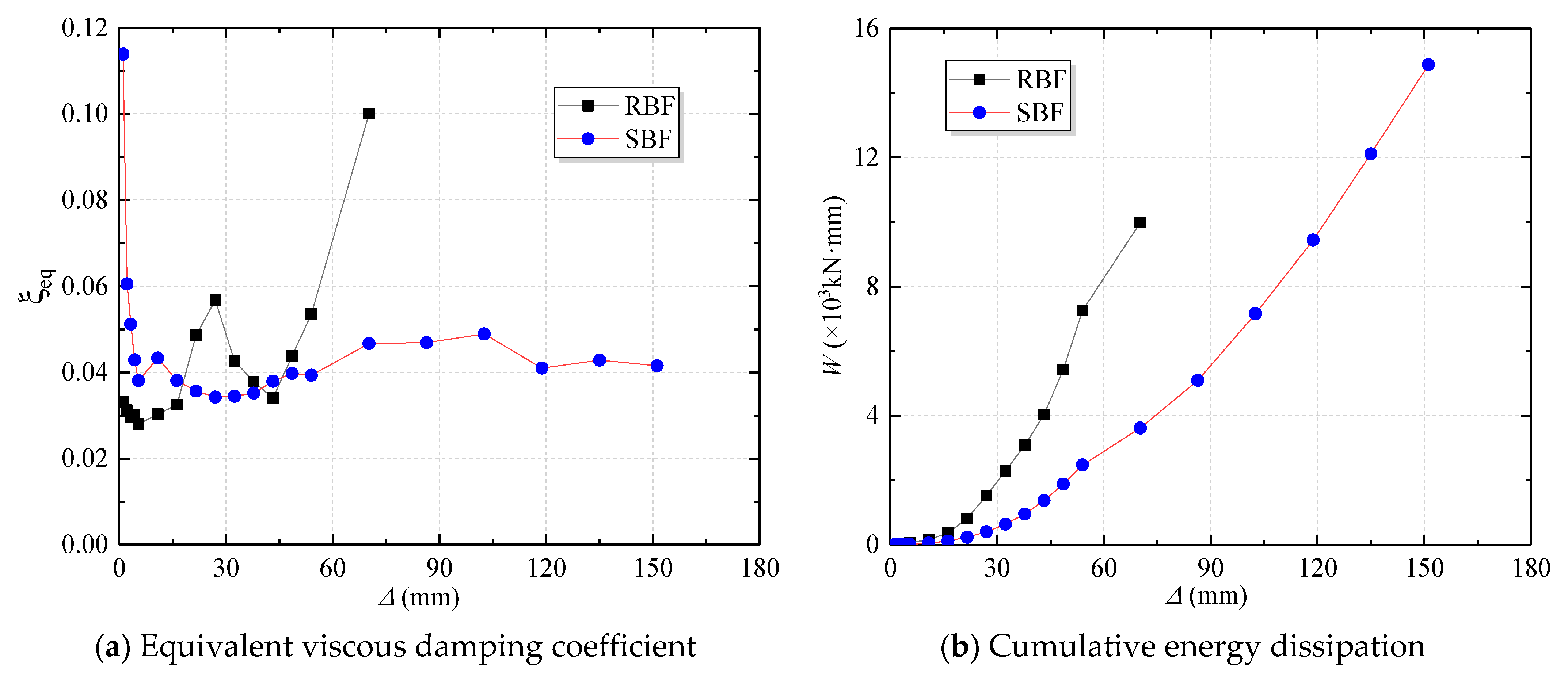

3.6. Energy Dissipation

4. Finite Element Simulation

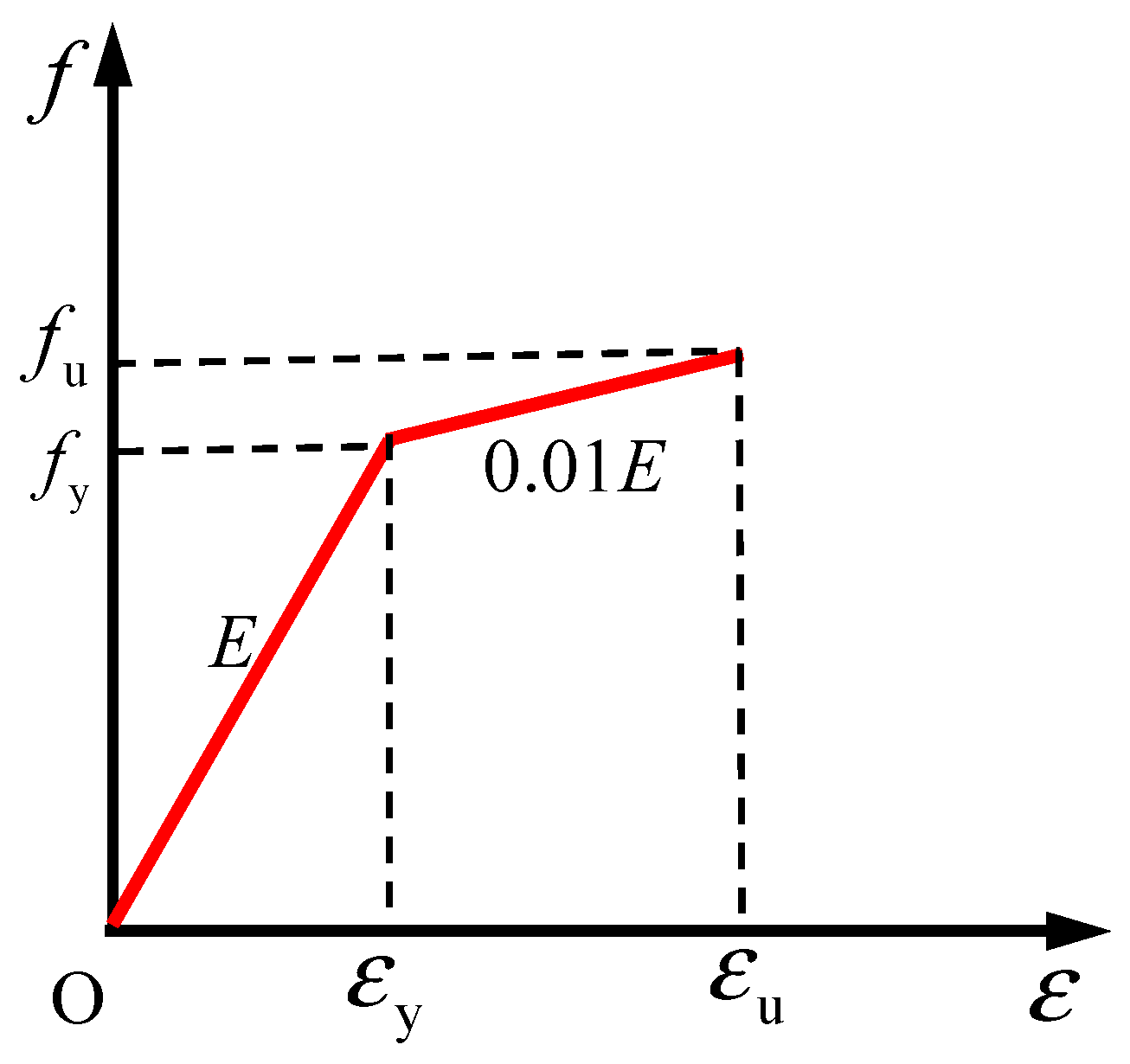

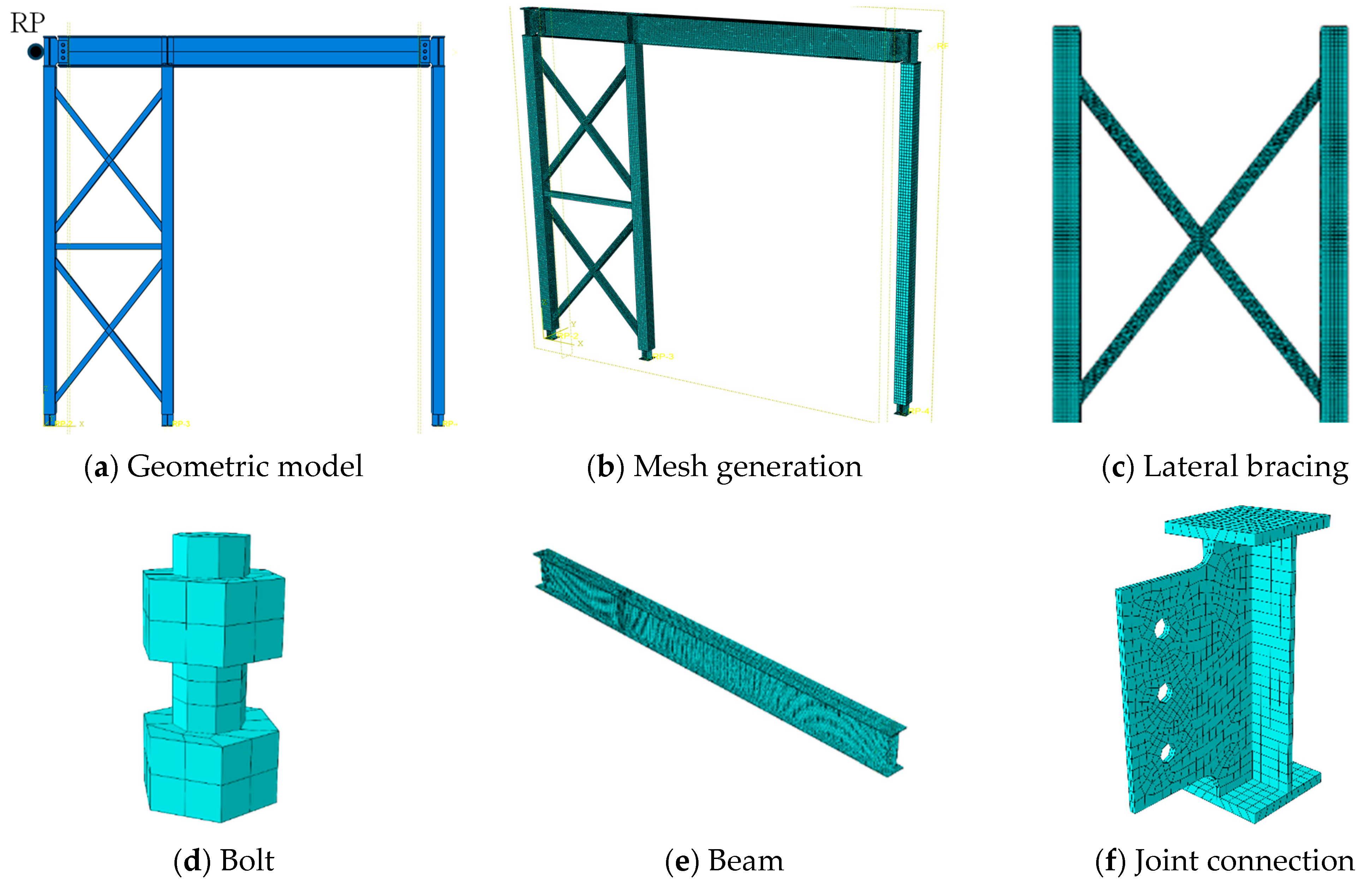

4.1. Modeling Details

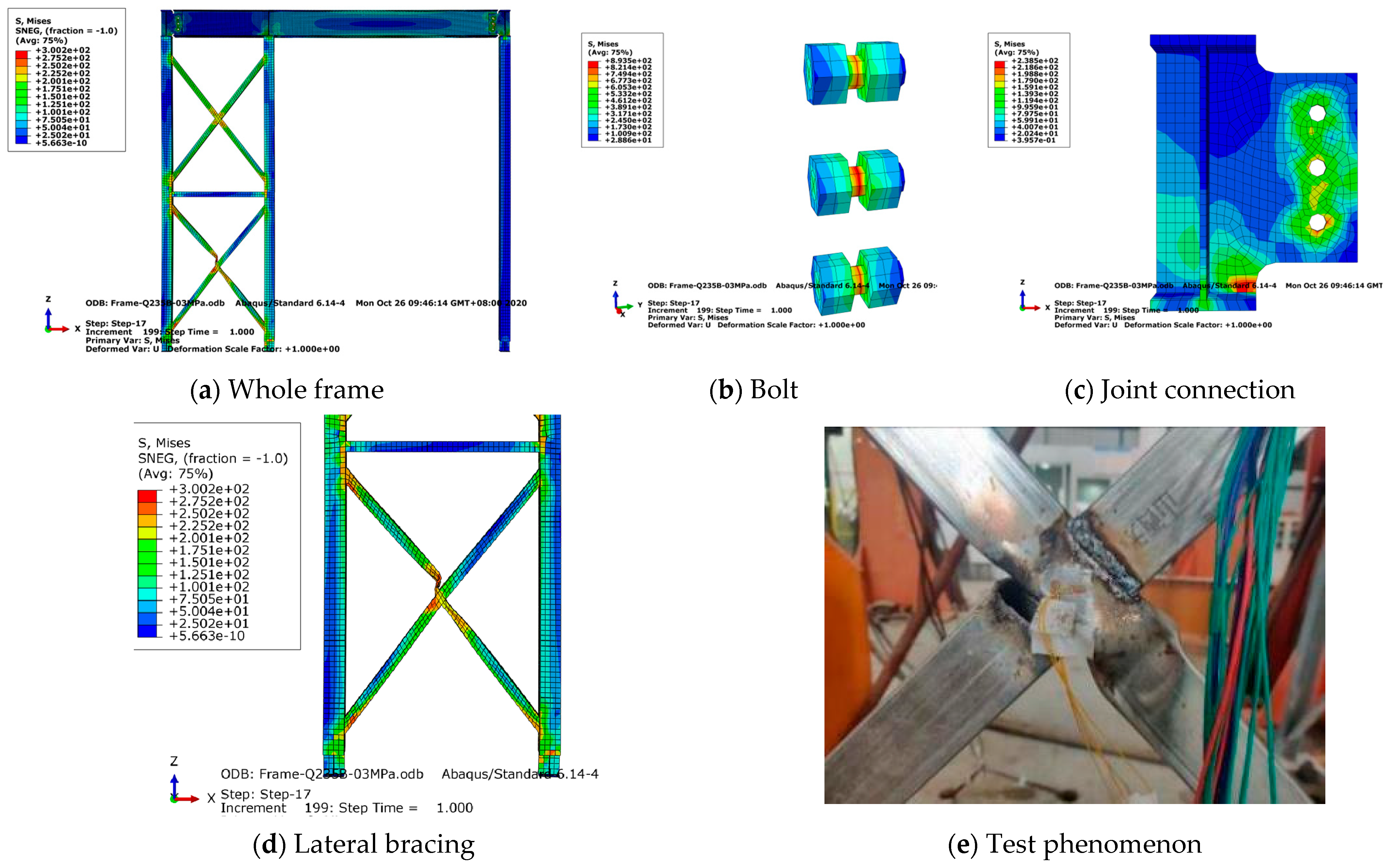

4.2. Comparison of Failure Modes

4.3. Date Comparison

5. Conclusions

- The failure mode of the RBF under cyclic loading is characterized by fractures at the two diagonal braces, whereas the failure mode of the FBF results primarily from large deformations and bending of the flexible tension rods. The RBF exhibits brittle failure, while the FBF exhibits ductile failure.

- The bearing capacity of the FBF is lower than that of the RBF, with its peak bearing capacity being only 69.1% (positive direction) and 76.0% (reverse direction) of the RBF. However, it experiences larger deformations, with its ultimate displacement being 2.7 times (positive direction) and 2.5 times (reverse direction) that of the RBF. The FBF has higher ductility.

- The strength and stiffness of the RBF decrease significantly in the later stages of loading. In contrast, the FBF can maintain certain levels of strength and stiffness even under large deformations, thereby ensuring the stability of the structure.

- The hysteresis curve of the FBF is smoother, and its equivalent viscous damping coefficient remains stable throughout the loading process. The total energy dissipation of the FBF is 1.49 times that of the RBF, primarily due to the inelastic response of the flexible bracing system.

- This numerical method uses C3D8R solid elements to model the connection joints, bolts, and I-beams, S4R shell elements to model the columns and beams, and applies horizontal loading through kinematic coupling. This approach not only simplifies the model but also enhances computational efficiency. The finite element results accurately reflect the structural failure behavior, with the difference in bearing capacity between the simulation and experimental results remaining within 80%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Xiao, C.B.; Ling, C.J. Investigation of traditional residential structures in Tibetan areas of Sichuan. Sichuan Build. Sci. 2013, 39, 93–98. [Google Scholar]

- Xinjian, W.; Qiong, L.; Shengmao, D. Field Study on Land Desertification in Northwest Sichuan. For. Grassl. Resour. Res. 2007, 16–20. [Google Scholar]

- Liu, S.; Fang, Y.J.; Li, G.; Cai, F.L.; Tang, X.Z. Causes for desertification in Ganzi prefecture and measures for the control. For. Inventory Plan. 2010, 35, 103–106. [Google Scholar]

- McKinstray, R.; Lim, J.B.; Tanyimboh, T.T.; Phan, D.T.; Sha, W. Comparison of optimal designs of steel portal frames including topological asymmetry considering rolled, fabricated and tapered sections. Eng. Struct. 2016, 111, 505–524. [Google Scholar] [CrossRef]

- Li, Z.L.; Zhang, C.T.; Fan, W.L.; Wang, R.H. Experimental research on seismic behavior of a new type of thin-walled square steel tube beam-column connection. Eng. Mech. 2013, 30, 72–81. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, T.; Wu, H.; Guan, Y.; Zhang, L. Cyclic performance of steel frame fabricated with cold-formed steel composite wall structure. Eng. Struct. 2022, 270, 114892. [Google Scholar] [CrossRef]

- Chuntao, Z.; Zhengliang, L.; Ruheng, W. Experiment research on seismic behavior of beam-column connection with welded haunch in cold-formed thin-walled square steel tube structure. J. Vib. Shock. 2012, 31, 60–67. [Google Scholar]

- Fahmy, M.F.; Ibrahim, H.A. Steel-FRP reinforced concrete moment-resisting frames under lateral loads: Numerical investigation. J. Compos. Constr. 2020, 24, 04020064. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Han, Q.; Du, X.L.; Zhang, J.Q.; Cheng, S.S.; Chen, J.Y. Additional viscous dampers for double-column rocking bridge system: Seismic response and overturning analysis. Soil Dyn. Earthq. Eng. 2021, 141, 106504. [Google Scholar] [CrossRef]

- Zeynalian, M.; Ronagh, H.R.; Hatami, S. Seismic characteristics of K-braced cold-formed steel shear walls. J. Constr. Steel Res. 2012, 77, 23–31. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, W.; Zhu, H.; An, R. Fatigue Behavior and Impedance Spectrum Characteristics of Cr-modified Stainless-Steel Rebars after Corrosion. Case Stud. Constr. Mater. 2025, 23, e04964. [Google Scholar] [CrossRef]

- Li, G.Q.; Fang, M.; Liu, Y. An experimental study on the seismic behavior of alc external wall panels in steel frames. China Civ. Eng. J. 2005, 10, 31–35. [Google Scholar]

- Zhang, A.; Ma, L.; Liu, X.; Jiang, Z. Finite element analysis on mechanical performance of steel frame structure with prefabricated external wall panel. J. Build. Struct. 2016, 37, 152–157. [Google Scholar]

- Zhao, D.; Chen, L.; Wang, W. Hysteretic behavior analysis of steel frame structure with ALC walls. J. Zhejiang Univ. Technol. 2010, 8, 448. [Google Scholar]

- Zhang, C.; Chen, Y. Resilience-based seismic design and cyclic behavior of assembled joints between self-compacting concrete-filled rectangular steel tube frame columns and H-shaped steel beams. J. Build. Eng. 2024, 91, 109556. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, S.; An, R.; Wang, Z. Seismic performance of a newly assembled joint between shaped steel beams and square steel tubular columns. J. Build. Eng. 2025, 100, 111748. [Google Scholar] [CrossRef]

- Flanagan, R.D.; Bennett, R.M. In-plane behavior of structural clay tile infilled frames. J. Struct. Eng. 1999, 125, 590–599. [Google Scholar] [CrossRef]

- de Matteis, G.; Landolfo, R. Diaphragm action of sandwich panels in pin-jointed steel structures: A seismic study. J. Earthq. Eng. 2000, 4, 251–275. [Google Scholar] [CrossRef]

- Rahai, A.; Hatami, F. Evaluation of composite shear wall behavior under cyclic loadings. J. Constr. Steel Res. 2009, 65, 1528–1537. [Google Scholar] [CrossRef]

- Niari, S.E.; Rafezy, B.; Abedi, K. Seismic behavior of steel sheathed cold-formed steel shear wall: Experimental investigation and numerical modeling. Thin-Walled Struct. 2015, 96, 337–347. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, H.; Liu, X.; Zhao, J.; Zhang, C. Cyclic performance of fully assembled joints between H-Beam and CFST shear wall. In Structures; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1655–1669. [Google Scholar]

- Qian, K.; Lan, X.; Li, Z.; Fu, F. Effects of steel braces on robustness of steel frames against progressive collapse. J. Struct. Eng. 2021, 147, 04021180. [Google Scholar] [CrossRef]

- Goggins, J.; Broderick, B.; Elghazouli, A.; Lucas, A. Experimental cyclic response of cold-formed hollow steel bracing members. Eng. Struct. 2005, 27, 977–989. [Google Scholar] [CrossRef]

- Roostaeyan, E.; Mirghaderi, S.R.; Ghazizadeh, S.; Zahrai, S.M. Through gusset connection for two-story X-braced frames, a numerical study. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; pp. 285–296. [Google Scholar]

- Shen, J.; Wen, R.; Akbas, B. Mechanisms in two-story X-braced frames. J. Constr. Steel Res. 2015, 106, 258–277. [Google Scholar] [CrossRef]

- Yoo, J.H.; Roeder, C.W.; Lehman, D.E. Simulated behavior of multi-story X-braced frames. Eng. Struct. 2009, 31, 182–197. [Google Scholar] [CrossRef]

- Yu, A.L.; Zhao, B.; Li, R.D. Experimental study on hysteretic behavior of K and Y-eccentrically braced steel frames. Build. Struct. 2010, 40, 9–12. [Google Scholar]

- Aydin, E.; Ozturk, B.; Sshin, E. Investigation of Behavior of Adjacent Planar Steel Frames Connected with Rigid Bars under Earthquake Effects. In Proceedings of the 6th World Conference on Structural Control and Health Monitoring (6WCSCM), Barcelona, Spain, 15–17 July 2014. [Google Scholar]

- Aydin, E.; Ozturk, B.; Duzel, E. Rehabilitation of planar building structures using steel diagonal braces and dampers. Rehabilitation 2012, 16, 18. [Google Scholar]

- Imam, M.H.; Mohiuddin, M.; Shuman, N.M.; Oyshi, T.I.; Debnath, B.; Liham, M.I.M.H. Prediction of seismic performance of steel frame structures: A machine learning approach. In Structures; Elsevier: Amsterdam, The Netherlands, 2024; p. 107547. [Google Scholar]

- Lazaridis, P.C.; Kavvadias, I.E.; Demertzis, K.; Iliadis, L.; Vasiliadis, L.K. Structural damage prediction of a reinforced concrete frame under single and multiple seismic events using machine learning algorithms. Appl. Sci. 2022, 12, 3845. [Google Scholar] [CrossRef]

- Kazemi, F.; Asgarkhani, N.; Lasowicz, N.; Jankowski, R. Development and experimental validation of a novel double-stage yield steel slit damper-buckling restrained brace. Eng. Struct. 2024, 315, 118427. [Google Scholar] [CrossRef]

- GB/T 228-2010; Metallic materials-Tensile Testing-Part 1: Method of Test at Room Temperature. China Press: Beijing, China, 2009.

- GB/T 2975-2018; Steel and steel products—Location and preparation of samples and test pieces for mechanical testing. State Administration for Market Regulation: Beijing, China, 2018.

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015. (In Chinese)

- Krawinkler, H. ATC-24: Guidelines for cyclic seismic testing of components of steel structures. In Redwood City, Report Prepared for the Applied Technology Council; ATC: Redwood City, CA, USA, 1992. [Google Scholar]

- Ni, X.; Cao, S.; Li, Y.; Liang, S. Stiffness degradation of shear walls under cyclic loading: Experimental study and modelling. Bull. Earthq. Eng. 2019, 17, 5183–5216. [Google Scholar] [CrossRef]

- Al Hasani, S.; Nasrellah, H.; Abdulraeg, A.A. Numerical study of reinforced Concrete beam by using ABAQUS software. Int. J. Innov. Technol. Interdiscip. Sci. 2021, 4, 733–741. [Google Scholar]

| Specimen | Yield Strength fy /MPa | Tensile Strength fu /MPa | Modulus of Elasticity E 105 MPa | Elongation δ /% |

|---|---|---|---|---|

| Diagonal brace | 368.12 | 435.21 | 192.85 | 21.93 |

| Column | 390.03 | 444.44 | 209.14 | 24.97 |

| Beam flange | 284.81 | 415.00 | 207.37 | 38.58 |

| Beam web | 249.28 | 430.04 | 209.30 | 41.19 |

| Horizontal tie rod | 276.45 | 417.71 | 213.98 | 45.63 |

| Flexible tension rod | 405.45 | 509.22 | 210.382 | 22.5 |

| Specimen | Direction | Δy/mm | Py/kN | Δmax/mm | Pmax/kN | Δu/mm | Pu/kN | μ |

|---|---|---|---|---|---|---|---|---|

| FW1 | Positive | 32.39 | 41.36 | 48.55 | 59.88 | 59.86 | 50.90 | 1.85 |

| Negative | −27.00 | −38.29 | −45.39 | −47.28 | −56.93 | −40.19 | 2.11 | |

| FW4 | Positive | 45.99 | 21.53 | 146.3 | 41.35 | 160.72 | 35.15 | 3.49 |

| Negative | −48.16 | −22.19 | −118.10 | −35.92 | −140.3 | −32.31 | 2.91 |

| Specimen | Direction | Δy/mm | Py/kN | Δmax/mm | Pmax/kN | Δu/mm | Pu/kN | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test | FEM | Test | FEM | Test | FEM | Test | FEM | Test | FEM | Test | FEM | ||

| RBF | Positive | 32.4 | 21.6 | 41.4 | 58.7 | 48.6 | 51.2 | 59.9 | 60.2 | 59.9 | 65.4 | 50.9 | 52.3 |

| Negative | −27.0 | −21.6 | −38.3 | −58.7 | −45.4 | −51.2 | −47.3 | −60.2 | −56.9 | −65.4 | −40.2 | −52.3 | |

| FBF | Positive | 46.0 | 28.7 | 21.5 | 24.3 | 146.3 | 132.5 | 41.4 | 36.2 | 160.7 | 164.9 | 35.2 | 32.1 |

| Negative | −48.2 | −28.7 | −22.2 | −24.3 | −118.1 | −132.5 | −35.9 | −36.2 | −140.3 | −164.9 | −32.3 | −32.1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, C.; Zhang, C.; An, R.; Cai, Y. Seismic Performance of Steel Structures with Base-Hinged Columns Under Rigidly and Flexibly Braced Systems. Buildings 2025, 15, 2881. https://doi.org/10.3390/buildings15162881

Shi C, Zhang C, An R, Cai Y. Seismic Performance of Steel Structures with Base-Hinged Columns Under Rigidly and Flexibly Braced Systems. Buildings. 2025; 15(16):2881. https://doi.org/10.3390/buildings15162881

Chicago/Turabian StyleShi, Chenwei, Chuntao Zhang, Renbing An, and Yongxiang Cai. 2025. "Seismic Performance of Steel Structures with Base-Hinged Columns Under Rigidly and Flexibly Braced Systems" Buildings 15, no. 16: 2881. https://doi.org/10.3390/buildings15162881

APA StyleShi, C., Zhang, C., An, R., & Cai, Y. (2025). Seismic Performance of Steel Structures with Base-Hinged Columns Under Rigidly and Flexibly Braced Systems. Buildings, 15(16), 2881. https://doi.org/10.3390/buildings15162881