1. Introduction

Global warming and its associated dangerous impacts, such as droughts, hurricanes, tsunamis, floods, glacier melting and species loss et al. are the biggest challenges faced by modern human society [

1]. In the field of civil engineering and construction, the high demand for reinforced concrete is an important factor causing high CO

2 emissions. This is because the CO

2 generated during the concrete production process accounts for 5–8% of the total global CO

2 emissions, with the majority (95%) of CO

2 emissions coming from cement manufacturing. The production of one ton of ordinary Portland cement (OPC) will release nearly one ton of CO

2, accompanied by the release of harmful gases SO

2 and NO

x [

2,

3]. Therefore, it is necessary to seek new materials, new methods, and new processes to reduce cement consumption in order to reduce gas emissions from various aspects, which is the responsibility of people all over the world. Many researchers have made tremendous efforts to search for environmentally friendly alternatives to cement and steel bars with low pollution and energy consumption. The extensive research on plant-based, mineral-based and animal-based natural fibers [

4,

5,

6,

7] and different supplementary cementitious materials (SCMs) [

8,

9,

10,

11,

12,

13,

14] is in line with these goals. For example, Musa Adamu et al. [

10,

11] used high-volume fly ash (HVFA) as SCMs, and designed experimental mixtures using response surface methodology to study the effects of plastic waste and graphene nanoplatelets on the mechanical and durability properties of concrete. Pattharaphon et al. [

12] designed high-strength concrete using coal bottom ash (CBA) as cement and fine aggregate replacements, and evaluated the properties of concrete through compressive strength, modulus of elasticity, autogenous shrinkage, and heat evolution to determine the optimal percentage of CBA.

Li et al. reported that replacing OPC as a binder for concrete composite materials can reduce greenhouse gas emissions by nearly 80% in the construction industry, which is an important component of achieving green and environmentally friendly building tasks [

15]. Among the numerous alternative options, geopolymer, as a new entrant in the field of building materials, has received great attention from the scientific community. The concept of geopolymer has a long history and belongs to non-metallic materials in amorphous to semi-crystalline states. A large number of mineral waste residues and by-products of various types (blast furnace slag, fly ash, silica fume, metakaolin, rice husk ash, and wheat straw ash, etc.) can be used as raw materials for its production. After careful design, geopolymer cement can offer advantages of low cost, low energy consumption, and low emissions. The internal components of industrial waste or by-products endow geopolymer cement with excellent mechanical properties, acid and alkali resistance, fire resistance, and high temperature resistance [

16,

17,

18,

19,

20].

So far, geopolymer cement, which has similar performance to OPC but obvious environmental advantages, has been regarded as the most likely alternative to OPC. The Pitcha Jongvivatsakul team had achieved some results in studying the use of industrial waste and by-products in geopolymers [

21,

22,

23,

24,

25]. As they found, the addition of rice husk ash (RHA) can improve the uniformity of the microstructure of high calcium fly ash geopolymer prepared containing borax, thereby improving the compressive strength and flexural strength of geopolymer mortar containing hydrated or anhydrous borax [

21]. In addition, they also found that using rice husk ash instead of nano-SiO

2 to act on recycled aggregate high-calcium fly ash geopolymer concrete can effectively improve the strength of recycled aggregate geopolymer concrete (RAGC), which is due to the improved microstructure and denser matrix. However, the addition of materials rich in SiO

2 has an adverse effect on the post-fire residual strength of geopolymer concrete made from recycled polymers [

22]. When natural fine aggregates were partially replaced by granite waste, the slump flow rate of fresh hardened polymer concrete increased with the increase in the proportion of granite waste in the mixture. When granite waste was used to replace the natural sand by up to 50%, geopolymer concrete exhibited poor post-fire residual strength, especially when using oven-dried aggregates [

23]. Hafiz et al. [

24] investigated the effect of graphene nanoplatelets (GNPs) on the engineering performance of fly ash-based geopolymer concrete containing crumb rubber (CR). CR replacement significantly reduced the mechanical properties of geopolymer concrete, but the addition of GNPs can alleviate the negative impact of CR and significantly improve the mechanical properties of geopolymer concrete. Sani et al. [

25] conducted a multiscale investigation on the impact of recycled plastic aggregate (RPA) replacing fine aggregates on the performance of one-part alkali-activated mortar (OPAAM). The mechanical properties of OPAAM decreased with the increase in RPA content in the mixture, but the mixture with 10% RPA exhibited the highest compressive strength, approximately 46 MPa.

The resource utilization of coal gangue (CG), fly ash (FA), and other industrial wastes poses a more severe challenge to China, which takes coal as the main energy structure, and it is necessary to seek multiple ways and aspects of the resource utilization of coal industrial wastes. In recent years, the recycling of CG for power generation and building materials is one of the effective ways of its resource utilization, among which many research results have been obtained as the coarse aggregate of concrete [

26,

27,

28]. The properties and composition of CG are similar to those of natural gravel. Through a systematic production process, a new type of artificial gravel can be obtained, which can be used as CA in concrete materials [

26]. Wang et al. [

27] found that as the replacement rate of CG coarse aggregate increases, the elastic modulus and dry shrinkage rate of the corresponding concrete approximately decrease linearly. However, the magnitude of the decrease in concrete performance is closely related to the type and dosage of CG. Therefore, studying the dosage of CG used as coarse aggregate in different types of concrete has guiding significance for the application of this type of concrete. According to reports, China is the country with the largest production of FA, and the utilization rate has basically reached 67% [

29]. The rise in geopolymer SCMs has also provided opportunities for the further expansion and utilization of FA. Related studies have shown that the incorporation of raw materials such as FA and slag into geopolymer manufacturing is attracting global interest, and some components of these industrial wastes determine the final performance of geopolymers [

30,

31]. For example, compared to OPC concrete, Ghafoor et al. [

32] found that FAGPC can exhibit higher compressive strength under appropriate mix proportions and curing conditions [

32]. In addition, the particle uniformity of FA can make the microstructure of its geopolymer composite material denser, thereby exhibiting better resistance to sulfate corrosion. In concrete, the quality of FA as a substitute for cement is basically limited to 15–20% of the total cementitious material [

33]. Therefore, due to the consideration of increasing the utilization rate of CG and FA in the field of concrete materials, the modification of fly ash-based geopolymer concrete and the study of CG as CA are supplements to the blank demand.

Compared with traditional ordinary cement structures, GPC exhibits excellent sustainability. However, the lack of tensile and bending load resistance of concrete systems is the main obstacle to practical application problems, as this can lead to severe disintegration and sudden collapse of structural components without prior warning [

34]. There is no doubt that the same issue of brittleness is also a research hotspot in GPC. Most research has successfully transformed the failure mode of concrete into ductile failure using industrial synthetic fibers in brittle geopolymer media [

35,

36,

37,

38,

39,

40]. For example, Peem et al. [

38] used micro carbon fiber (CF) as a reinforcing material to improve the mechanical properties of fly ash geopolymer containing fine recycled concrete aggregate (RCA). The addition of CF can increase the nucleation sites of the geopolymerization reaction and the bridging effect of fibers. The incorporation of 0.2% CF can result in geopolymer mortar containing 100% RCA with higher compressive and splitting tensile strengths. In addition, Peem et al. [

39] also found that polypropylene (PP) fibers can effectively improve the flexural performance of alkali-activated fly ash (AAF) concrete containing granite industrial waste (GW). The fiber-reinforced AAF concrete containing GW exhibited extensive cracking in the core after fire, with the residual compressive strength of 25–39% after 30 min of fire exposure. Pattharaphon et al. [

40] evaluated the compressive and flexural strength of alkali-activated fly ash mortar containing superabsorbent polymers (SAPs) and polypropylene (PP) fibers. PP significantly improved the flexural capacity of cement mortar, while the compressive strength began to decrease after 28 d. Compared with samples without SAPs, samples produced using SAPs can effectively maintain residual compression and flexural strength.

However, when considering the selection of industrial fiber-reinforced GPC, special attention should be paid to the raw material development, environmental cost, self-performance, and the compatibility between fiber and matrix of industrial fiber [

7]. The extensive use of industrial fibers is undoubtedly contradictory to global efforts to reduce greenhouse gas emissions. In addition, in areas where recycling and reuse are not feasible, most industrial fibers are difficult to handle, which means that the economic and environmental costs at the end of the service life of corresponding concrete structures are increased. This is also contrary to the goal of maximizing the recycling and utilization of construction demolition waste to reduce the negative impact of the construction industry on the environment. Therefore, with increasing attention to environmental issues, building materials researchers are considering using natural fibers (NFs) as reinforcing materials instead of industrial fibers for cementitious composite materials [

7,

41,

42,

43,

44] to increase their ductility and tensile stress.

NF sources include plants, animals, and minerals. Plant-based natural fibers (such as coconut fiber, bamboo fiber, etc.) have many limitations, such as being significantly affected by growing environments, exhibiting large mechanical performance variability, insufficient alkali resistance (prone to degradation in high-alkali cement-based environments), and weak interfacial bonding with geopolymer matrices. Therefore, researchers have turned their attention to natural mineral fibers, among which basalt fiber (BF) is a typical example. BF is produced by melting and drawing basalt rock, making it an environmentally friendly material with high-temperature resistance, corrosion resistance, high hardness, and excellent wear resistance. In the field of construction engineering, it is considered a promising potential alternative to carbon fiber and glass fiber [

30]. Compared in depth with synthetic industrial fibers, BF causes less environmental pollution. More importantly, BF raw materials are abundant, and the energy consumption of the melting and drawing process is much lower than that of synthetic fiber production. At the same time, BF also possesses unique advantages that are irreplaceable by other industrial fibers, namely its good chemical compatibility with geopolymers (rich in silicon and aluminum) due to its natural volcanic rock composition. It is considered a potential substitute for carbon fiber and glass fiber in the field of construction engineering in the future [

41,

42,

43,

44]. Zeng et al. [

42] found that under the same volume fraction, BF had a better strengthening effect on the compressive toughness of concrete materials than polypropylene fiber. Punurai et al. [

43] found that with the increase in BF content, the flexural strength of the mixed geopolymer slurry increased, and the drying shrinkage rate decreased. When the content of BF is 40%, its 28 d bending strength can be increased by 64%. Yang et al. [

44] reported that adding 6 kg/m

3 of BF to concrete can delay early cracking and reduce lateral strain of the concrete. Therefore, for concrete with different usage requirements, the optimal amount of BF incorporation requires extensive research. As Bakytzhan et al. [

45] adopted a method combining experimental and numerical techniques based on the COMSOL (version 6.2) finite element method (FEM), they ultimately determined that a fiber content range of 0.25% to 0.5% can enhance material performance.

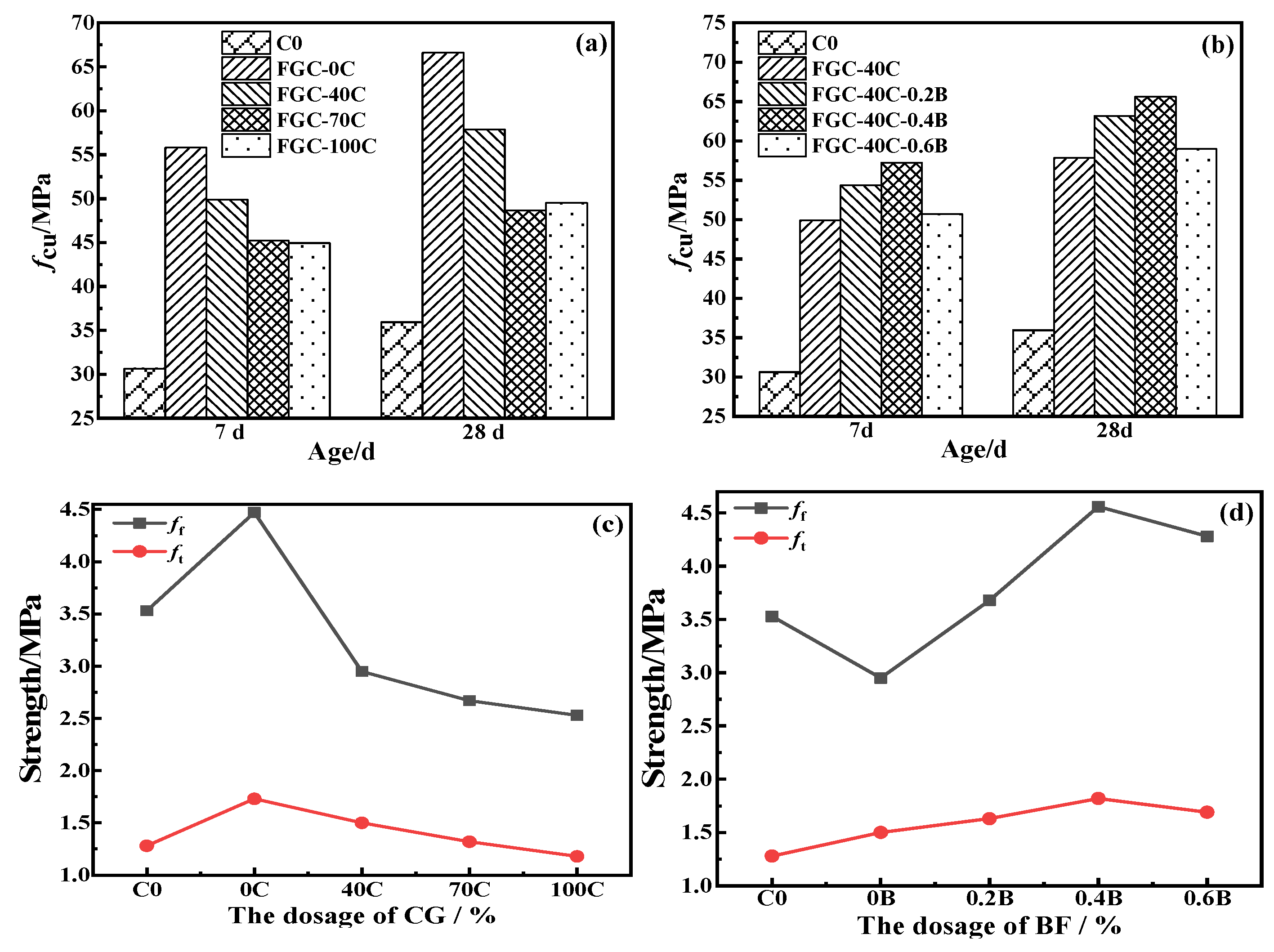

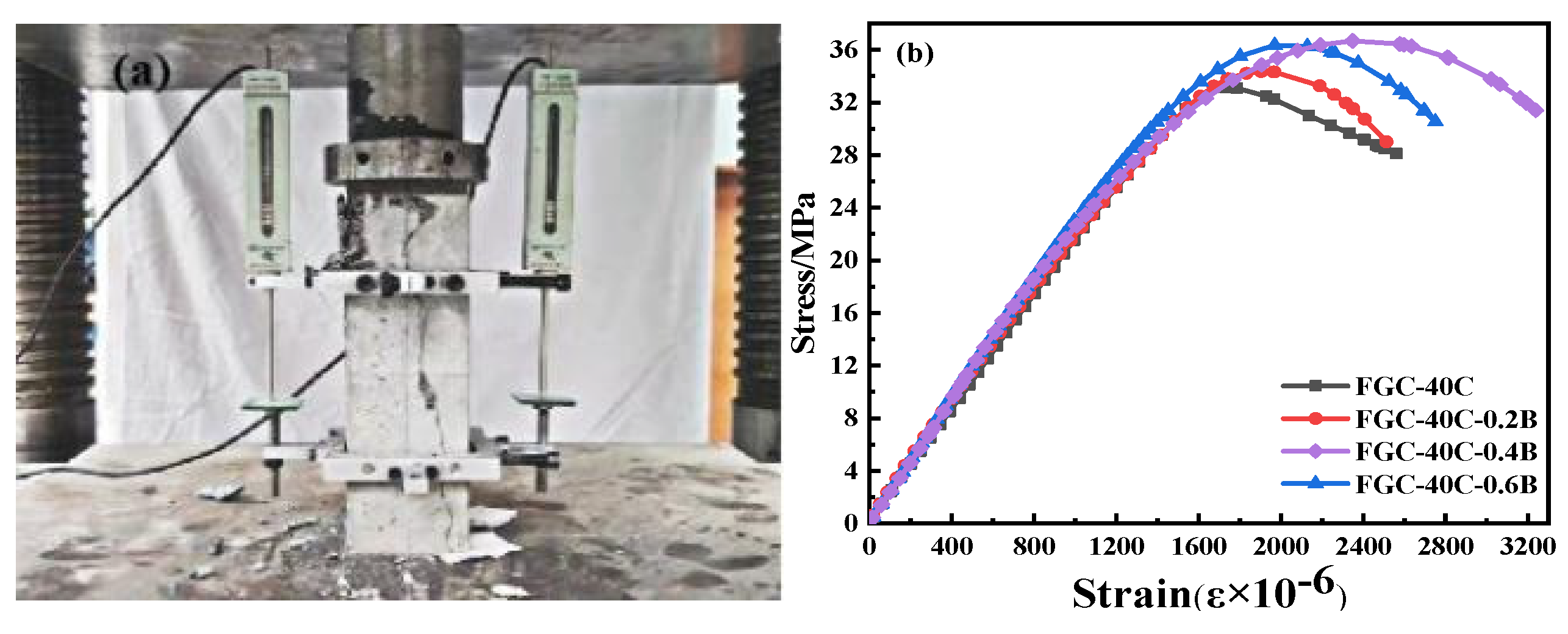

Based on the above literature, we deeply understand that researchers in the relevant field have taken a positive attitude towards reducing the demand for ordinary Portland cement and reducing greenhouse gas emissions by replacing some OPC with in situ polymer cementitious supplementary materials, and actively call for systematic research on geopolymer cementitious materials. However, when blocky coal gangue and other waste materials are used as CA for concrete, while realizing the resource utilization of industrial waste, their material deterioration has a negative impact on the mechanical properties of concrete. However, inspired by numerous research results on fiber-reinforced concrete, researchers have found that fibers can also be applied to enhance the performance of geopolymer concrete caused by replacing coarse aggregates with CG. In addition, with the increasing awareness of environmental protection, the selection of natural fiber-reinforced materials has become a research hotspot. However, the above literature review also indicates that the current research on the performance of geopolymer concrete reinforced with different natural fibers and different coarse aggregate substitutes is mainly focused on experimental research. However, in order to achieve practical engineering applications of corresponding concrete materials, a large number of multi-type fiber-reinforced geopolymer concrete combination experimental research work is urgently needed to fill the relevant data gaps for the writing of relevant specifications. Therefore, this study uses BF as reinforcing materials to conduct compressive tests, flexural tests, splitting tensile tests, and axial compressive tests. The compressive strength, flexural strength, splitting tensile strength, and stress–strain curve are used as evaluation indicators to compare and analyze the mechanical properties of ordinary concrete, CG-FA-GPC, and BF-CG-FA-GPC. The influence of CG and BF on the mechanical properties of FA-GPC is discussed in order to provide positive data supplementation for the study of natural BF reinforced FA-GPC.