Optimization of Ventilation Performance in Large-Section Highway Tunnels: The Role of Deflector Shields in Jet Fan Systems

Abstract

1. Introduction

2. Field Test

2.1. Engineering Background

2.2. Test Design

2.3. Distribution of Measuring Points

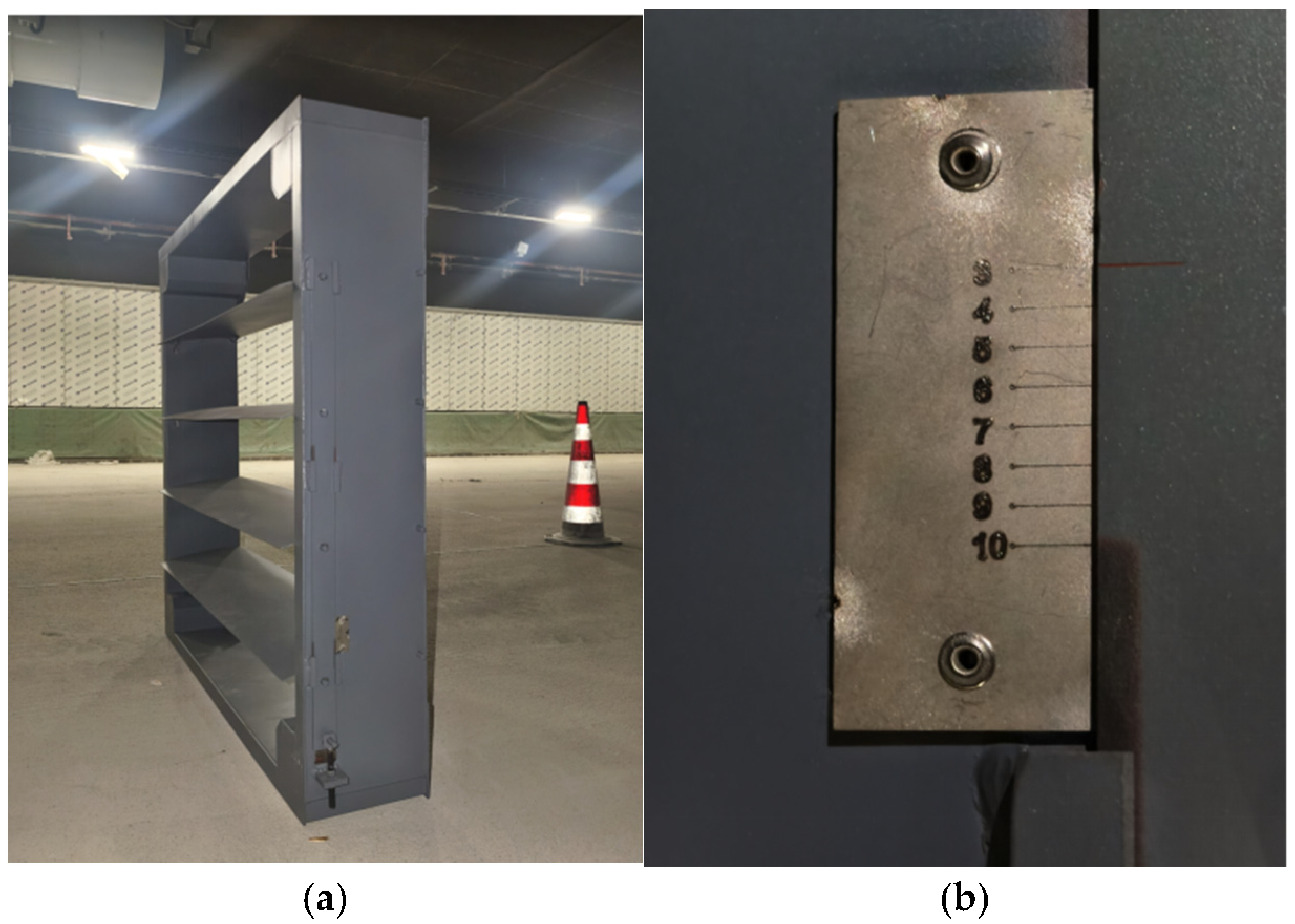

2.4. Selection and Arrangement of Test Equipment

2.5. Testing Process

2.6. Evaluation Index

3. Results and Discussion

3.1. Pressure Rise Coefficient Analysis

- (1)

- Static pressure analysis for each working case

- (2)

- Analysis of pressure rise coefficient for each working condition

3.2. Wind Speed Uniformity Analysis

4. Conclusions

- (1)

- Regardless of the deflector plate quantity or pitch angle, the static pressure in the test section initially increases with distance from the jet fan, reaching a peak before rapidly decreasing. For three or four deflector plates, the static pressure distribution varies with the pitch angle; higher pitch angles correspond to greater peak static pressures and more pronounced pressure attenuation. In contrast, when five deflector plates are used, the influence of pitch angle on static pressure distribution is minimal, with both peak values and attenuation amplitudes remaining relatively consistent across different test sections.

- (2)

- All test conditions exhibit higher rise pressure coefficients than the control group. For configurations with three or four deflector plates, the rise pressure coefficient increases with pitch angle up to 8°, after which it declines. In contrast, when five deflector plates are used, the rise pressure coefficient remains relatively stable across different pitch angles, fluctuating around a consistently high level. Overall, a higher rise pressure coefficient is observed under the cases of four deflector plates at pitch angles of 8° and 10°, as well as five deflector plates at pitch angles of 4°, 6°, 8°, and 10°. The maximum pressure rise coefficient is achieved with four deflector plates at a pitch angle of 8°.

- (3)

- When the number of deflector plates is five, the deflection effect is excessively strong, leading to a sharp drop in average wind speed approximately 15 m downstream of the fan and resulting in extensive low-wind-speed regions further downstream. In contrast, the configurations with four deflector plates at 8° and 10° demonstrate improved wind speed uniformity downstream, with fewer low-velocity zones and more balanced airflow distribution.

- (4)

- Based on the combined analysis of the pressure rise coefficient and wind speed uniformity, it is concluded that the optimal ventilation performance of the jet fan is achieved with four deflector plates at a pitch angle of 8°.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dirks, K.N.; Johns, M.D.; Hay, J.E.; Sturman, A.P. A semi-empirical model for predicting the effect of changes in traffic flow patterns on carbon monoxide concentrations. Atmos. Environ. 2003, 37, 2719–2724. [Google Scholar] [CrossRef]

- Lizbetin, J.; Stopka, O.; Nemec, F. Methodological Assessment of Environmental Indicators in Combined Transport in Comparison with Direct Road Freight Transport. In Proceedings of the 20th International Scientific Conference Transport Means, Juodkrantė, Lithuania, 5–7 October 2016; pp. 151–155. [Google Scholar]

- Hong, K.; Feng, H. Development Trends and Views of Highway Tunnels in China over the Past Decade. China J. Highw. Transp. 2020, 33, 62–76. [Google Scholar]

- Zhang, J.; Wu, J.; Yan, C.; Gou, X.; Ye, L.; Feng, J. Construction Technology of Super-large Section of Highway Tunnels with Four or More Lanes in China. China J. Highw. Transp. 2020, 33, 14–31. [Google Scholar]

- Miao, J.; Kao, A.; Wu, C. Numerical study of spacing effect on unsteady blade aerodynamics in a transonic turbine stage with different turbulence models. J. Chin. Inst. Eng. 2004, 27, 103–117. [Google Scholar] [CrossRef]

- Wang, H.; Liu, S. Application and Comparison of Different Turbulence Models in the Three-dimensional Numerical Simulation of Cyclone Separators. J. Eng. Therm. Energy Power 2003, 18, 337–342. [Google Scholar]

- Barrefors, G. Air pollutants in road tunnels. Sci. Total Environ. 1996, 189, 431–435. [Google Scholar] [CrossRef]

- Li, Q.; Chen, C. Survey and measurement of the vehicle pollutant emission in urban underground bifurcate tunnel, China. Sustain. Cities Soc. 2019, 48, 101519. [Google Scholar] [CrossRef]

- Li, Y.; Yi, L.; Chen, S. Numerical Study on Influence of Impacts from Environmental Factor on CO Concentration in Tunnel with Longitudinal Ventilation. In Proceedings of the 2nd International Conference on Electronics, Network and Computer Engineering, Yinchuan, China, 13–14 August 2016; Volume 67, pp. 395–399. [Google Scholar]

- Zhang, H.; Chen, S.; Chen, L. A Study on Large Power Jet Ventilation Technology in Long Tunnel Construction. Appl. Mech. Mater. 2011, 94–96, 1800–1804. [Google Scholar] [CrossRef]

- Yang, C.; Wang, Z. Current Status and Development Trend of Ventilation Technology for Highway Tunnel. Chin. J. Undergr. Space Eng. 2011, 7, 819–824. [Google Scholar]

- Betta, V.; Cascetta, F.; Musto, M.; Rotondo, G. Numerical study of the optimization of the pitch angle of an alternative jet fan in a longitudinal tunnel ventilation system. Tunn. Undergr. Space 2009, 24, 164–172. [Google Scholar] [CrossRef]

- Lee, S.C.; Lee, S.; Lee, J. CFD analysis on ventilation characteristics of jet fan with different pitch angle. KSCE J. Civ. Eng. 2014, 18, 812–818. [Google Scholar] [CrossRef]

- Chen, T.; Li, Y.; Xu, Z.; Kong, J.; Liang, Y.; Wang, B.; Fan, C. Study of the optimal pitch angle of jet fans in road tunnels based on turbulent jet theory and numerical simulation. Build. Environ. 2019, 165, 106390. [Google Scholar] [CrossRef]

- Wang, F.; Wang, M.; He, S.; Zhang, J.; Deng, Y. Computational study of effects of jet fans on the ventilation of a highway curved tunnel. Tunn. Undergr. Space Technol. 2010, 25, 382–390. [Google Scholar] [CrossRef]

- Suo, L.; Li, S.; Wu, F.; Zhao, P.; Wen, J.; Qi, P.; Diao, Z. The Effect of Distance between Jet Fans on Gas Transport, Energy Conservation, and Emission Reduction in Long Highway Tunnels. Sustainability 2024, 16, 6990. [Google Scholar] [CrossRef]

- Kim, J.Y.; Yang, S.H. Numerical and Experimental Analysis of Tunnel Flow Induced by Jet Fan. KSFM J. Fluid Mach. 2010, 13, 59–64. [Google Scholar] [CrossRef]

- Tao, H.; Xu, Z.; Zhang, Y.; Zhang, X.; Fan, C. Application of the longitudinal ventilation system in the underground interconnected infrastructure: Assessment of flow distribution and confluence ratio. J. Wind Eng. Ind. Aerodyn. 2023, 239, 105466. [Google Scholar] [CrossRef]

- Henri, C. Device for Deflecting a Stream of Elastic Fluid Projected into an Elastic Fluid. U.S. Patent 2,052,869, 1 September 1936. [Google Scholar]

- Triboix, A.; Marchal, D. Stability analysis of the mechanism of jet attachment to walls. Int. J. Heat Mass Transf. 2002, 45, 2769–2775. [Google Scholar] [CrossRef]

- Singh, R.; Gyuro, M.L. Numerical Analysis of Turbulent Jets in Quiescent Medium. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition 2016, Seoul, Republic of Korea, 13–17 June 2016; Volume 1. UNSP V001T09A001. [Google Scholar]

- Yu, F.; He, Y.; Li, G. Optimization on ventilation effect of jet fan in highway tunnel. Comput. Eng. Appl. 2010, 46, 214–216. [Google Scholar]

- Gao, F.; Zhang, J.; Liu, W. Rsearch on Influence of Curvature of High Altitude Tunnel on InstallationParameters of Jet Fan. Chin. J. Undergr. Space Eng. 2021, 17, 608–617. [Google Scholar]

- Lu, Y.; Fu, S.; Li, L. Simulation of Optimal Layout of Jet Fans in Large Rectangular Sectional Underwater Tunnel. J. Highw. Transp. Res. Dev. 2021, 38, 81–86, 121. [Google Scholar]

- Zhao, L.; Yan, Z. Computational Fluid Dynamics (CFD) Analysis of Spatial Layout Optimization of Jet Ventilation Fan Used in Two-lane Road Tunnel. Tunn. Constr. 2016, 36, 411–417. [Google Scholar]

- JTG/T D70/2-02-2014; CMCT. Guidelines for Design Ventilation of Highway Funnels. China Communication Press: Beijing, China, 2014; pp. 29–62.

- Xue, Y.; Li, X.; Li, N.; Zheng, S.; Wang, Z. Experimental Analysis and Simulation of a Centrifugal Jet Fan for Impulse Ventilation Systems. J. Build. Eng. 2022, 57, 104836. [Google Scholar] [CrossRef]

- Karaaslan, S.; Hepkaya, E.; Yucel, N. CFD simulation of longitudinal ventilation systems in a scaled short tunnel. Isi Bilim. Ve Tek. Derg. J. Therm. Sci. Technol. 2013, 33, 63–77. [Google Scholar]

- Klopfenstein, R., Jr. Air velocity and flow measurement using a Pitot tube. ISA Trans. 1998, 37, 257–263. [Google Scholar] [CrossRef]

- Ren, R.; Xie, Y. Study on Influence Factors of Jet Fans Ventilation Effect in Submarine Immersed Tunnel. Fluid Mach. 2016, 44, 43–47. [Google Scholar]

- Tian, X.; Zhang, S.; Awbi Hazim, B.; Liao, C.; Cheng, Y.; Lin, Z. Multi-indicator evaluation on ventilation effectiveness of three ventilation methods: An experimental study. Build. Environ. 2020, 180, 107015. [Google Scholar] [CrossRef]

- Sandberg, M.; Sjöberg, M. The use of moments for assessing air quality in ventilated rooms. Build. Environ. 1983, 18, 181–197. [Google Scholar] [CrossRef]

- Yong, F.; Jianguo, D.; Bernadette, K. Air flow behavior and gas dispersion in the recirculation ventilation system of a twin-tunnel construction. Tunn. Undergr. Space Technol. 2016, 58, 30–39. [Google Scholar] [CrossRef]

| Equipment | Impeller Diameter (mm) | Outlet Flow (m3/s) | Outlet Flow Rate (m/s) | Axial Thrust (N) | Motor Power (kW) |

|---|---|---|---|---|---|

| APR-37 kW | 1120 | 34.5 | 35.5 | 1260 | 37 |

| Number | Number of Deflector Plates (Piece) | Pitch Angle of Deflector (°) |

|---|---|---|

| 1 | 3 | 0 |

| 2 | 3 | 4 |

| 3 | 3 | 6 |

| 4 | 3 | 8 |

| 5 | 3 | 10 |

| 6 | 4 | 4 |

| 7 | 4 | 6 |

| 8 | 4 | 8 |

| 9 | 4 | 10 |

| 10 | 5 | 4 |

| 11 | 5 | 6 |

| 12 | 5 | 8 |

| 13 | 5 | 10 |

| Deflector Plates Quantity | Pitch Angle (°) | Actual Pressure Rise Value (Pa) |

|---|---|---|

| 3 | 0 | 3.68742 |

| 3 | 4 | 4.77789 |

| 3 | 6 | 3.79822 |

| 3 | 8 | 6.49818 |

| 3 | 10 | 4.68862 |

| 4 | 4 | 4.56317 |

| 4 | 6 | 4.63719 |

| 4 | 8 | 7.88234 |

| 4 | 10 | 7.11923 |

| 5 | 4 | 6.85527 |

| 5 | 6 | 7.58705 |

| 5 | 8 | 7.34637 |

| 5 | 10 | 7.85065 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Cao, K. Optimization of Ventilation Performance in Large-Section Highway Tunnels: The Role of Deflector Shields in Jet Fan Systems. Buildings 2025, 15, 2859. https://doi.org/10.3390/buildings15162859

Wang K, Cao K. Optimization of Ventilation Performance in Large-Section Highway Tunnels: The Role of Deflector Shields in Jet Fan Systems. Buildings. 2025; 15(16):2859. https://doi.org/10.3390/buildings15162859

Chicago/Turabian StyleWang, Kai, and Kai Cao. 2025. "Optimization of Ventilation Performance in Large-Section Highway Tunnels: The Role of Deflector Shields in Jet Fan Systems" Buildings 15, no. 16: 2859. https://doi.org/10.3390/buildings15162859

APA StyleWang, K., & Cao, K. (2025). Optimization of Ventilation Performance in Large-Section Highway Tunnels: The Role of Deflector Shields in Jet Fan Systems. Buildings, 15(16), 2859. https://doi.org/10.3390/buildings15162859