1. Introduction

The construction industry is well-known for generating considerable carbon emissions, adversely affecting its environmental and economic sustainability, as well as the high costs associated with a building’s lifecycle [

1]. The construction industry accounts for around 30% to 40% of total carbon emissions across all sectors [

2]. Consequently, to attain energy conservation objectives and fulfil emission reduction goals, the global construction industry has emphasised the need to decrease carbon emissions from buildings, acknowledging the imperative to reduce energy consumption [

3]. In this context, green building (GB) was used to alleviate detrimental environmental impacts [

4,

5]. The GBs can be defined as buildings constructed using environmentally conscious and resource-efficient methods to minimise their negative environmental impacts at every stage of their lifecycle, from construction to demolition [

4,

6]. Therefore, GB practices are being utilised to address the growing demand for energy services. Because the GBs are specifically constructed to provide a sustainable and eco-friendly structure that optimises the utilisation of land, water, energy, and materials for the benefit of human beings [

7,

8,

9,

10].

With increased efforts to reduce operational energy (OE), the GB’s operational energy usage is decreasing, although embodied energy (EE) usage is either rising or remaining unchanged [

11,

12,

13]. Ng et al. [

12] revealed that operational energy efficiency parameters get the greatest scores across green building certification systems, ranging from 19 to 61%, whereas EE only accounts for 9–12.5%. Amiri et al. [

11] noted that limited emphasis and consideration were given to embodied energy efficiency in both LEED and BREEAM rating systems; Crawford and Stephan [

14] illustrated that the green building council standards overlooked the assessment of EE concerning envelope materials, specifically insulation and triple-glazed windows, which are utilised to attain enhanced operational energy savings in certified GBs (i.e., passive houses). In addition, the building’s EE may account for up to 60% of the life cycle energy in an energy-efficient building and 40% in a net-zero energy building [

15]. However, the recent updated version of LEED v5 has included the embodied carbon/LCA optimisation credit, which can directly impact the reduction of embodied carbon and EE of green buildings [

16]. This emphasised that there are initiatives underway in the green rating systems to address EE in newer versions. Therefore, this background emphasises that the material related to EE merits the attention of practitioners and researchers [

17,

18].

Therefore, few scholars investigate the various aspects of EE in residential and non-residential green buildings. Residential green buildings are primarily designed for living purposes, with a greater emphasis on comfort, health, and efficiency for occupants. The non-residential green buildings serve various commercial, institutional, and industrial functions, focusing on productivity, energy efficiency, and minimising environmental impact across a broader range of activities and uses [

19,

20]. Ng et al. [

12] conducted research using life cycle energy assessment techniques to analyse the EE and OE of both conventional and green-rated non-residential buildings, using hotspot analysis to examine the trade-offs between EE production and OE savings across five kinds of insulating envelopes in Malaysia. This study is limited to the assessment of EE on building insulation materials. Lee et al. [

13] examined the influence of concrete and steel GBs on the EE of the building framework of industrial halls. This study only focuses on EE assessment regarding construction materials related to the framework of a building. Gharehbaghi et al. [

21] assessed the high-rise green buildings EE and OE in Australia, and this study’s EE assessment mainly focuses on structural, doors, windows and building envelope elements related materials. Even though Gharehbaghi et al. [

21] study focuses on three elements of buildings, it is limited to eight types of building materials, including concrete blocks, in-situ concrete, galvanised steel, glass, MDF sheets, plasterboard, plywood, and steel. Mao [

22] analysed the life cycle energy of a green office building (GOB) in Beijing, China, using the LCA approach and energy reduction measures were proposed by focusing on operational and end-of-life stages. Le et al. [

23] analyse the life cycle energy analysis of a green office building in Vietnam. However, this study did not provide energy reduction measures. Therefore, it is revealed that existing studies are either focused on a single element [

13] or limited to specific building elements [

22] and their associated materials [

12]. This background emphasised that the existing studies primarily focus on residential and green buildings, while limited studies have been conducted on green office buildings.

Therefore, it is noted that the existing literature on quantitative insights of GOBs EE focuses on developing countries in the global east, such as China and Vietnam, where quantitative insights on GOBs EE are lacking in developing countries in the global south. Chi et al. [

24] emphasised that buildings in the global south use much more resources and energy compared to those in developed countries. For example, Africa, Malaysia, Sri Lanka, and India account for higher energy consumption of 57%, 48%, 35%, and 33%, respectively, greater than the average of about 30%. Thus, these countries are encouraged to take steps to promote green buildings through government initiatives and policies aimed at sustainable development [

25,

26]. Moreover, existing studies have limitations in proposing EE reduction measures, which could potentially involve the use of low-EE materials in green office buildings, where using low-EE materials can play a vital role in reducing EE in buildings [

27,

28,

29,

30,

31]. Thus, to address these gaps, this study aims to assess the embodied energy of construction materials (cradle-to-gate) in green office buildings in Sri Lanka using the Life Cycle Assessment (LCA) technique and propose the EE reduction potential using the low-EE materials. Moreover, this study discusses the impact of green building certification criteria (Green

SL rating) on the embodied energy of green buildings, which is important for implementing the EE reduction measures in GBs. Cradle-to-gate refers to a partial life cycle assessment boundary that considers all environmental impacts and energy inputs from the extraction of raw materials (“cradle”) up to the point a product leaves the factory gate, excluding the use and end-of-life phases [

32]. This boundary is commonly applied in embodied energy studies, as it captures the stages most relevant to material production and construction, excluding the variability of operational and disposal phases. In the context of buildings, it includes processes such as raw material extraction, manufacturing, transportation, and on-site construction activities [

33].

The LCA is a highly suitable technique for evaluating the environmental impact of buildings. This method systematically measures the environmental impacts associated with all stages of a building’s life cycle, from construction to demolition, providing a comprehensive view of its environmental footprint [

34,

35,

36]. Office buildings have a greater disparity in purpose and technological elements, which may include a larger proportion of valuable metals and other materials. Additionally, office buildings have temporal fluctuations that are influenced by the dynamics of the economy [

37]. Therefore, this study selected green office buildings as a category of the GBs.

2. Materials and Methods

A summary of the study’s methodology is given in this section. Kothari [

38] claims that the case study technique is a kind of qualitative analysis that provides careful and in-depth observations about a situation, individual, or organisation. A researcher may gain a deeper understanding of a complex topic or object by gaining more experience or building on prior knowledge through a case study [

39]. Yin [

39] and Creswell & Creswell [

40] stated that case studies are applicable to research question that have the following traits: (1) research questions that seek to provide an answer to a “How” or “Why” question; (2) actor behaviours that researchers are powerless to control; (3) pertinent contextual conditions; and (4) ambiguous boundaries between phenomenon and context. Based on the research gap, this study’s research question is “How much embodied energy is emitted from the cradle-to-gate boundary of the green office buildings in Sri Lanka?”. Thus, case study-based research methodologies were established since this study focuses on evaluating an EE related to the cradle-to-gate of green office buildings in Sri Lanka.

Using convenience sampling, two typical green office buildings, including data such as Bill of Quantities (BOQs) and drawings, were collected from the two contracting organisations in Sri Lanka. Convenience sampling offers flexibility in selecting participants, which can be advantageous in studies where specific participant characteristics are not critical to the research objectives [

41,

42]. Due to confidentiality issues regarding the project data and client data, the sample size was limited to two. The selected two buildings were chosen due to their platinum certification level under the Green

SL V2.0 rating system. The platinum certification is the highest level of certification that can be obtained under the Green

SL V2.0 rating system, and it is intended to integrate best practices for material selection, energy efficiency, and environmental performance. This enables researchers to raise important questions regarding the blind spots in reducing embodied energy within the green rating certification system and allows the identification of the potential EE reduction strategies based on the identified EE hotspots. This is the primary reason for selecting platinum-certified green office buildings for the study. The selected two buildings are representative of typical Sri Lankan green office buildings in terms of concrete frame construction, material use (such as ready-mixed concrete, reinforcement steel, plywood, clay brick, cement blocks, structural steel, galvanized iron, Zn/Al sheets, gypsum board, ceramic tiles, cement plaster, cement mortar, aluminium, glass and paint), and construction methods (reinforced concrete structures) and design features. The two buildings were designated as a medium-rise (4–11 stories) category.

Despite having gross floor areas (GFAs) that varied greatly (9510 m

2 vs. 1881 m

2), the two buildings were chosen because they are platinum-level green certified, have data availability, and are similarly representative of Sri Lanka’s GOBs. The primary aim is to assess the cradle-to-gate EE per unit area (GJ/m

2), which enables normalised cross-comparison, rather than to compare them in absolute terms. It allows the identification of the EE hotspots and design inefficiencies, regardless of building size. In addition, a small sample size allows for getting in-depth insights into the EE of GOBs rather than generalising the findings. Thus, this study focuses not on making generalisations but rather on creating a “force of example” through an illustrative case study [

43]. As a result, the chosen two case studies provide insightful information on material-related embodied energy in a range of practical Sri Lankan green office building types. By following the LCA methodological framework, which includes goal and scope definition, inventory analysis, impact assessment, and interpretation, the cradle-to-gate environmental impact was assessed. Subsequent subsections address the LCA phases, following

Section 2.1, which provides the profile of the selected green building cases.

2.1. Profile of the Selected Green Building Cases

The selection of green office buildings as the subject of this study was influenced by the rising demand for office space in Sri Lanka. Bills of quantities (BOQ) and architectural drawings of a convenience sample of two green office building projects were gathered as data sources, along with cost consulting and contractor practices firms in Sri Lanka. This represented Sri Lankan green office buildings, even though it was done so through non-probability means. The Green

SL Rating System for New Buildings (Version 2.0) certified the buildings in this sample with a platinum rating as green office buildings. The profiles of the selected two GBs are given in

Table 1.

The following sections describe the LCA stages adapted for this study.

2.2. Defining the Goal and Scope

This study evaluated the EE of the two green office buildings in Sri Lanka. Due to the lack of data in all life cycle stages of the selected case studies, the scope of this study is limited to the design development stage. By conducting this research in the early phases of building design, the assessment of EE during the design stage helps to optimise the chances for EE reduction through analysis, decision-making, and action. The structure’s foundation, roof, and façade were designated as the elemental boundary. This study only considered the significant materials used for the building’s structure, envelope, and finishes. Due to a lack of data on other elements, such as temporary construction, building services, and furnishings, these were excluded from the scope of work. According to Yang [

44], a comprehensive system boundary is unnecessary for a process-based analysis. Consequently, this study’s building life cycle boundary is considered the cradle-to-gate system boundary. Thus, this study encompasses only the following life cycle stages: raw material supply, raw material transport, and manufacturing stages. The functional unit of the study was considered one square meter (m

2) of GFA of the building.

2.3. Lifecycle Inventory Analysis

Inventory analysis involves aggregating data and performing computations necessary to quantify essential inputs and outcomes. The life cycle inventory examined the inputs (materials and energy) and outputs (embodied energy) throughout the cradle-to-gate phase of the building life cycle. Inputs included design drawings, bills of quantities, technical requirements, and reports from relevant Sri Lankan and international agencies. Logical assumptions were formulated in the absence of enough facts, aided by proficient construction specialists. The principal elements of the structure were meticulously assessed. The manufacturer’s material qualities and relevant standards were considered when translating the main material (m3, m2, or m) into mass (kg). When this was impractical owing to the intricacy of the work unit, each work unit was subdivided into fundamental material components.

Despite the variability of EE in building materials across countries due to factors such as raw materials, production technologies, energy sources, and energy quality, the absence of a current, country-specific EE database forced the researchers to utilise the Inventory of Carbon and Energy (ICE) to obtain EE values for the building materials or products employed in the chosen sample buildings. Consequently, the EE values were derived using the relevant Sri Lankan-specific literature [

45,

46,

47] and ICE version 2.0, created by the University of Bath, UK [

27]. Accordingly, reinforcement steel, clay brick, structural steel, Zn/Al sheets, aluminium, glass and paint materials associated with the Sri Lanka country-specific embodied energy coefficient were obtained from the existing literature [

45,

46,

47]. Ready-mixed concrete, plywood, cement block, galvanised iron, gypsum board, ceramic tiles, cement plaster, and cement mortar associated embodied energy coefficients were obtained from ICE version 2.0, as Sri Lankan-specific data were not available [

48]. Hammond and Jones [

49] propose that, in the absence of country-specific data, such as in Sri Lanka, ‘proxy data’ can be used. This is acknowledged as a significant limitation and emphasises the need for further efforts to create a database specific to Sri Lanka [

28,

31,

49,

50]. Moreover, many previous Sri Lankan-specific studies [

40,

41,

42,

43,

44] and other South Asian countries, such as India, Bangladesh, and Nepal, have also utilised ICE data in their research due to the country- or region-specific data available [

51,

52,

53].

The EE from cradle-to-gate was computed using the following Formulae (1) and (2) [

54], and the analysis was carried out manually using Microsoft Excel.

E,embodied,i, and Eembodied are the embodied energies (MJ) of building material i and the building, respectively. βi (MJkg−1) and mi (kg) are the embodied energy coefficient and the mass of the building material i, respectively.

2.4. Lifecycle Impact Assessment

In this stage, life cycle inventory analysis data were used to assess the relevance of environmental consequences. EE was considered one of the possible environmental effects in this study. The results were presented as EE per unit of GFA (in GJ/m2) of the selected green office buildings.

3. Results

This section presents and discusses the key findings concerning the cradle-to-gate EE of the selected two green office buildings in Sri Lanka.

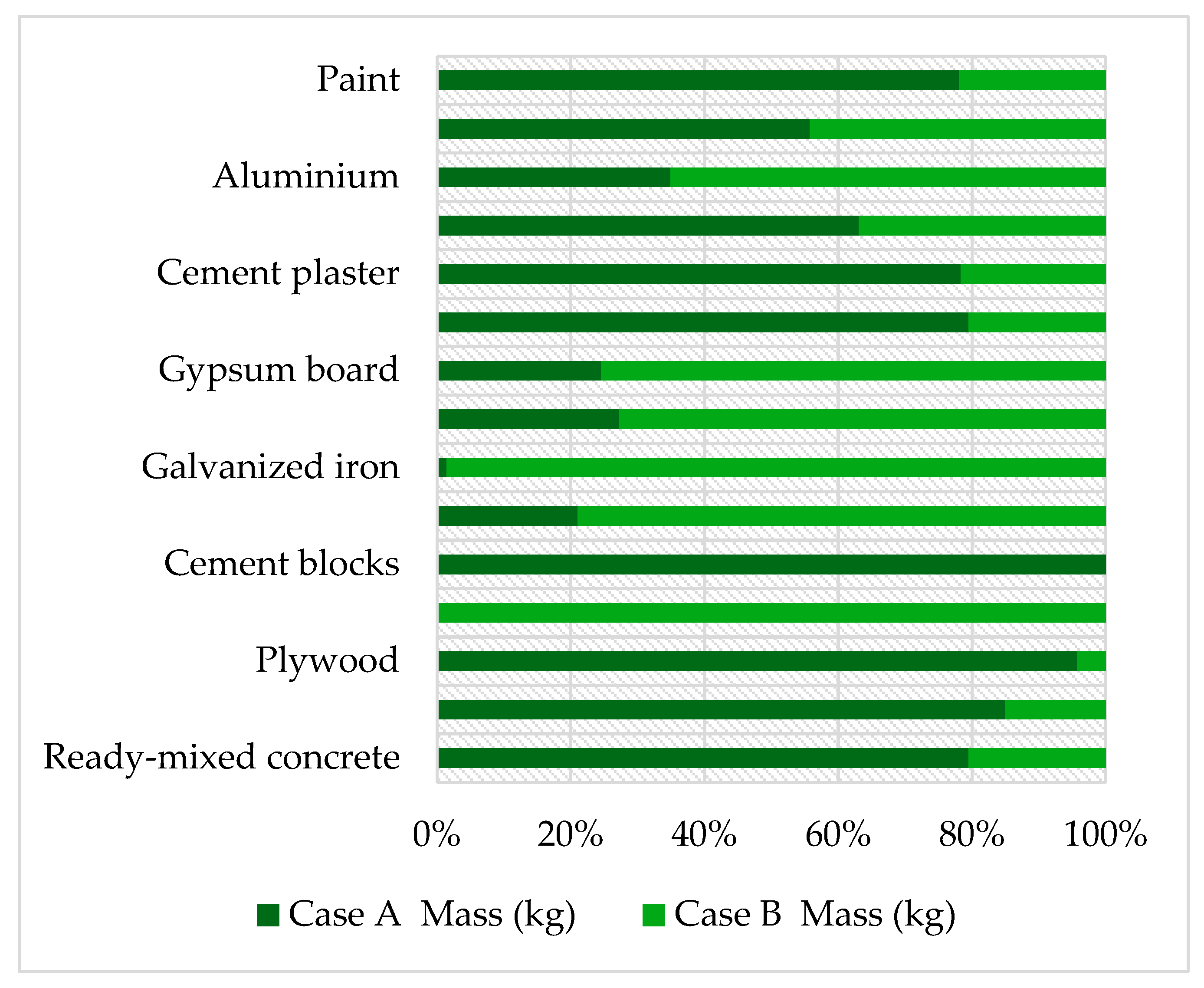

3.1. Composition of Materials Mass Analysis of the Case Studies

Using the collected data, the mass of materials utilised in the chosen green office buildings was calculated, and the results are shown in

Table 2 and

Figure 1 (Cases A and B) below. The materials used for Case A had a total mass of 24,164,655.20 kg and a material flow of 2540.97 kg/m

2 of GFA, according to the results. With a material flow of 3363.67 kg/m

2 of GFA, Case B had a total material mass of 6,327,060.50 kg. In both situations, the most significant mass material was ready-mix concrete, accounting for 72.31% of the total mass of materials in Case A and 71.39% in Case B. Although both cases have a very close percentage of ready-mix concrete mass to the total material mass, there is a significant difference in the proportions of ready-mix concrete between Cases A and B. This significant difference in the volume of ready-mix concrete between Cases A and B was attributed to differences in structural design, particularly in the foundation systems and structural elements such as columns, beams, and slabs. For example, both buildings used pile foundations; however, Case A implemented a stronger and more diverse pile system, consisting of 14 piles with a diameter of 600 mm, 9 piles with a diameter of 800 mm, 26 piles with a diameter of 1000 mm, and 18 piles with a diameter of 1200 mm. Conversely, Case B had a slightly simpler foundation design, consisting of 12 piles with a diameter of 600 mm and 14 piles with a diameter of 750 mm. Furthermore, Case A had a significantly larger gross floor area (9510 m

2) than Case B (1881 m

2), necessitating a more robust structural system to support the larger constructed form. The differences in size and structural configuration account for the increased volume of ready-mix concrete used in Case A, resulting in a higher contribution to EE. Additionally, Case A reinforcing steel and plywood accounted for 4.52% of the building’s overall mass in structural components. Plywood, steel reinforcement, and Case B accounted for 2.66% of the building’s overall mass. Consequently, in both instances, the bulk of the materials is almost entirely composed of elements related to building structures, such as plywood, reinforcing, and ready-mix concrete.

Furthermore, solid cement blocks contribute the second highest to Case A’s total material mass (17.55% of the building’s total mass). In Case A, clay bricks provide the second-highest contribution to the building’s total material mass (10.87% of the building’s total mass). In both case studies, the cement mortar also comprises a significant portion of material mass (Case A: 3.59% and Case B: 8.02%). It is highlighted that the building envelope materials, comprising cement mortar and solid cement blocks, accounted for a significant portion of Case A’s total material mass (21.14% of the structure’s total material mass). Comparably, cement mortar and clay brick building envelope materials comprised a significant portion of Case B’s total materials mass (18.89% of the structure’s total material mass). Furthermore, in both cases, the mass of every other material was shared by a very small amount.

3.2. Cradle-to-Gate Embodied Energy of the Case Studies

Figure 2 and

Table 3 show the results of the cradle-to-gate embodied energy of Case A and Case B. As a result, in Case A, the total EE related to the cradle-to-gate of certain green office buildings is 60,366.38 GJ, while in Case B, it is 21,963.11 GJ. According to the findings, Case A’s gross floor area had an EE of 6.35 GJ/m

2, whereas Case B’s had an EE of 11.68 GJ/m

2. The primary EE component in both scenarios is reinforcement steel, which accounts for 23.77% of the overall EE in Case B and 48.64% in Case A. However, as

Table 2 demonstrates, the reinforcing steel material accounted for only 3.72% of the total material mass in Case A and 2.52% of the total material mass in Case B. This disproportionately high EE concerning its mass of material might be attributed, at least in part, to the reinforcing material’s high embodied energy coefficient (32.690 MJ/kg) compared to comparable structural materials. Considering this substantial impact, EE reduction strategies such as using recycled reinforcing steel or high-strength steel to minimise volume requirement could be helpful in reducing the EE.

Section 3.6.1 provides an in-depth examination of these solutions, emphasising their potential to enhance material efficiency while maintaining structural integrity.

In Case A, ready-mixed concrete accounted for the second-highest amount of EE material with 15,900.77 GJ, or 26.34% of the total EE. However, ready-mixed concrete accounted for 4110.62 GJ (18.72% of the total EE in Case B) and was the third-largest EE material. The findings in

Table 3 show that critical structural components, including plywood, reinforcement, and ready-mixed concrete, contributed 79.81% of the total EE in Case A. Key structural components like plywood, reinforcement, and ready-mixed concrete contributed 43.08% of the total EE in Case B, as

Table 3 illustrates. The data show that aluminium is the second-largest EE material, with 5176.55 GJ of EE (23.57% of the total EE in Case B). Furthermore, with 2781.87 GJ (4.61% of the total EE in Case A), aluminium ranked as the fifth-largest EE material in Case A. However, aluminium shares very little material mass in the two case studies; Case A shared 0.08% of the total material mass (Refer

Table 2), while Case B shared 0.55% of the total mass (Refer

Table 2). Similar to the EE scenario with reinforcing steel, the primary cause of the aluminium material’s disproportionately high EE compared to its mass is its high embodied energy coefficient (147.480 MJ/kg).

The significant difference in EE related to the aluminium in Case A and Case B occurs due to design differences in the aluminium frame systems. While both case studies included casement and sliding windows, Case B had somewhat heavier aluminium components. Case A used a 41 mm casement aluminium section; however, Case B utilised an 80 mm section, which has a weight that is roughly 148.04% more per linear meter. Similarly, Case A employed a 70 mm aluminium section for sliding windows, whereas Case B utilised an 80 mm section, resulting in an increased aluminium mass. Furthermore, for internal walls, Case A used a 76 mm aluminium partition section. In contrast, Case B utilised a 100 mm piece, which is 158.50% heavier per linear meter than the 41 mm casement aluminium section. Thus, these design differences between Case A and Case B result in a higher EE in Case B compared to Case A under the aluminium material.

Cement blocks are the most energy-intensive material related to the building envelope; in Case A, they emitted 5641.33 GJ or 9.31% of the total energy equivalent. Similarly, in Case B, clay brick supplied 2564.64 GJ (11.68% of total EE), making it the highest contributing EE material in the building envelope category. Moreover, the total EE of the chosen GBs is substantially less than that of cement block and clay block EE due to the contributions of cement mortar (1.39% of the total EE in Case A and 2.24% of the total EE in Case B) and Zn/Al sheet (0.14% of the total EE in Case A and 1.06% of the total EE in Case B). Furthermore, it is noteworthy that Zn/Al material had the second-highest EE coefficient value in both case studies. However, because of the low material usage, Zn/Al became Case A’s least significant EE contribution. However, since Case B used more Zn/Al material than Case A did, there was a higher emission of EE associated with the Zn/Al material in Case B.

With 0.88% of the total EE in Case A, ceramic tiles are the finishing material that contributes the most to energy efficiency. Ceramic tiles, on the other hand, ranked third among the finishing category’s EE materials in Case B, accounting for 0.62% of the case’s total EE emissions. It is essential to note that the ceramic tile’s mass contribution to the overall mass of the components is 0.18% in both situations. On the other hand, compared to Case B, the amount of ceramic tile needed for Case A is approximately four times that of Case B. Under finishing materials, gypsum board is the largest emitter of EE, accounting for 5.80% of the total emissions in Case B. In contrast, gypsum board contributed only 0.69% of the total EE in Case A. The primary reason for this circumstance is that Case B uses more gypsum board than Case A. As

Table 4 and

Table 5 demonstrate, aluminium also shared the highest embodied energy coefficient value. Furthermore, as the EE coefficient values of galvanised and structural steel were found to be very high, these materials should get further attention. However, due to decreased usage, structural steel and galvanised iron became the least EE materials in Case A. However, Case B utilises more structural steel and galvanised iron components than Case A. The high quantity of structural steel and galvanised iron components in Case B resulted in a large EE. Therefore, the discussion and findings above (

Table 3) demonstrated the need to pay more attention to material quantity utilisation to lower the EE associated with construction materials.

3.3. Contribution of Building Elements to Total Mass and Embodied Energy

To assess the EE of the selected GB building elements, such as the structure, building envelope, finishes, doors, windows, and roof, the material mass and EE values provided in

Table 3 were further elaborated. The allocation of mass and embodied energy of the GBs to each building element is shown in

Table 4. Designing structures based on elements rather than building materials is a frequent practice. Presenting the findings in elemental form will make it easier for building designers to assess the environmental consequences of different design options throughout the life cycle.

Accordingly, as shown in

Table 4, “Mass (%)” represents the ratio of the material mass of each construction element in relation to the overall mass of the chosen materials included within the cradle-to-gate system boundary. The findings shown in

Table 4 indicate that in both case studies, the structural element accounts for the most significant proportion of material mass and embodied energy. This is attributed to the considerable amount of reinforcement steel and ready-mixed concrete used for piling works, columns, beams, and slabs. The structural element accounts for about 75% of the overall material mass of the chosen GBs. Furthermore, the Case A structural element accounted for 76.83% of the overall EE, whereas the Case B structural element contributed 43.08% to the total EE. The building envelope element accounts for the second largest proportion of material mass and EE. This is primarily due to the extensive usage of cement blocks in constructing building walls in Case A. However, the Case B building envelope element accounts for the second-largest proportion of material mass due to the high quantity of clay bricks used in the wall. Nevertheless, the building envelope element in Case B becomes the third-highest EE element. Moreover, it is essential to mention that in Case B, the doors and windows components have the second-greatest EE. Furthermore, the doors and windows contribute substantially to EE in Case A. However, the primary cause of this condition is the use of a small amount of aluminium inside doors and windows, coupled with a high value for the coefficient of embodied energy.

Furthermore, the roof element in Case B contributes significantly to the total EE. The main reason is the high EE coefficient value of Zn/Al sheets, structural steel, and galvanised iron. However, Case A had less canopy roof area than Case B. Therefore, it resulted in a low quantity of Zn/Al sheets, structural steel, and galvanised iron for the roof in Case A, which became the lowest EE building element in Case A. In addition, the results in

Table 4 show that the finishing element also impacts the EE of both GBs.

3.4. Comparison of This Study’s Results with the Previous Studies

To understand the EE of green office buildings in Sri Lanka,

Table 6 compares the findings of this research and those of prior studies. Nevertheless, since there is no established standard for measuring the EE of green office buildings on a worldwide scale (EE benchmark for GBs), particularly in Sri Lanka, this study’s results were compared to previous research on the EE of conventional office buildings in Sri Lanka and the global context that focused on construction materials. This comparison allows us to identify whether the EE of GBs falls within a lower or higher range of values, which is critical for evaluating whether green building certification systems adequately account for EE credit criteria in GBs, as further discussed in

Section 3.7. Studies conducted throughout the building material production phase (Cradle-to-gate) were utilised as a standard reference point for comparison, ensuring consistency, even though the case studies employed diverse definitions of system boundaries and varying levels of detail, depending on the available data.

Accordingly, it was identified that few existing studies in the global context have assessed the conventional office building cradle-to-gate EE using the hybrid LCA model and the process LCA method, as shown in

Table 6. However, studies of traditional office building cradle-to-gate EE do not exist in the Sri Lankan context. However, it was identified that only one study, carried out by Kumanayake et al. [

41], assessed the cradle-to-gate embodied carbon of a conventional office building in Sri Lanka using the process LCA method. To compare this study’s findings with the previous Sri Lankan context study, using the Kumanayake et al. [

49] study, we have derived the EE of that Sri Lankan conventional office building as shown in

Table 5. Because the system boundary, density values and method used in this study are equal to the Kumanayake et al. [

49] study’s system boundary, density values and method; accordingly, the results showed that the conventional office building shown in the Kumanayake et al. [

49] study’s EE is 11.29 GJ/m

2.

The findings shown in

Table 5 and the other past studies of one green office building and a conventional office building, cradle-to-gate EE in a global context, were compared and shown in

Table 6. According to the comparison in

Table 6, the Sri Lankan Case study B GB has recorded the highest EE among all conventional and green office buildings, with a value of 11.68 GJ/m

2. The lowest EE was found in the Greek conventional building, 1.93 GJ/m

2. Therefore, the comparison results revealed that Case A’s value of EE, at 69.61%, is higher than the lowest EE of the conventional office building, and Case B’s EE, at 83.48%, is higher than the lowest EE of the traditional office building. In addition, compared to the results of this study with the Sri Lankan conventional office building EE, it is evident that Case A’s value of EE is 77.80%, which is lower than the Sri Lankan traditional office building EE. However, Case B’s value of EE is 3.34%, which is higher than the Sri Lankan conventional office building EE. The comparison results indicated that this study Case A and China green office building EE has small EE deviation (China green office building EE is less than 0.33 GJ/m

2), while Case B has significant deviation compared to the China green office building EE (China green office building EE is less than 5.66 GJ/m

2), which is worth of detail comparison. The comparison of the Vietnam green office building and this study revealed that the Vietnam green office building has 0.89 GJ/m

2 higher embodied energy compared to Case A. However, the Vietnam green office building has 4.44 GJ/m

2 less embodied energy compared to Case B. The detailed comparison of Case A, Case B, and green office buildings in China and Vietnam is summarised and discussed in

Table 7. Additionally, the comparison revealed that China’s GOB EE is 28.59% less than China’s conventional office building. Therefore, it is revealed that the selected green office buildings have high EE, even though both are platinum-rated green office buildings. In addition, the variation in the contents of different assessments is primarily influenced by the use of various procedures and inventories, which are dependent on the availability of data [

58,

59,

60,

61,

62,

63,

64,

65,

66,

67,

68].

Hence, it can be evident that there is a need for more openness and enhanced data quality assessment [

61,

62]. De Wolf et al. [

63] suggested that the Green Building Council of each country may provide a standardised approach for calculating EE and EC. The substantial disparities in EE outcomes among the case studies underscore the inconsistencies in the data used, which is sourced from diverse origins and countries [

64]. Azari and Abbasabadi [

62] highlight the existence of conflicting datasets for variables such as EE coefficients, transit factors, construction factors, waste factors, etc. Notwithstanding this inconsistency, using outdated or geographically irrelevant data is standard practice. De Wolf et al. [

63] stress the need for the law to mandate the creation of environmental product declaration databases to enhance the precision of EE assessments. On the other hand, highlights the importance of having data related to the specific location of a project [

65,

66].

Table 6.

Comparison of this study’s results with the previous studies.

Table 6.

Comparison of this study’s results with the previous studies.

| Reference | [67] | [68] | [69] | [49] | [23] | [24] | This Study

Case A | This Study

Case B |

|---|

| Building type | Conventional office building | Conventional office building | Conventional office building | Conventional office building | Green office building | Green office building | Green office building | Green office building |

| No. of floors | 38 floors above ground | 13 floors | 5 floors | 3 floors | 3 floors + mezzanine floor | 7 basement floors + 9 floors | 3 basement floors + 18 floors | Lower floor + 7 floors | 9 floors |

| Structure | Reinforced concrete | Reinforced concrete | Reinforced concrete | Reinforced concrete | Reinforced concrete | Sub-structure: Reinforced concrete

Superstructure: Structural steel | Reinforced concrete | Reinforced concrete | Reinforced concrete |

| Research boundary | Cradle-to-gate | Cradle-to-gate | Cradle-to-gate | Cradle-to-gate | Cradle-to-gate | Cradle-to-grave | Cradle-to-grave | Cradle-to-gate | Cradle-to-gate |

| Assessment method | Hybrid LCA model | Process LCA method | Process LCA method | Process LCA method | Process LCA method | Process LCA method | Process LCA method | Process LCA method | Process LCA method |

| EE result | 6.8 GJ/m2 | 8.43 GJ/m2 | 1.93 GJ/m2 | 3.27 GJ/m2 | 11.29 GJ/m2 | 6.02 GJ/m2 | 7.24 GJ/m2 | 6.35 GJ/m2 | 11.68 GJ/m2 |

| The deviation percentage from this study’s result | Case A—7.09%

Case B—(41.78%) | Case A—32.76%

Case B—(27.83%) | Case A—(69.61%)

Case B—(83.48%) | Case A—(48.50%)

Case B—(72.00%) | Case A—77.80%

Case B—(3.34%) | Case A—(5.20%)

Case B—(48.46%) | Case A 14.02%

Case B—(38.01%) | Case B—(45.63%) | Case A—83.94% |

| Country | Thailand | China | Greece | Greece | Sri Lanka | China | Vietnam | Sri Lanka | Sri Lanka |

Table 7.

Detailed comparison of this study and the GOB in China and Vietnam.

Table 7.

Detailed comparison of this study and the GOB in China and Vietnam.

| Building Parameters | [23] | [24] | Case A | Case B |

|---|

| Location | China | Vietnam | Sri Lanka | Sri Lanka |

| GFA | 30,191 m2 | 14,112 m2 | 9510 m2 | 1881 m2 |

| No. of floors | 7 basement floors + 9 floors | 3 basement floors + 18 floors | 8 floors | 9 floors |

| Foundation | Not mentioned | Reinforced concrete bored piles and concrete foundation slab, and

walls | Piling | Piling |

| Structure | Sub-structure: Reinforced concrete | Reinforced concrete | Reinforced concrete | Reinforced concrete |

| Superstructure: Structural steel |

| Used materials | Concrete, Structural steel, Block, Cement, Gypsum, Glass, Stone, Aluminium, Wood, Bitumen, Copper, Paint | Ready-mixed concrete, Reinforcement steel, Structural steel, Sand, Aggregate, Cement, Cement mortar, Concrete bricks, Galvanized iron, Plasterboard, Glass, Paint, Ceramic tiles, Marble stone, Wood (work form), PVC pipe, Steel doors, MDF (doors), Timber (doors), Doors and windows (Aluminium Framed) | Ready-mixed concrete, Reinforcement steel, Plywood, Cement block, Structural steel, Galvanised iron, Zn/Al sheets, Gypsum board, Ceramic tiles

Cement plaster, Cement mortar, Aluminium, Glass, Paint | Ready-mixed concrete, Reinforcement steel, Plywood, Clay brick, Structural steel, Galvanised iron, Zn/Al sheets, Gypsum board, Ceramic tiles

Cement plaster, Cement mortar, Aluminium, Glass, Paint |

| Cradle-to-gate EE/m2 | 6.02 GJ/m2 | 7.24 GJ/m2 | 6.35 GJ/m2 | 11.68 GJ/m2 |

| EE hotspot materials | Structural Steel—33.50% | Reinforcement steel—30.55% | Reinforcement steel—48.64% | Reinforcement steel—23.77% |

| Concrete—24.70% | Ready-mixed concrete—23.60% | Ready-mixed concrete—26.34% | Ready-mixed concrete—18.72% |

| Aluminium—21.50% | PVC pipe—21.13% | Cement block—9.35% | Aluminium—23.57% |

| Other materials—20.40% | Other materials—24.72% | Other materials—15.67% | Other materials—33.94% |

As indicated the

Table 7, among these four green office buildings China GOB has the smallest EE amounting, 6.02 GJ/m

2, the Case A is the second smallest EE GOB (6.35 GJ/m

2), the Vietnam GOB shares the third smallest EE (7.24 GJ/m

2), and Case B has the highest EE (11.68 GJ/m

2). These deviations are mainly caused by different factors influenced by project scale, structural system, material usage, construction methods and data quality. The building scale plays a vital role in the embodied energy of buildings. For example, China GOB has 30,191 m

2 of GFA and structural system configurations with 7 floors of reinforced concrete sub-structure and 9 floors of structural steel superstructure. The Vietnam GOB has a GFA of 14,112 and a reinforced concrete structure across 18 floors. While Case A is a 9510 m

2 of GFA with 8-floor reinforced concrete building, and Case B is the smallest building with 1881 m

2 of GFA, which consists of 9-floor reinforced concrete structural system. Therefore, larger buildings like those in China and Vietnam benefit from economies of scale, enabling more efficient distribution of high-EE materials across broader floor areas, thereby reducing per-unit EE. Conversely, Case B’s compact structure amplifies the relative EE impact of foundational and core materials, leading to an inflated EE/m

2.

The materials composition also has an impact on EE. In China’s case, the two main EE hotspots include structural steel (33.50%) and concrete (24.70%). In Vietnam case, two EE major contributors to EE including reinforcement steel (30.55%), ready-mixed concrete (23.60%), a similar composition to Case A and B which reinforcement steel (Case A—48.64%, Case B—23.77%), ready-mixed concrete (Case A—26.34%, Case B—18.72%). Even though all four cases use the concrete material, the deviation could result from the structural steel use in China’s study, whereas Cases A and B use reinforcement steel, which has a higher EE coefficient value (32.69 MJ/kg) compared to China’s structural steel EE coefficient value (29 MJ/kg).

In addition, the hybrid structural system in the China case may provide a better material efficiency ratio, where structural steel, although high in EE per unit compared to concrete EE, is effectively used in the superstructure, potentially minimising concrete volume and enhancing load distribution, thus optimising the overall EE. All three other studies (Vietnam, Case A, and Case B) mainly use a structural system constructed with reinforcement steel and ready-mixed concrete. Studies have shown that hybrid systems, such as structural steel-concrete composites, can significantly reduce the embodied energy of buildings [

70]. Moreover, adopting other hybrid structural systems, such as steel-timber composite floors and shear walls in a steel structure, resulted in a 107.5% decrease in embodied energy compared to a concrete structure [

29].

Additionally, local building methods and data quality affect the estimated results in the studies. For example, the Vietnam study [

24] relied largely on international EE coefficients due to data shortages, which inflated the estimated results. The China study [

24] and this study use both local and international EE coefficients data to derive the EE estimate results. In addition, the China study and this study excluded the MEP services system-related EE due to the lack of data, while the Vietnam study includes the plumbing-related (PVC pipe) EE for their assessment, which is the third highest EE contributor in the Vietnam study.

Elemental Comparison of EE in Green Office Buildings and Conventional Office Buildings in Sri Lanka

This study’s results are further evaluated with the results of

Table 5 to provide more insights into the EE value of Sri Lankan green office buildings and to generalise the findings of this study. Accordingly, the comparison results are shown in

Table 8.

The comparison in

Table 8 shows that the highest EE contribution of the selected GBs and conventional office buildings came from the structural element. This is due to the use of reinforcement steel and ready-mixed concrete in the structural elements of all three buildings. However, it was noted that Kumanayake et al. [

49] did not consider the plywood material in their assessment of the conventional office building. However, it is necessary to note that in the selected GBs, the plywood also shared a considerable amount of EE. For example, Case A had 0.31 GJ/m

2, and Case B had 0.07 GJ/m

2 of embodied energy related to the plywood material. Thus, considering all possible materials for assessing EE or EC can improve the transparency and validity of the results. Additionally, the GBs and conventional offices utilised cement mortar as a common material for the building envelope. Additionally, Case A utilised a cement block, whereas Case B and the conventional office employed a clay brick as the building envelope material. The comparison showed that when considering the building envelope element, Case A has significantly lower EE consumption compared to the building envelope-related EE of Case B and the conventional office building. The brick’s high embodied energy coefficient value (3.730 MJ/kg) compared to the cement block (1.33 MJ/kg) could be the main reason for this. All three buildings utilised gypsum boards, ceramic tiles, cement plaster, and paint for their finishing elements. Additionally, conventional office buildings often use mineral fibre sheets for ceiling work. However, the results showed that the finish element had the lowest EE contribution of all three buildings. The low quantity of EE compared to the other building elements is the key reason for the low amount of EE in the finishing element.

Moreover, both buildings used aluminium and glass materials for the doors and windows. Case A had the lowest EE compared to Case B and the conventional office doors and windows element-related EE amount. As discussed in

Section 3.2, using higher-weighted aluminium sections for the doors, windows, and partitions in Case B, compared to Case A, significantly increases the embodied energy of the doors and windows elements in Case B. All three buildings used the same materials for the roof element: Zn/Al sheet, structural steel, and galvanised steel. However, all three materials had high embodied energy coefficient values, resulting in high EE under this element. For example, Case B Zn/Al material shared 0.10% of the total material mass. Nevertheless, it contributed 1.06% of EE to the total EE in Case B. The high value of the embodied energy coefficient of Zn/Al material is the main reason for this situation. However, it was noted that Kumanayake et al. [

49] did not consider the Zn/Al material in their assessment of the conventional office building. As explained, the Zn/Al sheet shared a considerable amount of EE, and its consideration improves the transparency and validity of the results. Accordingly, the above comparison and discussion show that even though the case study buildings are GBs, they use traditional construction materials like conventional buildings, resulting in high EE, like conventional office buildings.

The results indicated that the Case A embodied energy hotspots are materials such as reinforcement steel, ready-mixed concrete, cement block, plywood, and aluminium. Case B embodied energy hotspots materials included reinforcement steel, aluminium, ready-mixed concrete, clay bricks, and galvanised iron. Therefore, it is revealed that in both GBs, reinforcement steel, ready-mixed concrete, cement blocks/clay bricks, and aluminium are the typical EE hotspots, which account for 88.94% of total EE in Case A and 77.74% of total EE in Case B. Chen et al. [

71] revealed that concrete, steel, and brick accounted for over 70% of the total EE of a building. Therefore, these findings align with those of Chen et al. [

71]. As shown in

Table 6 and

Table 7, when compared to the Sri Lankan conventional ad green office total EE, Case A had 77.80% lower value and Case B had 3.34% higher value, which raises concerns about addressing the reduction of embodied energy in green building rating tools. This concern was previously emphasised in existing studies, which recommended that green building certificates should increase the weight of sustainable construction materials, as the significance of EE and EC is substantially growing in line with current carbon neutrality goals [

11,

12,

72].

3.5. Sensitivity Analysis

When assessing the embodied energy of buildings, uncertainty always exists in the source of embodied energy coefficient values. Therefore, it is essential to estimate the range of uncertainty associated with the embodied energy coefficient values, which in turn results in uncertainty in the building’s embodied energy. Sensitivity analysis is an approach of uncertainty analysis that examines the extent of impact on findings when certain factors vary, and it is often used in LCA studies to evaluate uncertainties. Thus, the sensitivity analysis is employed in this study, and one key sensitivity factor, the embodied energy coefficient values, is obtained from the ICE version 2.0. Accordingly, as discussed in

Section 2.3, the following materials, including ready-mixed concrete, plywood, cement block, galvanised iron, gypsum board, ceramic tiles, cement plaster, and cement mortar, were selected from the ICE version 2.0. Namal [

73] reported that the cradle-to-gate embodied energy of cement production in Sri Lanka is 4.896 MJ/kg, whereas the ICE version 2.0 cement cradle-to-gate embodied energy is 4.500 MJ/kg [

48], which represents an 8.09% lower value compared to the Sri Lankan EE. Another study in Sri Lanka showed that the cradle-to-gate embodied carbon coefficient of cement is 0.100 kg CO

2e/kg [

74]. In contrast, the ICE version 2.0 cement cradle-to-gate embodied carbon is 0.107 kg CO

2e/kg [

48], which is 7.0% higher than the Sri Lankan value. Therefore, the variation range of the EE coefficient sensitivity factor for ready-mixed concrete, cement plaster, and cement mortar materials is set from −10% to 10% of the original value extracted from ICE version 2.0.

The reinforcement steel cradle-to-gate embodied energy in Sri Lanka is 32.69 MJ/kg [

46], where the ICE version 2.0 reinforcement steel cradle-to-gate embodied energy is 29.20 MJ/kg [

48], which is 10.68% lower than the Sri Lankan value. The cradle-to-gate embodied carbon coefficient of steel is 1.396 kg CO

2e/kg [

74]. In contrast, the ICE version 2.0 cement cradle-to-gate embodied carbon is 1.370 kg CO

2e/kg [

48], which is 1.86% lower than the Sri Lankan value. Hence, the galvanised iron material variation range of the EE coefficient sensitivity factor is set from −10% to 10% of the original value. Kumanayake [

74] revealed that the cradle-to-gate embodied carbon of ceramic tiles in Sri Lanka has a 5.13% higher embodied carbon value compared to the ICE version 2.0. Thus, the variation range of the EE coefficient sensitivity factor for ceramic tile materials is also set from −10% to 10% of the original value. Moreover, studies on plywood and gypsum board materials relevant to the Sri Lankan context were lacking. Hence, the variation range of the EE coefficient sensitivity factor for plywood and gypsum board materials is also set from −10% to 10% of the original value, and results are shown in

Figure 3.

The sensitivity analysis revealed that the total EE under −10% of the original coefficient value of Case A is 57,693.38 GJ, and Case B is 21,206.99 GJ, which is 4.43% and 3.44% lower than the original scenario, respectively. Under 10% of the original coefficient value of Case A is 63,039.37 GJ, and Case B is 22,719.23 GJ, which is 4.43% and 3.44% higher than the original scenario, respectively.

The embodied energy assessment results revealed that reinforcement steel, ready-mix concrete, cement block, clay bricks, and aluminium are the EE hotspots in both cases. Hence, the following section discusses the strategies to reduce the EE of the identified embodied energy hotspots in Cases A and B. Using the low-EE materials is one of the significant strategies to reduce the EE in buildings [

27,

28,

29,

30,

31]. However, due to the absence of data on low EE construction materials in the Sri Lankan context, the low EE materials recommended by existing studies are used to identify how much EE can be reduced by using low EE materials rather than high EE hotspot materials.

3.6. Strategies to Reduce the EE of Selected GBs

3.6.1. Reduction of Reinforcement Steel EE

It was identified that the reinforcement steel made the highest contribution to EE in both GBs. The reinforcement steel accounted for a minimal total weight compared to the overall weight of the materials used in the GBs. As discussed in

Section 3.2, the high embodied energy coefficient value of reinforcement steel (32.690 MJ/kg) is the critical reason. Therefore, reinforcement steel-related EE can be reduced by evaluating optimisation strategies for structural systems and components, as well as modifying the materials and dimensions of their thickness [

75,

76]. Zhang and Wang [

76] assert that using high-strength steel enables the reduction of element thickness, thereby leading to a decrease in EE.

Moreover, recycled steel yields a material with structural properties comparable to those of newly produced steel. Steel recycling is one of the most effective solutions for managing building materials at the end of their life cycle [

77,

78]. The significant reduction in both EE (ranging from 40% to 45%) and EC (up to 60%) is the reason for this, together with the fact that almost all steel waste can be reused in the production of new steel [

79]. For example, Chiniforush et al. [

29] stated that there is 59% recycled reinforcement steel in Australia, and this reinforcement steel cradle-to-gate EE is 17.40 MJ/kg. If we use this recycled reinforcement steel instead of virgin reinforcement steel for this study, Case A and Case B, it resulted in reducing the 25.89% and 12.65% (13,733.63 GJ in Case A and 2441.35 GJ in Case B) of total EE, respectively. Using recycled reinforcement steel does not impact the structure’s structural integrity. The American Iron and Steel Institute has stated that structural steel retains all its metallurgical properties when recycled using essential oxygen or electric arc furnace technology. Therefore, the performance characteristics of recycled steel are equivalent to those of virgin steel [

29]. Hence, steel manufacturers in Sri Lanka should take the initiative to produce recycled reinforcement steel, and construction industry professionals need to adopt recycled reinforcement steel instead of virgin reinforcement steel.

3.6.2. Reduction of Ready-Mixed Concrete EE

The results revealed that the ready-mixed concrete was the second-highest EE material in Case A and the third-highest EE material in Case B (15,900.77 GJ in Case A and 4110.62 GJ in Case B). Accordingly, the concrete EE can reduce and optimise building structures with less material consumption. For example, the structures of column heads, ribs and beams, post-tensioning, and thin concrete shells) can reduce the EE by 8% [

80], 17–22% [

81], 28–41% [

80] and 53–58% [

82], respectively. In addition, enhancing the performance of building structural elements, such as their strength and resilience, may decrease the quantity of materials required to withstand equivalent stresses. Consequently, this can contribute to reducing building EE. Studies have shown that doubling the concrete compressive strength may result in a 36% decrease in concrete use and an 11% reduction in associated EE [

83]. Substituting conventional concrete with alternative low-EE concrete is another key strategy for reducing the embodied energy of traditional concrete materials [

84,

85,

86]. For example, with fibre-reinforced high-performance concrete, the EE in precast concrete facades may be decreased by 50% [

87]. However, to enhance the material performance, significant amounts of cement, superplasticisers, and discontinuous fibres may be used during production, potentially leading to an increase in EE. Fantilli et al. [

88] found that reducing EE using high-strength concrete is more beneficial in tall structures than shorter ones. In addition, using ultrahigh-volume low-carbon cement instead of ordinary Portland cement can reduce the EE related to concrete, masonry, and plastering works [

89,

90].

Substituting reinforced concrete (RC) with bio-based materials, such as lumber, is a viable strategy for reducing EE related to the concrete. Timber is gaining significant attention in the building sector because of its environmental and economic advantages throughout its life cycle [

91,

92]. Research conducted on an 18-storey building in Sydney showed that using a wood structure in its entirety might reduce EE by 13–26% and a cost reduction of 5% compared to RC construction with a flat plate floor [

93]. Hence, using recycled aggregate instead of virgin aggregate and substituting cementitious materials (SCM) for Portland cement for concrete works can reduce the EE of concrete. Cordoba et al. [

94] suggested that using 20% recycled coarse aggregate reduces raw material use by ~8.9%, and using SCM without Portland cement would reduce EC by ~13.6%. Accordingly, we have identified several green concrete and their cradle-to-gate EE values from the existing literature. Using these alternative concrete EE values, we have assessed the potential EE reduction of the selected GBs, and the results are shown in

Table 9 below. Accordingly, the results show that the proposed green concrete can reduce ~8% to ~13% of total EE in Case A and ~5% to ~9% in Case B.

3.6.3. Reduction of Cement Block and Clay Brick EE

The results shown in

Table 3 indicate that cement block is the third-highest EE material in Case A, and clay brick is the fourth-highest EE material in Case B. Using alternative low-EE materials for masonry work is the most promising strategy to reduce EE. This has been previously proven by various studies [

97,

98,

99,

100,

101]. For example, Dabaieh et al. [

102] revealed that when sun-dried bricks are used instead of fired bricks, a reduction of up to 5907 kg CO

2e/kg (in CO

2 emissions) and 5305 MJ of embodied energy for every 1000 bricks produced could be achieved. In addition, Reddy [

103] revealed that using fly ash blocks instead of cement blocks can reduce the EE related to the block wall. Therefore, we have analysed the potential EE reduction using alternative wall materials for Cases A and B, and the results are shown below in

Table 10. Accordingly, as shown in

Table 3, Case A has used the cement block. Thus, we have proposed a fly ash block for Case A by considering the dimensions and strength of the fly ash block. Accordingly, the results showed that using fly ash blocks instead of traditional cement blocks can reduce 4.63% of total EE in Case A. Additionally, we have proposed using sun-dried brick for Case B, considering its dimensions and strength. Accordingly, the results revealed that using sun-dried brick instead of conventional fired brick can reduce the 11.68% of total EE in Case B. In addition, Jayawardana et al. [

31] revealed that employing the same wall material with varying configurations can reduce the EE, such as varied brick bond patterns, to decrease the element’s overall weight. The technique used in the study maintains the same wall thickness or volume, ensuring that there will be no alteration in the operation of the enclosed areas.

3.6.4. Reduction of Aluminium EE

The aluminium material also significantly contributed to the total EE of both GBs. Accordingly, 4.61% of total EE was shared by aluminium, and it was the fourth-highest EE material in Case A. 23.57% of total EE was contributed by aluminium, and it was the second-highest EE material in Case B. However, it was identified that the total material mass of the aluminium in both case studies is low compared to the other material mass of the GBs. For example, the aluminium in Case A accounted for only 0.08% of the total mass of the material. In Case B, it accounted for only 0.55% of the total mass of the material. However, both case studies exhibited high EE consumption concerning aluminium, despite their material mass being significantly low. The main underlying reason for this situation is the high embodied energy coefficient of aluminium (147.480 MJ/kg) compared to all other materials. Therefore, the existing literature suggests that using timber instead of aluminium to prepare doors and windows is the most suitable strategy to reduce the EE related to aluminium doors and windows [

105,

106]. Asdrubali et al. [

107] and Asif [

108] revealed that double-glazed aluminium-clad windows have higher embodied energy than timber windows.

3.6.5. General Strategies to Reduce EE

In addition to the above-discussed strategies, minimisation of materials consumption, utilisation of reusable or recycled materials, use of local/regional materials, and utilisation of eco-labelling materials are other key common strategies that can be used to reduce the EE of the buildings [

12,

71,

109,

110]. For example, recycling, reusing, and recovering destroyed waste have been identified as viable solutions for minimising the energy embedded in construction materials [

54]. Recycling was determined to possess the most significant capacity for energy conservation, with a potential of 53%, compared to re-use and cremation [

111]. Additionally, Jayasinghe and Palliyaguru [

106] found that the Sri Lankan building sector relies heavily on imported steel supplies. Hence, decreasing the quantity of imported materials is essential to minimise EE. Maritime and cargo transportation methods release significant amounts of EE. To address these issues, the GBCSL rating tool, version 2.1, promotes the use of locally created construction materials and products for GBs [

112]. In addition, Lawrence [

113] states that using bio-based renewable materials in construction may significantly decrease the energy required to create structures by harnessing photosynthesis to capture and store carbon emissions.

3.7. Impact of Green Building Certification Criteria on the Embodied Energy of Green Buildings

Both Case A and Case B achieved a Platinum-rated certificate under the Green

SL rating system v2.0 by scoring 82 and 81 out of 100, respectively (Refer to

Table 11). The review of the scoring breakdown revealed that there is no direct point allocation to reporting or reducing the EE of GBs. However, it can be observed that the “Materials, Resources & Waste Management” category, among eight categories in the Green

SL rating system v2.0, has at least an indirect impact on the embodied energy of the GBs through credit criteria such as building reuse, resource reuse, local/regional materials, and construction waste management. Even though, as shown in

Table 11, the high embodied energy GBs also can achieve the maximum rating, which is Platinum-rated certificate without achieving the significant score under the Materials, Resources & Waste Management criteria (Case A only achieved 5 scores out of 14 and Case B achieved 7 scores out of 14 under Materials, Resources & Waste Management criteria). This highlights a notable gap in the Green

SL rating system v2.0, where operational energy is strongly weighted (Case A and B scored 19 out of 22 in the Energy & Atmosphere criteria), and achieving a platinum-rated certificate that addresses the operational energy section is necessary. However, addressing the embodied energy remains optional. This is not only related to the Green

SL rating v2.0, where most of the existing green building rating tools have this gap. For example, Ng et al. [

12] revealed that 19–61% scores are allowing for improving the operational energy, whereas 9–12.5% are allowing for addressing the EE of GBs in many green building rating tools such as BEAM, BREEAM, CASBEE, GBI, Green Mark, GreenRE, Green Ship, Green Star and LEED. This gap was previously highlighted by various researchers as well [

11,

14]. Recent updates to green building rating systems are addressing this gap, where LEED v5 has included the embodied carbon/LCA optimisation credit, which can directly impact the reduction of embodied carbon and EE of GBs [

17]. Thus, it is recommended that the Green

SL rating tool also required to incorporate more credit criteria to address the EE of GBs.

4. Discussion

The current study’s finding shows the two green buildings’ cradle-to-gate EE assessment and potential EE reduction strategies for the Sri Lankan buildings. This study’s results revealed that the cradle-to-gate EE of Case A is 60,366.38 GJ, and Case B is 21,963.11 GJ. According to the comparison shown in

Table 6 and

Table 7, this study’s results align with those of previous studies. In addition, Case A had 38,403.27 GJ EE compared to Case B. The primary reason for this situation is that Case A had a total of 9510 m

2 GFA, while Case B had only 1881 m

2 GFA. Therefore, when considering the size of the selected GBs, Case A had over five times the GFA area compared to Case B. However, when comparing the total EE of Case A and Case B, Case A had over ~2.7 times the EE compared to Case B. In other words, when considering the EE/GFA value, Case A had 6.35 GJ/m

2 while Case B had 11.68 GJ/m

2. As shown in

Table 8, the doors and windows element in Case A shared 0.37 GJ/m

2, while Case B shared 3.08 GJ/m

2 for the same element, which is ~8 times higher than the Case A value. In addition, Case A used cement blocks for the wall masonry works, which had low EE. However, Case B used clay brick with over ~2.8 times EE compared to a cement block.

Table 8 shows that the building envelope element in Case A shared 0.68 GJ/m

2, while Case B shared 1.62 GJ/m

2 for the same element, which is ~2.3 times higher than the Case A value. Thus, it is evident that the high material consumption of aluminium in Case B, compared to Case A, and the use of clay brick instead of cement block are the main reasons for the high EE value of 11.68 GJ/m

2 in Case B compared to Case A.

As shown in

Table 4, the structural element is the most significant component of the building’s total EE for both GBs. In Case A, it accounts for 79.78% (26.34% for ready-mixed concrete, 48.64% for reinforcement steel, and 4.83% for plywood). In Case B, it accounts for 43.08% (18.72% for ready-mixed concrete, 23.77% for reinforcement steel, and 0.59% for plywood). Kumanayake et al. [

49] reported that reinforcement steel and concrete are widely used in Sri Lanka for constructing commercial buildings. In addition, Dimoudi and Tompa [

69] and Wu et al. [

68] revealed that the structural element shared 59–67% of the EE of conventional office buildings. Since the selected GBs used traditional construction materials, as shown in

Table 8, these findings agree with the previous studies by Dimoudi and Tompa [

69] and Wu et al. [

68].

The reinforcement steel was the highest EE material in both GBs, contributing to 29,362.48 GJ in Case A and 5219.61 GJ in Case B. Although reinforcement steel contributed a low percentage to the overall material mass, as shown in

Table 2, a high EE coefficient value resulted in a high EE for the reinforcement material in both GBs. As discussed in

Section 3.6.1, recycled reinforcement steel can reduce the total EE by 25.89% and 12.65% in Case A and Case B, respectively. In addition, ready-mix concrete was the second-highest EE in Case A and the third-highest EE in Case B, which shared 26.34% and 18.72% of the total EE in Case A and Case B, respectively. Accordingly, using the proposed alternative concrete materials shown in

Table 10, Case A can reduce the ~total EE by 8% to ~13%, and Case B can reduce ~the total EE by 5% to ~9%.

Moreover, the results highlighted that both cement blocks in Case A and clay bricks in Case B had significantly higher embodied energy consumption. In Sri Lanka, masonry works mainly use cement blocks or clay bricks. Although various masonry materials exist, burnt clay brick (53.1% of total wall materials) and cement blocks (33.8% of total wall materials) are the most prominent in the building sector for wall construction in Sri Lanka [

114]. Therefore, results revealed that using fly ash block instead of traditional cement block can reduce 4.64% of total EE in Case A. Similarly, sun-dried brick instead of conventional fired brick can reduce 11.68% of total EE in Case B. Therefore, it is evident that using low EE materials, Case A can reduce ~43% of total EE, and Case B can reduce ~33% of total EE. Reddy [

103] reported that using low-energy materials and techniques yields a 50% reduction in total embodied energy in buildings. Therefore, it is emphasised that using low-EE materials can play a vital role in reducing EE and other environmental impacts in buildings. Moreover, the present study suggests that minimisation of materials consumption, utilisation of reusable or recycled materials, use of local/regional materials, utilisation of eco-labelling materials, and use of bio-based renewable materials significantly reduce EE in buildings.

However, there are still several obstacles in the way of Sri Lanka’s building industry’s actual adoption of such low EE material substitutes. The scarcity of approved low EE materials in the local context is one of the main obstacles. For instance, recycled reinforcing steel is neither commercially manufactured or quality-certified in Sri Lanka, despite being extensively utilised in nations like Australia and the UK. Similarly, the low-EE concrete and low-EE fly ash block are gaining attention in global green construction. However, in Sri Lanka, they are either not utilised in projects, technically unverified, or not produced at scale in the local market. Their acceptance and performance verification are made more difficult by the absence of standardised embodied energy databases, Environmental Product Declarations (EPDs), and acknowledged standards specific to Sri Lanka. In addition to the availability of materials, technological feasibility issues must be carefully considered. Furthermore, conventional reinforced concrete systems are the core of the Sri Lankan construction sector buildings, and contractors and consultants lack the technical know-how or training necessary to use alternative building materials or methods. Thus, it is necessary to have upskilling, pilot testing, and revisions to construction standards and rules.

From an economic perspective, due to constrained supply chains, reliance on imports, or a lack of economies of scale, many green options, such as lightweight aluminium substitutes, high-performance recycled aggregates, and geopolymer cement, may be more costly upfront. These expenses are unlikely to be covered by private developers or contractors without legislative assistance, such as tax breaks, subsidies for green materials, or requirements for public procurement. Due to this, even highly promising materials could become economically unfeasible in the short to medium term, particularly for small-scale or cost-sensitive applications. Since Sri Lanka’s green building grading systems do not currently need embodied energy, there is minimal institutional impetus to take low EE materials into account outside of volunteer efforts. This regulatory gap constrains investment in low EE material technology and demand. Multistakeholder cooperation between government organisations, the GBCSL, academic institutions, professionals, and material producers is necessary to close this gap and create more low-EE buildings in Sri Lanka.

Recommendations

Based on the study’s findings, the following recommendations are suggested to reduce the embodied energy of buildings and achieve decarbonisation targets in the built environment in Sri Lanka.

Incorporate embodied energy into green building certification frameworks—As shown in

Table 11, the Green

SL rating system ignores the EE as a key performance parameter of the GB certificate. The results of this study show that due to this gap, the platinum-rated green building also results in high EE. Thus, it is suggested that the Green

SL rating system, as well as other policies that govern the building construction in Sri Lanka, need to incorporate the measures such as providing EE benchmarks value, prerequisite LCA documentation throughout the design phase, and additional points for projects that achieve material efficiency or using low-EE alternatives materials to address the policy gap.

Establish a national EE database for construction materials and set an EE benchmark value. The absence of local EE data necessitated the use of proxy values from the Sri Lankan-specific literature and the ICE v2.0 database, a limitation of this research. Hence, it is necessary to develop a Sri Lankan-specific EE database for construction materials. This database is crucial for conducting more accurate LCA assessments, and designers, engineers, and legislators can refer to it when selecting materials for low-energy buildings. Furthermore, as discussed in

Section 3.4, it is necessary to have EE benchmark values for GBs to evaluate the GBs in terms of EE.

Promote local production and supply of low EE construction materials—As shown in the results, using the low EE materials instead of high EE materials has a substantial potential to reduce overall EE, up to 43% in Case A and 33% in Case B. However, the Sri Lankan market does not provide these substitute materials. Therefore, stakeholders from the public and commercial sectors should invest in the regional production and certification of low-EE products. Supportive policies, including manufacturing incentives, import tax breaks for eco-friendly products, and expedited permit processing, can accelerate market preparedness and acceptance.

Integrate EE considerations into public procurement and project planning—Setting the standard for sustainable procurement is one way that government-led building projects may take the lead. Incorporating EE concerns into material specification standards and public project procurement is advised. Sri Lanka’s EE increase demand and progressively shifts market norms towards more environmentally friendly construction methods by requiring or promoting the use of low-EE materials in public structures, such as government buildings, hospitals, and schools.

Build capacity among industry professionals on embodied energy principles—Construction professionals’ knowledge and technical proficiency are essential for the effective use of low EE methods. There is presently a lack of formal training on life cycle thinking and EE principles among many industry players, such as contractors, engineers, and quantity surveyors. Therefore, it is crucial to implement technical standards, organised training programs, and useful toolkits that assist professionals in efficiently evaluating, comparing, and using low EE materials throughout the design and construction stages.

5. Conclusions

This study assesses the cradle-to-gate embodied energy of two platinum-rated green office buildings in Sri Lanka using the LCA methodology. The results revealed that the cradle-to-gate embodied energy is 6.35 GJ/m2 and 11.68 GJ/m2 for the gross floor area in Case A and Case B, respectively. The results highlighted that reinforcement steel, ready-mix concrete, cement blocks, clay bricks, and aluminium are the EE hotspots in both cases. Using low embodied energy materials such as recycled steel, green concrete, fly ash blocks, or sun-dried brick instead of high EE materials has the opportunity to reduce the ~43% and ~33% of total EE in Case A and Case B, respectively. In addition, the results suggested that (1) minimisation of materials consumption, (2) utilisation of reusable or recycled materials, (3) use of local/regional materials, (4) utilisation of eco-labelling materials, and (5) using bio-based renewable materials also have a significant contribution to reducing EE in buildings.

Although this study provides strong evidence that material substitution can theoretically result in significant reductions in embodied energy. However, the practical implementation of these gains will require overcoming local material constraints, technical design barriers, economic affordability, and policy criteria. Hence, technical and economic feasibility studies, pilot-scale implementations, and the development of an embodied energy and carbon database tailored to Sri Lanka should be the immediate measures to be implemented. A significant shift towards low embodied energy construction in Sri Lanka’s building industry also requires national-level measures, such as legislative changes, incentives for low EE materials, and social formation.

5.1. Limitations

Although this work has made significant contributions, it also has certain limitations. Due to the absence of a country-specific EE database for construction materials in Sri Lanka, this research utilised EE coefficient values for various materials obtained from Sri Lankan-specific literature and the ICE V2.0 database. This may have introduced discrepancies due to regional differences in material production technologies and energy sources. Therefore, future research should prioritise the development of a localised EE database for Sri Lankan construction materials, using primary data collection from manufacturers, suppliers, and lifecycle inventories. The scope of this study is limited to the cradle-to-gate boundary, and the assessment did not consider the mechanical, electrical and plumbing services related to EE due to the lack of data. Hence, future research studies should aim to extend the boundary to a full life cycle assessment (cradle-to-grave or cradle-to-cradle (including the life-cycle stage)), and incorporate MEP components to reflect total building EE better. Additionally, this study is limited by its examination of only two platinum-rated green office buildings within a similar urban environment, due to concerns about maintaining client and project data confidentiality, as well as the absence of necessary information in several potential projects. Future work should consider broadening the sample size to include buildings of different certification levels, typologies, and climatic or urban locations.