Study on Residual Load-Bearing Capacity of Composite Steel Truss Bridge Girders After Vehicle Fire

Abstract

1. Introduction

2. Vehicle Fire Temperature Field of Composite Steel Truss Bridge Girder

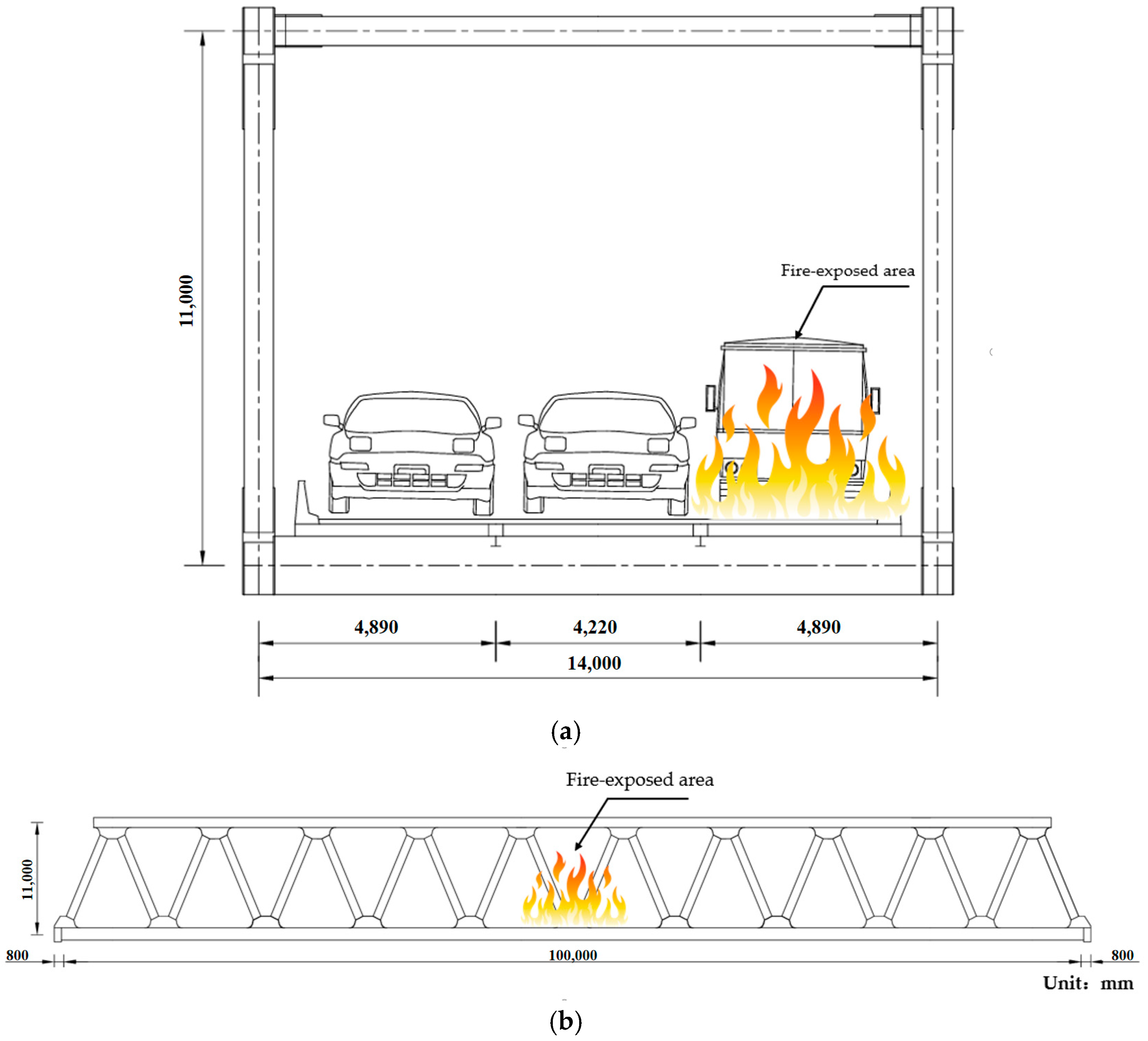

2.1. Selection of Research Subjects

2.2. The Most Unfavorable Location for Fire

2.3. Temperature Field of Oil Tanker Fire

2.3.1. Model Verification

2.3.2. Simulation of Fire Temperature Field

3. Residual Load-Bearing Capacity

3.1. Model Establishment

3.2. The Remaining Load-Bearing Capacity of the Truss After a Vehicle Fire

3.3. The Remaining Load-Bearing Capacity of the Composite Steel Truss Bridge Girder

3.3.1. Bridge Structural Failure Path

3.3.2. Structural Load-Displacement Curve

- Fire characteristic temperature;

- 2.

- Load level;

- 3.

- Cooling method;

3.3.3. Assessment Methods of Residual Load-Bearing Capacity

4. Conclusions

- (1)

- This study develops a realistic temperature field model for the girders of composite steel truss bridges subjected to oil tanker fires. Utilizing Computational Fluid Dynamics (CFD), a numerical model was established to simulate various fire scenarios in an open environment. The analysis focused on the temperature variations and maximum temperatures attained by individual truss members during these events. The results indicate that the most critical scenario involves a fire on the outermost lane of the bridge deck at the mid-span. Specifically, truss members situated directly above the fire’s epicenter reached the highest temperatures, with thermal values diminishing as the distance from the fire source increased.

- (2)

- By considering the deformation of the truss during the fire event, the analysis identified the most critically affected members and subsequently evaluated their residual load-bearing capacity. The findings demonstrate that the upper chord members are the most vulnerable to fire-induced damage. Furthermore, it was determined that the choice of post-fire cooling method significantly influences the final residual load-bearing capacity.

- (3)

- An evaluation method was established to assess the residual load-bearing capacity of composite steel truss bridge girders, which comprehensively considers truss deformation effects and structural steel strength degradation. This study analyzed the decline in residual load-bearing capacity following a vehicle fire and discovered that higher fire exposure temperatures and increased load levels shorten the elastic stage, reducing residual capacity. At characteristic fire temperatures below 700 °C, the load-bearing capacity damage is classified as Grade II, whereas temperatures above 800 °C escalate the damage to Grade IV. Post-fire, when characteristic temperatures exceed 700 °C, water immersion cooling results in greater load-bearing capacity loss.

- (4)

- The proposed methodology and classification standards provide a robust scientific foundation for the post-fire safety assessment of composite steel truss bridges. This framework enables the rapid and accurate determination of damage levels, which can guide systematic emergency response efforts and mitigate the risk of secondary disasters from sudden structural collapse. Moreover, it offers theoretical support for decisions regarding traffic restoration, thereby minimizing economic losses and social disruption. The findings also serve as a crucial reference for design optimization, the formulation of fire prevention strategies, and post-disaster repair and reinforcement protocols, ultimately contributing to the enhanced safety and fire resilience of steel bridge structures.

- (5)

- While this study provides valuable insights into the post-fire residual capacity of composite steel truss bridges, several limitations should be acknowledged as avenues for future research. Firstly, the investigation was confined to a single fire scenario; future work should therefore explore a broader range of fire types and locations to enhance the generalizability of the findings. Secondly, fire scenario data were generated exclusively through CFD simulations, with model validation relying on a limited set of the existing literature. Consequently, further research would greatly benefit from validation against large-scale experimental data obtained from physical bridge fire tests. Such empirical data are essential for improving the model’s accuracy and practical applicability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, G.; He, S.; Song, C.; Huang, Q.; Kodur, V.K.; Zhang, Y. Review on Fire Resistance of Steel Structural Bridge Girders. China J. Highw. Transp. 2021, 34, 1–11. [Google Scholar] [CrossRef]

- Xing, W.; Lin, X.; Zongyi, W.; Zhirui, K. State-of-the-art review of steel-concrete composite bridges in 2020. J. Civ. Environ. Eng. 2021, 43, 107–119. [Google Scholar] [CrossRef]

- Zhang, G.; Li, X.; Tang, C.; Song, C.; Ding, Y. Behavior of steel box bridge girders subjected to hydrocarbon fire and bending-torsion coupled loading. Eng. Struct. 2023, 296, 116906. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, X.; Lu, Z.; Song, C.; Li, X.; Tang, C. Review and discussion on fire behavior of bridge girders. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 422–446. [Google Scholar] [CrossRef]

- Zhang, G.; He, S.H.; Hou, W. Review on fire resistance of prestressed-concrete bridge. J. Chang. Univ. (Nat. Sci. Ed.) 2018, 38, 1–10. [Google Scholar] [CrossRef]

- Zhang, G.; Song, C.; Li, J.; He, S.; Li, X.; Tang, C. Evaluation method of load -carrying capacity of steel-concrete composite girders after fire exposure. J. Chang. Univ. (Nat. Sci. Ed.) 2021, 41, 1–11. [Google Scholar] [CrossRef]

- Gang, Z.; Xuyang, L.; Chenhao, T.; Chaojie, S.; Zhuoya, Y. Experimental and Evolution Mechanism for Fire Resistance of Continuous Steel Box Girder. China J. Highw. 2023, 36, 58–70. [Google Scholar] [CrossRef]

- Zhang, G.; Li, X.; Tang, C.; Song, C.; Yuan, Z. Experimental study on fire resistance of steel truss -concrete composite bridge girder under HC fire on conditions. J. Build. Struct. 2024, 45, 160–173. [Google Scholar] [CrossRef]

- Li, X.; Zhang, G.; Yuan, Z.; Tang, C.; Wan, H.; Lu, Z. Failure behavior of continuous steel-concrete composite box bridge girder under fuel fire. J. Chang. Univ. (Nat. Sci. Ed.) 2023, 43, 40–50. [Google Scholar] [CrossRef]

- Wan, H.; Zhang, G.; Xiong, X. A chain approach for evaluating thermal behaviors downwind of rectangular fires. Int. Commun. Heat Mass Transf. 2025, 161, 108533. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, G.; Ding, Y.; Lu, Z.; Wang, S. An approach for predicting fire response of steel truss-concrete composite bridge girders subjected to semi-open fires. Eng. Struct. 2025, 335, 120390. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, G.; Tang, C.; Wang, S.; Lu, Z. Evaluating fire performance of through continuous composite steel Warren-truss bridge girders: Experimental and numerical investigation. Eng. Struct. 2025, 326, 119591. [Google Scholar] [CrossRef]

- Rackauskaite, E.; Kotsovinos, P.; Jeffers, A.; Rein, G. Structural analysis of multi-storey steel frames exposed to travelling fires and traditional design fires. Eng. Struct. 2017, 150, 271–287. [Google Scholar] [CrossRef]

- Tang, Z.; Wei, T.; Ma, Y.; Chen, L. Residual Strength of Steel Structures After Fire Events Considering Material Damages. Arab. J. Sci. Eng. 2019, 44, 5075–5088. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, M.-C.; Kodur, V.; Li, G.-Q. Behavior of welded connections after exposure to elevated temperature. J. Constr. Steel Res. 2017, 130, 88–95. [Google Scholar] [CrossRef]

- Maraveas, C.; Fasoulakis, Z.; Tsavdaridis, K.D. Post-fire assessment and reinstatement of steel structures. J. Struct. Fire Eng. 2017, 8, 181–201. [Google Scholar] [CrossRef]

- Filiz, P.; Murat, B.; Kadir, O. An experimental study on fire damage of structural steel members in an industrial building. Eng. Fail. Anal. 2017, 80, 341–351. [Google Scholar] [CrossRef]

- Esam, A.; Venkatesh, K. An approach for evaluating the residual strength of fire exposed bridge girders. J. Constr. Steel Res. 2013, 88, 34–42. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Zeinoddini, M.; Darian, A.S. Modelling of I-shaped beam-to-tubular column connection subjected to post-fire conditions. Int. J. Steel Struct. 2014, 14, 513–528. [Google Scholar] [CrossRef]

- He, A.; Liang, Y.; Zhao, O. Experimental and numerical studies of austenitic stainless steel CHS stub columns after exposed to elevated temperatures. J. Constr. Steel Res. 2019, 154, 293–305. [Google Scholar] [CrossRef]

- Flodr, J.; Krejsa, M.; Lehner, P. Temperature and Structural Analysis of Omega Clip. Int. J. Steel Struct. 2019, 19, 1295–1301. [Google Scholar] [CrossRef]

- BS EN 1991-1-2:2002; Eurocode 1: Actions on Structures-Part 1-2: General Actions Actions on Structures Exposed to Fire. BSI Standards Limited: London, UK, 2002.

- Temelli, U.E.; Gultek, A.S.; Uzunoglu, C.P.; Sayin, B. A multidisciplinary analysis of the fire propagation in the aspiration system of a building. Case Stud. Constr. Mater. 2023, 19, e02375. [Google Scholar] [CrossRef]

- Alos-Moya, J.; Paya-Zaforteza, I.; Garlock, M.; Loma-Ossorio, E.; Schiffner, D.; Hospitaler, A. Analysis of a bridge failure due to fire using computational fluid dynamics and finite element models. Eng. Struct. 2014, 68, 96–110. [Google Scholar] [CrossRef]

- Joonho, C.; Rami, H.-A.; Sun, K.H. Integrated fire dynamic and thermomechanical modeling of a bridge under fire. Struct. Eng. Mech. 2012, 42, 815–829. [Google Scholar] [CrossRef]

- Peris-Sayol, G.; Paya-Zaforteza, I.; Alos-Moya, J.; Hospitaler, A. Analysis of the influence of geometric, modeling and environmental parameters on the fire response of steel bridges subjected to realistic fire scenarios. Comput. Struct. 2015, 158, 333–345. [Google Scholar] [CrossRef]

- GB/T1591-2018; High Strength Low Alloy Structural Steels. Standardization Administration of the People’s Republic of China: Beijing, China, 2018.

- Chuntao, Z.; Bin, J.; Junjie, W. Influence of artificial cooling methods on post-fire mechanical properties of Q355 structural steel. Constr. Build. Mater. 2020, 252, 119092. [Google Scholar] [CrossRef]

- Chuntao, Z.; Hongjie, Z.; Li, Z. Effect of interaction between corrosion and high temperature on mechanical properties of Q355 structural steel. Constr. Build. Mater. 2021, 271, 121605. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for the Design of Concrete Structures. Ministry of Housing and Urban—Rural Development of the People’s Republic of China: Beijing China, 2010.

- Gang, Z.; Chenhao, T.; Xuyang, L.; Xiaocui, Z.; Zelei, L.; Chaojie, S. Fire resistance of steel truss-concrete composite bridge girder. J. Build. Struct. 2023, 44, 214–226. [Google Scholar] [CrossRef]

- Alos-Moya, J.; Paya-Zaforteza, I.; Hospitaler, A.; Rinaudo, P. Valencia bridge fire tests: Experimental study of a composite bridge under fire. J. Constr. Steel Res. 2017, 138, 538–554. [Google Scholar] [CrossRef]

| Location | Cross-Sectional Form | Width | Height | Vertical Version | Top Plate | ||

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | ||

| Winding bar |  | 600 | 960 | 960 | 36 | 600 | 32 |

| Lower chord |  | 600 | 1200 | 1200 | 36 | 600 | 32 |

| Web member |  | 600 | 960 | 960 | 32 | 600 | 28 |

| 600 | 960 | 960 | 32 | 600 | 24 | |

| Horizontal bracing |  | 400 | 960 | 928 | 10 | 400 | 16 |

| End transverse bracing | 400 | 960 | 912 | 16 | 400 | 24 | |

| Horizontal diagonal bar |  | 400 | 350 | 318 | 10 | 400 | 16 |

| Longitudinal beam |  | 600 | 300 | 272 | 12 | 600 | 16 |

| Middle crossbeam |  | 700 | 400 | 1168 | 14 | 700 | 16 |

| End crossbeam |  | 960 | 1200 | 1144 | 20 | 960 | 24 |

| Fire Scene | Oil Pool Size (m) | Location of the Fire | HRR (kW) | Test Serial Number | Location of the Oil Pool | |

|---|---|---|---|---|---|---|

| x (m) | z (m) | |||||

| Scene 1 | 0.5 | mid-span | 415 | 1 | 3.00 | 0.2 |

| 2 | ||||||

| Scene 2 | 0.75 | mid-span | 1131 | 3 | 3.00 | 0.2 |

| 4 | ||||||

| Scene 3 | 0.5 | bearing | 415 | 5 | 5.27 | 0.5 |

| 6 | 5.59 | |||||

| 7 | 5.59 | |||||

| Scene 4 | 0.75 | mid-span | 1131 | 8 | 3.00 | 0.8 |

| Measuring Point | Test Value/°C | Calculated Value/°C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Text 1 | Text 2 | Text 3 | Text 4 | Text 7 | Text 8 | Text 1–2 | Text 3–4 | Text 7 | Text 8 | |

| V1 | 786 | 765 | 796 | 863 | 847 | 908 | 751 | 989 | 857 | 1026 |

| V2 | 597 | 535 | 873 | 873 | 649 | 885 | 633 | 945 | 724 | 970 |

| V3 | 431 | 455 | 813 | 840 | 675 | 901 | 444 | 841 | 637 | 970 |

| V4 | 282 | 315 | 745 | 743 | 527 | 908 | 368 | 770 | 577 | 940 |

| V5 | 280 | 308 | 758 | 702 | 589 | 926 | 349 | 726 | 544 | 914 |

| GC1 | 141 | 164 | 264 | 279 | 133 | 422 | 142 | 314 | 128 | 408 |

| GC2 | 175 | 205 | 362 | 389 | 151 | 639 | 177 | 376 | 143 | 515 |

| GC3 | 268 | 326 | 607 | 707 | 184 | 941 | 270 | 646 | 165 | 841 |

| GC4 | 288 | 288 | 644 | 737 | 234 | 921 | 263 | 634 | 204 | 914 |

| GC5 | 166 | 172 | 378 | 431 | 289 | 594 | 181 | 414 | 272 | 526 |

| GC6 | 139 | 148 | 279 | 323 | 546 | 504 | 138 | 307 | 558 | 414 |

| Number | Temperature | Number | Temperature | Number | Temperature | Number | Temperature | Number | Temperature |

|---|---|---|---|---|---|---|---|---|---|

| F1 | 1000.5 °C | F9 | 356.2 °C | S1 | 826.8 °C | X1 | 1015.0 °C | H1 | 1015.0 °C |

| F2 | 987.5 °C | F10 | 360.5 °C | S2 | 803.2 °C | X2 | 1015.0 °C | H2 | 1015.0 °C |

| F3 | 803.2 °C | F11 | 352.3 °C | S3 | 226.9 °C | X3 | 261.1 °C | H3 | 529.07 °C |

| F4 | 818.9 °C | F12 | 358.3 °C | S4 | 230.7 °C | X4 | 254.3 °C | H4 | 488.5 °C |

| F5 | 286.8 °C | F13 | 270.2 °C | S5 | 222.6 °C | X5 | 1015.0 °C | H5 | 488.2 °C |

| F6 | 290.2 °C | F14 | 266.0 °C | S6 | 222.0 °C | X6 | 1015.0 °C | - | - |

| F7 | 166.5 °C | F15 | 180.4 °C | S7 | 73.6 °C | X7 | 244.1 °C | - | - |

| F8 | 165.0 °C | F16 | 192.3 °C | S8 | 77.8 °C | X8 | 210.9 °C | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhou, S.; Yang, K.; Zhang, G. Study on Residual Load-Bearing Capacity of Composite Steel Truss Bridge Girders After Vehicle Fire. Buildings 2025, 15, 2820. https://doi.org/10.3390/buildings15162820

Wang S, Zhou S, Yang K, Zhang G. Study on Residual Load-Bearing Capacity of Composite Steel Truss Bridge Girders After Vehicle Fire. Buildings. 2025; 15(16):2820. https://doi.org/10.3390/buildings15162820

Chicago/Turabian StyleWang, Shichao, Shenquan Zhou, Kan Yang, and Gang Zhang. 2025. "Study on Residual Load-Bearing Capacity of Composite Steel Truss Bridge Girders After Vehicle Fire" Buildings 15, no. 16: 2820. https://doi.org/10.3390/buildings15162820

APA StyleWang, S., Zhou, S., Yang, K., & Zhang, G. (2025). Study on Residual Load-Bearing Capacity of Composite Steel Truss Bridge Girders After Vehicle Fire. Buildings, 15(16), 2820. https://doi.org/10.3390/buildings15162820