Does the Modular Construction Project Outperform the Traditional One? A Comparative Life Cycle Analysis Study in Hong Kong

Abstract

1. Introduction

- What are the quantitative differences in GHG emissions, cost, time efficiency, and safety performance between MiC and traditional construction methods in Hong Kong’s residential projects?

- Which specific life cycle stages contribute most significantly to the environmental and economic disparities between the two methods?

- How do Hong Kong’s high-density urban constraints influence MiC performance outcomes compared to other findings?

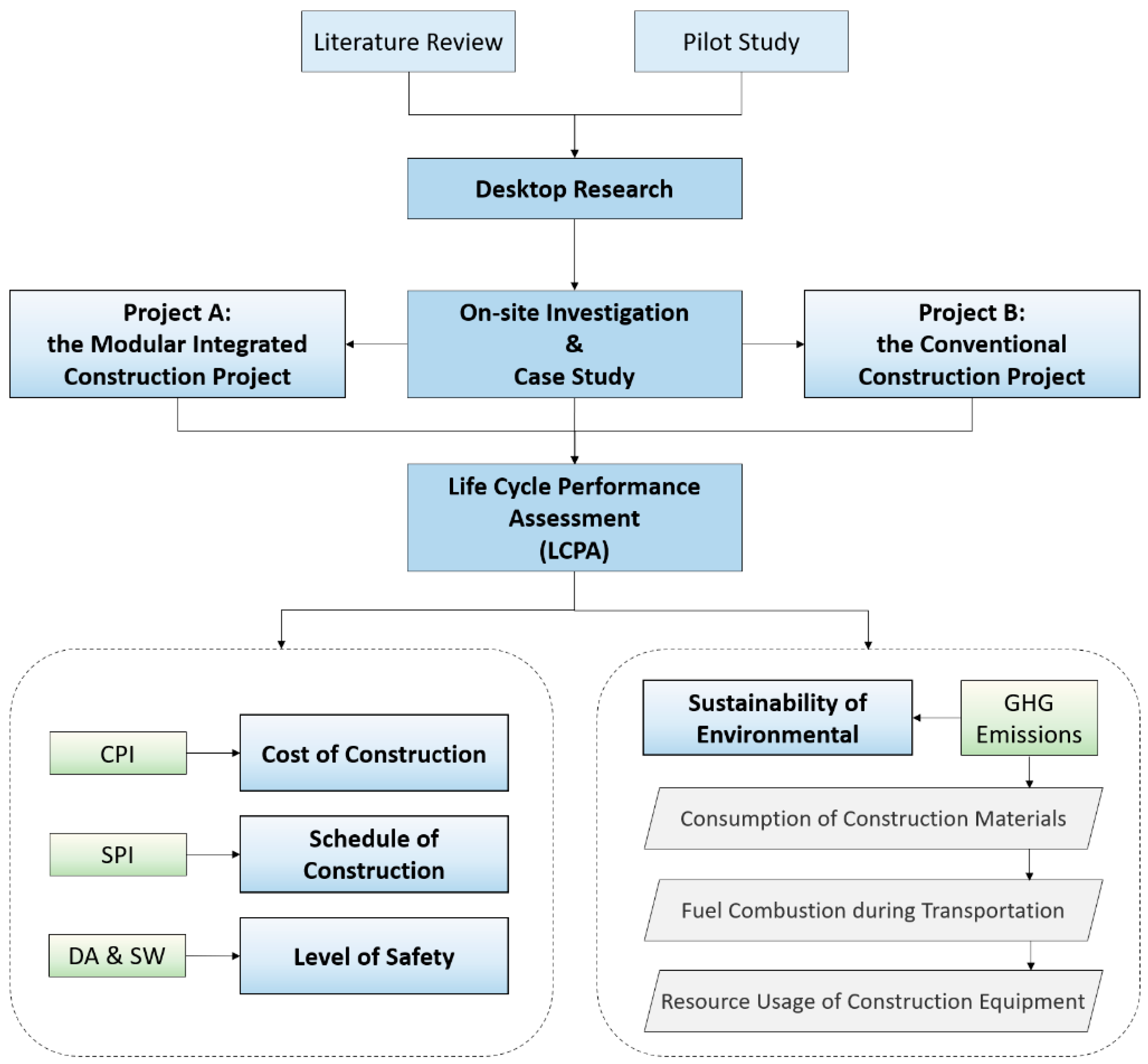

2. Methodology

2.1. Life Cycle Performance Assessment (LCPA)

- Cost: Measured by cost performance index (CPI). The cost performance increases with a decreasing CPI value.

- Time: Measured by the schedule performance index (SPI). Better time performance is indicated by a higher SPI value.

- Safety: The duration of exposure to bad weather and the quantity of dangerous activities (including elevated work) are the indicators used to determine the degree of safety.

- Environment: Quantitative analysis of environmental sustainability is achieved by measuring GHG emissions.

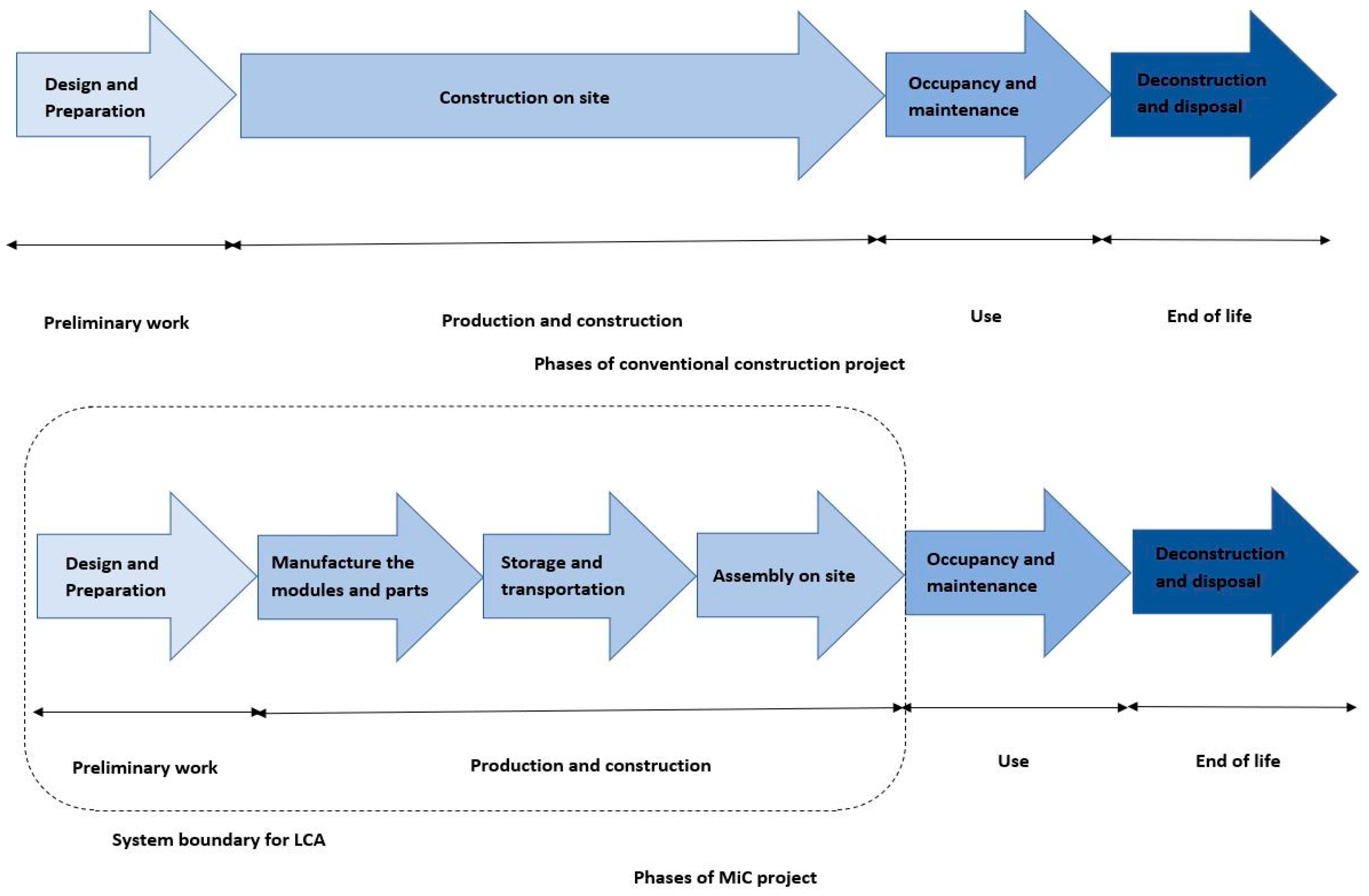

2.2. Calculation Boundaries

2.2.1. Cost of Construction

2.2.2. Schedule of Construction

2.2.3. Level of Safety

2.2.4. Sustainability of Environmental

- E1: Embodied carbon in main permanent construction materials;

- E2: Transport emissions from construction materials logistics;

- E3: Waste/soil transport fuel combustion;

- E4: Modular components delivery emissions;

- E5: Operational energy consumption (equipment/technologies), covering water, electricity, diesel, and oil.

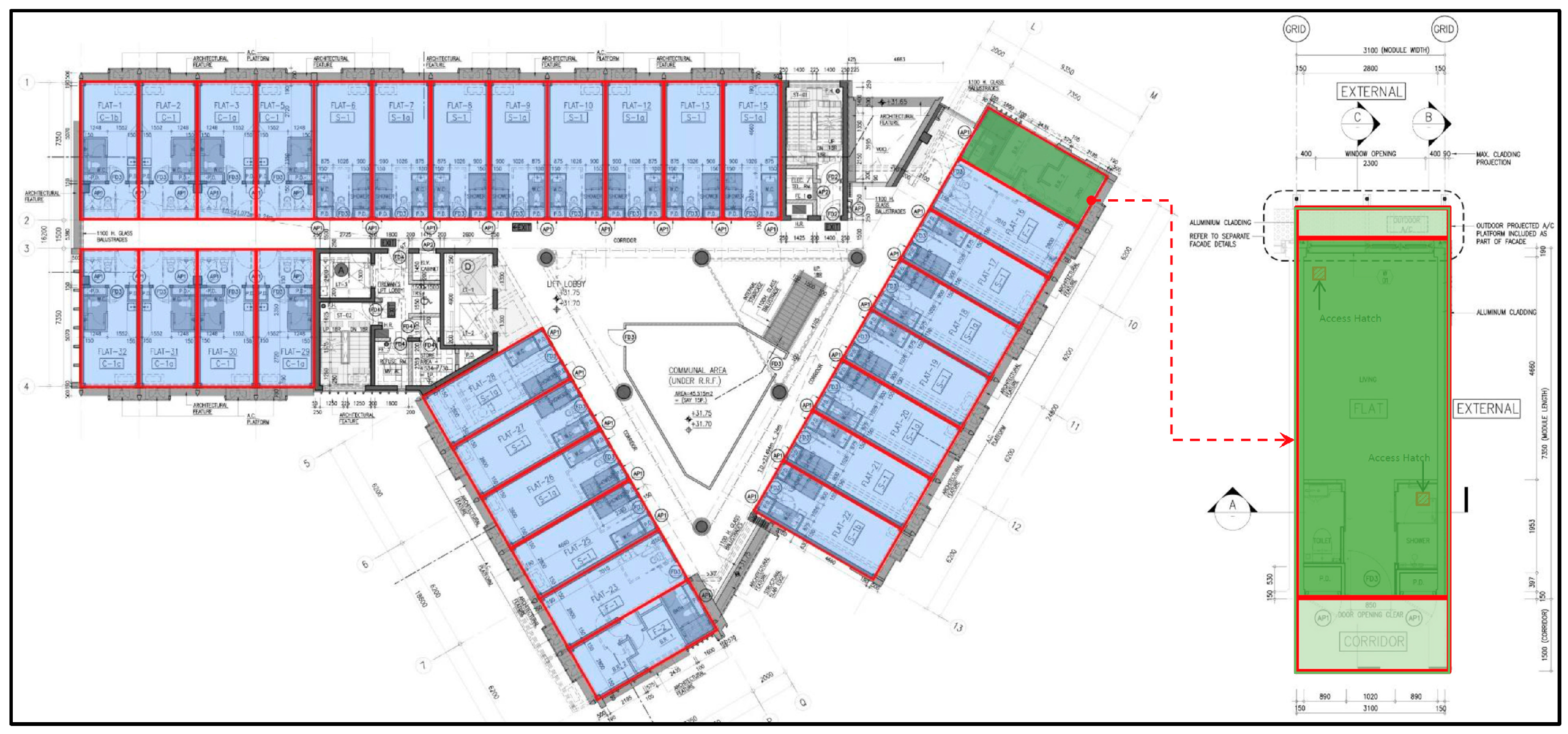

3. Case Study

3.1. Description of the Targeted Projects

3.2. Data Acquisition on Environmental Sustainability

3.2.1. Transportation and Consumption of Construction Materials

3.2.2. Resource Utilization for Construction Equipment

3.2.3. Transportation of Construction Waste and Prefabricated Components

4. Result and Discussion

4.1. CPI, SPI, and Safety Level

4.2. Environmental Sustainability

4.2.1. Total GHG Emissions

4.2.2. Embodied GHG Emissions of Construction Materials

4.2.3. GHG Emissions of Transportation

4.2.4. Operational Carbon and Energy Demand of Construction Equipment (E5)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- CSD. Key Statistics on Business Performance and Operating Characteristics of the Building, Construction and Real Estate Sectors. Available online: https://www.censtatd.gov.hk/en/wbr.html?ecode=B10800112023AN23&scode=330 (accessed on 3 April 2025).

- Zhang, S.; Rong, X.; Bakhtawar, B.; Tariq, S.; Zayed, T. Assessment of Feasibility, Challenges, and Critical Success Factors of MiC Projects in Hong Kong. J. Archit. Eng. 2021, 27, 04020047. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Shen, G.Q.P.; Lu, W.; Huang, G.Q. An Internet of Things-enabled BIM platform for modular integrated construction: A case study in Hong Kong. Adv. Eng. Inform. 2019, 42, 100997. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.-S. The hindrance to using prefabrication in Hong Kong’s building industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Jin, X.; Ekanayake, E.M.A.C.; Shen, G.Q.P. Critical policy drivers for Modular integrated Construction projects in Hong Kong. Build. Res. Inf. 2021, 50, 467–484. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- BCA. Prefabricated Prefinished Volumetric Construction (PPVC). Available online: https://www1.bca.gov.sg/buildsg/productivity/design-for-manufacturing-and-assembly-dfma/prefabricated-prefinished-volumetric-construction-ppvc (accessed on 12 February 2020).

- Steinhardt, D.; Manley, K.; Bildsten, L.; Widen, K. The structure of emergent prefabricated housing industries: A comparative case study of Australia and Sweden. Constr. Manag. Econ. 2020, 38, 483–501. [Google Scholar] [CrossRef]

- Olayiwola, K.; Perera, S.; Kagioglou, M.; Jin, X.; Sharafi, P. A PESTEL Analysis of Problems Associated with the Adoption of Offsite Construction: A Systematic Literature Review. Buildings 2025, 15, 2146. [Google Scholar] [CrossRef]

- Cavalieri, F.; Bellotti, D.; Caruso, M.; Nascimbene, R. Comparative evaluation of seismic performance and environmental impact of traditional and dissipation-based retrofitting solutions for precast structures. J. Build. Eng. 2023, 79, 107918. [Google Scholar] [CrossRef]

- Zhou, J.X.; Huang, L.; Shen, G.Q.; Wu, H.; Luo, L. Modeling stakeholder-associated productivity performance risks in modular integrated construction projects of Hong Kong: A social network analysis. J. Clean. Prod. 2023, 423, 138699. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, M.; Pan, W.; Wu, J. Multi-level systematic key performance indicators for modular construction supply chain: The case of Hong Kong. Eng. Constr. Archit. Manag. 2025; ahead-of-print. [Google Scholar] [CrossRef]

- CIC. Background on CITF. Available online: https://www.citf.cic.hk/?route=background (accessed on 1 January 2019).

- BuildingsDepartment. Modular Integrated Construction. Available online: https://www.bd.gov.hk/en/resources/codes-and-references/modular-integrated-construction/index.html (accessed on 25 November 2021).

- Pan, W.; Hon, C.K. Briefing: Modular integrated construction for high-rise buildings. Proc. Inst. Civ. Eng.-Munic. Eng. 2018, 173, 64–68. [Google Scholar] [CrossRef]

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Fung, I.W.H.; Sing, M.C.P.; Ogunlana, S.O. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, X.; Kang, K.; Wang, Z.; Zhong, R.Y.; Huang, G.Q. Blockchain-enabled cyber-physical smart modular integrated construction. Comput. Ind. 2021, 133, 103553. [Google Scholar] [CrossRef]

- Luo, L.; Qiping Shen, G.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef]

- Jin, X.; Shen, G.; Luo, L.; Zhou, X. Influence of policies on stakeholders to drive the success of modular integrated construction in Hong Kong. Eng. Constr. Archit. Manag. 2025, 32, 2814–2843. [Google Scholar] [CrossRef]

- Choi, J.O.; Chen, X.B.; Kim, T.W. Opportunities and challenges of modular methods in dense urban environment. Int. J. Constr. Manag. 2019, 19, 93–105. [Google Scholar] [CrossRef]

- EPA. Life Cycle Assessment: Principles and Practice. Available online: https://cfpub.epa.gov/si/si_public_record_report.cfm?Lab=NRMRL&dirEntryId=155087 (accessed on 12 August 2015).

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincon, L.; Vilarino, V.; Perez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; Garcia-Martinez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.-T.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef]

- Tao, X.; Mao, C.; Xie, F.; Liu, G.; Xu, P. Greenhouse gas emission monitoring system for manufacturing prefabricated components. Autom. Constr. 2018, 93, 361–374. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction Matters: Comparing Environmental Impacts of Building Modular and Conventional Homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Paya-Marin, M.; Lim, J.; Sengupta, B. Life-Cycle Energy Analysis of a Modular/Off-Site Building School. Am. J. Civ. Eng. Archit. 2013, 1, 59–63. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus modular construction methods: A comparative cradle-to-gate LCA for residential buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Neugebauer, S.; Forin, S.; Finkbeiner, M. From Life Cycle Costing to Economic Life Cycle AssessmentIntroducing an Economic Impact Pathway. Sustainability 2016, 8, 428. [Google Scholar] [CrossRef]

- Radujkovic, M.; Vukomanovic, M.; Dunovic, I.B. Application of Key Performance Indicators in South-Eastern European Construction. J. Civ. Eng. Manag. 2010, 16, 521–530. [Google Scholar] [CrossRef]

- Al-Jibouri, S.H.; Mawdesley, M.J. Comparisons of systems for measuring project performance. In Proceedings of the the 3rd World CIB Building Conference, Wellington, New Zealand, 2–6 April 2001. [Google Scholar]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- EPA. Understanding Global Warming Potentials. Available online: https://www.epa.gov/ghgemissions/understanding-global-warming-potentials (accessed on 18 October 2021).

- IPCC. Climate Change 2021: The Physical Science Basis. Available online: https://www.ipcc.ch/report/sixth-assessment-report-working-group-i/ (accessed on 6 August 2021).

- Yan, H.; Shen, Q.; Fan, L.C.H.; Wang, Y.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- Alcorn, A. Embodied Energy and CO2 Coefficients for NZ Building Materials; Centre for Building Performance Research: Wellington, New Zealand, 2003. [Google Scholar]

- Chen, T.Y.; Burnett, J.; Chau, C.K. Analysis of embodied energy use in the residential building of Hong Kong. Energy 2001, 26, 323–340. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, Y. Cases for life-cycle energy consumption and environmental emissions in residential buildings. J. Tsinghua Univ. Sci. Technol. 2010, 50, 330–334. [Google Scholar]

- EMSD; EPD. Guidelines to Account for and Report on Greenhouse Gas Emissions and Removals for Buildings (Commercial, Residential or Institutional Purposes); Electrical and Mechanical Services Department and Environmental Protection Department: Hong Kong, China, 2010.

- Wuni, I.Y.; Mazher, K.M. Ending the suitability quantification dilemma: Intelligent decision support system for modular integrated construction in a high-density metropolis. Constr. Innov. 2024, 24, 1026–1047. [Google Scholar] [CrossRef]

- Zakaria, S.A.S.; Gajendran, T.; Skitmore, M.; Brewer, G. Key factors influencing the decision to adopt industrialised building systems technology in the Malaysian construction industry: An inter-project perspective. Archit. Eng. Des. Manag. 2017, 14, 27–45. [Google Scholar]

| Construction Materials | CO2 Emission Factor (kg CO2-e/kg) | (kg CO2-e/kg) | |

|---|---|---|---|

| Cement | 2.5% | 0.653 | 0.698 |

| Brick | 2.5% | 0.230 | 0.246 |

| Steel | 5.0% | 0.352 | 0.367 |

| Glass | 0.5% | 1.735 | 1.854 |

| Ready-mixed concrete | 2.5% | 0.113 | 0.120 |

| Insulating materials | 5.0% | 0.140 | 0.145 |

| Modes of Transportation | Type of Energy | Energy Consumption (MJ/ton km) | Emission Factors (g/MJ) | (kg CO2-e/ton km) | ||

|---|---|---|---|---|---|---|

| CO2 | CH4 | N2O | ||||

| Truck | Gas | 3.663 | 74.800 | 0.010 | 0.012 | 0.288 |

| Truck (>16t) | Diesel | 2.423 | 74.800 | 0.070 | 0.030 | 0.207 |

| Train | Diesel | 0.362 | 74.800 | 0.010 | 0.086 | 0.036 |

| Ship | Diesel | 0.468 | 74.800 | 0.007 | 0.002 | 0.035 |

| Energy Types | Emission Factors | |||

|---|---|---|---|---|

| CO2 | CH4 | N2O | ||

| Diesel/oil | 2.614 (kg/L) | 0.024 (g/L) | 0.007 (g/L) | = 2.617 (kg CO2-e/L) |

| Electricity | 0.500 (kg/kWh) | - | - | = 0.500 (kg CO2-e/kWh) |

| Water | - | - | - | = 0.414 (kg CO2-e/m3) |

| Items | Project A: MiC | Project B: Conventional |

|---|---|---|

| Building types | Residential | Residential |

| Location | Hong Kong | Hong Kong |

| Total floor area | 15,300.00 m2 | 44,640.00 m2 |

| Floor area of each unit | 17.00–46.17 m2 | 9.40–23.60 m2 |

| Floor to floor height | 3.05 m | 2.75 m |

| Number of basements | 1 Floors | 1 Floor |

| Foundations | Socket-H piles | Bored pile foundation |

| Structure system | Frame–shear wall structure with MiC modules | Frame–shear wall structure |

| Height | 59.40 m | 104.00 m |

| Precast level | 70.00% | 16.31% |

| Structure frame | Beams, columns, slabs, and structure wall (cast-in-place reinforced concrete); MiC modules (off-site precast reinforced concrete and structural steel) | Cast-in-place reinforced concrete |

| Structure frame (for staircase and corridor slabs) | Cast-in-place reinforced concrete | Off-site reinforced concrete |

| External works (for facades) | Off-site prefabricated aluminum and glass | Off-site reinforced concrete |

| External works (for roof) | Cast-in-place reinforced concrete | Cast-in-place reinforced concrete |

| Internal works (for partition wall) | Partition walls laid on site (dry wall and brick) | Off-site reinforced lightweight wall panels (dry wall) |

| Materials | Consumption (tons) | Transportation Distance (km) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Project A | Project B0 | Project A | Project B0 | |||||||

| On-Site | Off-Site | Total | On-Site | Off-Site | Total | * | ** | |||

| Ready-mixed concrete | 9877 | 6971 | 16,848 | 21,795 | 2543 | 24,338 | 4 | 27 | 4 | 27 |

| Cement | 400 | 0 | 400 | 527 | 0 | 527 | - | 20 | - | 20 |

| Steel | 1015 | 1466 | 2481 | 2446 | 109 | 2555 | 1600 | 6330 | 1600 | 6330 |

| Glass | 26 | 61 | 87 | 218 | 0 | 218 | 160 | 100 | - | 100 |

| Brick | 134 | 38 | 172 | 544 | 0 | 544 | 315 | 20 | - | 20 |

| Insulating materials | 143 | 484 | 627 | 54 | 0 | 54 | 130 | 9 | - | 9 |

| Resource | Project A | Project B0 | ||

|---|---|---|---|---|

| Off-Site | On-Site | Off-Site | On-Site | |

| Diesel/oil (L) | 84.00 | 115,000.00 | 0.00 | 157,661.00 |

| Electricity (kWh) | 22.00 | 185,431.00 | 14,567.00 | 69,218.00 |

| Tap water (m3) | 3642.00 | 6315.00 | 685.00 | 9940.00 |

| Project | Construction Waste | Prefabricated Components (tons) | ||

|---|---|---|---|---|

| Volume (tons) | Distance (km) | Volume (tons) | Distance (km) | |

| Project A | 852.00 | 27.00 | 6971.00 | 180.00 |

| Project B0 | 16,508.00 | 27.00 | 2543.00 | 180.00 |

| Project A | Project B | Reduction of GHG Emissions | |||||

|---|---|---|---|---|---|---|---|

| Off-Site | On-Site | Total (x) | Off-Site | On-Site | Total (y) | y-x | |

| E1 | 1619.29 | 1710.01 | 3329.29 | 354.79 | 4194.25 | 4549.04 | 1219.75 |

| E2 | 508.83 | 281.44 | 790.27 | 38.32 | 670.59 | 708.91 | −81.36 |

| E3 | 0.03 | 4.58 | 4.62 | 0.00 | 92.26 | 92.26 | 87.65 |

| E4 | 43.92 | 0.00 | 43.92 | 16.02 | 0.00 | 16.02 | −27.90 |

| E5 | 1.74 | 396.28 | 398.02 | 7.57 | 451.32 | 458.89 | 60.87 |

| Sum | 4566.12 | 5825.13 | 1259.01 | ||||

| Dimensions | Indicators | Project A | Project B |

|---|---|---|---|

| Cost | Total budget cost | HKD 700 million | HKD 768 million |

| Actual total cost | HKD 700 million | HKD 720 million | |

| CPI | 1.000 | 1.067 | |

| Time | Estimated construction period | 395 days | 1140 days |

| Actual construction period | 330 days | 1110 days | |

| SPI | 1.197 | 1.027 | |

| Safety | The number of dangerous activities | 0 | 0 |

| The time of exposure to bad weather (as a proportion of the actual construction period) | 24 days (7.27%) | 86 days (7.74%) | |

| Environment | E1 | 3329.29 tonsCO2-e | 4549.04 tonsCO2-e |

| E2 | 790.27 tonsCO2-e | 708.91 tonsCO2-e | |

| E3 | 4.62 tonsCO2-e | 92.26 tonsCO2-e | |

| E4 | 43.92 tonsCO2-e | 16.02 tonsCO2-e | |

| E5 | 398.02 tonsCO2-e | 458.89 tonsCO2-e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Lam, S.-K.; Wu, Z.; Gong, L.; Li, H.; Jiang, M. Does the Modular Construction Project Outperform the Traditional One? A Comparative Life Cycle Analysis Study in Hong Kong. Buildings 2025, 15, 2811. https://doi.org/10.3390/buildings15162811

Wang Y, Lam S-K, Wu Z, Gong L, Li H, Jiang M. Does the Modular Construction Project Outperform the Traditional One? A Comparative Life Cycle Analysis Study in Hong Kong. Buildings. 2025; 15(16):2811. https://doi.org/10.3390/buildings15162811

Chicago/Turabian StyleWang, Ying, Siu-Kei Lam, Zezhou Wu, Lulu Gong, Heng Li, and Mingyang Jiang. 2025. "Does the Modular Construction Project Outperform the Traditional One? A Comparative Life Cycle Analysis Study in Hong Kong" Buildings 15, no. 16: 2811. https://doi.org/10.3390/buildings15162811

APA StyleWang, Y., Lam, S.-K., Wu, Z., Gong, L., Li, H., & Jiang, M. (2025). Does the Modular Construction Project Outperform the Traditional One? A Comparative Life Cycle Analysis Study in Hong Kong. Buildings, 15(16), 2811. https://doi.org/10.3390/buildings15162811