Development of an Optimization Algorithm for Designing Low-Carbon Concrete Materials Standardization with Blockchain Technology and Ensemble Machine Learning Methods

Abstract

1. Introduction

- (1)

- How can ensemble machine learning methods enhance the accuracy of predicting the compressive strength and sustainability performance of low-carbon concrete compared to traditional regression and simulation models?

- (2)

- What are the key challenges in adopting AI-driven low-carbon concrete d sign, and how can blockchain-enhanced traceability address issues like data reliability and stakeholder collaboration in the construction industry?

2. Model

2.1. Detailed Description of the Proposed Model

2.2. Machine Learning Component: Random Forest Regressor (RFR)

2.3. Model Analysis

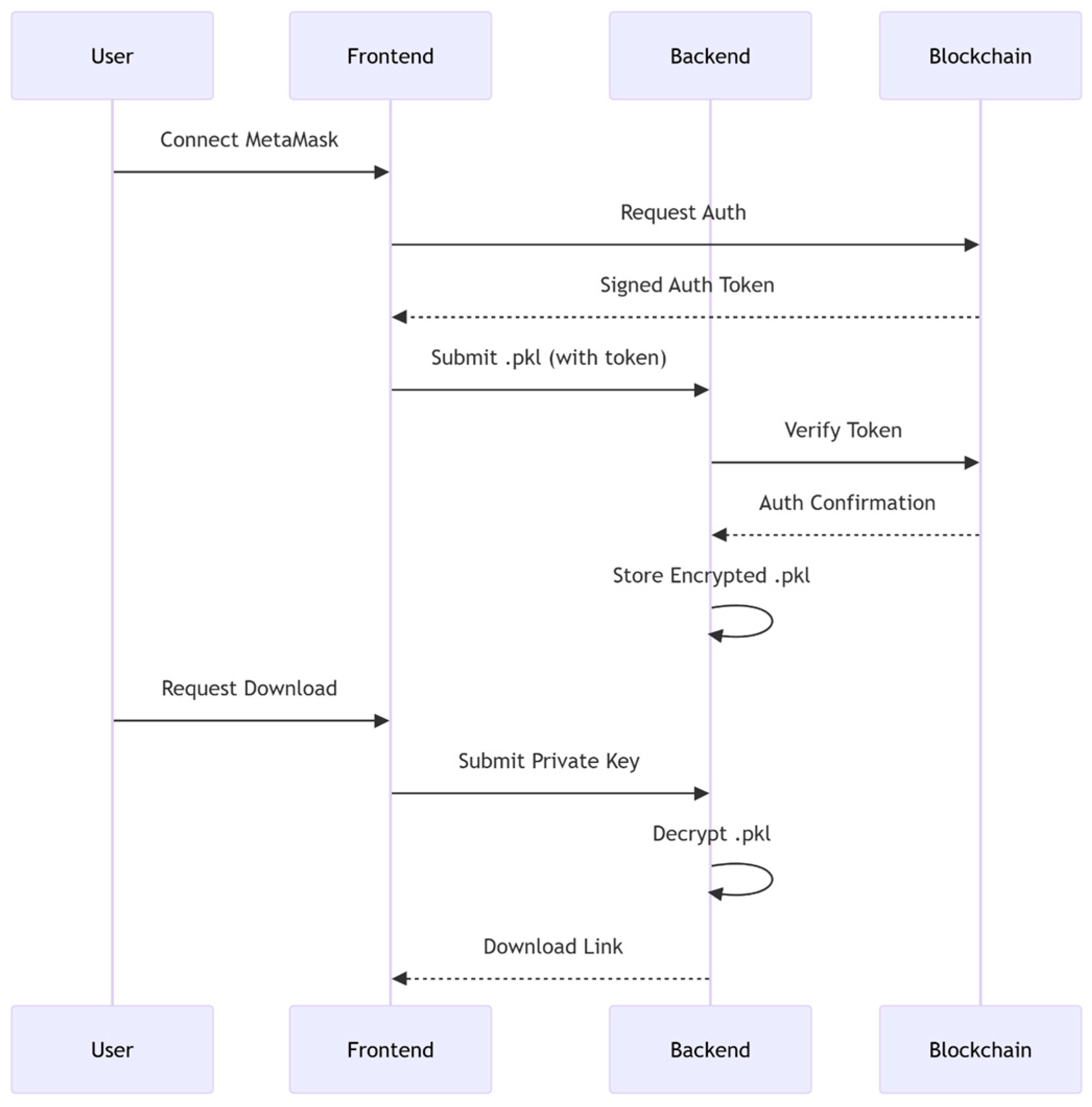

2.4. Blockchain Technology Component

2.5. Hybrid Model Workflow

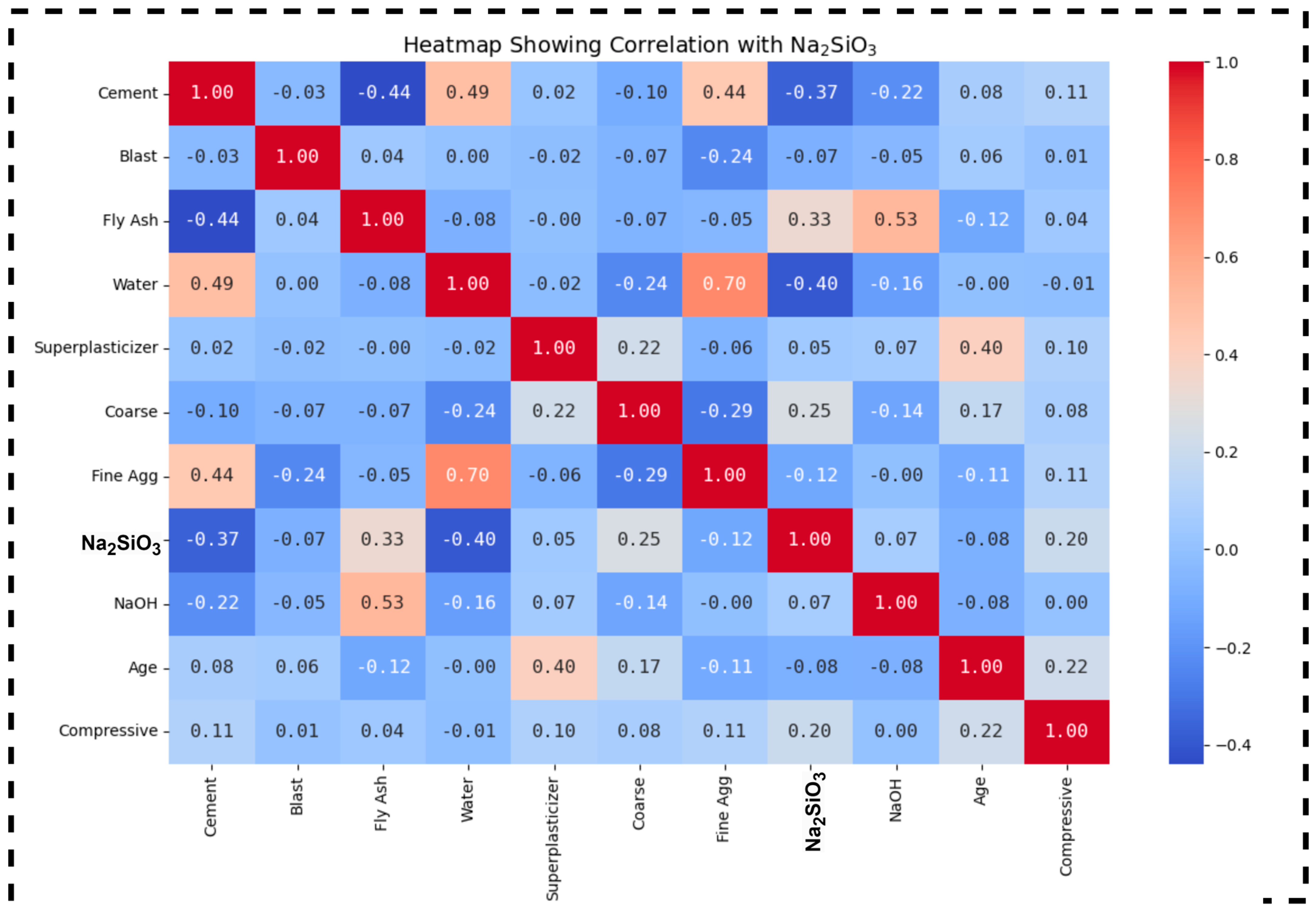

2.6. Data Feature and Selection

3. Research Methodology

3.1. Machine Learning

3.2. Blockchain Technology

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Abbreviation | Full Term | Description | Measurement Unit |

|---|---|---|---|

| w/c | Water–Cement Ratio | Ratio of water to cement in concrete mix | Decimal (0.5–0.8) |

| CPJ | Cement Grade | Portland cement classification (CPJ 35 or CPJ 42.5 used in study) | - |

| W | Water | Total water content in mix | kg/m3 |

| C | Cement | Total cement content | kg/m3 |

| R Sand | River Sand | Fine aggregate sourced from rivers | kg/m3 |

| Q Sand | Quarry Sand | Fine aggregate sourced from quarries | kg/m3 |

| G 5/15 | Gravel 5–15 mm | Coarse aggregate (5–15 mm particle size) | kg/m3 |

| G 15/25 | Gravel 15–25 mm | Coarse aggregate (15–25 mm particle size) | kg/m3 |

| EPD | Environmental Product Declaration | Tokenized sustainability credential for carbon tracking | |

| DID | Decentralized Identifier | Blockchain-based user authentication standard | |

| IPFS | Interplanetary File System | Distributed storage for model files | |

| HSM | Hardware Security Module | Secure hardware for private key management | |

| Parameter | Cement | Blast | Fly Ash | Water | Super Plasticizer | Coarse Aggregate | Fine Aggregate | Na2SiO3 | NAOH | Age | Compressive Strength |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Count | 752 | 752 | 752 | 752 | 752 | 752 | 752 | 752 | 752 | 752 | 752 |

| Mean | 257.3103 | 29.38705 | 162.7484 | 153.3245 | 3.140528 | 671.9908 | 804.9908 | 6.074035 | 9.745806 | 47.22367 | 37.91569 |

| STD | 164.9837 | 103.7698 | 183.3163 | 71.36635 | 5.310532 | 512.863 | 390.8386 | 23.28694 | 60.72815 | 70.27353 | 39.86671 |

| Min | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 1.76 |

| 25% | 120 | 0 | 0 | 132 | 0 | 0 | 606 | 0 | 0 | 7 | 21.9175 |

| 50% | 293.6 | 0 | 120 | 170 | 0.46 | 932 | 735 | 0 | 0 | 28 | 32.595 |

| 75% | 380 | 0 | 240 | 194 | 3.3325 | 1099.498 | 868 | 0 | 0 | 56 | 44.125 |

| Max | 611 | 900 | 1245 | 242.5 | 23.6 | 1370 | 1603 | 194 | 684.8 | 364 | 444 |

| Ratio | N0 of Bags | Total Cost (FCFA) | Cost in USD | CO2 Emission (8%) |

|---|---|---|---|---|

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:1.5:3 | 1.50 | 5000.00 | 8.33 | 0.67 |

| 1:1.5:3 | 1.50 | 5000.00 | 8.33 | 0.67 |

| 1:1.5:3 | 1.30 | 5000.00 | 8.33 | 0.67 |

| 1:1.5:3 | 1.50 | 5000.00 | 8.33 | 0.67 |

| 1:1.5:3 | 1.50 | 5000.00 | 8.33 | 0.67 |

| 1:1.5:3 | 1.50 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:2:4 | 2.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 1:3:3 | 3.00 | 5000.00 | 8.33 | 0.67 |

| 40.67 |

| S/N | CPJ | MIX RATIO | w/c | W (kg) | C (kg) | R SAND (kg) | Q SAND (kg) | G 5/15 (kg) | G 15/25 (kg) | FCJ = 28 (Mpa) | Materials Sum | Total Cost (FCFA) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 42.5 | 1:2:4 | 0.5–0.55 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 24.1 | 4034.1 | 403,410 |

| 2 | 42.5 | 1:2:4 | 0.56–0.6 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 24 | 3964.0 | 396,400 |

| 3 | 42.5 | 1:2:4 | 0.61–0.65 | 1800 | 350 | 640 | 0.00 | 480 | 720 | 23.9 | 4013.9 | 401,390 |

| 4 | 42.5 | 1:2:4 | 0.66–0.70 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 23.8 | 4033.8 | 403,380 |

| 5 | 42.5 | 1:2:4 | 0.71–0.75 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 22.8 | 3962.8 | 396,280 |

| 6 | 42.5 | 1:2:4 | 0.76–0.80 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 22.1 | 3962.1 | 396,210 |

| 7 | 42.5 | 1:2:4 | 0.5–0.55 | 1820 | 350 | 320 | 320.00 | 480 | 720 | 24.5 | 4034.5 | 403,450 |

| 8 | 42.5 | 1:2:4 | 0.56–0.6 | 1750 | 350 | 320 | 320.00 | 480 | 720 | 24.35 | 3964.35 | 396,435 |

| 9 | 42.5 | 1:2:4 | 0.61–0.65 | 1800 | 350 | 320 | 320.00 | 480 | 720 | 24.2 | 4014.2 | 401,420 |

| 10 | 42.5 | 1:2:4 | 0.66–0.70 | 1820 | 350 | 320 | 320.00 | 480 | 720 | 24 | 4034.0 | 403,400 |

| 11 | 42.5 | 1:2:4 | 0.71–0.75 | 1750 | 350 | 320 | 320.00 | 480 | 720 | 23.2 | 3963.2 | 396,320 |

| 12 | 42.5 | 1:2:4 | 0.76–0.80 | 1750 | 350 | 320 | 320.00 | 480 | 720 | 22.5 | 3962.5 | 396,250 |

| 13 | 42.5 | 1:2:4 | 0.5–0.55 | 1820 | 350 | 256 | 384.00 | 480 | 720 | 24.6 | 4034.6 | 403,460 |

| 14 | 42.5 | 1:2:4 | 0.56–0.6 | 1750 | 350 | 256 | 384.00 | 480 | 720 | 24.2 | 3964.2 | 396,420 |

| 15 | 42.5 | 1:2:4 | 0.61–0.65 | 1800 | 350 | 256 | 384.00 | 480 | 720 | 23.8 | 4013.8 | 401,380 |

| 16 | 42.5 | 1:2:4 | 0.66–0.70 | 1820 | 350 | 256 | 384.00 | 480 | 720 | 23.3 | 4033.3 | 403,330 |

| 17 | 42.5 | 1:2:4 | 0.71–0.75 | 1750 | 350 | 256 | 384.00 | 480 | 720 | 22.6 | 3962.6 | 396,260 |

| 18 | 42.5 | 1:2:4 | 0.76–0.80 | 1820 | 350 | 256 | 384.00 | 480 | 720 | 22.1 | 4032.1 | 403,210 |

| 19 | 42.5 | 1:3:3 | 0.5–0.55 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 22.5 | 3962.5 | 396,250 |

| 20 | 42.5 | 1:3:3 | 0.56–0.6 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 22.1 | 4032.1 | 403,210 |

| 21 | 42.5 | 1:3:3 | 0.61–0.65 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 21.6 | 3961.6 | 396,160 |

| 22 | 42.5 | 1:3:3 | 0.66–0.70 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 21.5 | 3961.5 | 396,150 |

| 23 | 42.5 | 1:3:3 | 0.71–0.75 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 20.5 | 4030.5 | 403,050 |

| 24 | 42.5 | 1:3:3 | 0.76–0.80 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 20 | 4030.0 | 403,000 |

| 25 | 42.5 | 1:3:3 | 0.5–0.55 | 1750 | 350 | 320 | 320.00 | 480 | 720 | 22.7 | 3962.7 | 396,270 |

| 26 | 42.5 | 1:3:3 | 0.56–0.6 | 1750 | 350 | 320 | 320.00 | 480 | 720 | 22.3 | 3962.3 | 396,230 |

| 27 | 42.5 | 1:3:3 | 0.61–0.65 | 1820 | 350 | 320 | 320.00 | 480 | 720 | 21.7 | 4031.7 | 403,170 |

| 28 | 42.5 | 1:3:3 | 0.66–0.70 | 1750 | 350 | 320 | 320.00 | 480 | 720 | 21.1 | 3961.1 | 396,110 |

| 29 | 42.5 | 1:3:3 | 0.71–0.75 | 1800 | 350 | 320 | 320.00 | 480 | 720 | 20.5 | 4010.5 | 401,050 |

| 30 | 42.5 | 1:3:3 | 0.76–0.80 | 1820 | 350 | 320 | 320.00 | 480 | 720 | 19.8 | 4029.8 | 402,980 |

| 31 | 42.5 | 1:3:3 | 0.5–0.55 | 1750 | 350 | 256 | 384.00 | 480 | 720 | 22.9 | 3962.9 | 396,290 |

| 32 | 42.5 | 1:3:3 | 0.56–0.6 | 1750 | 350 | 256 | 384.00 | 480 | 720 | 22.5 | 3962.5 | 396,250 |

| 33 | 42.5 | 1:3:3 | 0.61–0.65 | 1820 | 350 | 256 | 384.00 | 480 | 720 | 22 | 4032.0 | 403,200 |

| 34 | 42.5 | 1:3:3 | 0.66–0.70 | 1750 | 350 | 256 | 384.00 | 480 | 720 | 21.4 | 3961.4 | 396,140 |

| 35 | 42.5 | 1:3:3 | 0.71–0.75 | 1800 | 350 | 256 | 384.00 | 480 | 720 | 20.8 | 4010.8 | 401,080 |

| 36 | 42.5 | 1:3:3 | 0.76–0.80 | 1820 | 350 | 256 | 384.00 | 480 | 720 | 20.1 | 4030.1 | 403,010 |

| 37 | 42.5 | 1:1.5:3 | 0.5–0.55 | 1750 | 400 | 590 | 0.00 | 450 | 700 | 25.8 | 3915.8 | 391,580 |

| 38 | 42.5 | 1:1.5:3 | 0.56–0.60 | 1750 | 400 | 590 | 0.00 | 450 | 700 | 24.5 | 3914.5 | 391,450 |

| 39 | 42.5 | 1:1.5:3 | 0.61–0.65 | 1720 | 400 | 590 | 0.00 | 450 | 700 | 25 | 3885.0 | 388,500 |

| 40 | 42.5 | 1:1.5:3 | 0.66–0.70 | 1720 | 400 | 590 | 0.00 | 450 | 700 | 24.4 | 3884.4 | 388,440 |

| 41 | 42.5 | 1:1.5:3 | 0.71–0.75 | 1720 | 400 | 590 | 0.00 | 450 | 700 | 23.9 | 3883.9 | 388,390 |

| 42 | 42.5 | 1:1.5:3 | 0.76–0.80 | 1720 | 400 | 590 | 0.00 | 450 | 700 | 23.1 | 3883.1 | 388,310 |

| 43 | 35 | 1:2:4 | 0.5–0.55 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 22.6 | 3962.6 | 396,260 |

| 44 | 35 | 1:2:4 | 0.56–0.60 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 22.1 | 3962.1 | 396,210 |

| 45 | 35 | 1:2:4 | 0.61–0.65 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 21.7 | 4031.7 | 403,170 |

| 46 | 35 | 1:2:4 | 0.66–0.70 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 21.2 | 3961.2 | 396,120 |

| 47 | 35 | 1:2:4 | 0.71–0.75 | 1800 | 350 | 640 | 0.00 | 480 | 720 | 20.5 | 4010.5 | 401,050 |

| 48 | 35 | 1:2:4 | 0.76–0.80 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 19.4 | 4029.4 | 402,940 |

| 49 | 35 | 1:3:3 | 0.5–0.55 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 22.6 | 3962.6 | 396,260 |

| 50 | 35 | 1:3:3 | 0.56–0.60 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 22.2 | 3962.2 | 396,220 |

| 51 | 35 | 1:3;3 | 0.61–0.65 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 21.7 | 4031.7 | 403,170 |

| 52 | 35 | 1:3:3 | 0.66–0.70 | 1750 | 350 | 640 | 0.00 | 480 | 720 | 21.2 | 3961.2 | 396,120 |

| 53 | 35 | 1:3:3 | 0.71–0.75 | 1800 | 350 | 640 | 0.00 | 480 | 720 | 20.5 | 4010.5 | 401,050 |

| 54 | 35 | 1:3:3 | 0.76–0.80 | 1820 | 350 | 640 | 0.00 | 480 | 720 | 20 | 4030.0 | 403,000 |

| 21,516,245 | 35,860.22 |

References

- Jacobs, A.; Hitch, M. Experimental mineral carbonation: Approaches to accelerate CO2 sequestration in mine waste materials. Int. J. Min. Reclam. Environ. 2011, 25, 321–331. [Google Scholar] [CrossRef]

- Ferdaus, M.; Dam, T.; Anavatti, S.; Das, S. Digital technologies for a net-zero energy future: A comprehensive review. Renew. Sustain. Energy Rev. 2024, 202, 114681. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Tang, Y.; Chen, Q.; Sun, W.; Fang, X.; Tao, Y.; Shang, B. Recent Advances in Machine Learning for Building Envelopes: From Prediction to Optimization. SRN Electron. J. 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5079321 (accessed on 20 July 2025).

- Schmidt, J.; Marques, M.R.G.; Botti, S.; Marques, M.A.L. Recent advances and applications of machine learning in materials science. Comput. Mater. Sci. 2019, 156, 443–458. [Google Scholar]

- Li, J.; Ni, W.; Wang, X.; Zhu, S.; Wei, X.; Jiang, F.; Zeng, H.; Hitch, M. Mechanical activation of medium basicity steel slag under dry condition for carbonation curing. J. Build. Eng. 2022, 50, 104123. [Google Scholar] [CrossRef]

- Xi, C.; Cao, S.-J. Challenges and Future Development Paths of Low Carbon Building Design: A Review. Buildings 2022, 12, 163. [Google Scholar] [CrossRef]

- Chau, C.-K.; Leung, T.M.; Ng, W.Y. A Review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Mirmozaffari, M.; Yazdani, M.; Boskabadi, A.; Dolatsara, H.A.; Kabirifar, K.; Golilarz, N.A. A Novel Machine Learning Approach Combined with Optimization Models for Eco-efficiency Evaluation. Appl. Sci. 2020, 10, 5210. [Google Scholar] [CrossRef]

- Shamsabadi, E.A.; Roshan, N.; Hadigheh, S.A.; Nehdi, M.L.; Khodabakhshian, A.; Ghalehnovi, M. Machine learning-based compressive strength modelling of concrete incorporating waste marble powder. Constr. Build. Mater. 2022, 324, 126592. [Google Scholar] [CrossRef]

- Almansour, F.; Al-Bukhaiti, N. Predicting the strength of fiber reinforced polymer materials externally bonded to masonry using artificial intelligent techniques. Front. Struct. Civ. Eng. 2025, 19, 242–261. [Google Scholar] [CrossRef]

- Wang, S.; Xia, P.; Chen, K.; Gong, F.; Wang, H.; Wang, Q.; Zhao, Y.; Jin, W. Prediction and optimization model of sustainable concrete properties using machine learning, deep learning and swarm intelligence: A review. J. Build. Eng. 2023, 80, 108065. [Google Scholar] [CrossRef]

- Cao, G.; Li, Z. Numerical flow simulation of fresh concrete with viscous granular material model and smoothed particle hydrodynamics. Cem. Concr. Res. 2017, 100, 263–274. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Song, Y.; Hou, M.; Xu, Y. Development of low-cost engineered cementitious composites using Yellow River silt and unoiled PVA fiber. Constr. Build. Mater. 2024, 425, 136063. [Google Scholar] [CrossRef]

- Mortar, N.A.M.; Kamarudin, H.; Rafiza, R.A.; Meor, T.; Rosnita, M. Compressive Strength of Fly Ash Geopolymer Concrete by Varying Sodium Hydroxide Molarity and Aggregate to Binder Ratio. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 2nd Joint Conference on Green Engineering Technology & Applied Computing, Bangkok, Thailand, 4–5 February 2020; IOP Publishing: Bristol, UK, 2020; Volume 864. [Google Scholar]

- Sonebi, M.; Cevik, A.; Grünewald, S.; Walraven, J. Modelling the fresh properties of self-compacting concrete using support vector machine approach. Constr. Build. Mater. 2016, 106, 55–64. [Google Scholar] [CrossRef]

- Ahmad, S.; Umar, A.; Masood, A. An appraisal of the models for the prediction of compressive strength of thermally damaged self-compacting concrete. Mater. Today Proc. 2022, 65, 478–483. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Riofrio, A.; Soleymani, A.; Baykara, H.; Kontoni, D.-P.N.; Mahdi, H.A.; Jahangir, H. Global warming potential-based life cycle assessment and optimization of the compressive strength of fly ash-silica fume concrete; environmental impact consideration. Front. Built Environ. 2022, 8, 992552. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Riofrio, A.; Baykara, H.; Soleymani, A.; Mahdi, H.A.; Jahangir, H.; Ibe, K. Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures. Sustainability 2022, 14, 9573. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kontoni, D.-P.N.; Ebid, A.M.; Dabbaghi, F.; Soleymani, A.; Jahangir, H.; Nehdi, M.L. Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations. Buildings 2022, 12, 948. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Baldovino, J.d.J.A.; E Onyia, M. Hydraulic conductivity predictive model of RHA-ameliorated laterite for solving landfill liner leachate, soil and water contamination and carbon emission problems. Int. J. Low-Carbon. Technol. 2022, 17, 1134–1144. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Onyia, M.E.; Amanamba, E.C. Estimating the swelling potential of non-carbon–based binder (NCBB)-treated clayey soil for sustainable green subgrade using AI (GP, ANN, and EPR) techniques. Int. J. Low-Carbon Technol. 2022, 17, 807–815. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Tome, S.; Ebid, A.M.; Usungedo, T.; Van, D.B.; Etim, R.K.; Onuoha, I.C.; Attah, I.C. Effect of desiccation on ashcrete (HSDA)-treated soft soil used as flexible pavement foundation: Zero carbon stabilizer approach. Int. J. Low-Carbon. Technol. 2022, 17, 563–570. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Gnananandarao, T.; Ebid, A.M.; Mahdi, H.A.; Ghadikolaee, M.R.; Al-Ajamee, M. Evaluating the Compressive Strength of Recycled Aggregate Concrete Using Novel Artificial Neural Network. Civ. Eng. J. 2022, 8, 1679–1693. [Google Scholar] [CrossRef]

- Alyhya, W.; Kulasegaram, S.; Karihaloo, B. Simulation of the flow of self-compacting concrete in the V-funnel by SPH. Cem. Concr. Res. 2017, 100, 47–59. [Google Scholar] [CrossRef]

- Atwoli, L.; Erhabor, G.E.; Gbakima, A.A.; Haileamlak, A.; Kayembe Ntumba, J.M.; Kigera, J.; Laybourn-Langton, L.; Mash, B.; Muhia, J.; Zielinski, C.; et al. COP27 Climate Change Conference: Urgent action needed for Africa and the world: Wealthy nations must step up support for Africa and vulnerable countries in addressing past, present and future impacts of climate change. Int. J. Low-Carbon Technol. 2022, 62, ezac492. [Google Scholar] [CrossRef] [PubMed]

- Mahjoubi, S.; Barhemat, R.; Meng, W.; Bao, Y. AI-guided auto-discovery of low-carbon cost-effective ultra-high performance concrete (UHPC). Resour. Conserv. Recycl. 2023, 189, 106741. [Google Scholar] [CrossRef]

- Peng, X.; Tao, Y.; Wang, C.; Zhong, Z. Research on low-carbon supply chain decision-making under carbon cap-and-trade and subsidy policy. Int. J. Low-Carbon. Technol. 2022, 17, 1061–1074. [Google Scholar] [CrossRef]

- Peng, X.; Tao, Y.; Wang, C.; Zhong, Z. Research on low-carbon supply chain decision-making under different incentive models. Int. J. Low-Carbon. Technol. 2022, 17, 696–709. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Chen, Z.; Li, F. Influence of recycled plastic and fly ash fillers on the performance of porous asphalt mixtures. Constr. Build. Mater. 2023, 369, 130473. [Google Scholar] [CrossRef]

- DeRousseau, M.; Kasprzyk, J.; Srubar, W. Computational design optimization of concrete mixtures: A review. Cem. Concr. Res. 2018, 109, 42–53. [Google Scholar] [CrossRef]

- Young, B.A.; Hall, A.; Pilon, L.; Gupta, P.; Sant, G. Can the compressive strength of concrete be estimated from knowledge of the mixture proportions?: New insights from statistical analysis and machine learning methods. Cem. Concr. Res. 2019, 115, 379–388. [Google Scholar] [CrossRef]

- Provis, J. A concrete future. Commun. Eng. 2022, 1, 32. [Google Scholar] [CrossRef]

- Kocak, Y.; Nas, S. The effect of using fly ash on the strength and hydration characteristics of blended cements. Constr. Build. Mater. 2014, 73, 25–32. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J.; Liu, C.; Zheng, J. Prediction of Rubber Fiber Concrete Strength Using Extreme Learning Machine. Front. Mater. 2021, 7, 582635. [Google Scholar] [CrossRef]

- Zou, Z.P. Prediction of elastic modulus of ordinary and high-strength concrete based on machine learning. Model. Simul. 2024, 13, 2591. [Google Scholar] [CrossRef]

- Hussain, F.; Khan, S.A.; Khushnood, R.A.; Hamza, A.; Rehman, F. Machine Learning-Based Predictive Modeling of Sustainable Lightweight Aggregate Concrete. Sustainability 2022, 15, 641. [Google Scholar] [CrossRef]

- Siddique, R.; Aggarwal, P.; Aggarwal, Y. Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks. Adv. Eng. Softw. 2011, 42, 780–786. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, D.; Lee, J.; Lee, C. Residual strength of concrete subjected to fatigue based on machine learning technique. Struct. Concr. 2022, 23, 2274–2287. [Google Scholar] [CrossRef]

- Al-Shamiri, A.K.; Yuan, T.-F.; Kim, J.H. Non-Tuned Machine Learning Approach for Predicting the Compressive Strength of High-Performance Concrete. Materials 2020, 13, 1023. [Google Scholar] [CrossRef]

- Mahjoob, M.; Fazeli, S.S.; Milanlouei, S.; Tavassoli, L.S.; Mirmozaffari, M. A modified adaptive genetic algorithm for multi-product multi-period inventory routing problem. Sustain. Oper. Comput. 2022, 3, 1–9. [Google Scholar] [CrossRef]

- Mirmozaffari, M.; Shadkam, E.; Khalili, S.M.; Kabirifar, K.; Yazdani, R.; Gashteroodkhani, T.A. A novel artificial intelligent approach: Comparison of machine learning tools and algorithms based on optimization DEA Malmquist productivity index for eco-efficiency evaluation. Int. J. Energy Sect. Manag. 2021, 15, 523–550. [Google Scholar] [CrossRef]

- Jin, L.; Duan, J.; Fan, T.; Jiao, P.; Dong, T.; Wu, Q. Using GA—BP Coupling Algorithm to Predict the High-performance Concrete Mechanical Property. KSCE J. Civ. Eng. 2023, 27, 684–697. [Google Scholar] [CrossRef]

- Arbaoui, A.; Ouahabi, A.; Jacques, S.; Hamiane, M. Concrete Cracks Detection and Monitoring Using Deep Learning-Based Multiresolution Analysis. Electronics 2021, 10, 1772. [Google Scholar] [CrossRef]

- Zhang, F.; Wen, B.; Niu, D.; Li, A.; Guo, B. Optimized Design of Low-Carbon Mix Ratio for Non-Dominated Sorting Genetic Algorithm II Concrete Based on Genetic Algorithm-Improved Back Propagation. Materials 2024, 17, 4077. [Google Scholar] [CrossRef]

- Islam, N.; Kashem, A.; Das, P.; Ali, N.; Paul, S. Prediction of high-performance concrete compressive strength using deep learning techniques. Asian J. Civ. Eng. 2024, 25, 327–341. [Google Scholar] [CrossRef]

- Farshadfar, Z.; Mucha, T.; Tanskanen, K. Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review. Logistics 2024, 8, 108. [Google Scholar] [CrossRef]

- Tan, S.; Liu, G. A low carbon management model for regional energy economies based on blockchain technology. Heliyon 2023, 9, e19966. [Google Scholar] [CrossRef]

- Jain, A.; Sharma, A.; Jately, V.; Azzopardi, B. Sustainable Energy Solutions with Artificial Intelligence, Blockchain Technology, and Internet of Things; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Scott, D.J.; Broyd, T.; Ma, L. Exploratory literature review of blockchain in the construction industry. Autom. Constr. 2021, 132, 103914. [Google Scholar] [CrossRef]

- Kiu, M.S.; Chia, F.C.; Wong, P.F. Exploring the potentials of blockchain application in construction industry: A systematic review. Int. J. Constr. Manag. 2022, 22, 2931–2940. [Google Scholar] [CrossRef]

- Li, Z.; Yoon, J.; Zhang, R.; Rajabipour, F.; Srubar, W.V., III; Dabo, I.; Radlińska, A. Machine learning in concrete science: Applications, challenges, and best practices. NPJ Comput. Mater. 2022, 8, 127. [Google Scholar] [CrossRef]

- Kumar, M.; Samui, P.; Kumar, D.R.; Asteris, P.G. State-of-the-art XGBoost, RF and DNN based soft-computing models for PGPN piles. Géoméch. Geoengin. 2024, 19, 975–990. [Google Scholar] [CrossRef]

- Asteris, P.G.; Lemonis, M.E.; Le, T.-T.; Tsavdaridis, K.D. Evaluation of the ultimate eccentric load of rectangular CFSTs using advanced neural network modeling. Eng. Struct. 2021, 248, 113297. [Google Scholar] [CrossRef]

- Omran, B.A.; Chen, Q.; Jin, R. Comparison of Data Mining Techniques for Predicting Compressive Strength of Environmentally Friendly Concrete. J. Comput. Civ. Eng. 2016, 30, 04016029. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Redmond, A.; Hore, A.; Alshawi, M.; West, R. Exploring how information exchanges can be enhanced through Cloud BIM. Autom. Constr. 2012, 24, 175–183. [Google Scholar] [CrossRef]

- Suichies, B. 2015. Why Blockchain Must Die in 2016. Available online: https://medium.com/@bsuichies/why-blockchain-must-die-in-2016-e992774c03b4 (accessed on 20 July 2025).

- Scott, B. How Can Cryptocurrency and Blockchain Technology Play a Role in Building Social and Solidarity Finance; Working Paper No. 2016-1; UNRISD: Geneva, Switzerland, 2016. [Google Scholar]

- Kakavand, H.; Kost De Sevres, N.; Chilton, B. The Blockchain Revolution: An Analysis of Regulation and Technology Related to Distributed Ledger Technologies. 2017. Available online: https://ssrn.com/abstract=2849251 (accessed on 20 July 2025).

- Motlagh, S.A.T.; Naghizadehrokni, M. An Extended Multi-Model Regression Approach for Compressive Strength Prediction and Optimization of Concrete Mixtures. Appl. Soft Comput. 2021, 112, 107777. [Google Scholar] [CrossRef]

- Javed, M.F.; Ali, H.S.; Khan, A. Machine Learning–Based Prediction of Waste Foundry Sand Concrete Properties Using Hybrid SVR Optimization Techniques. Constr. Build. Mater. 2024, 369, 130473. [Google Scholar]

- Li, J.; Greenwood, D.; Kassem, M. Blockchain in the built environment: Analysing current applications and developing an emergent framework. Autom. Constr. 2019, 102, 288–307. [Google Scholar] [CrossRef]

- Shojaei, A.; Zuo, J. Application of blockchain technology in the construction industry: A systematic review. Buildings 2021, 11, 334. [Google Scholar]

- Turk, Ž.; Klinc, R. Potentials of Blockchain Technology for Construction Management. Procedia Eng. 2017, 196, 638–645. [Google Scholar] [CrossRef]

- Perera, S.; Nanayakkara, S.; Rodrigo, M.N.N.; Senaratne, S.; Weinand, R. Blockchain technology: Is it hype or real in the construction industry? J. Ind. Inf. Integr. 2020, 17, 100125. [Google Scholar] [CrossRef]

- Khalid, S.W.; Al-Hadad, B.M.A. A comparison study of using polyethylene terephthalate and limestone fillers on porous asphalt mixture behaviours. Ain Shams Eng. J. 2023, 15, 102426. [Google Scholar] [CrossRef]

- Haq, M.; Khan, A.; Naqvi, T.; Yusuf, M.; Kamyab, H.; Chelliapan, S. Parametric analysis of RSB sensors for concrete strength monitoring using hybrid EMI and WP techniques: Numerical investigation. Ain Shams Eng. J. 2023, 15, 102457. [Google Scholar] [CrossRef]

- Al-Bassam, M.; Sonnino, A.; Bano, M.; Danezis, G. Blockchain Scalability and its Foundations in Distributed Systems. arXiv 2020, arXiv:2001.00826. [Google Scholar]

- Androulaki, E.; Barger, A.; Bortnikov, V.; Cachin, C.; Christidis, K.; De Caro, A.; Enyeart, D.; Ferris, C.; Laventman, G.; Manevich, Y.; et al. Hyperledger Fabric: A Distributed Operating System for Permissioned Blockchains. arXiv 2018, arXiv:arXiv:1801.10228. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nwetlawung, Z.E.; Lin, Y.-H. Development of an Optimization Algorithm for Designing Low-Carbon Concrete Materials Standardization with Blockchain Technology and Ensemble Machine Learning Methods. Buildings 2025, 15, 2809. https://doi.org/10.3390/buildings15162809

Nwetlawung ZE, Lin Y-H. Development of an Optimization Algorithm for Designing Low-Carbon Concrete Materials Standardization with Blockchain Technology and Ensemble Machine Learning Methods. Buildings. 2025; 15(16):2809. https://doi.org/10.3390/buildings15162809

Chicago/Turabian StyleNwetlawung, Zilefac Ebenezer, and Yi-Hsin Lin. 2025. "Development of an Optimization Algorithm for Designing Low-Carbon Concrete Materials Standardization with Blockchain Technology and Ensemble Machine Learning Methods" Buildings 15, no. 16: 2809. https://doi.org/10.3390/buildings15162809

APA StyleNwetlawung, Z. E., & Lin, Y.-H. (2025). Development of an Optimization Algorithm for Designing Low-Carbon Concrete Materials Standardization with Blockchain Technology and Ensemble Machine Learning Methods. Buildings, 15(16), 2809. https://doi.org/10.3390/buildings15162809