Acoustic Emission Monitoring Method for Multi-Strand Fractures in Post-Tensioned Prestressed Hollow Core Slab Bridges Using Waveguide Rods

Abstract

1. Introduction

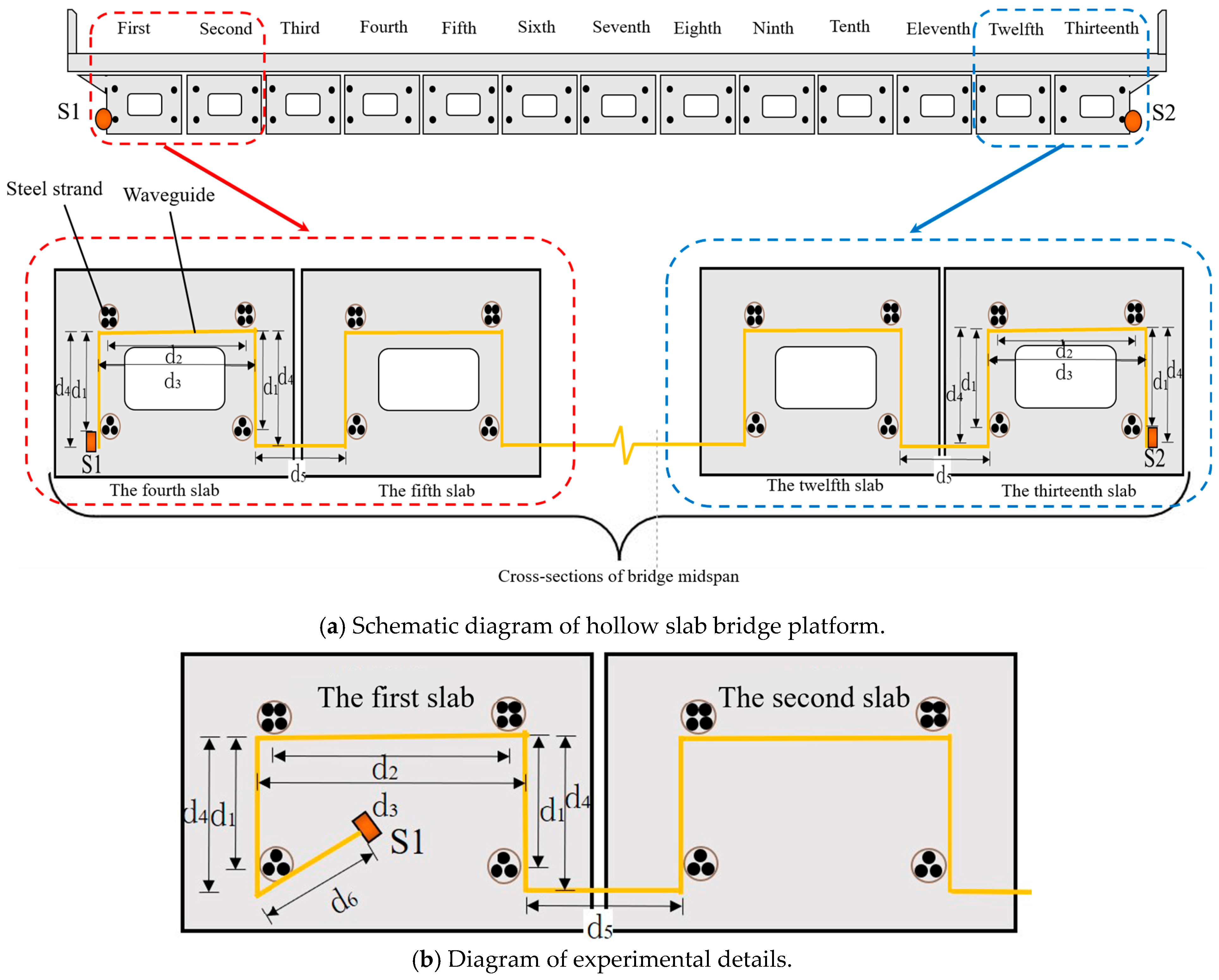

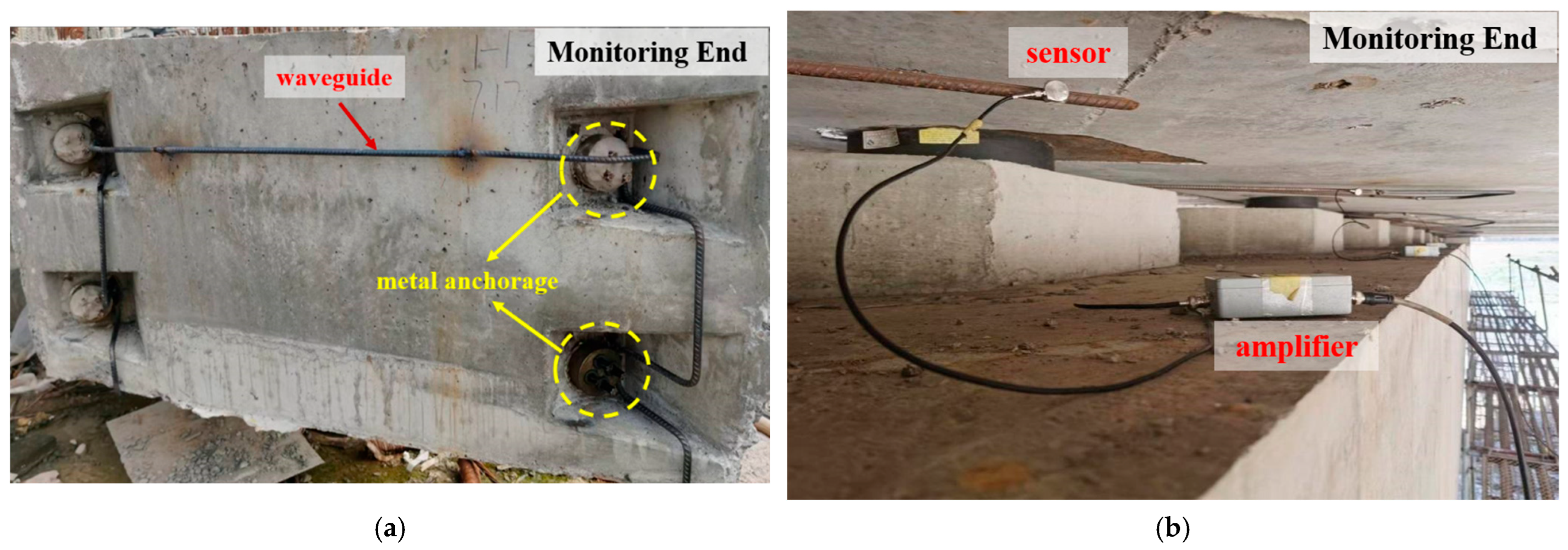

2. Multi-Plate Series Strand Fracture Test

2.1. Series Test Scheme for Multiple Hollow Plates Based on Waveguide Rod

2.2. Methods for Achieving Different Numbers of Strand Fractures

2.3. Test Procedure for AE Monitoring of Strand Fractures

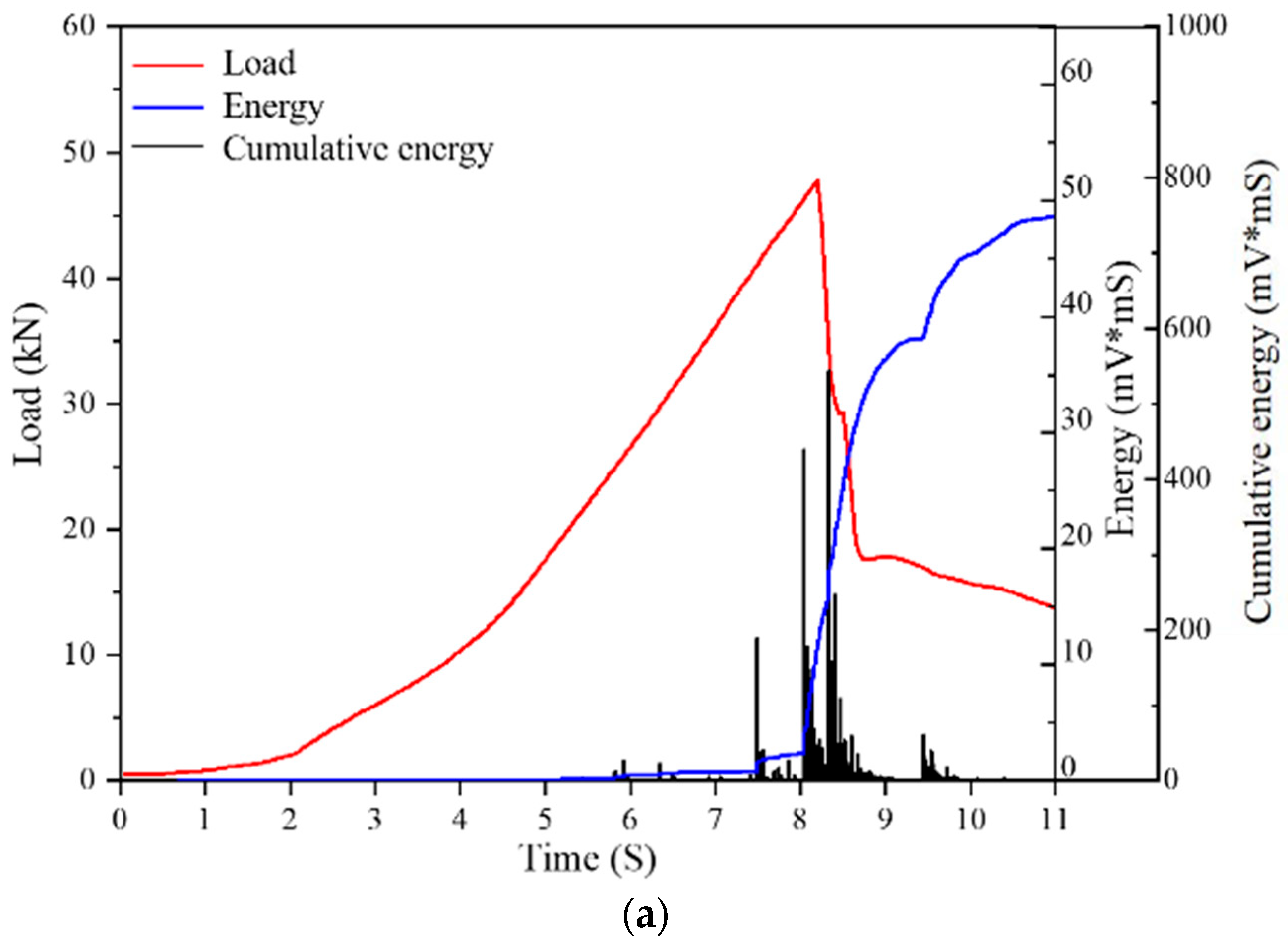

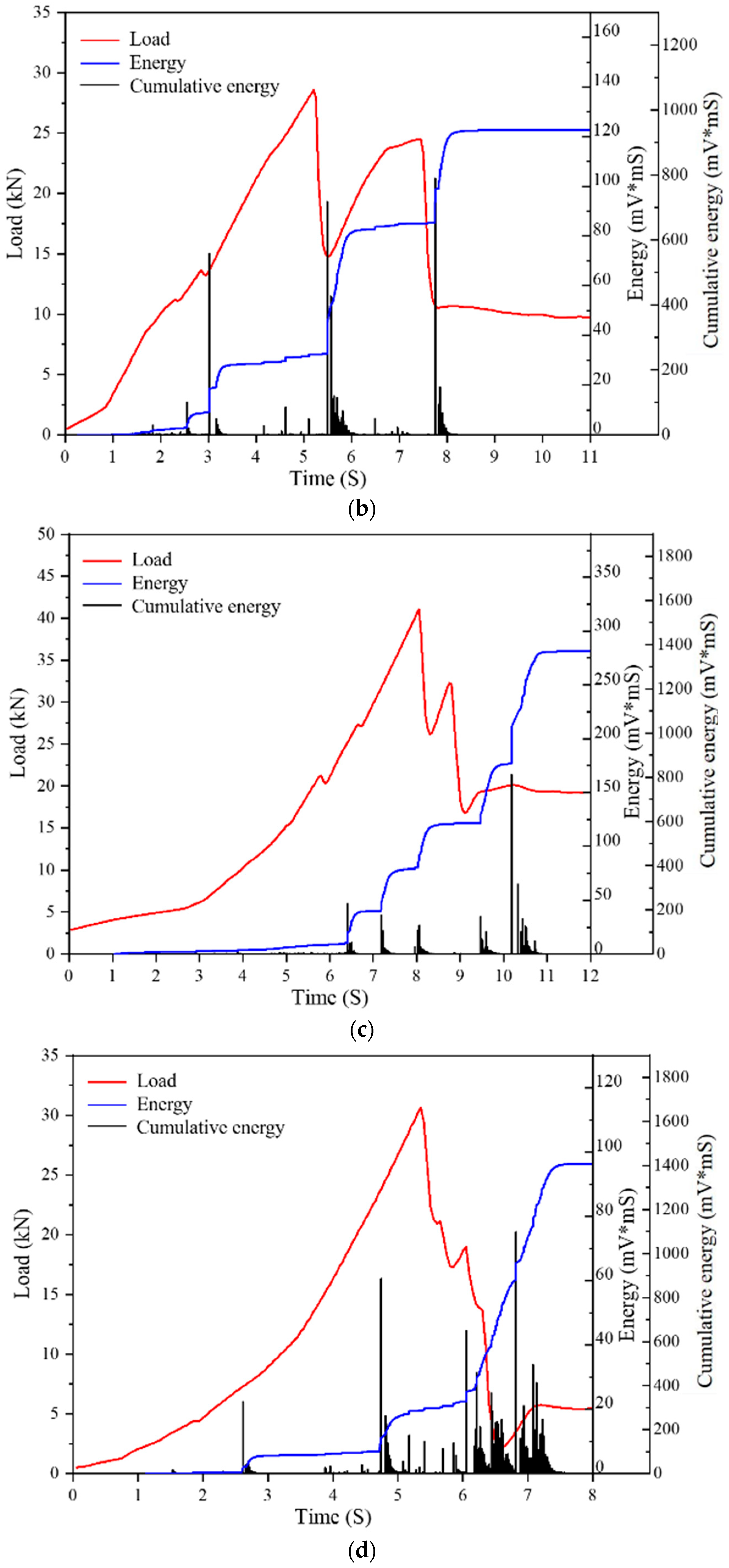

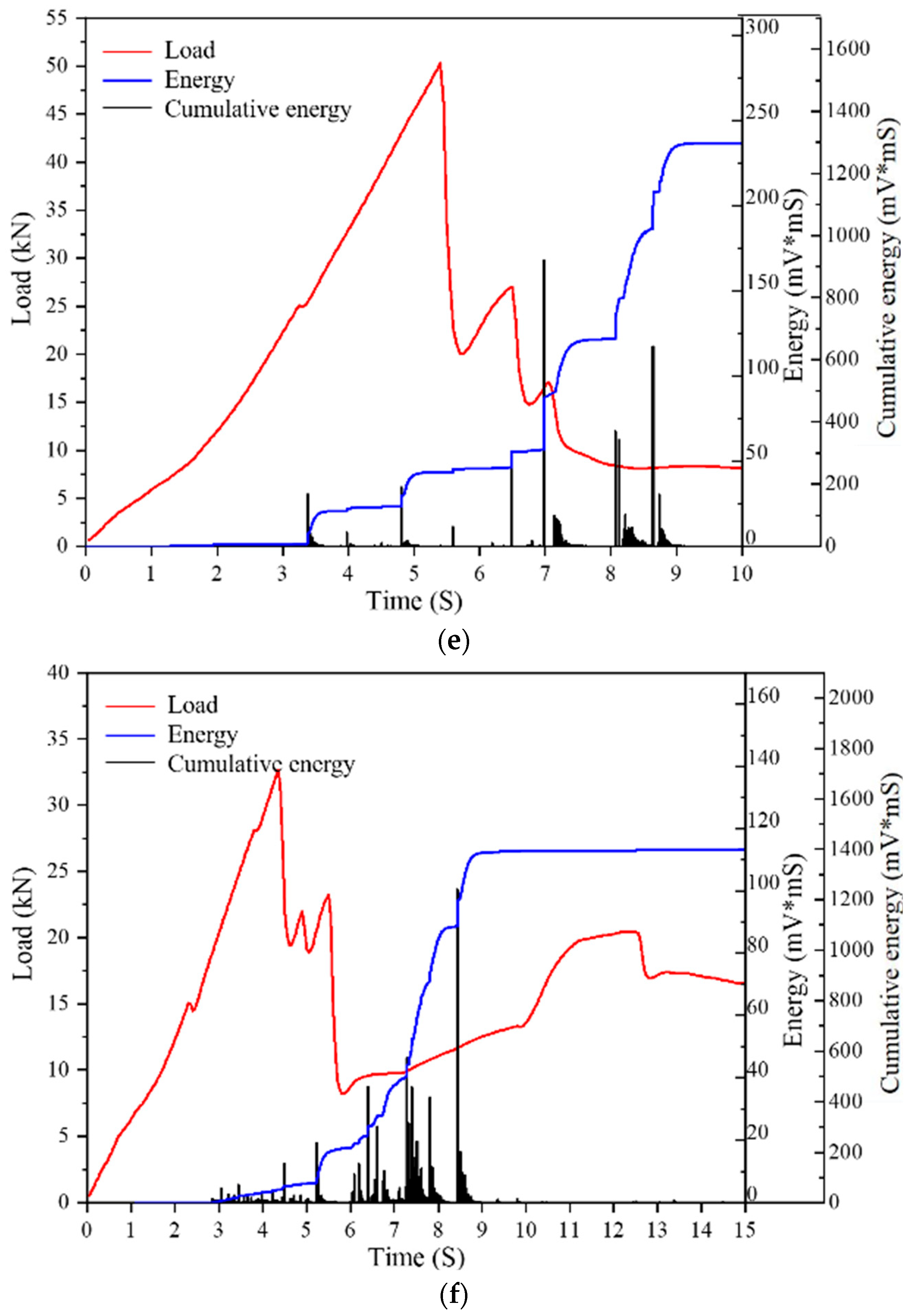

3. Analysis of AE Identification Results for Multiple Fractures in Steel Strands

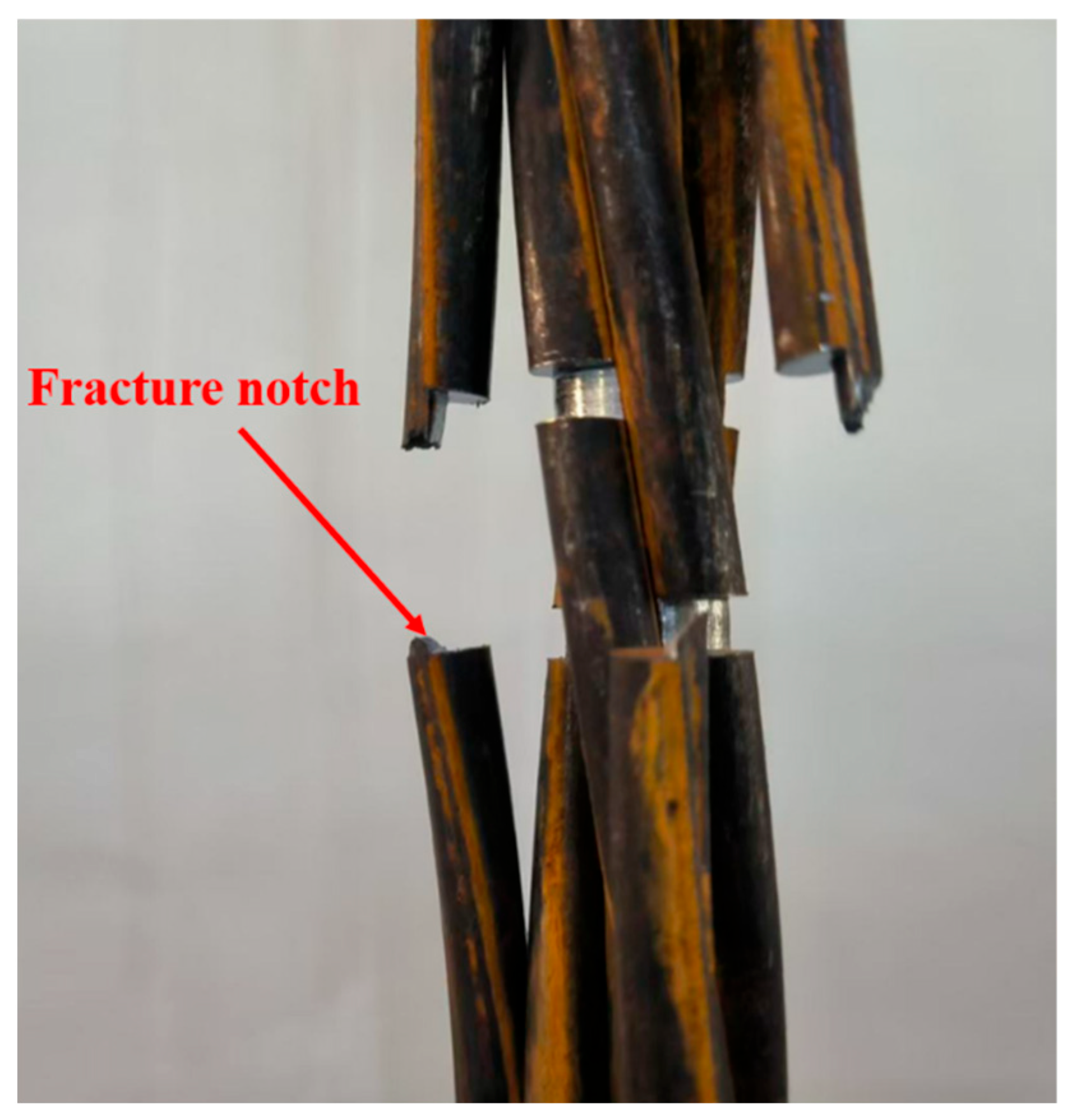

3.1. Analysis of Strand Fracture Results

3.2. Analysis of Identification Results of Number of Strand Fractures Without Signal Attenuation

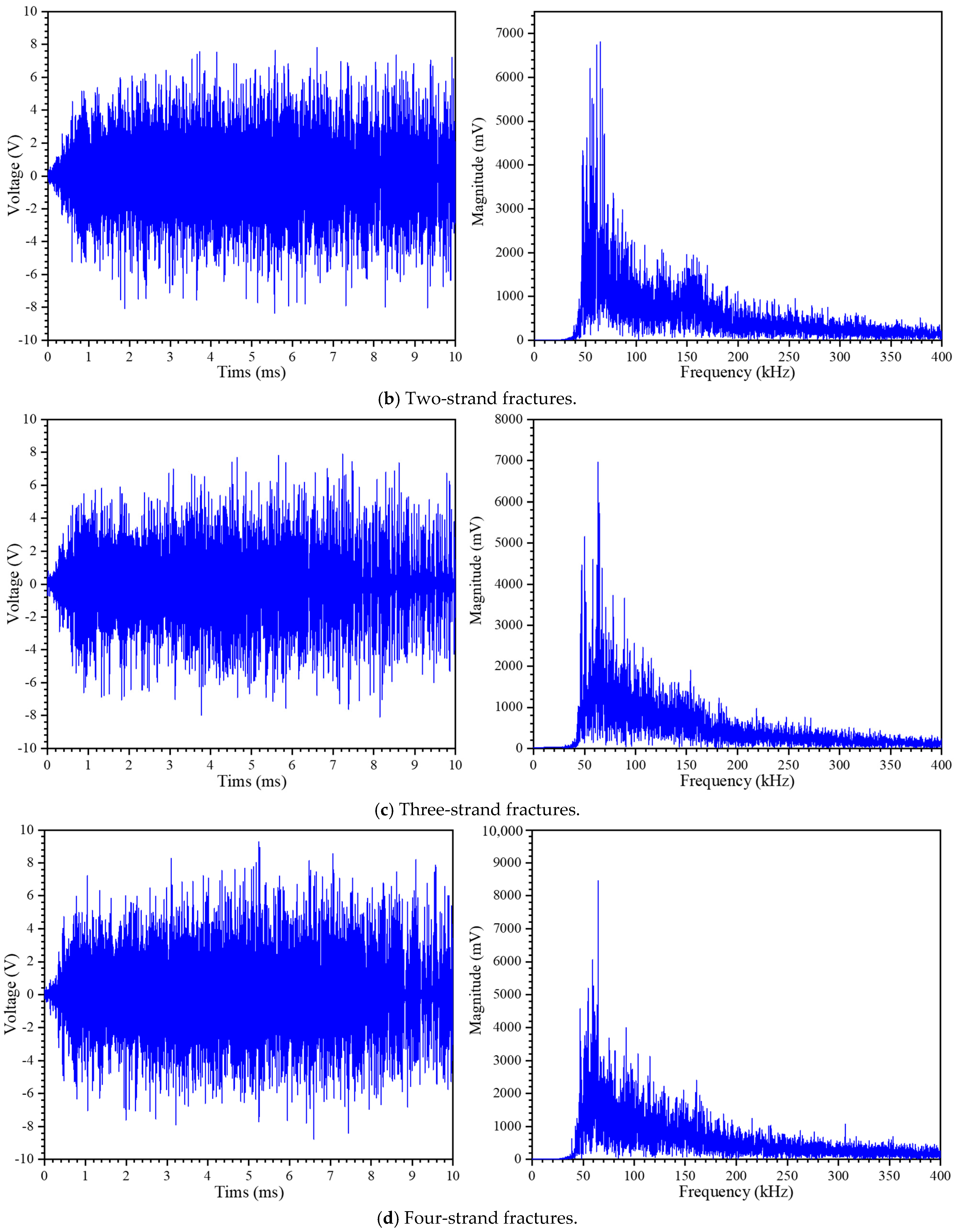

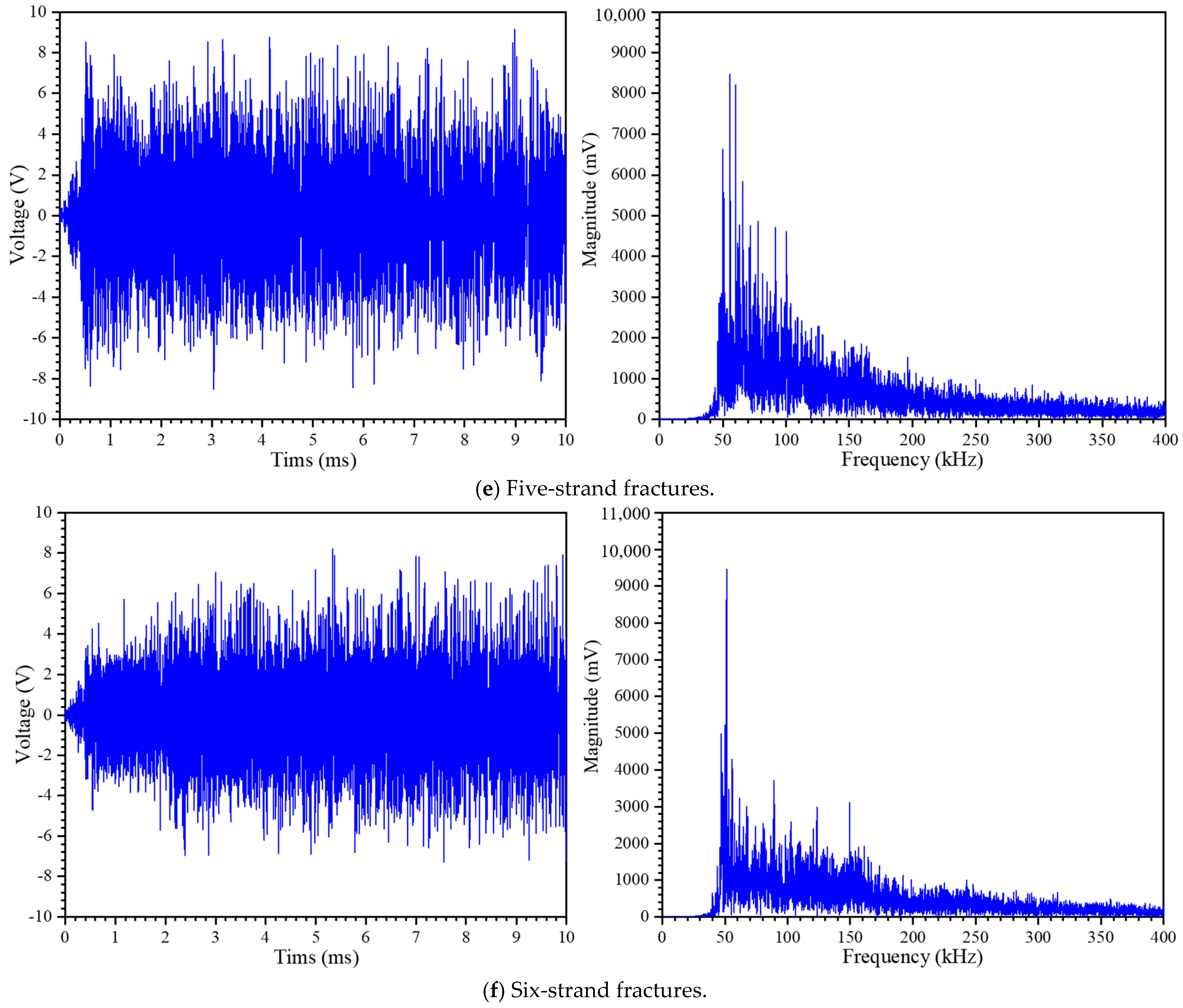

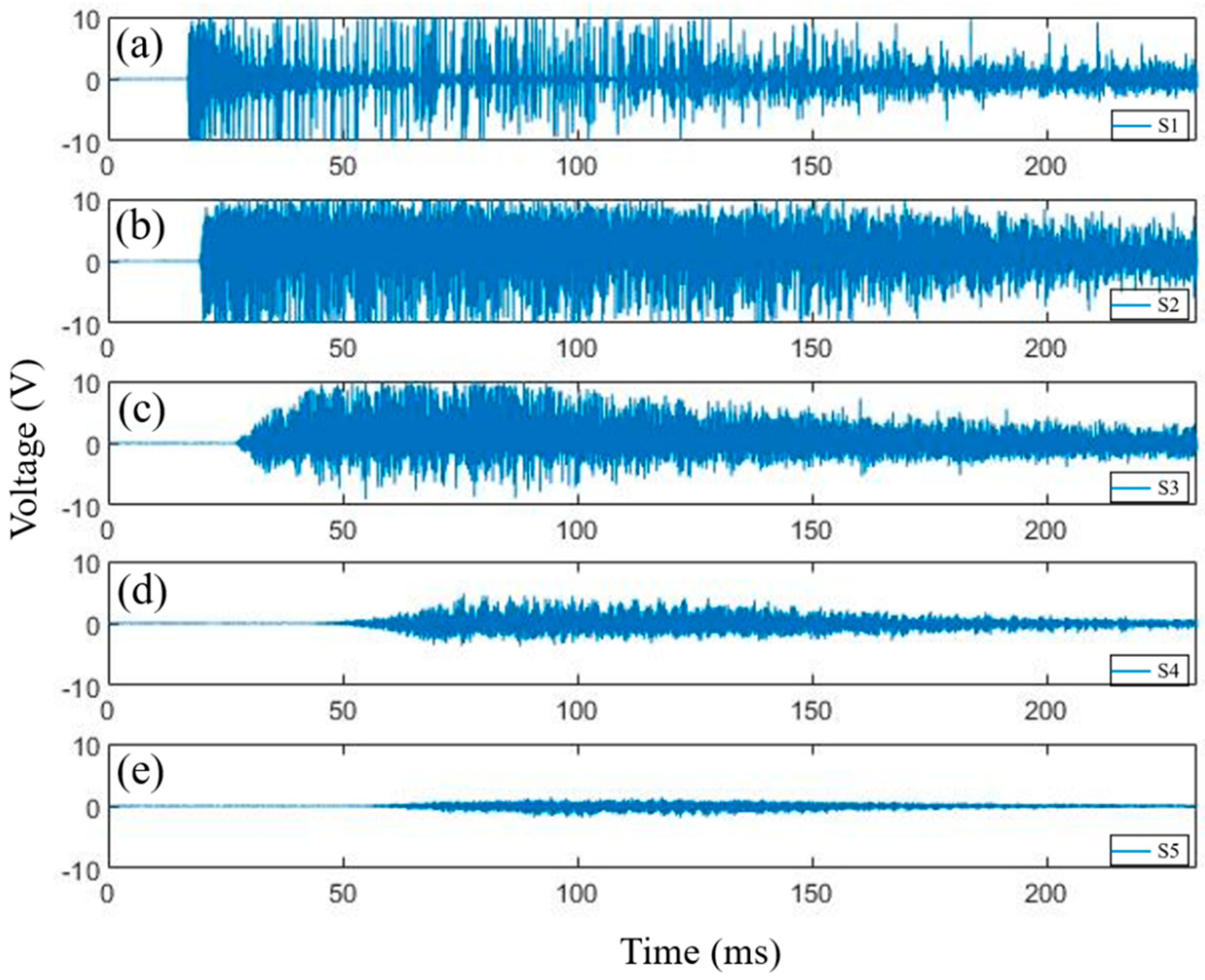

3.2.1. Feature Analysis of Strand Fracture Signals

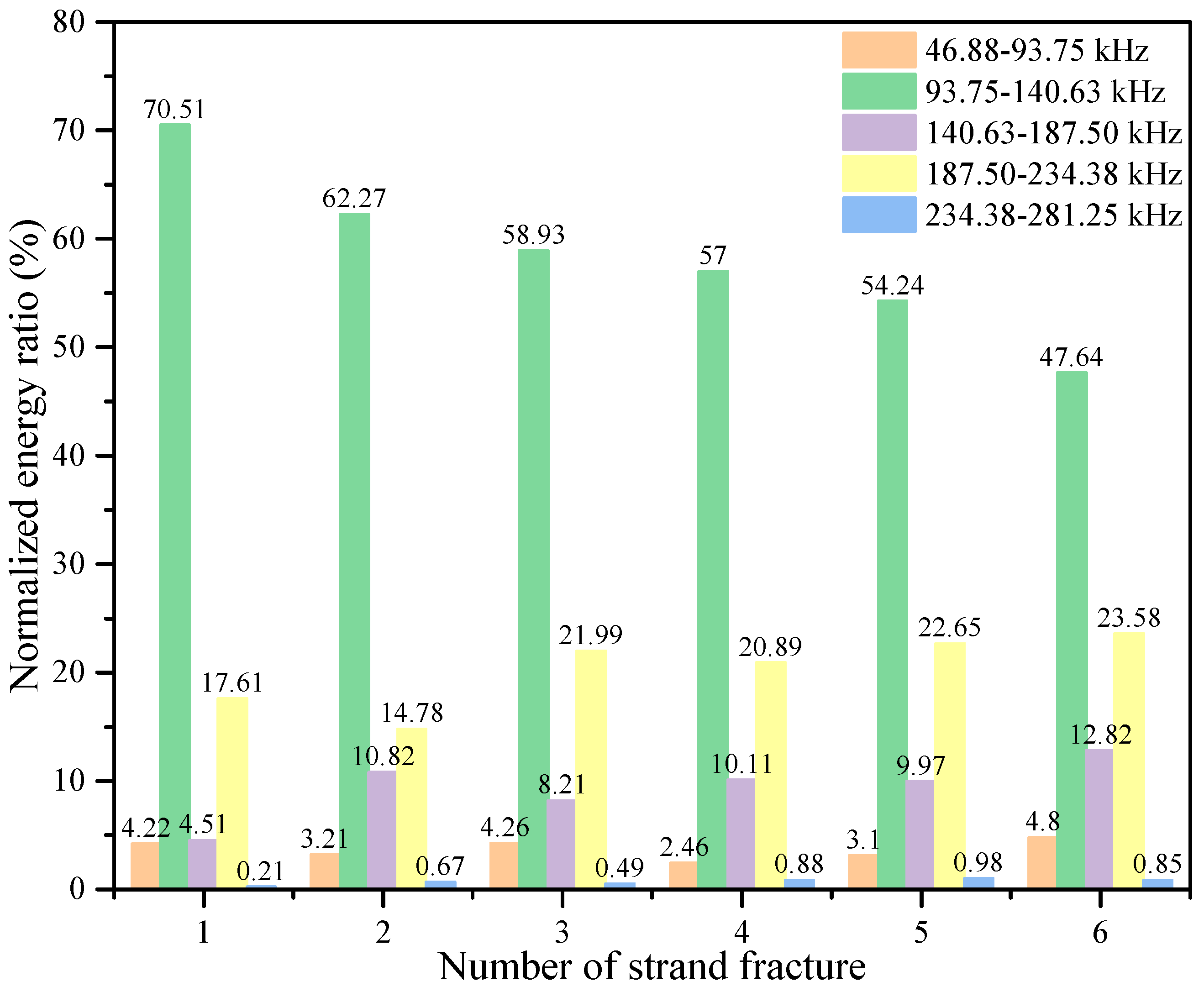

3.2.2. WPT Results

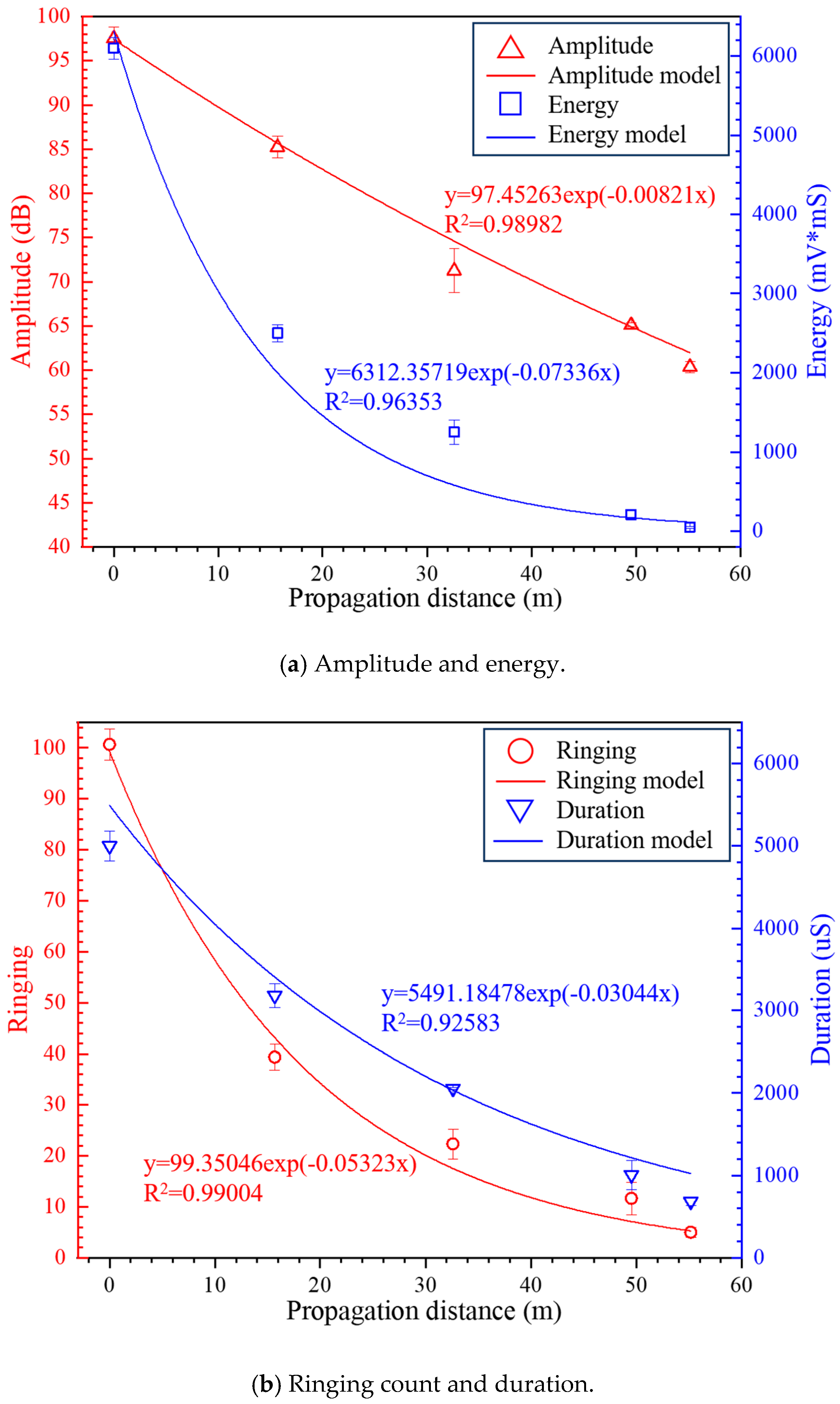

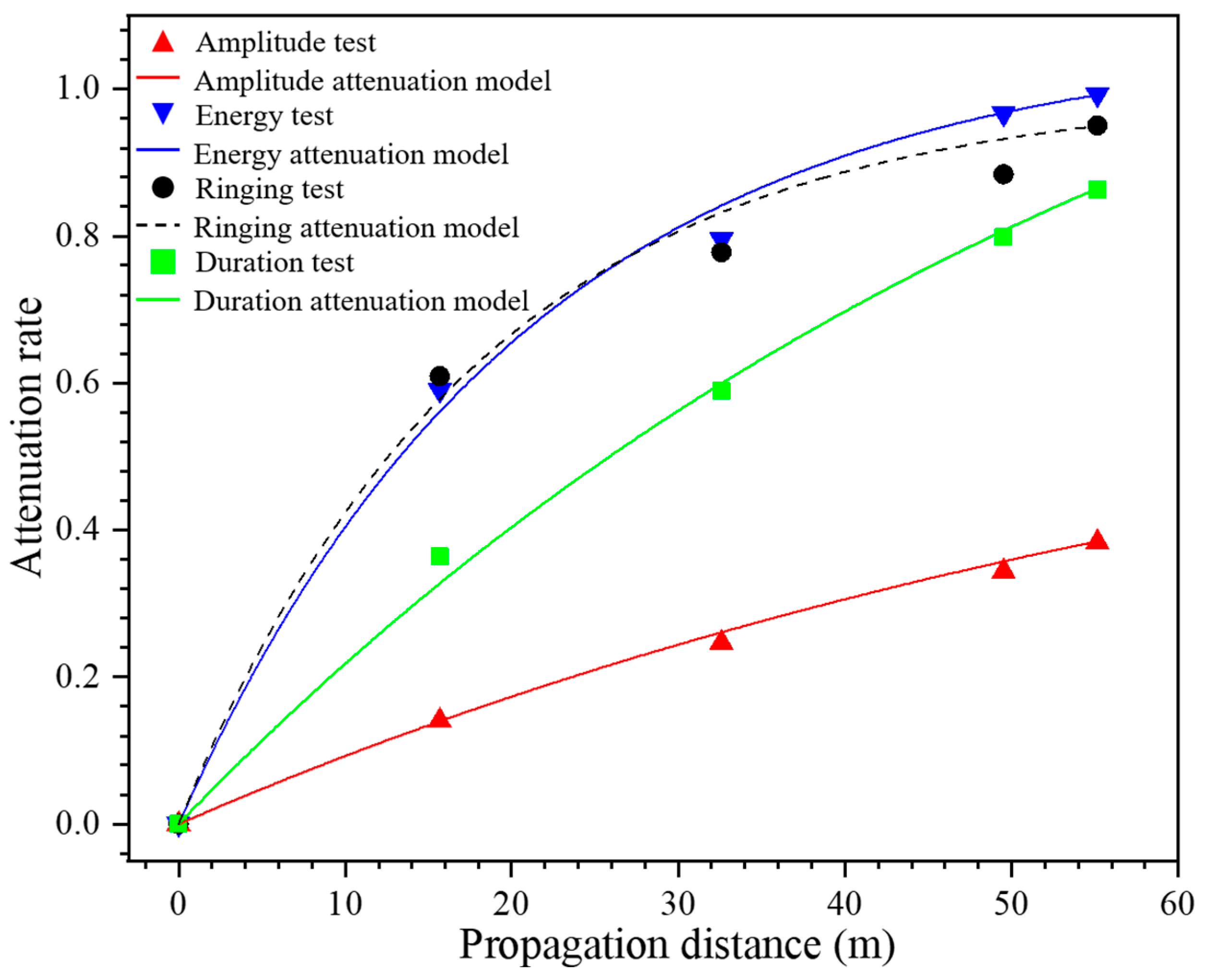

3.3. An Analysis of the Maximum Monitoring Distance for Identifying the Number of Strand Fractures

4. Conclusions

- The main frequency amplitude of AE signals is positively correlated with the number of strand fractures. Changes in the main frequency amplitude can serve as an effective criterion for identifying the number of broken wires and predicting the fracture state of the strand.

- The 93.75–140.63 kHz frequency band in a strand fracture signal contains the highest energy and is the most sensitive and critical frequency band for monitoring strand fractures. As the number of strand fractures increases, the energy distribution of the AE signals shifts towards higher-frequency bands.

- Amplitude is the optimal AE parameter for engineering monitoring of steel strand fractures. Compared to duration, energy, and ringing counts, amplitude exhibits the lowest and slowest decay rate during propagation, making it more effective for long-distance monitoring and well-suited for practical engineering applications.

- An attenuation curve model of AE signals based on actual strand fracture damage was established, with the farthest propagation distance of the AE signal calculated to be 103 m. This allows for the monitoring of strand fractures in bridge steel strands up to 23 series plates, meeting the monitoring requirements for most prestressed steel strand bridges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, H.; Yang, J.; Tang, R.; Yang, C.; Xu, F. Monitoring and Analysis of Prestress Loss in Prestressed Box Girder Bridges Strengthened with External Prestressing. Sensors 2024, 24, 4549. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Liu, D.; Chen, X.; Zhang, J. Experimental Study on Shear Performance of Bond-Tooth Dry Joints in Prestressed Assembled Concrete Beams. J. Build. Eng. 2023, 68, 106189. [Google Scholar] [CrossRef]

- Zhu, W.; Shen, Q.; Qin, H. Monitoring of Prestress and Bond Stress of Self-Sensing FBG Steel Strand. Measurement 2021, 177, 109246. [Google Scholar] [CrossRef]

- Campione, G.; Zizzo, M. Influence of Strands Corrosion on the Flexural Behavior of Prestressed Concrete Beams. Structures 2022, 45, 1366–1375. [Google Scholar] [CrossRef]

- Ahmed, M.; El-Sayed, A.K.; Alhozaimy, A.M.; Al-Negheimish, A.I.; Alabdulkarim, A. Prediction of Strand Corrosion Damage in Prestressed Concrete Beams through Visual Inspection of Corrosion Concrete Cracking. Constr. Build. Mater. 2024, 416, 135232. [Google Scholar] [CrossRef]

- Ward, D.B.; Dang, C.N.; Floyd, R.W.; Hale, W.M. Prestress Losses of Double-Tee Girders Cast with Lightweight Self-Consolidating Concrete. J. Build. Eng. 2016, 7, 133–142. [Google Scholar] [CrossRef]

- De Abreu, M.; Iordachescu, M.; Santos, P.; Valiente, A. Damage Tolerance and Collapse Mechanism of Failed Prestressing Steel Strands in a 50-Year-Old Urban Viaduct. Eng. Fail. Anal. 2024, 159, 108101. [Google Scholar] [CrossRef]

- Yuyama, S.; Yokoyama, K.; Niitani, K.; Ohtsu, M.; Uomoto, T. Detection and Evaluation of Failures in High-Strength Tendon of Prestressed Concrete Bridges by Acoustic Emission. Constr. Build. Mater. 2007, 21, 491–500. [Google Scholar] [CrossRef]

- Páez, P.M.; Sensale-Cozzano, B. Prestress Loss in Unbonded Prestressed Concrete Beams Based on the Strain Reduction Coefficient. Mater. Struct. 2024, 57, 167. [Google Scholar] [CrossRef]

- Saeedifar, M.; Zarouchas, D. Damage Characterization of Laminated Composites Using Acoustic Emission: A Review. Compos. Part B Eng. 2020, 195, 108039. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Machine-Learning-Based Methods for Acoustic Emission Testing: A Review. Appl. Sci. 2022, 12, 10476. [Google Scholar] [CrossRef]

- Gutkin, R. On Acoustic Emission for Failure Investigation in CFRP Pattern Recognition and Peak Frequency Analyses. Mech. Syst. Signal Process. 2011, 25, 1393–1407. [Google Scholar] [CrossRef]

- Mangual, J.; ElBatanouny, M.; Ziehl, P.; Matta, F. Corrosion Damage Quantification of Prestressing Strands Using Acoustic Emission. J. Mater. Civ. Eng. 2013, 25, 1326–1334. [Google Scholar] [CrossRef]

- Saha, I.; Vidya Sagar, R. Classification of the Acoustic Emissions Generated during the Tensile Fracture Process in Steel Fibre Reinforced Concrete Using a Waveform-Based Clustering Method. Constr. Build. Mater. 2021, 294, 123541. [Google Scholar] [CrossRef]

- Ashraf, S.; Rucka, M. Comparative Study on Fracture Evolution in Steel Fibre and Bar Reinforced Concrete Beams Using Acoustic Emission and Digital Image Correlation Techniques. Case Stud. Constr. Mater. 2024, 20, e03359. [Google Scholar] [CrossRef]

- Guo, R.; Zhang, X.; Lin, X.; Huang, S. Active and Passive Monitoring of Corrosion State of Reinforced Concrete Based on Embedded Cement-Based Acoustic Emission Sensor. J. Build. Eng. 2024, 89, 109276. [Google Scholar] [CrossRef]

- Zhao, S.; Li, G.; Wang, C. Bridge Cable Damage Identification Based on Acoustic Emission Technology: A Comprehensive Review. Measurement 2024, 237, 115195. [Google Scholar] [CrossRef]

- Tayfur, S.; Zhang, T.; Mahdi, M.; Issa, M.; Ozevin, D. Cluster-Based Sensor Selection Framework for Acoustic Emission Source Localization in Concrete. Measurement 2023, 219, 113293. [Google Scholar] [CrossRef]

- Liu, X.; Du, P.; Xue, S.; Ma, Y.; Wang, H.; Li, W.; Zhang, P. Study on Spectral Statistical Characteristics of Acoustic Emission Signals from the Leakage of Buried Gas Pipelines. Energy 2025, 320, 135068. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Yu, Y.; Qin, R.; Wang, J.; Zhang, S.; Su, Y.; Wen, G.; Cheng, W.; Chen, X. Microleakage Acoustic Emission Monitoring of Pipeline Weld Cracks under Complex Noise Interference: A Feasible Framework. J. Sound Vib. 2025, 604, 118980. [Google Scholar] [CrossRef]

- Goldaran, R.; Turer, A.; Kouhdaragh, M.; Ozlutas, K. Identification of Corrosion in a Prestressed Concrete Pipe Utilizing Acoustic Emission Technique. Constr. Build. Mater. 2020, 242, 118053. [Google Scholar] [CrossRef]

- Zhang, L.; Qiu, G.; Chen, Z. Structural Health Monitoring Methods of Cables in Cable-Stayed Bridge: A Review. Measurement 2021, 168, 108343. [Google Scholar] [CrossRef]

- Pirskawetz, S.M.; Schmidt, S. Detection of Wire Breaks in Prestressed Concrete Bridges by Acoustic Emission Analysis. Dev. Built Environ. 2023, 14, 100151. [Google Scholar] [CrossRef]

- Qu, H.; Li, T.; Cain, J.A.; Chen, G. Early Detection of Wire Fracture in 7-Wire Strands through Multiband Wavelet Analysis of Acoustic Emission Signals. Eng. Struct. 2020, 207, 110227. [Google Scholar] [CrossRef]

- Li, D.; Tan, M.; Zhang, S.; Ou, J. Stress Corrosion Damage Evolution Analysis and Mechanism Identification for Prestressed Steel Strands Using Acoustic Emission Technique. Struct. Control Health Monit. 2018, 25, e2189. [Google Scholar] [CrossRef]

- Thirumalaiselvi, A. Pattern Recognition Enabled Acoustic Emission Signatures for Crack Characterization during Damage Progression in Large Concrete Structures. Appl. Acoust. 2021, 175, 107797. [Google Scholar] [CrossRef]

- Aldahdooh, M.A.A.; Muhamad Bunnori, N. Crack Classification in Reinforced Concrete Beams with Varying Thicknesses by Mean of Acoustic Emission Signal Features. Constr. Build. Mater. 2013, 45, 282–288. [Google Scholar] [CrossRef]

- Li, S.-L.; Zhao, Y.-Q.; Kang, Z.-Z.; Wang, C. Acoustic Emission Technology-Based Waveguide Localization Method for Damaged Internal Tendons of in-Service Post-Tensioned Hollow Slab Bridges. Measurement 2024, 237, 114919. [Google Scholar] [CrossRef]

- Li, S.-L.; Feng, J.; Wang, T.-G.; Liu, B.; Wu, G.-M.; Kang, Z.-Z. Spatial Acoustic Emission Localization Method for Damage to Prestressed Steel Strands of Girders Using Special-Shaped Waveguide Rods. Measurement 2024, 235, 114951. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, H.; Tian, T.; Deng, D.; Hu, M.; Ma, J.; Gao, D.; Zhang, J.; Ma, S.; Yang, L.; et al. A Review on Guided-Ultrasonic-Wave-Based Structural Health Monitoring: From Fundamental Theory to Machine Learning Techniques. Ultrasonics 2023, 133, 107014. [Google Scholar] [CrossRef]

- Zima, B.; Kędra, R. Baseline-Free Debonding Detection in Reinforced Concrete Structures by Elastic Wave Propagation. Measurement 2021, 172, 108907. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, F.; Cao, Q.; Pan, H.; Wang, X.; Lin, Z. Deep Learning-Enriched Stress Level Identification of Pretensioned Rods via Guided Wave Approaches. Buildings 2022, 12, 1772. [Google Scholar] [CrossRef]

- Yu, H.; Lu, L.; Qiao, P. Localization and Size Quantification of Surface Crack of Concrete Based on Rayleigh Wave Attenuation Model. Constr. Build. Mater. 2021, 280, 122437. [Google Scholar] [CrossRef]

- Sause, M.G.R.; Horn, S. Quantification of the Uncertainty of Pattern Recognition Approaches Applied to Acoustic Emission Signals. J. Nondestruct. Eval. 2013, 32, 242–255. [Google Scholar] [CrossRef]

- Liu, G. Experimental Research on the Ultrasonic Attenuation Mechanism of Coal. J. Geophys. Eng. 2017, 14, 502–512. [Google Scholar] [CrossRef]

- Käding, M.; Marx, S. Acoustic Emission Monitoring in Prestressed Concrete: A Comparative Study of Signal Attenuation from Wire Breaks and Rebound Hammer Impulses. Appl. Sci. 2024, 14, 3045. [Google Scholar] [CrossRef]

- Li, F.; Huang, L.; Zhang, H.; Yang, T. Attenuation of Acoustic Emission Propagation along a Steel Strand Embedded in Concrete. KSCE J. Civ. Eng. 2018, 22, 222–230. [Google Scholar] [CrossRef]

- Hou, J.; Wang, C.; Li, S.; Jiang, N.; Xu, B.; Wu, G. Study on Propagation Mechanism and Attenuation Law of Acoustic Emission Waves for Damage of Prestressed Steel Strands. Measurement 2023, 219, 113240. [Google Scholar] [CrossRef]

- Li, S.; Chang, S.; Li, P.; Zhang, X.; Jiang, N. Optimization of Concrete Surface Sensor Arrangement for Acoustic Emission Monitoring of Prestressed Steel Strand Damage in T-Beams. Appl. Acoust. 2024, 223, 110082. [Google Scholar] [CrossRef]

- Yu, X.; Montrésor, S.; Bentahar, M.; Mechri, C. Cluster Analysis of Acoustic Emission Signals for the Damage Pattern Recognition of Polymer Concrete. Appl. Acoust. 2023, 211, 109533. [Google Scholar] [CrossRef]

- Xu, J.; Luo, X.; Qiu, X.; Hu, G. Wavelet and Fractal Analysis of Acoustic Emission Characteristic of Fatigue Damage of Asphalt Mixtures. Constr. Build. Mater. 2022, 349, 128643. [Google Scholar] [CrossRef]

- Zhao, G.; Luo, D.; Su, G.; Chen, B.; Huang, J. Experimental Research on the Evolutionary Characteristics of Acoustic Signals for Concrete Cracking under Uniaxial Compression. Appl. Acoust. 2022, 191, 108671. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, K.; Ren, H.; Ning, J. Quantitative Acoustic Emission Investigation on the Crack Evolution in Concrete Prisms by Frequency Analysis Based on Wavelet Packet Transform. Struct. Health Monit. 2022, 21, 1046–1060. [Google Scholar] [CrossRef]

- Wulan, T.; Li, G.; Huo, Y.; Zhao, F.; Yu, J.; Chang, J.; Yang, W.; Kou, Z. Study on the Meso-Damage Characteristics of RC Beam under Shear Failure Based on Acoustic Emission and Numerical Analysis. J. Build. Eng. 2024, 96, 110341. [Google Scholar] [CrossRef]

- Barile, C. Damage Characterization in Composite Materials Using Acoustic Emission Signal-Based and Parameter-Based Data. Compos. Part B 2019, 178, 107469. [Google Scholar] [CrossRef]

- Han, L. Feature Extraction Method of Bearing AE Signal Based on Improved FAST-ICA and Wavelet Packet Energy. Mech. Syst. Signal Process. 2015, 62–63, 91–99. [Google Scholar] [CrossRef]

- Qiao, S.; Zhou, W.; Liang, Y.; Liu, J.; Liu, S. Cluster Analysis on Damage Pattern Recognition in Carbon/Epoxy Composites Using Acoustic Emission Wavelet Packet. J. Reinf. Plast. Compos. 2022, 42, 1006–1021. [Google Scholar] [CrossRef]

| Test Condition | Condition 1 | Condition 2 | Condition 3 | Condition 4 |

|---|---|---|---|---|

| Loading Rate (mm/min) | 3 | 6 | 9 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, W.; Niu, S.; Liu, W.; Li, J.; Si, S.; Qi, X.; Li, S.; Jiang, N.; Chen, S.; Wu, G. Acoustic Emission Monitoring Method for Multi-Strand Fractures in Post-Tensioned Prestressed Hollow Core Slab Bridges Using Waveguide Rods. Buildings 2025, 15, 2576. https://doi.org/10.3390/buildings15142576

Yan W, Niu S, Liu W, Li J, Si S, Qi X, Li S, Jiang N, Chen S, Wu G. Acoustic Emission Monitoring Method for Multi-Strand Fractures in Post-Tensioned Prestressed Hollow Core Slab Bridges Using Waveguide Rods. Buildings. 2025; 15(14):2576. https://doi.org/10.3390/buildings15142576

Chicago/Turabian StyleYan, Wei, Shiwei Niu, Wei Liu, Juan Li, Shu Si, Xilong Qi, Shengli Li, Nan Jiang, Shuhan Chen, and Guangming Wu. 2025. "Acoustic Emission Monitoring Method for Multi-Strand Fractures in Post-Tensioned Prestressed Hollow Core Slab Bridges Using Waveguide Rods" Buildings 15, no. 14: 2576. https://doi.org/10.3390/buildings15142576

APA StyleYan, W., Niu, S., Liu, W., Li, J., Si, S., Qi, X., Li, S., Jiang, N., Chen, S., & Wu, G. (2025). Acoustic Emission Monitoring Method for Multi-Strand Fractures in Post-Tensioned Prestressed Hollow Core Slab Bridges Using Waveguide Rods. Buildings, 15(14), 2576. https://doi.org/10.3390/buildings15142576