Autonomous Earthwork Machinery for Urban Construction: A Review of Integrated Control, Fleet Coordination, and Safety Assurance

Abstract

1. Introduction

2. Materials and Methods

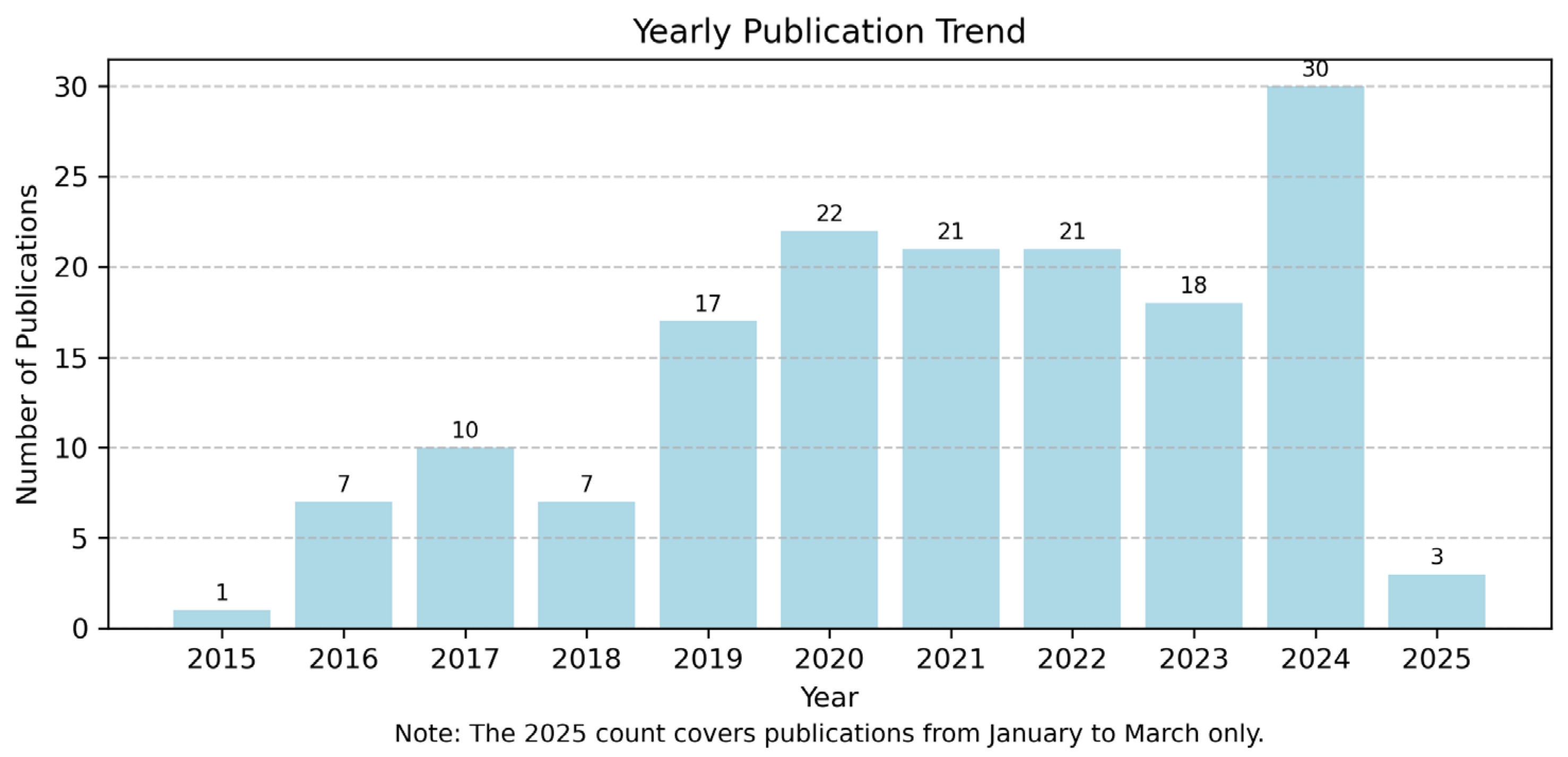

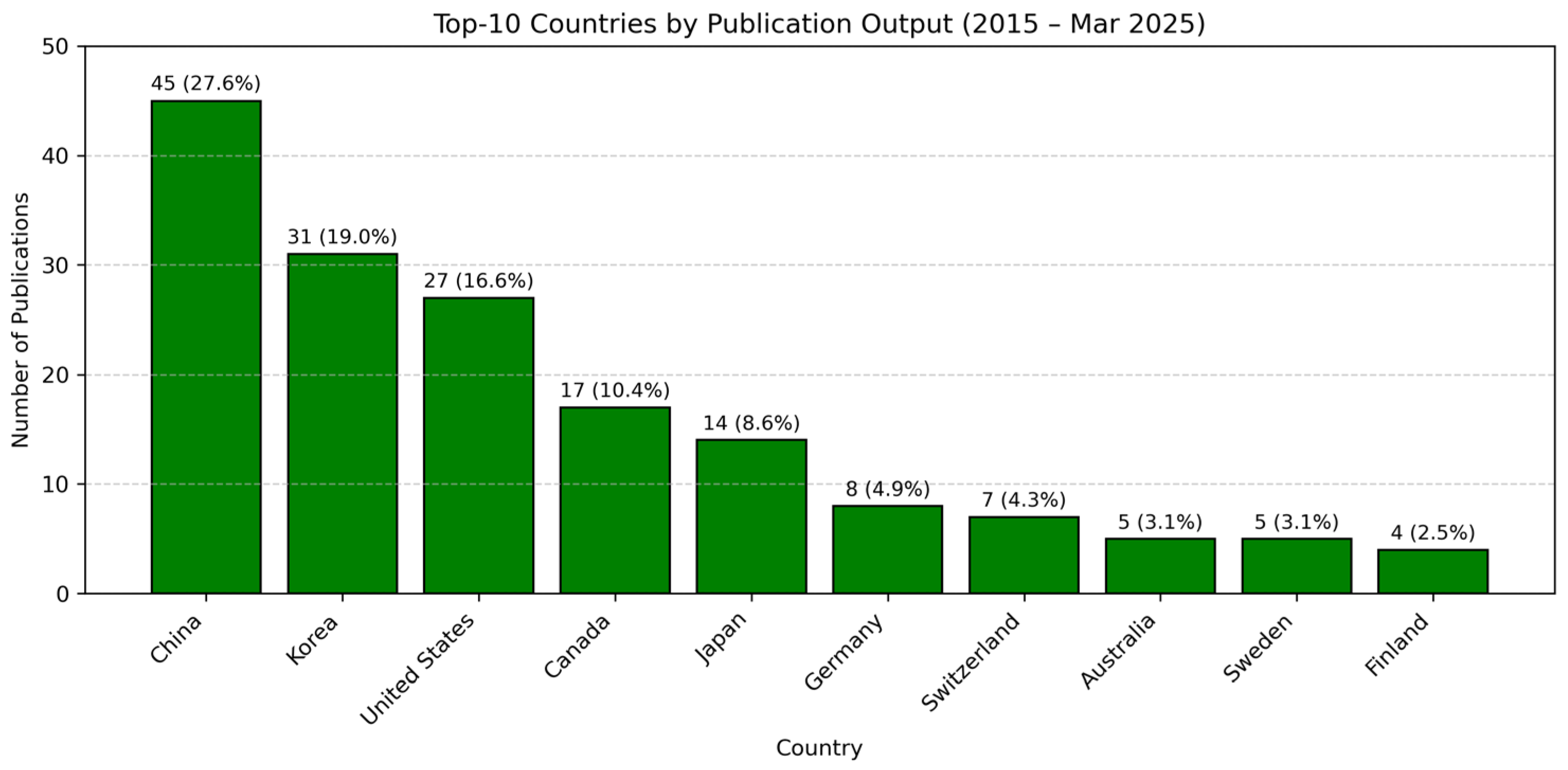

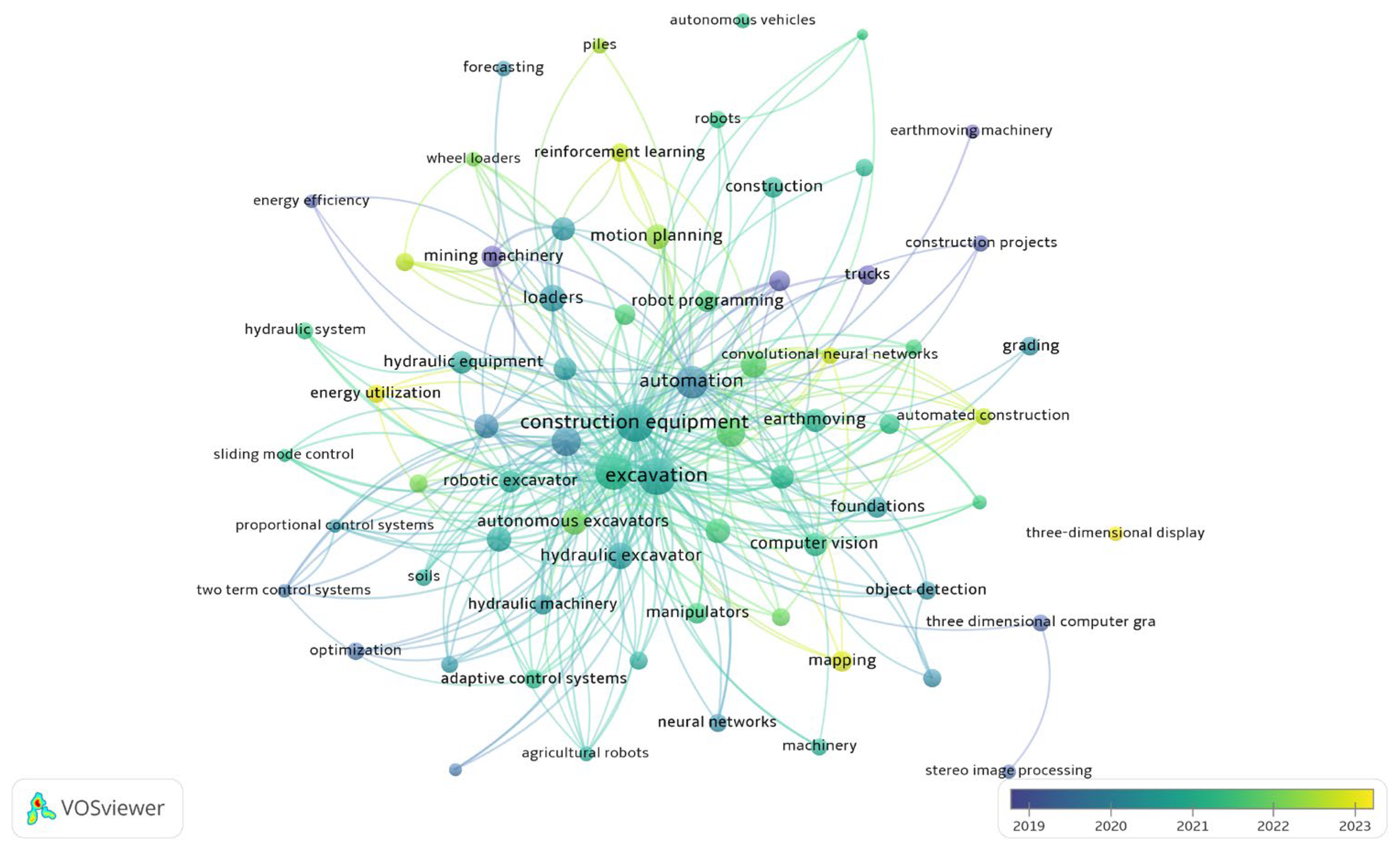

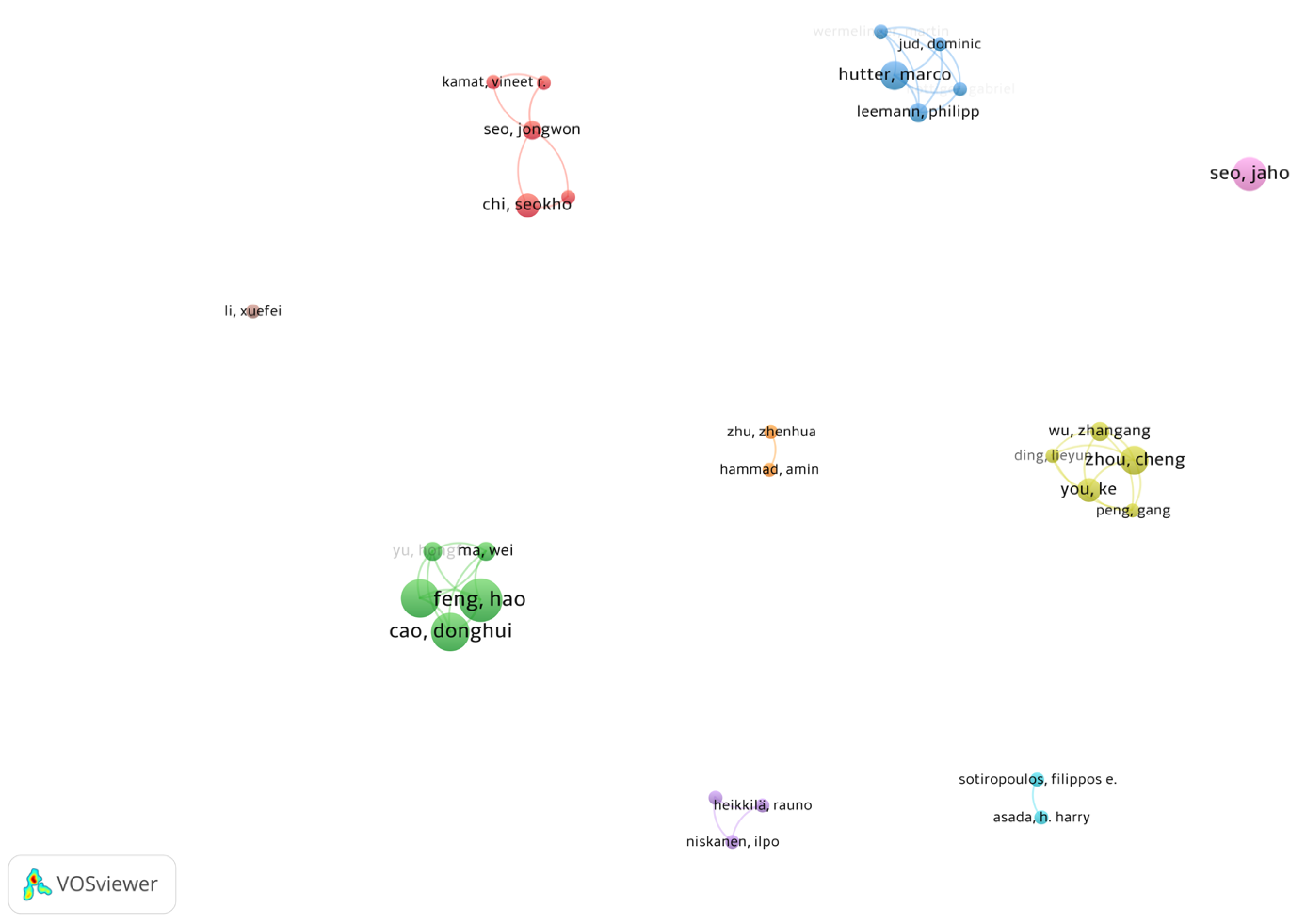

3. Bibliometric Analysis

4. Results and Discussion

- Autonomous Earthwork Machinery: This theme encompasses advances in environmental sensing and scene understanding. Representative keywords include deep learning; computer vision; simultaneous localization and mapping (SLAM); and light detection and ranging (LiDAR).

- Integrated Control Systems: Focusing on precise actuation and trajectory execution, this domain is reflected by keywords such as controllers; trajectories; sliding-mode control; model-predictive control; and adaptive control systems.

- Risk Mitigation Strategies: Covering methods to prevent, detect, and manage on-site hazards, this theme is signaled by keywords like collision-free trajectory planning; construction safety; active safety systems; and subsurface hazard detection.

- Fleet Interoperability: Addressing coordination among heterogeneous machines, this area is defined by terms such as unmanned aerial vehicles (UAV); unmanned ground vehicles (UGV); fleet operations; and multi-platform coordination.

4.1. Autonomous Earthwork Machinery

4.2. Integrated Control Systems

4.3. Risk Mitigation Strategies

4.4. Fleet Interoperability

5. Research Gaps, Opportunities, and Priority Directions

- Advanced perception and adaptive AI;

- Digital twins and integrated project management;

- Fleet collaboration and multi-machine autonomy;

- Safety assurance and regulatory frameworks;

- Human–automation collaboration and workforce adaptation.

5.1. Advanced Perception and Adaptive AI

5.2. Digital Twins and Integrated Project Management

5.3. Fleet Collaboration and Multi-Machine Autonomy

5.4. Safety Assurance and Regulatory Frameworks

5.5. Human–Automation Collaboration and Workforce Adaptation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nguyen, H.A.D.; Ha, Q.P. Robotic autonomous systems for earthmoving equipment operating in volatile conditions and teaming capacity: A survey. Robotica 2023, 41, 486–510. [Google Scholar] [CrossRef]

- Zhou, Z.; Abdi, E.; Chea, C.P.; Bai, Y. Global path planning for autonomous construction vehicles in building construction: A comparative study with a focus on vehicle kinematic characteristics. J. Build. Eng. 2024, 93, 109837. [Google Scholar] [CrossRef]

- Liu, J.; Liu, C.; Han, M.; Wan, Z.; Li, T.; Jia, X. Path planning algorithm for articulated loader based on bidirectional Dubins curve. Meas. Sci. Technol. 2025, 36, 026309. [Google Scholar] [CrossRef]

- Zhang, T.; Fu, T.; Ni, T.; Yue, H.; Wang, Y.; Song, X. Data-driven excavation trajectory planning for unmanned mining excavator. Autom. Constr. 2024, 162, 105395. [Google Scholar] [CrossRef]

- Choi, S.; Borchardt, J. Evolution of Automated & Autonomous Machines & Equipment in Construction: An Overview. In Proceedings of the 11th Annual World Conference of the Society for Industrial and Systems Engineering, Virtual, 6–7 October 2022. [Google Scholar]

- Shapira, A.; Lucko, G.; Schexnayder, C.J. Cranes for Building Construction Projects. J. Constr. Eng. Manag. 2007, 133, 690–700. [Google Scholar] [CrossRef]

- Rasul, A.; Seo, J.; Khajepour, A. Development of sensing algorithms for object tracking and predictive safety evaluation of autonomous excavators. Appl. Sci. 2021, 11, 6366. [Google Scholar] [CrossRef]

- Feng, H.; Yin, C.; Li, R.; Ma, W.; Yu, H.; Cao, D.; Zhou, J. Flexible virtual fixtures for human-excavator cooperative system. Autom. Constr. 2019, 106, 102897. [Google Scholar] [CrossRef]

- You, K.; Peng, G.; Ding, L.; Dou, Q.; Wu, Z.; Zhou, C. Smart T-box of unmanned earthwork machinery for Internet of Vehicles. Autom. Constr. 2022, 144, 104589. [Google Scholar] [CrossRef]

- Hiraoka, K.; Yamamoto, T.; Kozui, M.; Koiwai, K.; Yamashita, K. Design of a Database-Driven Assist Control for a Hydraulic Excavator Considering Human Operation. J. Rob. Mechatron. 2023, 35, 703–710. [Google Scholar] [CrossRef]

- Guo, D.H.; Wang, X.X.; Zhang, X.X.; Duan, X.F. Control System Design for Accurate Operation of Auxiliary Excavator Clusters. Appl. Math. Nonlinear Sci. 2024, 9, 1–12. [Google Scholar] [CrossRef]

- Arruda, H.; Silva, E.R.; Lessa, M.; Proença, D., Jr.; Bartholo, R. VOSviewer and bibliometrix. J. Med. Libr. Assoc. JMLA 2022, 110, 392. [Google Scholar] [CrossRef]

- Orduña-Malea, E.; Costas, R. Link-based approach to study scientific software usage: The case of VOSviewer. Scientometrics 2021, 126, 8153–8186. [Google Scholar] [CrossRef]

- Chen, J.; Zaïane, O.R.; Goebel, R. Detecting communities in social networks using max-min modularity. In Proceedings of the 2009 SIAM International Conference on Data Mining, Sparks, NV, USA, 30 April–2 May 2009; pp. 978–989. [Google Scholar]

- Feng, H.; Yin, C.B.; Weng, W.W.; Ma, W.; Zhou, J.J.; Jia, W.H.; Zhang, Z.L. Robotic excavator trajectory control using an improved GA based PID controller. Mech. Syst. Signal Process. 2018, 105, 153–168. [Google Scholar] [CrossRef]

- Feng, H.; Qiao, W.; Yin, C.; Yu, H.; Cao, D. Identification and compensation of non-linear friction for a electro-hydraulic system. Mech. Mach. Theory 2019, 141, 1–13. [Google Scholar] [CrossRef]

- Feng, H.; Yin, C.; Ma, W.; Yu, H.; Cao, D. Parameters identification and trajectory control for a hydraulic system. ISA Trans. 2019, 92, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Song, Q.; Ma, S.; Ma, W.; Yin, C.; Cao, D.; Yu, H. A new adaptive sliding mode controller based on the RBF neural network for an electro-hydraulic servo system. ISA Trans. 2022, 129, 472–484. [Google Scholar] [CrossRef]

- Feng, H.; Song, Q.; Yin, C.; Cao, D. Adaptive Impedance Control Method for Dynamic Contact Force Tracking of Robotic Excavators. J. Constr. Eng. Manag. 2022, 148, 04022124. [Google Scholar] [CrossRef]

- Feng, H.; Jiang, J.; Ding, N.; Shen, F.; Yin, C.; Cao, D.; Li, C.; Liu, T.; Xie, J. Multi-objective time-energy-impact optimization for robotic excavator trajectory planning. Autom. Constr. 2023, 156, 105094. [Google Scholar] [CrossRef]

- Feng, H.; Yin, C.; Cao, D. Trajectory Tracking of an Electro-Hydraulic Servo System With an New Friction Model-Based Compensation. IEEE ASME Trans. Mechatron. 2023, 28, 473–482. [Google Scholar] [CrossRef]

- Feng, H.; Chang, X.; Jiang, J.; Yin, C.; Cao, D.; Li, C.; Xie, J. Friction compensation control method for a typical excavator system based on the accurate friction model. Expert Sys. Appl. 2024, 254, 124494. [Google Scholar] [CrossRef]

- Jud, D.; Hottiger, G.; Leemann, P.; Hutter, M. Planning and Control for Autonomous Excavation. IEEE Robot. Autom. 2017, 2, 2151–2158. [Google Scholar] [CrossRef]

- Jud, D.; Leemann, P.; Kerscher, S.; Hutter, M. Autonomous free-form trenching using a walking excavator. IEEE Robot. Autom. 2019, 4, 3208–3215. [Google Scholar] [CrossRef]

- Jud, D.; Kerscher, S.; Wermelinger, M.; Jelavic, E.; Egli, P.; Leemann, P.; Hottiger, G.; Hutter, M. HEAP—The autonomous walking excavator. Autom. Constr. 2021, 129, 103783. [Google Scholar] [CrossRef]

- Aghimien, D.O.; Aigbavboa, C.O.; Oke, A.E.; Thwala, W.D. Mapping out research focus for robotics and automation research in construction-related studies: A bibliometric approach. J. Eng. Des. Technol. 2020, 18, 1063–1079. [Google Scholar] [CrossRef]

- Azar, E.R.; Kamat, V.R. Earthmoving equipment automation: A review of technical advances and future outlook. J. Inf. Technol. Constr. 2017, 22, 247–265. [Google Scholar]

- Dadhich, S.; Bodin, U.; Andersson, U. Key challenges in automation of earth-moving machines. Autom. Constr. 2016, 68, 212–222. [Google Scholar] [CrossRef]

- Zhao, Q.; Gao, L.; Wu, D.; Meng, X.; Qi, J.; Hu, J. E-GTN: Advanced Terrain Sensing Framework for Enhancing Intelligent Decision Making of Excavators. Appl. Sci. 2024, 14, 6974. [Google Scholar] [CrossRef]

- Zhang, B.; Hu, J.; Yang, T.; Chen, Y.; Hong, H. Enhanced Motion Estimation for Autonomous Excavation: Accelerated Semantic Segmentation and ORB Features for Unstructured Environments. IEEE Access 2024, 12, 157516–157530. [Google Scholar] [CrossRef]

- Helian, B.; Huang, X.; Yang, M.; Bian, Y.; Geimer, M. Computer vision-based excavator bucket fill estimation using depth map and faster R-CNN. Autom. Constr. 2024, 166, 105592. [Google Scholar] [CrossRef]

- Zou, Z.; Chen, J.; Pang, X. Task space-based dynamic trajectory planning for digging process of a hydraulic excavator with the integration of soil–bucket interaction. Proc. Inst. Mech. Eng. Part K J. Multi-body Dyn. 2019, 233, 598–616. [Google Scholar] [CrossRef]

- Li, R.; Zhou, C.; Dou, Q.; Hu, B. Complete coverage path planning and performance factor analysis for autonomous bulldozer. J. Field. Rob. 2022, 39, 1014–1034. [Google Scholar] [CrossRef]

- Miron, Y.; Goldfracht, Y.; Ross, C.; Castro, D.D.; Klein, I. Autonomous Dozer Sand Grading Under Localization Uncertainties. IEEE Robot. Autom. 2023, 8, 65–72. [Google Scholar] [CrossRef]

- Hutter, M.; Leemann, P.; Hottiger, G.; Figi, R.; Tagmann, S.; Rey, G.; Small, G. Force Control for Active Chassis Balancing. IEEE ASME Trans. Mechatron. 2017, 22, 613–622. [Google Scholar] [CrossRef]

- Eraliev, O.M.U.; Lee, K.H.; Shin, D.Y.; Lee, C.H. Sensing, perception, decision, planning and action of autonomous excavators. Autom. Constr. 2022, 141, 104428. [Google Scholar] [CrossRef]

- Dong, H.Q.; Gam, N.T.; Cuong, H.M.; Tuan, L.A. Fractional-order fast terminal back-stepping sliding mode control of autonomous robotic excavators. J. Frankl. Inst. 2024, 361, 106686. [Google Scholar] [CrossRef]

- Rigotti-Thompson, M.; Torres-Torriti, M.; Auat Cheein, F.A.; Troni, G. H∞-Based Terrain Disturbance Rejection for Hydraulically Actuated Mobile Manipulators with a Nonrigid Link. IEEE ASME Trans. Mechatron. 2020, 25, 2523–2533. [Google Scholar] [CrossRef]

- Bender, F.A.; Goltz, S.; Braunl, T.; Sawodny, O. Modeling and Offset-Free Model Predictive Control of a Hydraulic Mini Excavator. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1682–1694. [Google Scholar] [CrossRef]

- Sun, D.; Hwang, S.; Han, J. Lever Control for Position Control of a Typical Excavator in Joint Space Using a Time Delay Control Method. J. Intell. Robot. Syst. Theor. Appl. 2021, 102, 63. [Google Scholar] [CrossRef]

- Azulay, O.; Shapiro, A. Wheel Loader Scooping Controller Using Deep Reinforcement Learning. IEEE Access 2021, 9, 24145–24154. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Yu, Y.; Kong, L. Wearable insole pressure system for automated detection and classification of awkward working postures in construction workers. Autom. Constr. 2018, 96, 433–441. [Google Scholar] [CrossRef]

- Yajima, R.; Katsuma, S.; Suzuki, M.; Matsushita, F.; Hamasaki, S.; Chun, P.J.; Nagatani, K.; Yamauchi, G.; Hashimoto, T.; Yamashita, A.; et al. Development of an excavator-avoidance system for buried pipes. Adv. Rob. 2021, 35, 1468–1483. [Google Scholar] [CrossRef]

- You, K.; Zhou, C.; Ding, L.; Chen, W.; Zhang, R.; Xu, J.; Wu, Z.; Huang, C. Earthwork digital twin for teleoperation of an automated bulldozer in edge dumping. J. Field. Rob. 2023, 40, 1945–1963. [Google Scholar] [CrossRef]

- Ishikawa, K.; Harada, H.; Osaki, H.; Tsugawa, S.; Tachibana, S.; Fujisawa, H.; Terui, T.; Nakamura, K.; Inagawa, Y. Automatic Excavation System with Multiple Excavators in the Pneumatic Caisson Method. J. Rob. Mechatron. 2024, 36, 961–972. [Google Scholar] [CrossRef]

- Naghshbandi, S.N.; Varga, L.; Hu, Y. Technology capabilities for an automated and connected earthwork roadmap. Constr. Innov. 2022, 22, 768–788. [Google Scholar] [CrossRef]

- Xiao, B.; Kang, S.C. Vision-Based Method Integrating Deep Learning Detection for Tracking Multiple Construction Machines. J. Comput. Civ. Eng. 2021, 35, 04020071. [Google Scholar] [CrossRef]

- Kim, D. Soil Sharing and Equipment Operations Through Digitalization of Large-Scale Earthworks. Buildings 2024, 14, 3981. [Google Scholar] [CrossRef]

- Elmakis, O.; Shaked, T.; Degani, A. Vision-Based UAV-UGV Collaboration for Autonomous Construction Site Preparation. IEEE Access 2022, 10, 51209–51220. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, Z.; Lu, T.; Jiang, X. PMF-SLAM: Pose-Guided and Multiscale Feature Interaction-Based Semantic SLAM for Autonomous Wheel Loader. IEEE Sens. J. 2024, 24, 11625–11638. [Google Scholar] [CrossRef]

- Choros, K.A.; Job, A.T.; Edgar, M.L.; Austin, K.J.; McAree, P.R. Can Hyperspectral Imaging and Neural Network Classification be Used for Ore Grade Discrimination at the Point of Excavation? Sensors 2022, 22, 2687. [Google Scholar] [CrossRef]

- Fernando, H.; Marshall, J. What lies beneath: Material classification for autonomous excavators using proprioceptive force sensing and machine learning. Autom. Constr. 2020, 119, 103374. [Google Scholar] [CrossRef]

- Sardarmehni, T.; Song, X. Path Planning and Energy Optimization in Optimal Control of Autonomous Wheel Loaders Using Reinforcement Learning. IEEE Trans. Veh. Technol. 2023, 72, 9821–9834. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, J.; Feng, C.; Wang, Q. Hybrid-driven autonomous excavator trajectory generation combining empirical driver skills and optimization. Autom. Constr. 2024, 165, 105523. [Google Scholar] [CrossRef]

- Tsuzuki, R.; Hara, K.; Usui, D. Development of a Highly Efficient Trajectory Planning Algorithin Backfilling Task for Autonomous Excavators by Imitation of Experts and Numerical Optimization. J. Rob. Mechatron. 2024, 36, 263–272. [Google Scholar] [CrossRef]

- Park, S.; Kim, S. 3D Point Cloud Dataset of Heavy Construction Equipment. Appl. Sci. 2024, 14, 3599. [Google Scholar] [CrossRef]

- Lee, J.G.; Hwang, J.; Chi, S.; Seo, J. Synthetic Image Dataset Development for Vision-Based Construction Equipment Detection. J. Comput. Civ. Eng. 2022, 36, 04022020. [Google Scholar] [CrossRef]

- Nakamura, R.; Domae, M.; Morimoto, T.; Izumikawa, T.; Fujii, H. Dynamic Visualization of Construction Sites with Machine-Borne Sensors Toward Automated Earth Moving. J. Rob. Mechatron. 2024, 36, 294–308. [Google Scholar] [CrossRef]

- Hiltunen, M.; Heikkilä, R.; Niskanen, I.; Immonen, M. Open InfraBIM for remote and autonomous excavation. Autom. Constr. 2023, 156, 105148. [Google Scholar] [CrossRef]

- Liu, Z.; Kim, J.I.; Yoo, W.S. Decision support for railway track facility management using OpenBIM. Autom. Constr. 2024, 168, 105840. [Google Scholar] [CrossRef]

- Kim, J.; Chi, S. Multi-camera vision-based productivity monitoring of earthmoving operations. Autom. Constr. 2020, 112, 103121. [Google Scholar] [CrossRef]

- Bügler, M.; Borrmann, A.; Ogunmakin, G.; Vela, P.A.; Teizer, J. Fusion of Photogrammetry and Video Analysis for Productivity Assessment of Earthwork Processes. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 107–123. [Google Scholar] [CrossRef]

- Li, D.; Lu, M. Classical Planning Model-Based Approach to Automating Construction Planning on Earthwork Projects. Comput.-Aided Civ. Infrastruct. Eng. 2019, 34, 299–315. [Google Scholar] [CrossRef]

- Li, D.; Lu, M. Automated Generation of Work Breakdown Structure and Project Network Model for Earthworks Project Planning: A Flow Network-Based Optimization Approach. J. Constr. Eng. Manag. 2017, 143, 04016086. [Google Scholar] [CrossRef]

- El-Abbasy, M.S.; Elazouni, A.; Zayed, T. MOSCOPEA: Multi-objective construction scheduling optimization using elitist non-dominated sorting genetic algorithm. Autom. Constr. 2016, 71, 153–170. [Google Scholar] [CrossRef]

- Liu, Y.; You, K.; Jiang, Y.; Wu, Z.; Liu, Z.; Peng, G.; Zhou, C. Multi-objective optimal scheduling of automated construction equipment using non-dominated sorting genetic algorithm (NSGA-III). Autom. Constr. 2022, 143, 104587. [Google Scholar] [CrossRef]

- Alshibani, A.; Moselhi, O. Productivity based method for forecasting cost & time of earthmoving operations using sampling GPS data. J. Inf. Technol. Constr. 2016, 21, 39–56. [Google Scholar]

- Markiz, N.; Jrade, A. An expert system to optimize cost and schedule of heavy earthmoving operations for earth- and rock- filled dam projects. J. Civ. Eng. Manag. 2017, 23, 222–231. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, Z.; Hammad, A. Critical Review and Road Map of Automated Methods for Earthmoving Equipment Productivity Monitoring. J. Comput. Civ. Eng. 2022, 36, 03122001. [Google Scholar] [CrossRef]

- Rasul, A.; Seo, J.; Khajepour, A. Development of integrative methodologies for effective excavation progress monitoring. Sensors 2021, 21, 364. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Lee, S.S.; Seo, J.; Kamat, V.R. Modular data communication methods for a robotic excavator. Autom. Constr. 2018, 90, 166–177. [Google Scholar] [CrossRef]

- Kim, J.; Chi, S.; Seo, J. Interaction analysis for vision-based activity identification of earthmoving excavators and dump trucks. Autom. Constr. 2018, 87, 297–308. [Google Scholar] [CrossRef]

- Ansaripour, A.; Heydariaan, M.; Kim, K.; Gnawali, O.; Oyediran, H. ViPER+: Vehicle Pose Estimation Using Ultra-Wideband Radios for Automated Construction Safety Monitoring. Appl. Sci. 2023, 13, 1581. [Google Scholar] [CrossRef]

- Khiyavi, O.A.; Seo, J.; Lin, X. Three-Dimensional Metal Pipe Detection for Autonomous Excavators Using Inexpensive Magnetometer Sensors. IEEE Sens. J. 2023, 23, 24383–24392. [Google Scholar] [CrossRef]

- Tiusanen, R.; Malm, T.; Ronkainen, A. An overview of current safety requirements for autonomous machines—Review of standards. Open Eng. 2020, 10, 665–673. [Google Scholar] [CrossRef]

- Wickberg, P.; Fattouh, A.; Afshar, S.; Bohlin, M. Exploring Dynamic Map Validation at Construction Sites: A Case Study and Feasibility Analysis. In Proceedings of the 2024 IEEE 27th International Conference on Intelligent Transportation Systems (ITSC), Edmonton, AB, Canada, 24–27 September 2024; pp. 3865–3871. [Google Scholar]

- Seo, M.; Gupta, S.; Ham, Y. Exploratory study on time-delayed excavator teleoperation in virtual lunar construction simulation: Task performance and operator behavior. Autom. Constr. 2024, 168, 105871. [Google Scholar] [CrossRef]

- Jin, Z.; Pagilla, P.R. Shared Control with Efficient Subgoal Identification and Adjustment for Human-Robot Collaborative Tasks. IEEE Trans. Control Syst. Technol 2022, 30, 326–335. [Google Scholar] [CrossRef]

- Wang, X.; Veeramani, D.; Zhu, Z. Gaze-aware hand gesture recognition for intelligent construction. Eng. Appl. Artif. Intell. 2023, 123, 106179. [Google Scholar] [CrossRef]

- Dadhich, S.; Bodin, U.; Sandin, F.; Andersson, U. From tele-remote operation to semi-automated wheel-loader. Int. J. Electr. Electron. Eng. Telecommun. 2018, 7, 178–182. [Google Scholar] [CrossRef][Green Version]

- Melenbrink, N.; Werfel, J.; Menges, A. On-site autonomous construction robots: Towards unsupervised building. Autom. Constr. 2020, 119, 103312. [Google Scholar] [CrossRef]

| Search String |

|---|

| TITLE-ABS-KEY ((((autonomous OR automated OR robotic) AND (excavator * OR dozer * OR loader * OR earthwork OR “heavy machinery” OR “construction equipment”)) OR (“integrated control system” OR “machine control” OR “fleet management system” OR “fleet interoperability” OR “multi-machine coordination”)) AND (construction OR “civil engineering”)) OR TITLE-ABS-KEY(((“risk assessment” OR “risk mitigation” OR “safety standard” OR “safety protocol”) AND (autonomous OR automated OR robotic OR “integrated control system” OR “machine control” OR “fleet management” OR “fleet interoperability”)) AND (construction OR earthwork)) AND PUBYEAR > 2014 AND PUBYEAR < 2026 AND (LIMIT-TO (SRCTYPE, “j”)) AND (LIMIT-TO (DOCTYPE, “ar”) OR LIMIT-TO (DOCTYPE, “re”)) AND (LIMIT-TO (LANGUAGE, “English”)) AND (LIMIT-TO (SUBJAREA, “ENGI”)) |

| Index Keyword | Frequency |

|---|---|

| Construction equipment | 109 |

| Excavation | 91 |

| Excavators | 82 |

| Automation | 28 |

| Robotics | 28 |

| Deep learning | 21 |

| Loaders | 21 |

| Construction industry | 20 |

| Hydraulic excavator | 19 |

| Wheels | 18 |

| Controllers | 18 |

| Autonomous excavators | 17 |

| Construction sites | 17 |

| Robotic excavator | 16 |

| Trajectories | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Kim, J.I. Autonomous Earthwork Machinery for Urban Construction: A Review of Integrated Control, Fleet Coordination, and Safety Assurance. Buildings 2025, 15, 2570. https://doi.org/10.3390/buildings15142570

Liu Z, Kim JI. Autonomous Earthwork Machinery for Urban Construction: A Review of Integrated Control, Fleet Coordination, and Safety Assurance. Buildings. 2025; 15(14):2570. https://doi.org/10.3390/buildings15142570

Chicago/Turabian StyleLiu, Zeru, and Jung In Kim. 2025. "Autonomous Earthwork Machinery for Urban Construction: A Review of Integrated Control, Fleet Coordination, and Safety Assurance" Buildings 15, no. 14: 2570. https://doi.org/10.3390/buildings15142570

APA StyleLiu, Z., & Kim, J. I. (2025). Autonomous Earthwork Machinery for Urban Construction: A Review of Integrated Control, Fleet Coordination, and Safety Assurance. Buildings, 15(14), 2570. https://doi.org/10.3390/buildings15142570