Ultrasonic Pulse Velocity for Real-Time Filament Quality Monitoring in 3D Concrete Printing Construction

Abstract

1. Introduction

1.1. Background

1.1.1. Shear Vane Test

1.1.2. Rotational Rheometer Test

1.1.3. Ultrasonic Pulse Velocity Test

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Designs

2.3. Mix Preparation

2.4. Experiments

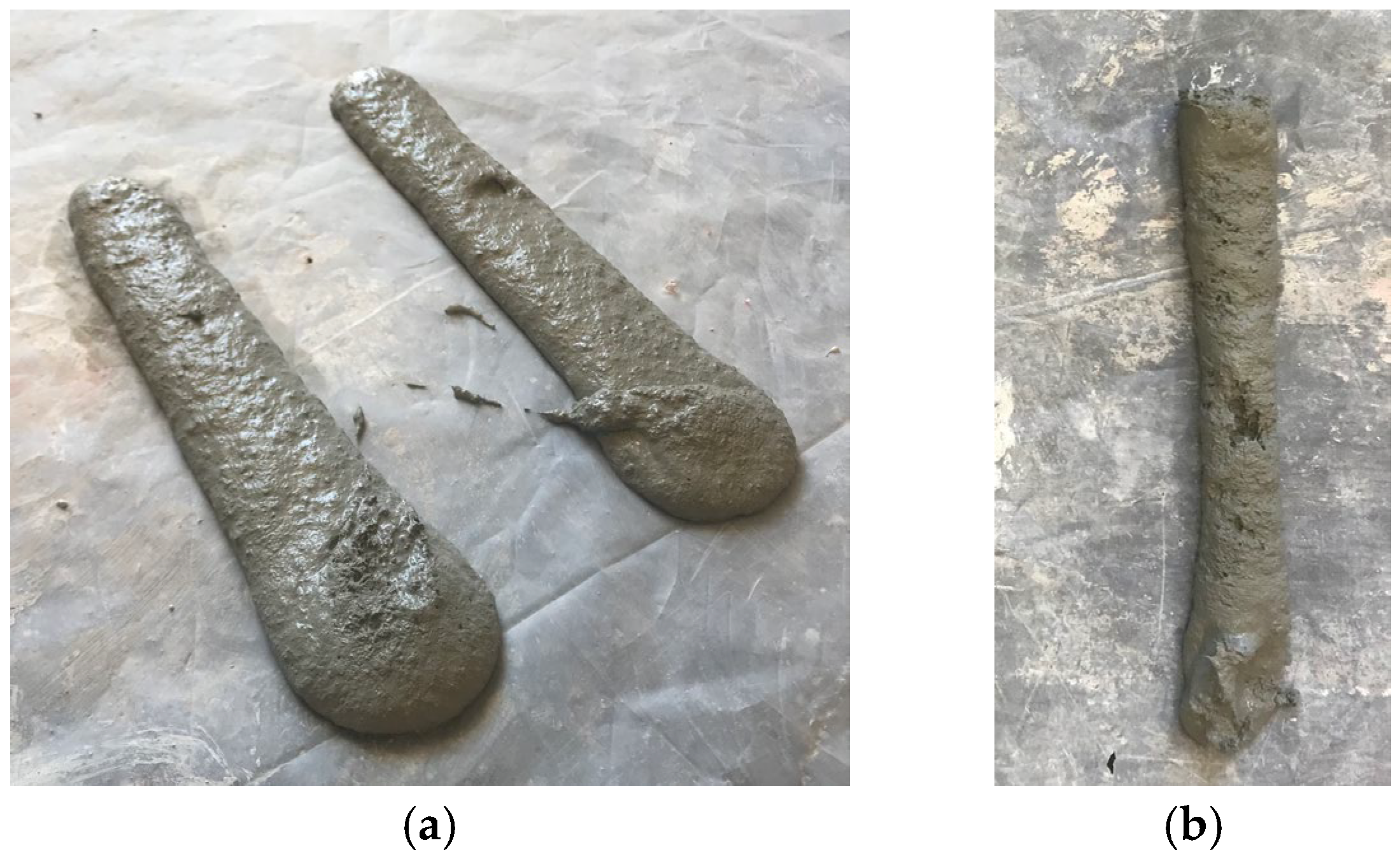

2.4.1. Extrudability Test

2.4.2. Pocket Hand Vane Test

2.4.3. Rotational Viscometer Test

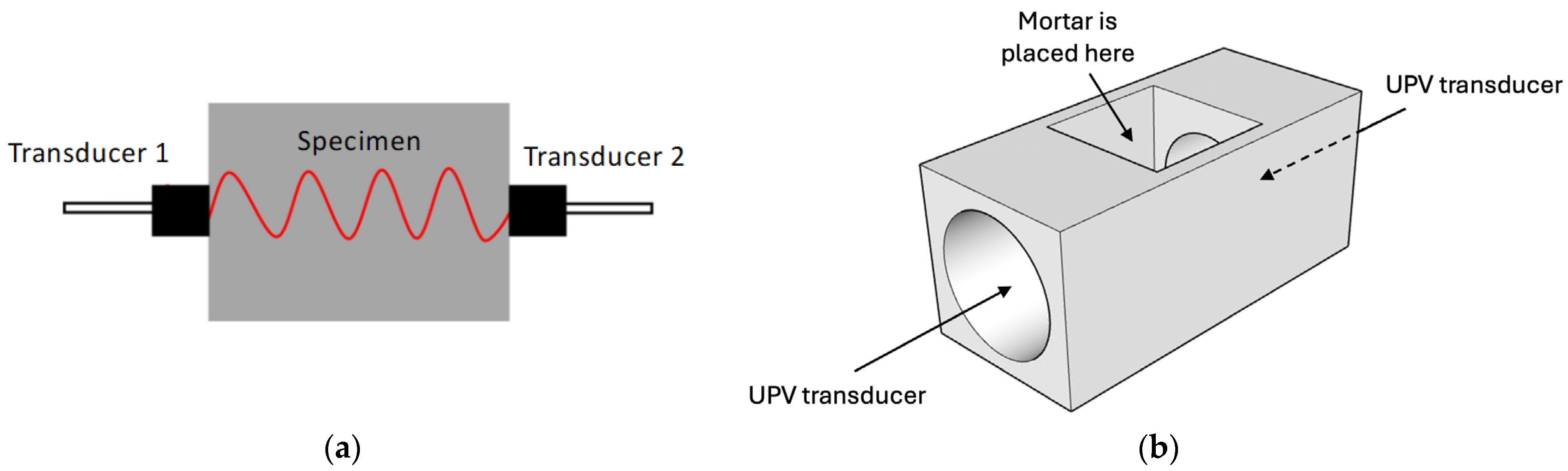

2.4.4. Ultrasonic Pulse Velocity Test

2.4.5. Particle Size Distribution

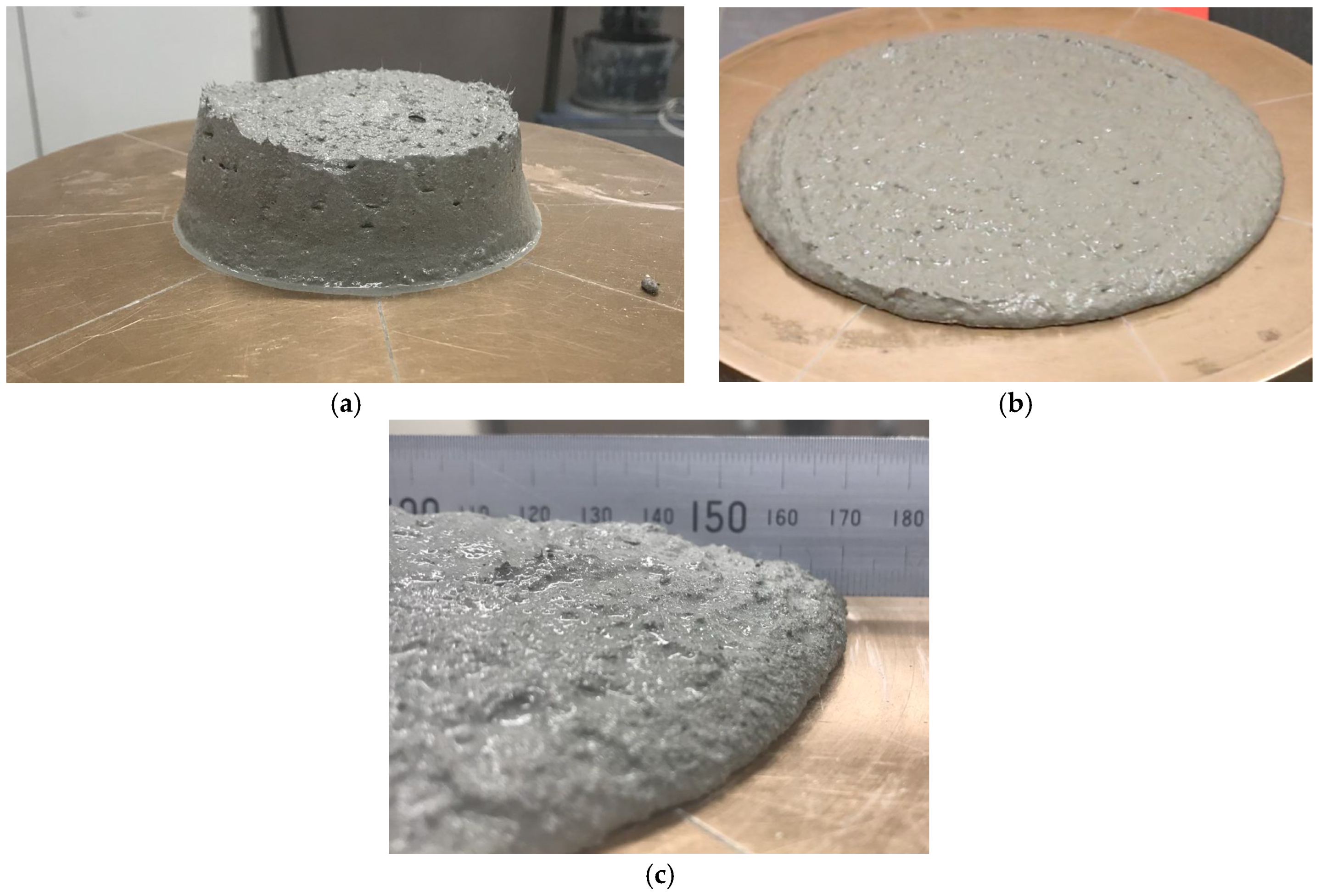

2.4.6. Flow Table Test

2.4.7. Isothermal Calorimetry and Reactivity Test

3. Results and Discussion

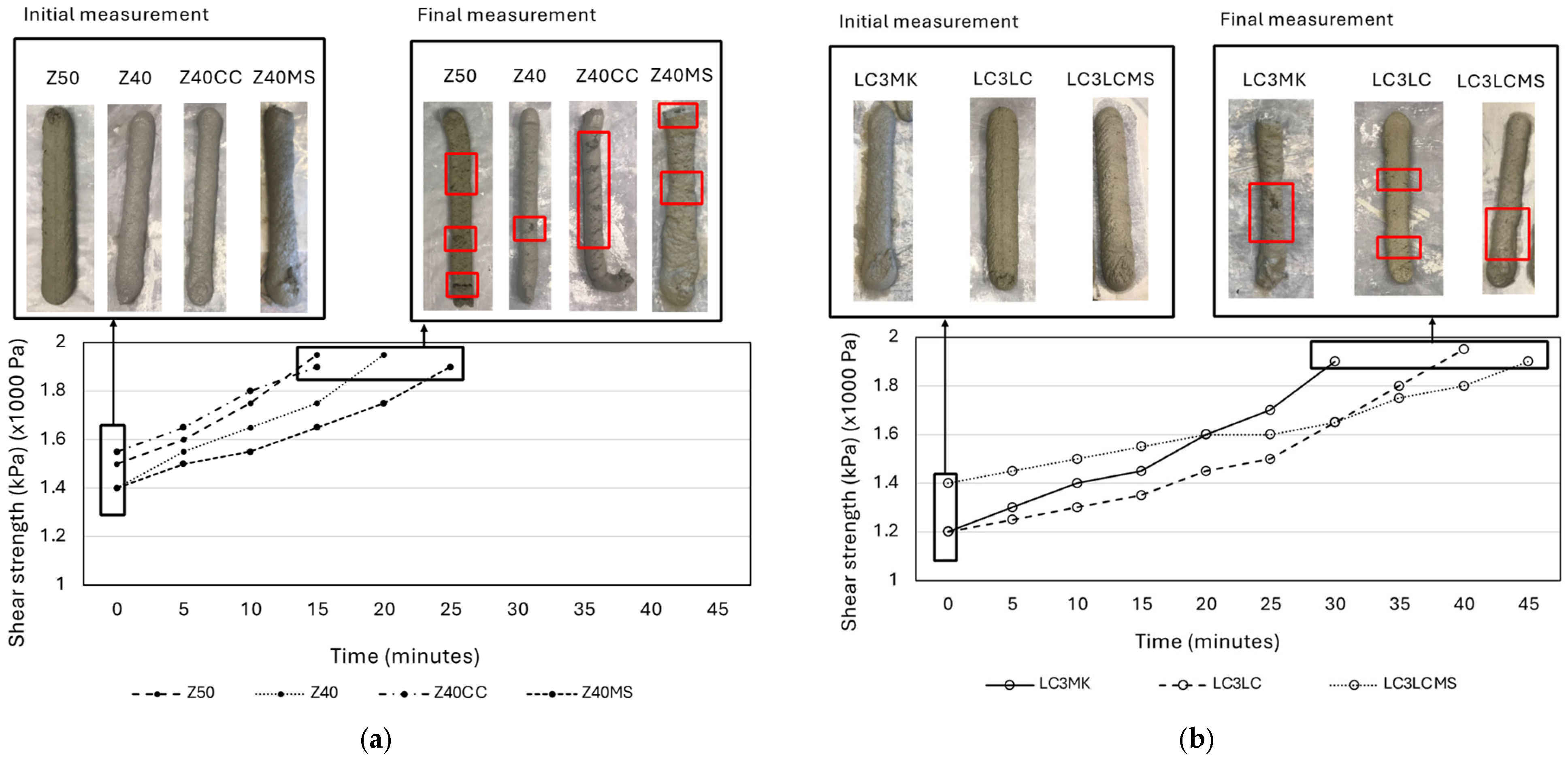

3.1. Shear Vane Test

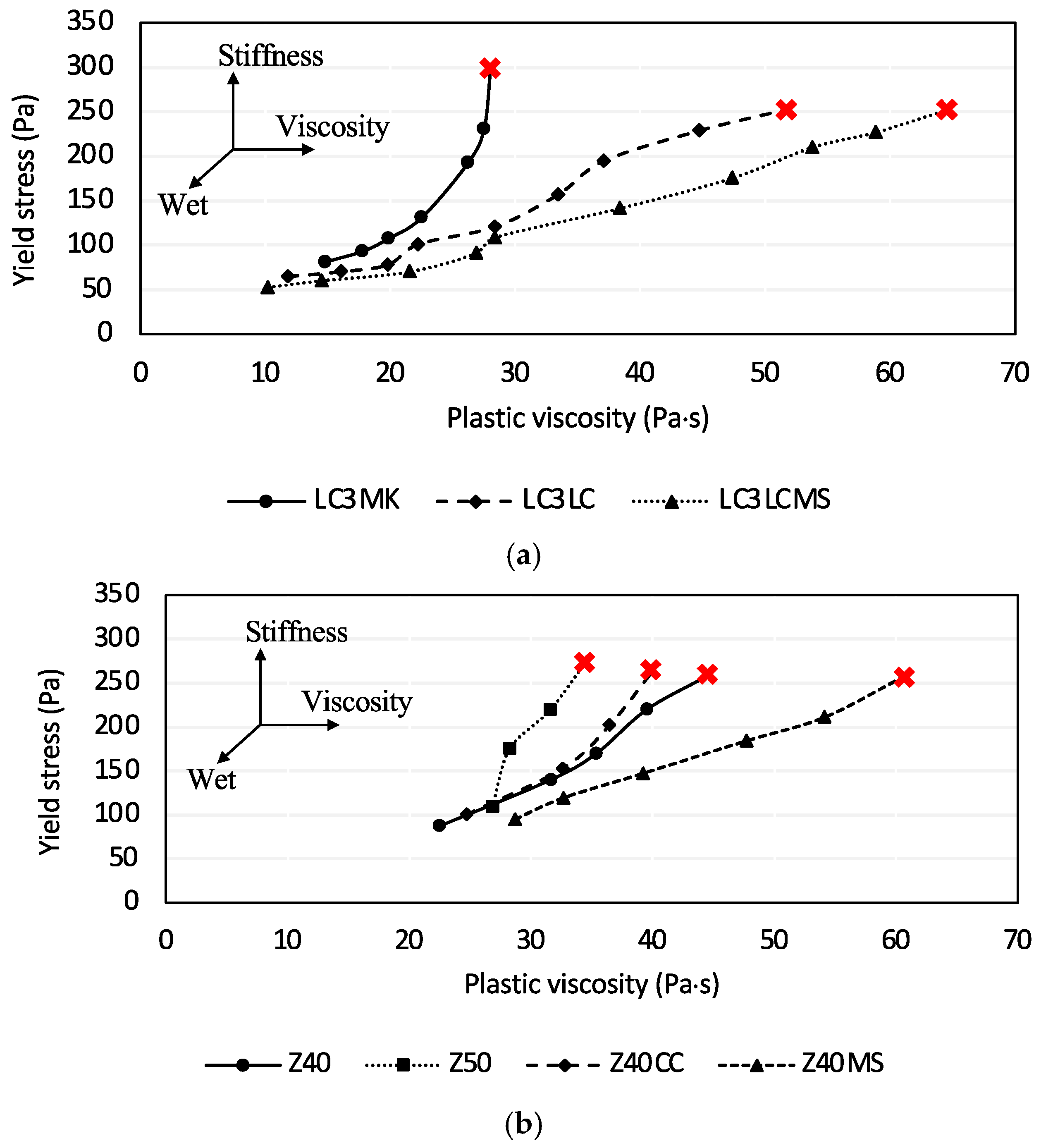

3.2. Rotational Rheometer

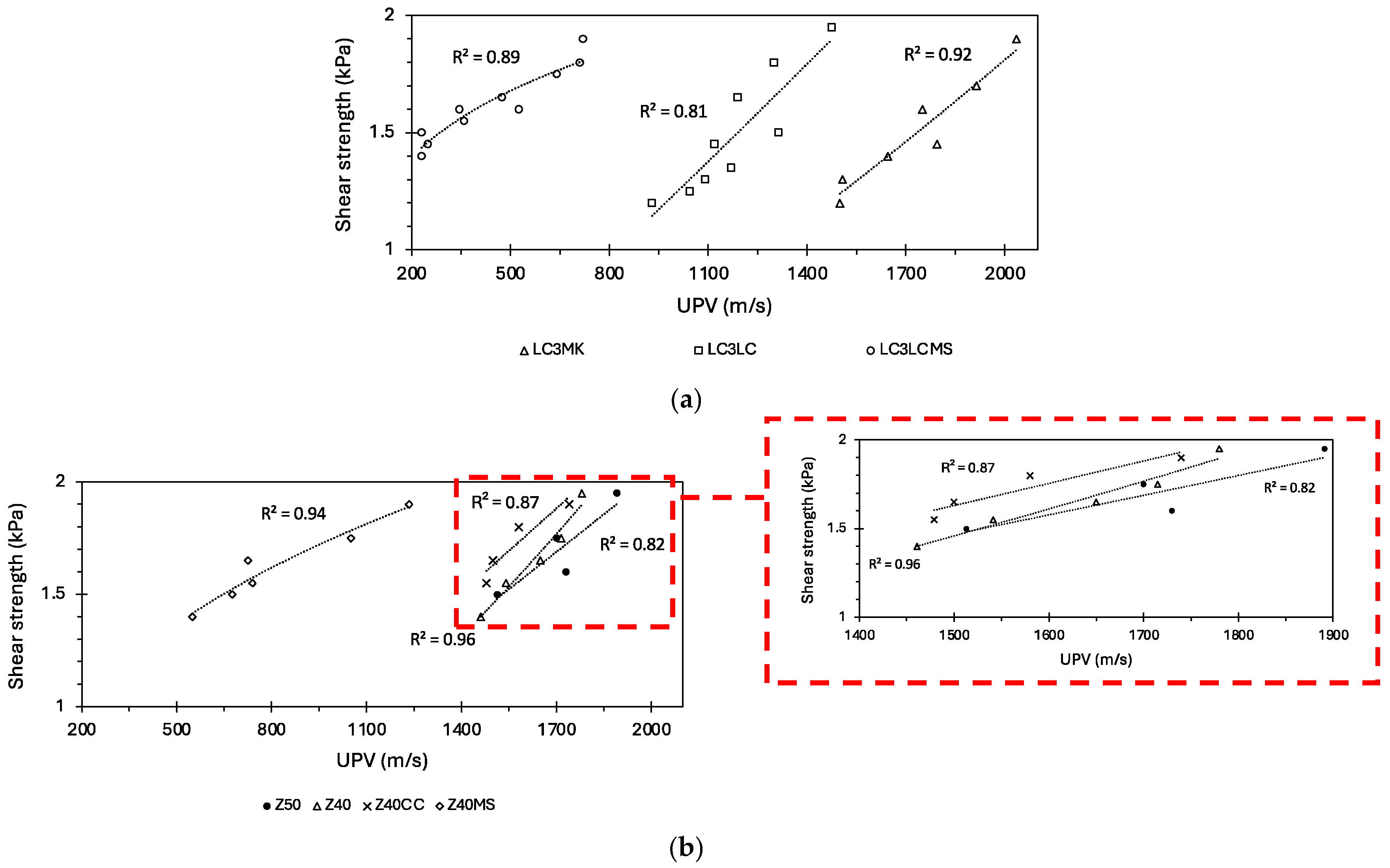

3.3. Ultrasonic Pulse Velocity

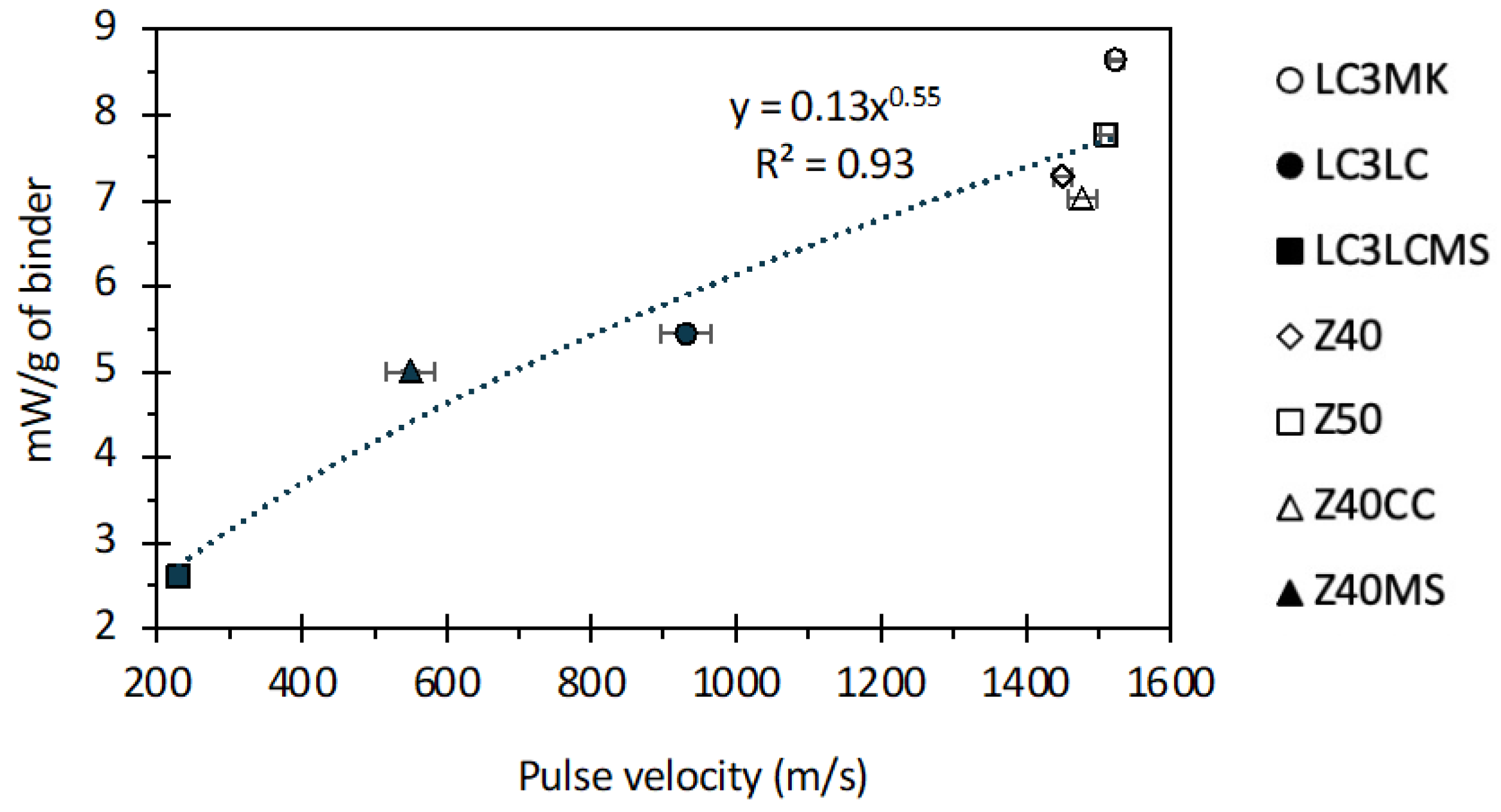

3.4. Flow Table Test Correlations

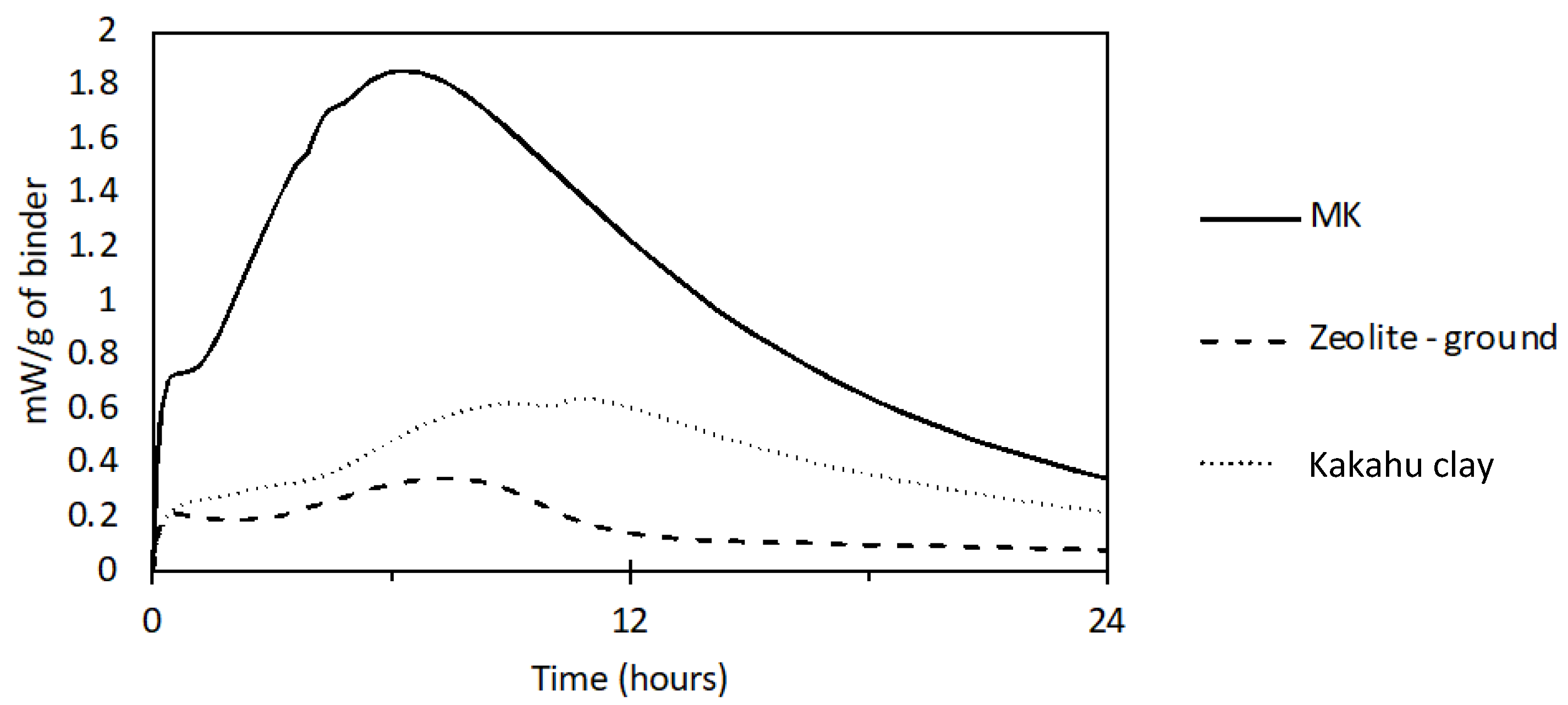

3.5. Reactivity of the SCMs

3.6. Initial Mixing Reaction—The Rate of Heat Generation

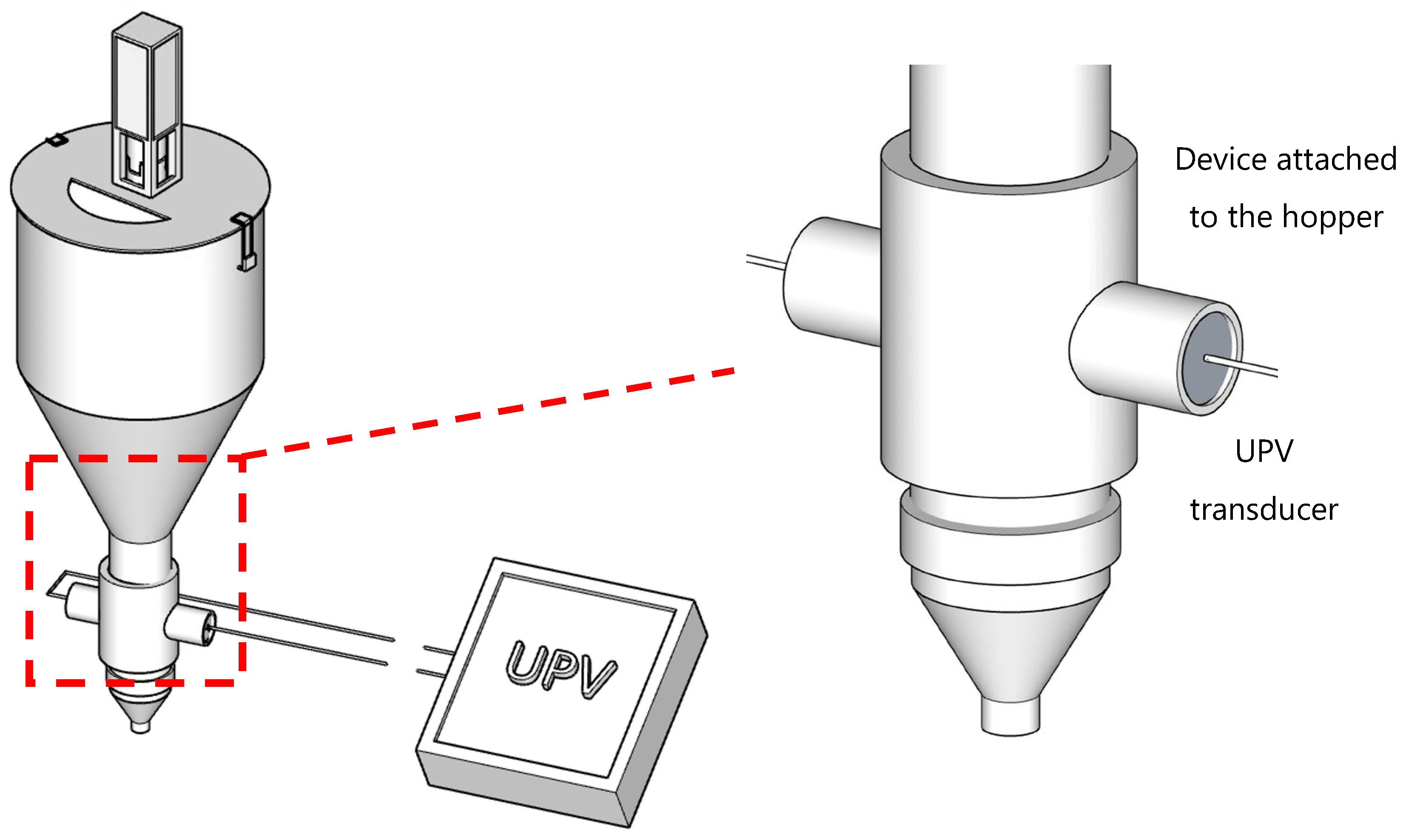

3.7. Prototype for Measuring Active Mortar Flows in 3DCP

- Material characterization and calibration:

- ○

- Preliminary tests to establish the relation between pulse velocity, rheological properties, and hydration kinetics of specific mix designs.

- ○

- Define an optimal pulse velocity value/range for the printable mixes under study.

- Real-time monitoring:

- ○

- Continuous UPV measurements during the printing process to assess the mix behaviour.

- ○

- Detect potential deviations from the predefined pulse velocity value/range that may indicate rheological inconsistencies.

- Process control and adjustment:

- ○

- Apply corrective actions (e.g., adjustments on the admixture dosage, printing parameters) to maintain printing quality.

4. Conclusions

- The incorporation of mussel shell powder into the LC3 system (LC3LCMS) resulted in a reduction in workability (greater initial shear strength) compared to their counterparts with MK and CaCO3 (LC3MK and LC3LC). However, the relative deformation as well as the spread of the printed filament were greater in LC3LCMS.

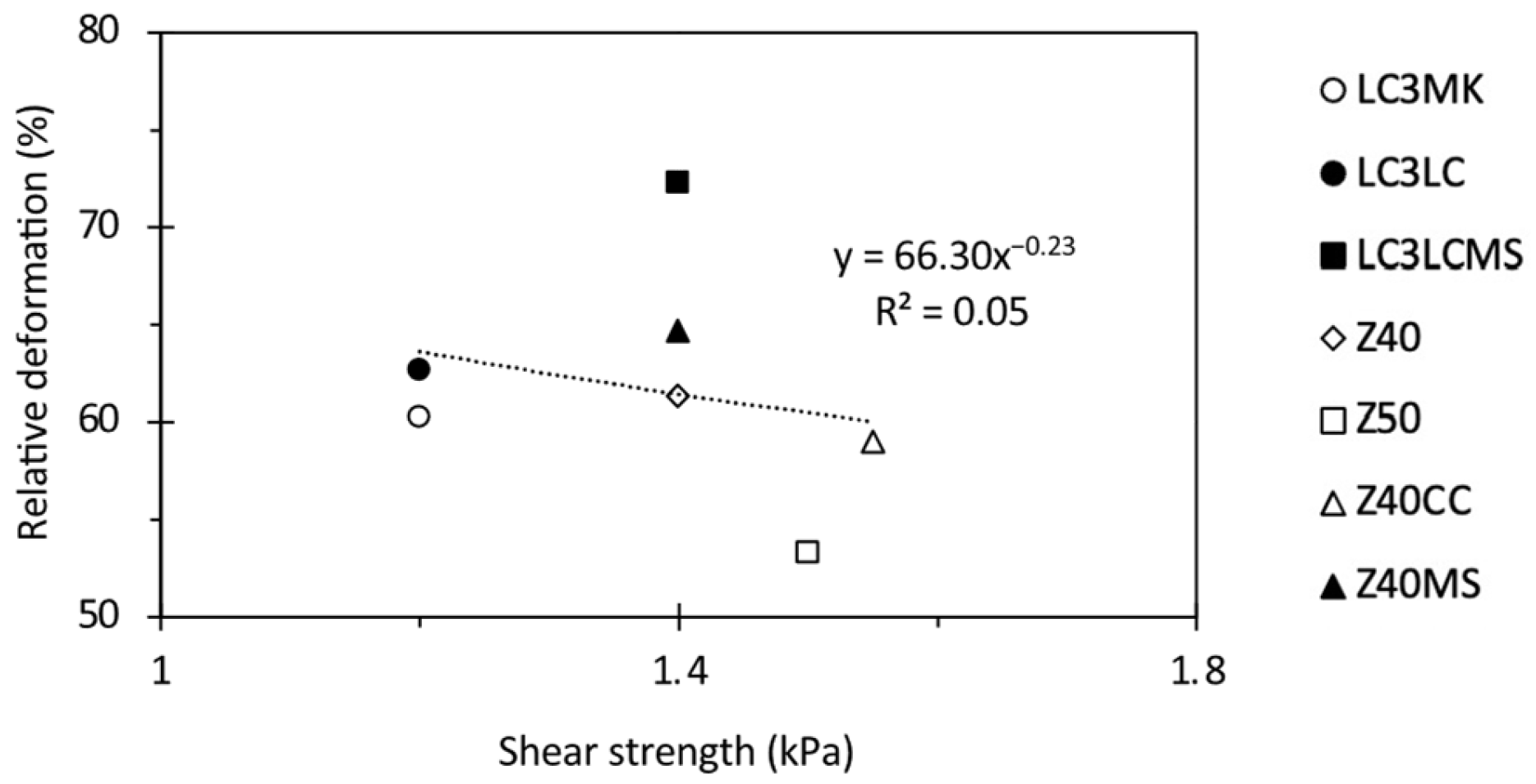

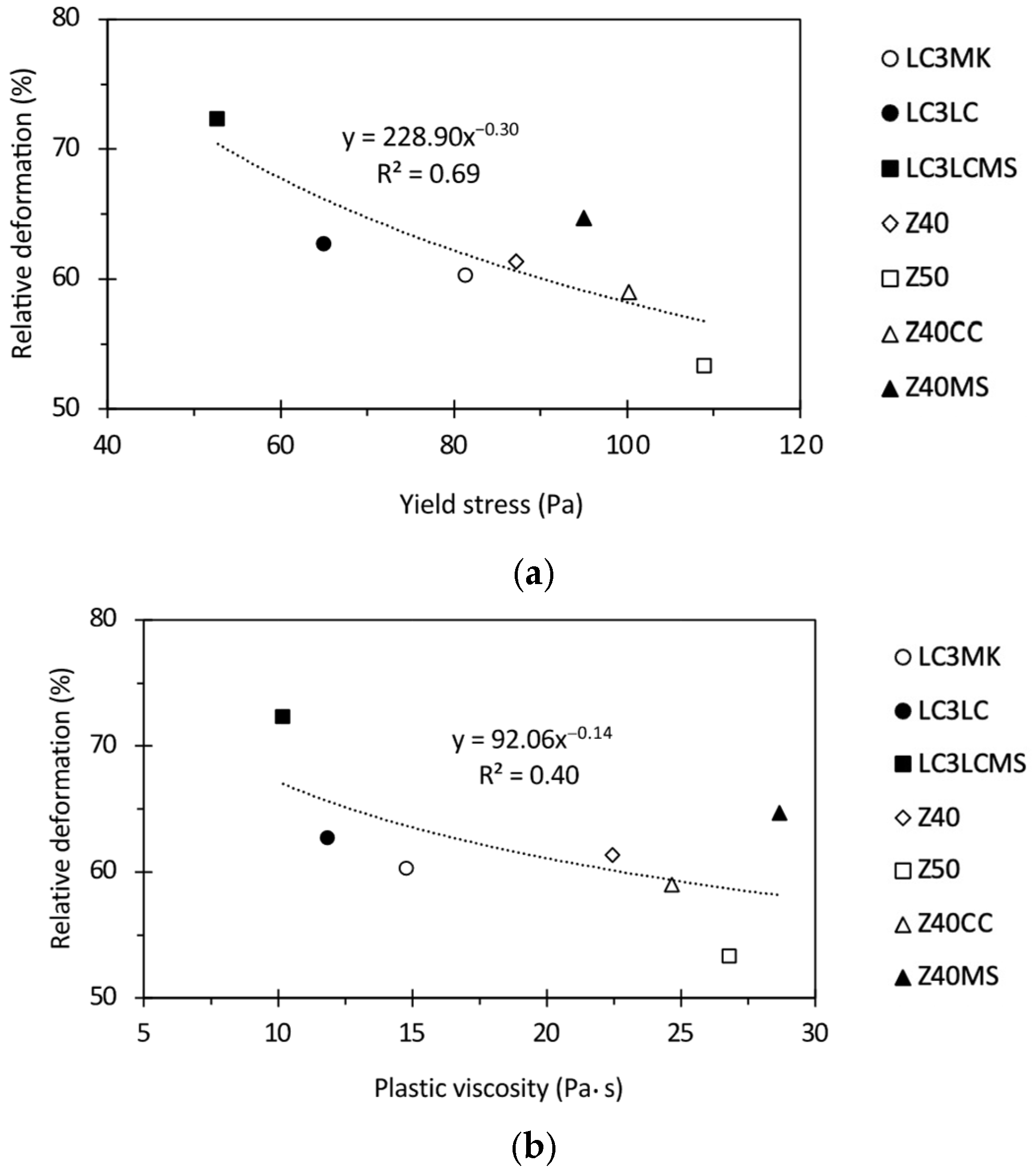

- No correlation (R2 = 0.05) was found between the results from the flow table test and the shear strength (static yield stress). LC3LCMS and Z40MS exhibited greater relative deformation than Z40 for the same value of shear strength. Poor correlations were obtained between the relative deformation and the dynamic yield stress and plastic viscosity (R2 = 0.69 and R2 = 0.40, respectively). This indicates that the flow table test is not suitable to characterize printable cementitious materials, as suggested in other publications [6,55].

- The printability window is limited by a dynamic yield stress value of ~250 Pa, regardless of the viscosity values of the mixes. The yield stress was the same for all the mixes tested.

- A strong correlation (R2 = 0.93) was observed between the heat released during the initial mixing reaction and the UPV measurements. This suggests that the early heat evolution (e.g., due to ettringite formation) may have a significant influence on the UPV results.

- The UPV results were influenced by the mix design, being grouped in different pulse velocity ranges according to the initial heat released. Initial pulses of ~230 m/s, ~550 m/s, ~930 m/s, and ~1500 m/s were obtained, at which the different mixes were considered optimal for extrudability at the beginning of the test.

- The UPV test has the potential to be used as an effective real-time monitoring technique during the printing process. To ensure optimal quality control and extrudability, the pulse velocity (mix-specific) should be determined for the printable mix beforehand.

5. Recommendations for Future Research

- Evaluate the influence of admixtures and viscosity-modifying agents normally used to adjust the setting time and consistency of the mixes for 3DCP (e.g., retarder, accelerator, superplasticiser) on the pulse velocity measurements.

- Quantify the ettringite content and provide a more accurate model to estimate its influence on the UPV.

- Conduct the UPV test during the printing process while there is an active flow through the printer.

- Develop a repeatable standard mix to investigate variabilities within the different methodologies to assess the rheological properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmed, G.H.; Askandar, N.H.; Jumaa, G.B. A review of largescale 3DCP: Material characteristics, mix design, printing process, and reinforcement strategies. Structures 2022, 43, 508–532. [Google Scholar] [CrossRef]

- Ma, G.; Buswell, R.; da Silva, W.R.L.; Wang, L.; Xu, J.; Jones, S.Z. Technology readiness: A global snapshot of 3D concrete printing and the frontiers for development. Cem. Concr. Res. 2022, 156, 106774. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. The role of early age structural build-up in digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Ivanova, I.; Mechtcherine, V. Possibilities and challenges of constant shear rate test for evaluation of structural build-up rate of cementitious materials. Cem. Concr. Res. 2020, 130, 105974. [Google Scholar] [CrossRef]

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J. Rheometry for Concrete 3D Printing: A Review and an Experimental Comparison. Buildings 2022, 12, 1190. [Google Scholar] [CrossRef]

- Nicolas, R.; Richard, B.; Nicolas, D.; Irina, I.; Temitope, K.J.; Dirk, L.; Viktor, M.; Romain, M.; Arnaud, P.; Ursula, P.; et al. Assessing the fresh properties of printable cement-based materials: High potential tests for quality control. Cem. Concr. Res. 2022, 158, 106836. [Google Scholar] [CrossRef]

- Siccardi, P.; Berger, X.; Jean, R.; Jolin, M.; Bissonnette, B.; Beaupré, D. Study of the Mixing Completion in Concrete Production by Means of an on-Board Sensor System; RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2020; pp. 338–345. [Google Scholar] [CrossRef]

- Chen, Y.; Rodriguez, C.R.; Li, Z.; Chen, B.; Çopuroğlu, O.; Schlangen, E. Effect of different grade levels of calcined clays on fresh and hardened properties of ternary-blended cementitious materials for 3D printing. Cem. Concr. Compos. 2020, 114, 103708. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Weng, Y.; Lu, B.; Li, M.; Liu, Z.; Tan, M.J.; Qian, S. Empirical models to predict rheological properties of fiber reinforced cementitious composites for 3D printing. Constr. Build. Mater. 2018, 189, 676–685. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. Mater. Constr. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, R.A.; Buswell, R.; Law, A.G.F.; Gibb, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete. Constr. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Qian, Y.; Kawashima, S. Distinguishing dynamic and static yield stress of fresh cement mortars through thixotropy. Cem. Concr. Compos. 2018, 86, 288–296. [Google Scholar] [CrossRef]

- RILEM, RILEM, Technical Committees. Available online: https://www.rilem.net/activetcs (accessed on 5 November 2024).

- Li, F.; Shen, W.; Qing, Y.; Hu, X.; Li, Z.; Shi, C. An overview on the effect of pumping on concrete properties. Cem. Concr. Compos. 2022, 129, 104501. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K. Active Rheology Control of Cementitious Materials; CRC: Boca Raton, FL, USA, 2023. [Google Scholar]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Technologies for improving buildability in 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104144. [Google Scholar] [CrossRef]

- Demont, L.; Mesnil, R.; Ducoulombier, N.; Caron, J.F. Affordable inline structuration measurements of printable mortar with a pocket shear vane. Constr. Build. Mater. 2023, 408, 133602. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Banfill, P.F.G.; Sedran, T.; Wallevik, O. Comparison of Concrete Rheometers: International Tests at LCPC. 2000. Available online: https://www.researchgate.net/publication/242380320 (accessed on 7 January 2025).

- Alghamdi, H.; Nair, S.A.O.; Neithalath, N. Insights into material design, extrusion rheology, and properties of 3D-printable alkali-activated fly ash-based binders. Mater. Des. 2019, 167, 107634. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahi, B.; Khayat, K.H.; Ramesh, A.; Sanjayan, J.G. Rheological characterization of ultra-high performance concrete for 3D printing. Cem. Concr. Compos. 2023, 136, 104854. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and harden properties of the high-thixotropy 3D printing concrete. Constr. Build. Mater. 2019, 201, 278–285. [Google Scholar] [CrossRef]

- Ye, G.; van Breugel, K.; Fraaij, A.L.A. Experimental Study on Ultrasonic Pulse Velocity Evaluation of the Microstructure of Cementitious Material at Early Age; Heron: San Diego, CA, USA, 2001; Volume 46, ISSN 0046-7316. [Google Scholar]

- Serdar, M.; Gabrijel, I.; Schlicke, D.; Staquet, S.; Azenha, M. Springer Tracts in Civil Engineering Advanced Techniques for Testing of Cement-Based Materials; Springer: Berlin/Heidelberg, Germany, 2020; Available online: http://www.springer.com/series/15088 (accessed on 7 January 2025).

- Sharma, S.; Mukherjee, A. Monitoring freshly poured concrete using ultrasonic waves guided through reinforcing bars. Cem. Concr. Compos. 2015, 55, 337–347. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Grosse, C.U. Continuous monitoring of setting and hardening of mortar and concrete. Constr. Build. Mater. 2004, 18, 145–154. [Google Scholar] [CrossRef]

- Boumiz, A.; Vernet, C.; Tenoudjif, F.C. Mechanical Properties of Cement Pastes and Mortars at Early Ages Evolution with Time and Degree of Hydration. Adv. Cem. Based Mater. 1996, 3, 94–106. [Google Scholar] [CrossRef]

- Keating, J.; Hannant, D.J.; Hibbert, A.P. Comparison of shear modulus and pulse velocity techniques to measure the build-up of structure in fresh cement pastes used in oil well cementing. Cem. Concr. Res. 1989, 19, 554–566. [Google Scholar] [CrossRef]

- New Zealand Geotechnical Society (NZGS) and Ministry of Business Innovation & Employment (MBIE), Earthquake geotechnical engineering practice, New Zealand Geotechnical Society: Ministry of Business Innovation & Employment, 2016. Available online: https://fl-nzgs-media.s3.amazonaws.com/uploads/2016/11/Module-2-Geotech-investigate-EQ-engineer-final.pdf (accessed on 19 January 2025).

- Omran, A.F.; Naji, S.; Khayat, K.H. Portable Vane Test to Assess Structural Buildup at Rest of Self-Consolidating Concrete. 2009. Available online: https://www.researchgate.net/publication/258295923_Portable_Vane_Test_to_Assess_Structural_Buildup_at_Rest_of_Self-Consolidating_Concrete (accessed on 10 February 2025).

- de la Flor Juncal, L.; Loporcaro, G.; Scott, A.; Clucas, D. Exploring the Use of Zeolite, Calcined Clay and Mussel Shells Powder in 3d Concrete Printing (3dcp) Mixes. 2023. Available online: https://www.researchgate.net/publication/380465278_Exploring_the_use_of_Zeolite_Calcined_Clay_and_Mussel_Shells_powder_in_3D_Concrete_Printing (accessed on 16 December 2024).

- Northcoat, J.W.; Wemyss, J.M.; De La, L.; Juncal, F.; Loporcaro, G. Exploring the Feasibility of Zeolite-Modified Blended Cement for 3d Concrete Printing: A Sustainable Alternative for the Concrete Construction Industry. 2023. Available online: https://www.researchgate.net/publication/380465283_Exploring_the_feasibility_of_Zeolite-modified_blended_cement_for_3D_Concrete_Printing_a_sustainable_alternative_for_the_concrete_construction_industry (accessed on 16 December 2024).

- O’malley, E.S.; Wright, S.G. Review of Undrained Shear Strength Testing Methods Used by the Texas State Department of Highways and Public Transportation. 1987. Available online: https://library.ctr.utexas.edu/digitized/texasarchive/phase2/446-1f.pdf (accessed on 10 February 2025).

- ConTec user’s guide; ConTec-Viscometer2003.

- ASTM C230/C230M-23; Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: Montgomery, PA, USA, 2023. [CrossRef]

- ASTM C1437-20; Test Method for Flow of Hydraulic Cement Mortar. ASTM International: Montgomery, PA, USA, 2020. [CrossRef]

- Cho, S.; Kruger, J.; Bester, F.; van den Heever, M.; van Rooyen, A.; van Zijl, G. A Compendious Rheo-Mechanical Test for Printability Assessment of 3D Printable Concrete; RILEM Bookseries; Springer: Berlin/Heidelberg, Germany, 2020; pp. 196–205. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Papachristoforou, M.; Mitsopoulos, V.; Stefanidou, M. Evaluation of workability parameters in 3D printing concrete. Procedia Struct. Integr. 2018, 10, 155–162. [Google Scholar] [CrossRef]

- ASTM C1897-20; Standard Test Methods for Measuring the Reactivity of Supplementary Cementitious Materials by Isothermal Calorimetry and Bound Water Measurements. ASTM International: Montgomery, PA, USA, 2020. [CrossRef]

- Bjrn, A.; de La Monja, P.S.; Karlsson, A.; Ejlertsson, J.; Rheological, B.H. Rheological Characterization. In Biogas; InTech: Hong Kong, China, 2012. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Makul, N.; Siripattarapravat, C. Utilization of ground waste seashells in cement mortars for masonry and plastering. J. Environ. Manag. 2012, 111, 133–141. [Google Scholar] [CrossRef]

- Souidi, A.; Maaloufa, Y.; Amazal, M.; Atigui, M.; Oubeddou, S.; Mounir, S.; Idoum, A.; Aharoune, A. The effect of mussel shell powder on the thermal and mechanical properties of plaster. Constr. Build. Mater. 2024, 416, 135142. [Google Scholar] [CrossRef]

- Juncal, L.d.l.F.; Scott, A.; Clucas, D.; Loporcaro, G. Permeability and electrical resistivity of 3D-printed mortars using local materials (zeolite, calcined clay, and mussel shell powder), Aotearoa—New Zealand. Case Stud. Constr. Mater. 2025, 22, e04448. [Google Scholar] [CrossRef]

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar] [CrossRef]

- Sabir, B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Hu, J. Comparison between the effects of superfine steel slag and superfine phosphorus slag on the long-term performances and durability of concrete. J. Therm. Anal. Calorim. 2017, 128, 1251–1263. [Google Scholar] [CrossRef]

- Rehman, A.U.; Birru, B.M.; Kim, J.H. Set-on-demand 3D Concrete Printing (3DCP) construction and potential outcome of shotcrete accelerators on its hardened properties. Case Stud. Constr. Mater. 2023, 18, e01955. [Google Scholar] [CrossRef]

- Alexa-Stratulat, S.M.; Olteanu, I.; Toma, A.M.; Pastia, C.; Banu, O.M.; Corbu, O.C.; Toma, I.O. The Use of Natural Zeolites in Cement-Based Construction Materials—A State of the Art Review. Coatings 2024, 14, 18. [Google Scholar] [CrossRef]

- Radulović, D.; Terzić, A.; Pezo, L.; Andrić, L.; Grigorova, I. The chemometric study of limestone physico-chemical properties and thermal behavior for application in construction composites. Sci. Sinter. 2017, 49, 247–261. [Google Scholar] [CrossRef]

- Wallevik, J.E. Rheological properties of cement paste: Thixotropic behavior and structural breakdown. Cem. Concr. Res. 2009, 39, 14–29. [Google Scholar] [CrossRef]

- Tattersall, G.H. Workability and Quality Control of Concrete; CRC: Boca Raton, FL, USA, 2005. [Google Scholar]

- Shah, V.; Parashar, A.; Scott, A. Understanding the importance of carbonates on the performance of Portland metakaolin cement. Constr. Build. Mater. 2022, 319, 126155. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Q.; Shu, X.; Wang, X.; Ran, Q. Influence of Sulfates on Formation of Ettringite during Early C3A Hydration. Materials 2022, 15, 6934. [Google Scholar] [CrossRef]

- Ramachandran, V.S. Concrete Admixtures Handbook: Properties, Science, and Technology, 2nd ed.; Noyes Publications: Park Ridge, NJ, USA, 1995. [Google Scholar]

- Roussel, N.; Ovarlez, G.; Garrault, S.; Brumaud, C. The origins of thixotropy of fresh cement pastes. Cem. Concr. Res. 2012, 42, 148–157. [Google Scholar] [CrossRef]

- Jakob, C.; Jansen, D.; Ukrainczyk, N.; Koenders, E.; Pott, U.; Stephan, D.; Neubauer, J. Relating ettringite formation and rheological changes during the initial cement hydration: A comparative study applying XRD analysis, rheological measurements and modeling. Materials 2019, 12, 2957. [Google Scholar] [CrossRef]

| Oxides | OPC | MK | Local clay | CaCO3 | Mussel shells | Zeolite | Gypsum | Fine Agg. |

|---|---|---|---|---|---|---|---|---|

| CaO | 70.34 | 0.03 | 0.17 | 96.71 | 98.2 | 3.55 | 46.83 | 1.41 |

| SiO2 | 16.90 | 50.68 | 60.3 | 1.35 | 0.10 | 74.95 | 0.19 | 74.5 |

| Fe2O3 | 3.83 | 0.42 | 2.4 | 0.40 | 0.06 | 1.85 | 0.03 | 3.24 |

| MgO | 0.76 | nd * | 0.83 | 0.58 | 0.05 | 1.35 | 0.11 | 1.04 |

| SO3 | 3.23 | 0.05 | 0.07 | 0.02 | 0.25 | 0.03 | 52.17 | 0.03 |

| Al2O3 | 3.19 | 46.22 | 32.25 | 0.63 | 0.033 | 14.87 | 0.07 | 13.3 |

| K2O | 0.54 | 0.13 | 2.35 | 0.10 | 0.011 | 2.15 | nd * | 3.34 |

| TiO2 | 0.39 | 2.01 | 1.35 | nd * | nd * | 0.26 | nd * | 0.47 |

| Na2O | 0.25 | 0.20 | 0.07 | 0.05 | 0.78 | 0.81 | 0.07 | 2.37 |

| P2O5 | 0.11 | 0.10 | 0.03 | 0.01 | 0.11 | 0.032 | 0.005 | 0.13 |

| MnO | 0.10 | nd * | 0.015 | 0.03 | nd * | 0.047 | nd * | 0.05 |

| Sum | 99.64 | 99.83 | 99.84 | 99.89 | 99.6 | 99.9 | 99.48 | 99.88 |

| Binder (%) | Sand, Water, PVA Fibres, and SP Mass Ratios | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mixes | OPC | MK | LC | CC | MS (Powder) | Z | Gypsum | S/B | W/B | PVA/B | SP/B |

| LC3MK | 55 | 30 | 12 | - | - | 3 | 1.5 | 0.42 | 0.225 | 0.45 | |

| LC3LC | 55 | - | 30 | 12 | - | - | 3 | ||||

| LC3LCMS | 55 | - | 30 | - | 12 | - | 3 | ||||

| Z40 | 60 | - | - | - | - | 40 | - | 1.25 | |||

| Z50 | 50 | - | - | - | - | 50 | - | 1.5 | |||

| Z40CC | 50 | - | - | 10 | - | 40 | - | ||||

| Z40MS | 50 | - | - | - | 10 | 40 | - | ||||

| Mix | Open Time (in min) |

|---|---|

| LC3MK | 25–30 |

| LC3LC | 35–40 |

| LC3LCMS | 40–45 |

| Z50 | 10–15 |

| Z40 | 15–20 |

| Z40CC | 10–15 |

| Z40MS | 20–25 |

| (μm) | (μm) | |

|---|---|---|

| MK | 4.97 | 14.8 |

| Zeolite (75 psi) | 5.39 | 15.6 |

| CaCO3 | 20.9 | 70.4 |

| Mussel shell powder | 6.47 | 40.8 |

| Kakahu clay | 9.25 | 164.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de la Flor Juncal, L.; Scott, A.; Clucas, D.; Loporcaro, G. Ultrasonic Pulse Velocity for Real-Time Filament Quality Monitoring in 3D Concrete Printing Construction. Buildings 2025, 15, 2566. https://doi.org/10.3390/buildings15142566

de la Flor Juncal L, Scott A, Clucas D, Loporcaro G. Ultrasonic Pulse Velocity for Real-Time Filament Quality Monitoring in 3D Concrete Printing Construction. Buildings. 2025; 15(14):2566. https://doi.org/10.3390/buildings15142566

Chicago/Turabian Stylede la Flor Juncal, Luis, Allan Scott, Don Clucas, and Giuseppe Loporcaro. 2025. "Ultrasonic Pulse Velocity for Real-Time Filament Quality Monitoring in 3D Concrete Printing Construction" Buildings 15, no. 14: 2566. https://doi.org/10.3390/buildings15142566

APA Stylede la Flor Juncal, L., Scott, A., Clucas, D., & Loporcaro, G. (2025). Ultrasonic Pulse Velocity for Real-Time Filament Quality Monitoring in 3D Concrete Printing Construction. Buildings, 15(14), 2566. https://doi.org/10.3390/buildings15142566