Evaluation of High-Performance Pervious Concrete Mixed with Nano-Silica and Carbon Fiber

Abstract

1. Introduction

2. Materials and Methods

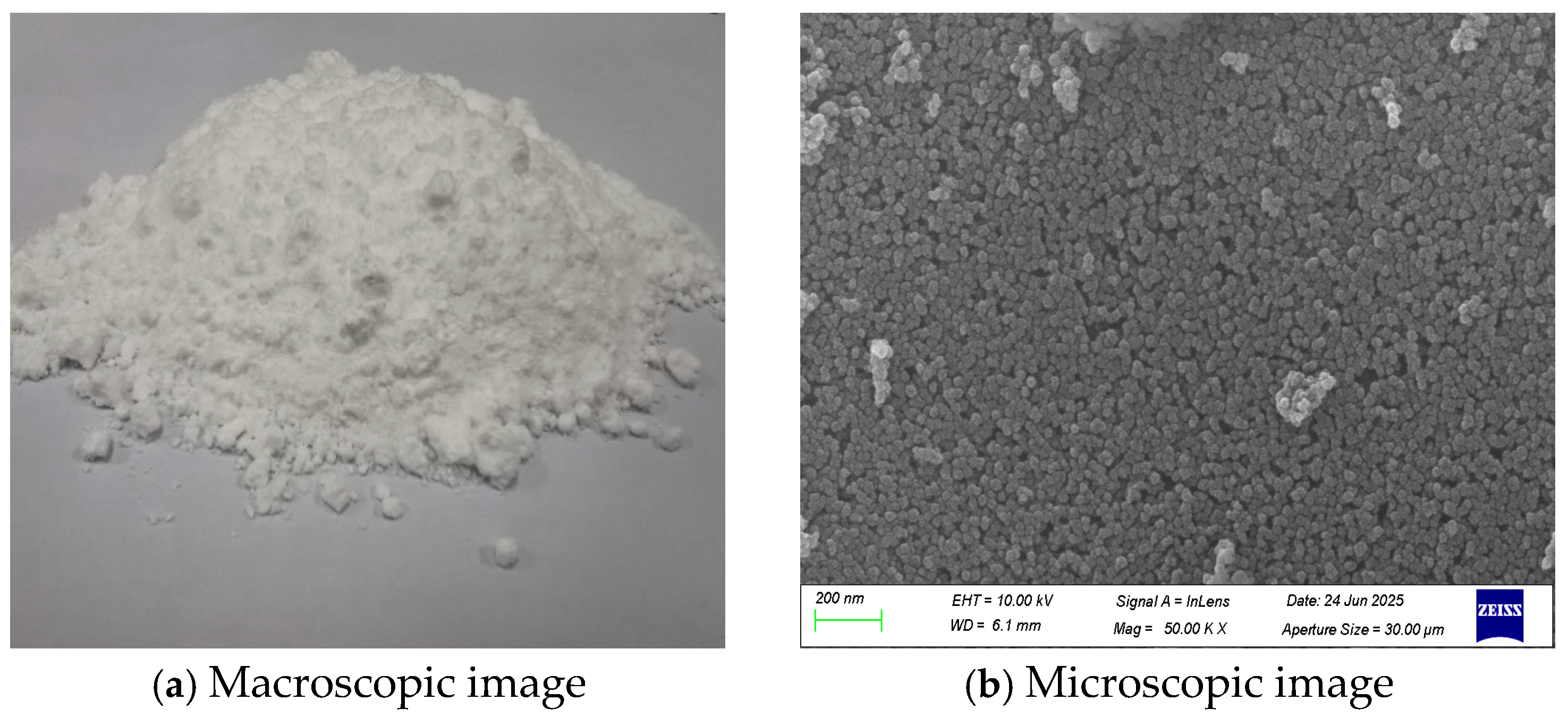

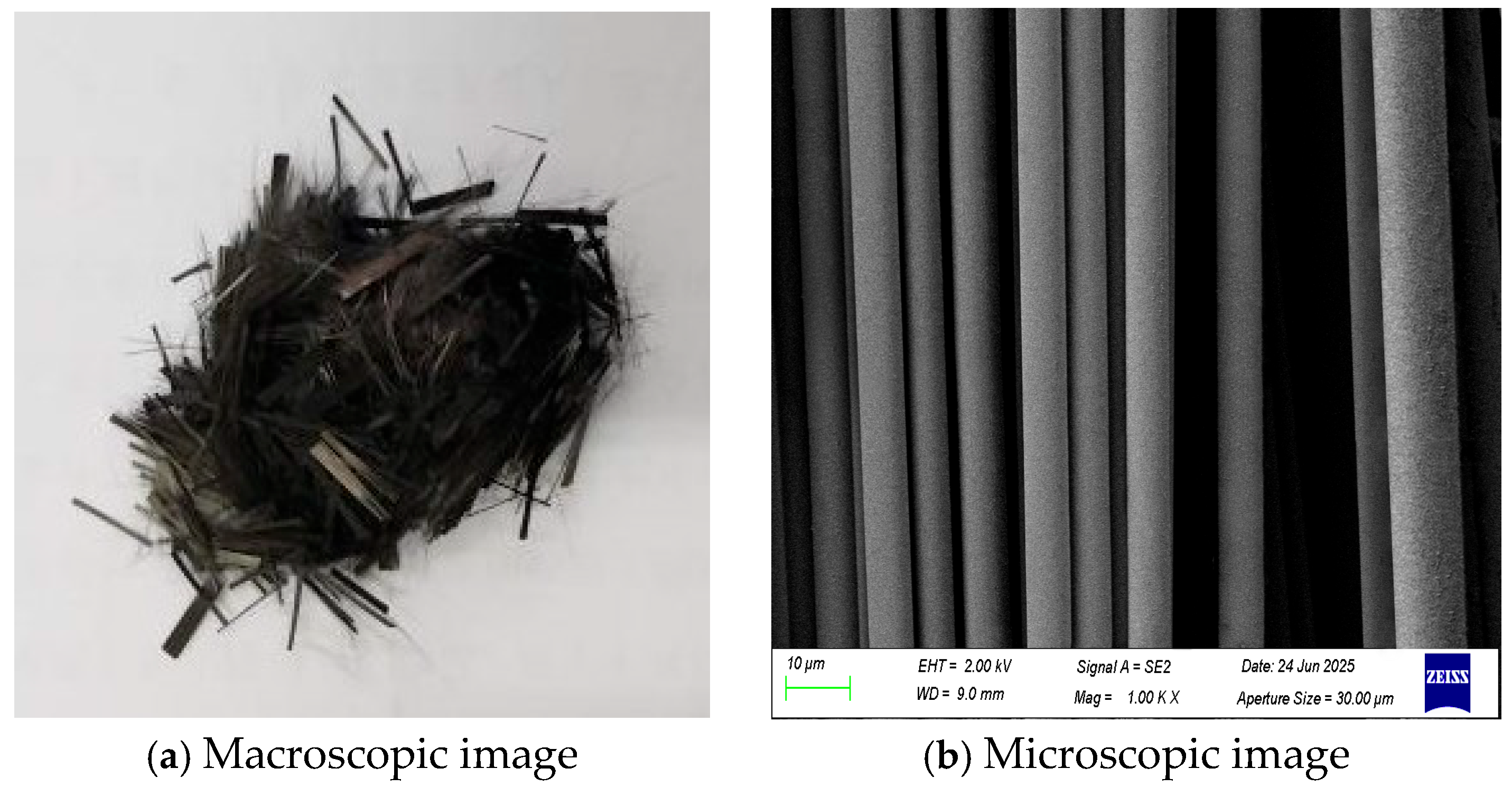

2.1. Materials

2.2. Studied Parameters

2.3. Response Surface Design

2.4. Testing Methods and Sample Preparation

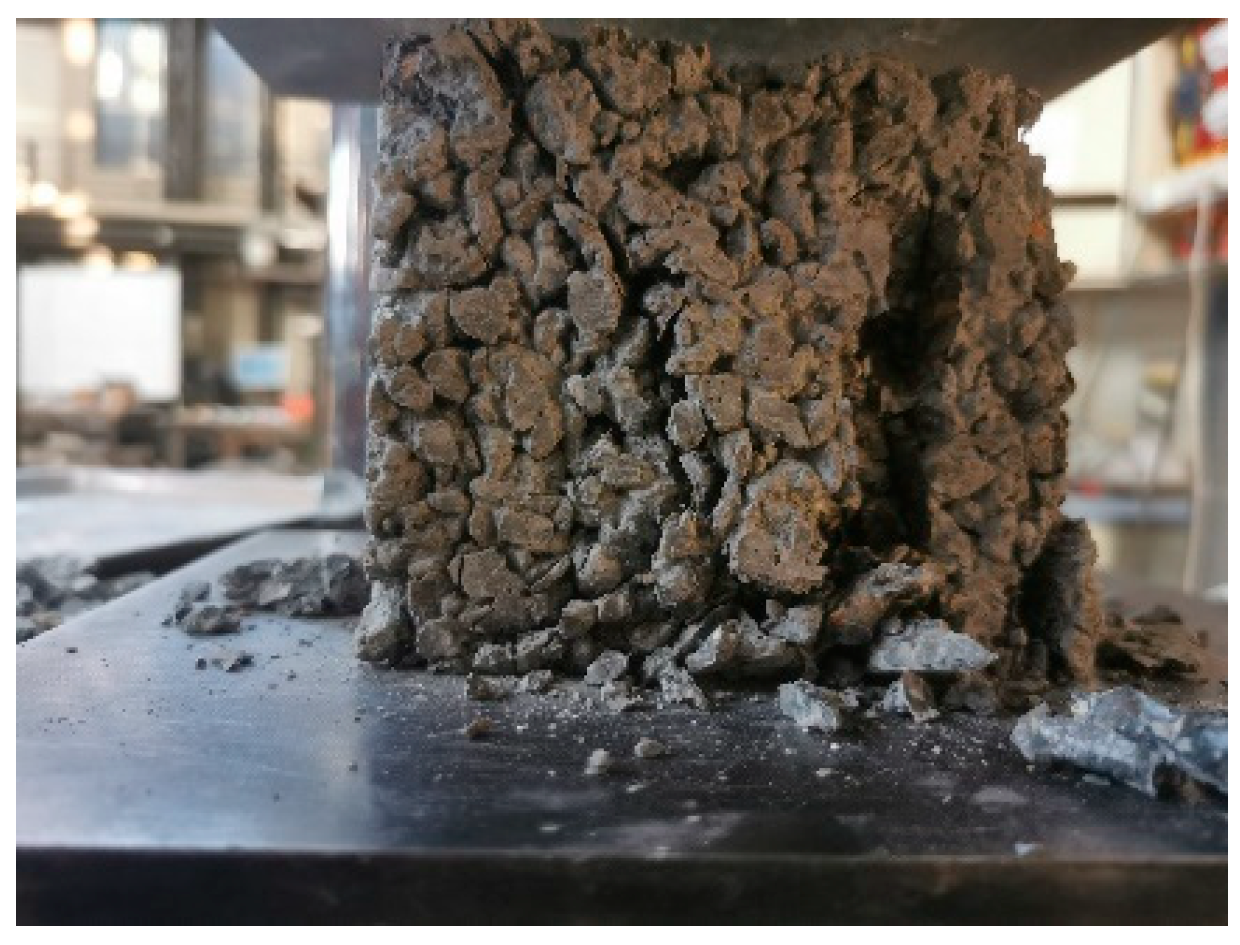

Sample Preparation

- (1)

- Add cement, fly ash, sand, and coarse aggregate; mix for 60 s;

- (2)

- Add carbon fiber; mix for 30 s;

- (3)

- Add nano-silica and water-reducing admixture to water, then pour half of the solution into the mixture;

- (4)

- Mix for 90 s;

- (5)

- Pour in the remaining 50% of water; mix for 120 s;

- (6)

- Obtain freshly mixed pervious concrete, as shown in Figure 4.

3. Results

3.1. Responses and Prediction Models

3.2. Effects of the Factors on Responses

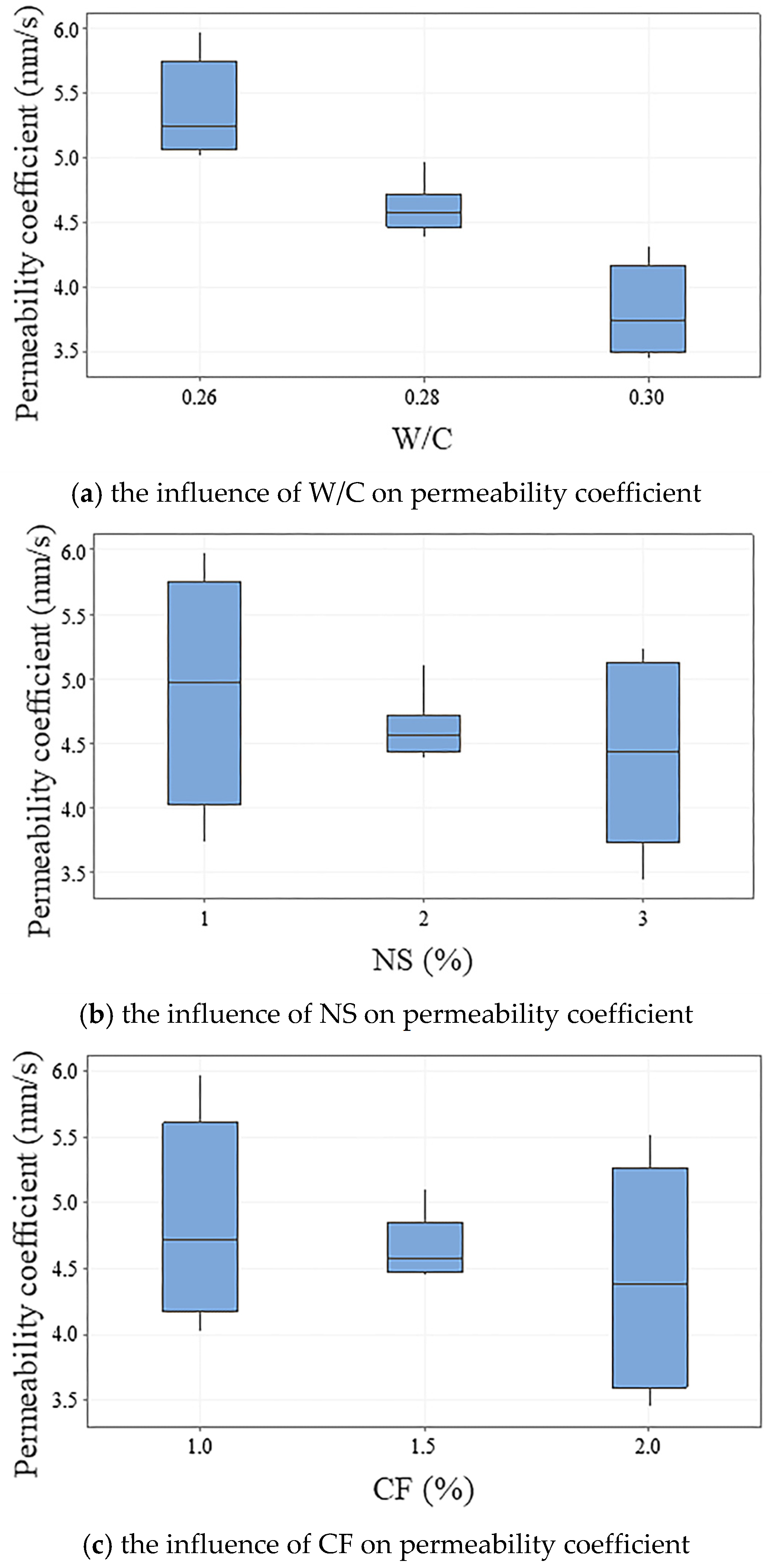

3.2.1. Permeability Coefficient

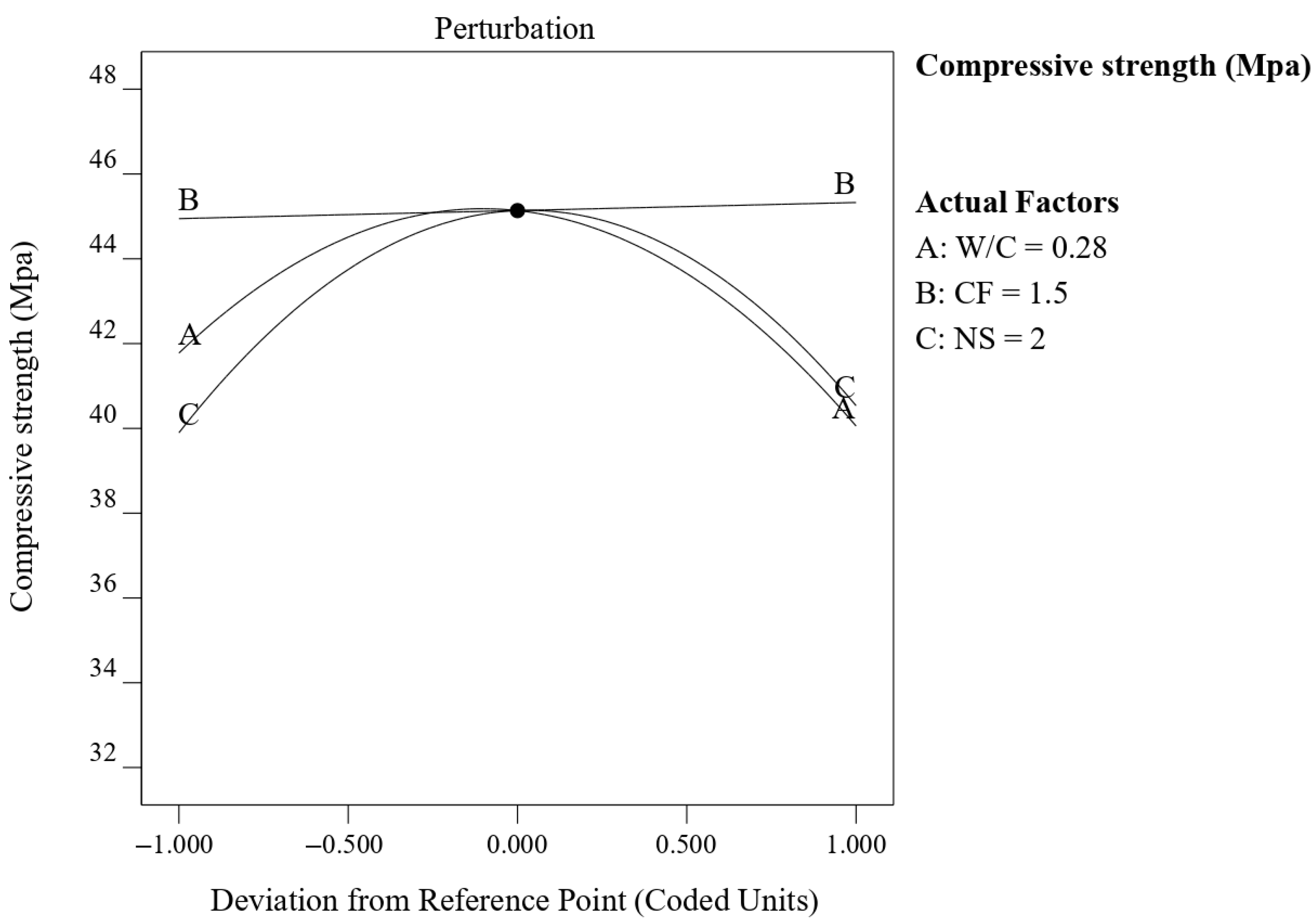

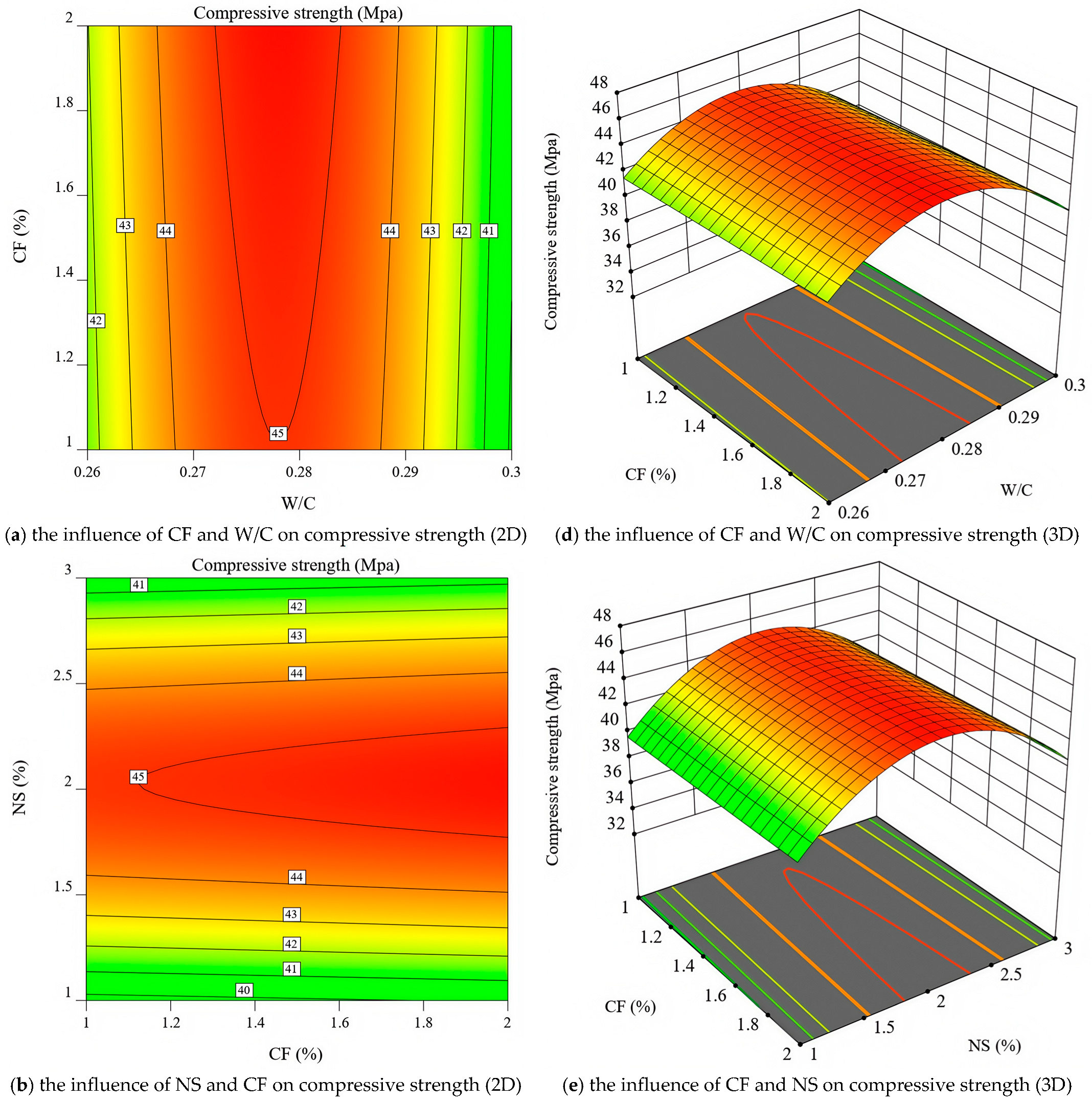

3.2.2. Compressive Strength

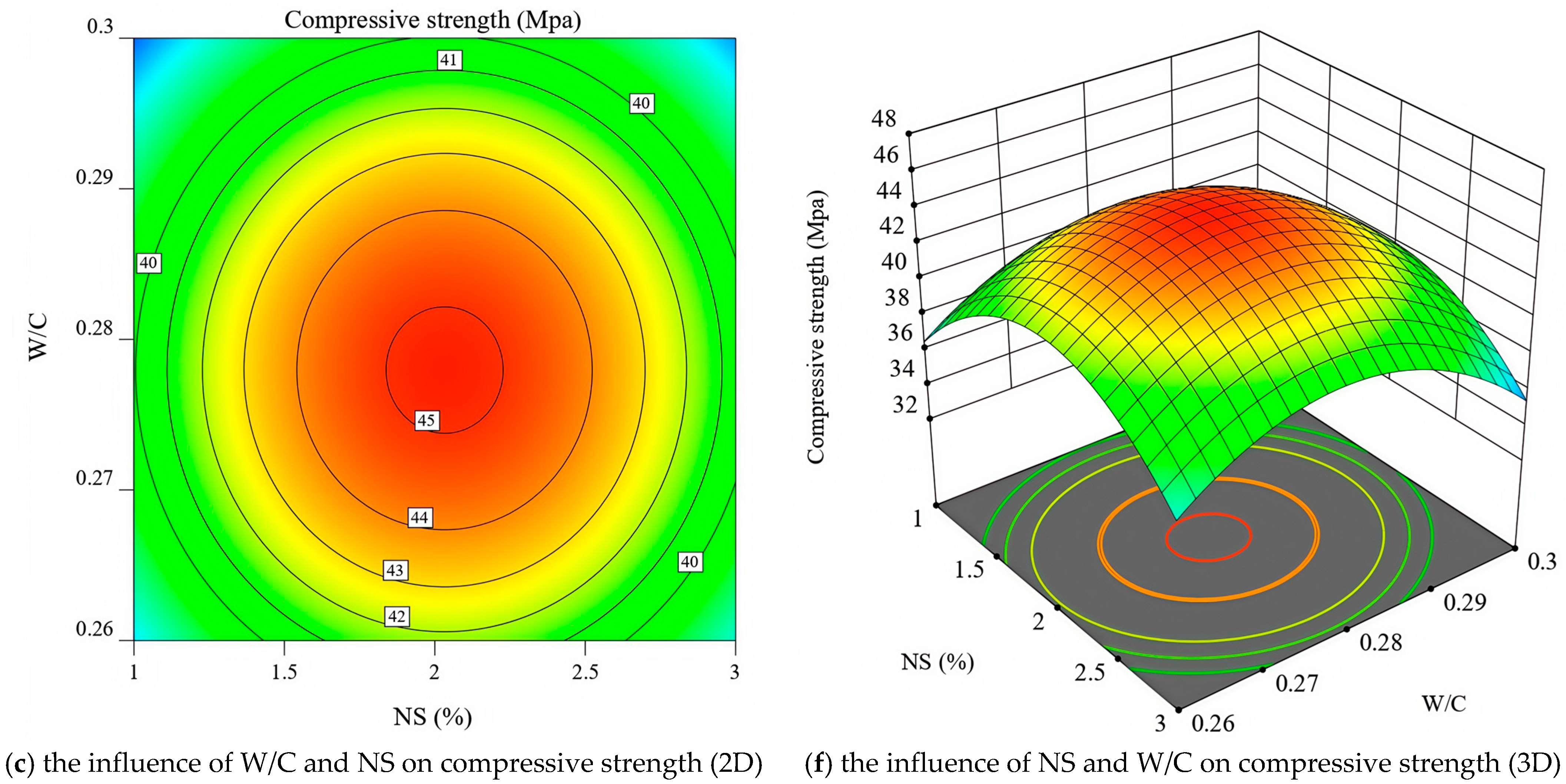

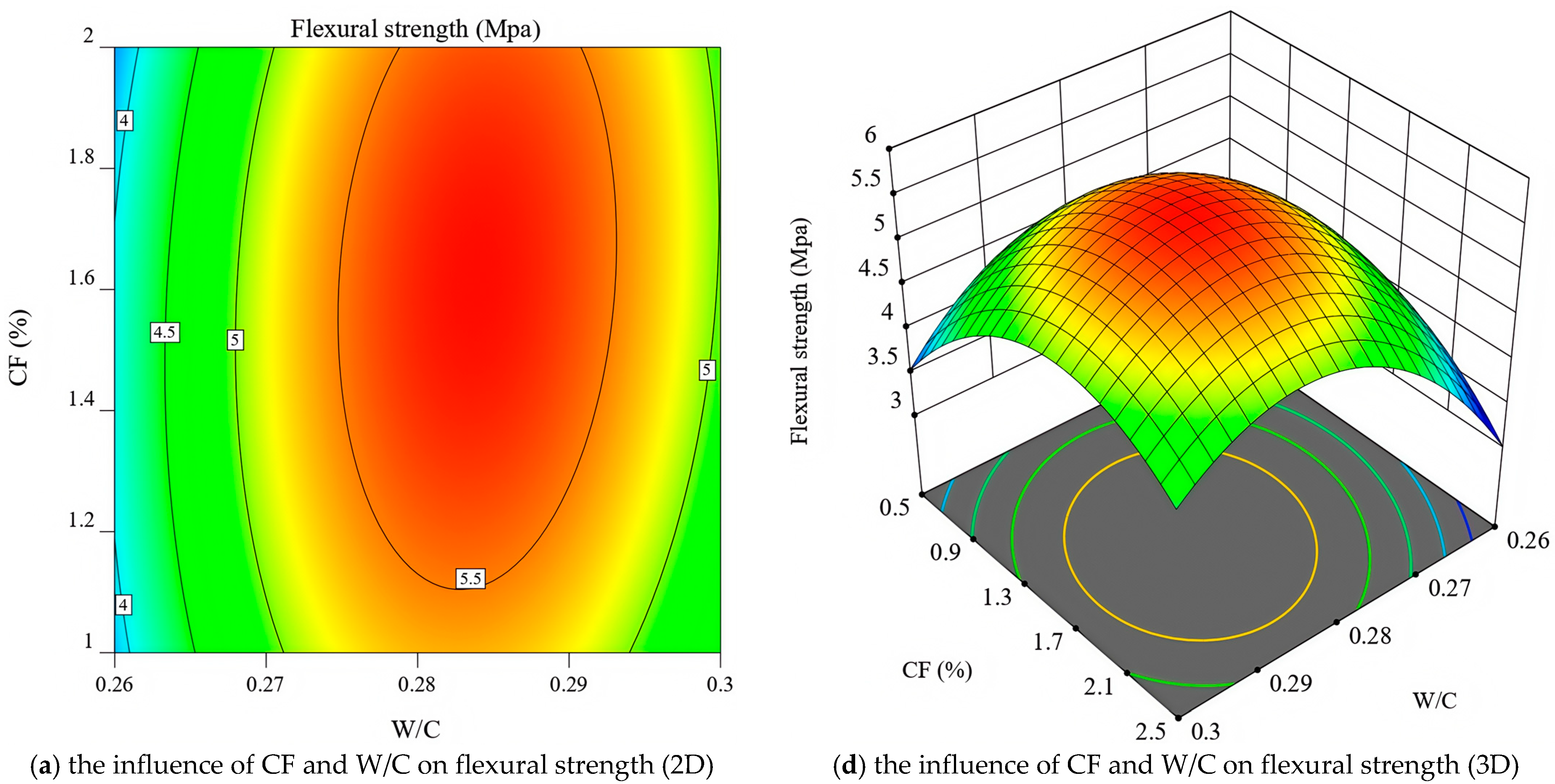

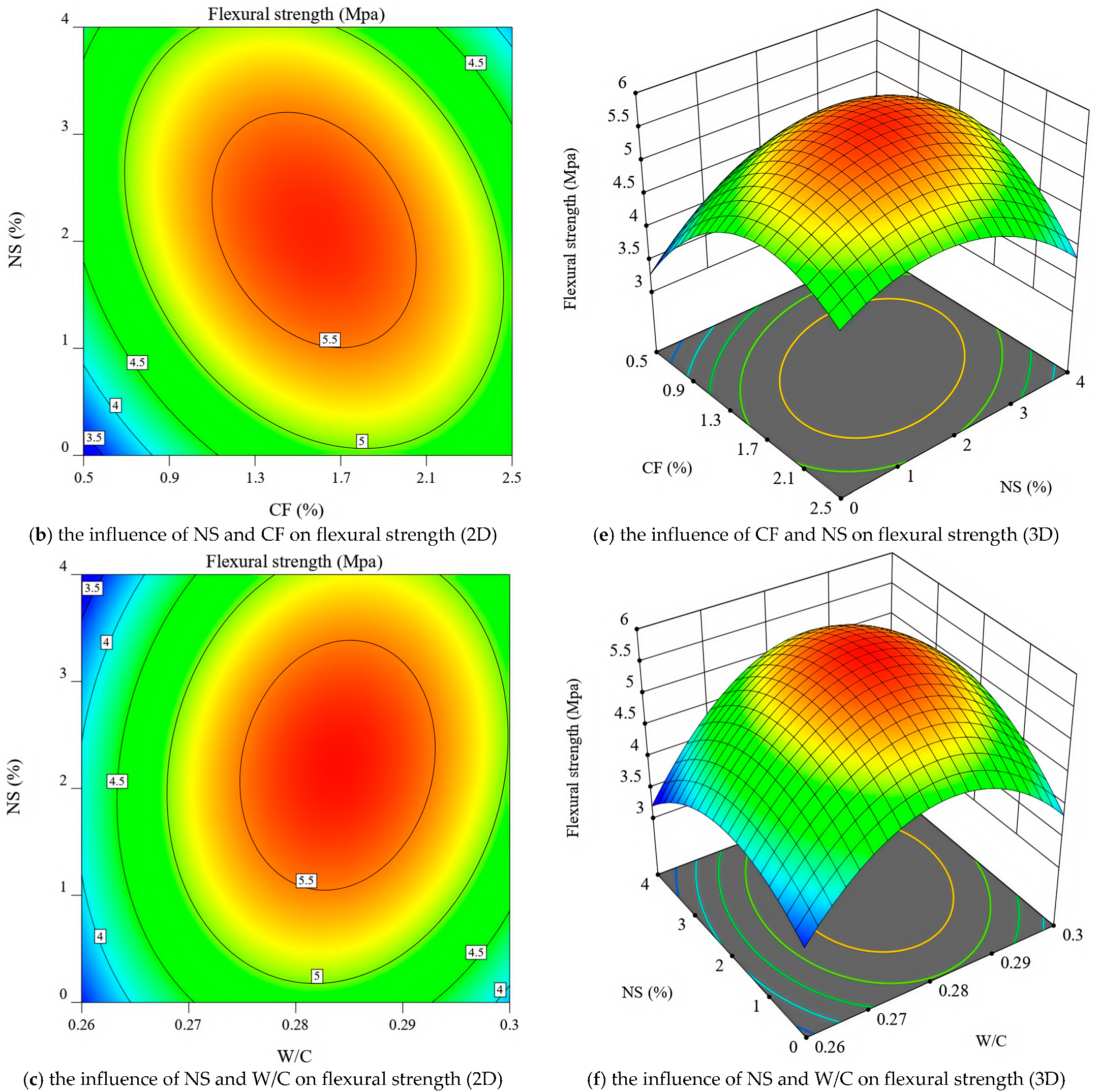

3.2.3. Flexural Strength

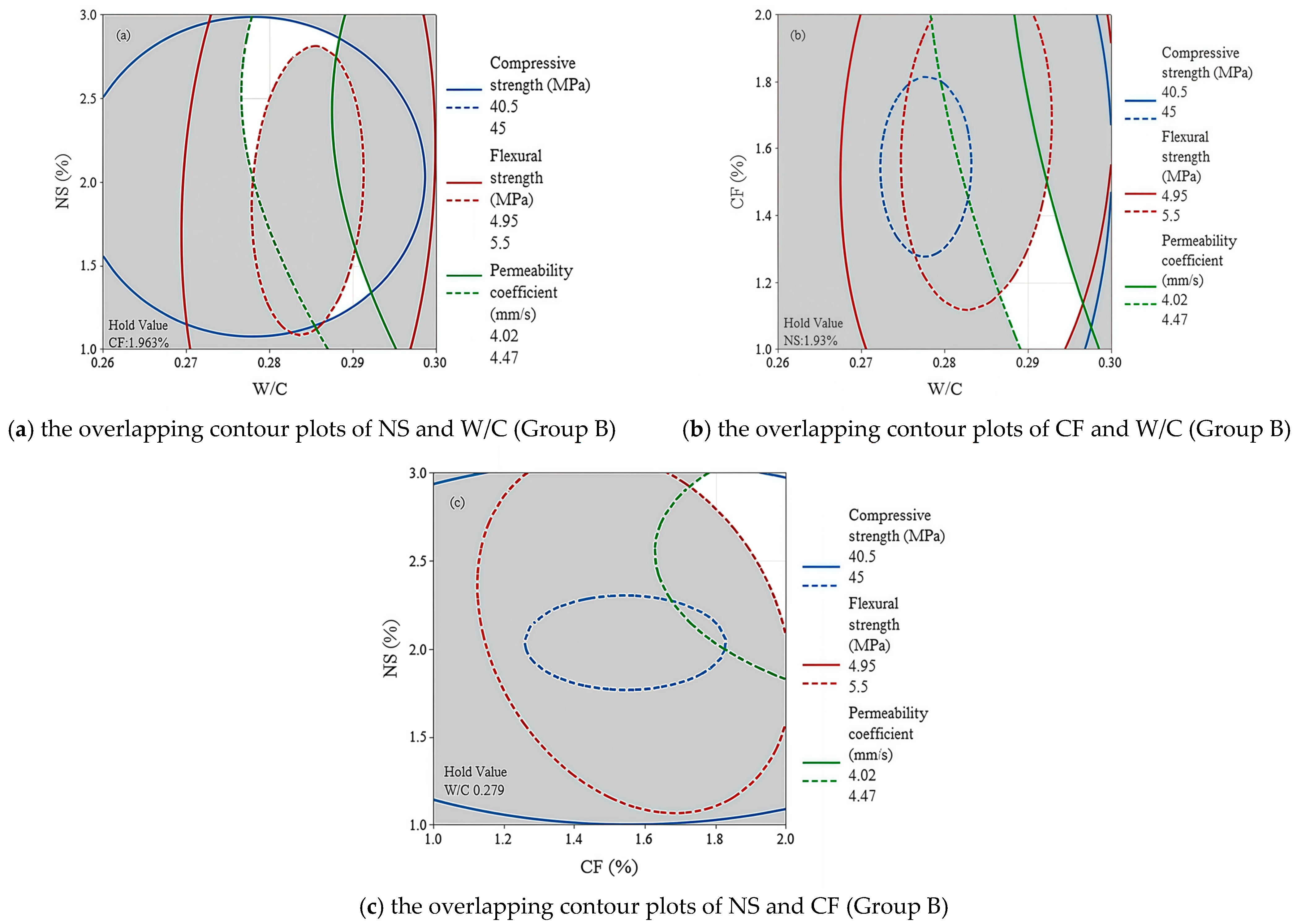

3.3. Response Optimization

3.4. Overlay Contour Plots

3.5. Statistical Model Validation

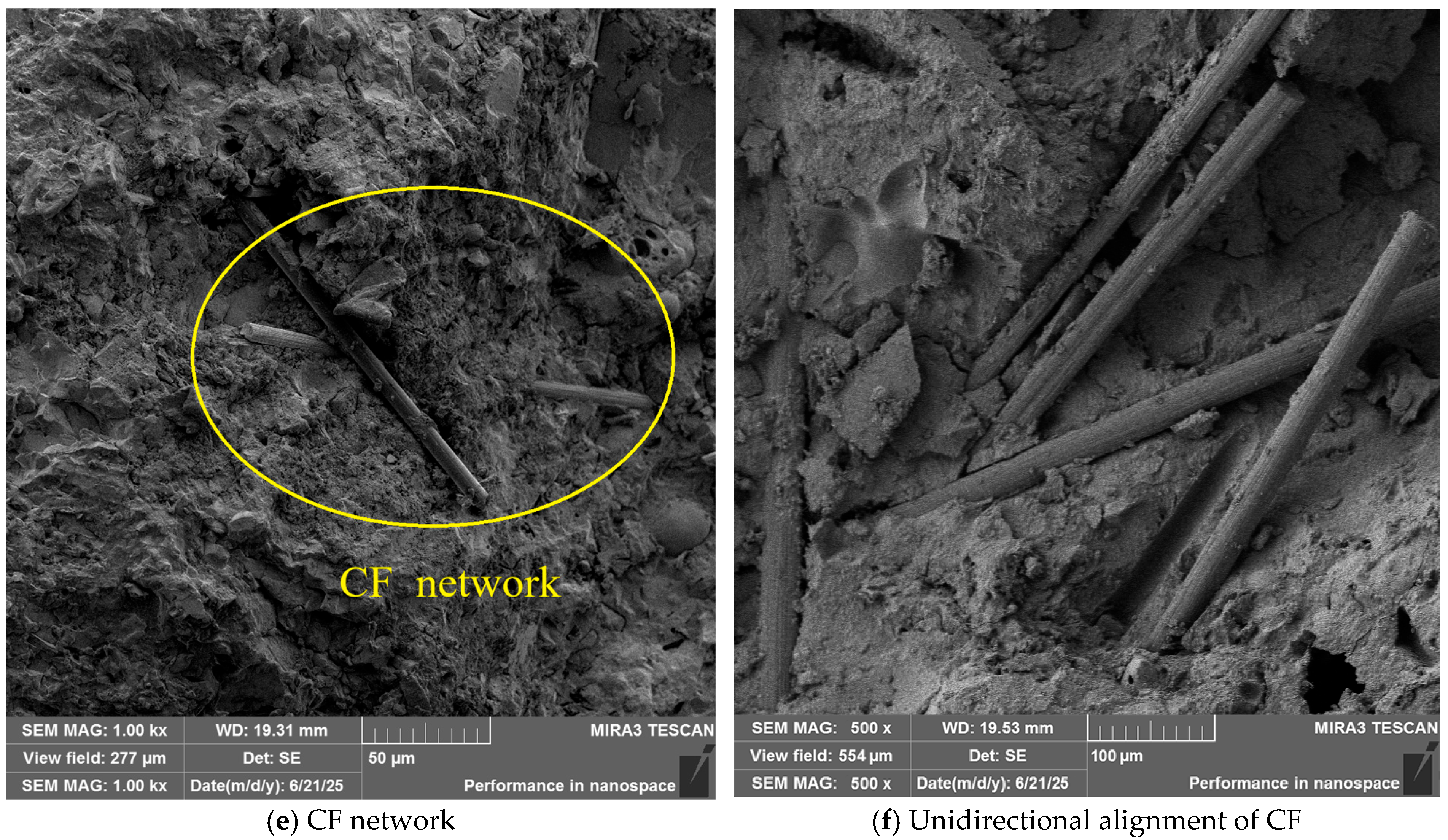

3.6. Scanning Electron Microscope (SEM) Investigations

4. Conclusions

- (1)

- W/C ratio is the primary factor influencing the various properties of pervious concrete. Selecting an appropriate W/C ratio is the foremost task in producing high-performance pervious concrete. An increase in W/C ratio leads to a decrease in the permeability coefficient of pervious concrete, while the mechanical properties initially increase and subsequently decrease. A W/C ratio of 0.28 yields the optimal mechanical performance.

- (2)

- CF causes a substantial decrease in the permeability of pervious concrete. Simultaneously, the addition of CF has almost no effect on the compressive strength. However, the flexural strength initially increases and then decreases with increasing CF content, with the optimal CF dosage being 1.6%.

- (3)

- NS significantly reduces the permeability of pervious concrete but markedly enhances its mechanical strength. The optimal NS dosages for achieving the highest compressive strength and flexural strength are 1.9% and 2.2%, respectively.

- (4)

- The permeability of pervious concrete generally exhibits an inverse relationship with its mechanical strength; compressive strength and flexural strength demonstrate a proportional relationship.

- (5)

- The synergistic interaction between W/C ratio, NS, and CF significantly exacerbated the reduction in the permeability of pervious concrete.

- (6)

- W/C ratio, NS, and CF exhibited no significant synergistic effect on the compressive strength. However, a distinct interactive effect was observed concerning the flexural strength.

- (1)

- Non-motorized lanes on municipal arterial roads: High-performance pervious concrete provides sufficient structural support and fatigue resistance, mitigating common issues in conventional pervious concrete such as surface raveling, aggregate detachment, and structural failure.

- (2)

- Bus stop platforms: Bus stops experience frequent acceleration and deceleration, as well as concentrated loads, which impose extreme demands on pavement strength. High-performance pervious concrete can withstand the repeated rolling and braking impact of buses while effectively eliminating surface water ponding on platforms.

- (3)

- Internal roads in logistics parks and warehousing areas: Internal roads are frequently subjected to heavy traffic from industrial vehicles (e.g., forklifts, light trucks) and localized high-pressure loads from stacked goods. High-performance pervious concrete ensures long-term stability under industrial operating conditions while managing site stormwater runoff.

- (4)

- Ground paving for electric vehicle (EV) charging stations: In areas requiring installation of charging pile foundations and enduring the static/dynamic loads from EV parking and charging, high-performance pervious concrete provides robust foundational support and enables the rapid drainage of rainwater, eliminating safety hazards associated with water accumulation in charging zones.

- (1)

- (2)

- Molecular dynamics simulations should be employed to investigate the interfacial molecular interactions between nano-silica (NS), carbon fiber (CF), and other hydration products within the cement matrix. This approach would provide deeper insights into the influence of these materials at the molecular level on the performance of high-performance pervious concrete [87].

- (3)

- Low-carbon concrete materials are currently an urgent requirement for achieving sustainable human development. Based on this study, further researchers should focus on developing high-performance pervious concrete utilizing low-carbon cementitious materials, such as limestone calcined clay cement (LC3) and hybrid alkaline cement incorporating carbon sequestration technologies [88,89], while conducting comprehensive life cycle assessments (LCAs) to evaluate their environmental impacts [90,91].

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| W/C | Water-to-cement ratio |

| NS | Nano-silica |

| CF | Carbon fiber |

| PC | Pervious concrete |

| FA | Fly ash |

| RSM | Response surface methodology |

References

- Yang, J.; Jiang, G. Experimental study on properties of pervious concrete pavement materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material–Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar]

- ACI 522R-10; Report on Pervious Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2010.

- Deo, O.; Neithalath, N. Compressive behavior of pervious concretes and a quantification of the influence of random pore structure features. Mater. Sci. Eng. A 2010, 528, 402–412. [Google Scholar]

- McCain, G.N.; Dewoolkar, M.M. Porous concrete pavements: Mechanical and hydraulic properties. Transp. Res. Rec. 2010, 2164, 66–75. [Google Scholar]

- Adresi, M.; Yamani, A.; Tabarestani, M.K.; Rooholamini, H. A comprehensive review on pervious concrete. Constr. Build. Mater. 2023, 407, 133308. [Google Scholar]

- Chiriac, R.; Kiss, Z. Fiber reinforced polymers in pervious concrete-a state of the art review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Saint-Raphaël, France, 7–11 October 2024; p. 012025. [Google Scholar]

- Sathiparan, N.; Dassanayake, D.; Subramaniam, D. Utilization of supplementary cementitious materials in pervious concrete: A review. Int. J. Environ. Sci. Technol. 2024, 21, 5883–5918. [Google Scholar]

- Li, J.; Xia, J.; Di Sarno, L.; Gong, G. Fiber utilization in pervious concrete: Review on manufacture and properties. Constr. Build. Mater. 2023, 406, 133372. [Google Scholar]

- López-Carrasquillo, V.; Hwang, S. Comparative assessment of pervious concrete mixtures containing fly ash and nanomaterials for compressive strength, physical durability, permeability, water quality performance and production cost. Constr. Build. Mater. 2017, 139, 148–158. [Google Scholar]

- Vieira, G.L.; Schiavon, J.Z.; Borges, P.M.; da Silva, S.R.; de Oliveira Andrade, J.J. Influence of recycled aggregate replacement and fly ash content in performance of pervious concrete mixtures. J. Clean. Prod. 2020, 271, 122665. [Google Scholar]

- Liu, H.; Luo, G.; Wang, L.; Wang, W.; Li, W.; Gong, Y. Laboratory evaluation of eco-friendly pervious concrete pavement material containing silica fume. Appl. Sci. 2019, 9, 73. [Google Scholar]

- Song, H.W.; Pack, S.W.; Nam, S.H.; Jang, J.C.; Saraswathy, V. Estimation of the permeability of silica fume cement concrete. Constr. Build. Mater. 2010, 24, 315–321. [Google Scholar]

- Amala, M.; Meenachi, A.; Gopalan, A.; Nanduri, P.R.K.; Ramesh, K. An experimental investigation of M30 grade self compacting concrete using mineral admixtures. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Amala, M.; Umarani, C. Experimental investigation on mechanical and microstructural properties of self-compacting geopolymer concrete with different mineral admixtures. Mater. Res. Express 2024, 11, 095305. [Google Scholar]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of fly ash and metakaolin on pervious concrete properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar]

- Chen, Y.; Wang, K.; Wang, X.; Zhou, W. Strength, fracture and fatigue of pervious concrete. Constr. Build. Mater. 2013, 42, 97–104. [Google Scholar]

- Zhang, B.; Tan, H.; Shen, W.; Xu, G.; Ma, B.; Ji, X. Nano-silica and silica fume modified cement mortar used as Surface Protection Material to enhance the impermeability. Cem. Concr. Compos. 2018, 92, 7–17. [Google Scholar]

- Ahmed, M.A.; Hassanean, Y.A.; Assaf, K.A.; Shawkey, M.A. The Effect of Incorporation of Ferrite Nano-particles on Compressive Strength and Re-sistivity of Self-Compacting Concrete. Open J. Civ. Eng. 2015, 5, 131. [Google Scholar]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar]

- Ramadhansyah, P.J.; Mohd Ibrahim, M.Y.; Mohd Rosli, H.; Warid, M.N.; Wan Ibrahim, M.H. Porous concrete pavement containing nano-silica: Pre-review. Adv. Mater. Res. 2014, 911, 454–458. [Google Scholar]

- Wang, Y.; Hughes, P.; Niu, H.; Fan, Y. A new method to improve the properties of recycled aggregate concrete: Composite addition of basalt fiber and nano-silica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar]

- Jalal, M.; Mansouri, E.; Sharifipour, M.; Pouladkhan, A.R. Mechanical, rheological, durability and microstructural properties of high performance self-compacting concrete containing SiO2 micro and nanoparticles. Mater. Des. 2012, 34, 389–400. [Google Scholar]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar]

- Ren, J.; Lai, Y.; Gao, J. Exploring the influence of SiO2 and TiO2 nanoparticles on the mechanical properties of concrete. Constr. Build. Mater. 2018, 175, 277–285. [Google Scholar]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar]

- Mohammed, B.S.; Adamu, M. Mechanical performance of roller compacted concrete pavement containing crumb rubber and nano silica. Constr. Build. Mater. 2018, 159, 234–251. [Google Scholar]

- Shirgir, B.; Hassani, A.; Khodadadi, A. Experimental study on permeability and mechanical properties of nanomodified porous concrete. Transp. Res. Rec. 2011, 2240, 30–35. [Google Scholar]

- Valderrama, R.; Santos, D.; Eyzaguirre, C. Influence of nanosilica and polypropylene fibers on the permeability, compressive and flexural strength of pervious concrete. In Proceedings of the E3S Web of Conferences, Les Mureaux, France, 21–22 November 2024; p. 04001. [Google Scholar]

- Alimohammadi, V.; Maghfouri, M.; Nourmohammadi, D.; Azarsa, P.; Gupta, R.; Saberian, M. Stormwater runoff treatment using pervious concrete modified with various nanomaterials: A comprehensive review. Sustainability 2021, 13, 8552. [Google Scholar] [CrossRef]

- Seifeddine, K.; Amziane, S.; Toussaint, E. State of the art on the mechanical properties of pervious concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 7727–7755. [Google Scholar]

- Ma, L.; Sun, M.; Zhang, Y. The Mechanical and Self-Sensing Properties of Carbon Fiber-and Polypropylene Fiber-Reinforced Engineered Cementitious Composites Utilizing Environmentally Friendly Glass Aggregate. Buildings 2024, 14, 938. [Google Scholar]

- Hesami, S.; Ahmadi, S.; Nematzadeh, M. Effects of rice husk ash and fiber on mechanical properties of pervious concrete pavement. Constr. Build. Mater. 2014, 53, 680–691. [Google Scholar]

- Jiang, Z.W.; Sun, Z.P.; Wang, P.M. Effects of some factors on properties of porous pervious concrete. J. Build. Mater. 2005, 8, 513–519. [Google Scholar]

- Huang, B.; Wu, H.; Shu, X.; Burdette, E.G. Laboratory evaluation of permeability and strength of polymer-modified pervious concrete. Constr. Build. Mater. 2010, 24, 818–823. [Google Scholar]

- Wu, H.; Huang, B.; Shu, X.; Dong, Q. Laboratory evaluation of abrasion resistance of portland cement pervious concrete. J. Mater. Civ. Eng. 2011, 23, 697–702. [Google Scholar]

- Shah, A.A.; Ribakov, Y. Recent trends in steel fibered high-strength concrete. Mater. Des. 2011, 32, 4122–4151. [Google Scholar]

- Zheng, Y.; Lv, X.; Hu, S.; Zhuo, J.; Wan, C.; Liu, J. Mechanical properties and durability of steel fiber reinforced concrete: A review. J. Build. Eng. 2024, 82, 108025. [Google Scholar]

- Lee, M.-G.; Wang, W.-C.; Wang, Y.-C.; Hsieh, Y.-C.; Lin, Y.-C. Mechanical properties of high-strength pervious concrete with steel fiber or glass fiber. Buildings 2022, 12, 620. [Google Scholar] [CrossRef]

- Rodin, I.I.I.H.; Rangelov, M.; Nassiri, S.; Englund, K. Enhancing mechanical properties of pervious concrete using carbon fiber composite reinforcement. J. Mater. Civ. Eng. 2018, 30, 04018012. [Google Scholar]

- Rangelov, M.; Nassiri, S.; Haselbach, L.; Englund, K. Using carbon fiber composites for reinforcing pervious concrete. Constr. Build. Mater. 2016, 126, 875–885. [Google Scholar]

- Lang, L.; Duan, H.; Chen, B. Properties of pervious concrete made from steel slag and magnesium phosphate cement. Constr. Build. Mater. 2019, 209, 95–104. [Google Scholar]

- Li, J.; Zhang, Y.; Liu, G.; Peng, X. Preparation and performance evaluation of an innovative pervious concrete pavement. Constr. Build. Mater. 2017, 138, 479–485. [Google Scholar]

- Fei, M.; Luo, C.; Zheng, X.; Fu, T.; Ling, K.; Chen, H.; Liu, W.; Qiu, R. High-performance pervious concrete using cost-effective modified vinyl ester as binder. Constr. Build. Mater. 2024, 414, 134908. [Google Scholar]

- Shen, P.; Lu, J.X.; Zheng, H.; Liu, S.; Poon, C.S. Conceptual design and performance evaluation of high strength pervious concrete. Constr. Build. Mater. 2021, 269, 121342. [Google Scholar]

- Lian, C.; Zhuge, Y. Optimum mix design of enhanced permeable concrete–an experimental investigation. Constr. Build. Mater. 2010, 24, 2664–2671. [Google Scholar]

- Bonicelli, A.; Giustozzi, F.; Crispino, M. Experimental study on the effects of fine sand addition on differentially compacted pervious concrete. Constr. Build. Mater. 2015, 91, 102–110. [Google Scholar]

- GB 175-2020; Portland Cement. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2020. (In Chinese)

- Khankhaje, E.; Kim, T.; Jang, H.; Kim, C.-S.; Kim, J.; Rafieizonooz, M. Properties of pervious concrete incorporating fly ash as partial replacement of cement: A review. Dev. Built Environ. 2023, 14, 100130. [Google Scholar]

- Jo, B.W.; Kim, C.H.; Tae, G.H.; Park, J.B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar]

- Singh, L.P.; Bhattacharyya, S.K.; Mishra, G.; Ahalawat, S. Reduction of calcium leaching in cement hydration process using nanomaterials. Mater. Technol. 2012, 27, 233–238. [Google Scholar]

- Kontoleontos, F.; Tsakiridis, P.E.; Marinos, A.; Kaloidas, V.; Katsioti, M. Influence of colloidal nanosilica on ultrafine cement hydration: Physicochemical and microstructural characterization. Constr. Build. Mater. 2012, 35, 347–360. [Google Scholar]

- Singh, L.P.; Bhattacharyya, S.K.; Ahalawat, S. Preparation of size controlled silica nano particles and its functional role in cementitious system. J. Adv. Concr. Technol. 2012, 10, 345–352. [Google Scholar]

- Rahul, R.; Kumar, M.S.R. Influence of nano-silica and shredded plastics in pervious concrete. Matéria 2024, 29, e20240127. [Google Scholar]

- Wang, J.; Yang, Y.; Chu, J.; Mo, K.H.; Yap, P.S. Recent developments in utilization of nano silica in self-compacting concrete: A review. Struct. Concr. 2023, 24, 7524–7548. [Google Scholar]

- Nie, L.; Li, X.; Li, J.; Zhu, B.; Lin, Q. Analysis of high performance concrete mixed with nano-silica in front of sulfate attack. Materials 2022, 15, 7614. [Google Scholar] [CrossRef] [PubMed]

- Chithra, S.; Kumar, S.S.; Chinnaraju, K. The effect of Colloidal Nano-silica on workability, mechanical and durability properties of High Performance Concrete with Copper slag as partial fine aggregate. Constr. Build. Mater. 2016, 113, 794–804. [Google Scholar]

- Chen, P.W.; Chung, D.D. Concrete reinforced with up to 0.2 vol% of short carbon fibres. Composites 1993, 24, 33–52. [Google Scholar]

- Segura, I.; Faneca, G.; Torrents, J.; Aguado, A. Self-sensing concrete made from recycled carbon fibres. Smart Mater. Struct. 2019, 28, 105045. [Google Scholar]

- Nguyen, H.; Carvelli, V.; Fujii, T.; Okubo, K. Cement mortar reinforced with reclaimed carbon fibres, CFRP waste or prepreg carbon waste. Constr. Build. Mater. 2016, 126, 321–331. [Google Scholar]

- More, F.M.D.S.; Subramanian, S.S. Impact of fibres on the mechanical and durable behaviour of fibre-reinforced concrete. Buildings 2022, 12, 1436. [Google Scholar] [CrossRef]

- Box, G.E.; Wilson, K.B. On the experimental attainment of optimum conditions. Breakthr. Stat. Methodol. Distrib. 1992, 270–310. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M.T. Investigating the effect of mixture design parameters on pervious concrete by statistical modelling. Constr. Build. Mater. 2013, 38, 147–154. [Google Scholar]

- Mohammed, B.S.; Achara, B.E.; Nuruddin, M.F.; Yaw, M.; Zulkefli, M.Z. Properties of nano-silica-modified self-compacting engineered cementitious composites. J. Clean. Prod. 2017, 162, 1225–1238. [Google Scholar]

- Ferdosian, I.; Camões, A. Eco-efficient ultra-high performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017, 84, 146–156. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Specification for Pervious Cement Concrete Pavement; China Architecture & Building Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architecture & Building Press: Beijing, China, 2002. (In Chinese) [Google Scholar]

- Zhang, M.H.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar]

- Singh, A.; Sampath, P.V.; Biligiri, K.P. A review of sustainable pervious concrete systems: Emphasis on clogging, material characterization, and environmental aspects. Constr. Build. Mater. 2020, 261, 120491. [Google Scholar]

- Zhong, R.; Leng, Z.; Poon, C.S. Research and application of pervious concrete as a sustainable pavement material: A state-of-the-art and state-of-the-practice review. Constr. Build. Mater. 2018, 183, 544–553. [Google Scholar]

- Land, G.; Stephan, D. The influence of nano-silica on the hydration of ordinary Portland cement. J. Mater. Sci. 2012, 47, 1011–1017. [Google Scholar]

- Madani, H.; Bagheri, A.; Parhizkar, T. The pozzolanic reactivity of monodispersed nanosilica hydrosols and their influence on the hydration characteristics of Portland cement. Cem. Concr. Res. 2012, 42, 1563–1570. [Google Scholar]

- Mohammed, B.S.; Adamu, M. Non-destructive evaluation of nano silica-modified roller-compacted rubbercrete using combined SonReb and response surface methodology. Road Mater. Pavement Des. 2019, 20, 815–835. [Google Scholar]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar]

- Hu, Y.; Wang, Z.; Chen, Z.; Wang, C.; Ding, S.; Nie, Z.; Hou, T.; Zhao, G. The Improving Role of Basalt Fiber on the Sulfate–Chloride Multiple Induced Degradation of Cast-In-Situ Concrete. Materials 2024, 17, 4454. [Google Scholar]

- Rehder, B.; Banh, K.; Neithalath, N. Fracture behavior of pervious concretes: The effects of pore structure and fibers. Eng. Fract. Mech. 2014, 118, 1–6. [Google Scholar]

- Meddah, M.S.; Bencheikh, M. Properties of concrete reinforced with different kinds of industrial waste fibre materials. Constr. Build. Mater. 2009, 23, 3196–3205. [Google Scholar]

- Xiong, C.; Li, Q.; Lan, T.; Li, H.; Long, W.; Xing, F. Sustainable use of recycled carbon fiber reinforced polymer and crumb rubber in concrete: Mechanical properties and ecological evaluation. J. Clean. Prod. 2021, 279, 123624. [Google Scholar]

- Romualdi, J.P.; Mandel, J.A. Tensile strength of concrete affected by uniformly distributed and closely spaced short lengths of wire reinforcement. J. Proc. 1964, 61, 657–672. [Google Scholar]

- Landis, C.M.; McMeeking, R.M. Stress concentrations in composites with interface sliding, matrix stiffness and uneven fiber spacing using shear lag theory. Int. J. Solids Struct. 1999, 36, 4333–4361. [Google Scholar]

- Pan, N. Theoretical determination of the optimal fiber volume fraction and fiber-matrix property compatibility of short fiber composites. Polym. Compos. 1993, 14, 85–93. [Google Scholar]

- Ali, A.H.; Mohamed, H.M.; Benmokrane, B.; ElSafty, A. Theory-based approaches and microstructural analysis to evaluate the service life-retention of stressed carbon fiber composite strands for concrete bridge applications. Compos. Part B Eng. 2019, 165, 279–292. [Google Scholar]

- Liu, W.; Chen, P. Theoretical analysis and experimental investigation of the occurrence of fiber bridging in unidirectional laminates under Mode I loading. Compos. Struct. 2021, 257, 113383. [Google Scholar]

- Xie, N.; Akin, M.; Shi, X. Permeable concrete pavements: A review of environmental benefits and durability. J. Clean. Prod. 2019, 210, 1605–1621. [Google Scholar]

- Wu, H.; Liu, Z.; Sun, B.; Yin, J. Experimental investigation on freeze–thaw durability of Portland cement pervious concrete (PCPC). Constr. Build. Mater. 2016, 117, 63–71. [Google Scholar]

- Liu, M.; Dai, W.; Li, M.; Jin, W.; Yang, X.; Han, Y.; Huang, M. Mechanism of interface performance enhancement of nano-SiO2 modified polyvinyl alcohol fiber reinforced geopolymer concrete: Experiments, microscopic characterization, and molecular simulation. J. Build. Eng. 2024, 98, 111062. [Google Scholar]

- Wang, Y.-S.; Meng, L.-Y.; Chen, L.; Wang, X.-Y. An innovative strategy for CO2 conversion and utilization: Semi-wet carbonation pretreatment of wollastonite to prepare carbon-fixing products and produce LC3. Cem. Concr. Compos. 2025, 160, 106050. [Google Scholar]

- Wang, Y.-S.; Lin, R.; Wang, X.-Y. Insights on solid CO2 mixing method for hybrid alkaline cement (HAC): Performance, sustainability, and experimental system improvement. Cem. Concr. Compos. 2025, 161, 106096. [Google Scholar]

- Liu, J.; Li, H.; Wang, Y.; Zhang, H. Integrated life cycle assessment of permeable pavement: Model development and case study. Transp. Res. Part D Transp. Environ. 2020, 85, 102381. [Google Scholar]

- Chen, X.; Wang, H. Life-cycle assessment and multi-criteria performance evaluation of pervious concrete pavement with fly ash. Resour. Conserv. Recycl. 2022, 177, 105969. [Google Scholar]

| Properties | Standard Value [49] | Actual Value | |

|---|---|---|---|

| Physical properties | Specific surface area (m2/kg) | ≥300 | 329 |

| Initial set (min) | ≥45 | 192 | |

| Final set (min) | ≤600 | 240 | |

| Chemical properties | Loss on ignition (%) | ≤5.0 | 3.64 |

| MgO (%) | ≤5.0 | 1.01 | |

| CaO (%) | ≥66.0 | 66.54 | |

| SiO2 (%) | ≥20.0 | 21.03 | |

| Al2O3 (%) | ≥4.0 | 4.36 | |

| Fe2O3 (%) | ≥2.0 | 2.32 | |

| CaSO4·2H2O (%) | ≥2.0 | 2.14 | |

| SO3 (%) | ≤3.5 | 2.16 | |

| Cl− (%) | ≤0.06 | 0.021 | |

| Index | Fineness (%) | Water Demand Ratio (%) | Loss on Ignition (%) | Moisture Content (%) | SO3 (%) | CaO3 (%) | Stability (Reye Method) (mm) | Intensity Activity Index (%) |

|---|---|---|---|---|---|---|---|---|

| Value | 14.2 | 99 | 0.77 | 0.11 | 0.1 | 0.68 | 3 | 74 |

| Index | SiO2 (%) | Fe (%) | Mn (%) | Pb (%) | Specific Surface Area (m2/g) | Mean Grain Size (nm) | Bulk Density (g/cm3) |

|---|---|---|---|---|---|---|---|

| Value | 99.1 | 0.01 | 0.002 | 0.00001 | 202 | 22 | 0.15 |

| Index | Tensile Strength (MPa) | Tensile Modulus (GPa) | Density (g/cm3) | Diameter (μm) | Length (mm) | Carbon Content (%) |

|---|---|---|---|---|---|---|

| Value | 3500 | 228 | 1.75 | 7 | 6 | >95 |

| Factor | Code | Levels of Code | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| W/C | A | 0.26 | 0.28 | 0.3 |

| CF (%) | B | 1 | 1.5 | 2 |

| NS (%) | C | 1 | 2 | 3 |

| Group | W/C | CF | NS | Content (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | (%) | Cement | Fly ash | NS | CA | Sand | CF | Water | SP | ||

| 1 | 0.26 | 1 | 1 | 394.27 | 44.3 | 4.43 | 1553 | 108.7 | 2.50 | 113 | 2.2 |

| 2 | 0.3 | 1 | 1 | 394.27 | 44.3 | 4.43 | 1553 | 108.7 | 2.50 | 130.7 | 2.2 |

| 3 | 0.26 | 2 | 1 | 394.27 | 44.3 | 4.43 | 1553 | 108.7 | 4.99 | 113 | 2.2 |

| 4 | 0.3 | 2 | 1 | 394.27 | 44.3 | 4.43 | 1553 | 108.7 | 4.99 | 130.7 | 2.2 |

| 5 | 0.26 | 1 | 3 | 385.41 | 44.3 | 13.29 | 1553 | 108.7 | 2.50 | 113 | 2.2 |

| 6 | 0.3 | 1 | 3 | 385.41 | 44.3 | 13.29 | 1553 | 108.7 | 2.50 | 130.7 | 2.2 |

| 7 | 0.26 | 2 | 3 | 385.41 | 44.3 | 13.29 | 1553 | 108.7 | 4.99 | 113 | 2.2 |

| 8 | 0.3 | 2 | 3 | 385.41 | 44.3 | 13.29 | 1553 | 108.7 | 4.99 | 130.7 | 2.2 |

| 9 | 0.26 | 1.5 | 2 | 389.84 | 44.3 | 8.86 | 1553 | 108.7 | 3.74 | 113 | 2.2 |

| 10 | 0.3 | 1.5 | 2 | 389.84 | 44.3 | 8.86 | 1553 | 108.7 | 3.74 | 130.7 | 2.2 |

| 11 | 0.28 | 1 | 2 | 389.84 | 44.3 | 8.86 | 1553 | 108.7 | 2.50 | 121.8 | 2.2 |

| 12 | 0.28 | 2 | 2 | 389.84 | 44.3 | 8.86 | 1553 | 108.7 | 4.99 | 121.8 | 2.2 |

| 13 | 0.28 | 1.5 | 1 | 394.27 | 44.3 | 4.43 | 1553 | 108.7 | 3.74 | 121.8 | 2.2 |

| 14 | 0.28 | 1.5 | 3 | 385.41 | 44.3 | 13.29 | 1553 | 108.7 | 3.74 | 121.8 | 2.2 |

| 15-19 | 0.28 | 1.5 | 2 | 389.84 | 44.3 | 8.86 | 1553 | 108.7 | 3.74 | 121.8 | 2.2 |

| Test Number | Design of Tests | Permeability Coefficient | Compressive Strength | Flexural Strength | ||

|---|---|---|---|---|---|---|

| A | B | C | mm/s | MPa | ||

| 1 | −1 | −1 | 0 | 5.97 | 36.4 | 3.64 |

| 2 | 1 | −1 | 0 | 4.32 | 33.7 | 4.02 |

| 3 | −1 | 1 | 0 | 5.52 | 36.5 | 3.84 |

| 4 | 1 | 1 | 0 | 3.74 | 34.4 | 4.64 |

| 5 | −1 | −1 | 1 | 5.24 | 37.2 | 3.77 |

| 6 | 1 | −1 | 1 | 4.02 | 34.8 | 4.53 |

| 7 | −1 | 1 | 1 | 5.01 | 37.4 | 3.42 |

| 8 | 1 | 1 | 1 | 3.45 | 35.1 | 4.82 |

| 9 | −1 | 0 | 0 | 5.11 | 41.7 | 3.96 |

| 10 | 1 | 0 | 0 | 4.06 | 42.6 | 5.01 |

| 11 | 0 | −1 | 0 | 4.72 | 44.7 | 5.39 |

| 12 | 0 | 1 | 0 | 4.38 | 45.3 | 5.48 |

| 13 | 0 | 0 | −1 | 4.97 | 41.6 | 5.42 |

| 14 | 0 | 0 | 1 | 4.44 | 41.3 | 5.57 |

| 15 | 0 | 0 | 0 | 4.54 | 45.6 | 5.64 |

| 16 | 0 | 0 | 0 | 4.63 | 44.3 | 5.73 |

| 17 | 0 | 0 | 0 | 4.49 | 44.9 | 5.69 |

| 18 | 0 | 0 | 0 | 4.72 | 45.2 | 5.70 |

| 19 | 0 | 0 | 0 | 4.57 | 43.5 | 5.79 |

| Response | Regression Equation |

|---|---|

| Permeability coefficient | R1 = −9.32 + 160.81 A − 0.43 B − 2.30 C + 4.06 A × C − 371.13 A2 + 0.23 C2 |

| Compressive strength | R2 = − 791.06 + 5866.58 A + 0.38 B + 20.00 C − 10552.82 A2 − 4.92 C2 |

| Flexural strength | R3 = − 228.93 + 1658.06 A − 0.20 B − 0.60 C + 13.25 A × B + 6.13 A × C − 0.22 B × C − 2978.99 A2 − 0.97B2 − 0.18C2 |

| Response | Source | Sum of Squares | Degrees of Freedom | Mean Square | F-value | p-Value |

|---|---|---|---|---|---|---|

| Permeability coefficient R2 0.9845 Adjusted R2 0.9767 Predicted R2 0.9534 | Model | 7.30 | 6 | 1.22 | 126.94 | <0.0001 |

| A-W/C | 6.05 | 1 | 5.27 | 631.20 | <0.0001 | |

| B-CF | 0.4709 | 1 | 0.4709 | 49.11 | 0.0001 | |

| C-NS | 0.5570 | 1 | 0.5570 | 58.08 | <0.0001 | |

| AC | 0.0528 | 1 | 0.0528 | 5.51 | 0.0369 | |

| A2 | 0.0695 | 1 | 0.0695 | 7.25 | 0.0196 | |

| C2 | 0.1692 | 1 | 0.1692 | 17.64 | 0.0012 | |

| Residual | 0.1151 | 12 | 0.0096 | |||

| Lack of Fit | 0.0837 | 8 | 0.0105 | 1.33 | 0.4153 | |

| Pure Error | 0.0314 | 4 | 0.0078 | |||

| Compressive strength | Model | 321.60 | 5 | 64.32 | 53.88 | <0.0001 |

| A-W/C | 7.40 | 1 | 7.40 | 6.20 | 0.0271 | |

| B-CF | 0.3610 | 1 | 0.3610 | 0.3024 | 0.5917 | |

| R2 0.9540 | C-NS | 1.02 | 1 | 1.02 | 0.8579 | 0.3712 |

| Adjusted R2 | A2 | 56.23 | 1 | 56.23 | 47.10 | <0.0001 |

| 0.9363 | C2 | 76.42 | 1 | 76.42 | 64.02 | <0.0001 |

| Predicted R2 | Residual | 15.52 | 13 | 1.19 | 1.42 | 0.3874 |

| 0.8868 | Lack of Fit | 12.82 | 9 | 1.42 | 2.11 | 0.2457 |

| Pure Error | 2.70 | 4 | 0.6750 | |||

| Flexural | Model | 12.55 | 9 | 1.39 | 278.30 | <0.0001 |

| strength | A-W/C | 1.93 | 1 | 1.93 | 384.76 | <0.0001 |

| B-CF | 0.0722 | 1 | 0.0722 | 14.42 | 0.0042 | |

| R2 0.9964 | C-NS | 0.0302 | 1 | 0.0302 | 6.04 | 0.0363 |

| Adjusted R2 | AB | 0.1405 | 1 | 0.1405 | 28.04 | 0.0005 |

| 0.9928 Predicted R2 0.9717 | AC | 0.1201 | 1 | 0.1201 | 23.97 | 0.0009 |

| BC | 0.0968 | 1 | 0.0968 | 19.33 | 0.0017 | |

| A2 | 3.88 | 1 | 3.88 | 774.57 | <0.0001 | |

| B2 | 0.1595 | 1 | 0.1595 | 31.84 | 0.0003 | |

| C2 | 0.0901 | 1 | 0.0901 | 17.99 | 0.0022 | |

| Residual | 0.0451 | 9 | 0.0050 | |||

| Lack of Fit | 0.0329 | 5 | 0.0066 | 2.16 | 0.2383 | |

| Pure Error | 0.0122 | 4 | 0.0030 |

| Mix Design | Permeability (mm/s) | Compressive Strength (MPa) | Flexural Strength (MPa) | Desirability | |||

|---|---|---|---|---|---|---|---|

| W/C | CF (%) | NS (%) | Prediction | Prediction | Prediction | ||

| A | 0.263 | 1.208 | 1.359 | 5.5 | 40.44 | 4.29 | 0.928 |

| B | 0.279 | 1.963 | 1.93 | 4.468 | 45 | 5.5 | 0.981 |

| C | 0.284 | 1.597 | 2.162 | 4.311 | 44.8 | 5.8 | 0.984 |

| A | B | |||||

|---|---|---|---|---|---|---|

| Prediction | Actual | Error | Prediction | Actual | Error | |

| Permeability coefficient (mm/s) | 5.5 | 5.2 | 5.5% | 4.468 | 4.7 | 5.20% |

| Compressive strength (MPa) | 40.44 | 42 | 3.8% | 45 | 42 | 6.67% |

| Flexural strength (MPa) | 4.29 | 4.4 | 2.56% | 5.5 | 5.2 | 5.46% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Sun, M.; Zhang, Y.; Ma, L. Evaluation of High-Performance Pervious Concrete Mixed with Nano-Silica and Carbon Fiber. Buildings 2025, 15, 2407. https://doi.org/10.3390/buildings15142407

Sun M, Sun M, Zhang Y, Ma L. Evaluation of High-Performance Pervious Concrete Mixed with Nano-Silica and Carbon Fiber. Buildings. 2025; 15(14):2407. https://doi.org/10.3390/buildings15142407

Chicago/Turabian StyleSun, Mingxuan, Meng Sun, Yunlong Zhang, and Lijun Ma. 2025. "Evaluation of High-Performance Pervious Concrete Mixed with Nano-Silica and Carbon Fiber" Buildings 15, no. 14: 2407. https://doi.org/10.3390/buildings15142407

APA StyleSun, M., Sun, M., Zhang, Y., & Ma, L. (2025). Evaluation of High-Performance Pervious Concrete Mixed with Nano-Silica and Carbon Fiber. Buildings, 15(14), 2407. https://doi.org/10.3390/buildings15142407

_Su.png)