1. Introduction

Concrete, as the cornerstone of modern construction engineering, has undergone nearly two centuries of development and refinement since the invention of cement in 1824. It has become an indispensable foundational material in modern engineering structures, such as bridge engineering, civil engineering, transportation, and water conservancy projects [

1,

2]. According to statistics, the current annual consumption of concrete in China has reached a staggering 10.9 billion cubic meters, and it continues to show a trend of sustained growth. However, traditional concrete materials have many inherent flaws: their low tensile strength, significant self-weight, and marked brittleness make them prone to cracking under improper construction or stress conditions; the slow hardening rate of fresh concrete prolongs construction periods; and the presence of pores and micro-defects within hardened concrete compromises its long-term durability. Against this backdrop, enhancing the usability of concrete emerges as a critical initiative [

3,

4]. The addition of admixtures is one of the primary methods for enhancing concrete performance [

5]. Among them, nanomaterials exhibit exceptional physicochemical properties due to their unique surface effects and quantum size effects [

6]. Introducing nanomaterials into concrete offers a new approach to enhancing concrete performance. Since their application began in the field of concrete technology, related research has achieved remarkable advancements. Gaining a deep understanding of the effects of nanomaterials on concrete properties holds significant theoretical and practical importance. Among numerous nanomaterials, nano silica (NS), nano calcium carbonate (NC), and carbon nanotubes (CNTs) have emerged as research hotspots due to their unique reinforcement mechanisms and functional properties. Specifically, NS is renowned for its pozzolanic activity, NC excels in cost-effectiveness and nucleation effect, while CNTs distinguish themselves with their exceptional electrical conductivity and fiber reinforcement effect [

7].

NS, one of the most extensively studied nanomaterials for concrete modification, manifests as an amorphous white powder with an average particle size of approximately 20 nanometers, boasting non-toxic, odorless, and environmentally friendly characteristics. Its primary advantages reside in exceptionally high pozzolanic activity and micro-aggregate filling effects. When incorporated into concrete, the abundant silanol groups (Si-OH) on the surface of NS undergo pozzolanic reactions with calcium hydroxide (Ca(OH)

2)—a hydration product of cement—to generate supplementary calcium silicate hydrate (C-S-H) gel. This secondary gel formation mechanism enhances the microstructure density and strength development of the cementitious matrix. Simultaneously, the incorporation of NS enables microscale optimization of the interfacial transition zone (ITZ) structure, achieving densification modification of the concrete matrix while concurrently enhancing its macroscopic performance parameters—including workability characteristics, load-bearing capacity, and durability indicators. This dual-scale enhancement mechanism stems from both the pozzolanic reaction-driven C-S-H gel augmentation and the particle packing effect induced by nanoscale silica particles, which collectively refine the pore structure and reduce microcrack propagation pathways within the cementitious composite [

8,

9,

10].

NC is an economical and practical nanomaterial for modification purposes, with its cost being only about one-tenth that of NS. Despite this affordability, NC possesses unique nucleation effects and interfacial strengthening capabilities. NC has a specific gravity of approximately 2.7–2.8 g/cm3 and a melting point of up to 1339 °C. Its particle sizes typically range from 10 to 100 nanometers, granting it an extremely large specific surface area. During the cement hydration process, NC particles act as nucleation centers for the precipitation of hydration products, accelerating the hydrolysis of major clinker minerals such as tricalcium silicate (C3S). This, in turn, shortens the setting time and enhances the early-stage strength of the concrete.

CNTs represent a class of high-end nanomaterials for modification purposes, demonstrating immense potential in the concrete field due to their unique tubular structures and exceptional electromechanical properties. Multi-walled carbon nanotubes (MWCNTs) are the most widely applied type in concrete. Their typical dimensions feature an inner diameter ranging from 3 to 5 nm, an outer diameter between 8 and 15 nm, a length of 3 to 12 μm, and a density of approximately 2.15 g/cm3.

This review conducts a literature search using keywords such as “NS”, “NC”, “CNTs”, “mechanical properties”, and “durability performance” based on the Scopus database, Buildings, Materials, and the China National Knowledge Infrastructure (CNKI) database. Although there have been review articles on these three types of nanomaterials, they have not incorporated research findings from recent years, nor have they conducted relevant comparative analyses. This review primarily focuses on summarizing the effects of three distinct types of nanomaterials on the mechanical properties and durability of concrete while also offering insights into future development trends. In this review, over 80 academic papers were sourced from the Scopus database. The relevant influencing factors were systematically categorized, and each category was summarized. By comparing the research findings of different scholars, empirical evidence was provided regarding the impacts of these factors. This study offers valuable references for identifying key research focuses and directions in the study of the effects of three different nanomaterials on concrete.

This study provides a comprehensive review of the impacts of three distinct nanomaterials on the performance of concrete, particularly focusing on mechanical properties and durability aspects. Furthermore, it delves into an analysis of their respective action mechanisms and offers a comparative evaluation of these three nanomaterials. The abbreviated forms of professional terms in this paper are presented in

Table 1.

2. Nano-SiO2

2.1. The Impact of NS Dioxide on the Mechanical Properties of Concrete

2.1.1. The Influence of NS Dioxide on the Compressive Strength (or Compressive Performance) of Concrete

NS is characterized by its high purity, ultra-fine particle size, and remarkable pozzolanic reactivity, exhibiting excellent material properties. When an appropriate amount of NS is incorporated into concrete, it can enhance the hydration reaction rate of cement, leading to the formation of C-S-H gel. Meanwhile, NS continues to participate in secondary hydration reactions, consuming a portion of Ca(OH)

2, and thereby improving the compressive strength of the concrete [

11]. From the perspective of enhancing the compressive strength of concrete, there exists an optimal dosage range for NS incorporation. Excessive NS dosage can lead to a decline in the concrete’s compressive strength [

12]. Additionally, the particle size of NS, the addition process employed, and the uniformity of its distribution within the concrete matrix all influence the final compressive strength performance in different ways. Hu et al. [

13] conducted a specialized study on foam concrete with a cement–fly ash composite cementitious system, systematically analyzing the influence pattern of NS incorporation on its 28-day compressive strength. The experimental results indicate that the introduction of NS can significantly enhance the compactness of the foam concrete matrix through the synergistic effects of nano-filling and pozzolanic reactions, leading to a noticeable upward trend in the 28-day cube compressive strength. Ye et al. [

14] investigated the reinforcing effects of NS incorporated at dosages ranging from 1% to 3% in high-strength concrete. Their study revealed that NS could enhance the compressive strength of concrete throughout the entire curing period, with particularly pronounced strengthening effects observed during the early stages (1–7 days). When an optimal dosage (0.1–0.2%) of NS is incorporated into ordinary concrete, the compressive strength at 7 days of age can be increased by 40%, and at 28 days, it can be enhanced by 30%. The strength enhancement increased with the NS dosage. Notably, the 3% NS dosage group demonstrated the optimal performance in terms of early-age strength improvement, showing compressive strength increases of 20%, 30%, and 26% at 1 day, 3 days, and 7 days of age, respectively, compared to the control group. However, excessive addition of NS led to particle agglomeration, making it difficult to achieve uniform micro-scale dispersion within the concrete matrix. This dispersion defect directly deteriorated the workability of fresh concrete and reduced the structural density after hardening, ultimately constraining the expected reinforcing effects of NS on concrete performance. Najigivi et al. [

15,

16] discovered through comparative experiments that, in terms of enhancing the compressive strength of concrete, NS with an average particle size of 50 nm exhibited a more favorable dosage-effect relationship compared to the 10 nm specification. When the NS dosage was controlled within the range of 1% to 2%, the strength enhancement of the 50 nm particle size sample group was significantly superior to that of the smaller particle size control group. Ghafari et al. [

17] revealed through systematic research that in ultra-high performance concrete (UHPC) systems, there exists a critical dosage threshold of 3% for NS. When the dosage exceeds this value, the micro-scale dispersibility of NS particles within the cement matrix significantly decreases, leading to the formation of localized agglomeration zones. These zones subsequently result in the appearance of zones with weakened mechanical properties within the concrete specimens. The optimal dosage is highly dependent on the concrete system. High-strength concrete may tolerate a slightly higher dosage (e.g., 3%), whereas the UHPC system is more sensitive to agglomeration, with the critical threshold possibly being at 3% or even lower. Ordinary concrete exhibits good performance with a specific particle size at a dosage of 1–2%. There is a general consensus that exceeding a certain value (usually around 3% or lower) will lead to a decrease in strength. Research indicates that it is not necessarily true that smaller particle sizes always yield better results. At a dosage of 1–2%, 50 nm NS is more effective in enhancing strength compared to 10 nm NS. This challenges the intuitive notion that “smaller is always better,” highlighting the limitations imposed by the difficulty of dispersion and the risk of agglomeration for smaller particle sizes. The high specific surface area of smaller particles makes them more prone to agglomeration, which in turn affects their effective dispersion and reactivity.

2.1.2. The Impact of NS on the Tensile and Flexural Properties of Concrete

Ganesh et al. [

18] revealed through experiments that within the dosage range of 1% to 2%, NS can significantly enhance the tensile strength of high-strength concrete. Test data show that the tensile properties of concrete specimens within this dosage range improve by 17% to 24% compared to the control group, demonstrating the enhancing potential of NS as a nano-modifier. Jalal et al. [

19] confirmed through composite modification experiments that the synergistic incorporation of 2% NS and 10% fly ash into a self-compacting concrete (SCC) system can significantly enhance its tensile properties. Test data indicate that, under this formulation, the tensile strength of concrete specimens increases by 35.9% compared to the blank control group, demonstrating the synergistic strengthening effect of the nano-mineral composite modification technology. As the tensile stress within the concrete gradually increases and the tensile deformation continues to accumulate, microscopic initial cracks within the matrix continuously propagate and interconnect, eventually evolving into macroscopic cracks observable by the naked eye. The tensile load-bearing capacity of concrete essentially depends on the tensile strength characteristics of its ITZ, aggregate phase, and cement mortar matrix. Observations via scanning electron microscopy (SEM) have revealed that significant pore structures exist within the matrix of ordinary concrete. When NS is incorporated, it reacts with the cement hydration product Ca(OH)

2 through a pozzolanic reaction, generating C-S-H gel. This gel product effectively densifies the pore structure through the micro-aggregate filling effect, significantly improving the bonding performance of the aggregate-paste ITZ. Ultimately, this leads to an enhancement in the tensile strength of the concrete [

20]. Li et al. [

21] conducted nano-modification tests in UHPC systems, demonstrating that the sole incorporation of NS significantly optimized the flexural load-bearing performance (as illustrated in

Figure 1). Test data indicated that with increasing NS dosage, the flexural strength of UHPC initially increased and then decreased, reaching a peak at a 1% dosage, with enhancements of 27% (at 3 days) and 21% (at 28 days) compared to the control group. Notably, the enhancing effect of NS on the early-age flexural performance of UHPC was more pronounced, with its strengthening effect exhibiting a decaying characteristic as the curing age increased.

Zhang et al. [

22] revealed through nano-modification experiments that introducing 2.5% NS alone into a polymer mortar system can significantly enhance its flexural load-bearing capacity. Test data show that, under this dosage, the flexural strength of mortar specimens increases by 31.3% compared to the blank control group, validating the effectiveness of NS’s nano-strengthening effect in polymer–matrix composites.

2.1.3. The Impact of NS on the Mechanical Properties of Concrete After Exposure to High Temperatures

Research indicates that after exposure to high temperatures, high-strength concrete exhibits a more pronounced deterioration rate in mechanical properties compared to normal concrete, with the descending branch of its complete stress–strain curve displaying a steeper morphological characteristic. To address the issue of mechanical property degradation in concrete after exposure to high temperatures, researchers proposed a synergistic reinforcement strategy involving the composite incorporation of nanomaterials and fibrous materials [

23]. Gao et al. [

24] discovered through axial compression tests on concrete after high-temperature exposure that specimens incorporating 1% NS exhibited an 11.5% increase in peak stress compared to the control group, along with a 33.3% enlargement in the enclosed area of the stress–strain curve. This indicates that NS has a significant reinforcing effect on concrete degraded by high temperatures. The reason for this lies in the high pozzolanic reactivity of NS, which significantly accelerates the hydration process of concrete. The surface active sites of NS promote the chemical bonding of calcium hydroxide (CH), a hydration product, thereby inducing the formation of high-density C-S-H gel. Meanwhile, NS particles act as nucleating agents, providing heterogeneous nucleation sites for the formation of C-S-H gel. This leads to the development of a radial, clustered structure centered around the nanoparticles. Such optimization of the microstructure significantly improves the micromechanical properties of the ITZ, ultimately achieving a densification and enhancement of the concrete matrix’s microstructure [

25,

26]. Heika et al. [

27] revealed through performance tests on cement-based materials after high-temperature exposure that when the NS dosage was 1%, the residual compressive strength of composite cement paste significantly increased after high-temperature treatment. Experimental data showed that during the temperature rise to 450 °C, the compressive strength of the specimens exhibited a nonlinear growth trend and reached its peak at this temperature point. However, when the temperature rose to 1000 °C, the strength value experienced a sharp decline, indicating that the incorporation of NS optimized the mechanical properties at medium temperatures, but severe performance degradation still occurred under extremely high-temperature conditions. The reason for this is that the decomposition of part of the C-S-H gel at high temperatures leads to an increase in internal porosity, a decrease in compactness, and a significant reduction in compressive strength of the matrix. Some scholars argue that NS can enhance cement hydration through an internal high-pressure mechanism, leading to the formation of more C-S-H gel with a lower calcium-to-silicon ratio. This, in turn, improves the compactness of the specimens. The summary of the effects of NS on the mechanical properties of concrete is presented in

Table 2. Bastami et al. [

28] revealed through performance tests on concrete in high-temperature environments that the incorporation of NS can significantly improve the compressive and tensile strength indices of specimens after high-temperature exposure. The study particularly noted that within the temperature range of 400 °C to 800 °C, the mass loss rate of the NS-modified group was only 2.66%, representing a 35.6% reduction compared to the 4.13% loss rate of the control group. This enhancement in mass retention ability confirms the improving effect of NS on the high-temperature stability of concrete. The reason behind this phenomenon is that the loss rate of physically bound water within the matrix rises sharply under high-temperature conditions, leading to a rapid decrease in the compactness of the control group concrete.

2.2. The Impact of NS on the Durability of Concrete

2.2.1. The Impact of NS on the Chloride Ion Penetration Resistance of Concrete

Among the various factors influencing the durability of concrete, permeability performance plays a pivotal role. By enhancing the impermeability of concrete, the erosion effects of harmful media on the concrete matrix can be significantly curbed, thereby further improving the corrosion and erosion resistance of the concrete.

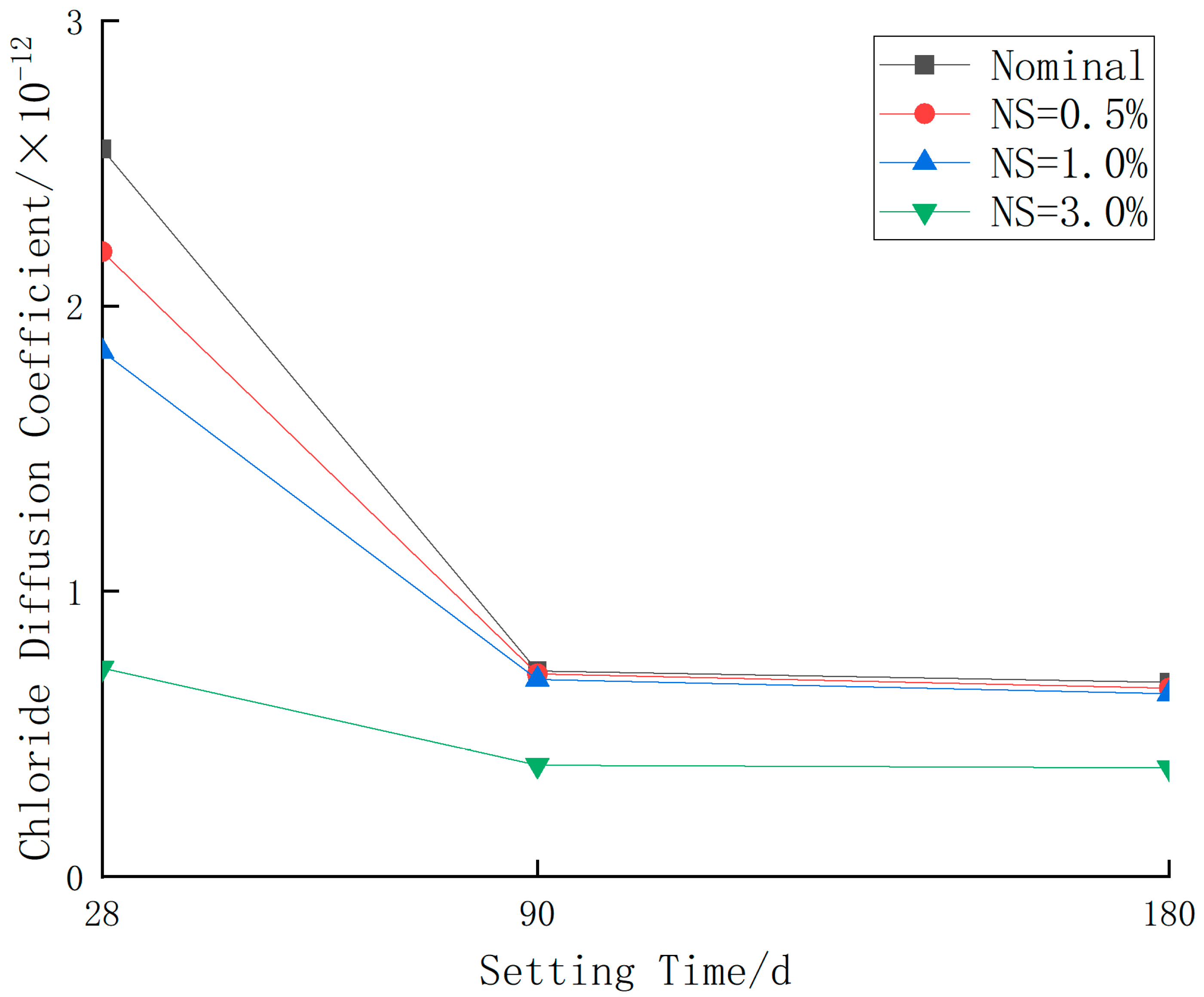

Li [

33], in exploring the impact of the composite addition of NS and fly ash on concrete properties, pointed out that the incorporation of NS improves both the early-stage and long-term chloride ion penetration resistance of concrete (as detailed in

Figure 2). Experimental data showed that when the NS dosage was controlled at 0.5% and 1%, the chloride ion penetration coefficients of the specimens did not exhibit a significant decreasing trend compared to the control group. However, when the NS dosage was increased to 3%, the chloride ion penetration coefficients of the specimens at the same period significantly decreased by 56–66% compared to the control group, indicating that this dosage level can significantly enhance the chloride ion penetration resistance of concrete.

Similarly, Said et al. [

34] conducted a systematic study on the effect of NS dosage on the chloride ion penetration resistance of concrete. The experimental results indicated that when the NS incorporation ratio was within the range of 3% to 6%, the permeability resistance of concrete specimens showed a significant improvement trend. Specifically, the test group with a 6% NS dosage exhibited a 60% increase in chloride ion penetration resistance compared to the blank control group. Through microscopic analysis, the research team revealed that the enhancement mechanism of NS primarily stems from its optimization of the pore structure in the cement matrix. The nanoparticles refine the capillary pore size through a filling effect and improve pore connectivity, thereby significantly enhancing the compactness of the concrete material, ultimately manifesting as an improvement in macroscopic permeability resistance. Mohseni et al. [

35], in a comparative analysis of the effects of various nanomaterials on the comprehensive properties of concrete, found that when the dosage of NS reached 5%, the chloride ion penetration resistance of concrete specimens showed significant improvement. Research data indicated that, compared to test groups with the addition of other types of nanomaterials alone, concrete specimens with a 5% NS dosage exhibited superior enhancement in chloride ion migration resistance, suggesting that NS at this dosage level has a prominent enhancing effect on the durability of concrete. Du et al. [

36] experimentally demonstrated that even with an extremely low dosage of NS, the permeability resistance of concrete can be significantly improved. Research data showed that when the NS dosage was only 0.3%, the chloride ion penetration coefficient of the specimens decreased by 28.7% compared to the control group, while the chloride ion diffusion coefficient decreased by 31%. This indicates that trace amounts of nanomaterials can significantly enhance the barrier effect against ion migration. Similarly, Quercia et al. [

37] observed through experiments that introducing an appropriate amount of NS into the concrete system can significantly regulate the morphology of hydration products. Their research indicates that the incorporation of NS can inhibit the formation of large-sized silicate crystalline phases while inducing the formation of nanoscale C-S-H gel particles. This effect of microstructural optimization leads to a reduction in matrix porosity by 18% to 25%, manifesting macroscopically as a significant increase in the compactness of concrete specimens. Li et al. [

38], while investigating the impact of NS dosage on the durability of autoclaved concrete, discovered that when the NS dosage was 2%, the chloride ion penetration coefficient of the concrete reached its lowest value, showing a significant reduction of 83.5% compared to the control group. This study revealed that at this dosage, NS promoted the homogeneous distribution of hydration products and refined the pore structure, leading to a 37% reduction in the micro-porosity of the matrix and thus forming an effective barrier against ion diffusion. Shaikh et al. [

39] analyzed the pattern of influence of the NS dosage on the chloride ion penetration resistance of concrete through experiments. The results indicated that when the NS dosage was 2%, the chloride ion diffusion coefficient of the concrete specimens decreased by 27% compared to the blank control group. Furthermore, if 30% fly ash was additionally incorporated on this basis, the chloride ion diffusion coefficient of the compositely modified concrete could be further reduced to 62% of that of the control group. This demonstrates a significant synergistic blocking effect of multi-component nanomodification technology on ion transport channels.

2.2.2. The Impact of NS on the Freeze–Thaw Resistance of Concrete

Under the severe cold winter climate conditions in Northern China, when the pore water inside concrete undergoes phase change and freezes, the resulting volume expansion effect generates frost-heave stress. When this stress value exceeds the ultimate tensile strength of the concrete material, it leads to structural cracking damage in the matrix [

40,

41]. To mitigate the damage caused to buildings by freeze–thaw deterioration, some scholars have proposed incorporating NS into concrete to enhance its freeze–thaw resistance. Wang [

42] discovered in the study of concrete’s freeze–thaw resistance that when the dosage of NS was 5% and the water–cement ratio (W/B) was 0.25, the relative dynamic elastic modulus of the concrete specimens was maintained at 95.6%. However, the loss rate of dynamic elastic modulus significantly increased by 75% compared to the control group. Under this mix proportion condition, the optimizing effect of the nanomaterial on the matrix’s microstructure failed to fully counteract the development of pore defects caused by the low water–cement ratio, ultimately resulting in an exacerbated attenuation of the elastic modulus during the freeze–thaw cycle process. Zhang et al. [

43] confirmed, based on the results of rapid freezing-thawing cycle tests, that the freeze–thaw resistance of concrete reached its optimal state when the NS dosage was 3%. This mix proportion significantly enhanced the durability of concrete under freeze–thaw cycles by optimizing the pore structure of the matrix and the distribution of hydration products. Guo‘s [

44] experiments demonstrated that adding 1% NS to concrete could effectively fill internal pores, thereby significantly improving the freeze–thaw resistance of the concrete. The researchers pointed out that the incorporation of NS could notably accelerate the pozzolanic reaction process and promote the generation of C-S-H gel. Its excellent specific surface area characteristics and nanoscale nucleation effect can provide numerous heterogeneous nucleation sites for the formation of C-S-H gel. This significantly enhances the compactness of the concrete matrix, effectively fills the micro-pore structure, and thus greatly improves the freeze–thaw durability of the concrete [

45,

46,

47].

2.3. The Impact of NS on the Microstructure of Concrete

Existing research indicates that the incorporation of an appropriate amount of NS can significantly enhance the mechanical properties and durability of concrete. The underlying mechanisms primarily stem from the pozzolanic effect, nucleation action, nanoscale effects, and the strengthening effect on the ITZ exhibited by NS. These effects synergize and interact within the concrete matrix, collectively improving the overall performance of the concrete. Due to its notable pozzolanic reactivity, NS can undergo a secondary chemical reaction with calcium hydroxide released during the cement hydration process, generating additional C-S-H gel products. This reaction process effectively strengthens the cohesion within the concrete matrix structure by increasing the volume fraction of the gel phase. During the early stage of the hydration reaction, NS can accelerate the hydration process of C

3S and promote the generation of C-S-H gel. As the hydration reaction progresses into the middle and late stages, NS reacts with the hydration products of C

3S formed in the early stage through a secondary hydration reaction, resulting in the formation of C-S-H gel with a lower calcium-to-silicon ratio and higher polymerization degree. Moreover, through its pozzolanic activity, NS can effectively absorb and refine the residual Ca(OH)

2crystals in the ITZ, thereby optimizing the microstructure and properties of the ITZ [

48].

Research conducted by Gaitero’s team [

49] demonstrates that the incorporation of NS significantly reduces the leaching rate of calcium ions in concrete, with the compressive strength of their specimens increasing by 30% compared to the control group. Their study indicates that NS optimizes the network structure of C-S-H gel by promoting the extension of siloxane tetrahedral chains within the hydration products. This, in turn, leads to the refinement of micro-pores, characterized by a reduction in the average size of micro-pores and an effective decrease in total porosity. Shaikh’s team [

50] confirmed through backscattered electron (BSE) imaging and X-ray diffraction (XRD) analysis that the composite incorporation of fly ash and NS in the concrete matrix can significantly optimize its microstructure. Their study reveals that the nanoscale particle size and high specific surface area characteristics of NS effectively promote the in-depth progression of secondary hydration reactions, generating C-S-H gel products with a low calcium-to-silicon ratio and high polymerization degree. This reconstruction of the microstructure results in a significant refinement of the pore network within the concrete matrix and a substantial improvement in the overall structural density. Tao et al. [

51,

52] confirmed through testing methods such as environmental scanning electron microscopy (ESEM) that the incorporation of NS can effectively optimize the microstructure of the relatively vulnerable ITZ in concrete and significantly reduce the porosity of the concrete matrix. Liu et al. [

53] conducted experimental research to investigate the influence of NS content on the properties of carbon fiber-reinforced concrete under different water-to-cement (w/c) ratios. The results indicate that, in a mix with a w/c ratio of 0.3, the incorporation of NS significantly reduces the porosity of the concrete. Moreover, when the w/c ratio is increased from 0.3 to 0.4, the addition of NS demonstrates a more pronounced improvement in the impermeability performance of the specimens. Kumar et al. [

54] discovered through SEM microstructure analysis that when the NS content is 2%, it can significantly improve the mechanical properties of concrete and effectively reduce matrix porosity. However, when the NS content exceeds the critical threshold of 2%, the performance-enhancing effect exhibits a diminishing trend. The study points out that an excessive amount of NS in the cement matrix tends to induce nanoparticle agglomeration, forming regions with microstructural defects. This leads to a weakening of the bond strength in the ITZ, ultimately resulting in a decline in the overall performance of the concrete. Ng’s team [

55] discovered in a targeted study on cement-based materials containing 30% fly ash that there exists an optimal threshold for NS content. When the NS content is 2%, the porosity of the specimens is optimized to 87% of that of the control group, forming the densest microstructure. However, when the NS content is further increased to 6%, the porosity shows a reverse growth trend. Their study reveals that NS exhibits a double-edged sword effect in composite cementitious systems: an appropriate amount of NS can optimize the pore network through nano-filling effects and pozzolanic reactions, while excessive addition can cause interfacial defects due to nanoparticle agglomeration, ultimately leading to a rebound in porosity.

2.4. The Application of NS in Concrete

As previously summarized, NS has numerous applications in concrete, but I believe the most significant ones can be broadly categorized into two aspects. The first aspect pertains to its application in enhancing mechanical properties. Multiple studies have confirmed the existence of a threshold dosage for NS, typically ranging from 1% to 3%. For high-performance concrete, when the dosage is 2% to 3%, the 28-day compressive strength and elastic modulus reach their peak values, with increases of 10% and 11%, respectively. However, excessive incorporation (>3%) leads to a decrease in strength due to the agglomeration effect. The second aspect concerns its application in improving durability. Nano-silica reacts with calcium hydroxide in the cement hydration products through its high pozzolanic activity, nucleation effect, and filling effect, generating more C-S-H gel and resulting in a denser concrete structure, thereby enhancing durability. For instance, the study conducted by Ibrahim M et al. [

56] primarily evaluated the long-term performance of NS-enhanced alkali-activated fly ash pozzolanic concrete in sodium sulfate and magnesium sulfate environments. The results indicated that the incorporation of NS significantly improved the concrete’s resistance to sulfate attack, thereby reducing strength loss.

3. Nano-CaCO3

3.1. The Impact of NC on the Mechanical Properties of Concrete

3.1.1. The Impact of NC on the Compressive Strength of Concrete

NC specifically refers to calcium carbonate particles with a particle size at the nanoscale. Compared to conventional micron-sized calcium carbonate, nano-sized particles possess a higher specific surface area and superior dispersion properties, which can significantly enhance their interfacial interactions with cement-based materials. When NC is introduced into the concrete system, it can optimize and improve the service performance of concrete in multiple dimensions through a synergistic mechanism combining physical filling effects and chemical reactivity [

57]. The introduction of NC can significantly enhance the mechanical properties and durability indicators of concrete. Its nanoscale effects optimize concrete performance through the following mechanisms: Firstly, the nucleating effect of the particles promotes the formation of a densely packed structure of cement hydration products, leading to increases in both the compressive strength and fracture energy of the concrete. Secondly, the interfacial strengthening effect of the nano-filler optimizes the load transfer paths, effectively inhibiting the initiation and propagation of microcracks. Furthermore, the high specific surface area characteristic of NC, through dual actions of physical filling and chemical modification, reduces the porosity of the concrete matrix and establishes a multiscale impermeable barrier. This ultimately results in a synergistic improvement in the chloride ion penetration resistance and carbonation resistance of the concrete [

58].

The incorporation of NC can significantly enhance the strength and toughness of concrete. Its nanoscale characteristics optimize performance through the following mechanisms: Firstly, the physical filling effect of ultrafine particles effectively reduces the porosity of the concrete matrix, enhancing structural density. Secondly, nano-particles chemically interact with the cement hydration system, inducing the formation of more well-crystallized ettringite and C-S-H gel products. This nano-reinforcement effect reconstructs the mechanical transfer network of the cement paste at the microscale, leading to a substantial improvement in the macroscopic mechanical properties of the concrete. Guo et al. [

59] systematically investigated the influence of NC dosage on the mechanical properties of concrete by adjusting its content. Their study reveals that, within a reasonable dosage range, NC can simultaneously enhance mechanical indicators such as compressive strength and flexural strength, as well as optimize workability, through a synergistic effect of nano-modification and cement hydration products. Douba et al. [

60] compared the effects of the dry dispersion method and the ultrasonic method on the performance of cement modified with NC (at a dosage of 4%). They found that NC accelerated the heat release of hydration, enhanced the 28-day compressive strength of mortar, and validated its effective mechanism of coating cement particles through SEM analysis. The study by Sivasankaran et al. [

61] reveals that excessive incorporation of NS may actually weaken the internal structural density of concrete. This is primarily attributed to the tendency of NS nanoparticles to agglomerate. When the dosage exceeds a critical threshold, the nanoparticles tend to form agglomerates within the concrete matrix, leading to uneven dispersion. This non-uniform distribution makes it difficult for NS to effectively optimize the internal pore network and fully exert its nanoscale effects in strengthening the ITZ. Consequently, this limits the expression of its nano-reinforcement effects and ultimately results in a decrease in the internal structural density of the concrete. The study by Al et al. [

62] investigated the effects of NC on the pore structure and compressive strength of concrete bricks. The results demonstrated that NC-enhanced bricks (Brick A and Brick B) achieved significantly higher compressive strengths of 35.25 MPa and 33.28 MPa, respectively, after 28 days, in contrast to the 21 MPa compressive strength of conventional cement bricks (Brick N). These findings indicate that the addition of NC can improve matrix densification, thereby enhancing mechanical properties. Steve W. et al. [

63] highlighted the role of NC in enhancing the compressive strength of high-volume fly ash (HVFA) mortars and concretes. Their research revealed that the addition of 1% NC could significantly improve both the early-age and 28-day compressive strengths. These findings were further corroborated by analyses conducted using SEM and XRD.

3.1.2. The Impact of NC on the Tensile and Flexural Properties of Concrete

Wei [

64] conducted a systematic study on the synergistic effects of NC and polypropylene fibers on the properties of recycled aggregate concrete (RAC). The results indicated that with the increase in NC content, the compressive strength of polypropylene fiber-reinforced RAC showed a decreasing trend after 28 days of standard curing. The reduction in splitting tensile strength and flexural strength was even more pronounced compared to the compressive strength. Microscopic analysis revealed that the incorporation of NC induced the formation of more C-S-H gel in the ITZ through pozzolanic reactions. This nano-reinforcement effect significantly improved the interfacial bonding performance between recycled aggregates and the cement matrix, thereby enhancing the densification degree of the internal structure of the concrete. Su [

65] conducted a systematic study on the composite modification of concrete using NS and NC, focusing on the regulatory mechanisms of the synergistic effects of multi-scale nanomaterials on the macroscopic properties and microstructure of concrete. The research demonstrated that when NS and NC were incorporated into the concrete matrix in a composite form, the compressive strength, splitting tensile strength, and chloride ion penetration resistance of the concrete all exhibited nonlinear variation characteristics with the increase in the total dosage of nanomaterials. Within a specific dosage range, the pozzolanic activity and nano-filling effects of the nanoparticles synergistically optimized the structure of the ITZ and promoted the densification of hydration products, significantly enhancing various performance indicators of the concrete. However, when the dosage exceeded a critical threshold, the agglomeration effect of the nanoparticles led to uneven dispersion in the matrix, resulting in performance degradation. Further comparative analysis indicated that NS, due to its higher pozzolanic reactivity, had a more significant effect on improving concrete performance compared to NC. This difference was mainly reflected in NS’s ability to promote the generation of C-S-H gel and its refined regulation of the pore structure.

Kariml et al. [

66] investigated the crack resistance parameters (fracture toughness and fracture energy) of warm mix asphalt (WMA) mixtures containing high contents of reclaimed asphalt pavement (RAP) using varying amounts of NC as a modifier. The study on crack resistance covered the entire range of Mode I/II fracture conditions. The results indicated that the addition of RAP enhanced both fracture toughness and fracture energy, regardless of the mode mix ratio and NC content (with average increases of 30% and 20%, respectively). NC also rendered the mixtures more crack-resistant, leading to a 30% increase in fracture energy and a 20% increase in fracture toughness. The optimal content of NC was calculated to be in the range of 2–4% (by binder weight), varying according to the considered variables. Due to the increased brittleness of the material resulting from the addition of RAP and NC, the flexibility index exhibited a decreasing trend. In separate evaluations, the influence of variables on strength parameters was studied using statistical methods, revealing that the fracture toughness in Mode II was approximately 1.2–1.5 times higher than that in Mode I. Zhang et al. [

67] conducted a study utilizing two types of nanoparticles, namely, SiO

2 nanoparticles and CaCO

3 nanoparticles, which were incorporated into a composite material along with polyvinyl alcohol (PVA) fibers at a volume fraction of 0.9%. The flowability of fresh cement-based composites was evaluated through slump flow tests. Our findings indicate that the addition of nanoparticles had a slightly detrimental effect on the flowability of PVA fiber-reinforced cement-based composites, with the flowability of the fresh mixture gradually decreasing as the nanoparticle content increased. The reduction in flowability was more pronounced for cement-based composites containing NS particles compared to those with NC particles. Both the incorporation of NS and NC particles significantly enhanced the durability of PVA fiber-reinforced cement-based composites. However, the improvement in durability was far more significant with NS than with NC. When the dosage of SiO

2 nanoparticles was less than 2.5%, the durability of the cement-based composite improved with an increase in NS content. Due to the filling effect of nanoparticles and the generation of the hydration product, C–S–H gel, the microstructure of PVA fiber-reinforced cement-based composites became denser. Both SiO

2 and CaCO

3 nanoparticles improved the microstructure of PVA fiber-reinforced cement-based composites, and within the composite, NS particles might be more conducive to the reinforcing effect of PVA fibers compared to NC particles.

3.1.3. The Influence of NC on the Mechanical Properties of Concrete After Exposure to High Temperatures

NC primarily enhances the high-temperature performance of concrete through the following three mechanisms. The first is the physical filling effect, where nanoparticles fill the micropores and the interfacial transition zone in the cement paste, reducing porosity and optimizing the pore structure distribution. For detailed information, please refer to

Table 3. [

68]. The second is the hydration-promoting effect, with NC acting as nucleation sites to accelerate the cement hydration process, particularly promoting the formation of C-S-H gel [

69]. The third is microstructure optimization. Under high temperatures, stress mismatch arising from the shrinkage of cement paste and the expansion of aggregates is the main cause of interfacial damage. Nano-calcium carbonate alleviates this contradiction by improving the performance of the interfacial transition zone.

As the temperature rises, the compressive strength of all concrete specimens shows a downward trend. However, NC-modified concrete demonstrates superior strength retention at various temperature ranges. At 400 °C, the strength loss rate of the 0.5% NC group is approximately 30% lower than that of ordinary concrete; at 800 °C, it still reduces the loss by about 17%. This advantage stems from the better integrity maintained under high temperatures due to the optimized microstructure induced by NC. The summary of the effects of NC on the mechanical properties of concrete is presented in

Table 4.

3.2. The Impact of NC on the Durability Performance of Concrete

3.2.1. Freeze–Thaw Cycle Resistance

The incorporation of NC significantly optimizes the pore structure characteristics of the concrete matrix through the synergistic effects of nano-scale filling and pozzolanic reactions. Its highly reactive nanoparticles can undergo secondary reactions with cement hydration products, generating a dense C-S-H gel network that effectively blocks the connectivity of capillary pores. This densification modification of the microstructure significantly reduces the pathways for water migration during freeze–thaw cycles, inhibits the propagation of microcracks caused by ice crystal expansion, and thereby substantially enhances the damage tolerance and durability of the concrete under repeated freeze–thaw actions. Zhou et al. [

72], through a systematic study on the effects of varying dosages of NC on concrete properties, discovered that when the dosage of NC is within the optimal range, it can significantly enhance both the mechanical properties and freeze–thaw durability of the concrete. Qiu et al. [

73] systematically investigated the influence mechanism of multi-component synergistic modification on the freeze–thaw resistance of cement-based materials by compounding NC, silica fume, and epoxy resin. The microstructure of hardened cement pastes was characterized using SEM. The results indicated that the introduction of NC significantly optimized the pore structure characteristics of the cement matrix. Its nano-scale filling effect effectively reduced the connectivity of capillary pores while promoting the generation of C-S-H gel through pozzolanic reactions, thereby constructing a denser micro-network structure. This structural modification significantly enhanced the damage resistance of the cement paste under freeze–thaw cycles, as evidenced by a reduced mass loss rate and an improved relative dynamic elastic modulus retention after freeze–thaw cycling. Further analysis revealed that the composite effect of NC and silica fume further strengthened the bonding performance of the ITZ, while the film-forming properties of epoxy resin played a synergistic enhancing role by blocking water migration pathways, ultimately achieving multi-scale optimization of the freeze–thaw resistance of cement-based materials.

3.2.2. Impermeability and Chemical Resistance

LI et al. [

74] investigated the effects of doping NC in cement-based materials on the mechanical properties, shrinkage, and durability of concrete. By varying the NC content, they compared the performance of plain concrete (PC) with that of four other types of concrete. When an appropriate amount of NC was doped into the concrete, it exhibited favorable mechanical properties and durability. However, excessive doping of NC weakened both the mechanical properties and durability of the concrete. Detailed analysis revealed that the density of concrete with nanoparticles was significantly higher than that of plain concrete, while an excessive amount of NC led to local relaxation and expansion in the concrete. Additionally, NC increased the dry shrinkage of the concrete, with the shrinkage rate of nano-concrete at different ages being higher than that of plain concrete. In saline soil environments, salts severely corroded plain cement concrete, gradually deteriorating the concrete structure until it failed, which hindered the practical application of ordinary Portland cement concrete in such regions. Addressing the durability issues of concrete in harsh environments, Hakuzweyez et al. [

75] selected the compressive strength coefficient, flexural strength coefficient, relative dynamic elastic modulus, and relative mass as joint evaluation indicators to assess the sulfate corrosion resistance of NC-modified concrete. The results demonstrated that the addition of 1% NC could enhance the concrete’s resistance to sulfate corrosion, significantly extending its service life. The random Wiener process was found to be effective in predicting the durability deterioration process of concrete specimens. By integrating the lifetime data of the deterioration process, the reliability function of this method could directly reflect the lifespan of the concrete. Cao et al. [

76] pointed out that the chemical and physical effects of NC on concrete are more effective than those of micron-sized CaCO

3. However, due to the agglomeration phenomenon, the reinforcement effect of NC is somewhat diminished. Meng et al. [

77] revealed that NC contributes to enhancing mechanical properties due to its nucleation effect and filler effect. Sato and Diallo [

78] discovered that the nucleation effect of NC accelerates the hydration of tricalcium silicate in concrete. Meanwhile, Liu et al. [

79] reported that the addition of NC reduces the autogenous shrinkage of cement-based materials by decreasing porosity and reacting with tricalcium aluminate. Shaikh et al. [

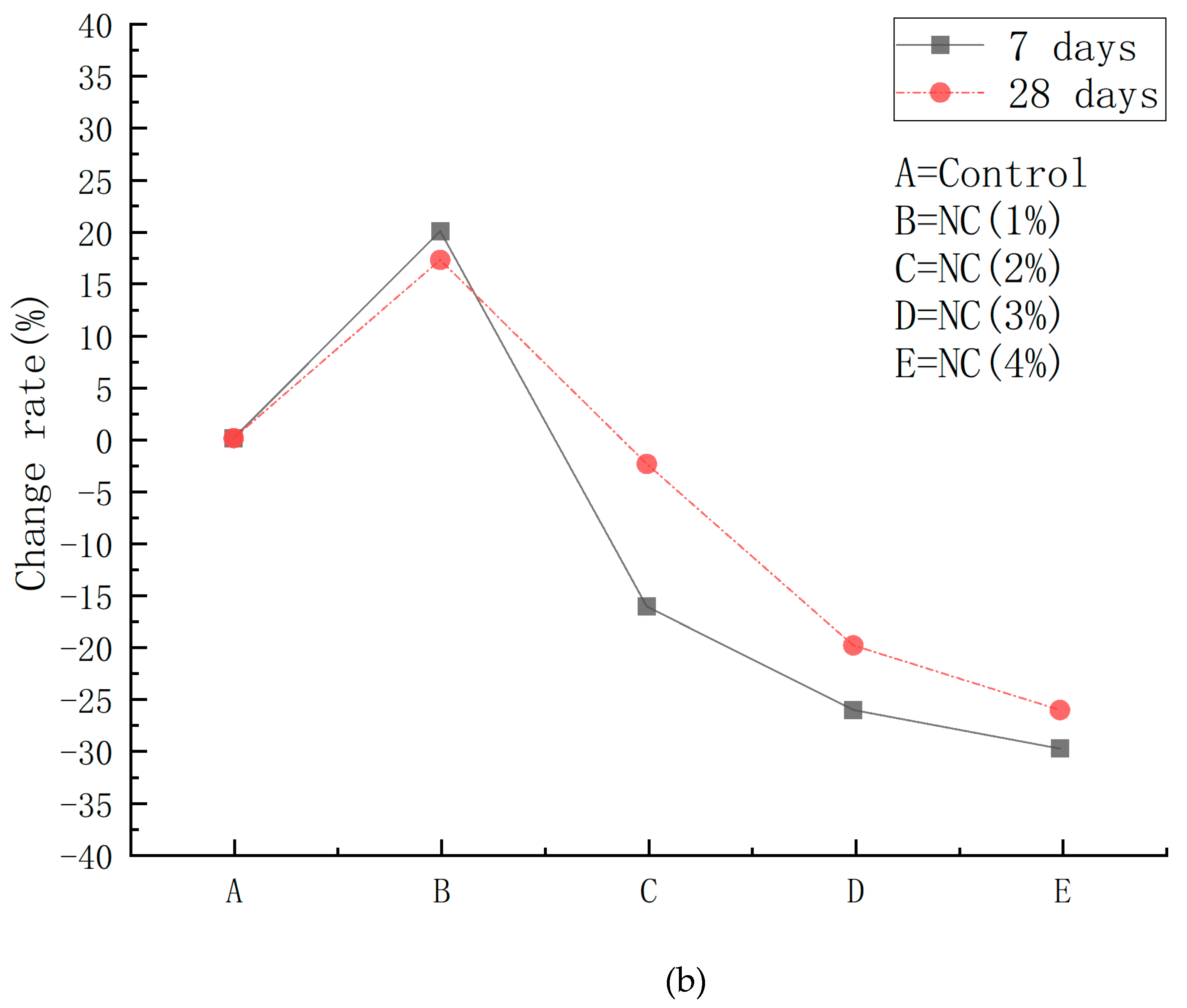

80] reported that the use of 1% NC resulted in a 146–148% increase in early-age compressive strength compared to the control group (as illustrated in

Figure 3a,b). At 90 days of age, the improvement in compressive strength due to NC was still ongoing, with the compressive strength of the mixture being approximately 40% higher than that of the control group. At 28 and 90 days of age, the mixture containing 1% NC reduced water absorption by 17% and 30%, respectively. They noted that at 28 days of age, 1% NC significantly reduced the permeable pore volume by 46%. At 28 and 90 days of age, the chloride ion permeability of the mixture containing 1% NC was reduced by 20% and 50%, respectively, compared to the control group. The chloride ion diffusion coefficient was decreased by approximately 73% due to the use of 1% NC. They pointed out that the presence of NC effectively reduced capillary porosity and refined the pore structure.

Poudyal et al. [

81] investigated the impact of NC dosage on the mechanical properties of Portland cement concrete through durability and hardening tests. They found that Portland cement concrete doped with 1% NC exhibited the best mechanical performance. Compared to ordinary Portland cement concrete, its compressive strength at 56 days of age increased by 7%, and its permeability coefficient decreased by 13%.

3.3. The Influence of Nano-Calcium Carbonate on the Microstructure of Concrete

3.3.1. Filling Effect and Pore Structure Optimization

Nanoparticles can fill the voids between cement particles as well as the nano- or micrometer-scale pores among hydration products. This leads to a significant reduction in the volume of capillary and transitional pores, a shift in pore size distribution toward smaller dimensions, more tortuous pores with reduced connectivity, and a denser matrix with fewer internal defects.

3.3.2. Nucleation Effect and Hydration Regulation

Nanoparticles of CaCO3 possess high surface energy and can serve as heterogeneous nucleation sites for hydration products, thereby reducing the nucleation energy barrier. This promotes early hydration, leading to the formation of finer C-S-H gels and resulting in a denser and more uniform distribution of hydration products at the microscopic scale.

3.3.3. Chemical Activity and Interface Strengthening

ITZ is a weak region between aggregates and cement paste, characterized by high porosity and the tendency for CH (calcium hydroxide) crystals to align directionally. NC can physically fill the pores in the ITZ region, nucleate there, and generate more C-S-H (calcium silicate hydrate) gels, resulting in a denser ITZ structure and significantly enhancing the interfacial strength and toughness. Additionally, CaCO

3 can react with tricalcium aluminate or hydrated aluminate phases in cement to form more stable carboaluminate compounds, thereby altering the early hydration pathway. Key research on the impact of NC on the microstructure of concrete is shown in

Table 5.

3.4. Application of NC in Concrete

In general, NC plays three roles in concrete. Firstly, it accelerates cement hydration. Nano-calcium carbonate particles can serve as effective nucleation sites for the precipitation of hydration products, thereby speeding up the hydration reaction process, especially in the early stages. Secondly, it enhances concrete strength. By accelerating hydration and exerting a filling effect, it reduces the number and size of harmful pores and optimizes the interfacial transition zone structure between the cement paste and aggregates. Moreover, with its particle size much smaller than that of cement particles, it can effectively fill the gaps between cement particles as well as the pores between finer hydration products, making the concrete structure denser. Thirdly, it improves concrete durability. The filling effect and a denser hydration product structure significantly reduce the total porosity and the proportion of harmful pores in concrete, lowering the porosity and increasing the compactness.

4. Carbon Nanotubes

4.1. The Effects of CNTs on the Mechanical Properties of Concrete

CNTs are nanoscale tubular materials formed by the special arrangement of carbon atoms and are important members of the carbon material family (such as graphene, diamond, etc.). Their structure can be regarded as seamless hollow tubular structures formed by curling single-layer or multi-layer graphene sheets. The diameters of CNTs typically range from 1 to 100 nanometers, and their lengths can reach micrometers or even millimeters. Due to their unique mechanical, electrical, and chemical properties, CNTs have been extensively studied as reinforcing materials for concrete. Nano-reinforcing materials like CNTs significantly enhance key mechanical performance indicators of concrete, such as compressive strength and flexural strength, through their unique nanoscale strengthening effects. Meanwhile, they optimize the matrix’s permeability resistance, long-term durability, and high-temperature stability. This multi-dimensional modification mechanism effectively alleviates the industry challenge that traditional concrete materials, due to their inherent defects, struggle to meet the stringent requirements of modern engineering projects. It provides an innovative technological pathway for the development of a new generation of high-performance cement-based composite materials. Xu et al. [

85] conducted systematic mechanical tests to thoroughly investigate the synergistic strengthening effect of the composite addition of PVA fibers and CNTs on the mechanical properties of concrete materials. Their study revealed that the two nanomaterials effectively inhibited the propagation paths of microcracks in the cement matrix through molecular-level bridging interactions. Their multi-scale filling effects significantly optimized the microstructure of the concrete ITZ. When the mass content of both PVA fibers and CNTs was controlled at 0.15%, the composite system exhibited the optimal mechanical performance. Under this ratio, the compressive strength, flexural strength, and fracture energy of the concrete all reached their peaks, validating the dual-factor strengthening mechanism of nanomodified materials in cement-based composites. This finding provides crucial theoretical support for the nanotechnology-based reinforcement of high-performance concrete.

4.1.1. The Impact of CNTs on the Compressive Performance of Concrete

Carbon fibers generally have diameters ranging from 5 to 10 micrometers, and their lengths vary significantly, from the millimeter scale up to the kilometer scale. Single-walled carbon nanotubes typically have diameters between 0.8 and 2 nanometers, while multi-walled carbon nanotubes usually have diameters ranging from 5 to 50 nanometers. The lengths of carbon nanotubes generally range from a few hundred nanometers to several tens of micrometers, although there are also ultra-long ones that can reach the centimeter to decimeter scale. Fu et al. [

86] investigated the dynamic compressive performance of CNT/CF (carbon nanotube/carbon fiber)-reinforced concrete and analyzed the mechanisms of CNTs and CFs from the perspective of their effects on hydration products and pore structure. The following conclusions can be drawn: the dynamic compressive strength of CNT/CF reinforced concrete exhibits a strain-rate strengthening effect. The addition of CNTs and CFs enhances the dynamic compressive strength, with the most significant enhancement observed when both CNTs and CFs are combined. CFs strengthen the strain-rate effect on dynamic compressive strength, while CNTs improve the ability of CFs to enhance this strain-rate effect. The addition of CNTs alone reduces the strain-rate effect. CNTs and CFs do not affect the content of various components in the cement hydration products. However, CNTs influence the growth morphology of CH, reducing the content of thin hexagonal plate-like CH crystals and increasing the content of hexagonal prismatic CH crystals. Consequently, the structure of the hydration products is refined, which contributes to improving the strength of the concrete but reduces the strain-rate effect on dynamic strength. Liu et al. [

87] demonstrated that the preparation of UHPC using MWCNTs is an effective method for enhancing the durability of concrete structures under complex environmental conditions. By varying the MWCNT content and water-to-binder ratio, MWCNT-UHPC specimens were prepared. The damage degree of the concrete under different salt corrosion conditions during 1500 freeze–thaw (FT) cycles was analyzed based on changes in compressive strength, mass loss rate, and relative dynamic elastic modulus (RDME). SEM and nuclear magnetic resonance (NMR) were employed to characterize the variations in micro-pore structure. The experimental results indicated that the optimal mix ratio was achieved with a water-to-binder ratio of 0.19 and an MWCNTs content of 0.1%. At this ratio, the compressive strength was 34.1% higher, and the flexural strength was 13.6% higher compared to when the MWCNT content was 0%. The experiments proved that the addition of carbon nanotubes significantly improved the compressive and flexural strengths of the concrete. The variation curves of compressive and flexural strengths of the specimens first increased and then decreased with an increase in MWCNT content. Considering cost factors, the optimal mix ratio was determined to be a water-to-binder ratio of 0.19 and an MWCNTs content of 0.1%. Multi-walled carbon nanotube UHPC prepared based on this optimal mix ratio exhibited excellent freeze–thaw resistance and salt corrosion resistance under the combined effects of salt corrosion and low temperature. After 1500 salt–freeze cycles, the microstructure of the concrete remained dense. The salt–freeze cycles had a significant impact on the changes in porosity but a lesser effect on the variations in mesopores and macropores. The greater the mass fraction of the erosive solution, the smaller the change in porosity. Calcium carbonate nanoparticles (CCNP) have also been receiving increasing attention for their ability to enhance the compressive strength of UHPC, particularly in relation to C-S-H nucleation and improvement of the ITZ [

88,

89,

90,

91].

The addition of CNTs to concrete can significantly improve its ductility, primarily through the following mechanisms:

The first mechanism is micro-crack bridging and arrest. CNTs possess an extremely high aspect ratio and strength. When micro-cracks start to appear within the concrete, CNTs act like “bridges” spanning across the crack surfaces. Through their own high tensile strength and the interfacial bonding force with the cement matrix, they prevent the further opening and propagation of the cracks.

The second mechanism is cement matrix reinforcement. CNTs can serve as nucleation sites for hydration products (such as C-S-H gel), promoting the formation of denser and more uniform hydration products. A denser and more uniform matrix inherently possesses higher strength and toughness. The reinforced matrix can more effectively transfer stress to the CNTs and resist the initiation and development of micro-cracks, providing a better foundation for the CNTs to exert their bridging effect, thereby indirectly enhancing the overall ductility.

The third mechanism is the improvement in the ITZ. The ITZ is the weak region between the cement paste and aggregates (sand and stone), where cracks are most likely to initiate and propagate. CNTs can fill the pores in the ITZ region, forming a network or bridging structure within the ITZ, and improving the structure and performance of the hydration products in this region.

The fourth mechanism is the energy dissipation mechanism. When crack propagation encounters CNTs, additional energy is required to overcome the interfacial bonding force between the CNTs and the matrix or to break the CNTs themselves.

4.1.2. The Impact of CNTs on the Tensile Properties of Concrete

Researchers discussed the influence of multi-walled CNTs on the strength characteristics of hydrated Portland cement paste. Various cement–CNT composites and equivalent control groups were prepared by blending CNTs at concentrations of 0.5%, 0.75%, and 1.0% (by weight of cement) to examine the strength gain in cement composites. Cylindrical specimens with dimensions of approximately 15.8 mm × 31.6 mm were prepared for compressive strength and flexural tensile strength tests to measure the mechanical strength of the composites. The specimens were tested at curing periods of 7, 28, 60, 90, and 180 days, with at least three samples tested for each curing age. The results indicated an increase in compressive strength and flexural tensile strength in Portland cement–CNT composites with a CNT content of 0.5% by weight of cement. At 28 days of curing, the increases in compressive strength and tensile strength relative to the control group were 15% and 36%, respectively. However, the strength decreased when the CNT content exceeded 0.5% [

92]. Additionally, SEM and transmission electron microscopy (TEM) observations were conducted to examine the microstructural integration of the cement–CNT paste. Lan [

93] demonstrated that incorporating CNTs into concrete can improve its fracture toughness. The crack resistance of CNT-reinforced concrete was evaluated through ring tests and three-point bending beam fracture tests. The fracture parameters of the CNT-reinforced concrete were analyzed using the double-K fracture parameters, and the results indicated that CNTs can enhance crack resistance.

4.1.3. The Impact of CNTs on the Flexural Performance of Concrete

Through theoretical analysis and experimental verification, researchers have demonstrated that the failure modes of CNTs in cement-based composites can be adjusted by varying their content, and that there exists a critical content range within which both fracture and pull-out failures coexist but are not dominant. In the composite system, the interfacial interaction mechanisms between carbon nanotubes and the matrix exhibit significant variations with changes in content. When carbon nanotubes are dispersed at low concentrations, their curved configurations form mechanical anchoring effects within the matrix, leading to the preferential occurrence of fracture failure in individual carbon nanotubes under stress rather than interfacial debonding. However, as the filling amount of carbon nanotubes increases, the inter-tube spacing decreases exponentially, promoting spatial overlap of the stress influence zones and ITZs of adjacent carbon nanotubes. This microstructural evolution leads to two key effects: Firstly, the interfacial bonding strength between individual carbon nanotubes and the matrix is no longer characterized independently but is instead influenced by the coupled damage evolution of neighboring carbon nanotubes. Secondly, the collective pull-out mechanism gradually replaces the single-tube fracture mode. When the tube spacing is less than a critical value, the interfacial shear stress required for the pull-out process is transmitted through the nanotube clusters via stress concentration effects, ultimately resulting in synergistic debonding behavior at the macroscopic scale. This content-dependent transition in failure modes provides a theoretical basis for optimizing the interfacial design of carbon nanotube-reinforced composites [

94]. Experimental studies have demonstrated that the CNT content exhibits a nonlinear reinforcing effect on the mechanical properties of composites. In terms of compressive performance, a peak strengthening effect is observed when the CNT volume fraction reaches 1.0 vol%, with a 12.7% increase in compressive strength, indicating the formation of an optimal stress transfer network at this content. For flexural performance, a dual-stage strengthening mechanism exists: when the CNT content reaches 0.5 vol%, the percolation threshold effect is triggered, resulting in a 35.6% increase in flexural strength; as the content further increases to 1.5 vol%, through the rearrangement and synergistic strengthening mechanism of the CNT network, the flexural strength jumps to 45.6%, exhibiting a post-percolation strengthening characteristic. Microstructural analysis validates the above-mentioned evolution of macroscopic properties: as the CNT content increases from 0.5 vol% to 1.5 vol%, the average spacing between CNTs continuously decreases according to theoretically predicted relationships, but the rate of spacing decrease shows a decaying trend. This indicates efficient dispersion of CNTs in the experimental system. Notably, even at a high content of 1.5 vol%, the agreement between the spacing decrease rate and the theoretical inverse relationship is maintained, confirming the effectiveness of the preparation process in controlling CNT dispersion and providing experimental evidence for the design of high-performance nanocomposites. When conducting flexural tests on composites containing CNTs, the critical content (typically referring to the CNT content range where significant changes in mechanical properties occur or the optimal values are achieved) generally falls between 0.1 wt% and 1.0 wt%. The most common and notably effective range is from 0.3 wt% to 0.7 wt%. For low CNT contents (<0.3 wt%), dispersion is relatively easier, and the improvement in properties may be slight or not readily apparent (depending on the quality of dispersion). In contrast, for high CNT contents (>0.7 wt%), dispersion becomes extremely challenging, agglomeration intensifies, and the flexural strength starts to decline. Therefore, when dispersion is good within the optimal range (0.3–0.7 wt%), both the flexural strength and modulus typically reach their maximum values, and toughness may also be enhanced. This represents the ideal state where CNTs effectively bear and transfer stress.

4.1.4. The Impact of CNTs on the High-Temperature Mechanical Properties of Concrete

CNTs enhance the high-temperature anti-spalling resistance and thermal stability. Han et al. [

95] systematically compared the performance of carbon nanomaterials such as graphene oxide (GO), CNTs, and graphite (GP) at temperatures ranging from 250 to 1000 °C. Through methods like thermogravimetric analysis and micro-computed tomography (micro-CT), they found that CNTs significantly suppressed concrete spalling by reducing vapor pressure and thermal stress. In particular, at 750 °C, the compressive strength retention rate of samples containing 0.1% CNTs increased by more than 15%. Other researchers have discovered that CNTs reduce the risk of concrete spalling by filling pores and bridging microcracks. Their high thermal conductivity mitigates temperature gradients and reduces the thermal stress concentration. SHI Xiao-dong et al. [

96] found that when the dosage of MWCNTs was in the range of 0.08–0.10 wt%, the residual compressive strength of concrete reached 45–50% after exposure to 600 °C, which was 20% higher than that of the control group. This improvement was attributed to the repair of high-temperature defects by the hydrophilic groups on the surface of CNTs. Tian et al. [

97] confirmed through research on the properties of concrete materials under high-temperature conditions (600 °C) that the nano-reinforcing effect of MWCNTs could significantly suppress the strength deterioration caused by high temperatures, with the strength retention rate increasing by 11% to 27%. This performance enhancement was mainly attributed to the nano-filling mechanism of MWCNTs: on one hand, their high aspect ratio structures formed a three-dimensional heat conduction network within the matrix, effectively alleviating thermal stress concentration; on the other hand, the interfacial bonding between the nanotubes and cement hydration products could delay the initiation and propagation of microcracks, thereby maintaining the structural integrity of the material at high temperatures. In terms of optimizing the cooling process, research revealed that spray cooling exhibited superior thermal shock damage control capabilities compared to traditional immersion cooling, with the strength retention rate increasing by 14%. This was primarily due to the gradient cooling characteristic of spray cooling, which could reduce the interfacial debonding effects caused by rapid quenching. The aforementioned findings provide dual technical pathways for the performance regulation of high-temperature concrete materials through nano-modification and process optimization. A summary of the effects of carbon nanotubes on the mechanical properties of concrete is presented in

Table 6.

4.2. The Impact of Carbon Nanotubes on the Durability of Concrete

4.2.1. Crack Resistance

Ramezanl et al. [

102] confirmed through research on the inhibition mechanism of the alkali-silica reaction (ASR) that the nano-reinforcing effect of CNTs can significantly enhance the durability of cement-based composites. Under ASR attack conditions, specimens modified with pristine CNTs (with an aspect ratio of 800 and a water-to-cement ratio of 0.45) exhibited dual performance optimizations: after 14 days of ASR exposure, their expansion deformation was reduced by 73% compared to the reference group, indicating that CNTs effectively suppressed the expansion effect of ASR gel through nano-confinement; after 28 days of ASR exposure, the dynamic elastic modulus was increased by 24% compared to the reference group, confirming that the nano-reinforcing network of CNTs could maintain the structural integrity of the material. Microscopic mechanism analysis reveals that the inhibitory effect of CNTs stems from a multi-scale strengthening effect: firstly, high-aspect-ratio CNTs form a three-dimensional heat conduction-stress transfer network within the matrix, promoting the directional growth of hydration products through a “nucleation effect” and optimizing the pore structure of the ITZ; secondly, the nano-scale dispersion of CNTs generates a “micro-fiber crack-arresting effect,” effectively constraining the volume expansion of ASR reaction products; thirdly, the chemical bonding between CNTs and C-S-H gel enhances the interfacial bonding strength. The aforementioned synergistic effects endow CNT-modified cement-based materials with dual advantages of expansion inhibition and elastic modulus retention under ASR attack conditions, providing crucial experimental evidence for nano-inhibition technology against alkali-aggregate reactions. Meanwhile, SEM images combined with X-ray energy dispersive spectroscopy (EDS) analysis confirm that well-dispersed CNTs reduce damage caused by the ASR through two primary mechanisms: firstly, by altering the elemental composition and atomic ratios of the alkali-silica gel, and secondly, by bridging cracks and densifying the C-S-H gel structure.

Malayali et al. [

103] confirmed the effectiveness of a multi-scale reinforcement strategy in optimizing the performance of eco-friendly concrete through a synergistic composite study involving coconut fiber (5 wt%) and CNTs (5–15 wt%). Experiments demonstrated that when the CNT content reached 15 wt%, the compressive strength of the composite material significantly increased to 47 MPa (approximately a 38% improvement compared to the reference group), while the water absorption rate significantly decreased to 2.8% (a reduction of 65%), exhibiting an excellent synergistic enhancement effect on both mechanical properties and durability. Through analysis, the nano-reinforcing effect of CNTs achieves performance breakthroughs via a dual-pathway mechanism: firstly, CNTs form a nano-filling network at the ITZ between coconut fiber and the cement matrix, optimizing interfacial bonding strength through a “crystal bridge effect” and effectively inhibiting the initiation and propagation of microcracks; secondly, the high aspect ratio structure of CNTs constructs a three-dimensional heat conduction-stress transfer pathway within the matrix, significantly reducing the hygrothermal deformation coefficient of concrete and thereby lowering the risk of dry shrinkage cracks by 42%. Under hygrothermal coupling conditions, the nano-confinement effect of CNTs can delay moisture penetration pathways, increasing the dynamic water contact angle by 27%. Combined with the crack-arresting and toughening effects of coconut fiber, the durability coefficient of the composite material is enhanced by 19% compared to single-doped systems. Zhan et al. [

104] proposed dispersing carbon nanotubes onto alumina nanocomposites as a coating via pulse ultrasonication in an alcohol–ether solvent. Compared to conventional techniques, this method resulted in a 12-fold increase in fracture toughness. Lu et al. [

105] utilized a CNTs/PVA nanocolloid emulsion (containing 0.3% CNTs + 1.0% PVA) to reduce the drying shrinkage of concrete by 76% (at 7 days) and decrease the capillary water absorption rate by 25.7%. Microstructural analysis revealed that the CNTs/PVA formed an interpenetrating network, inhibiting moisture migration and reducing shrinkage stress-induced cracks. Jang et al. [

106], though primarily focusing on CNT fibers themselves, proposed a diazonium salt-based cross-linking strategy to enhance the inter-tube load transfer efficiency (with a specific strength of 4.73 GPa/(g/cm

3)). This technology can be transferred to the field of CNT-reinforced concrete. By forming covalent bonds, it can improve the CNTs-cement matrix interfacial bonding, thus delaying crack propagation.

4.2.2. Corrosion Resistance and Impermeability

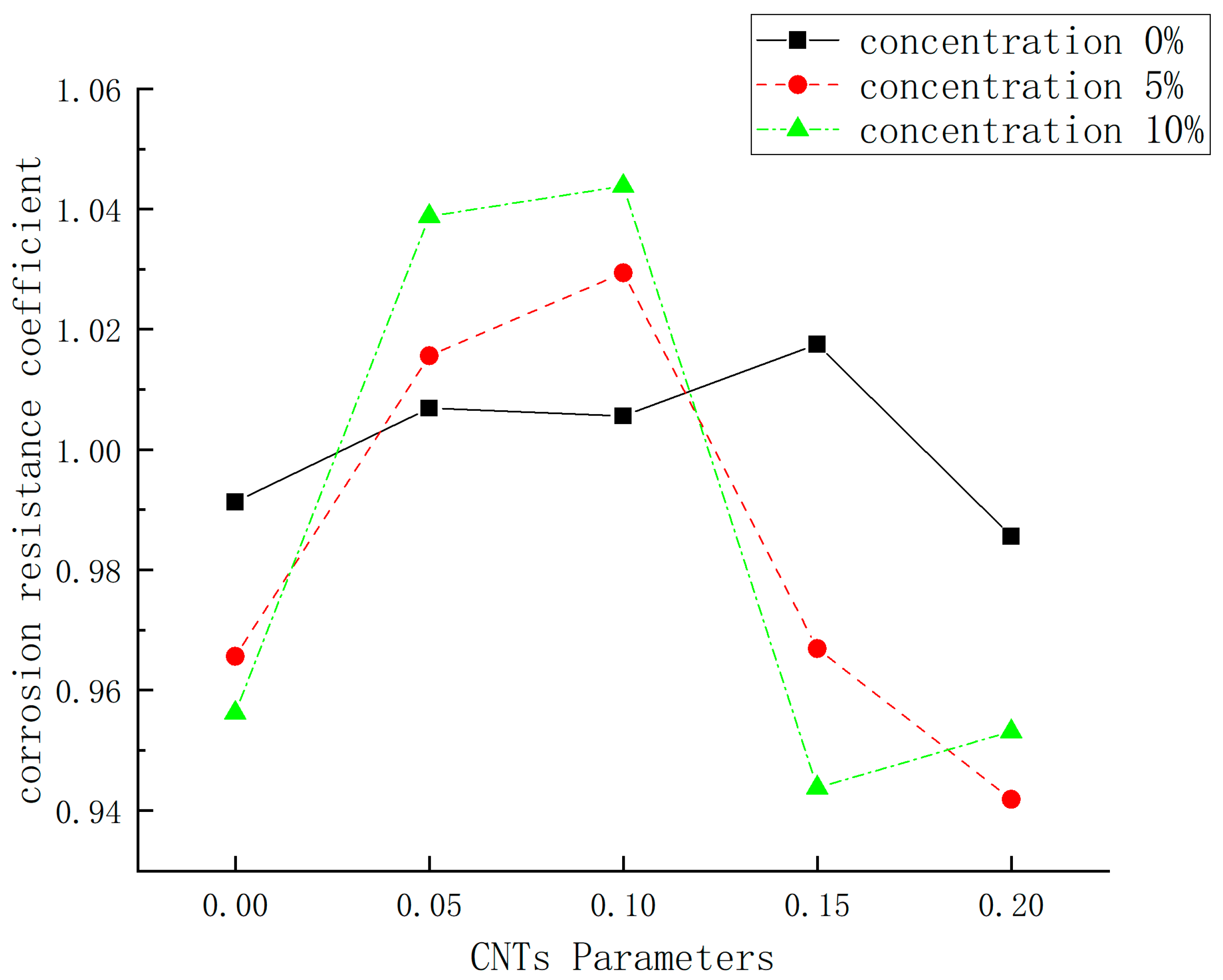

Rafieizonooz et al. [

107] conducted a study on the regulation mechanism of chloride ion transport behavior in UHPC using CNTs, revealing breakthrough advancements in the enhancement of concrete durability through nano-modification technology. The research indicates that when the CNT content is 0.05 wt%, the chloride ion diffusion coefficient of UHPC reaches its minimum, showing a 58% reduction compared to the reference group. This non-linear response characteristic aligns with the percolation theory, suggesting that nano-fillers form continuous conductive pathways within the matrix. In situ observations via SEM reveal that CNTs construct a three-dimensional nano-bridging network among cement hydration products. Their high aspect ratio structures promote the dense packing of ettringite and C-S-H gel through a “nucleation-inducing effect,” reducing porosity by 42% and refining the most probable pore size from 18 nm to 7 nm, thereby significantly optimizing the microscopic mass transfer channels in concrete. In terms of durability characterization, salt-spray accelerated corrosion tests demonstrate that the chloride ion penetration depth of CNTs-modified UHPC is reduced by 63% compared to the reference group, and the surface chloride ion concentration is decreased by 56%. A service—life prediction model based on Fick’s second law shows that, under the same corrosion grade, the incorporation of CNTs extends the structural service life by more than 30%. This performance enhancement is mainly attributed to the multi-scale reinforcement mechanism of CNTs: at the nanoscale, CNTs strengthen the ITZ through chemical bonding, forming a “nano-locking effect”; at the microscale, the CNT network effectively blocks crack propagation paths and reduces the penetration rate of corrosive media.

Both Carriço et al. [

108] and Bogas et al. [

109] confirmed through the Rapid Chloride Migration test that the incorporation of CNTs can significantly reduce the chloride ion diffusion coefficient of concrete, and this effect is universally applicable under different water–cement ratios. However, they proposed different explanations for the mechanism of CNTs. Carriço et al. proposed, from the perspectives of ionic interactions and local electric fields, that the difference in migration rates between cations and chloride ions in the pore solution of concrete can generate a local electric field. This electric field impedes chloride ion diffusion through an electroneutrality-constraining mechanism. The addition of CNTs may optimize chloride ion transport behavior through the following pathways: Firstly, the nano-filling effect of CNTs can refine the pore structure, reducing the connectivity of ion migration channels and thus decreasing the driving force for chloride ion diffusion driven by chemical potential gradients. Secondly, the surface chemical properties of CNTs may modulate the ionic environment in the pore solution, weakening the electrostatic repulsion of cations on chloride ions. Thirdly, the three-dimensional network structure of CNTs can disperse the intensity of the local electric field, preventing the formation of rapid chloride ion migration channels triggered by electric field concentration. In addition, Carriço et al. emphasized that the nucleation effect of CNTs can promote the dense packing of cement hydration products, further blocking the diffusion paths of chloride ions. However, they argued that CNTs themselves have almost no direct impact on enhancing resistance to chloride ion penetration; their role is mainly manifested in optimizing the microstructure of concrete. Bogas et al., from the perspectives of concrete transport mechanisms and pore structure evolution, proposed that chloride ion diffusion in concrete is the result of a multi-physical field coupling effect involving diffusion, convection, capillary suction, and electric field-induced pressure. The incorporation of CNTs reduces the chloride ion diffusion coefficient through a dual-mechanism: At the micro-scale, CNTs can fill the microscopic pores between cement hydration products, particularly having a significant refining effect on the pore structure of the ITZ, thereby blocking the preferential diffusion paths of chloride ions. At the meso-scale, the bridging effect of CNTs can inhibit the initiation and propagation of concrete cracks, reducing the rapid chloride ion transport networks formed by cracks. Bogas et al. specifically pointed out that CNTs can better enhance the chloride penetration resistance in the cracked regions of concrete. This is because the bridging action of CNTs at the cracks can effectively prevent the rapid penetration of chloride ions along the cracks. In addition, they also emphasized the regulatory role of the water–cement ratio on the efficacy of CNTs. They noted that in high systems with a water–cement ratio, the pore structure optimization effect of CNTs is more pronounced, while in systems with a low water–cement ratio, the inhibition effect of CNTs on crack propagation is dominant.