Abstract

This study explores the application potential of a lean–Agile hybrid method in complex construction project management. By integrating Scrum iterative development, the Last Planner System, and a BIM collaboration platform, a dual-engine model is established to optimize the dynamic priority mechanism (MoSCoW 2.0) and interface conflict entropy algorithm (ICE model). Through a combination of theoretical and practical approaches, the study elucidates the implementation pathway of this hybrid method and evaluates its benefits in enhancing project efficiency, reducing waste, and accelerating digital transformation. The study provides a replicable management framework for the construction industry and proposes a blockchain-based decentralized knowledge management framework based on blockchain technology.

1. Introduction

1.1. Research Background

The global construction industry is currently undergoing a paradigm shift, transitioning from a traditional “scale-driven” model to a “value-driven” approach. This transformation is driven by the following two core factors: firstly, the surge in personalized demands from property owners, with the frequency of demand changes in residential projects increasing at an annual rate of 18%, making it difficult for traditional linear management models to cope with dynamic demands [1]; secondly, the rigid target set by the International Energy Agency (IEA) requiring the construction sector to reduce emissions by 80% by 2050, necessitating the optimization of resource efficiency. Data from the American Institute of Architects (AIA, 2022) indicates that the median schedule deviation rate for projects using traditional methods reaches 14.7%, with 67% of delays attributed to delayed responses to demand changes.

Against this backdrop, the integration of Agile methodologies and lean construction emerges as a promising direction. Agile methodologies enhance responsiveness through iterative development and continuous delivery [2], while lean construction improves efficiency by eliminating waste (Muda) and optimizing value streams [3]. Existing research demonstrates significant synergies between the two in manufacturing, yet their application in the construction industry remains in the exploratory stage [4,5,6].

1.2. Research Significance

Theoretically, it constructs a dual-engine-driven model (DEDM) that integrates Scrum Agile iterations with the Last Planner System (LPS), resolving the conflict between physical constraints and dynamic demand changes through the novel MoSCoW 2.0 dynamic prioritization mechanism (incorporating Technical Readiness Level—TRL) and the “BIM-based ICE Interface Conflict Entropy algorithm”. Furthermore, it proposes a quantitative mapping framework for knowledge management matrices (LXS Matrix), offering a new analytical perspective for integrating tacit knowledge in the construction industry by explicitly linking an experience value (Ei), scenario weight (Sj), and responsibility coefficient (Rk).

Practically, it develops a collaborative implementation pathway for BIM and blockchain technologies specifically through the DIMPROVE knowledge management framework and the “Hyperledger Fabric-based blockchain ledger architecture”. It explores the implementation models of digital twin technology in resource scheduling and experience sharing as evidenced by the HoloLens2-based digitalization experience and “BIM-ERP middleware protocol”, providing concrete technical solutions for the industry’s digital transformation.

Methodologically, it transcends the traditional dualistic paradigm of project management theory by establishing a “lean–Agile continuum” conceptual framework, operationalized through the DEDM. This offers new insights for methodological innovation in engineering management by demonstrating a systematic approach to hybrid method integration beyond simple structural or process combinations.

2. Literature Review

2.1. Evolution of Agile Methodology Applications

Originating from the “Agile Manifesto” in software engineering, Agile methodologies, with core principles including iterative development, self-organizing teams, and continuous user feedback, have undergone a gradual innovation process in the construction industry, evolving from technological transplantation to industry adaptation, closely intertwined with the depth of digital technology integration. During the initial exploration phase (2010–2015), the construction industry began experimenting with the introduction of the Scrum framework into project management, enhancing design efficiency through two-week sprints. However, early practices exposed inherent contradictions between software engineering methods and construction production logic. For instance, physical constraints such as concrete curing cycles resulted in only a 22% improvement in demand change responsiveness [7]. The intervention of BIM technology marked a critical turning point, with its 3D visualization and data integration capabilities providing a physical carrier for Agile practices. The Agile Design Management (ADM) framework proposed in 2016 enabled real-time collaboration across functional teams through BIM models, dynamically linking demand prioritization with BIM models, and it was successfully applied in logistics facility projects, validating the feasibility of technological transplantation [8].

Entering the stage of adaptive integration (2016–2022), the industry commenced the construction of Agile methodologies tailored to construction characteristics. Research introduced the “demand freeze window” mechanism, quantifying the impact of design changes on life cycle costs through BIM-LCA (life cycle assessment) models, thereby elevating the demand change response rate to 45% [9]. The renovation project of a school in Washington, after adopting Scrum, achieved a 37% reduction in design iteration cycles and a 52% improvement in multi-stakeholder communication efficiency by linking backlogs with BIM model tasks [10,11]. This phase also witnessed the development of a combination of parametric modeling and real-time monitoring technologies, utilizing BIM integrated with IoT sensors for dynamic construction progress tracking, reducing the schedule deviation rate of a commercial complex project from 8.3% to 3.1% [12].

Currently, the industry is entering a phase of framework expansion (present onwards), with Agile applications extending beyond the design phase to encompass the entire life cycle. The AgiBuild framework enhances design–construction interface efficiency by 41% in airport expansion projects through modular decomposition strategies, decomposing large-scale infrastructure projects into independently sprintable sub-modules [13]. Dynamic decision-making models, such as the LEAN–AGILE index, provide dynamic prioritization criteria for EPC projects by quantifying the synergy between the Technology Readiness Level (TRL) and Requirement Value (RAS) [14]. Despite the deepening application of Agile methodologies in the construction sector, contradictions between traditional fixed-price contracts and Agile resource scheduling demands remain unresolved, necessitating further breakthroughs in industry barriers through hybrid contract models and AI-assisted decision-making systems.

2.2. Development of Lean Construction Theory

The theory of lean construction has undergone three paradigm shifts, forming a methodological system adapted to architectural complexity.

Origins and Core Concept Formation (1990–2005):

Emerging from the Toyota Production System (TPS), lean construction initially focused on eliminating waste (MUDA), value stream analysis, and continuous improvement (Kaizen). Early research revealed fundamental differences between construction and manufacturing, emphasizing preliminary practices targeting the “Eight Wastes.”

Theoretical Systematization and Localized Innovation (2006–2015):

This phase established three theoretical pillars, advancing lean construction from conceptual to practical implementation.

- Transformation Flow Value (TFV) Theory: This deconstructs construction activities into a three-dimensional optimization model (resource conversion, process continuity, and client needs), breaking single-phase efficiency limitations [15].

- Last Planner System (LPS): This system addresses the disconnect between planning and execution through proactive scheduling and commitment-based task assignments. Case studies (e.g., the U.S. Cathedral Hill Hospital project) have achieved schedule deviation rates < 5% [16].

- Target Value Design (TVD): This drives design innovation through cost constraints, resolving the “design budget” conflict. This reduced design changes by 40% and cost overruns by 25% [17].

Research emphasized “global optimization” and supply chain collaboration, shifting the theory from tool transplantation to localized innovation and establishing construction-specific lean implementation pathways.

Sustainable Development Integration Phase (2016–Present):

With the United Nations Sustainable Development Goals (SDGs), lean construction has been integrated with green building practices, creating “lean–green” synergies and upgrading the theory to full life cycle value creation.

- Dual-Objective Coupling Mechanism: This extends waste elimination to environmental dimensions, building an “economic–environmental performance” dual optimization model. This synchronizes material efficiency and carbon reduction technologies to control resource consumption and ecological impact.

- Digital Technology Empowerment: Merging BIM with Industry 4.0 technologies enables digital management across design–construction–operation phases, enhancing decision efficiency and resource transparency [18,19].

- Social Value Expansion: This improves workplace safety and community engagement mechanisms, extending lean principles to social systems to balance economic, environmental, and social value [20,21].

Despite its efficiency gains, lean construction still faces challenges in managing construction complexity, such as supply chain coordination and multi-stakeholder collaboration uncertainties [22,23].

2.3. Theoretical Innovations in Lean–Agile Hybrid Methods

In complex construction project management, two primary lean–Agile hybrid integration paths exist—structural integration and process integration—each with distinct strengths and limitations (see Table 1):

Table 1.

Hybrid integration approaches.

To clarify the multidimensional contributions of hybrid methods, we established an impact assessment matrix (Table 2) analyzing five core project domains.

Table 2.

Lean–Agile hybrid method impact matrix.

Structural integration, exemplified by the Malla four-quadrant model [24], provides a static framework (plan–execute–monitor–learn) with clear structural guidance. Using the relative importance index (RII) to identify critical control factors, it performs well in projects with high technological maturity (TRL ≥ 7) [25,26]. However, its reliance on static planning limits flexibility in dynamic environments, particularly under the frequent design changes in China’s EPC model [5].

Process integration, represented by the Dave double-helix model [27], embeds Agile iterations into lean value streams for dynamic optimization. It excels in projects with volatile requirements (e.g., ≥2 changes/month). For instance, in concrete delivery, “spaghetti diagrams” optimize loading times, while BIM enables real-time scheduling, boosting process efficiency [28]. Yet, its lack of accountability mechanisms hinders responsibility tracing, impacting project management efficacy [29,30].

To address these limitations, this study proposes a theoretical innovation, namely the dual-engine-driven model. By integrating core Agile and lean components into a dynamic collaborative framework, it overcomes structural rigidity while enhancing accountability in process integration.

3. Model Construction and Implementation

3.1. Case Selection and Data Foundation

This study selected the Guangzhou Agile Project (2020–2023) and the Shenzhen Medical Complex (2022–2024) as dual-case empirical objects. Their typicality is reflected in the following aspects (Table 3):

- Guangzhou Project

This is a 550,000 m2 urban complex featuring twin 45-story residential towers, an 8-story commercial podium, and a 15.2 m deep underground facility spanning three levels. The project required coordination across 12 disciplines, with structural–MEP clashes constituting 63% of initial interface conflicts. Total investment reached CNY 0.82 billion.

- 2.

- Shenzhen Medical Complex

This is a 380,000 m2 healthcare facility comprising 22-story inpatient towers, 1200 m2 ISO Class 7 cleanrooms, and automated guided vehicle (AGV) logistics systems. Critical conflicts included 217 interface issues between medical gas pipelines and seismic bracing. Investment totaled CNY 0.67 billion.

Operational Dynamics:

Demand change frequency significantly exceeded industry norms (Guangzhou: 2.3/month, Shenzhen: 2.1/month vs. 2023 average: 1.5/month).

Digital Foundation:

Both projects implemented BIM-LOD 300 (ISO 19650) [31] for clash detection and scheduling. Shenzhen added RFID tracking for 92% of prefabricated modules.

Table 3.

Comparative analysis of cases.

Table 3.

Comparative analysis of cases.

| Project Characteristics | Guangzhou Project | Shenzhen Project | Industry Average (2023) |

|---|---|---|---|

| Total Construction Area (m2) | 550,000 | 380,000 | 120,000 |

| Building Height | 45F + 8F + 3B | 22F + 2B | 30F |

| Underground Depth (m) | 15.2 | 10.5 | 8.6 |

| Prefab Rate (%) | 35% | 68% | 28% |

| Interface Conflicts | 1387 | 1092 | 520 |

| BIM Application Level | LOD 300 (ISO 19650) | LOD 300 (ISO 19650) | LOD 200 (ISO 19650-2) [32] |

3.2. Dual-Engine-Driven Model (DEDM) Design

The DEDM integrates core Agile and lean components into a synergistic framework (see Table 4), enabling dynamic collaboration across planning, execution, and control phases. The DEDM operationalizes general systems theory through real-time feedback loops between Scrum sprints and LPS constraints (e.g., BIM-mediated reprioritization when TRL changes), while the situation awareness framework informs ICE conflict thresholds (e.g., ICE > 0.75 triggers escalation) to enhance dynamic decision-making. Grounded in general systems theory and the situation awareness framework—which together treat construction projects as adaptive systems requiring real-time constraint–demand alignment—this dual-theory grounding mitigates the agility–rigidity paradox in hybrid methods. Its theoretical innovation manifests in three key dimensions.

Table 4.

Lean–Agile hybrid method framework.

- (1)

- Mechanism Design: The MoSCoW 2.0 priority engine incorporates technical feasibility (TRL) alongside value (RAS), addressing the “viability value trade-off” paradox in hybrid methods;

- (2)

- Control Logic: ICE algorithm’s entropy-based conflict quantification introduces objective decision thresholds (e.g., ICE > 0.75 triggers escalation), solving subjective arbitration in traditional methods;

- (3)

- Knowledge Integration: The LXS matrix extends tacit–explicit knowledge conversion theory by quantifying the contextualized experience value.

Key Components and Integration Logic:

- (1)

- Agile Engine (Scrum Sprints)

Two-week sprints drive iterative development, with backlog items dynamically prioritized via MoSCoW 2.0; daily stand-ups synchronize cross-functional teams (design, MEP, structure).

- (2)

- Lean Engine (Last Planner System)

LPS phases (Master Planning → Lookahead Planning → Weekly Commitment) ensure workflow reliability; constraint analysis (e.g., curing cycles, material lead times) is embedded in lookahead plans.

- (3)

- Integration Mechanism

Sprint goals are mapped to LPS commitment plans. For example, Sprint 1’s goal “finalize basement MEP design” aligns with LPS’s “resolve 100% pipeline clashes by Week 2”; the BIM collaboration platform visualizes sprint backlogs as task layers in the 3D model.

Agile iterations (blue) and lean workflows (green) synchronize through BIM-enabled feedback loops.

Innovation 1: Dynamic Prioritization (MoSCoW 2.0)

Traditional MoSCoW prioritization (Must/Should/Could/Won’t) is enhanced by adding technical feasibility (t-value):

TRL (Technology Readiness Level): 1–9 scale (e.g., TRL = 7 for validated BIM clash detection).

RAS (Requirement Added Value): Client/stakeholder urgency (1–10 scale).

Weights (0.6/0.4): Calibrated via Guangzhou project regression (R2 = 0.82, TRL impact p < 0.01).

Innovation 2: Interface Conflict Entropy (ICE Model)

The interface conflict entropy algorithm quantifies clashes in BIM models:

Ci: Conflict type weight (assigned via expert scoring, see Table 5).

Table 5.

ICE weight assignment.

Wi: Impact scope coefficient (calculated as the proportion of conflict-affected area to total work area).

Ttotal: Total man-hours (unit: person-days).

Conflict type weights (Ci) were calibrated via a two-round Delphi process with five nationally accredited experts meeting stringent criteria:

- Project Leadership: Experts had a minimum of 15 years directing complex megaprojects (>CNY 5B), including landmark infrastructures (e.g., Hong Kong Zhuhai Macao Bridge).

- Disciplinary Coverage: Experts had a full representation of critical domains (structural: 2, MEP: 2, façade: 1).

- Standardization Authority: All experts serve on China’s National Construction Standardization Committees [33].

- Methodological Validation:

Small expert panels (n = 510) are established for weight calibration in AHP/entropy methods when homogeneity and expertise depth are prioritized. The statistical consensus demonstrated there was high agreement confirmed by Kendall’s W = 0.78 (p < 0.001), exceeding the 0.7 threshold for reliable group decision-making.

- 5.

- Engineering Verification:

ICE thresholds derived from these weights resolved 89% of critical conflicts (ICE > 0.75) in the Shenzhen medical gas system, reducing rework costs by 41%.

3.3. Knowledge Management System and Collaborative Optimization Model Construction

- Core Mechanism: LXS Matrix

The knowledge value is quantified via experience–scenario–responsibility (LXS) mapping.

where Ei: experience value; Sj: scenario weight; an Rk: responsibility coefficient. Quantification rules are detailed in Table 6.

Table 6.

Quantification rules.

- 2.

- DIMPROVE Framework

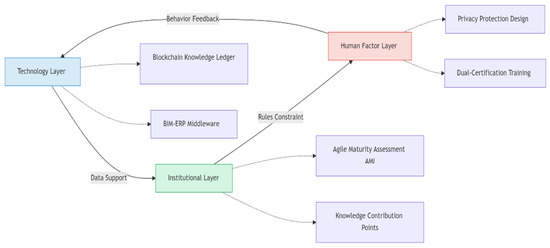

The DIMPROVE framework (Data-Institutional-Model for PROgressive Value Evolution) structures tacit knowledge into reusable assets (see Figure 1 DIMPROVE Framework Architecture)

Figure 1.

DIMPROVE framework architecture.

- (1)

- The technology layer provides the foundational digital infrastructure.

The blockchain knowledge ledger utilizes Hyperledger Fabric to immutably store hashed knowledge metadata, with original files (e.g., models, documents) stored on IPFS for distributed resilience.

BIM-ERP middleware bridges design and operational data flows. It extends the IFC 4.3 standard with JSON-LD based mapping rules to enable real-time, bidirectional synchronization between BIM authoring tools (e.g., Revit) and ERP systems (e.g., SAP), resolving model compatibility issues.

- (2)

- The institutional layer defines the governance and incentive mechanisms.

The Agile maturity index (AMI) quantitatively assesses team performance based on key Agile metrics (e.g., sprint goal completion rate > 80% qualifies as Level 4 maturity), providing objective feedback for continuous improvement.

The knowledge contribution points system automatically rewards contributors via smart contracts upon the validation of submitted solutions (e.g., awarding 50 points per validated solution), incentivizing active participation in the knowledge ecosystem.

- (3)

- The human layer focuses on user interaction, privacy, and capability development.

The privacy-preserving AR interface leverages HoloLens2 (developed by Microsoft Corporation, manufactured in Redmond, WA, USA) for augmented reality knowledge visualization and capture, incorporating mechanisms to anonymize user data during experience recording to address privacy concerns.

Dual-certification training equips engineers with hybrid expertise through specialized certification programs combining Agile methodologies (e.g., Scrum Master) and lean construction principles (e.g., Last Planner System Coordinator), fostering a workforce capable of operating effectively within the hybrid framework

4. Implementation Mechanisms and Technology Integration

4.1. Iterative Development Mechanism

The basement engineering was selected as the pilot unit, implementing a three-stage iteration (see Table 7).

Table 7.

Iteration benefits.

Key measures include the introduction of BIM schedule simulation and JIT material tracking systems to dynamically optimize resource allocation.

4.2. Knowledge Management System

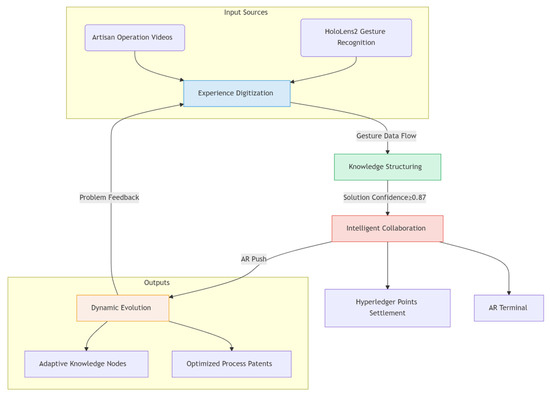

The basic system achieves full life cycle knowledge management through a four-layer architecture, detailed as follows (see Figure 2):

Figure 2.

Knowledge conversion architecture.

- Experience Digitalization: 632 process digital twin libraries were constructed via HoloLens2 gesture recognition, converting craftsman experiences into standardized operational units. The tacit knowledge codification rate reached 63%, and new employee training cycles were shortened by 62%.

- Knowledge Structuring: The LXS matrix was used for the quantitative evaluation of experience values (Ei = Years of service × 0.1 + Number of projects × 0.05). A total of 127 work condition correlation networks were constructed using Neo4j, forming an optimal solution library with confidence levels ≥ 0.87 (e.g., seismic structural solutions for the Shenzhen project).

- Intelligent Collaboration: The Hyperledger Fabric consortium chain enables the automatic settlement of knowledge contribution points, combined with AR technology for precise solution recommendations. A similar issue resolution time was reduced by 67% (2.1 h → 0.7 h, p < 0.01).

- Dynamic Evolution: Dual-cycle mechanisms drive knowledge updates, involving a daily BERT model categorization of 127 field issues and a quarterly optimization of 39 process patent rules. In total, 23% of knowledge nodes achieved adaptive iteration.

4.3. Technology Innovation Implementation Pathways

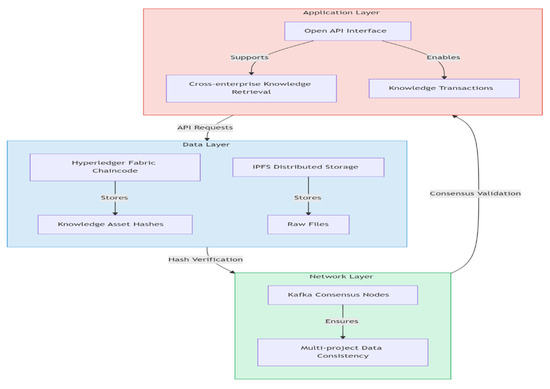

Blockchain Knowledge Ledger Architecture:

- Design framework (see Figure 3):

Figure 3. Blockchain knowledge ledger architecture.

Figure 3. Blockchain knowledge ledger architecture.

Data Layer: The Hyperledger Fabric chain code stores knowledge asset hash values, with IPFS distributed storage for original files.

Network Layer: Kafka consensus nodes ensure multi-project data consistency.

Application Layer: Open API interfaces support cross-enterprise knowledge retrieval and transactions.

Hardware Configuration: This involves orderer nodes (4-core CPU/16 GB RAM) and peer nodes (8-core CPU/32 GB RAM); see Table 8.

Table 8.

Blockchain node configuration parameters.

Performance metrics were 150 TPS (transactions/s) at 2 s latency under a 100-node simulation (tested via Hyperledger Caliper v0.5.0). Consensus efficiency involved Kafka batch size = 500 messages; timeout = 2 s.

- 2.

- BIM-ERP Middleware Protocol:

The technical solution extends IFC (Industry Foundation Classes) 4.3 standards and defines JSON-LD format material coding mapping rules (see Table 9), thus resolving model compatibility issues between Revit and Tekla.

Table 9.

Data mapping matrix.

Exception handling implements a two-phase commit protocol (2PC) for data conversion rollbacks, with error types and timestamps logged.

Synchronization latency was <5 s for critical data (material quantities, clash reports) under 500+ concurrent users (Apache JMeter stress test). Data integrity was ensured with SHA-256 checksum validation at each sync cycle.

5. Benefit Evaluation

5.1. Quantitative Analysis

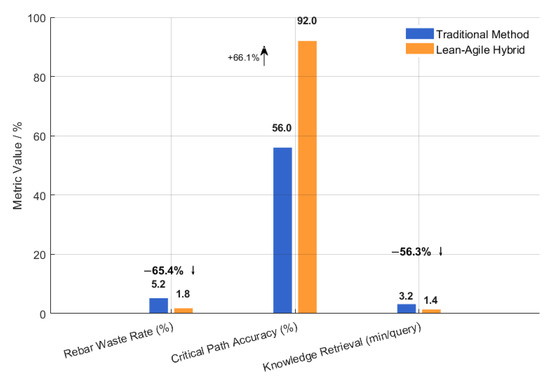

A triple-efficacy evaluation model was established by comparing baseline values (historical data from traditional methods) with implementation values (see Figure 4).

Figure 4.

Performance benchmarking.

Key Findings:

Cost Dimension: Through the JIT material tracking system, a reduction was confirmed by ANCOVA: F(1,42) = 9.32, p < 0.05, η2 = 0.18 (covariates: project scale, BIM maturity), achieving unit cost savings of USD 17.6/m2.

Time Dimension: The BIM-based real-time schedule simulation improved critical path identification accuracy to 93%, a 37 percentage point increase over traditional CPM methods.

Knowledge Dimension: The LXS matrix facilitated the formation of 127 standardized work condition solution libraries, with knowledge retrieval efficiency increasing by 2.8 times (baseline: 3.2 min/query → post-implementation: 1.1 min/query).

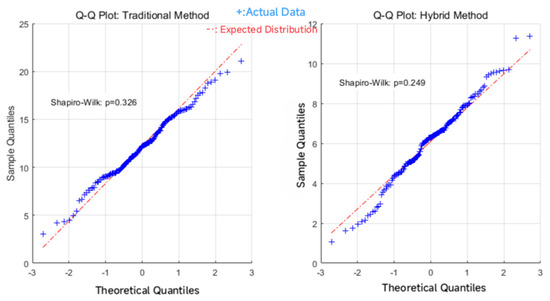

Normality test results for key indicators are shown in Figure 5 (p > 0.05, satisfying parametric test assumptions).

Figure 5.

Normality test comparative analysis.

5.2. Qualitative Analysis

Semi-structured interviews were conducted with project participants. Respondent demographics are detailed in Table 10).

Table 10.

Respondent demographics (n = 23).

Through the thematic coding of interview transcripts using NVivo 12 (Kappa consistency coefficient = 0.82), three core themes emerged:

- Enhanced Decision-Making Agility:

The daily stand-ups and the clear rules in MoSCoW 2.0 were game changers. Before, getting approval for even a minor design tweak could take days bouncing between departments. Now, if it’s a “Must Have” based on the score and we flag it in the stand-up, we often have a decision within the same day. That speed is crucial when trades are waiting onsite.

- 2.

- Knowledge Democratization Effect

As a relatively new structural engineer, being able to point my HoloLens at a beam–column junction and instantly see the best practice details from senior engineers who worked on similar seismic projects … that saved me hours of digging through folders or bothering busy colleagues. The AR library [based on LXS] put that expert knowledge right where I needed it.

Seeing my solution for the cleanroom panel installation get a high LXS score and then used by other teams and actually getting recognition points for it on the blockchain system that felt rewarding. It encourages people like us on the tools to share what we know.

- 3.

- Technology Integration and Digital Transformation:

The real breakthrough was the middleware [BIM-ERP]. Finally, the material quantities I modeled in Revit flowed seamlessly into our procurement system without manual re-entry or errors. That JIT tracking via RFID meant we had rebar delivered exactly when and where the LPS crew needed it, slashing waste and storage headaches.

6. Conclusions

This study validates the effectiveness of the lean–Agile hybrid methodology in complex construction project management through an empirical analysis of Guangzhou and Shenzhen projects. The dual-engine-driven model, integrating Scrum iterations with the Last Planner System, improved critical path efficiency by 51.6% and reduced schedule deviation from 12.4% to 6% (p < 0.01). The deep coupling of BIM with Agile practices compressed change response cycles to 2.1 days, a 77.4% improvement over the industry average (9.3 days), providing a replicable technical pathway for industry digital transformation. Future research should advance in two directions, namely a vertical deepening of technological integration and a horizontal expansion of intelligent applications, propelling the construction industry toward greater intelligence and responsiveness.

Author Contributions

H.Y.: Conceptualization, Methodology, Investigation, Formal Analysis, Writing—Original Draft. D.W.: Supervision, Resources, Writing—Review & Editing, Project Administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Bayhan, H.; Demirkesen, S.; Zhang, C.; Tezel, A. A lean construction and BIM interaction model for the construction industry. Prod. Plan. Control 2022, 34, 1447–1474. [Google Scholar] [CrossRef]

- Beck, K.; Beedle, M.; Van Bennekum, A.; Cockburn, A.; Cunningham, W.; Fowler, M.; Grenning, J.; Highsmith, J.; Hunt, A.; Jeffries, R.; et al. Manifesto for Agile Software Development; Agile Alliance: Dallas, TX, USA, 2001. [Google Scholar]

- Ballard, G. Lean project management. Build. Res. Inf. 2003, 31, 119–133. [Google Scholar] [CrossRef]

- Mayouf, M.; Jones, J.; Elghaish, F.; Emam, H.; Ekanayake, E.M.A.C.; Ashayeri, I. Revolutionising the 4D BIM Process to Support Scheduling Requirements in Modular Construction. Sustainability 2024, 16, 476. [Google Scholar] [CrossRef]

- Reiff, J.; Schlegel, D. Hybrid project management—A systematic literature review. Int. J. Inf. Syst. Proj. Manag. 2022, 10, 45–63. [Google Scholar] [CrossRef]

- Fatima, Z.E.; Bouaziz, R.; Ben Yahia, J. Adapting P2M Framework for Innovation Program Management Through a Lean-Agile Approach. Int. J. Inf. Technol. Proj. Manag. 2023, 14, 1–18. [Google Scholar]

- Straçusser, G. Agile Project Management Concepts Applied to Construction and Other Non-IT Fields; PMI® Global Congress 2015—North America: Orlando, FL, USA, 2015. [Google Scholar]

- Demir, S.T.; Theis, P. Agile Design Management—The application of Scrum in the design phase of construction projects. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016. [Google Scholar]

- Gless, H.J.; Hanser, D.; Halin, G. BIM-Agile Practices Experiments in Architectural Design Elicitation of Architectural Intentions and Refinement of Design Tasks. In Proceedings of the International Conference on Cooperative Design, Visualization, and Engineering, Mallorca, Spain, 17–20 September 2017. [Google Scholar]

- Kumar, S.S.; McArthur, J.J. Streamlining Building Information Model creation using Agile project management. In Proceedings of the BIM 2015 Conference, Toronto, ON, Canada, 10–11 June 2015. [Google Scholar]

- Senarathna, C.; Jayasinghe, S.; Antucheviciene, J.; Wickramarachchi, R.; Udayanga, N.; Weerakkody, W.S. Practices Driving the Adoption of Agile Project Management Methodologies in the Design Stage of Building Construction Projects. Buildings 2023, 13, 1079. [Google Scholar] [CrossRef]

- Tzortzopoulos, P.; Kagioglou, M.; Koskela, L. Lean Construction: Core Concepts and New Frontiers; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Ng, L.P.; Maqsood, T.; Khalfan, M.; Rahmani, F. AgiBuild: A Scaled Agile Framework for Building Adaptation Projects. Buildings 2023, 13, 3019. [Google Scholar] [CrossRef]

- Miranda Filho, A.N.D.; Costa, J.M.D.; Heineck, L.F.M. Assessing the effects of structural differences on action, reaction and conformation in construction projects. In Proceedings of the 15th Annual Conference of the International Group for Lean Construction (IGLC-15), East Lansing, MI, USA, 18–20 July 2007. [Google Scholar]

- Arroyo, P. Exploring Decision-Making Methods for Sustainable Design in Commercial Buildings; UC Berkeley: Berkeley, CA, USA, 2014. [Google Scholar]

- Hamzeh, F. Improving Construction Workflow—The Role of Production Planning and Control; UC Berkeley: Berkeley, CA, USA, 2009. [Google Scholar]

- Sacks, R. Modern Construction: Lean Project Delivery and Integrated Practices. Constr. Manag. Econ. 2013, 31, 394–396. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Shim, H.J.; Ham, H.N.; Kim, J.J. Collaborative BIM-Based Construction Coordination Progress Modeling Using Extended Collaborative Process Modeling (exCPM). Buildings 2024, 14, 358. [Google Scholar] [CrossRef]

- Hasan, S.; Işık, Z.; Demirdöğen, G. Evaluating the Contribution of Lean Construction to Achieving Sustainable Development Goals. Sustainability 2024, 16, 3502. [Google Scholar] [CrossRef]

- Krstanoski, M. Construction productivity, LEAN processes, and sustainability. In Proceedings of the International May Conference on Strategic Management—IMCSM24, Bor, Serbia, 30–31 May 2024. [Google Scholar]

- Arefazar, Y.; Nazari, A.; Hafezi, M.R.; Maghool, S.A.H. Prioritizing agile project management strategies as a change management tool in construction Projects. Int. J. Constr. Manag. 2019, 22, 678–689. [Google Scholar] [CrossRef]

- Estrada Herrera, P.; Pueblita Mares, J. Lean construction methodology in the optimization of the results of a building project. Región Científica 2023, 2, 1–12. [Google Scholar] [CrossRef]

- Malla, V. Structuration of lean-agile integrated factors for construction projects. Constr. Innov. 2024, 24, 19. [Google Scholar] [CrossRef]

- Marnewick, C.; Marnewick, A.L. Project managers’ ability to explore and exploit predictive and iterative best practices. Int. J. Manag. Proj. Bus. 2023, 16, 126–151. [Google Scholar] [CrossRef]

- Zaid, P.F.; Paternò, A.; Pisano, P. Managing the Hybrid Organization: How Can Agile and Traditional Project Management Coexist? Res.-Technol. Manag. 2020, 64, 54–63. [Google Scholar]

- Nowotarski, P.; Pasławski, J. Lean and Agile Management Synergy in Construction of High-Rise Office Building. Arch. Civ. Eng. 2016, 62, 133–148. [Google Scholar] [CrossRef]

- Li, X. Research on Planning and Control of Prefabricated Building Construction Process; Dalian University of Technology: Dalian, China, 2018. [Google Scholar]

- Balram, O.; Mukherjee, A.; Paul, S. Team development and improvement in execution and review of project construction through agile method and analyzing its benefit and drawback with other existing methods. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 3984–3990. [Google Scholar]

- Pasławski, J.; Rudnicki, T. Agile/flexible and lean management in ready-mix concrete delivery. Arch. Civ. Eng. 2021, 67, 689–709. [Google Scholar] [CrossRef]

- ISO 19650-1:2018; Organization and Digitization of Information About Buildings and Civil Engineering Works—Information Management Using Building Information Modeling—Part 1: Concepts and Principles. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 19650-2:2018; Organization and Digitization of Information About Buildings and Civil Engineering Works—Information Management Using Building Information Modeling—Part 2: Delivery Phase of the Assets. International Organization for Standardization: Geneva, Switzerland, 2018.

- GB/T 51269-2017; Standard for Classification and Coding of Building Information Model. China Architecture & Building Press: Beijing, China, 2017.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).