Characterization of the Mechanical Properties of Fiber-Reinforced Modified High Water Content Materials

Abstract

1. Introduction

2. Experimental Program

2.1. Test Sample Design

2.2. Raw Materials

2.3. Specimen Preparation

3. Experimental Results and Discussion

3.1. Stress Strain Curve

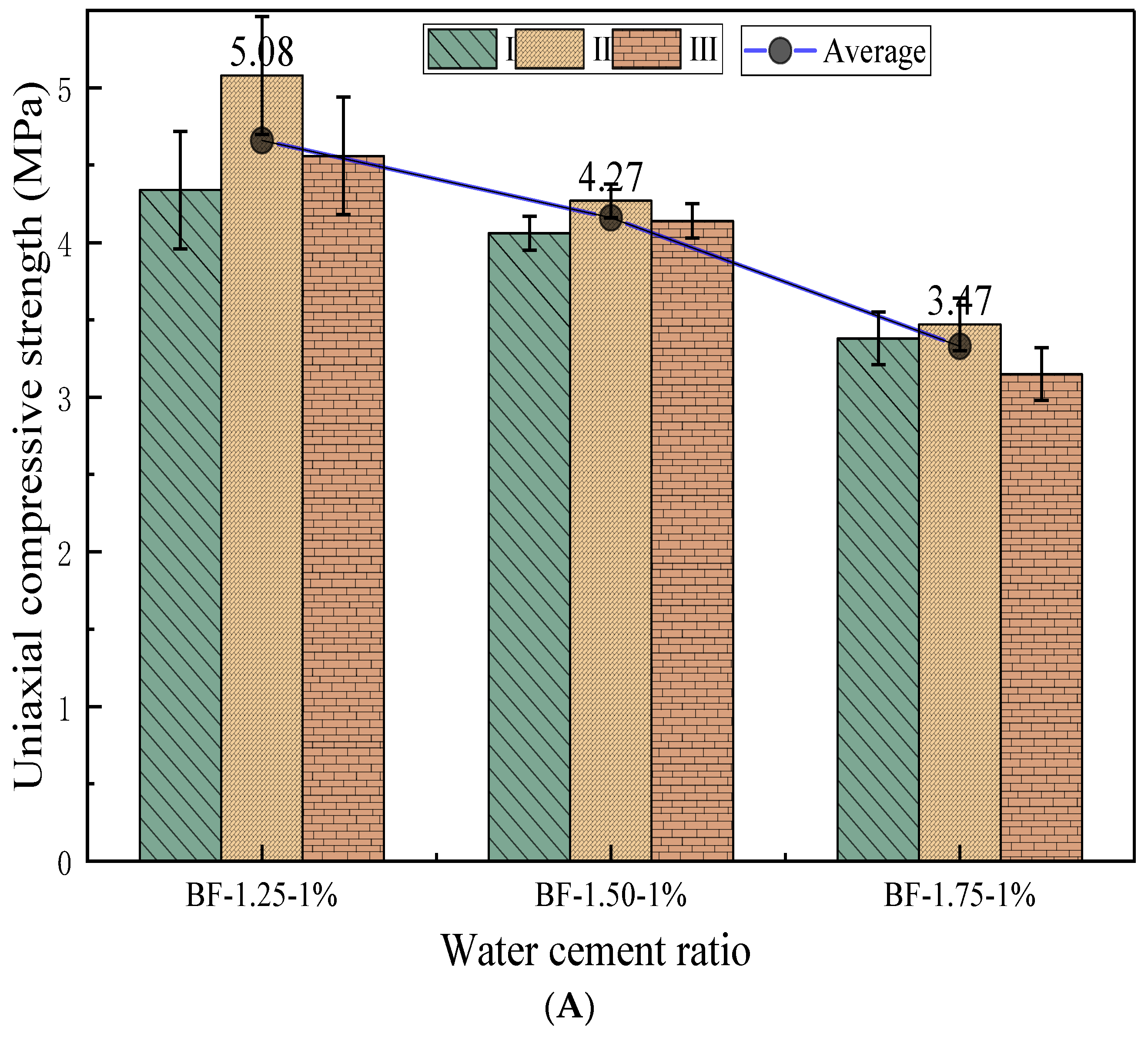

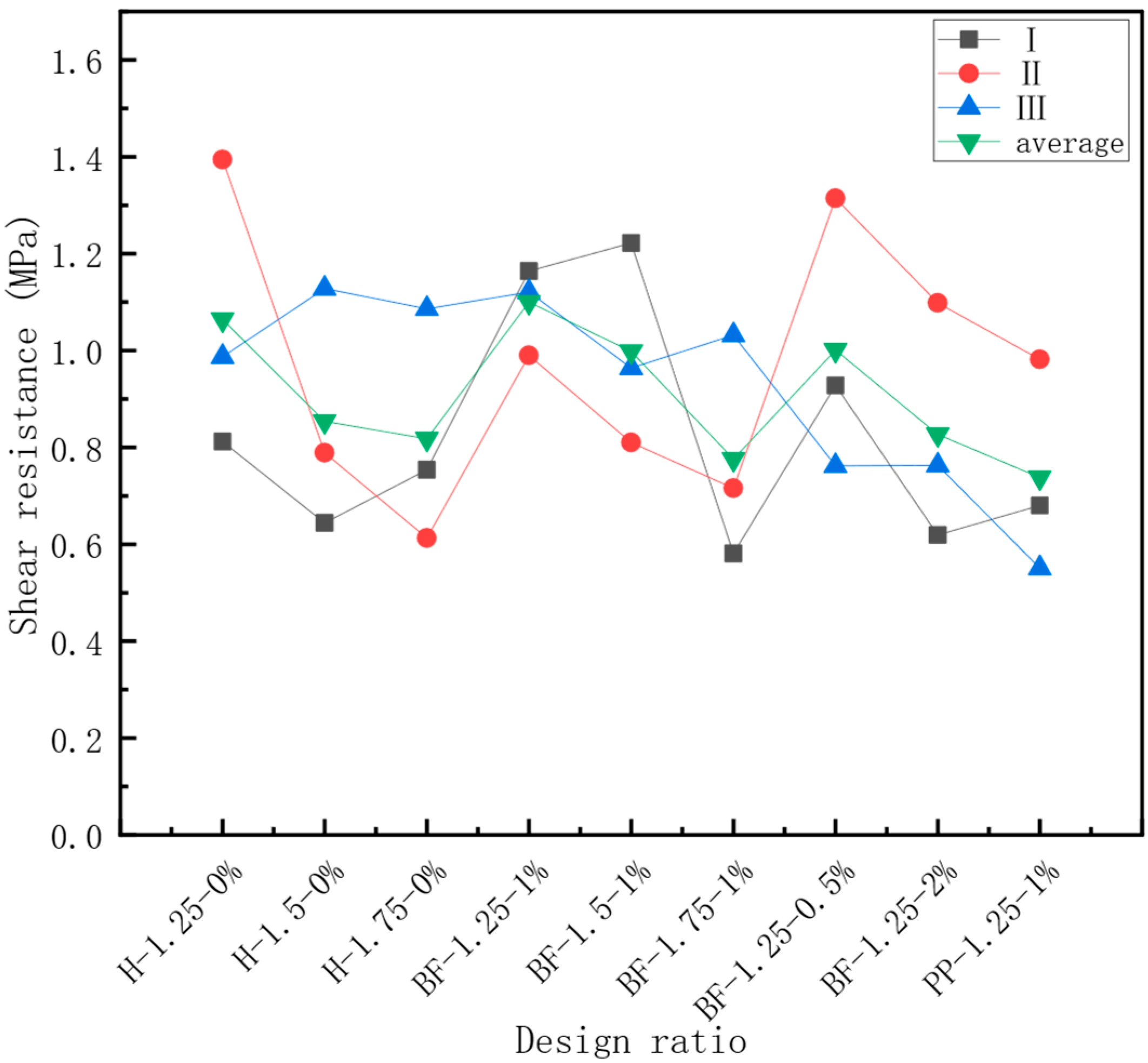

3.2. Uniaxial Compressive Strength Test of Specimen

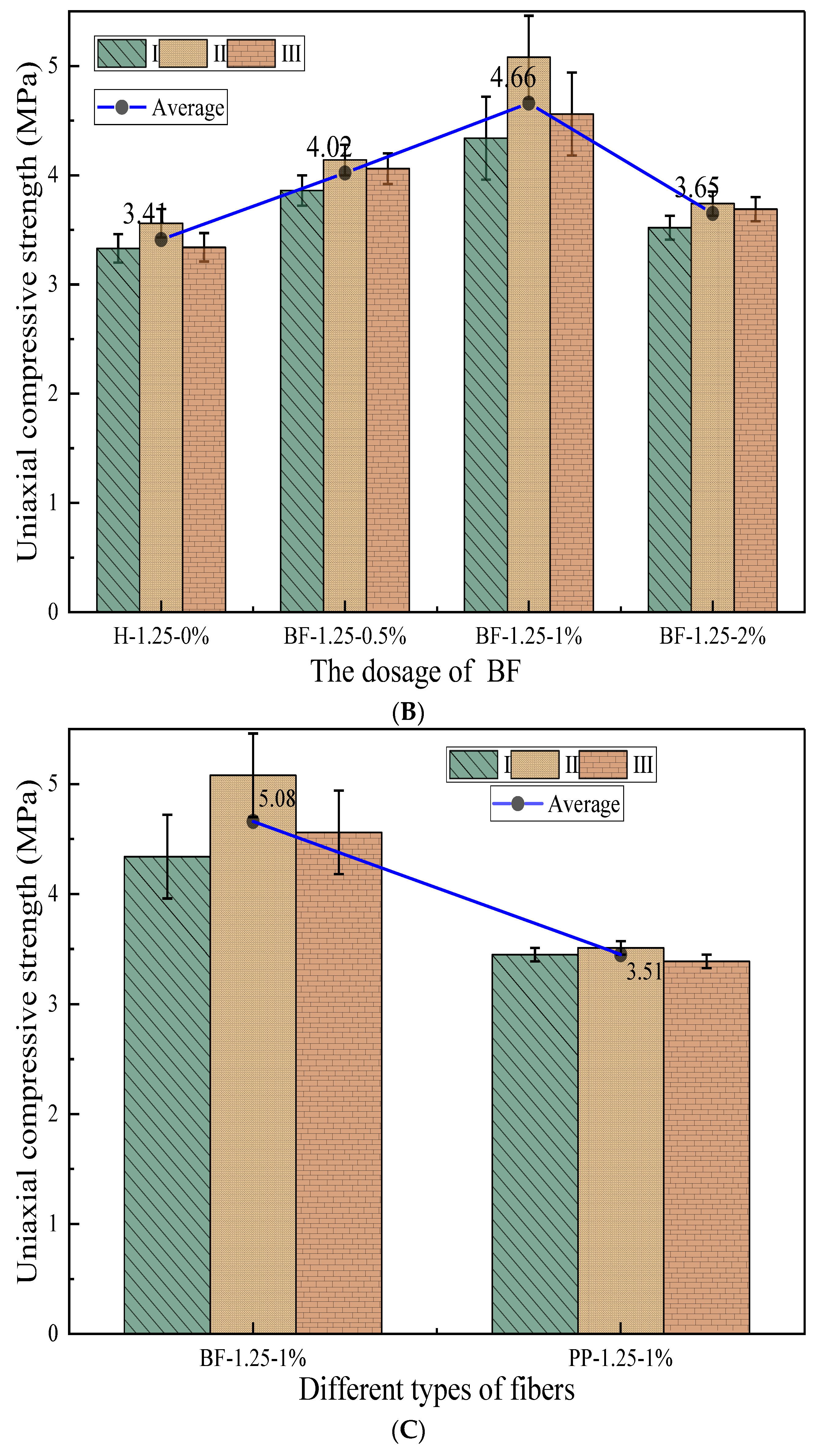

3.3. Tensile Strength Test

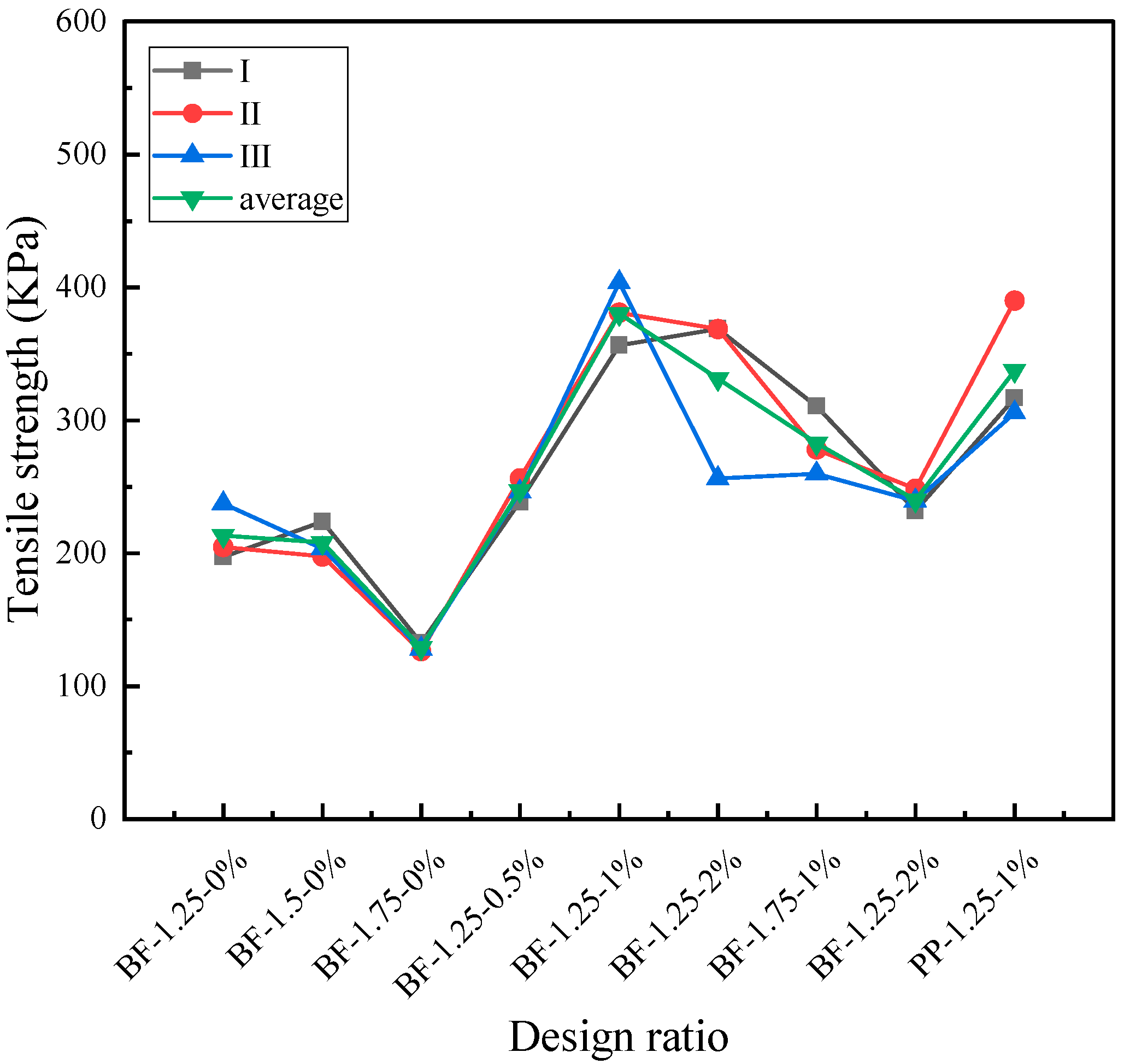

3.4. Shear Strength Test

3.5. Material Performance Evaluation Based on Comparative Analysis

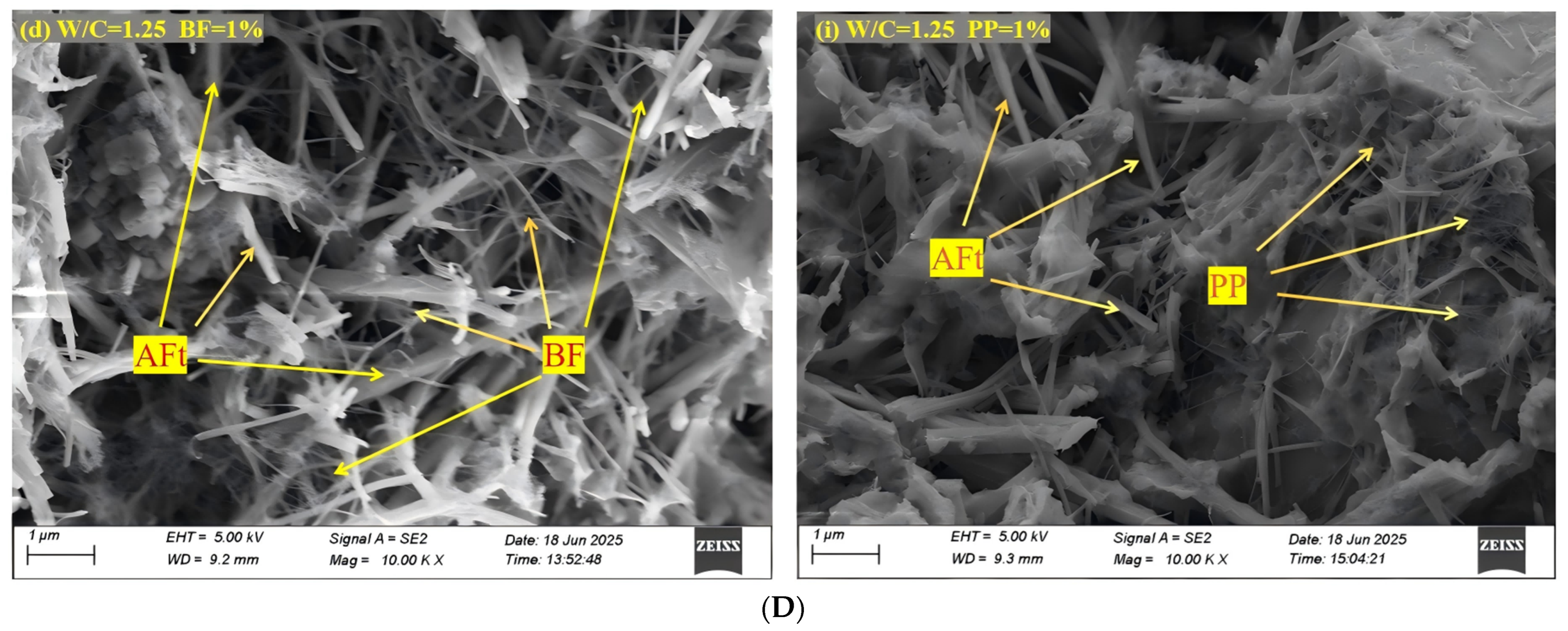

4. Micromorphological Analysis

5. Conclusions

- (1)

- Identification of Optimal Configuration: The combination of 1% basalt fiber content with a ratio of 1.25 yielded the highest compressive strength of 5.08 MPa, establishing it as the optimal configuration for mining backfill applications. This configuration effectively balances the integrity of the matrix with the efficiency of fiber reinforcement.

- (2)

- Comparison of Fiber Types: Basalt fiber exhibited superior performance relative to polypropylene fiber, with an average compressive strength that was 1.21 MPa higher. Scanning Electron Microscopy (SEM) analysis indicated that basalt fibers form stronger interfacial bonds with the matrix, characterized by dense hydration products adhering to the fiber surface, whereas polypropylene fibers displayed weaker interfacial bonding and inadequate bonding density.

- (3)

- Effects of Ratio: An increase in the ratio from 1.25 to 1.75 led to a significant reduction in strength across all mechanical properties. Specifically, the compressive strength decreased from 5.08 MPa to 3.15 MPa, which can be attributed to increased porosity and a reduction in bonding capacity at higher ratios.

- (4)

- Optimization of Fiber Content: A fiber dosage of 1% was determined to be optimal for all strength parameters. Lower dosages (0.5%) resulted in inadequate fiber dispersion and weak network formation, while higher dosages (2%) led to fiber aggregation, stress concentrations, and diminished reinforcement efficiency.

- (5)

- Microstructural Validation: SEM analysis at a magnification of 10,000 confirmed the establishment of an effective three-dimensional fiber network under optimal conditions. The 6 mm basalt fibers demonstrated excellent dispersion, robust bonding with the matrix, and effective bridging mechanisms that inhibit crack propagation, thereby enhancing the overall performance of the material.

- (6)

- Engineering Implications: The optimized basalt fiber-modified high-water material exhibits improved ductility and mechanical performance, making it suitable for mining backfill applications. It offers enhanced crack resistance and long-term stability compared to conventional high-water materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.; Pan, J.; Xia, Y.; Du, T.; Liu, W.; Zhang, C. Mechanism and prevention of coal bursts in gob-side roadway floor under thick and hard roof in the deep mining area of Ordos. Int. J. Coal Sci. Technol. 2024, 11, 80. [Google Scholar] [CrossRef]

- Xue, H.; Jiang, B.; He, M.; Zhang, C.; Wang, Y.; Zhang, S.; Deng, Y. Mechanism and validation of pressure relief and energy reduction of automatically formed roadway by roof cutting in deep coal mines. Bull. Eng. Geol. Environ. 2025, 84, 77. [Google Scholar] [CrossRef]

- Zhao, W.; Zhao, D.; Wang, K.; Fan, L.; Zhao, Z.; Dong, H.; Shu, L. Will greenhouse gas emissions increase with mining depth in coal mines? An analysis of gas occurrence under varying in-situ stress conditions. Sci. Total Environ. 2024, 945, 173957. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, R.; Song, D.; Li, N.; Zhang, K.; Xi, D. Deformation and damage dynamic characteristics of coal-rock materials in deep coal mines. Int. J. Damage Mech. 2019, 28, 58–78. [Google Scholar] [CrossRef]

- Bo, L.; Yang, S.; Liu, Y.; Wang, Y.; Zhang, Z. Research on the data validity of a coal mine solid backfill working face sensing system based on an improved transformer. Sci. Rep. 2023, 13, 11092. [Google Scholar] [CrossRef]

- Lyu, J.; Song, Z.; Chen, H.; Qi, Z.; Yu, B.; Hu, H. Behavior of backfill material made of high-water material and recycled concrete lumps for highwall mining. Case Stud. Constr. Mater. 2024, 21, e03777. [Google Scholar] [CrossRef]

- Xing, K.; Cheng, J.; Zhen, Z.; Wan, Z.; Han, Z.; Yan, W.; Lv, J.; Yang, Y. Effect of super-high water materials backfilling on stress decrease and energy release during strip coal pillar mining, A case study. Heliyon 2024, 10, e37441. [Google Scholar] [CrossRef]

- Sun, Y.; Xie, S.; Wu, C.; Cui, J.; Chen, D.; Guo, F.; Jiang, Z.; Ren, Y.; Lu, W. Influence of the ultra-fine fly ash dosages on the mechanical properties of the sulfoaluminate cement-based high water backfilling material. Sci. Rep. 2023, 13, 1564. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Li, M.; Wang, J.; Yang, P.; Xu, M. Effect of fly ash on properties and hydration of calcium sulphoaluminate cement-based materials with high water content. Rev. Adv. Mater. Sci. 2024, 63, 20240046. [Google Scholar] [CrossRef]

- Ma, X.; Liu, C.; Zhai, L.; Xie, S.; Wu, C.; Yang, J. Study on hydration mechanism and ratio optimization of slag powder modified high-water material. Sci. Rep. 2025, 15, 6175. [Google Scholar] [CrossRef]

- Wu, H.K.; Liu, C.W.; Zhang, Z.; Miao, Y.C. Time effect of chloride erosion on physical and mechanical properties of high-water-content materials. Adv. Mater. Sci. Eng. 2020, 2020, 2730283. [Google Scholar] [CrossRef]

- He, W.; Liu, L.; Fang, Z.; Gao, Y.; Sun, W. Effect of polypropylene fiber on properties of modified magnesium-coal-based solid waste backfill materials. Constr. Build. Mater. 2023, 362, 129695. [Google Scholar] [CrossRef]

- Xie, S.; Sun, Y.; Wang, E.; Chen, D.; Wu, X.; Qi, P. Experimental and mechanistic research on modifying the mechanic properties of the high water backfill material by electrochemical treatment. Sci. Rep. 2020, 10, 17027. [Google Scholar] [CrossRef]

- Ren, C.; Wang, W.; Yao, Y.; Wu, S.; Yao, X. Complementary use of industrial solid wastes to produce green materials and their role in CO2 reduction. J. Clean. Prod. 2020, 252, 119840. [Google Scholar] [CrossRef]

- Pang, Z.; Lu, C.; Liu, J.; Yao, Y.; Wang, J. Experimental study of tensile properties of strain-hardening cementitious composites (SHCCs) reinforced with innovative twisted basalt fibers. Structures 2023, 48, 1977–1988. [Google Scholar] [CrossRef]

- Wang, D.L.; Tang, C.S.; Pan, X.H.; Liu, B.; Shi, B. Coupling effect of fiber reinforcement and MICP stabilization on the tensile behavior of calcareous sand. Eng. Geol. 2023, 317, 107090. [Google Scholar] [CrossRef]

- Song, D.; Wang, B.; Tao, W.; Wang, X.; Zhang, W.; Dai, M.; Li, J.; Zhou, Z. Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites. Nanotechnol. Rev. 2022, 11, 3020–3030. [Google Scholar] [CrossRef]

- Zhang, H.; He, B.; Cheng, Y.; Tang, Y.; Ren, Q.; Zhu, X.; Jiang, Z. Strengthening and embrittlement effect of cryogenic temperature on fiber reinforced geopolymer composite. Cem. Concr. Compos. 2024, 153, 105727. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, X.; Li, X.; Ning, J.; Liu, Y.; Yang, S. Research and development of steel fiber reinforced concrete filling material and its application in gob-side entry retaining technology in deep mines. Buildings 2024, 14, 722. [Google Scholar] [CrossRef]

- Manikandan, V.; Jappes, J.W.; Kumar, S.S.; Amuthakkannan, P.J.C.P.B.E. Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites. Compos. Part B Eng. 2012, 43, 812–818. [Google Scholar] [CrossRef]

- Chen, H.; Xie, C.; Fu, C.; Liu, J.; Wei, X.; Wu, D. Orthogonal analysis on mechanical properties of basalt-polypropylene fiber mortar. Materials 2020, 13, 2937. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Lou, C.; Lyu, X. Experimental study on direct tensile fatigue performance of basalt fiber reinforced concrete. Sci. Rep. 2024, 14, 765. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.T.; Bui, T.T.; Bui, Q.B. Fiber reinforced concrete for slabs without steel rebar reinforcement: Assessing the feasibility for 3D-printed individual houses. Case Stud. Constr. Mater. 2022, 16, e00950. [Google Scholar] [CrossRef]

- Dong, H. Preparation and performance analysis of polypropylene fiber-reinforced concrete composite. Asia-Pac. J. Chem. Eng. 2020, 15, e2445. [Google Scholar] [CrossRef]

- Islam, M.S.; Church, J.S.; Miao, M. Effect of removing polypropylene fibre surface finishes on mechanical performance of kenaf/polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1687–1693. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Cao, K.; Sun, L. Review on the durability of polypropylene fibre-reinforced concrete. Adv. Civ. Eng. 2021, 2021, 6652077. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Phetprapai, T.; Singsang, W.; Phetchuay, C.; Thumrongvut, J.; Tabyang, W. Utilization of recycled plastic waste in fiber reinforced concrete for eco-friendly footpath and pavement applications. Sustainability 2022, 14, 6839. [Google Scholar] [CrossRef]

- Kumar, S.; Doshi, H.; Srinivasarao, M.; Park, J.O.; Schiraldi, D.A. Fibers from polypropylene/nano carbon fiber composites. Polymer 2002, 43, 1701–1703. [Google Scholar] [CrossRef]

- Xu, J.; Li, H.; Huang, S.; Pi, Z.; Chen, J.; Chen, X.; Song, J. Comparative study on the properties of basalt and steel fiber reinforcement waste rock concrete. Sci. Rep. 2025, 15, 15103. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

| Series | Groups | Samples | Ratio (W/C) | Fiber Types | Fiber Admixture (in %) |

|---|---|---|---|---|---|

| Series 1 | H-1.25-0.0 | H-1.25-0.0%-I, II, III | 1.25 | - | 0 |

| H-1.50-0.0 | H-1.50-0.0%-I, II, III | 1.5 | - | 0 | |

| H-1.75-0.0 | H-1.75-0.0%-I, II, III | 1.75 | - | 0 | |

| Series 2 | BF-1.25-1.0 | BF-1.25-1.0%-I, II, III | 1.25 | basalt fiber | 1% |

| BF-1.50-1.0 | BF-1.50-1.0%-I, II, III | 1.5 | basalt fiber | 1% | |

| BF-1.75-1.0 | BF-1.75-1%-I, II, III | 1.75 | basalt fiber | 1% | |

| BF-1.25-0.5 | BF-1.25-0.5%-I, II, III | 1.25 | basalt fiber | 0.5% | |

| BF-1.25-2.0 | BF-1.25-2.0%-I, II, III | 1.25 | basalt fiber | 2% | |

| PP-1.25-1.0 | PP-1.25-1.0%-I, II, III | 1.25 | polypropylene fiber | 1% |

| Sample Number | E1 (GPa) | E2 (GPa) | E3 (GPa) | E2/E1 Ratio | Peak Intensity (MPa) |

|---|---|---|---|---|---|

| H-1.25-0.0% | 0.86–1.00 | 2.42–2.68 | 0.31–0.47 | 2.7–2.8 | 4.10 |

| H-1.50-0.0% | 0.72–0.84 | 2.18–2.42 | 0.28–0.38 | 2.9–3.0 | 3.74 |

| H-1.75-0.0% | 0.46–0.56 | 1.32–1.52 | 0.16–0.26 | 2.8–3.2 | 1.89 |

| BF-1.25-1.0% | 1.18–1.32 | 3.15–3.45 | 0.62–0.78 | 2.6–2.7 | 5.36 |

| BF-1.25-0.5% | 0.86–1.00 | 2.42–2.68 | 0.31–0.47 | 2.7–2.8 | 4.10 |

| BF-1.25-2.0% | 0.68–0.82 | 1.92–2.18 | 0.22–0.35 | 2.7–2.9 | 3.20 |

| PP-1.25-1.0% | 0.72–0.86 | 1.95–2.22 | 0.25–0.38 | 2.6–2.7 | 3.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, B.; Lyu, J.; Zhang, Z.; Song, Z.; Liu, S. Characterization of the Mechanical Properties of Fiber-Reinforced Modified High Water Content Materials. Buildings 2025, 15, 2283. https://doi.org/10.3390/buildings15132283

Song B, Lyu J, Zhang Z, Song Z, Liu S. Characterization of the Mechanical Properties of Fiber-Reinforced Modified High Water Content Materials. Buildings. 2025; 15(13):2283. https://doi.org/10.3390/buildings15132283

Chicago/Turabian StyleSong, Bao, Jinxing Lyu, Zhiyi Zhang, Zhimeng Song, and Songxiang Liu. 2025. "Characterization of the Mechanical Properties of Fiber-Reinforced Modified High Water Content Materials" Buildings 15, no. 13: 2283. https://doi.org/10.3390/buildings15132283

APA StyleSong, B., Lyu, J., Zhang, Z., Song, Z., & Liu, S. (2025). Characterization of the Mechanical Properties of Fiber-Reinforced Modified High Water Content Materials. Buildings, 15(13), 2283. https://doi.org/10.3390/buildings15132283