Torsional Strengthening of RC Beams with Openings Using Hybrid SHCC–Glass Fiber Mesh Composites

Abstract

1. Introduction

2. Experimental Program

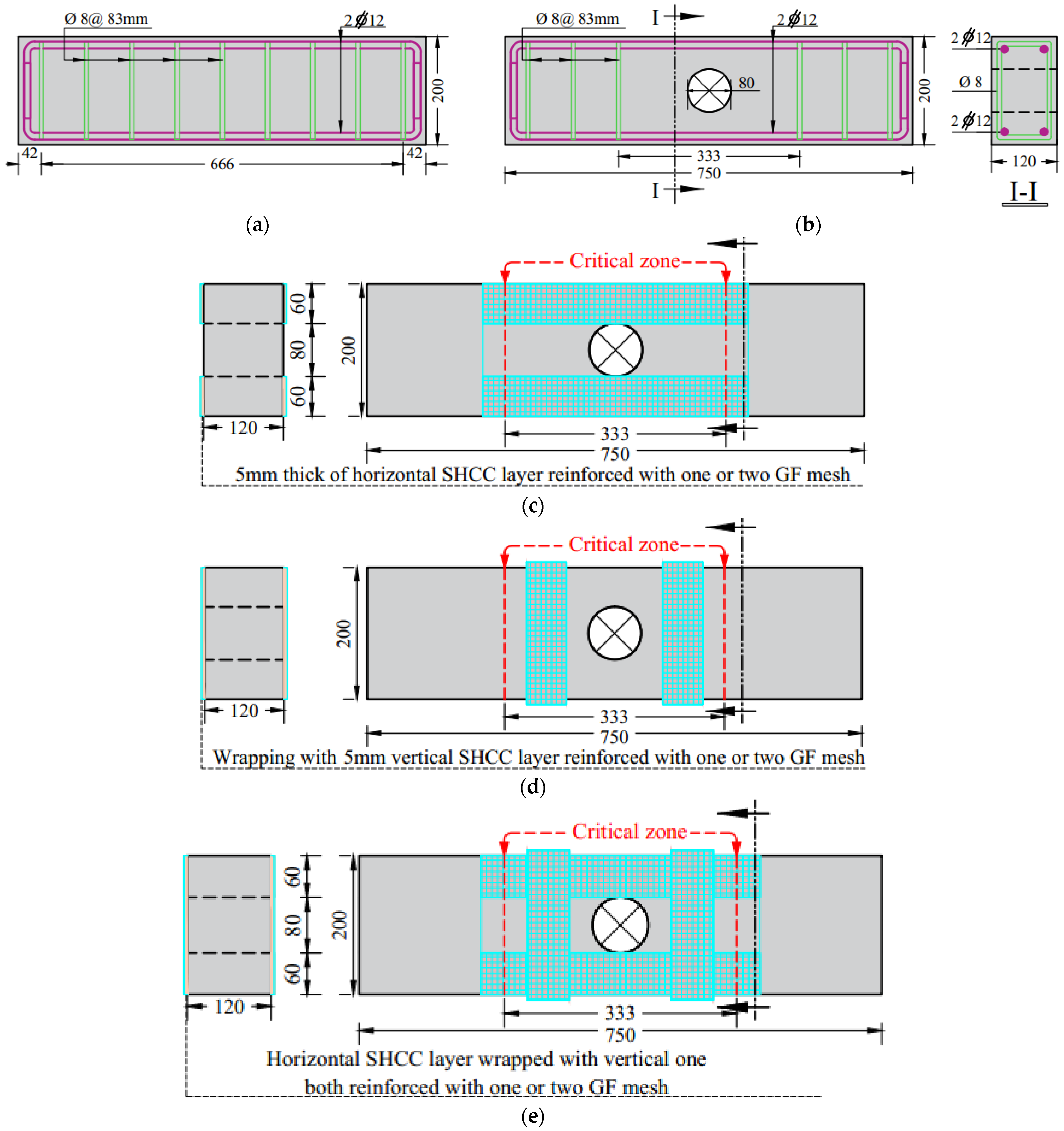

2.1. Specimen Details

2.2. Material Properties

2.2.1. Concrete Mixes

2.2.2. Reinforcing Rebar and Glass Fiber Mesh

2.2.3. ADDIBOND 65

2.3. Casting and Strengthening Procedures

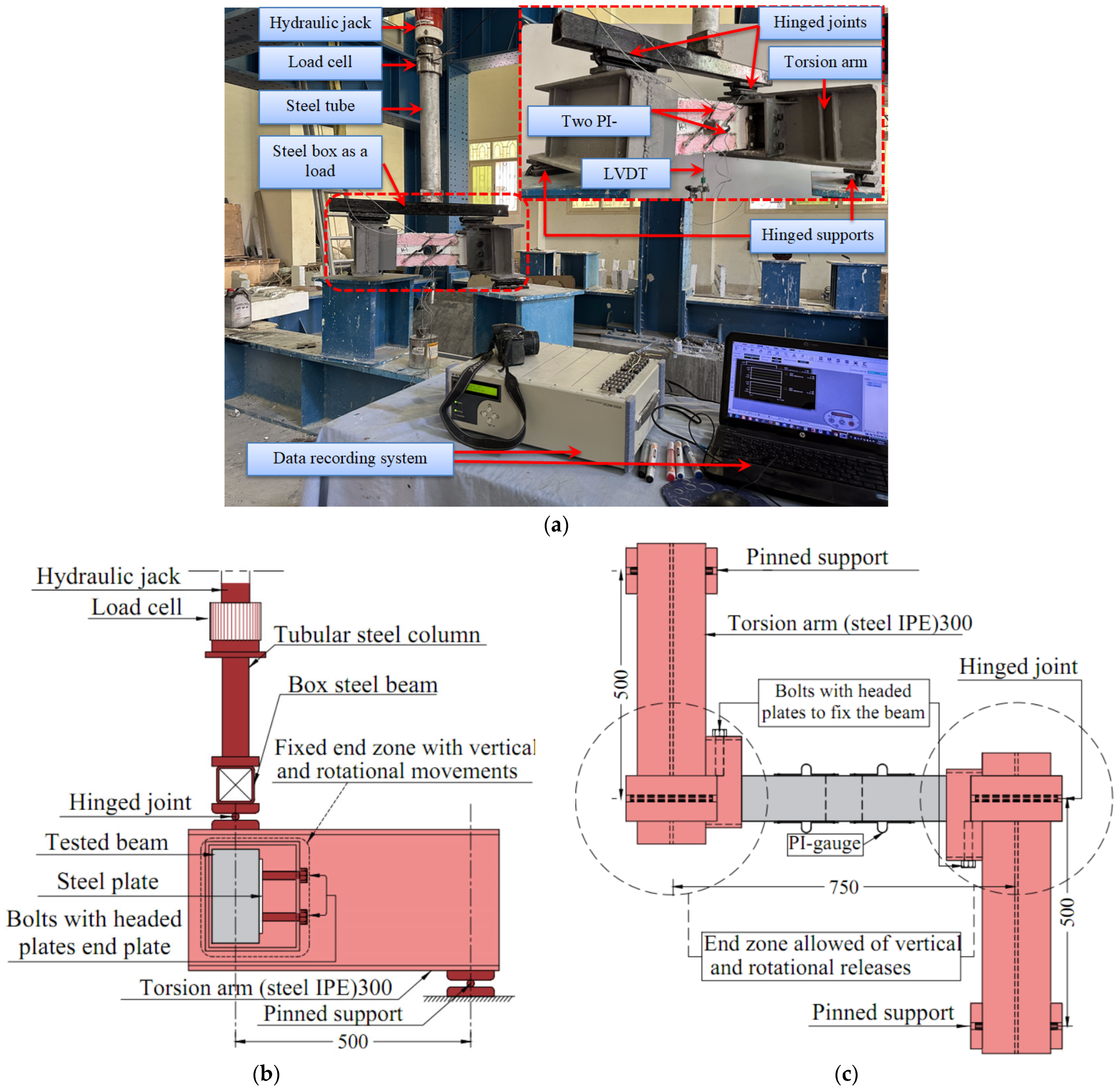

2.4. Test Setup and Loading Arrangement

3. Results of Tests and Discussion

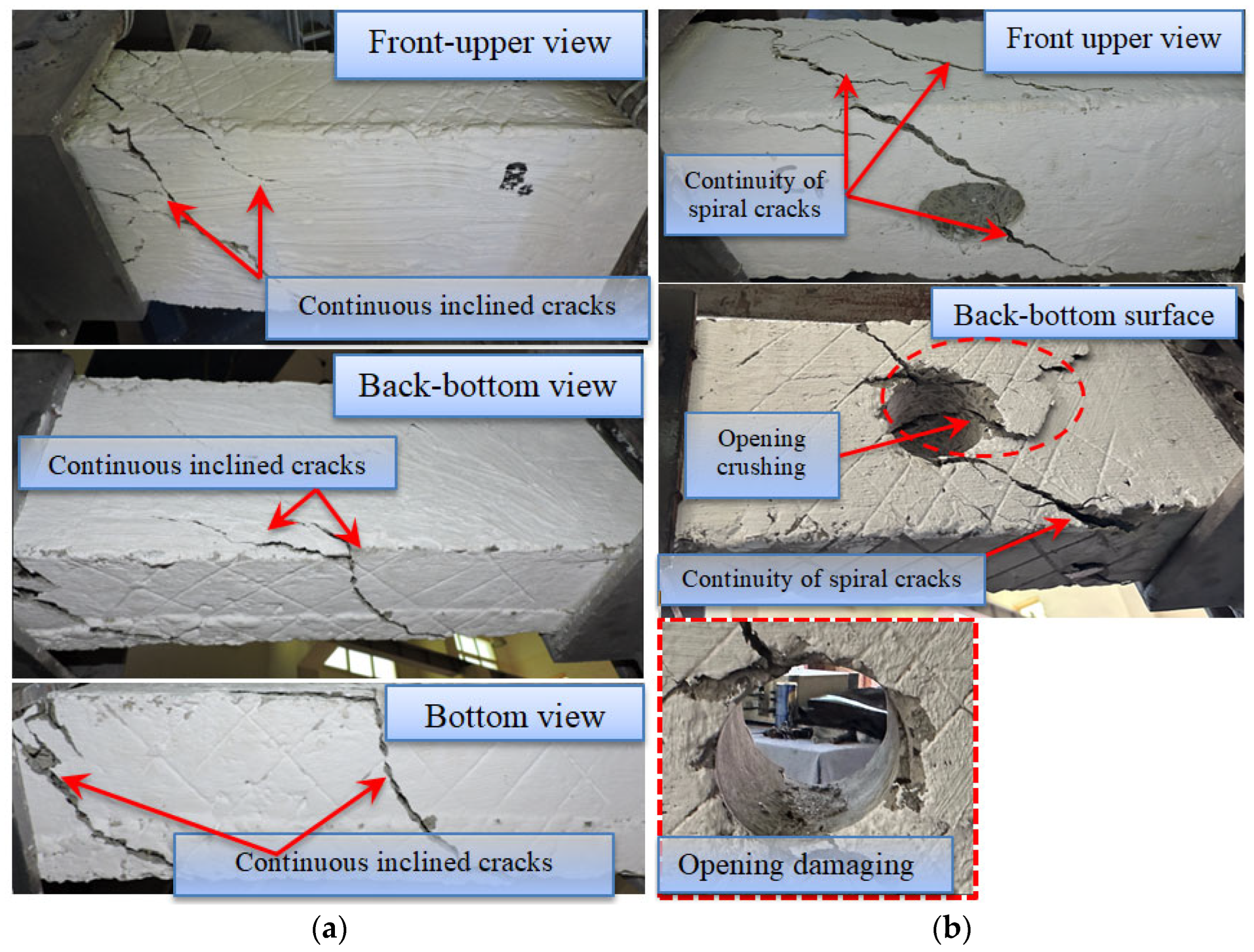

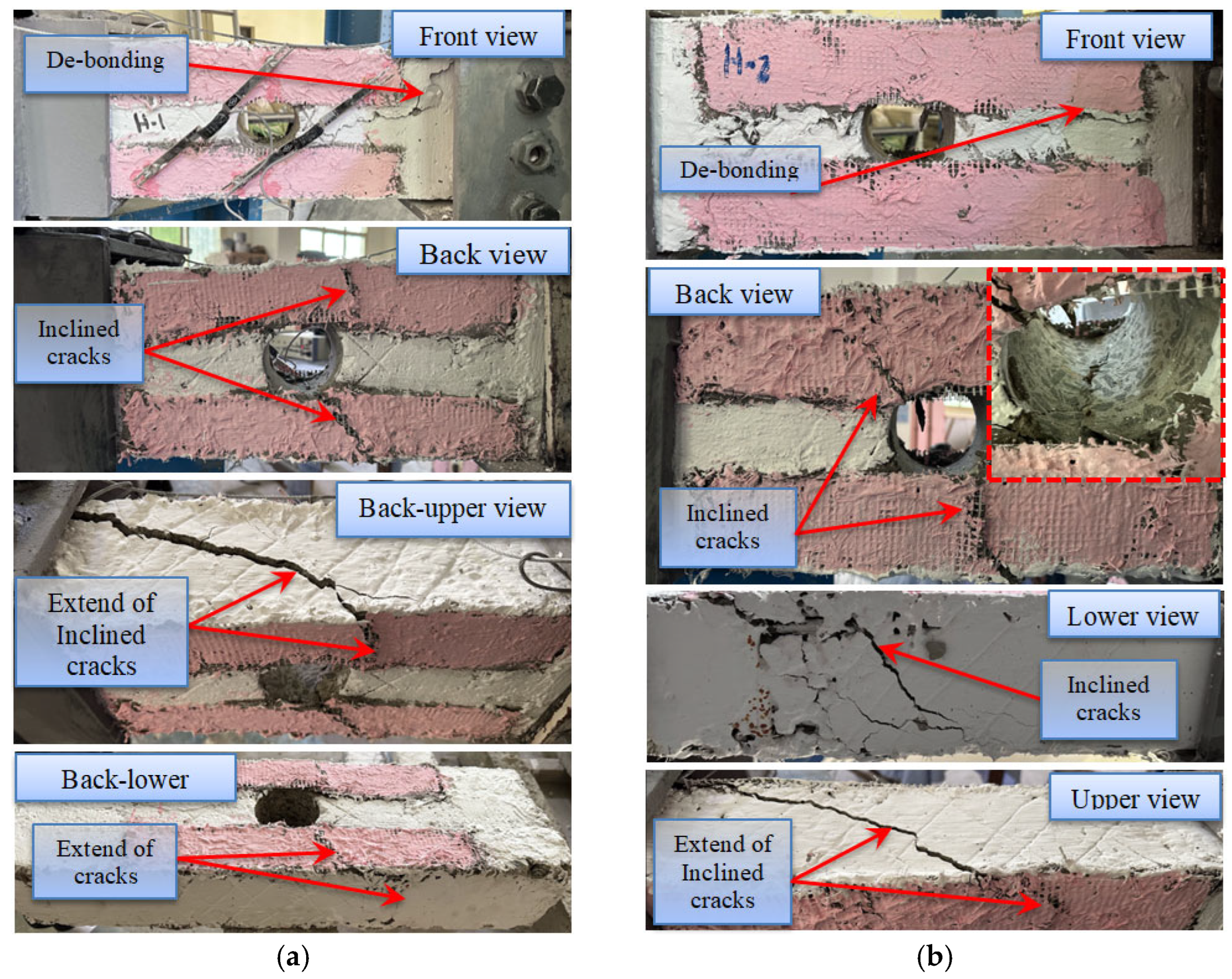

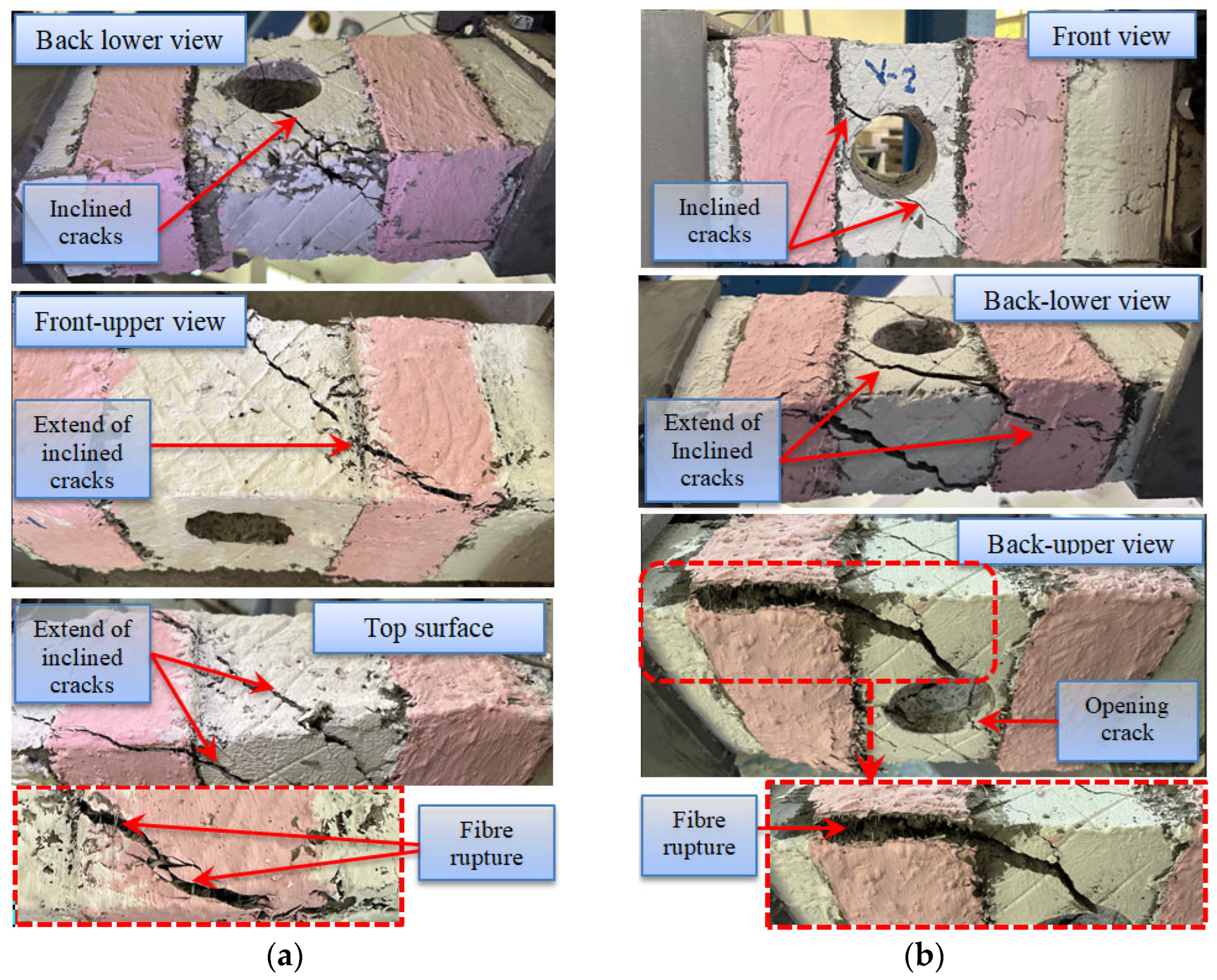

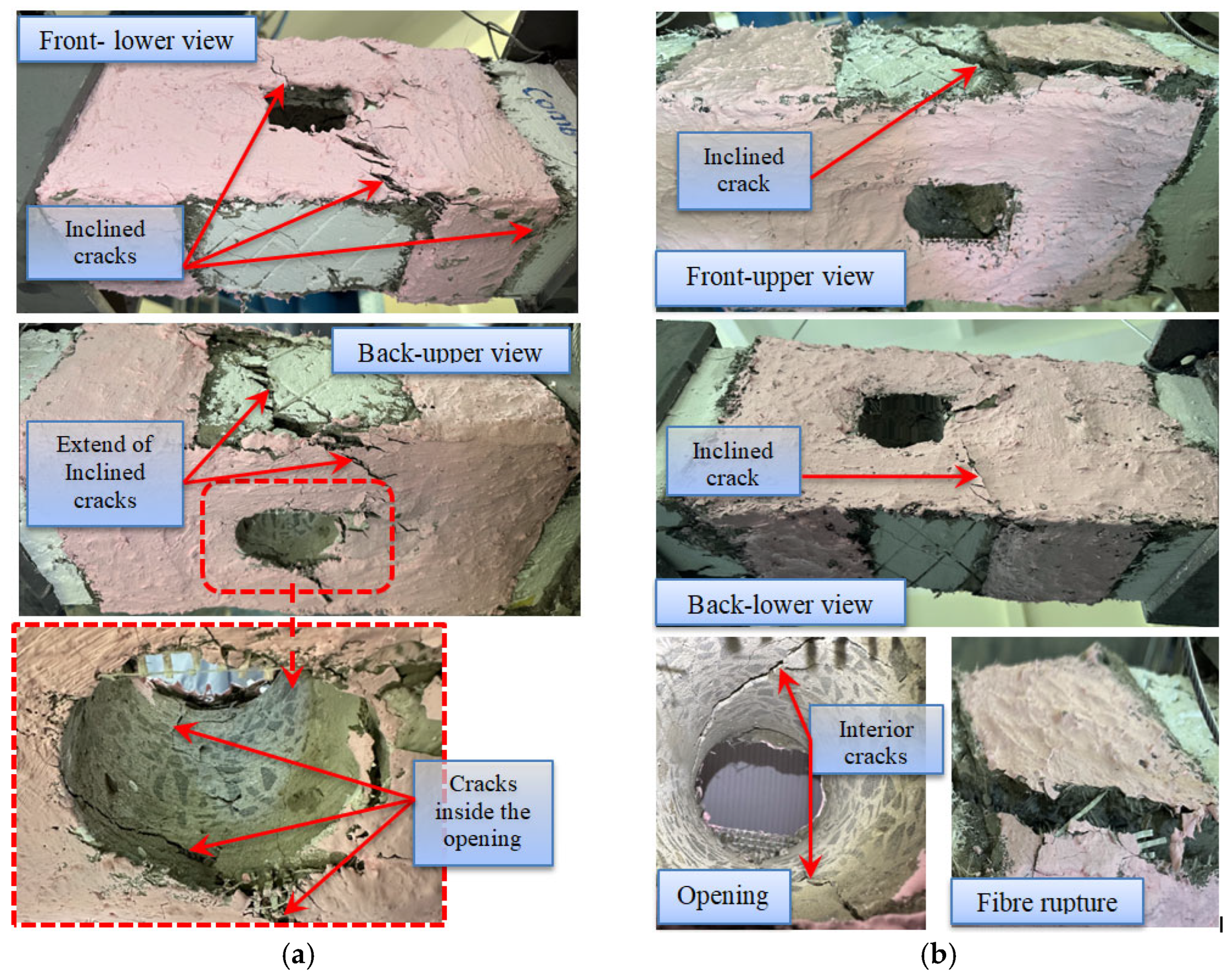

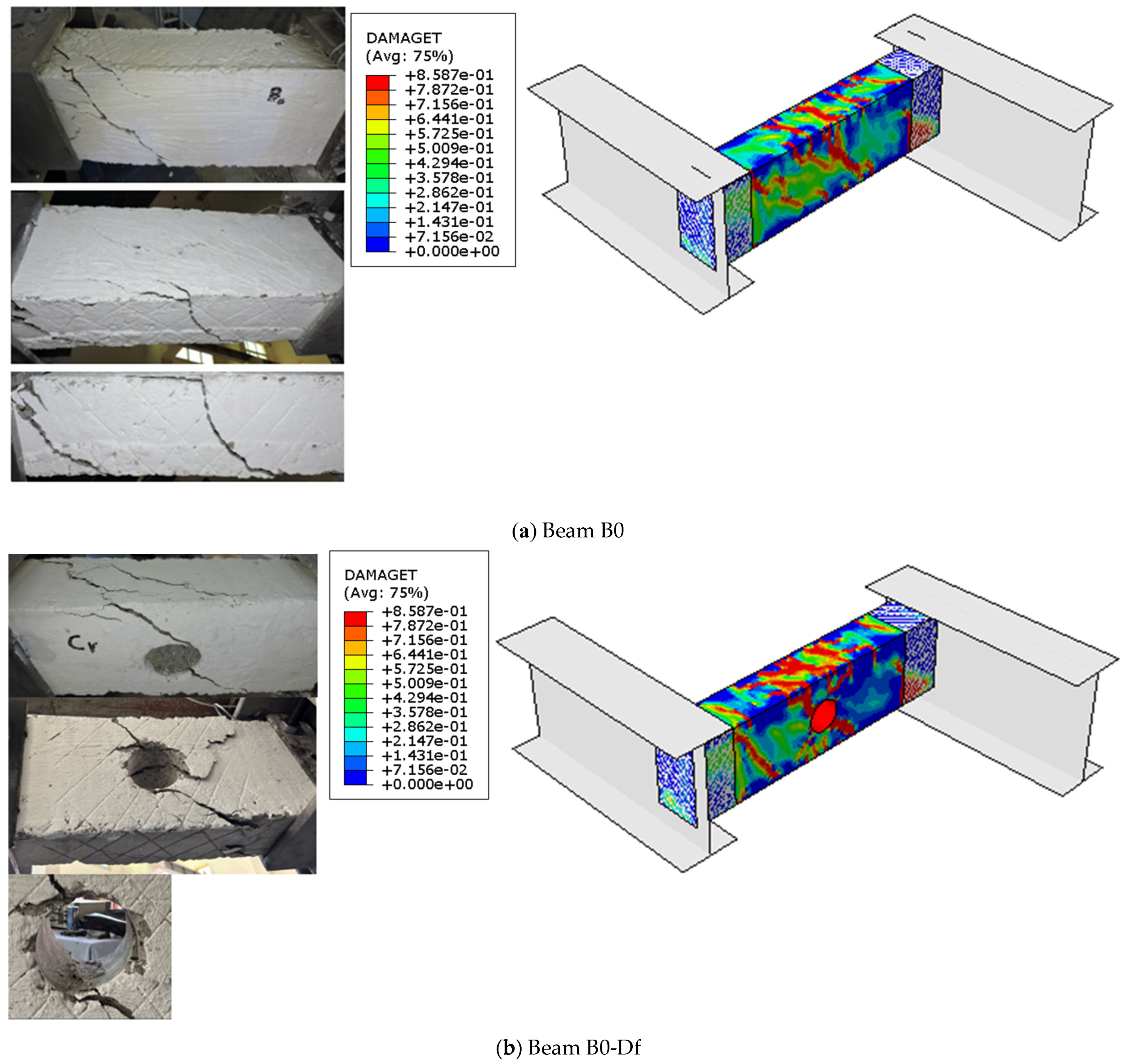

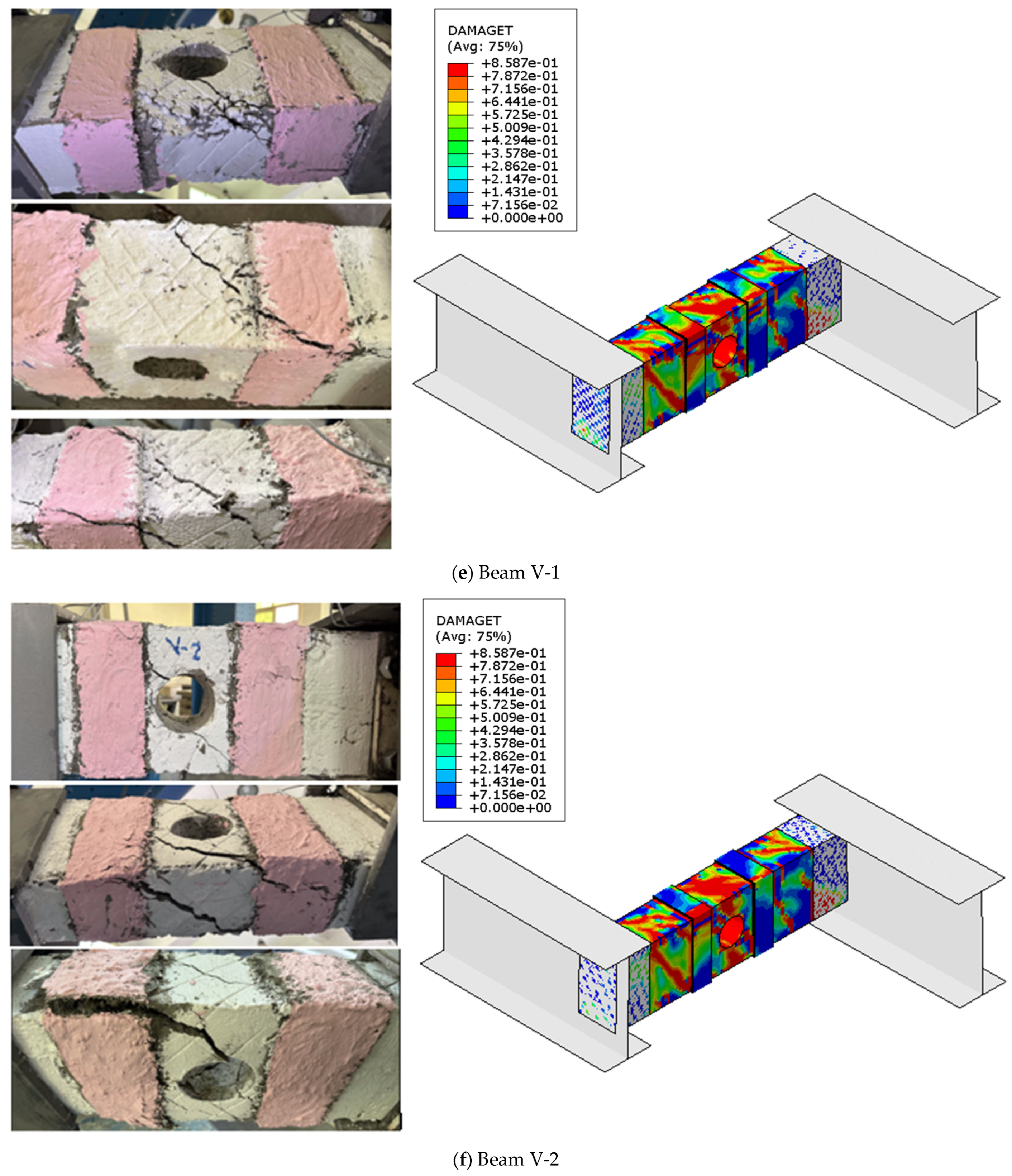

3.1. Failure Patterns

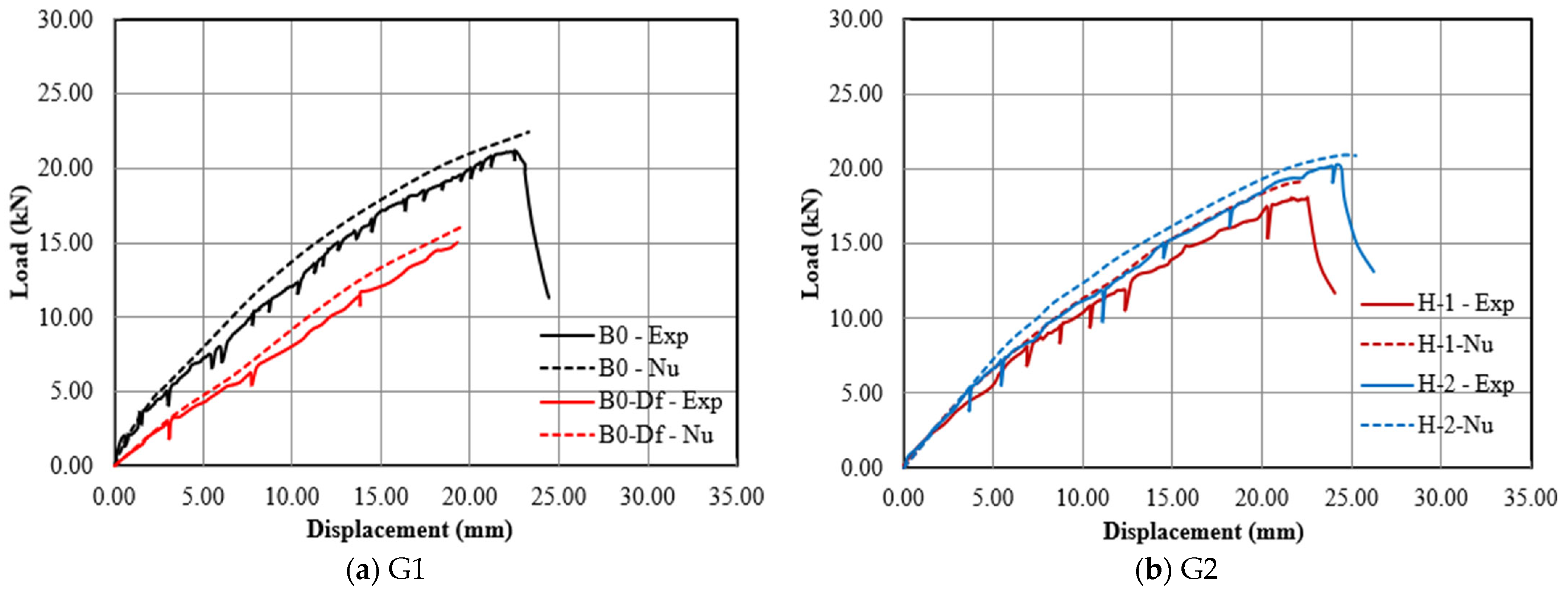

3.2. Load—Displacement Curves

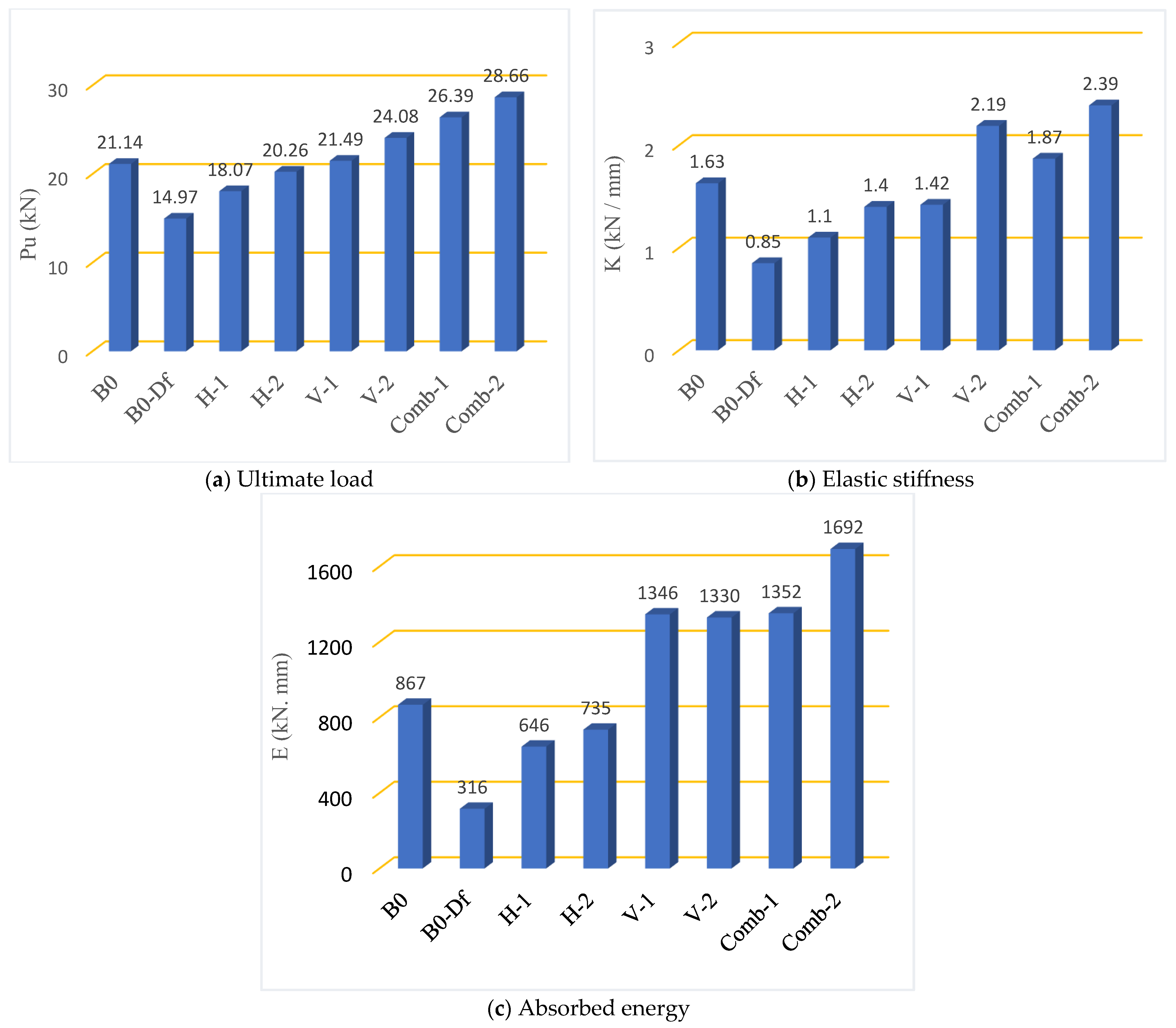

3.3. Ultimate Strength

3.4. Elastic Stiffness and Absorbed Energy

4. Numerical Investigation

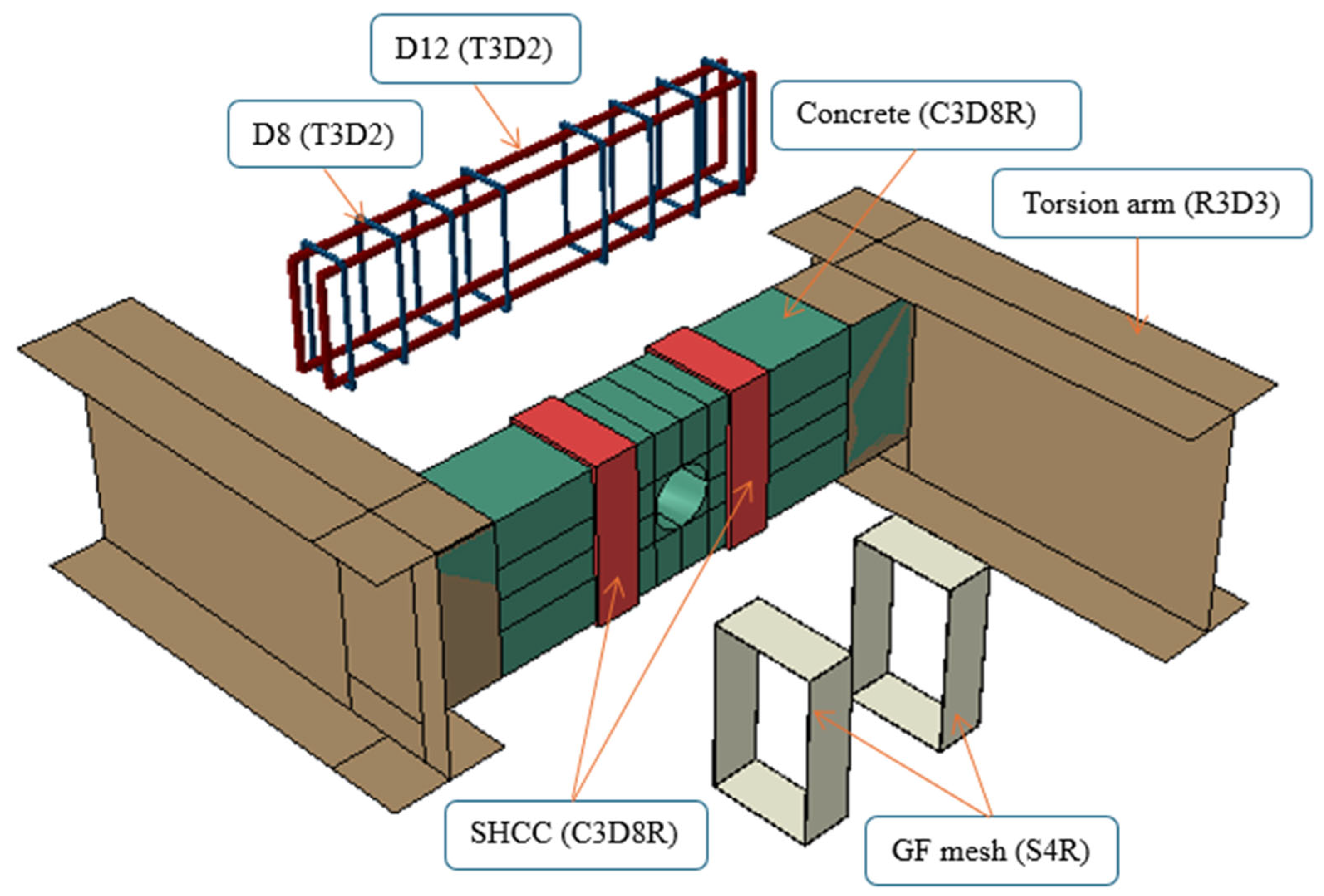

4.1. Model Setup and Interactions

4.2. Materials Laws

4.3. FEM Verification

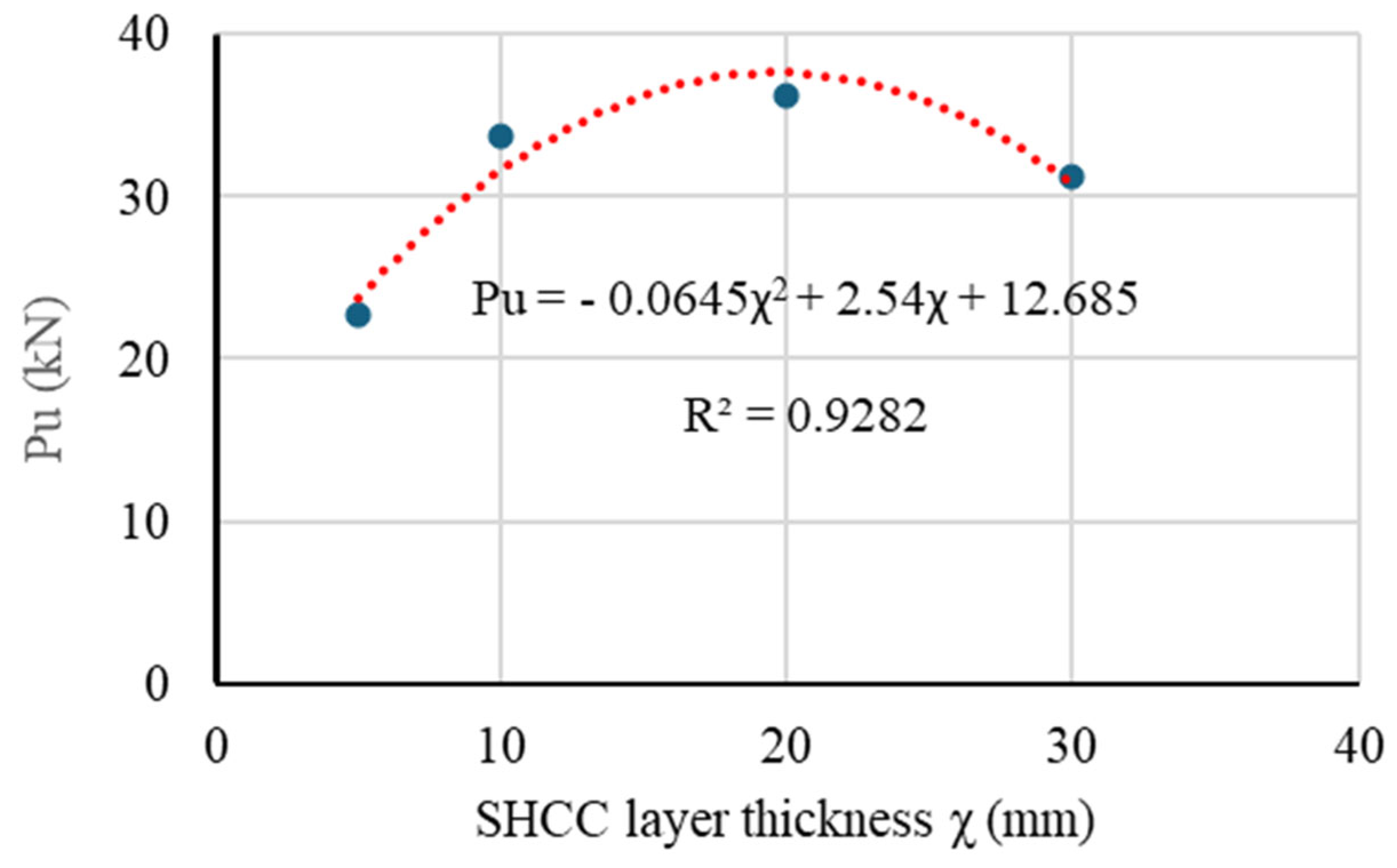

5. Parametric Study

6. Conclusions

- Stress concentrations around the opening accelerated crack propagation, leading to premature failure.

- Strengthened beams showed delayed crack initiation, reduced crack widths, and improved post-cracking ductility due to the strain-hardening properties of SHCC and the crack-bridging effect of GF mesh.

- The presence of a circular opening reduced the ultimate torsional capacity by 29%, elastic stiffness by 48%, and energy absorption by 64% compared to the solid beam.

- Horizontal SHCC strips improved torsional capacity by 21–35%, while vertical SHCC strips provided even greater enhancement (44–61%).

- The combined horizontal and vertical SHCC configuration demonstrated the best performance, increasing the ultimate load by 76–91% and energy absorption by 328–436% compared to the defective beam.

- Double-layer GF mesh reinforcement consistently outperformed single-layer reinforcement in all configurations, enhancing ductility and crack resistance.

- A parametric study revealed that an optimal SHCC thickness of 20 mm maximizes punching shear capacity, beyond which gains diminish.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mansur, M.; Tan, K.-H. Concrete Beams with Openings: Analysis and Design; CRC Press: Boca Raton, FL, USA, 1999; Volume 20. [Google Scholar]

- Venugopal, M. Behaviour of GFRP Retrofitted Rectangular RC Beams with Small Web Openings Under Torsion: Experimental Study. Ph.D. Thesis, National Institute of Technology, Odisha, India, 2014. [Google Scholar]

- Mansur, M.A.; Ting, S.K.; Lee, S.-L. Torsion tests of R/C beams with large openings. J. Struct. Eng. 1983, 109, 1780–1791. [Google Scholar] [CrossRef]

- Hasnat, A.; Wafa, F.F.; Akhtaruzzaman, A.A. Prestressed concrete beams with small opening under torsion. J. Struct. Eng. 1988, 114, 1626–1643. [Google Scholar] [CrossRef]

- Robert, J.B.; Prabhavathy, R.A.; Joanna, P.; Singh, S.C.E.; Murugan, S.; Rajkumar, S.; Sharma, S. Flexural Behaviour of RC Beams with a Circular Opening at the Flexural Zone and Shear Zone Strengthened Using Steel Plates. Adv. Civ. Eng. 2021, 2021, 6733402. [Google Scholar] [CrossRef]

- Hamoda, A.; Yehia, S.A.; Abadel, A.A.; Sennah, K.; Shahin, R.I. Strengthening of simply supported deep beams with openings using steel-reinforced ECC and externally bonded CFRP sheets. Mag. Concr. Res. 2024, 77, 154–170. [Google Scholar]

- Hamoda, A.; Yehia, S.A.; Ahmed, M.; Abadel, A.A.; Baktheer, A.; Shahin, R.I. Experimental and numerical analysis of deep beams with openings strengthened with galvanized corrugated and flat steel sheets. Case Stud. Constr. Mater. 2024, 21, e03522. [Google Scholar] [CrossRef]

- Hamoda, A.; Shahin, R.I.; Abadel, A.A.; Sennah, K.; Ahmed, M.; Yehia, S.A. Shear strengthening of normal concrete deep beams with openings using strain-hardening cementitious composites with glass fiber mesh. Structures 2025, 71, 107994. [Google Scholar] [CrossRef]

- Salama, A.E.; Kassem, M.E.; Mahmoud, A.A. Torsional behavior of T-shaped reinforced concrete beams with large web openings. J. Build. Eng. 2018, 18, 84–94. [Google Scholar] [CrossRef]

- Hekal, G.M.; Ramadan, B.A.; Meleka, N.N. Behavior of RC beams with large openings subjected to pure torsion and retrofitted by steel or CFRP plates. ERJ. Eng. Res. J. 2020, 43, 127–138. [Google Scholar] [CrossRef]

- Mouwainea, E. Experimental Study of Reinforced Concrete Hollow Beams Under Torsion. Master’s Thesis, Al-Mustansiriya University, Baghdad, Iraq, 2014. [Google Scholar]

- Halicka, A. Influence new-to-old concrete interface qualities on the behaviour of support zones of composite concrete beams. Constr. Build. Mater. 2011, 25, 4072–4078. [Google Scholar] [CrossRef]

- Tan, K.H.; Tjandra, R.A. Strengthening of RC continuous beams by external prestressing. J. Struct. Eng. 2007, 133, 195–204. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Z.; Chen, Y.; Song, C.; Li, J.; Zhong, M. Torsional behavior of steel reinforced concrete beam with welded studs: Experimental investigation. J. Build. Eng. 2022, 48, 103879. [Google Scholar] [CrossRef]

- Al-Bayati, G.; Al-Mahaidi, R.; Kalfat, R. Torsional strengthening of reinforced concrete beams using different configurations of NSM FRP with epoxy resins and cement-based adhesives. Compos. Struct. 2017, 168, 569–581. [Google Scholar] [CrossRef]

- Al-Mahaidi, R.; Hii, A.K. Bond behaviour of CFRP reinforcement for torsional strengthening of solid and box-section RC beams. Compos. Part B Eng. 2007, 38, 720–731. [Google Scholar] [CrossRef]

- Chalioris, C.E. Torsional strengthening of rectangular and flanged beams using carbon fibre-reinforced-polymers–Experimental study. Constr. Build. Mater. 2008, 22, 21–29. [Google Scholar] [CrossRef]

- Jing, M.; Raongjant, W.; Li, Z. Torsional strengthening of reinforced concrete box beams using carbon fiber reinforced polymer. Compos. Struct. 2007, 78, 264–270. [Google Scholar] [CrossRef]

- Naser, M.; Hawileh, R.; Abdalla, J. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar]

- Gao, W.; Teng, J.; Dai, J.-G. Effect of temperature variation on the full-range behavior of FRP-to-concrete bonded joints. J. Compos. Constr. 2012, 16, 671–683. [Google Scholar] [CrossRef]

- Gao, W.-Y.; Dai, J.-G.; Teng, J. Analysis of Mode II debonding behavior of fiber-reinforced polymer-to-substrate bonded joints subjected to combined thermal and mechanical loading. Eng. Fract. Mech. 2015, 136, 241–264. [Google Scholar] [CrossRef]

- Li, V.C. On engineered cementitious composites (ECC) a review of the material and its applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Toshiyuki, K.; Kabele, P.; Fukuyama, H.; Uchida, Y.; Suwada, H.; Slowik, V. Strain Hardening Cement Composites: Structural Design and Performance: State-of-the-Art Report of the RILEM Technical Committee 208-HFC, SC3; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 6. [Google Scholar]

- Mechtcherine, V. Novel cement-based composites for the strengthening and repair of concrete structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Huang, B.-T.; Li, Q.-H.; Xu, S.-L.; Zhou, B. Strengthening of reinforced concrete structure using sprayable fiber-reinforced cementitious composites with high ductility. Compos. Struct. 2019, 220, 940–952. [Google Scholar] [CrossRef]

- Li, V.C.; Horii, H.; Kabele, P.; Kanda, T.; Lim, Y. Repair and retrofit with engineered cementitious composites. Eng. Fract. Mech. 2000, 65, 317–334. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Engineered cementitious composites: Can composites be accepted as crack-free concrete? Transp. Res. Rec. 2010, 2164, 1–8. [Google Scholar] [CrossRef]

- Pan, Z.; Wu, C.; Liu, J.; Wang, W.; Liu, J. Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr. Build. Mater. 2015, 78, 397–404. [Google Scholar] [CrossRef]

- Kim, S.-W.; Park, W.-S.; Jang, Y.-I.; Feo, L.; Yun, H.-D. Crack damage mitigation and shear behavior of shear-dominant reinforced concrete beams repaired with strain-hardening cement-based composite. Compos. Part B Eng. 2015, 79, 6–19. [Google Scholar] [CrossRef]

- Afefy, H.M.E.-D.; Mahmoud, M.H. Structural performance of RC slabs provided by pre-cast ECC strips in tension cover zone. Constr. Build. Mater. 2014, 65, 103–113. [Google Scholar] [CrossRef]

- Jiang, J.; Luo, J.; Yu, J.; Wang, Z. Performance improvement of a fiber-reinforced polymer bar for a reinforced sea sand and seawater concrete beam in the serviceability limit state. Sensors 2019, 19, 654. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chen, Y.-S. Innovative ECC jacketing for retrofitting shear-deficient RC members. Constr. Build. Mater. 2016, 111, 408–418. [Google Scholar] [CrossRef]

- Wang, G.; Yang, C.; Pan, Y.; Zhu, F.; Jin, K.; Li, K.; Nanni, A. Shear behaviors of RC beams externally strengthened with engineered cementitious composite layers. Materials 2019, 12, 2163. [Google Scholar] [CrossRef]

- Hamoda, A.; Ghalla, M.; Yehia, S.A.; Ahmed, M.; Abadel, A.A.; Baktheer, A.; Shahin, R.I. Experimental and numerical investigations of the shear performance of reinforced concrete deep beams strengthened with hybrid SHCC-mesh. Case Stud. Constr. Mater. 2024, 21, e03495. [Google Scholar] [CrossRef]

- Liao, Q.; Su, Y.; Yu, J.; Yu, K. Torsional behavior of BFRP bars reinforced engineered cementitious composites beams without stirrup. Eng. Struct. 2022, 268, 114748. [Google Scholar] [CrossRef]

- ECP. Egyptian Code for Design and Construction of Reinforced Concrete Structures (ECP-203); Housing and Building National Research Center: Cairo, Egypt, 2018. [Google Scholar]

- Addibond 65 Technical Data Sheet from Chemicals for Modern Building (CMB). International Company. Available online: https://www.cmbegypt.com/cmb/datasheets/en/pdf/5-bonding_agents_adhesive/addibond%2065.pdf (accessed on 22 June 2025).

- Alwis, W.; Mansur, M.A. Torsional strength of r/c beams containing rectangular openings. J. Struct. Eng. 1987, 113, 2248–2258. [Google Scholar] [CrossRef]

- Al-Bayati, G.; Al-Mahaidi, R.; Hashemi, M.J.; Kalfat, R. Torsional strengthening of RC beams using NSM CFRP rope and innovative adhesives. Compos. Struct. 2018, 187, 190–202. [Google Scholar] [CrossRef]

- Mohsin, M.S.; Alwash, N.A.; Kadhum, M.M. Structural behavior of reinforced concrete beams with out of plane part. Case Stud. Constr. Mater. 2021, 15, e00767. [Google Scholar] [CrossRef]

- Mahdi, H.M.; Abbas, R.M. Effect of openings on the torsional behavior of SCC box beams under monotonic and repeated loading. Civ. Eng. J. 2023, 9, 2300–2314. [Google Scholar] [CrossRef]

- Jabbar, S.; Hejazi, F.; Mahmod, H.M. Effect of an opening on reinforced concrete hollow beam web under torsional, flexural, and cyclic loadings. Lat. Am. J. Solids Struct. 2016, 13, 1576–1595. [Google Scholar] [CrossRef]

- Hamoda, A.; Abadel, A.A.; Shahin, R.I.; Ahmed, M.; Baktheer, A.; Yehia, S.A. Shear strengthening of simply supported deep beams using galvanized corrugated sheet filled with high-performance concrete. Case Stud. Constr. Mater. 2024, 21, e04085. [Google Scholar] [CrossRef]

- Hamoda, A.; Shahin, R.; Ahmed, M.; Abadel, A.; Yehia, S. Flexural behavior of normal concrete circular beams strengthened using engineered cementitious composite and stainless steel tube. Mag. Concr. Res. 2024, 77, 171–188. [Google Scholar] [CrossRef]

- Hamoda, A.; Shahin, R.I.; Ahmed, M.; Abadel, A.A.; Baktheer, A.; Yehia, S.A. Strengthening of reinforced concrete columns incorporating different configurations of stainless-steel plates. Structures 2024, 64, 106577. [Google Scholar] [CrossRef]

- Hussein, H.H.; Walsh, K.K.; Sargand, S.M.; Steinberg, E.P. Interfacial properties of ultrahigh-performance concrete and high-strength concrete bridge connections. J. Mater. Civ. Eng. 2016, 28, 04015208. [Google Scholar] [CrossRef]

- Limpaninlachat, P.; Kunawisarut, A.; Bui, L.V.H.; Jirawattanasomkul, T.; Jongvivatsakul, P.; Likitlersuang, S. Flexural and shear behavior of ultra-high performance concrete segmental joints. Structures 2023, 56, 104913. [Google Scholar] [CrossRef]

- Ahmed, M.; Yehia, S.; Shahin, R.; Emara, M.; Patel, V.I.; Liang, Q.Q. Numerical analysis of circular steel–reinforced concrete-filled steel tubular stub columns. Mag. Concr. Res. 2023, 76, 303–318. [Google Scholar] [CrossRef]

- Ahmed, M.; Shahin, R.I.; Yehia, S.A.; Emara, M.; Patel, V.I.; Liang, Q.Q. Nonlinear analysis of square steel-reinforced concrete-filled steel tubular short columns considering local buckling. Struct. Concr. 2024, 25, 69–84. [Google Scholar] [CrossRef]

- Yehia, S.A.; Fayed, S.; Shahin, R.I.; Ramadan, B.A. Effect of existing holes under the loading plate on local compressive strength of plain concrete blocks: An experimental and numerical study. Case Stud. Constr. Mater. 2024, 21, e03937. [Google Scholar] [CrossRef]

- Yehia, S.A.; Shahin, R.I.; Fayed, S. Compressive behavior of eco-friendly concrete containing glass waste and recycled concrete aggregate using experimental investigation and machine learning techniques. Constr. Build. Mater. 2024, 436, 137002. [Google Scholar]

- Shahin, R.I.; Fayed, S.; Yehia, S.A. Compressive behavior of high strength concrete stuffed inside aluminum tube considering bolted bonding: An experimental and numerical study. Structures 2025, 75, 108675. [Google Scholar] [CrossRef]

- Carreira, D.J.; Chu, K.-H. Stress-strain relationship for plain concrete in compression. ACI J. 1985, 82, 797–804. [Google Scholar]

- Zhou, J.; Pan, J.; Leung, C.K. Mechanical behavior of fiber-reinforced engineered cementitious composites in uniaxial compression. J. Mater. Civ. Eng. 2015, 27, 04014111. [Google Scholar] [CrossRef]

| Group | Beam’s Name | Group’s Aim | Opening Exist | Strengthening | |

|---|---|---|---|---|---|

| Configuration | No. of GF Mesh | ||||

| G1 | B0 | Baseline group | Solid | ---- | ---- |

| B0-Df | Opening | ---- | ---- | ||

| G2 | H-1 | Effect of horizontal SHCC strips | Opening | Horizontal | One |

| H-2 | Two | ||||

| G3 | V-1 | Effect of vertical SHCC strips | Opening | Vertical | One |

| V-2 | Two | ||||

| G4 | Comb-1 | Effect of combined strengthening techniques | Opening | Horizontal + Vertical | One |

| Comb-2 | Two | ||||

| Concrete | Cement | Sand | Limestone Aggregate | Silica-Fume | Water/Binder | PP (kg/m3) (%) | HRWR | fc’ (MPa) | ft (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| NC | 1 | 1.97 | 3.2 | --- | 0.42 | --- | --- | 32 | 2.56 |

| SHCC | 1.00 | 0.12 | --- | 0.18 | 0.20 | 20 (2%) | 0.02 | 64 | 5.31 |

| Material | Yield | Ultimate | Fracture | E (GPa) | |||

|---|---|---|---|---|---|---|---|

| σy (MPa) | ɛy (%) | σu (MPa) | ɛu (%) | σf (MPa) | ɛf (%) | ||

| Steel bars. D = 8 mm | 291 | 0.149 | 413 | 12.34 | 384 | 13.81 | 192 |

| Steel bars. D = 12 mm | 362 | 0.181 | 534 | 12.1 | 498 | 14.32 | 201 |

| GF mesh | --- | --- | --- | --- | 1544 | 3.78 | 92 |

| Group | Beam’s Name | Ultimate Stage | Initial Stiffness (K) | Absorbed Energy (E) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pu (kN) | Pu/PuB | Pu/Pu B-O | Δu (mm) | K | K/KB | K/KB-O | E | E/EB | E/EB-O | ||

| G1 | B0 | 21.14 | 1.00 | 1.41 | 22.52 | 1.63 | 1.00 | 1.92 | 867.29 | 1.00 | 2.74 |

| B0-Df | 14.97 | 0.71 | 1.00 | 19.27 | 0.85 | 0.52 | 1.00 | 316.00 | 0.36 | 1.00 | |

| G2 | H-1 | 18.07 | 0.85 | 1.21 | 22.57 | 1.10 | 0.68 | 1.30 | 645.68 | 0.74 | 2.04 |

| H-2 | 20.26 | 0.96 | 1.35 | 24.36 | 1.40 | 0.86 | 1.65 | 735.21 | 0.85 | 2.33 | |

| G3 | V-1 | 21.49 | 1.02 | 1.44 | 27.48 | 1.42 | 0.87 | 1.67 | 1345.94 | 1.55 | 4.26 |

| V-2 | 24.08 | 1.14 | 1.61 | 28.54 | 2.19 | 1.35 | 2.58 | 1329.52 | 1.53 | 4.21 | |

| G4 | Comb-1 | 26.39 | 1.25 | 1.76 | 29.71 | 1.87 | 1.15 | 2.20 | 1351.70 | 1.56 | 4.28 |

| Comb-2 | 28.66 | 1.36 | 1.91 | 31.16 | 2.39 | 1.46 | 2.81 | 1692.21 | 1.95 | 5.36 | |

| Beam’s ID | Pu | ∆u | ||||

|---|---|---|---|---|---|---|

| Exp | FE | Exp/FE | Exp | FE | Exp/FE | |

| B0 | 21.14 | 22.47 | 0.941 | 22.52 | 21.8832 | 1.029 |

| B0-Df | 14.97 | 16.07 | 0.932 | 19.27 | 18.3582 | 1.050 |

| H-1 | 18.07 | 19.25 | 0.939 | 22.57 | 21.0654 | 1.071 |

| H-2 | 20.26 | 20.9 | 0.969 | 24.36 | 23.7068 | 1.028 |

| V-1 | 21.49 | 22.66 | 0.948 | 27.48 | 25.944 | 1.059 |

| V-2 | 24.08 | 24.96 | 0.965 | 28.54 | 26.9028 | 1.061 |

| Comb-1 | 26.39 | 26.78 | 0.985 | 29.71 | 27.6736 | 1.074 |

| Comb-2 | 28.66 | 29.66 | 0.966 | 31.16 | 29.4032 | 1.060 |

| µ | 0.956 | 1.054 | ||||

| SD | 0.017 | 0.016 | ||||

| CoV | 0.018 | 0.015 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamoda, A.; Yehia, S.A.; Ahmed, M.; Abadel, A.A.; Sennah, K.; Patel, V.I.; Alghamdi, H. Torsional Strengthening of RC Beams with Openings Using Hybrid SHCC–Glass Fiber Mesh Composites. Buildings 2025, 15, 2237. https://doi.org/10.3390/buildings15132237

Hamoda A, Yehia SA, Ahmed M, Abadel AA, Sennah K, Patel VI, Alghamdi H. Torsional Strengthening of RC Beams with Openings Using Hybrid SHCC–Glass Fiber Mesh Composites. Buildings. 2025; 15(13):2237. https://doi.org/10.3390/buildings15132237

Chicago/Turabian StyleHamoda, Ahmed, Saad A. Yehia, Mizan Ahmed, Aref A. Abadel, Khaled Sennah, Vipulkumar Ishvarbhai Patel, and Hussam Alghamdi. 2025. "Torsional Strengthening of RC Beams with Openings Using Hybrid SHCC–Glass Fiber Mesh Composites" Buildings 15, no. 13: 2237. https://doi.org/10.3390/buildings15132237

APA StyleHamoda, A., Yehia, S. A., Ahmed, M., Abadel, A. A., Sennah, K., Patel, V. I., & Alghamdi, H. (2025). Torsional Strengthening of RC Beams with Openings Using Hybrid SHCC–Glass Fiber Mesh Composites. Buildings, 15(13), 2237. https://doi.org/10.3390/buildings15132237