Abstract

The regulatory mechanism of vinyl acetate-ethylene (VAE) in the interfacial properties of silicate cement–silica fume repair mortar was investigated by examining the effects of varying VAE contents (0 wt.% to 10.0 wt.%) on mortar fluidity, mechanical strength, and interfacial bonding strength. The interface microstructure was also examined to reveal its evolution. Results indicate that VAE enhances mortar fluidity through micro-filling and interfacial activity. At 10% VAE content, fluidity reached 265 mm, a 14.97% increase. However, VAE introduction reduced compressive and flexural strength due to pore induction at low dosages and polymer network interference at high dosages. By improving interfacial stress transfer and refining calcium sulfoaluminate (AFt) and C-S-H crystals in the interfacial transition zone, VAE increased the tensile bonding strength of the repaired mortar to 2.1 MPa at 28 days, a 133.3% increase, according to microscopic analysis. Based on performance analysis, 5.0 wt.% VAE is optimal, increasing interfacial bonding strength by 133.3% while limiting compressive strength loss to 9.4%, thus achieving interfacial collaborative optimization of the repaired mortar.

1. Introduction

Repair materials for cement concrete structures should have characteristics such as rapid hardening, high early-stage strength, low cost, and stable later-stage strength development [1,2]. Ordinary Portland cement–silica fume (OPC-SF) is widely used due to its excellent repair performance. However, OPC-SF repair mortar has issues like high brittleness and weak deformation ability. These issues reduce the long-term longevity of the restored structure by increasing the likelihood of breaking at the bonding interface between the mortar and the concrete substrate [3,4]. To address this drawback, some researchers have proposed introducing polymers into inorganic cementitious materials to optimize the microstructure of hydration products and enhance the flexibility of the materials and their interfacial bonding performance [5,6,7]. Due to its outstanding mechanical stability, chemical stability, and corrosion resistance, the vinyl acetate-ethylene copolymer (VAE) stands out as an ideal option for the modification of cement-based materials [8,9,10].

Kim et al. [11] looked into how four different polymers (acrylates, polyvinyl alcohol, styrene-butadiene rubber, and vinyl acetate-ethylene) affected the cement mortar’s mechanical characteristics. They discovered that the finest mechanical qualities were displayed by the cement mortar that contained VAE. At a designated dosage of 3%, VAE demonstrated the best comprehensive mechanical properties, increasing the 28-day compressive and flexural strengths by 33% and 63%, respectively, compared to the control group. The impact of polypropylene fibers and VAE on the compressive and tensile characteristics of foamed concrete was investigated by Shi et al. [12]. The combination of VAE and polypropylene fibers increased the energy absorption capacity, ductility index, and tensile–compressive strength ratio of foamed concrete by 13.4%, 5024.6%, and 190.7%, respectively. According to studies by Qin et al. [13], three polymer emulsions (SA, SB, VAE) impact the hydration behavior of cement components, which in turn affects the macroscopic properties of polymer–cement systems. The results indicated that the VAE-cement coating achieved the highest tensile strength in the dry state, exceeding SA/SB by approximately 25–40%. However, upon water exposure, hydrolysis of ester groups generated hydrophilic products and soluble small molecules, leading to a 43% strength loss and significantly increased brittleness. This demonstrates the poor long-term water resistance of VAE-modified coatings. Shi et al. [14] investigated that VAE copolymer enhances the flexural strength and toughness of repair mortar. Optimal performance occurred at 1.5% VAE dosage, yielding 46% higher 28-day flexural strength and 12% greater equivalent flexural toughness versus unmodified mortar. Although the dual-layer membrane structure model (CH crystal layer and calcium silicate hydrate gel layer) for the interfacial transition zone between OPC and aggregates has been proposed [15,16,17], current research predominantly focuses on optimizing the performance of individual materials. Systematic research on the microstructure of the bonding interface between repair mortar and concrete substrates is still lacking [18], and the essential weak spot of the bonding interface in repair systems is not given enough attention. This limits improvements in the overall effectiveness of repaired structures.

Therefore, this paper modifies the OPC-SF repair mortar by adding VAE to explore its mechanism of enhancing the interfacial bonding performance. The morphology and structure of the repair mortar’s hydration products are examined using micro-testing techniques like SEM and EDS in order to uncover the regulatory mechanism of VAE on the micro-scale interfacial characteristics of the mortar.

2. Materials and Methods

2.1. Material

This study utilized a combination of materials including cement, silica fume, sand, water-reducing agent, defoamer, vinyl acetate-ethylene copolymer (VAE), and water. The cement used was P.II52.5R Portland cement manufactured by Anhui Conch Cement Co., Ltd. (Wuhu, China). The silica fume was provided by Gansu Sanyuan Silicon Material Co., Ltd. (Lanzhou, China). The sand was natural medium-grained river sand, with a fineness modulus of 2.82. Natural coarse aggregate was used, and its particle size was 5–10 mm. The VAE was supplied by Jinzhou Qingjun Building Materials Co., Ltd. (Jinzhou, China). The defoamer was a powder-type product from Jinzhou Qingjun Building Materials Co., Ltd., (Jinzhou, China) and the water-reducing agent was a polycarboxylate-based high-performance one produced by Weike Building Materials Co., Ltd. (Yuncheng, China). The performance indices of the main materials are presented in Table 1, Table 2, Table 3 and Table 4.

Table 1.

Cement properties.

Table 2.

Chemical composition of the cement (%).

Table 3.

Silica fume properties.

Table 4.

Vinyl acetate-ethylene properties.

2.2. Mix Proportion Design

Based on a thorough analysis of pertinent literature and in conjunction with the material properties, five proportion mixes were prepared to reveal how VAE affects the characteristics of repair mortar. The compositions of the different mix proportions for the repair mortar are displayed in Table 5, in which the dosage of VAE is 0%, 2.5%, 5%, 7.5% and 10% of the weight of the cementitious material, respectively.

Table 5.

Repair mortar proportions (kg/m3).

The concrete substrate utilized in the tensile bond test had a mix proportion of 1:1.72:2.69:0.39 (cement, sand, gravel, and water). When this substrate was allowed to cure naturally for 28 days, its compressive strength reached 43.2 MPa. Table 6 displays the precise mix proportion.

Table 6.

Mix proportions of substrate concrete (kg/m3).

2.3. Experimental Methods

Repair mortar was prepared according to GB/T 31387-2015 (Reactive Powder Concrete) [19]. The row materials were weighed according to the design mix ratio and dry-mixed for 2 min. Pre-mixed superplasticizer solution was then added, followed by 6 min of wet mixing. The mixture was poured into mold-release-coated molds, leveled, and demolded after 24 h of hardening. Specimens were moist-cured for 6 days, and then air-cured until testing age.

Workability was tested per GB/T 2419-2005 (Test Method for Fluidity of Cement Mortar) [20]. Immediately after mixing, the mortar was placed into the test mold in two layers. The first layer (filled to approximately 2/3 of the mold height) was cross-cut 5 times in perpendicular directions and rodded 15 times from edge to center. The second layer (overfilled by 20 mm) was similarly cross-cut and rodded 10 times. After rodding, the mold collar was removed and the mold was lifted vertically. The flow table was activated immediately, completing 25 drops in 25 s. The final spread diameter was then measured.

Mechanical properties were tested according to GB/T 17671-2021 (Method for Testing Cement Mortar Strength, ISO Method) [21]. Flexural strength was determined using a flexural testing machine at a loading rate of 50 ± 10 N/s. The resulting prism halves were then subjected to compressive strength testing in a compression machine, loaded uniformly at 2400 ± 200 N/s until failure.

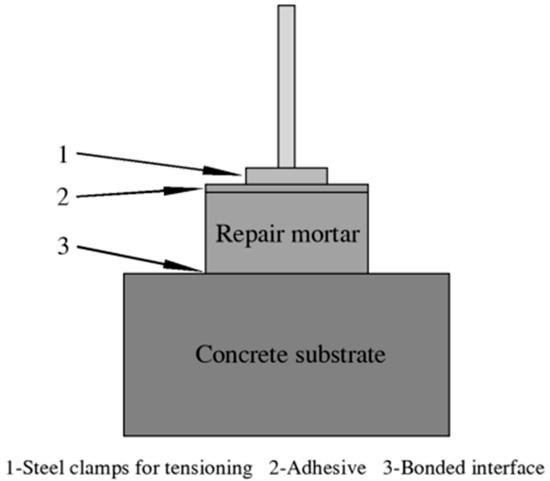

Tensile bond strength was evaluated per JGJ/T 70-2009 (Standard for Test Methods of Basic Properties of Construction Mortar) [22] using direct tensile testing. C40 concrete substrates were cured for 28 days, then roughened using an electric hammer, and overlaid with cement mortar. After curing to the specified age, pull-heads were epoxy-bonded to the mortar surface. Following adhesive hardening, peak tensile force was measured using a manual loading apparatus. Bond strength was calculated using Equation (1):

where fl is defined as bond strength (MPa), Pl is defined as peak load (kN), and A is defined as bonded area (mm2).

Figure 1 illustrates the test configuration.

Figure 1.

Sketch of tensile bond test.

The test steps for microscopic morphology analysis are as follows: A dry mortar block with dimensions ≤ 1 cm × 1 cm and a thickness of <0.5 cm is used as the sample. Droplets of the ultrasonically treated sample suspension were aspirated onto the surface of the silicon wafer or tin foil; then. They were allowed to dry naturally in air or placed under an infrared lamp to accelerate drying. After drying, they were pasted onto the sample stage and secured with conductive adhesive. After placing the sample, the chamber was evacuated to the target vacuum level, and, then, the voltage was increased and the sample stage raised to a suitable height. Finally, the sample position was located, the imaging parameters for magnification and scale were set, and the image was scanned and saved.

2.4. Processing Methods for Sample Measurement Values

In the flexural strength test, three samples are prepared and measured in each group. If one of the three measured values is beyond the scope of statistical validity, the value shall be excluded, and the average value of the remaining two measured values shall be taken as the result of the group. If two or more unreasonable values appear in the three measured values, the remaining one shall be taken as the flexural strength result.

In the compressive strength test, six samples are prepared and measured in each group. If one of the six measured values is beyond the scope of statistical rationality, the value shall be excluded, and the average value of the remaining five measured values shall be taken as the result of the group. If unreasonable values are still found after further analysis of the remaining five measured values, the results of this group shall be determined as invalid. If two or more unreasonable values appear in the six measured values, the results of this group shall be directly voided.

In the bond strength test, ten samples are prepared and measured in each group. If the difference between the strength value of a single specimen and the average value is more than 20%, the test value with the largest deviation shall be successively discarded until the difference between each test value and the average value does not exceed 20%. When the effective values of the 10 specimens are not less than 6, the average value of the remaining data shall be taken as the test result. When the effective values of the 10 specimens are less than 6, the test results of this group shall be invalid, and the specimens shall be re-prepared for the test.

Through the above processing methods, the statistical reliability of the test data is effectively guaranteed, ensuring that the obtained results are representative and can accurately reflect the relevant trends.

3. Results and Discussion

3.1. Influence of VAE Dosage on the Fluidity of Repair Mortar

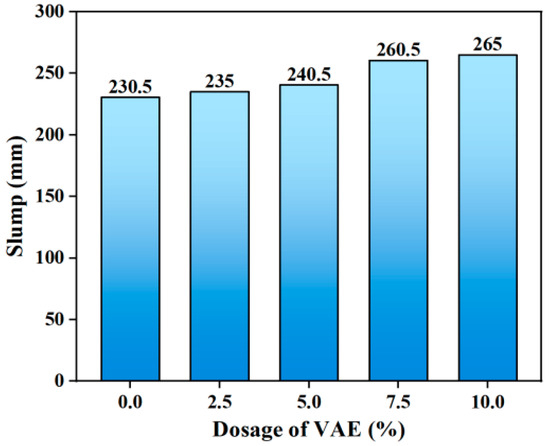

The impact of varying VAE dosages on the fluidity of OPC-SF repair mortar is depicted in Figure 2. The findings indicate that the mortar’s fluidity is trending upward as the VAE dosage is increased. The fluidities of the specimens with VAE dosages of 2.5 wt.%, 5.0 wt.%, 7.5 wt.%, and 10.0 wt.% increased by 1.95%, 4.34%, 13.02%, and 14.97%, respectively, in comparison to the reference group (0 wt.% VAE). A maximum fluidity increase of 14.97% is observed at the VAE dosage of 10.0 wt.%. This result demonstrates that a reasonable amount of VAE integration can successfully boost the fluidity of the repair mortar.

Figure 2.

Effect of VAE dosage on mortar fluidity.

The following synergistic effects are responsible for VAE’s improvement of fluidity [23,24,25]: (1) The micro-filling and lubricating effect: VAE particles, which typically range in size from 50 to 500 nm, can fill the cement matrix’s microporous structure, lowering internal frictional resistance and improving the relative sliding ability between particles. (2) Interfacial activity regulation: VAE copolymer stabilizes micro-bubbles by reducing solid–gas interfacial energy. Unlike entrapped or mechanically entrained air, these bubbles originate from gaseous products of chemical reactions between active mortar components. Normally unstable and susceptible to collapse, the bubbles are stabilized by VAE’s amphiphilic polymer structure which acts as a surfactant. The hydrophobic segments reduce surface tension, while mechanical shear organizes VAE particles and micro-bubbles into ball-bearing-like structures that enhance paste fluidity.

It should be mentioned, though, that the polymer film that results during VAE hydration [26] will strengthen the bonds between cement particles, raising the slurry’s viscosity. Existing studies have shown that when the VAE dosage continues to increase, the increase in viscosity will become the dominant factor, leading to an insignificant increase in fluidity [24]. The viscosity characteristics of the repair materials are another key index affecting their performance. Therefore, the effect of further increasing the VAE dosage is not significant from the perspective of fluidity. The dosage should be optimized by comprehensively considering other indicators to achieve a synergistic improvement in mortar performance.

3.2. Influence of VAE Dosage on the Flexural and Compressive Strengths of Repair Mortar

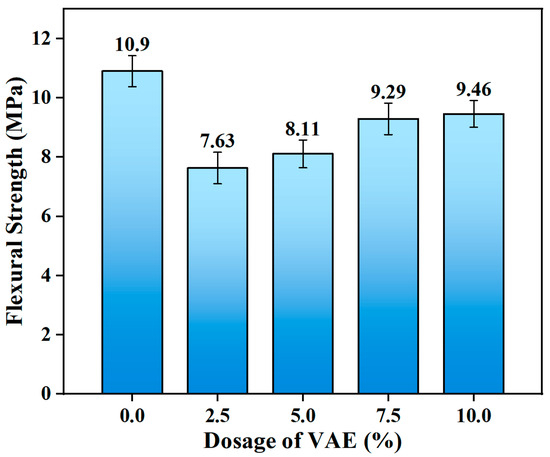

As shown in Figure 3, different VAE dosages have a nonlinear influence on the 28-day flexural strength of OPC-SF repair mortar. The findings indicate that as the VAE dosage increases from 0 wt.% to 10.0 wt.%, the flexural strength shows a non-monotonic evolution trend of first decreasing and then increasing. All modified groups’ flexural strengths, however, fall short of the reference group’s (0 wt.% VAE). The specimens with VAE dosages of 2.5 wt.%, 5 wt.%, 7.5 wt.% and 10.0 wt.% have flexural strengths of 7.63 MPa (a decrease of 30.0%), 8.11 MPa (a decrease of 25.6%), 9.29 MPa (a decrease of 14.8%), and 9.46 MPa (a decrease of 13.2%), respectively. It is important to note that at low dosages (2.5 wt.%), the strength loss is most noticeable, but at high dosages (10.0 wt.%), the reduction slows down.

Figure 3.

Effect of VAE dosage on mortar flexural strength (28 days).

The dynamic rivalry mechanism between the “defect effect” and “enhancement effect” that VAE introduced is responsible for this phenomenon: (1) Effect of pore-inducing: The mechanical continuity of the interfacial transition zone (ITZ) [9,27] is greatly weakened by VAE, which, due to its surface-active nature, entrains excessive micro-bubbles during mixing, increasing the number of stress-concentration spots. This effect dominates at the low-dosage stage, leading to a sharp decrease in flexural strength. (2) Polymer bridging effect: The polymer film created during hydration can create a three-dimensional interpenetrating network structure when the VAE dosage is ≥7.5% (see Section 3.4). Through physical anchoring and chemical bonding, it improves the interfacial interaction between aggregates and C-S-H gel. Furthermore, the hydration induction period is prolonged by the retarding impact of VAE [28], which encourages the uniform distribution of hydration products and helps to partially offset the strength loss brought on by pore defects.

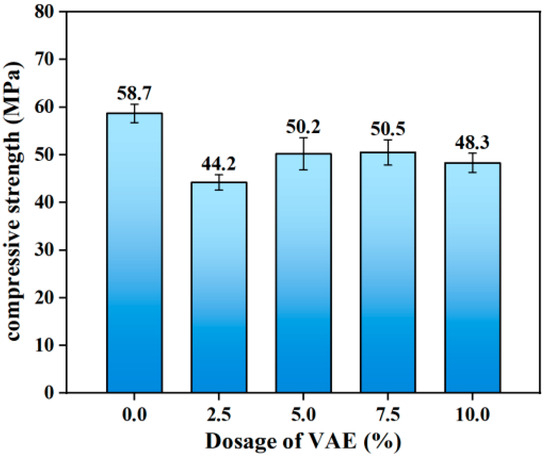

The findings show a substantial nonlinear relationship between the mortar’s compressive strength and the VAE dosage (see Figure 4). The reference group (0 wt.% VAE) has a 28-day compressive strength of 58.7 MPa. The compressive strengths exhibit a pattern known as “decrease-increase-decrease again” [9] when the VAE dosages are doped from 2.5 wt.% to 10.0 wt.%. These reduce to 44.2 MPa (a 24.7% decrease), 50.2 MPa (a 14.5% decrease), 50.5 MPa (a 14.0% decrease), and 48.3 MPa (a 17.7% decrease), respectively. There is an ideal dosage range since the compressive strength loss is lowest at the critical dosage (7.5 wt.%).

Figure 4.

Effect of VAE dosage on mortar compressive strength (28 days).

Due to differences in interfacial compatibility, the dispersed VAE particles decrease the stress transfer efficiency at low dosages (<5.0 wt.%). Furthermore, they are unable to properly bridge load-induced microcracks since no continuous polymer film is created. Through the energy-dissipation mechanism, the continuous polymer network slows the spread of cracks at medium doses (5.0 wt.% to 7.5 wt.%). In the meantime, the subsequent hydration reaction is encouraged by VAE’s water-retaining property. Together, the two effects raise the compressive strength. At large dosages (>7.5 wt.%), excessive VAE significantly elevates slurry viscosity. This viscosity surge hinders dense packing of cement particles. Simultaneously, it disrupts the topological connectivity of C-S-H gel. These combined effects ultimately result in strength degradation [29].

3.3. Influence of VAE Dosage on the Tensile Bond Strength of Repair Mortar

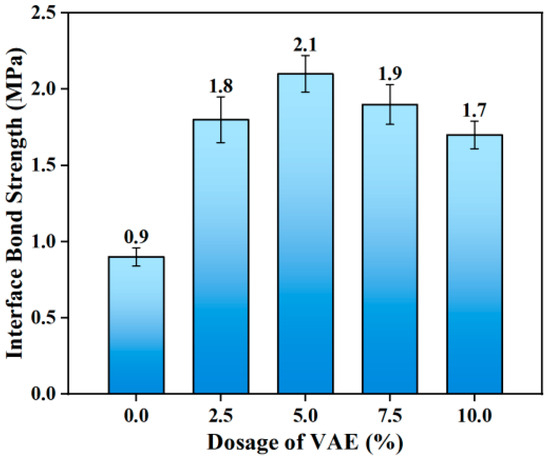

The impact of varying VAE dosages on the interfacial bond strength of OPC-SF repair mortar is shown in Figure 5. The findings demonstrate that there is a notable two-stage response in the interfacial bond strength as the VAE dosage increases. The 28-day interfacial bond strength improves by 133.3% from 0.9 MPa to 2.1 MPa when the VAE dosage is increased from 0 wt.% to 5.0 wt.%. This suggests that VAE has a large dose-dependent strengthening effect on interfacial characteristics in the low-dosage range. However, the bond strength exhibits a reversed attenuation pattern when the dosage surpasses 5.0 wt.%. The strengths of the 7.5 wt.% and 10.0 wt.% groups decreased to 1.9 MPa and 1.7 MPa, respectively, with strength loss rates of 9.5% and 19.0% when compared to the group that received the optimal dosage.

Figure 5.

Effect of VAE content on bond strength of OPC-SF repair mortar.

VAE’s synergistic effect with cement hydration products is responsible for improving the interfacial bond performance of repair mortar. The calcium silicate hydrate gel (C-S-H) and the continuous polymer film created by the VAE emulsion in the cement paste interpenetrate in a staggered fashion to create a composite three-dimensional network structure. This structure uses two mechanisms to optimize the interfacial properties: (1) Physical filling effect: By efficiently filling the nanoscale defects (<100 nm) in the interfacial transition zone (ITZ) and the micron-scale pores (50–200 μm) inside the mortar, the polymer–gel composite lowers porosity and increases interfacial density [30,31,32]. (2) Stress-buffering effect: The interface has a great energy-dissipation capacity due to the high ductility of the polymer film (elongation upon break > 200%). By uniformizing the stress distribution, it inhibits the development and spread of microcracks, postponing the failure of interfacial debonding [33].

It is worth noting that an excessive VAE dosage (>5.0 wt.%) will cause a degradation of interfacial properties. Research shows the following: (1) The mechanical interlocking action of hydration products is weakened at super-critical doses because an excessively thick polymer film (thickness > 1 μm) creates a dense barrier layer in the ITZ, limiting direct contact between cement particles and the substrate [34]. (2) High-concentration polymer adsorbed on cement particle surfaces causes a loose microstructure of hydration products, limits the bridging growth of C-S-H gel, and delays the hydration kinetic process of mineral phases such C3S and C2S [9]. The aforementioned findings suggest that in order to maximize the performance of the interfacial tensile bond strength, the VAE dosage must be kept below 5.0 wt.%.

3.4. Microscopic Morphology Analysis

For each group, we performed microscopic morphology analysis by keeping the water–cement ratio and sand–cement ratio constant.

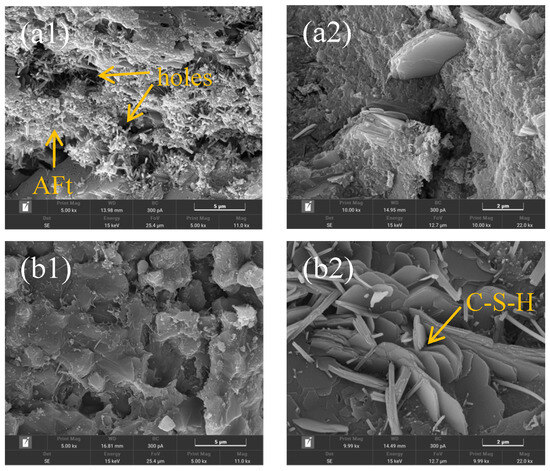

Figure 6 shows the SEM images of the hydration products of the reference group and the 5.0 wt.% VAE-modified group after 28-day hydration.

Figure 6.

Scanning electron microscope images to 28 days, (a1,a2) pure cement; (b1,b2) 5 wt.% VAE.

The compactness of the hydration products’ microstructure can be shown by contrasting Figure 6(a1,b1). The reference group exhibits many pores with interconnected microcracks with diameters ranging from 10 to 100 μm. The 5.0 wt.% VAE-modified group, on the other hand, has a very compact and evenly distributed microstructure, with a notable decrease in the quantity of big pores and interconnected microcracks. This suggests that VAE can efficiently fill the pores in the cement microstructure. Simultaneously, the reference group’s hydration products have relatively large crystal sizes and needle-rod-shaped AFt crystals and lamellar C-S-H crystals that mostly form in loosely structured places like pores and fractures. On the other hand, the AFt crystals developing in the pores are more uniformly distributed and considerably smaller in the microstructure of the 5.0 wt.% VAE-modified group. This suggests that the polymer contributes to the cement paste’s grain refinement. The polymer’s filling impact on the cement’s internal pores and the polymer film covering the hydration products’ surface are the two causes of this occurrence. Together, these two elements restrict the hydration products’ development range, which reduces the size of the crystal. This is also supported by Ma’s research [35].

3.5. EDS Spectrum Analysis

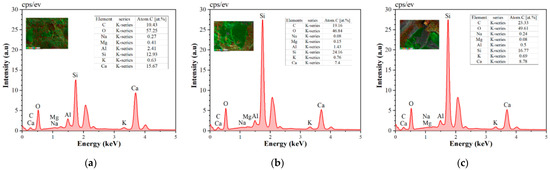

The elemental distribution of the reference group and VAE-modified cement mortar was characterized using EDS (see Figure 7). According to the analysis, the specimens’ primary constituents include carbon (C), oxygen (O), silicon (Si), and calcium (Ca). A quantitative comparison shows that the fraction of oxygen elements in the VAE-modified mortar considerably drops, the relative amount of carbon elements increases, and the silicon elements exhibit an enrichment trend.

Figure 7.

EDS diagram of repair mortar: (a) VAE-0 group; (b) VAE-2.5 group; (c) VAE-10 group.

In the cement matrix, carbon components mostly exist as carbonate phases (such as CaCO3), depending on the phase occurrence state. Through interfacial interactions, it chemically interacts with calcium silicate hydrate gel (C-S-H) to promote the heterogeneous nucleation of secondary calcium carbonate [36,37]. The matrix’s compactness is improved by the combined actions of pore filling and chemical bonding.

The cement matrix contains silicon elements primarily in the form of silicon oxide (SiO2). Nanoscale silicon dioxide (SiO2) particles, typically sourced from silica fume, are associated with the enrichment of silicon components. Through the physical filling mechanism, these particles maximize the cement paste’s pore structure. The aforementioned microstructural evolution can significantly increase the material’s durability and impermeability. The physical filling action of nanoscale SiO2 particles is responsible for the enrichment of silicon elements. Their specific surface area (>200 m2/g) contributes to the formation of a tight packing structure between cement particles. Consequently, the material’s durability and impermeability are significantly enhanced.

The decrease in oxygen element content, a characteristic of hydration products (such Ca(OH)2, C-S-H, etc.), suggests that the VAE polymer somewhat interferes with the cement-based material’s hydration process. This could be a result of the organic long chains of VAE forming an adsorption layer on cement particle surfaces, which slows down the rate at which Ca2+ dissolves. The EDS spectrum shows reduced Ca element content, confirming fewer early-stage hydration products. This reduction stems from interfacial control action.

According to the elemental composition and calcium–silicon ratio analysis, a low calcium–silicon ratio usually corresponds to a denser gel structure, higher gelling activity and stronger interfacial bonding ability. VAE can optimize the interfacial bonding performance by regulating the calcium–silicon ratio and microstructure of cement hydration products (densification of the C-S-H gel and refinement of the AFt crystals).

Compared with the reference (VAE-0) group, the increase in VAE content significantly reduces the calcium–silicon ratio, and the microstructure becomes more abundant while the gel particles are insufficiently closely connected [38], leading to a decrease in compressive strength relative to the reference group. However, with the increase in VAE content, the silicon–calcium ratio shows an upward trend. The C-S-H gel generated by hydration has a more dense structure [39]. Under the synergy with the polymer film, the compressive strength shows an upward trend, and the bond strength also increases. In the high-dosage (VAE-10) group, the balance of the calcium–silicon ratio is disrupted [40]. Although the amount of hydration products may relatively increase, the excessive polymer film forms a barrier, leading to the slowdown of the hydration process. Meanwhile, the hydration products fail to form strong chemical bonds due to the lack of effective contact, and the compactness decreases. In addition, the increase in fluidity hinders the close packing of cement particles, which corresponds to the deterioration of compressive strength and may also be one of the reasons for the decrease in bond strength. This is also supported by Wei’s research [38].

4. Conclusions

This study methodically examined how VAE affects the characteristics of OPC-SF repair mortar. The effects of different VAE dosages (0 wt.–10.0 wt.%) on the fluidity, mechanical properties, interfacial bond performance, and microstructure of the mortar are summarized in Table 7 below.

Table 7.

Effect of VAE doping on key performance parameters.

The following conclusions were drawn:

- The mortar’s fluidity is greatly enhanced by the use of VAE. When the VAE dosage is 10.0 wt.%, the fluidity reaches 265 mm, which is 14.97% higher than that of the reference group. The mechanism is ascribed to the interfacial activity and micro-filling action of VAE particles. They synergistically improve the rheological properties by reducing the internal frictional resistance of the slurry and stabilizing micro-bubbles.

- The addition of VAE leads to a decrease in compressive and flexural strengths. At the low-dosage stage (<5.0 wt.%), the pore-inducing effect dominates, damaging the mechanical continuity of the interfacial transition zone. At the high-dosage stage (≥7.5 wt.%), although the formation of the polymer network partially compensates for the defects, excessive VAE interferes with the cement hydration process and the connection of C-S-H gel, resulting in strength degradation.

- VAE significantly improves interfacial properties through cross-scale synergistic effects. When the VAE dosage is 5.0 wt.%, the 28-day interfacial bond strength reaches 2.1 MPa, which is 133.3% higher than that of the reference group. Microscopic analysis shows that VAE refines the sizes of ettringite (AFt) and C-S-H crystals in the interfacial transition zone, fills pores, and enhances the interfacial stress transfer and energy-dissipation capabilities through an organic–inorganic composite network.

- Based on the comprehensive performance analysis, 5.0 wt.% VAE is the optimal dosage for engineering applications. The dosage can be controlled while achieving a large increase in fluidity and significantly improve the interfacial bond performance (by 133.3%) and control the loss of mechanical properties (with a 9.4% decrease in compressive strength) at the same time, thus achieving the synergistic optimization of the interface between new and old concrete.

This study has analyzed the mechanism of action of VAE on the performance of silicate cement–silica fume repair mortar. In the follow-up, thermal analysis tests, quantitative characterization of porosity and other means will be used to deepen the research on the mechanism, and durability indicators such as freeze–thaw resistance and shrinkage rate will be introduced to evaluate the practical engineering applicability, so as to further improve the theoretical system and application technology framework of VAE-modified repair mortar.

Author Contributions

Conceptualization, B.L. and M.Z.; Methodology, K.D.; Formal analysis, K.D.; Resources, B.L. and M.Z.; Data curation, T.Y.; Writing—original draft preparation, K.D. and T.Y.; Writing—review and editing, M.Z. and T.Y.; Visualization, K.D. and T.Y.; Supervision, M.Z.; Project administration, M.Z.; Funding acquisition, B.L. and M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

Key Project of Guangdong Provincial Department of Education in Key Areas of Ordinary Colleges and Universities (Science and Technology Services for Rural Revitalization), grant number 2022ZDZX4003.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Bo Li is employed by the Guangzhou Expressway Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Adil, G.; Kevern, J.T.; Mann, D. Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Lou, Y.; Khan, K.; Amin, M.N.; Ahmad, W.; Deifalla, A.F.; Ahmad, A. Performance characteristics of cementitious composites modified with silica fume: A systematic review. Case Stud. Constr. Mater. 2023, 18, e01753. [Google Scholar] [CrossRef]

- Song, X.; Song, X.; Liu, H.; Huang, H.; Anvarovna, K.G.; Ugli, N.A.D.; Huang, Y.; Hu, J.; Wei, J.; Yu, Q. Cement-Based Repair Materials and the Interface with Concrete Substrates: Characterization, Evaluation and Improvement. Polymers 2022, 14, 1485. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zou, H.; Zhang, J.; Zhang, J.; Tang, Y.; Zhang, J.; Guo, Y.; Xiao, J. Interface bonding properties of new and old concrete: A review. Front. Mater. 2024, 11, 1389785. [Google Scholar] [CrossRef]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Nodehi, M.; Aguayo, F.; Madey, N.; Zhou, L. A Comparative Review of Polymer, Bacterial-based, and Alkali-Activated (also Geopolymer) Binders: Production, Mechanical, Durability, and Environmental impacts (life cycle assessment (LCA)). Constr. Build. Mater. 2024, 422, 135816. [Google Scholar] [CrossRef]

- Jiang, Z.; Shi, Z.; Yang, X.; Tian, X.; Xiao, Z.; Liu, C.; Huang, X. Experimental study on bonding properties and deformation characteristics of polyurethane polymer mortar-concrete interface. Rock Soil Mech. 2024, 45, 3545–3554. [Google Scholar]

- Zhang, N.; Mao, Z.; Sun, Q.; Luo, Y.; Zhang, P.; Wang, Q.; Yang, R.; Zhang, M.; Wang, D. The influence of polymer powder on the ion transportation and antierosion mechanism of cement mortar: From experiments to molecular dynamics simulation. Constr. Build. Mater. 2023, 409, 134171. [Google Scholar] [CrossRef]

- Cheng, J.; Shi, X.; Xu, L.; Zhang, P.; Zhu, Z.; Lu, S.; Yan, L. Investigation of the effects of styrene acrylate emulsion and vinyl acetate ethylene copolymer emulsion on the performance and microstructure of mortar. J. Build. Eng. 2023, 75, 106965. [Google Scholar] [CrossRef]

- Wang, Z.; Bai, E.; Zhou, J.; Liu, G.; Yang, N. Mechanical Properties of VAE Latex Powder/Carbon Fiber Co-modified Concrete. J. Build. Mater. 2024, 27, 487–495. [Google Scholar]

- Kim, M.O. Influence of Polymer Types on the Mechanical Properties of Polymer-Modified Cement Mortars. Appl. Sci. 2020, 10, 1061. [Google Scholar] [CrossRef]

- Shi, X.; Ning, B.; Na, F.; Zhao, W.; Zhang, C. Study on properties of re-dispersible latex powder and polypropylene fiber-reinforced lightweight foam concrete. J. Build. Eng. 2024, 95, 110156. [Google Scholar] [CrossRef]

- Qin, W.; Yue, W.; Shuai, H.; Lu, H.; Guang, H. Hydration behaviour of cement in polymer cement waterproof coating and its effect on the macroscopic performance. Constr. Build. Mater. 2023, 408, 133825. [Google Scholar]

- Shi, C.; Zou, X.; Wang, P. Influences of EVA and methylcellulose on mechanical properties of Portland cement-calcium aluminate cement-gypsum ternary repair mortar. Constr. Build. Mater. 2020, 241, 118035. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, B. Study on freeze-thaw deterioration model of new-to-old concrete based on pore surface fractal characteristics. Constr. Build. Mater. 2024, 421, 135757. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, J.; Qiao, P.; Wu, E.; Zhou, G. Mesoscale modeling of new-to-old concrete interface under combined shear and compressive loads. Eng. Fract. Mech. 2024, 307, 110331. [Google Scholar] [CrossRef]

- Shu, Y.; Shen, Z.; Zhang, H.; Sun, Y. Experimental investigation and peridynamic modelling on tensile failure of new-to-old concrete bonding zone. Structures 2025, 71, 108165. [Google Scholar] [CrossRef]

- Mokhtari, S.; Hassan, M. Performance of Bond between Old and New Concrete Layers: The Effective Factors, Durability and Measurement Tests—A Review. Infrastructures 2024, 9, 171. [Google Scholar] [CrossRef]

- GB/T 31387-2015; Reactive Powder Concrete. China National Standards: Beijing, China, 2015; p. 16.

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. China National Standards: Beijing, China, 2005; p. 12.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China National Standards: Beijing, China, 2021; p. 24.

- JGJ/T 70-2009; Standard for Test Method of Basic Properties of Construction Mortar. China National Standards: Beijing, China, 2009; 71p.

- Chaoyang, Z. Rheological Property, Mechanical Property, and Water Absorption Behavior of Latex-modified Cementitious Materials. Ph.D. Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2021. [Google Scholar]

- Ying, Z. Modification and Mechanism of Cement-Based Materials by Cellulose Ether and Latex Powder. Master’s Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2022. [Google Scholar]

- Negim, E.-S.; Kozhamzharova, L.; Khatib, J.; Bekbayeva, L.; Williams, C. Effects of Surfactants on the Properties of Mortar Containing Styrene/Methacrylate Superplasticizer. Sci. World J. 2014, 2014, 942978. [Google Scholar] [CrossRef][Green Version]

- Han, S.; Wang, Y.; Wang, Q.; Han, L.; Han, G. Film-formation processes of polymer emulsions in polymer-cement waterproof coatings and their effect on coatings’ macroscopic properties. Constr. Build. Mater. 2024, 438, 137137. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; Li, H.; Ren, Q. Performance and ITZ of pervious concrete modified by vinyl acetate and ethylene copolymer dispersible powder. Constr. Build. Mater. 2020, 235, 117532. [Google Scholar] [CrossRef]

- Yan, S.; Lu, H.; Zhou, Z.; Dong, Q.; Chen, X.; Wang, X. A polymer latex modified superfine cement grouting material for cement-stabilized macadam—Experimental and simulation study. Constr. Build. Mater. 2024, 413, 134893. [Google Scholar] [CrossRef]

- Han, D.; Chen, W.; Zhong, S. Influence of Latex Particles Size on Properties of Polymer-Modified Cement-Based Materials. J. Build. Mater. 2017, 20, 943–949. [Google Scholar]

- Shi, X.; Xu, L.; Feng, T.; Han, J.; Zhang, P. Research Progress of Water Dispersed Polymer Emulsion Modified Cement Mortar. Bull. Chin. Ceram. Soc. 2021, 40, 2497–2507. [Google Scholar]

- Wang, Z.; Mei, J.; Liao, Y.; Li, H.; Niu, Y. Durability of Cement-Based Materials with Nano SiO2 and VAE Composite Modification. J. Build. Mater. 2023, 26, 687–696. [Google Scholar]

- Chen, C.; Shao, L.; Wang, J.; Shan, J.; Jing, H.; Guo, M.; Ye, W. Early Drying Shrinkage Analysis of Vinyl Acetate-Ethylene Modified Plastering Mortar. Bull. Chin. Ceram. Soc. 2024, 43, 2778–2787. [Google Scholar]

- Lou, C.; Xu, J.; Liu, S.; Wang, T.; Ren, W. Effects of External Environments on the Fixed Elongation and Tensile Properties of the VAE Emulsion–Cement Composite Joint Sealant. Materials 2020, 13, 3233. [Google Scholar] [CrossRef]

- Na, Z.; Qian, S.; Pengyu, Z.; Dongmei, W.; Qin, W. Effects of Polymers on Waterproofing and Mechanical Properties of Mortar after Heat Treatment. Bull. Chin. Ceram. Soc. 2023, 42, 2703–2711. [Google Scholar]

- Ma, H.; Wang, R.; Xi, Z.; Gao, H.; Fryda, H.; Wang, P. Regulation and inhibition of early whitening of calcium aluminate cement/hemihydrate gypsum decorative mortar by polymer emulsion. Constr. Build. Mater. 2023, 393, 132023. [Google Scholar] [CrossRef]

- Tang, S.; Wang, Y.; Geng, Z.; Xu, X.; Yu, W.; A, H.; Chen, J. Structure, Fractality, Mechanics and Durability of Calcium Silicate Hydrates. Fractal Fract. 2021, 5, 47. [Google Scholar] [CrossRef]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A.K. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Wei, H.; Wan, H.; Yuan, S.; Liu, G.; Teng, J.; Shi, N.; Liu, Z. A new gelling material: Properties of recycled aggregate concrete under conditions of complete cement replacement using steel slag, ore slag, and fly ash. Constr. Build. Mater. 2025, 464, 140180. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Yu, P.; Zhao, S. Characterization of self-healing in cement-based materials with a low water-to-cement ratio during subsequent hydration. J. Build. Eng. 2024, 91, 109553. [Google Scholar] [CrossRef]

- Quan, W.; Huang, W.; Mao, W.; Yu, X.; Zhou, X.; Miao, X.; Hou, L. Preparing autoclaved aerated concrete using molybdenum tailings. J. Build. Eng. 2024, 95, 110138. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).