Circular Industrialized Construction: A Perspective Through Design for Manufacturing, Assembly, and Disassembly

Abstract

1. Introduction

2. Conceptual Review and Previous Work

2.1. Circular and Industrialized Construction

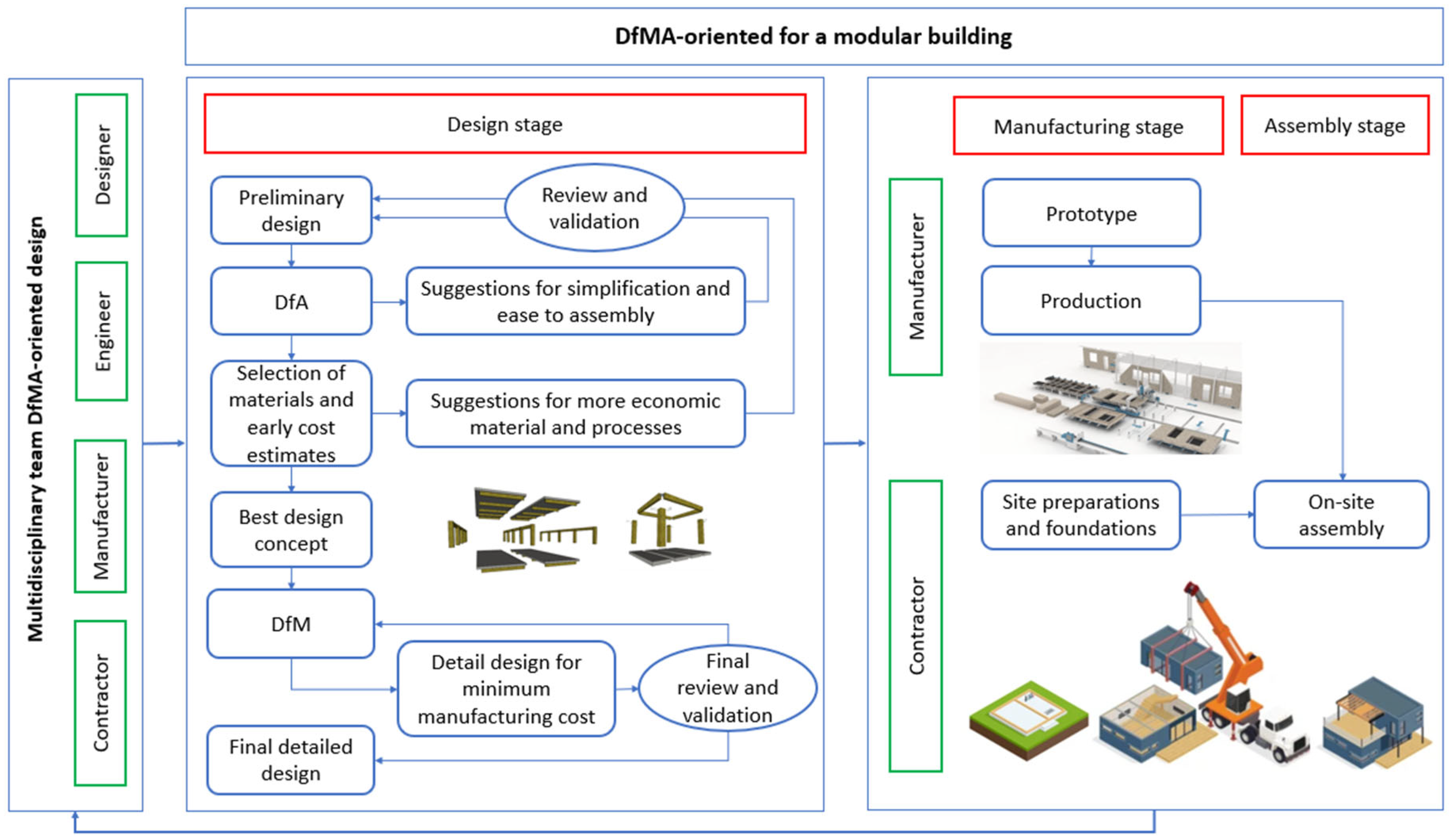

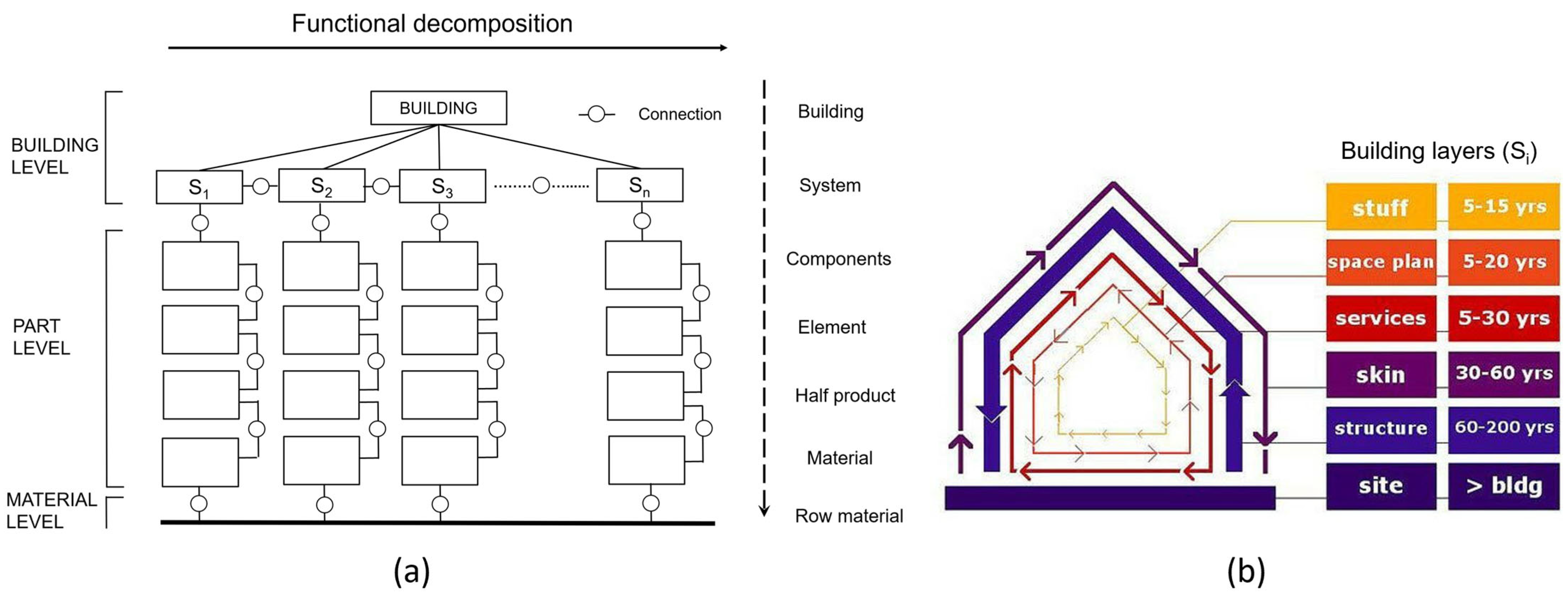

2.2. Overview of DfMA, DfD, and DfMAD Concepts

2.2.1. Design for Manufacturing and Assembly (DfMA)

2.2.2. Design for Disassembly (DfD)

2.2.3. Design for Manufacturing, Assembly, and Disassembly (DfMAD)

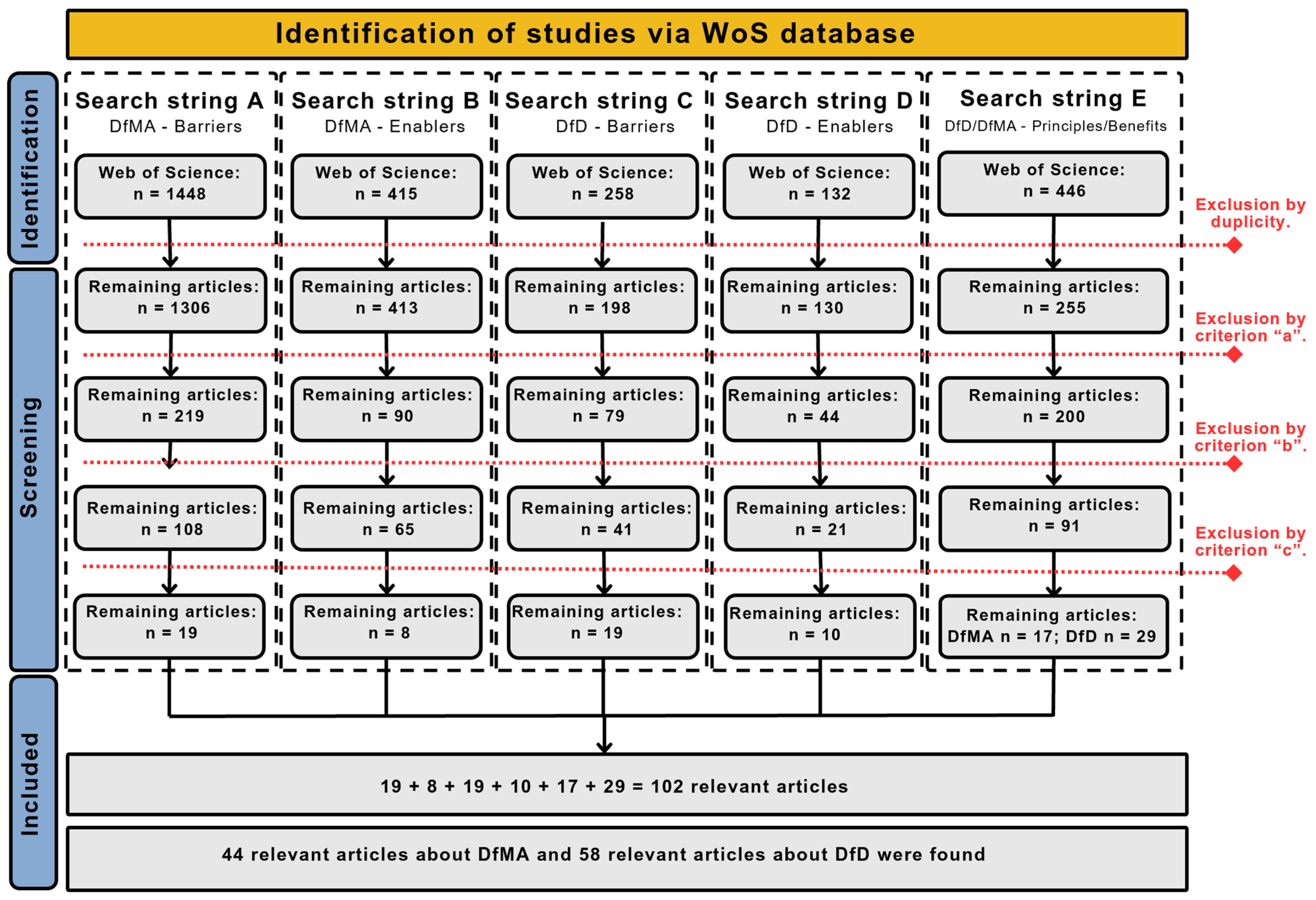

3. Materials and Methods

3.1. Stage 1—Data Collection

- (a)

- Non-peer-reviewed, unpublished, or outside the AECO field.

- (b)

- Lacking discussion on benefits, barriers, or enablers related to DfD or DfMA.

- (c)

- Not addressing DfD or DfMA principles.

3.2. Stage 2—Mapping and Content Analysis

3.3. Stage 3—DfMAD Definition

4. Results and Discussion

4.1. Data Collection

4.2. Mapping and Content Analysis

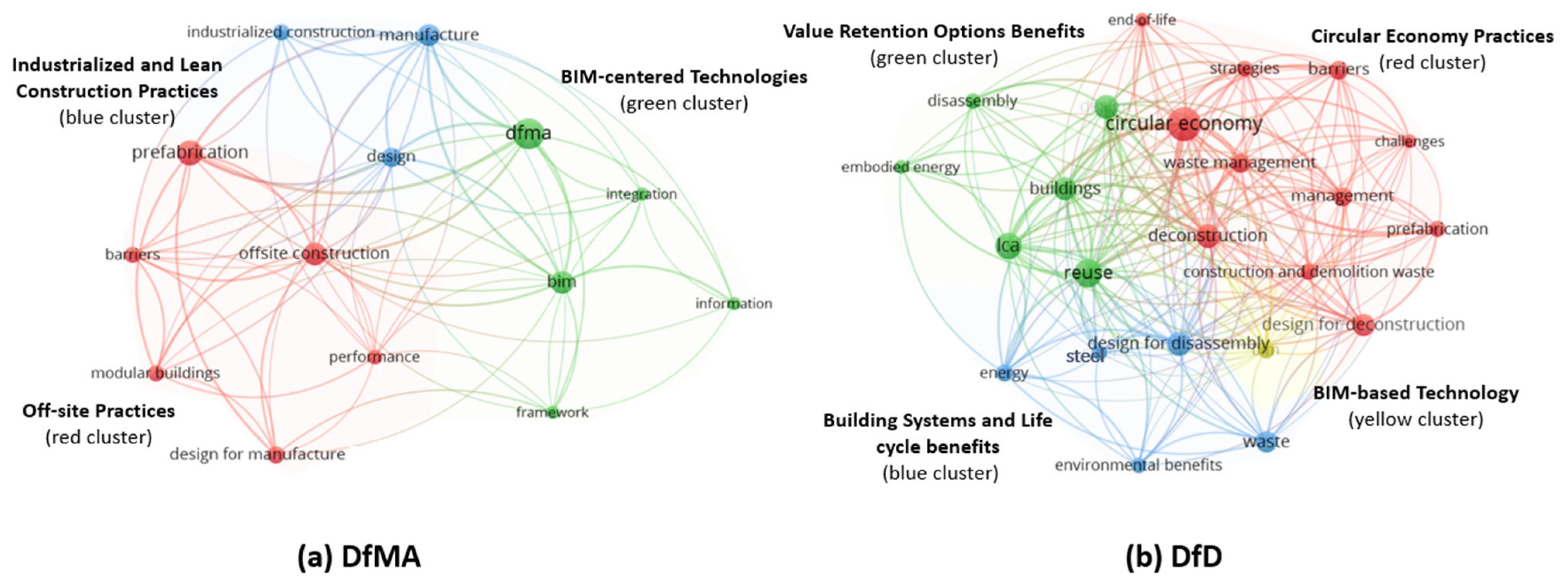

4.2.1. Science Mapping Results

4.2.2. Identified Patterns in DfMA Clusters

BIM-Centered Technologies

Industrialized and Lean Construction Practices

Off-Site Practices

4.2.3. Identified Patterns in DfD Clusters

Value Retention Options (VROs) Benefits

Building Systems and Life Cycle Benefits

Circular Economy (CE) Practices

BIM-Based Technology

4.2.4. Commonalities, Distinctions, and Research Gaps

Common Practices in Prefabrication and OSC

Life Cycle Scope Divergence: Manufacturing vs. End-of-Life

Distinct Environmental Contributions

Diverging Business Models

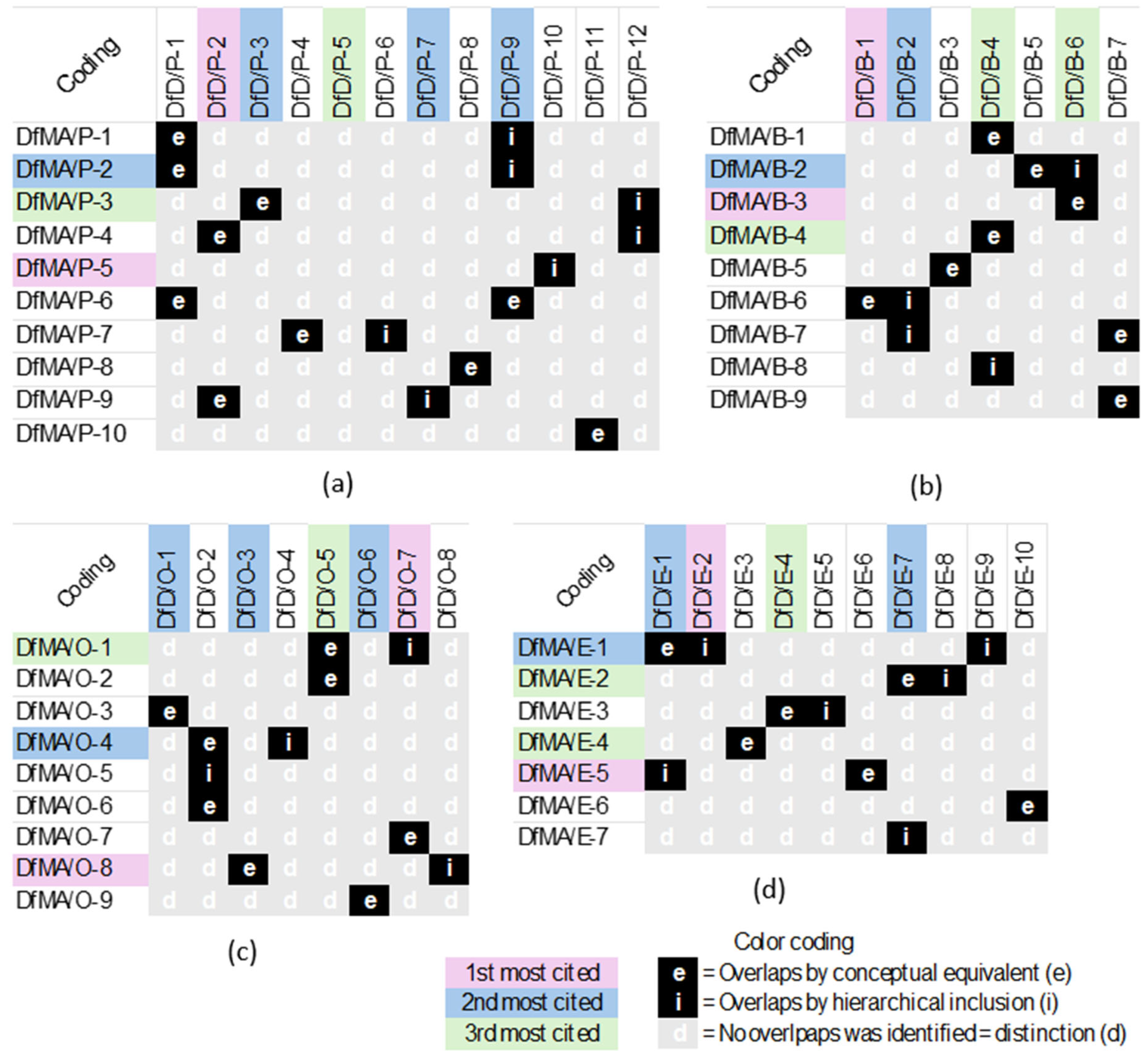

4.2.5. Cross-Mapping Analysis

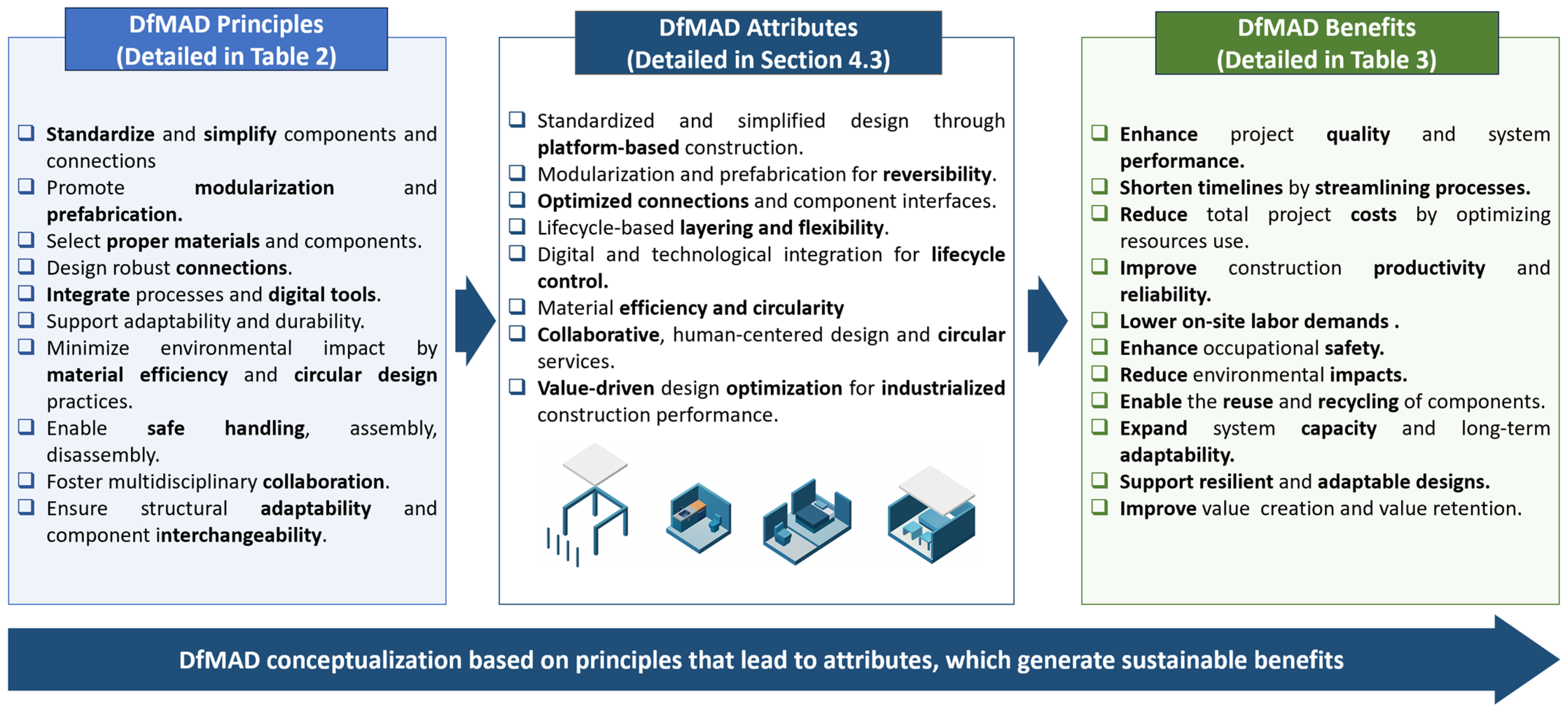

4.3. DfMAD Conceptualization

- Standardized and simplified design through platform-based construction: Simplify components, reduce part count, and standardize geometries, materials, and connection systems to enable platform-based construction. This approach enhances manufacturability, streamlines on-site assembly, and facilitates future disassembly across diverse building configurations.

- Modularization and prefabrication for reversibility: Employ modular systems and prefabricated assemblies that support efficient off-site production, rapid on-site assembly, and reversible construction.

- Optimized connections and component interfaces: Use accessible, mechanical, and demountable connection systems that are standardized and error-tolerant for both assembly and non-destructive disassembly.

- Life cycle-based layering and flexibility: Structure building systems in layers based on functional lifespan to support replacement, reuse, and long-term adaptability.

- Digital and technological integration for life cycle control: Leverage Construction 5.0 technologies—including BIM, digital twins, AI-driven simulations, robotics, and IoT—as a unified infrastructure for managing design, production, logistics, and end-of-life scenarios. BIM acts as the central data backbone, linking design intent with fabrication and operational intelligence.

- Material efficiency and circularity: Prioritize pure, reusable, low-impact, durable, low-maintenance, and separable materials to reduce embodied carbon, enable reuse, and support material circularity through end-of-life recovery.

- Collaborative, human-centered design and circular services: Engage multidisciplinary stakeholders—designers, contractors, manufacturers, clients, and platform providers—to co-develop solutions that support service-based models, adaptive reuse, and secondary material markets, ensuring both technological and social sustainability.

- Value-driven design optimization for industrialized construction performance: Apply lean production principles, value engineering, life cycle assessment, and continuous process improvement to enhance construction quality, reduce uncertainty, and deliver measurable value as cost-effectiveness.

4.4. Research Limitations

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AECO | Architecture, Engineering, Construction and Operations |

| AI | Artificial Intelligence |

| B | Benefits (Categorization) |

| BIM | Building Information Modeling |

| CCEF | The Circular Construction Evaluation Framework |

| CDW | Construction and Demolition Waste |

| CE | Circular Economy |

| CLT | Cross Laminated Timber |

| COA | Composite Optimized Assembly |

| DAS | Deconstructability Assessment Score |

| DEI | Disassembly Ease Index |

| DfA | Design for Assembly |

| DfC | Design for Circularity |

| DfD | Design for Disassembly |

| DfM | Design for Manufacturing |

| DfMA | Design for Manufacturing and Assembly |

| DfMAD | Design for Manufacturing, Assembly, and Disassembly |

| DfX | Design for Excellence |

| E | Enablers (Categorization) |

| EoL | End-of-Life |

| HVAC | Heating, Ventilation, and Air Conditioning |

| IBS | Industrialized Building System |

| ICT | Information and Communication Technologies |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

| LSL | Laminated Strand Lumber |

| LVL | Laminated Veneer Lumber |

| MFA | Material Flow Analysis |

| MMC- | Modern Methods of Construction |

| NZCBs | Net-Zero-Carbon Buildings |

| nZEBs | Nearly Zero-Energy Buildings |

| O | Obstacles/barriers (Categorization) |

| OSC | Off-Site Construction |

| OSM | Off-Site Manufacturing |

| P | Principles (Categorization) |

| PPVC | Prefabricate Prefinished Volumetric Construction |

| PPVU | Prefabricate Prefinished Volumetric Units |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| PSS | Product–Service System |

| RFID | Radio Frequency Identification |

| S-LCA | Social Life Cycle Assessment |

| VROs | Value Retention Options |

Appendix A

| Citation | Authors, Year | Article Title | Times Cited | Source Title | Document Type | ID | Category | Content Category |

|---|---|---|---|---|---|---|---|---|

| [129] | Jung & Yu, 2022 | Design for Manufacturing and Assembly (DfMA) Checklists for Off-Site Construction (OSC) Projects | 3 | SUSTAINABILITY | Article | A | DfMA | Barriers |

| [71] | Montazeri et al., 2024 | Design for Manufacturing and Assembly (DfMA) in Construction: A Holistic Review of Current Trends and Future Directions | - | BUILDINGS | Review | A | DfMA | Barriers |

| [74] | Hyun et al., 2022. | Integrated Off-Site Construction Design Process including DfMA Considerations | 6 | SUSTAINABILITY | Article | A | DfMA | Barriers |

| [98] | Rankohi et al., 2023 | Developing a Construction-Oriented DfMA Deployment Framework | 2 | BUILDINGS | Article | A | DfMA | Barriers |

| [6] | Abd Razak et al., 2022 | DfMA for a Better Industrialised Building System | 11 | BUILDINGS | Review | A | DfMA | Barriers |

| [132] | Y. Li et al., 2023 | Design for Manufacturing and Assembly (DfMA) of Standardized Modular Wood Components | - | TECHNOLOGY-ARCHITECTURE + DESIGN | Article | A | DfMA | Barriers |

| [115] | Nguyen et al., 2024 | BIM-based preassembly analysis for design for manufacturing and assembly of prefabricated bridges | 2 | AUTOMATION IN CONSTRUCTION | Article | A | DfMA | Barriers |

| [116] | C. Roxas, 2023 | Application of design for manufacturing and assembly on temporary shelters in the Philippines | 1 | INTERNATIONAL JOURNAL OF GEOMATE | Article | A | DfMA | Barriers |

| [97] | Wuni et al., 2023 | Exploring the challenges of implementing design for excellence in industrialized construction projects in China | 11 | BUILDING RESEARCH AND INFORMATION | Article | A | DfMA | Barriers |

| [117] | Qi & Costin, 2023 | BIM and Ontology-Based DfMA Framework for Prefabricated Component | 8 | BUILDINGS | Article | A | DfMA | Barriers |

| [75] | Gbadamosi et al., 2020 | Big data for Design Options Repository: Towards a DFMA approach for offsite construction | 42 | AUTOMATION IN CONSTRUCTION | Article | A | DfMA | Barriers |

| [8] | Tan et al., 2020 | Digital-enabled Design for Manufacture and Assembly (DfMA) in offsite construction: A modularity perspective for the product and process integration | 8 | ARCHITECTURAL ENGINEERING AND DESIGN MANAGEMENT | Article | A | DfMA | Barriers |

| [127] | Liu et al., 2023 | Prefabricated and Prefinished Volumetric Construction: Assessing Implementation Status, Perceived Benefits, and Critical Risk Factors in the Singapore Built Environment Sector | 1 | JOURNAL OF MANAGEMENT IN ENGINEERING | Article | A | DfMA | Barriers |

| [118] | Langston & Zhang, 2021 | DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia | 22 | SUSTAINABILITY | Article | A | DfMA | Barriers |

| [199] | Laovisutthichai & Lu, 2023 | Design for manufacture and assembly (DfMA) in architectural design meetings: from a case study to knowledge-to-action framework | 3 | SMART AND SUSTAINABLE BUILT ENVIRONMENT | Article | A | DfMA | Barriers |

| [72] | Gao et al., 2020. | Design for manufacture and assembly in construction: a review | 84 | BUILDING RESEARCH AND INFORMATION | Review | A | DfMA | Barriers |

| [130] | Orlowski et al., 2018 | Design and Development of Weatherproof Seals for Prefabricated Construction: A Methodological Approach | 17 | BUILDINGS | Article | A | DfMA | Barriers |

| [155] | Costa et al., 2023 | A Systematic Literature Review and Conceptual Framework of Construction Industrialization | 8 | JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT | Review | A | DfMA | Barriers |

| [189] | Sun et al., 2020 | Constraints Hindering the Development of High-Rise Modular Buildings | - | APPLIED SCIENCES-BASEL | Article | A | DfMA | Barriers |

| [200] | Abrishami & Martín-Durán, 2021 | BIM and DfMA: A Paradigm of New Opportunities | 16 | SUSTAINABILITY | Article | B | DfMA | Enablers |

| [11] | Wasim et al., 2022. | Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction—a review | 43 | INTERNATIONAL JOURNAL OF CONSTRUCTION MANAGEMENT | Review | B | DfMA | Enablers |

| [201] | Lu et al., 2021 | Design for manufacture and assembly (DfMA) in construction: the old and the new | 58 | ARCHITECTURAL ENGINEERING AND DESIGN MANAGEMENT | Article | B | DfMA | Enablers |

| [202] | Bao et al., 2022 | Design for manufacture and assembly (DfMA) enablers for offsite interior design and construction | 28 | BUILDING RESEARCH AND INFORMATION | Article | B | DfMA | Enablers |

| [124] | Tan et al., 2024 | MIVES multi-criteria framework to sustainability index of design for manufacture and assembly | - | JOURNAL OF CIVIL ENGINEERING AND MANAGEMENT | Article | B | DfMA | Enablers |

| [12] | Kedir & Hall, 2021. | Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities | 52 | JOURNAL OF CLEANER PRODUCTION | Review | B | DfMA | Enablers |

| [121] | Ginigaddara et al., 2024 | Industry 4.0 driven emerging skills of offsite construction: a multi-case study-based analysis | 1 | CONSTRUCTION INNOVATION-ENGLAND | Article | B | DfMA | Enablers |

| [122] | Potseluyko et al., 2022 | Game-like interactive environment using BIM-based virtual reality for the timber frame self-build housing sector | 11 | AUTOMATION IN CONSTRUCTION | Article | B | DfMA | Enablers |

| [24] | Kanters, 2018a | Design for Deconstruction in the Design Process: State of the Art | 51 | BUILDINGS | Review | C | DfD | Barriers |

| [165] | O. Akinade et al., 2020 | Design for deconstruction using a circular economy approach: barriers and strategies for improvement | 70 | PRODUCTION PLANNING & CONTROL | Article | C | DfD | Barriers |

| [7] | C.L.C. Roxas et al., 2023 | Design for Manufacturing and Assembly (DfMA) and Design for Deconstruction (DfD) in the Construction Industry: Challenges, Trends and Developments | 16 | BUILDINGS | Review | C | DfD | Barriers |

| [137] | Derikvand & Fink, 2023 | Design for Deconstruction: Benefits, Challenges, and Outlook for Timber-Concrete Composite Floors | 2 | BUILDINGS | Article | C | DfD | Barriers |

| [166] | Pittri, Godawatte, et al., 2024 | Examining the barriers to implementing design for deconstruction in the construction industry of a developing country | - | CONSTRUCTION INNOVATION-ENGLAND | Article | C | DfD | Barriers |

| [136] | Anastasiades et al., 2023 | Stakeholder perceptions on implementing design for disassembly and standardisation for heterogeneous construction components | 2 | WASTE MANAGEMENT & RESEARCH | Article | C | DfD | Barriers |

| [157] | Ding et al., 2018 | Experimental and numerical studies on design for deconstruction concrete connections: An overview | 21 | ADVANCES IN STRUCTURAL ENGINEERING | Review | C | DfD | Barriers |

| [173] | Incelli et al., 2023 | Circularity Indicators as a Design Tool for Design and Construction Strategies in Architecture | 2 | BUILDINGS | Article | C | DfD | Barriers |

| [1] | Ossio et al., 2023 | Circular economy in the built environment: A systematic literature review and definition of the circular construction concept | 7 | JOURNAL OF CLEANER PRODUCTION | Review | C | DfD | Barriers |

| [179] | Banihashemi et al., 2024 | Circular economy in construction: The digital transformation perspective | 1 | CLEANER ENGINEERING AND TECHNOLOGY | Article | C | DfD | Barriers |

| [148] | Selvaraj & Chan, 2024 | Recommendations for Implementing Circular Economy in Construction: Direct Reuse of Steel Structures | 1 | JOURNAL OF CONSTRUCTIONAL STEEL RESEARCH | Review | C | DfD | Barriers |

| [154] | Seeberg et al., 2024 | Systematic Mapping of Circular Economy in Structural Engineering | - | BUILDINGS | Review | C | DfD | Barriers |

| [181] | AlJaber et al., 2023 | Life Cycle Cost in Circular Economy of Buildings by Applying Building Information Modeling (BIM): A State of the Art | 4 | BUILDINGS | Review | C | DfD | Barriers |

| [203] | Viscuso, 2021 | Coding the circularity. Design for the disassembly and reuse of building components | 1 | TECHNE-JOURNAL OF TECHNOLOGY FOR ARCHITECTURE AND ENVIRONMENT | Article | C | DfD | Barriers |

| [172] | Bourke & Kyle, 2019 | Service life planning and durability in the context of circular economy assessments—initial aspects for review | 9 | CANADIAN JOURNAL OF CIVIL ENGINEERING | Article | C | DfD | Barriers |

| [174] | Azcárate-Aguerre et al., 2023 | Facades-as-a-Service: Systemic managerial, financial, and governance innovation to enable a circular economy for buildings. Lessons learnt from a full-scale pilot project in the Netherlands | 2 | FRONTIERS IN BUILT ENVIRONMENT | Article | C | DfD | Barriers |

| [167] | Lehmann, 2011 | Optimizing Urban Material Flows and Waste Streams in Urban Development through Principles of Zero Waste and Sustainable Consumption | 70 | SUSTAINABILITY | Article | C | DfD | Barriers |

| [114] | Ghisellini et al., 2018 | Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review | 305 | JOURNAL OF CLEANER PRODUCTION | Review | C | DfD | Barriers |

| [144] | Andersen et al., 2022 | Environmental benefits of applying selective demolition to buildings: A case study of the reuse of fa?ade steel cladding | 7 | RESOURCES CONSERVATION AND RECYCLING | Article | C | DfD | Barriers |

| [170] | Pittri, Agyekum, et al., 2024 | Drivers for design for deconstruction (DfD) implementation among design professionals | 2 | SMART AND SUSTAINABLE BUILT ENVIRONMENT | Article | D | DfD | Enablers |

| [175] | Hartwell et al., 2021 | Circular economy of facades: Real-world challenges and opportunities | 29 | RESOURCES CONSERVATION AND RECYCLING | Article | D | DfD | Enablers |

| [168] | Cruz Rios et al., 2021 | Barriers and Enablers to Circular Building Design in the US: An Empirical Study | 35 | JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT | Article | D | DfD | Enablers |

| [90] | Charef et al., 2022 | The transition to the circular economy of the construction industry: Insights into sustainable approaches to improve the understanding | 21 | JOURNAL OF CLEANER PRODUCTION | Article | D | DfD | Enablers |

| [169] | Charef et al., 2021 | Barriers to Implementing the Circular Economy in the Construction Industry: A Critical Review | 40 | SUSTAINABILITY | Article | D | DfD | Enablers |

| [180] | Aziminezhad & Taherkhani, 2023 | BIM for deconstruction: A review and bibliometric analysis | 10 | JOURNAL OF BUILDING ENGINEERING | Review | D | DfD | Enablers |

| [176] | Guerra & Leite, 2021 | Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers | 106 | RESOURCES CONSERVATION AND RECYCLING | Article | D | DfD | Enablers |

| [183] | Q. Chen et al., 2022 | Revamping construction supply chain processes with circular economy strategies: A systematic literature review | 36 | JOURNAL OF CLEANER PRODUCTION | Review | D | DfD | Enablers |

| [162] | Lehmann, 2013 | Low carbon construction systems using prefabricated engineered solid wood panels for urban infill to significantly reduce greenhouse gas emissions | 99 | SUSTAINABLE CITIES AND SOCIETY | Article | D | DfD | Enablers |

| [161] | Tirelli & Besana, 2023 | Moving toward Net Zero Carbon Buildings to Face Global Warming: A Narrative Review | 11 | BUILDINGS | Review | D | DfD | Enablers |

| [141] | Roberts et al., 2023 | Understanding the global warming potential of circular design strategies: Life cycle assessment of a design-for-disassembly building | 8 | SUSTAINABLE PRODUCTION AND CONSUMPTION | Article | E | DfD | Principles/Benefits |

| [152] | Lima et al., 2023 | Integration of BIM and design for deconstruction to improve circular economy of buildings | 3 | JOURNAL OF BUILDING ENGINEERING | Article | E | DfD | Principles/Benefits |

| [145] | S. Kim & Kim, 2023 | A design support tool based on building information modeling for design for deconstruction: A graph-based deconstructability assessment approach | 4 | JOURNAL OF CLEANER PRODUCTION | Article | E | DfD | Principles/Benefits |

| [80]. | Pristerà et al., 2024. | Taxonomy of design for deconstruction options to enable circular economy in buildings | - | RESOURCES ENVIRONMENT AND SUSTAINABILITY | Review | E | DfD | Principles/Benefits |

| [193] | Lisco & Aulin, 2024 | Taxonomy supporting design strategies for reuse of building parts in timber-based construction | - | CONSTRUCTION INNOVATION-ENGLAND | Article | E | DfD | Principles/Benefits |

| [164] | Jayawardana et al., 2023 | Evaluating the Circular Economy Potential of Modular Construction in Developing Economies-A Life Cycle Assessment | - | SUSTAINABILITY | Article | E | DfD | Principles/Benefits |

| [142] | Densley Tingley & Davison, 2012 | Developing an LCA methodology to account for the environmental benefits of design for deconstruction | 114 | BUILDING AND ENVIRONMENT | Article | E | DfD | Principles/Benefits |

| [178] | Marzouk & Elmaraghy, 2021 | Design for Deconstruction Using Integrated Lean Principles and BIM Approach | 18 | SUSTAINABILITY | Article | E | DfD | Principles/Benefits |

| [184] | Akanbi et al., 2019 | Disassembly and deconstruction analytics system (D-DAS) for construction in a circular economy | 107 | JOURNAL OF CLEANER PRODUCTION | Article | E | DfD | Principles/Benefits |

| [149] | Crowther, 2018 | Re-Valuing Construction Materials and Components Through Design for Disassembly | 12 | UNMAKING WASTE IN PRODUCTION AND CONSUMPTION: TOWARDS THE CIRCULAR ECONOMY | Article | E | DfD | Principles/Benefits |

| [89] | O.O. Akinade et al., 2015 | Waste minimisation through deconstruction: A BIM based Deconstructability Assessment Score (BIM-DAS) | 150 | RESOURCES CONSERVATION AND RECYCLING | Article | E | DfD | Principles/Benefits |

| [139] | Errante & De Capua, 2021 | Design for Disassembly and the rehabilitation of public housing stock. A case study | 1 | TECHNE-JOURNAL OF TECHNOLOGY FOR ARCHITECTURE AND ENVIRONMENT | Article | E | DfD | Principles/Benefits |

| [146] | Eckelman et al., 2018 | Life cycle energy and environmental benefits of novel design-for-deconstruction structural systems in steel buildings | 62 | BUILDING AND ENVIRONMENT | Article | E | DfD | Principles/Benefits |

| [156] | Xia et al., 2020 | Life cycle assessment of concrete structures with reuse and recycling strategies: A novel framework and case study | 91 | WASTE MANAGEMENT | Article | E | DfD | Principles/Benefits |

| [159] | Ottenhaus et al., 2023 | Design for adaptability, disassembly and reuse—A review of reversible timber connection systems | 4 | CONSTRUCTION AND BUILDING MATERIALS | Review | E | DfD | Principles/Benefits |

| [140] | Nie et al., 2024 | Exploring UAE’s transition towards circular economy through construction and demolition waste management in the pre-construction stage-A case study approach | 2 | SMART AND SUSTAINABLE BUILT ENVIRONMENT | Article | E | DfD | Principles/Benefits |

| [18] | Allam & Nik-Bakht, 2023 | From demolition to deconstruction of the built environment: A synthesis of the literature | 11 | JOURNAL OF BUILDING ENGINEERING | Article | E | DfD | Principles/Benefits |

| [84] | O’Grady et al., 2021. | Design for disassembly, deconstruction and resilience: A circular economy index for the built environment | 43 | RESOURCES CONSERVATION AND RECYCLING | Article | E | DfD | Principles/Benefits |

| [171] | Kręt-Grześkowiak & Baborska-Narożny, 2023 | Guidelines for disassembly and adaptation in architectural design compared to circular economy goals-A literature review | 4 | SUSTAINABLE PRODUCTION AND CONSUMPTION | Review | E | DfD | Principles/Benefits |

| [138] | Incelli & Cardellicchio, 2021 | Designing a steel connection with a high degree of disassembly: a practice-based experience | 2 | TECHNE-JOURNAL OF TECHNOLOGY FOR ARCHITECTURE AND ENVIRONMENT | Article | E | DfD | Principles/Benefits |

| [151] | Jaillon & Poon, 2014 | Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong | 199 | AUTOMATION IN CONSTRUCTION | Review | E | DfD | Principles/Benefits |

| [150] | Aye & Hes, 2012 | Green building rating system scores for building reuse | 15 | JOURNAL OF GREEN BUILDING | Article | E | DfD | Principles/Benefits |

| [153] | Timm et al., 2023 | Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment | 1 | BUILDINGS | Review | E | DfD | Principles/Benefits |

| [177] | Arrigoni et al., 2018 | Life cycle environmental benefits of a forward-thinking design phase for buildings: the case study of a temporary pavilion built for an international exhibition | 19 | JOURNAL OF CLEANER PRODUCTION | Article | E | DfD | Principles/Benefits |

| [188] | Abu-Ghaida et al., 2024 | Accounting for product recovery potential in building life cycle assessments: a disassembly network-based approach | - | INTERNATIONAL JOURNAL OF LIFE CYCLE ASSESSMENT | Article | E | DfD | Principles/Benefits |

| [147] | Vandervaeren et al., 2022 | More than the sum of its parts: Considering interdependencies in the life cycle material flow and environmental assessment of demountable buildings | 22 | RESOURCES CONSERVATION AND RECYCLING | Article | E | DfD | Principles/Benefits |

| [160] | Marino et al., 2021 | The circular design for a school in conditioned Quercus cerris hardwood glulam | - | VITRUVIO-INTERNATIONAL JOURNAL OF ARCHITECTURAL TECHNOLOGY AND SUSTAINABILITY | Article | E | DfD | Principles/Benefits |

| [143] | Buyle et al., 2019a | Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context | 72 | JOURNAL OF CLEANER PRODUCTION | Article | E | DfD | Principles/Benefits |

| [163] | Bryans et al., 2023 | Flatpack Architecture: Investigating Circularity Through Temporary, Demountable Buildings | - | TECHNOLOGY-ARCHITECTURE + DESIGN | Article | E | DfD | Principles/Benefits |

| [204] | Wuni et al., 2021 | Benefit Evaluation of Design for Excellence in Industrialized Construction Projects | 6 | JOURNAL OF ARCHITECTURAL ENGINEERING | Article | E | DfMA | Principles/Benefits |

| [205] | Hosseini et al., 2022 | Significant factors of implementing open building systems in malaysia | - | ARCHIVES FOR TECHNICAL SCIENCES | Article | E | DfMA | Principles/Benefits |

| [126] | Martínez et al., 2013 | Flexible field factory for construction industry | 32 | ASSEMBLY AUTOMATION | Article | E | DfMA | Principles/Benefits |

| [120] | Cao et al., 2022 | Ontology-based manufacturability analysis automation for industrialized construction | 9 | AUTOMATION IN CONSTRUCTION | Article | E | DfMA | Principles/Benefits |

| [119] | Vakaj et al., 2023 | An ontology-based cost estimation for offsite construction | 3 | JOURNAL OF INFORMATION TECHNOLOGY IN CONSTRUCTION | Article | E | DfMA | Principles/Benefits |

| [79] | Wasim et al., 2020 | An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings | 37 | JOURNAL OF BUILDING ENGINEERING | Article | E | DfMA | Principles/Benefits |

| [125] | Gbadamosi et al., 2019 | Offsite construction: Developing a BIM-Based optimizer for assembly | 82 | JOURNAL OF CLEANER PRODUCTION | Article | E | DfMA | Principles/Benefits |

| [134] | Wasim & Oliveira, 2022 | Efficient design of a prefabricated steel structure integrating design for manufacture and assembly concepts | 5 | AUSTRALIAN JOURNAL OF STRUCTURAL ENGINEERING | Article | E | DfMA | Principles/Benefits |

| [206] | M. Li et al., 2021 | DfMA-oriented design optimization for steel reinforcement using BIM and hybrid metaheuristic algorithms | 14 | JOURNAL OF BUILDING ENGINEERING | Article | E | DfMA | Principles/Benefits |

| [135] | Vaz-Serra et al., 2021 | Design for manufacture and assembly: A case study for a prefabricated bathroom wet wall panel | 11 | JOURNAL OF BUILDING ENGINEERING | Article | E | DfMA | Principles/Benefits |

| [207] | Dong et al., 2023 | DFMA-oriented modular and parametric design and secondary splitting of vertical PC components | 4 | SCIENTIFIC REPORTS | Article | E | DfMA | Principles/Benefits |

| [131] | Ros García & Sanglier Contreras, 2017 | Life-Cycle Assessment of Prototype Unit of Emergency Housing. The search for the zero | 6 | INFORMES DE LA CONSTRUCCION | Article | E | DfMA | Principles/Benefits |

| [113] | Yuan et al., 2018 | Design for Manufacture and Assembly-oriented parametric design of prefabricated buildings | 158 | AUTOMATION IN CONSTRUCTION | Article | E | DfMA | Principles/Benefits |

| [128] | K. Chen & Lu, 2018 | Design for Manufacture and Assembly Oriented Design Approach to a Curtain Wall System: A Case Study of a Commercial Building in Wuhan, China | 35 | SUSTAINABILITY | Article | E | DfMA | Principles/Benefits |

| [133] | Rojas Wettling et al., 2023 | IDM for the Conceptual Evaluation Process of Industrialized Timber Projects | 1 | ADVANCES IN CIVIL ENGINEERING | Article | E | DfMA | Principles/Benefits |

| [123] | I. Kim et al., 2024 | Client-centered detached modular housing: natural language processing-enabled design recommender system | - | JOURNAL OF COMPUTATIONAL DESIGN AND ENGINEERING | Article | E | DfMA | Principles/Benefits |

| [70] | Ling et al., 2023 | Impact of Digital Technology Adoption on the Comparative Advantage of Architectural, Engineering, and Construction Firms in Singapore | 2 | JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT | Article | E | DfMA | Principles/Benefits |

| Coding | Descriptor | Mentions | Frequency |

|---|---|---|---|

| DfMA/P-1 | Optimize cost through standardization and design simplification | [79,116,124,126,128,129,134,135,201] | 9 |

| DfMA/P-2 | Simplify assembly by minimizing component count and complexity | [79,113,116,124,125,128,129,133,135,199,201,207] | 12 |

| DfMA/P-3 | Promote modularization and prefabrication for efficient manufacture and assembly | [113,116,124,128,129,135,199,201,206,207] | 10 |

| DfMA/P-4 | Optimize component geometry, material selection, and tolerances for manufacturability and assembly | [113,116,119,124,128,129,135,199,201] | 9 |

| DfMA/P-5 | Integrate assembly logic and fabrication constraints from early design to secure quality and safety | [79,113,115,116,119,124,125,128,129,133,135,199,201] | 13 |

| DfMA/P-6 | Simplify and standardize connection systems for fast, reliable, and error-resistant assembly | [115,116,124,125,129,134,201] | 7 |

| DfMA/P-7 | Integrate workflow planning, site logistics, and digital technologies for efficient design | [125,128,134,135,199] | 5 |

| DfMA/P-8 | Promote multifunctionality and automation in component design | [124] | 1 |

| DfMA/P-9 | Minimize environmental impact through material efficiency and waste reduction | [125,128,129] | 3 |

| DfMA/P-10 | Foster multidisciplinary collaboration for integrated design and delivery | [79,135,199] | 3 |

| DfD/P-1 | Simplify and standardize elements and connections to facilitate disassembly | [7,24,80,89,149,152,159,166,171] | 9 |

| DfD/P-2 | Select non-hazardous, reusable, and easily separable materials | [7,24,80,89,145,149,152,153,159,166,171,184,193,198] | 14 |

| DfD/P-3 | Design with modular and prefabricated elements to support reversibility | [7,24,89,140,145,149,152,153,159,166,171,173] | 12 |

| DfD/P-4 | Integrate compatible technologies and digital tools to support disassembly | [145,152,159,171] | 4 |

| DfD/P-5 | Enable layered accessibility and parallel disassembly | [7,24,147,149,152,159,166,171,173,177] | 10 |

| DfD/P-6 | Ensure transparent, structured, and life cycle-oriented information management | [7,24,145,149,152,166,171,193,198] | 9 |

| DfD/P-7 | Maximize reuse and recycling through circular and non-destructive design | [80,89,140,145,152,153,159,171,177,184,188,193] | 12 |

| DfD/P-8 | Design for flexibility and lifespan-based layered replacement to minimize damage | [7,24,145,149,152,171] | 6 |

| DfD/P-9 | Use reversible, mechanical, and accessible connections | [7,24,80,89,145,149,152,153,159,166,171,198] | 12 |

| DfD/P-10 | Enable safe handling, movement, and access for effective disassembly | [7,24,152] | 3 |

| DfD/P-11 | Foster collaborative design, circular services, and secondary market integration | [7,145,171,184] | 4 |

| DfD/P-12 | Promote structural adaptability and component interchangeability | [7,152,173] | 3 |

| DfMA/B-1 | Enhances quality across design, assembly, and operational performance dimensions | [6,11,79,113,116,118,124,125,128,135,201] | 11 |

| DfMA/B-2 | Reduces project timelines through streamlined manufacturing and assembly processes | [6,7,11,79,113,115,116,118,124,134,135,201,207] | 13 |

| DfMA/B-3 | Lowers total project costs by optimizing resources and minimizing rework | [6,7,11,79,113,116,118,124,128,131,134,135,201,206,207] | 15 |

| DfMA/B-4 | Improves construction productivity, process efficiency, and execution control | [6,11,79,113,119,124,125,126,128,134,201,207] | 12 |

| DfMA/B-5 | Reduces on-site labor demands while enhancing safety, coordination, and teamwork | [6,11,113,115,118,124,125,128,134,201] | 10 |

| DfMA/B-6 | Mitigates environmental impacts through reduced waste, emissions, and resource consumption | [6,11,79,113,118,119,124,128,134,135,201] | 11 |

| DfMA/B-7 | Expands construction system capacity and supports integration with other strategies | [6,7,11,79,115,116,118,128,134,206,207] | 11 |

| DfMA/B-8 | Increases construction reliability through precision, repeatability, and design standardization | [6,7] | 2 |

| DfMA/B-9 | Facilitates spacious, adaptable interior layouts through modular and flexible design | [6,11] | 2 |

| DfD/B-1 | Reduces emissions, embodied carbon, and material use in construction processes | [80,90,136,141,142,146,151,164,177,179,188] | 11 |

| DfD/B-2 | Enables reuse, recycling, and low maintenance of building components | [25,80,87,142,146,164,177,188] | 8 |

| DfD/B-3 | Lowers labor demand and improves safety and productivity | [136,151] | 2 |

| DfD/B-4 | Enhances project coordination, constructability, and system performance | [90,142,146,151,163,164] | 6 |

| DfD/B-5 | Shortens schedules through streamlined and predictable assembly and disassembly processes | [90,151] | 2 |

| DfD/B-6 | Reduces project costs via material recovery, streamlined assembly, and less demolition waste | [80,136,146,151,163,177] | 6 |

| DfD/B-7 | Supports adaptable design strategies, policy development, and technology integration | [90,136,143,146,177] | 5 |

| DfMA/O-1 | Limited awareness of DfMA principles and operational requirements | [6,72,73,74,98,119,121,122,129,189,199,201] | 12 |

| DfMA/O-2 | Resistance to shifting from conventional to DfMA construction practices | [6,12,98,115,118,129,199,204] | 8 |

| DfMA/O-3 | Higher initial design costs and uncertain long-term returns hinder DfMA implementation | [6,55,73,97,98,118,122,129] | 8 |

| DfMA/O-4 | Lack of coordination, fragmented workflows, or non-integrated design processes | [6,11,73,75,97,116,117,121,122,127,129,130,199,200,202] | 15 |

| DfMA/O-5 | Logistics issues in manufacturing, transport, or assembly from planning and coordination failures | [6,11,72,75,116,127] | 6 |

| DfMA/O-6 | Contractual and supply chain misalignments disrupting stakeholder collaboration | [6,12,55,97,98,115,118,122,199,200,202] | 11 |

| DfMA/O-7 | Lack of proven demonstrations or performance data to validate DfMA effectiveness | [6,12,119,122,124,127,189,201,204] | 9 |

| DfMA/O-8 | Difficulty integrating DfMA in undocumented, complex, or atypical project conditions, compounded by limited technological availability. | [6,71,74,75,97,98,115,117,118,132,189,199,200,201,202,204] | 16 |

| DfMA/O-9 | Absence of enabling standards, codes, or policy frameworks to support DfMA | [6,71,73,97,98,118,119,124,189,201,202] | 11 |

| DfD/O-1 | Market and economic challenges hinder DfD adoption due to limited financial incentives | [1,114,136,146,154,161,165,166,167,168,169,176,179,181,203] | 15 |

| DfD/O-2 | Fragmented collaboration and supply chain coordination obstruct effective DfD integration | [1,7,136,154,167,173,175,181,183] | 9 |

| DfD/O-3 | Design and technical limitations compromise the constructability of DfD solutions | [1,90,136,137,146,157,161,162,166,168,172,175,176,181,203] | 15 |

| DfD/O-4 | Inefficient organizational structures weaken the operational execution of DfD | [1,7,114,136,161,165,167,174,179,181,183] | 11 |

| DfD/O-5 | Stakeholder resistance and low awareness impede the adoption of DfD practices | [1,114,137,154,161,167,168,169,170,174,175,181] | 12 |

| DfD/O-6 | Lack of policies and regulatory frameworks fails to support DfD-oriented construction processes | [1,136,146,154,161,162,165,166,167,168,169,174,176,181,203] | 15 |

| DfD/O-7 | Deficient knowledge and expertise prevent the effective implementation of DfD principles | [1,7,24,114,146,154,157,161,165,166,168,169,173,175,176,180,181,183] | 18 |

| DfD/O-8 | Limited access to digital tools and technologies restricts the application of DfD | [1,24,146,154,161,165,179,180,181] | 9 |

| DfMA/E-1 | Operational, technical, and practical knowledge support the effective implementation of DfMA | [6,71,72,75,124,129,130,132,189,199,202] | 11 |

| DfMA/E-2 | Organizational structures that integrate DfMA practices enable effective project delivery | [6,55,121,129,199,202] | 6 |

| DfMA/E-3 | Government support through incentives, regulations, and standards enables DfMA adoption | [6,7,189] | 3 |

| DfMA/E-4 | Stakeholder involvement and awareness of DfMA benefits enable effective implementation | [6,11,72,121,199,202] | 6 |

| DfMA/E-5 | Innovative technologies and methodologies enable the integration of DfMA in construction. | [6,72,73,75,115,118,122,124,129,132,200,202] | 12 |

| DfMA/E-6 | Site conditions and location logistics considered in design enable effective DfMA implementation | [6,11,116] | 3 |

| DfMA/E-7 | Organizational improvement needs drive DfMA adoption to boost efficiency and cut costs | [11,116,121,200,204] | 5 |

| DfD/E-1 | Implementation of techniques, methodologies, and software to support DfD adoption | [1,24,168,170,179,181] | 6 |

| DfD/E-2 | Education and clear information guide professionals toward correct DfD implementation | [1,7,24,165,168,170,176] | 7 |

| DfD/E-3 | Stakeholder awareness increases interest and commitment to adopting DfD practice | [136,170,173,176] | 4 |

| DfD/E-4 | Supportive policies and incentives provide legal and institutional backing for DfD | [1,24,114,170,176] | 5 |

| DfD/E-5 | Economic incentives and funding improve the financial viability of DfD implementation | [1,170,179] | 3 |

| DfD/E-6 | Technological innovations in digital tools, equipment, and materials streamline DfD adoption | [1,168,179] | 3 |

| DfD/E-7 | Managerial innovations such as new models and procedures enhance DfD integration | [1,165,168,174,176,179] | 6 |

| DfD/E-8 | Collaborative partnerships facilitate coordinated efforts to apply DfD | [1,168,170] | 3 |

| DfD/E-9 | Accessible case databases offer practical references to guide DfD adoption | [173,176,181] | 3 |

| DfD/E-10 | Adaptable processes support DfD by fitting site conditions, methods, and workflows | [7,136,172,173] | 4 |

References

- Ossio, F.; Salinas, C.; Hernández, H. Circular economy in the built environment: A systematic literature review and definition of the circular construction concept. J. Clean. Prod. 2023, 414, 137738. [Google Scholar] [CrossRef]

- UNEP. Global Status Report for Buildings and Construction: Beyond Foundations—Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector. United Nations Environment Programme. 2024. Available online: https://globalabc.org/resources/publications/global-status-report-buildings-and-construction-beyond-foundations (accessed on 29 January 2025). [CrossRef]

- Teh, S.H.; Wiedmann, T.; Moore, S. Mixed-unit hybrid life cycle assessment applied to the recycling of construction materials. J. Econ. Struct. 2018, 7, 13. [Google Scholar] [CrossRef]

- Qi, B.; Razkenari, M.; Costin, A.; Kibert, C.; Fu, M. A systematic review of emerging technologies in industrialized construction. J. Build. Eng. 2021, 39, 102265. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Navarro, I.J.; García, J.; Yepes, V. A systematic literature review on modern methods of construction in building: An integrated approach using machine learning. J. Build. Eng. 2023, 73, 106725. [Google Scholar] [CrossRef]

- Abd Razak, M.I.; Khoiry, M.A.; Wan Badaruzzaman, W.H.; Hussain, A.H. DfMA for a Better Industrialised Building System. Buildings 2022, 12, 794. [Google Scholar] [CrossRef]

- Roxas, C.L.C.; Bautista, C.R.; Dela Cruz, O.G.; Dela Cruz, R.L.C.; De Pedro, J.P.Q.; Dungca, J.R.; Lejano, B.A.; Ongpeng, J.M.C. Design for Manufacturing and Assembly (DfMA) and Design for Deconstruction (DfD) in the Construction Industry: Challenges, Trends and Developments. Buildings 2023, 13, 1164. [Google Scholar] [CrossRef]

- Tan, T.; Lu, W.; Tan, G.; Xue, F.; Chen, K.; Xu, J.; Wang, J.; Gao, S. Construction-Oriented Design for Manufacture and Assembly Guidelines. J. Constr. Eng. Manag. 2020, 146, 8. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef]

- Wasim, M.; Serra, P.V.; Ngo, T.D. Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction—A review. Int. J. Constr. Manag. 2022, 22, 3014–3022. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443. [Google Scholar] [CrossRef]

- Albattah, M.A.; Goodrum, P.M.; Taylor, T.R.B. New Metric of Workforce Availability among Construction Occupations and Regions. Pract. Period. Struct. Des. Constr. 2019, 24, 04019003. [Google Scholar] [CrossRef]

- Barbosa, F.; Woetzel, L.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction: A Route To Higher Productivity. 2017. Available online: http://www.mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/reinventing-construction-through-a-productivity-revolution (accessed on 29 January 2025).

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Circle Economy. Report: CGR Global 2022. Circ. Econ. 2022, 5, 1–26. [Google Scholar]

- Enkvist, P.-A.; Klevnäs, P.; Westerdahl, R.; Ahlén, A. How a ‘Materials Transition’ Can Support the Net-Zero Agenda. 2022. Available online: https://www.mckinsey.com/capabilities/sustainability/our-insights/how-a-materials-transition-can-support-the-net-zero-agenda (accessed on 29 January 2025).

- Allam, A.S.; Nik-Bakht, M. From demolition to deconstruction of the built environment: A synthesis of the literature. J. Build. Eng. 2023, 64, 105679. [Google Scholar] [CrossRef]

- Çimen, Ö. Construction and built environment in circular economy: A comprehensive literature review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Lanau, M.; Liu, G.; Kral, U.; Wiedenhofer, D.; Keijzer, E.E.; Yu, C.; Ehlert, C. Taking Stock of Built Environment Stock Studies: Progress and Prospects. Environ. Sci. Technol. 2019, 53, 8499–8515. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Antonini, E.; Boeri, A.; Lauria, M.; Giglio, F. Reversibility and Durability as Potential Indicators for Circular Building Technologies. Sustainability 2020, 12, 7659. [Google Scholar] [CrossRef]

- Kanters, J. Design for Deconstruction in the Design Process: State of the Art. Buildings 2018, 8, 150. [Google Scholar] [CrossRef]

- Khadim, N.; Agliata, R.; Marino, A.; Thaheem, M.J.; Mollo, L. Critical review of nano and micro-level building circularity indicators and frameworks. J. Clean. Prod. 2022, 357, 131859. [Google Scholar] [CrossRef]

- Sergio, M.; Franciosi, C.; Iannone, R. An approach to evaluate the impact of the introduction of a disassembly line in traditional manufacturing systems. J. Ind. Eng. Manag. 2022, 15, 215. [Google Scholar] [CrossRef]

- Attouri, E.; Lafhaj, Z.; Ducoulombier, L.; Linéatte, B. The current use of industrialized construction techniques in France: Benefits, limits and future expectations. Clean. Eng. Technol. 2022, 7, 100436. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Olawumi, T.O.; Saka, A.B. Assessment of symmetries and asymmetries on barriers to circular economy adoption in the construction industry towards zero waste: A survey of international experts. Build. Environ. 2023, 228, 109885. [Google Scholar] [CrossRef]

- Zairul, M. A thematic Review on Industrialised Building System (IBS) Publications from 2015–2019: Analysis of Patterns and Trends for Future Studies of IBS in Malaysia. Pertanika J. Soc. Sci. Humanit. 2021, 29, 635–652. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Hosseini, M.R.; Kocaturk, T.; Arnel, T.; Garofano, N.T. Circular economy in the Australian AEC industry: Investigation of barriers and enablers. Build. Res. Inf. 2023, 51, 56–68. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and drivers in a circular economy: The case of the built environment. Procedia CIRP 2019, 80, 619–624. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Wuni, I.Y. Mapping the barriers to circular economy adoption in the construction industry: A systematic review, Pareto analysis, and mitigation strategy map. Build. Environ. 2022, 223, 109453. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Saka, A.B.; Olawumi, T.O. Circular economy research on building construction and demolition waste: A review of current trends and future research directions. J. Clean. Prod. 2022, 357, 131927. [Google Scholar] [CrossRef]

- Yu, Y.; Yazan, D.M.; Junjan, V.; Iacob, M.-E. Circular economy in the construction industry: A review of decision support tools based on Information & Communication Technologies. J. Clean. Prod. 2022, 349, 131335. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; do Carmo Duarte Freitas, M.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Ribeirinho, M.J.; Mischke, J.; Strube, G.; Sjödin, E.; Blanco, J.L.; Palter, R.; Biörck, J.; Rockhill, D.; Andersson, T. The Next Normal in Construction; Mckinsey & Company: New York, NY, USA, 2020; p. 84. [Google Scholar]

- Podder, A.; Pless, S.; Rothgeb, S.; Klammer, N.; Blazek, C.; Louis, J.; Rashid, K. Integrating Energy Efficiency Strategies with Industrialized Construction for a Clean Energy Future. In Proceedings of the 2020 ACEEE Summer Study on Energy Efficiency in Buildings, Virtual, 17–21 August 2020; pp. 271–286. [Google Scholar]

- Battaïa, O.; Dolgui, A.; Heragu, S.S.; Meerkov, S.M.; Tiwari, M.K. Design for manufacturing and assembly/disassembly: Joint design of products and production systems. Int. J. Prod. Res. 2018, 56, 7181–7189. [Google Scholar] [CrossRef]

- Assael. RightSizer—Regenerative Build System. 2022. Available online: https://www.assael.co.uk/news/2022/design-resilience-building-for-longevity-the-route-to-net-zero/ (accessed on 20 January 2025).

- Lessing, J.; Brege, S. Industrialized Building Companies’ Business Models: Multiple Case Study of Swedish and North American Companies. J. Constr. Eng. Manag. 2018, 144, 2. [Google Scholar] [CrossRef]

- Lozano, D.; Martín, Á.; Serrano, M.A.; López-Colina, C. Design of Flexible Structural System for Building Customization. Adv. Civ. Eng. 2019, 2019, 2103830. [Google Scholar] [CrossRef]

- Kauppinen, L.; Annunen, P.; Haapasalo, H. Systematic literature review of themes and definitions of industrialized construction. Smart Sustain. Built Environ. 2024. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M.; Ojo, S.; Yam, M.C.H. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2022, 46, 103720. [Google Scholar] [CrossRef]

- Bendi, D. Developing an Offsite Readiness Framework for Indian Construction Organizations. Ph.D. Thesis, University of Salford, Salford, UK, 2017. [Google Scholar]

- Kamar, K.; Hamid, Z. Industrialized Building System (IBS): Revisiting Issues of Definition and Classification. Int. J. Emerg. Sci.—IJES 2011, 1, 120–132. [Google Scholar]

- de Moura Jorge, L.G.; Hammad, A.W.A.; Haddad, A.N.; Tam, V.W.Y.; Illankoon, C. Multi-objective optimisation of the level of prefabrication in construction projects. Proc. Inst. Civ. Eng.—Eng. Sustain. 2024, 177, 341–352. [Google Scholar] [CrossRef]

- Doermann, J.; Finzel, K.; Barrot, J. High-Rise Modular Construction—A Review of the Regulatory Landscape and Considerations for Growth. 2020. Available online: https://www.csagroup.org/wp-content/uploads/CSA-Group-Research-High-Rise-Modular-Construction.pdf?srsltid=AfmBOoq7f5ab1dkxT5zBLD97uzsFdKMqpi_y1CvzAdNnj5HvEgnf9Ljb (accessed on 29 January 2025).

- Teribele, A.; Turkienicz, B. Generative model and fixing guidelines for modular volumetric architecture. Rev. Constr. 2019, 17, 517–530. [Google Scholar] [CrossRef]

- Andersson, N.; Lessing, J. Industrialization of construction: Implications on standards, business models and project orientation. Organ. Technol. Manag. Constr. Int. J. 2020, 12, 2109–2116. [Google Scholar] [CrossRef]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat. Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, D.; Wang, D.; Xing, Y. Sustainable Performance of Buildings through Modular Prefabrication in the Construction Phase: A Comparative Study. Sustainability 2019, 11, 5658. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J.; Pérez, C.T. A proposed framework for Construction 4.0 based on a review of literature. In Proceedings of the 56th Annual Associated Schools of Construction (ASC) International, Liverpool, UK, 3–5 September 2020; Volume 1, pp. 301–309. [Google Scholar] [CrossRef]

- Costa, S.; Carvalho, M.S.; Pimentel, C.; Duarte, C. A Systematic Literature Review and Conceptual Framework of Construction Industrialization. J. Constr. Eng. Manag. 2023, 149, 2. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2022, 18, 93–113. [Google Scholar] [CrossRef]

- Durmisevic, E. Reversible Building Design Guidelines and Protocols. 2018. Available online: https://www.bamb2020.eu/wp-content/uploads/2018/12/Reversible-Building-Design-guidelines-and-protocol.pdf (accessed on 29 January 2025).

- Wang, K.; de Regel, S.; Debacker, W.; Michiels, J.; Vanderheyden, J. Why invest in a reversible building design? IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012005. [Google Scholar] [CrossRef]

- Hernández, H.; Ossio, F.; Silva, M. Assessment of Sustainability and Efficiency Metrics in Modern Methods of Construction: A Case Study Using a Life Cycle Assessment Approach. Sustainability 2023, 15, 6267. [Google Scholar] [CrossRef]

- Sergio, M.; Franciosi, C.; Iannone, R. A model for the economic assessment of disassembly-line integration in traditional manufacturing processes. Procedia Comput. Sci. 2021, 180, 308–317. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; do Carmo Duarte Freitas, M.; Tavares, S.F. Interactions between Lean Construction Principles and Circular Economy Practices for the Construction Industry. J. Constr. Eng. Manag. 2021, 147, 7. [Google Scholar] [CrossRef]

- Hall, D. Lecture 4: The Building as a Product: Platforms, Processes and Projects. Switzerland. 23 June 2023. Available online: https://www.youtube.com/watch?v=PGgV86IL_4o&t=1528s (accessed on 29 January 2025).

- Hall, D.M.; Whyte, J.K.; Lessing, J. Mirror-breaking strategies to enable digital manufacturing in Silicon Valley construction firms: A comparative case study. Constr. Manag. Econ. 2020, 38, 322–339. [Google Scholar] [CrossRef]

- Aksenova, G.; Oti-Sarpong, K. Beyond ‘platformania’ in the construction sector: Conceptualisations and implications of product platformisation in the UK. Constr. Manag. Econ. 2024, 42, 229–250. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection Criteria for Building Materials and Components in Line with the Circular Economy Principles in the Built Environment—A Review of Current Trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- Akhimien, N.G.; Latif, E.; Hou, S.S. Application of circular economy principles in buildings: A systematic review. J. Build. Eng. 2021, 38, 102041. [Google Scholar] [CrossRef]

- RIBA. DfMA Overlay to the RIBA Plan of Work. 2021. Available online: https://www.architecture.com/knowledge-and-resources/resources-landing-page/dfma-overlay-to-the-riba-plan-of-work (accessed on 12 January 2025).

- Dewagoda, K.G.; Ng, S.T.; Kumaraswamy, M.M.; Chen, J. Design for Circular Manufacturing and Assembly (DfCMA): Synergising Circularity and Modularity in the Building Construction Industry. Sustainability 2024, 16, 9192. [Google Scholar] [CrossRef]

- Kim, M.-K.; McGovern, S.; Belsky, M.; Middleton, C.; Brilakis, I. A Suitability Analysis of Precast Components for Standardized Bridge Construction in the United Kingdom. Procedia Eng. 2016, 164, 188–195. [Google Scholar] [CrossRef]

- Ling, F.Y.Y.; Heng, G.T.H.; Chang-Richards, A.; Chen, X.; Yiu, T.W. Impact of Digital Technology Adoption on the Comparative Advantage of Architectural, Engineering, and Construction Firms in Singapore. J. Constr. Eng. Manag. 2023, 149, 12. [Google Scholar] [CrossRef]

- Montazeri, S.; Lei, Z.; Odo, N. Design for Manufacturing and Assembly (DfMA) in Construction: A Holistic Review of Current Trends and Future Directions. Buildings 2024, 14, 285. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Li, B.; Huang, J. Digital-enabled Design for Manufacture and Assembly (DfMA) in offsite construction: A modularity perspective for the product and process integration. Archit. Eng. Des. Manag. 2023, 19, 267–282. [Google Scholar] [CrossRef]

- Hyun, H.; Kim, H.-G.; Kim, J.-S. Integrated Off-Site Construction Design Process including DfMA Considerations. Sustainability 2022, 14, 4084. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Oyedele, L.; Mahamadu, A.-M.; Kusimo, H.; Bilal, M.; Delgado, J.M.D.; Muhammed-Yakubu, N. Big data for Design Options Repository: Towards a DFMA approach for offsite construction. Autom. Constr. 2020, 120, 103388. [Google Scholar] [CrossRef]

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction: From Projects to Products. 2019. Available online: https://www.mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/modular-construction-from-projects-to-products (accessed on 29 January 2025).

- Tavares, V.; Lacerda, N.; Freire, F. Embodied energy and greenhouse gas emissions analysis of a prefabricated modular house: The ‘Moby’ case study. J. Clean. Prod. 2019, 212, 1044–1053. [Google Scholar] [CrossRef]

- Ng, M.S.; Hall, D.M. Toward Lean Management for Digital Fabrication: A Review of the Shared Practices of Lean, DfMA and dfab. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC 2019, Dublin, Ireland, 1–7 July 2019; pp. 725–736. [Google Scholar] [CrossRef]

- Wasim, M.; Han, T.M.; Huang, H.; Madiyev, M.; Ngo, T.D. An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings. J. Build. Eng. 2020, 32, 101474. [Google Scholar] [CrossRef]

- Pristerà, G.; Tonini, D.; Tornaghi, M.L.; Caro, D.; Sala, S. Taxonomy of design for deconstruction options to enable circular economy in buildings. Resour. Environ. Sustain. 2024, 15, 100153. [Google Scholar] [CrossRef]

- Ostapska, K.; Rüther, P.; Loli, A.; Gradeci, K. Design for Disassembly: A systematic scoping review and analysis of built structures Designed for Disassembly. Sustain. Prod. Consum. 2024, 48, 377–395. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Proc. Inst. Civ. Eng.—Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Ajayi, S.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A.; Bello, S.A.; Jaiyeoba, B.E.; Kadiri, K.O. Design for Deconstruction (DfD): Critical success factors for diverting end-of-life waste from landfills. Waste Manag. 2017, 60, 3–13. [Google Scholar] [CrossRef]

- O’Grady, T.M.; Minunno, R.; Chong, H.-Y.; Morrison, G.M. Interconnections: An Analysis of Disassemblable Building Connection Systems towards a Circular Economy. Buildings 2021, 11, 535. [Google Scholar] [CrossRef]

- Jansen, B.W.; van Stijn, A.; Gruis, V.; van Bortel, G. A circular economy life cycle costing model (CE-LCC) for building components. Resour. Conserv. Recycl. 2020, 161, 104857. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- ARUP. The Circular Economy in the Built Environment. 2016. Available online: https://www.arup.com/globalassets/downloads/insights/cirular-economy-in-the-built-environment.pdf (accessed on 29 January 2025).

- Cottafava, D.; Ritzen, M. Circularity indicator for residential buildings: Addressing the gap between embodied impacts and design aspects. Resour. Conserv. Recycl. 2021, 164, 105120. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Bilal, M.; Ajayi, S.O.; Owolabi, H.A.; Alaka, H.A.; Bello, S.A. Waste minimisation through deconstruction: A BIM based Deconstructability Assessment Score (BIM-DAS). Resour. Conserv. Recycl. 2015, 105, 167–176. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W.; Hall, D. The transition to the circular economy of the construction industry: Insights into sustainable approaches to improve the understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Dewagoda, K.G.; Ng, S.T.; Kumaraswamy, M.M. Design for Circularity: The Case of the Building Construction Industry. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 062026. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. A novel selective disassembly sequence planning method for adaptive reuse of buildings. J. Clean. Prod. 2018, 183, 998–1010. [Google Scholar] [CrossRef]

- ISO 20887:2020; Sustainability in Buildings and Civil Engineering Works—Design for Disassembly and Adaptability—Principles, Requirements and Guidance. ISO: Geneva, Switzerland, 2020.

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A circular construction evaluation framework to promote designing for disassembly and adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- Kanters, J. Circular Building Design: An Analysis of Barriers and Drivers for a Circular Building Sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Roxas, C.; Cruz, R.D.; De Pedro, J.; Tamani, B.M.; Roxas, N.R. A Unified Framework for Integrating Design for Manufacturing and Assembly (DfMA) and Design for Deconstruction (DfD) in the Construction Industry. In Proceedings of the DLSU Research Congress 2024, Manila, Philippines, 20–22 June 2024; Available online: https://www.dlsu.edu.ph/wp-content/uploads/pdf/conferences/research-congress-proceedings/2024/SEE-09.pdf (accessed on 3 May 2025).

- Wuni, I.Y.; Wu, Z.; Shen, G.Q. Exploring the challenges of implementing design for excellence in industrialized construction projects in China. Build. Res. Inf. 2023, 51, 301–315. [Google Scholar] [CrossRef]

- Rankohi, S.; Bourgault, M.; Iordanova, I.; Carbone, C. Developing a Construction-Oriented DfMA Deployment Framework. Buildings 2023, 13, 1050. [Google Scholar] [CrossRef]

- Hernández, H.; Díaz, L.; Rodríguez-Grau, G. Examining building deconstruction: Introducing a holistic index to evaluate the ease of disassembly. Resour. Conserv. Recycl. 2025, 218, 108215. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. Conceptualization of Circular Economy 3.0: Synthesizing the 10R Hierarchy of Value Retention Options; Springer: Berlin/Heidelberg, Germany, 2022; pp. 47–69. [Google Scholar] [CrossRef]

- Zou, P.X.W.; Sunindijo, R.Y.; Dainty, A.R.J. A mixed methods research design for bridging the gap between research and practice in construction safety. Saf. Sci. 2014, 70, 316–326. [Google Scholar] [CrossRef]

- Khan, K.S.; Kunz, R.; Kleijnen, J.; Antes, G. Five steps to conducting a systematic review. JRSM 2003, 96, 118–121. [Google Scholar] [CrossRef]

- Trifu, A.; Smîdu, E.; Badea, D.O.; Bulboacă, E.; Haralambie, V. Applying the PRISMA method for obtaining systematic reviews of occupational safety issues in literature search. MATEC Web Conf. 2022, 354, 00052. [Google Scholar] [CrossRef]

- Sánchez-Serrano, S.; Pedraza-Navarro, I.; Donoso-González, M. How to conduct a systematic review under PRISMA protocol? Uses and fundamental strategies for its application in the educational field through a practical case study. Bordón Rev. Pedagog. 2022, 74, 51–66. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and Adoption Challenges of AI in the Construction Industry: A PRISMA Review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Manual for VOSviewer Version 1.6.18. 2022. Available online: https://www.vosviewer.com/documentation/Manual_VOSviewer_1.6.18.pdf (accessed on 29 January 2025).

- Arruda, H.; Silva, E.R.; Lessa, M.; Proença, D., Jr.; Bartholo, R. VOSviewer and Bibliometrix. J. Med. Libr. Assoc. 2022, 110, 392–395. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Hossain, M.U. A review of the circularity gap in the construction industry through scientometric analysis. J. Clean. Prod. 2021, 298, 126870. [Google Scholar] [CrossRef]

- Stemler, S. An overview of content analysis. Pract. Assess. Res. Eval. 2000, 7, 17. [Google Scholar] [CrossRef]

- Hsieh, H.-F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef] [PubMed]

- Morse, J.M. Constructing Qualitatively Derived Theory: Concept Construction and Concept Typologies. Qual. Health Res. 2004, 14, 1387–1395. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, C.; Wang, Y. Design for Manufacture and Assembly-oriented parametric design of prefabricated buildings. Autom. Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Nguyen, D.-C.; Jeon, C.-H.; Roh, G.; Shim, C. BIM-based preassembly analysis for design for manufacturing and assembly of prefabricated bridges. Autom. Constr. 2024, 160, 105338. [Google Scholar] [CrossRef]

- Roxas, C.L.C. Application of design for manufacturing and assembly on temporary shelters in the philippines. Int. J. GEOMATE 2023, 24, 120–127. [Google Scholar] [CrossRef]

- Qi, B.; Costin, A. BIM and Ontology-Based DfMA Framework for Prefabricated Component. Buildings 2023, 13, 394. [Google Scholar] [CrossRef]

- Langston, C.; Zhang, W. DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia. Sustainability 2021, 13, 9219. [Google Scholar] [CrossRef]

- Vakaj, E.; Cheung, F.; Cao, J.; Tawil, A.-R.H.; Patlakas, P. An Ontology-Based Cost Estimation for Offsite Construction. J. Inf. Technol. Constr. 2023, 28, 220–245. [Google Scholar] [CrossRef]

- Cao, J.; Vakaj, E.; Soman, R.K.; Hall, D.M. Ontology-based manufacturability analysis automation for industrialized construction. Autom. Constr. 2022, 139, 104277. [Google Scholar] [CrossRef]

- Ginigaddara, B.; Perera, S.; Feng, Y.; Rahnamayiezekavat, P.; Kagioglou, M. Industry 4.0 driven emerging skills of offsite construction: A multi-case study-based analysis. Constr. Innov. 2024, 24, 747–769. [Google Scholar] [CrossRef]

- Potseluyko, L.; Rahimian, F.P.; Dawood, N.; Elghaish, F.; Hajirasouli, A. Game-like interactive environment using BIM-based virtual reality for the timber frame self-build housing sector. Autom. Constr. 2022, 142, 104496. [Google Scholar] [CrossRef]

- Kim, I.; Shin, J.; Shah, S.H.; Rehman, S.U. Client-centered detached modular housing: Natural language processing-enabled design recommender system. J. Comput. Des. Eng. 2024, 11, 137–157. [Google Scholar] [CrossRef]

- Tan, T.; Zheng, L.; Xue, F.; Bao, Z.; Fang, Z.; Liu, X. Mives multi-criteria framework to sustainability index of design for manufacture and assembly. J. Civ. Eng. Manag. 2024, 30, 234–247. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Mahamadu, A.-M.; Oyedele, L.O.; Akinade, O.O.; Manu, P.; Mahdjoubi, L.; Aigbavboa, C. Offsite construction: Developing a BIM-Based optimizer for assembly. J. Clean. Prod. 2019, 215, 1180–1190. [Google Scholar] [CrossRef]

- Martínez, S.; Jardón, A.; Víctores, J.G.; Balaguer, C. Flexible field factory for construction industry. Assem. Autom. 2013, 33, 175–183. [Google Scholar] [CrossRef]

- Liu, Z.; Hwang, B.-G.; Lim, J.M. Prefabricated and Prefinished Volumetric Construction: Assessing Implementation Status, Perceived Benefits, and Critical Risk Factors in the Singapore Built Environment Sector. J. Manag. Eng. 2023, 39, 6. [Google Scholar] [CrossRef]

- Chen, K.; Lu, W. Design for Manufacture and Assembly Oriented Design Approach to a Curtain Wall System: A Case Study of a Commercial Building in Wuhan, China. Sustainability 2018, 10, 2211. [Google Scholar] [CrossRef]

- Jung, S.; Yu, J. Design for Manufacturing and Assembly (DfMA) Checklists for Off-Site Construction (OSC) Projects. Sustainability 2022, 14, 11988. [Google Scholar] [CrossRef]

- Orlowski, K.; Shanaka, K.; Mendis, P. Design and Development of Weatherproof Seals for Prefabricated Construction: A Methodological Approach. Buildings 2018, 8, 117. [Google Scholar] [CrossRef]

- García, J.M.R.; Contreras, G.S. Análisis del Ciclo de Vida de una Unidad Prototipo de Vivienda de Emergencia. La búsqueda del impacto nulo. Inf. Constr. 2017, 69, e211. [Google Scholar] [CrossRef]

- Li, Y.; Yu, B.; Fingrut, A.; Li, J. Design for Manufacturing and Assembly (DfMA) of Standardized Modular Wood Components. Technol. Archit. Des. 2023, 7, 282–292. [Google Scholar] [CrossRef]

- Wettling, C.R.; Alvarez, C.M.; Bretones, P.G. IDM for the Conceptual Evaluation Process of Industrialized Timber Projects. Adv. Civ. Eng. 2023, 2023, 9200255. [Google Scholar] [CrossRef]

- Wasim, M.; Oliveira, O. Efficient design of a prefabricated steel structure integrating design for manufacture and assembly concepts. Aust. J. Struct. Eng. 2022, 23, 356–369. [Google Scholar] [CrossRef]

- Vaz-Serra, P.; Wasim, M.; Egglestone, S. Design for manufacture and assembly: A case study for a prefabricated bathroom wet wall panel. J. Build. Eng. 2021, 44, 102849. [Google Scholar] [CrossRef]

- Anastasiades, K.; Dockx, J.; van den Berg, M.; Rinke, M.; Blom, J.; Audenaert, A. Stakeholder perceptions on implementing design for disassembly and standardisation for heterogeneous construction components. Waste Manag. Res. J. Sustain. Circ. Econ. 2023, 41, 1372–1381. [Google Scholar] [CrossRef]

- Derikvand, M.; Fink, G. Design for Deconstruction: Benefits, Challenges, and Outlook for Timber–Concrete Composite Floors. Buildings 2023, 13, 1754. [Google Scholar] [CrossRef]

- Incelli, F.; Cardellicchio, L. Designing a steel connection with a high degree of disassembly: A practice-based experience. TECHNE—J. Technol. Archit. Environ. 2021, 22, 104–113. [Google Scholar] [CrossRef]

- Errante, L.; De Capua, A. Design for Disassembly and the rehabilitation of public housing stock. A case study. TECHNE—J. Technol. Archit. Environ. 2021, 22, 181–191. [Google Scholar] [CrossRef]

- Nie, P.; Dahanayake, K.C.; Sumanarathna, N. Exploring UAE’s transition towards circular economy through construction and demolition waste management in the pre-construction stage—A case study approach. Smart Sustain. Built Environ. 2024, 13, 246–266. [Google Scholar] [CrossRef]

- Roberts, M.; Allen, S.; Clarke, J.; Searle, J.; Coley, D. Understanding the global warming potential of circular design strategies: Life cycle assessment of a design-for-disassembly building. Sustain. Prod. Consum. 2023, 37, 331–343. [Google Scholar] [CrossRef]

- Tingley, D.D.; Davison, B. Developing an LCA methodology to account for the environmental benefits of design for deconstruction. Build. Environ. 2012, 57, 387–395. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Andersen, R.; Ravn, A.S.; Ryberg, M.W. Environmental benefits of applying selective demolition to buildings: A case study of the reuse of façade steel cladding. Resour. Conserv. Recycl. 2022, 184, 106430. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.-A. A design support tool based on building information modeling for design for deconstruction: A graph-based deconstructability assessment approach. J. Clean. Prod. 2023, 383, 135343. [Google Scholar] [CrossRef]

- Eckelman, M.J.; Brown, C.; Troup, L.N.; Wang, L.; Webster, M.D.; Hajjar, J.F. Life cycle energy and environmental benefits of novel design-for-deconstruction structural systems in steel buildings. Build. Environ. 2018, 143, 421–430. [Google Scholar] [CrossRef]

- Vandervaeren, C.; Galle, W.; Stephan, A.; De Temmerman, N. More than the sum of its parts: Considering interdependencies in the life cycle material flow and environmental assessment of demountable buildings. Resour. Conserv. Recycl. 2022, 177, 106001. [Google Scholar] [CrossRef]

- Selvaraj, S.; Chan, T.-M. Recommendations for Implementing Circular Economy in Construction: Direct Reuse of Steel Structures. J. Constr. Steel Res. 2024, 214, 108439. [Google Scholar] [CrossRef]

- Crowther, P. Chapter 18 Re-Valuing Construction Materials and Components Through Design for Disassembly. In Unmaking Waste in Production and Consumption: Towards the Circular Economy; Emerald Publishing Limited: Leeds, UK, 2018; pp. 309–321. [Google Scholar] [CrossRef]

- Aye, L.; Hes, D. Green building rating system scores for building reuse. J. Green. Build. 2012, 7, 105–112. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- de Lima, P.R.B.; de Souza Rodrigues, C.; Post, J.M. Integration of BIM and design for deconstruction to improve circular economy of buildings. J. Build. Eng. 2023, 80, 108015. [Google Scholar] [CrossRef]

- Timm, J.F.G.; Maciel, V.G.; Passuello, A. Towards Sustainable Construction: A Systematic Review of Circular Economy Strategies and Ecodesign in the Built Environment. Buildings 2023, 13, 2059. [Google Scholar] [CrossRef]

- Seeberg, H.R.; Haakonsen, S.M.; Luczkowski, M. Systematic Mapping of Circular Economy in Structural Engineering. Buildings 2024, 14, 1165. [Google Scholar] [CrossRef]

- Arredondo, P.W.C.; Silva, Y.F.; Araya-Letelier, G.; Hernández, H. Valorization of Recycled Aggregate and Copper Slag for Sustainable Concrete Mixtures: Mechanical, Physical, and Environmental Performance. Sustainability 2024, 16, 11239. [Google Scholar] [CrossRef]

- Xia, B.; Ding, T.; Xiao, J. Life cycle assessment of concrete structures with reuse and recycling strategies: A novel framework and case study. Waste Manag. 2020, 105, 268–278. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zhang, Q.; Akbarnezhad, A. Experimental and numerical studies on design for deconstruction concrete connections: An overview. Adv. Struct. Eng. 2018, 21, 2198–2214. [Google Scholar] [CrossRef]

- Navarro-Rubio, J.; Pineda, P.; García-Martínez, A. Sustainability, prefabrication and building optimization under different durability and re-using scenarios: Potential of dry precast structural connections. Sustain. Cities Soc. 2019, 44, 614–628. [Google Scholar] [CrossRef]

- Ottenhaus, L.-M.; Yan, Z.; Brandner, R.; Leardini, P.; Fink, G.; Jockwer, R. Design for adaptability, disassembly and reuse—A review of reversible timber connection systems. Constr. Build. Mater. 2023, 400, 132823. [Google Scholar] [CrossRef]

- Marino, F.P.R.; Lembo, F.; Di Lucchio, C. The circular design for a school in conditioned Quercus cerris hardwood glulam. Vitr.—Int. J. Archit. Technol. Sustain. 2021, 6, 72. [Google Scholar] [CrossRef]

- Tirelli, D.; Besana, D. Moving toward Net Zero Carbon Buildings to Face Global Warming: A Narrative Review. Buildings 2023, 13, 684. [Google Scholar] [CrossRef]

- Lehmann, S. Low carbon construction systems using prefabricated engineered solid wood panels for urban infill to significantly reduce greenhouse gas emissions. Sustain. Cities Soc. 2013, 6, 57–67. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Kulatunga, A.K.; Jayasinghe, J.A.S.C.; Zhang, G.; Osadith, S.A.U. Evaluating the Circular Economy Potential of Modular Construction in Developing Economies—A Life Cycle Assessment. Sustainability 2023, 15, 16336. [Google Scholar] [CrossRef]

- Bryans, T.; Berwyn, E.; Swallow, P.; Rose, C. Flatpack Architecture: Investigating Circularity Through Temporary, Demountable Buildings. Technol. Archit. Des. 2023, 7, 160–166. [Google Scholar] [CrossRef]

- Akinade, O.; Oyedele, L.; Oyedele, A.; Delgado, J.M.D.; Bilal, M.; Akanbi, L.; Ajayi, A.; Owolabi, H. Design for deconstruction using a circular economy approach: Barriers and strategies for improvement. Prod. Plan. Control 2020, 31, 829–840. [Google Scholar] [CrossRef]

- Pittri, H.; Godawatte, A.G.R.; Agyekum, K.; Botchway, E.A.; Dompey, A.M.A.; Oduro, S.; Asamoah, E. Examining the barriers to implementing design for deconstruction in the construction industry of a developing country. Constr. Innov. 2024. ahead of print. [Google Scholar] [CrossRef]

- Lehmann, S. Optimizing Urban Material Flows and Waste Streams in Urban Development through Principles of Zero Waste and Sustainable Consumption. Sustainability 2011, 3, 155–183. [Google Scholar] [CrossRef]

- Rios, F.C.; Grau, D.; Bilec, M. Barriers and Enablers to Circular Building Design in the US: An Empirical Study. J. Constr. Eng. Manag. 2021, 147, 10. [Google Scholar] [CrossRef]

- Charef, R.; Morel, J.C.; Rakhshan, K. Barriers to implementing the circular economy in the construction industry: A critical review. Sustainability 2021, 13, 12989. [Google Scholar] [CrossRef]

- Pittri, H.; Agyekum, K.; Botchway, E.A.; Alencastro, J.; Oladinrin, O.T.; Dompey, A.M.A. Drivers for design for deconstruction (DfD) implementation among design professionals. Smart Sustain. Built Environ. 2024, 13, 1134–1154. [Google Scholar] [CrossRef]

- Kręt-Grześkowiak, A.; Baborska-Narożny, M. Guidelines for disassembly and adaptation in architectural design compared to circular economy goals—A literature review. Sustain. Prod. Consum. 2023, 39, 1–12. [Google Scholar] [CrossRef]

- Bourke, K.; Kyle, B. Service life planning and durability in the context of circular economy assessments—Initial aspects for review. Can. J. Civ. Eng. 2019, 46, 1074–1079. [Google Scholar] [CrossRef]

- Incelli, F.; Cardellicchio, L.; Rossetti, M. Circularity Indicators as a Design Tool for Design and Construction Strategies in Architecture. Buildings 2023, 13, 1706. [Google Scholar] [CrossRef]

- Azcárate-Aguerre, J.F.; den Heijer, A.C.; Arkesteijn, M.H.; Vergara d’Alençon, L.M.; Klein, T. Facades-as-a-Service: Systemic managerial, financial, and governance innovation to enable a circular economy for buildings. Lessons learnt from a full-scale pilot project in the Netherlands. Front. Built Environ. 2023, 9, 1084078. [Google Scholar] [CrossRef]

- Hartwell, R.; Macmillan, S.; Overend, M. Circular economy of façades: Real-world challenges and opportunities. Resour. Conserv. Recycl. 2021, 175, 105827. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Arrigoni, A.; Zucchinelli, M.; Collatina, D.; Dotelli, G. Life cycle environmental benefits of a forward-thinking design phase for buildings: The case study of a temporary pavilion built for an international exhibition. J. Clean. Prod. 2018, 187, 974–983. [Google Scholar] [CrossRef]

- Marzouk, M.; Elmaraghy, A. Design for Deconstruction Using Integrated Lean Principles and BIM Approach. Sustainability 2021, 13, 7856. [Google Scholar] [CrossRef]

- Banihashemi, S.; Meskin, S.; Sheikhkhoshkar, M.; Mohandes, S.R.; Hajirasouli, A.; LeNguyen, K. Circular economy in construction: The digital transformation perspective. Clean. Eng. Technol. 2024, 18, 100715. [Google Scholar] [CrossRef]

- Aziminezhad, M.; Taherkhani, R. BIM for deconstruction: A review and bibliometric analysis. J. Build. Eng. 2023, 73, 106683. [Google Scholar] [CrossRef]

- AlJaber, A.; Alasmari, E.; Martinez-Vazquez, P.; Baniotopoulos, C. Life Cycle Cost in Circular Economy of Buildings by Applying Building Information Modeling (BIM): A State of the Art. Buildings 2023, 13, 1858. [Google Scholar] [CrossRef]