Big Data-Driven Implementation in International Construction Supply Chain Management: Framework Development, Future Directions, and Barriers

Abstract

1. Introduction

- (1)

- Data-related barriers

- (2)

- Technology-related barriers

- (3)

- Organizational and human resource barriers

- (4)

- Regulatory barriers

- (5)

- Economic and business barriers

- Comprehensive identification and classification of barriers through 62 rigorously screened studies from 2014 to 2024 using PRISMA 2020.

- An implementation framework tailored to construction projects, offering a practical roadmap for embedding BDA across project-based supply chain segments.

- A new barrier taxonomy of 21 specific obstacles grouped into five dimensions (data, technology, organizational and human, regulatory, economic) as well as targeted mitigation strategies for each.

- A forward-looking research agenda highlighting gaps in data governance, scalable infrastructure, real-time performance systems, skill development, and supportive policy frameworks, thereby steering future BD-CSCM investigations.

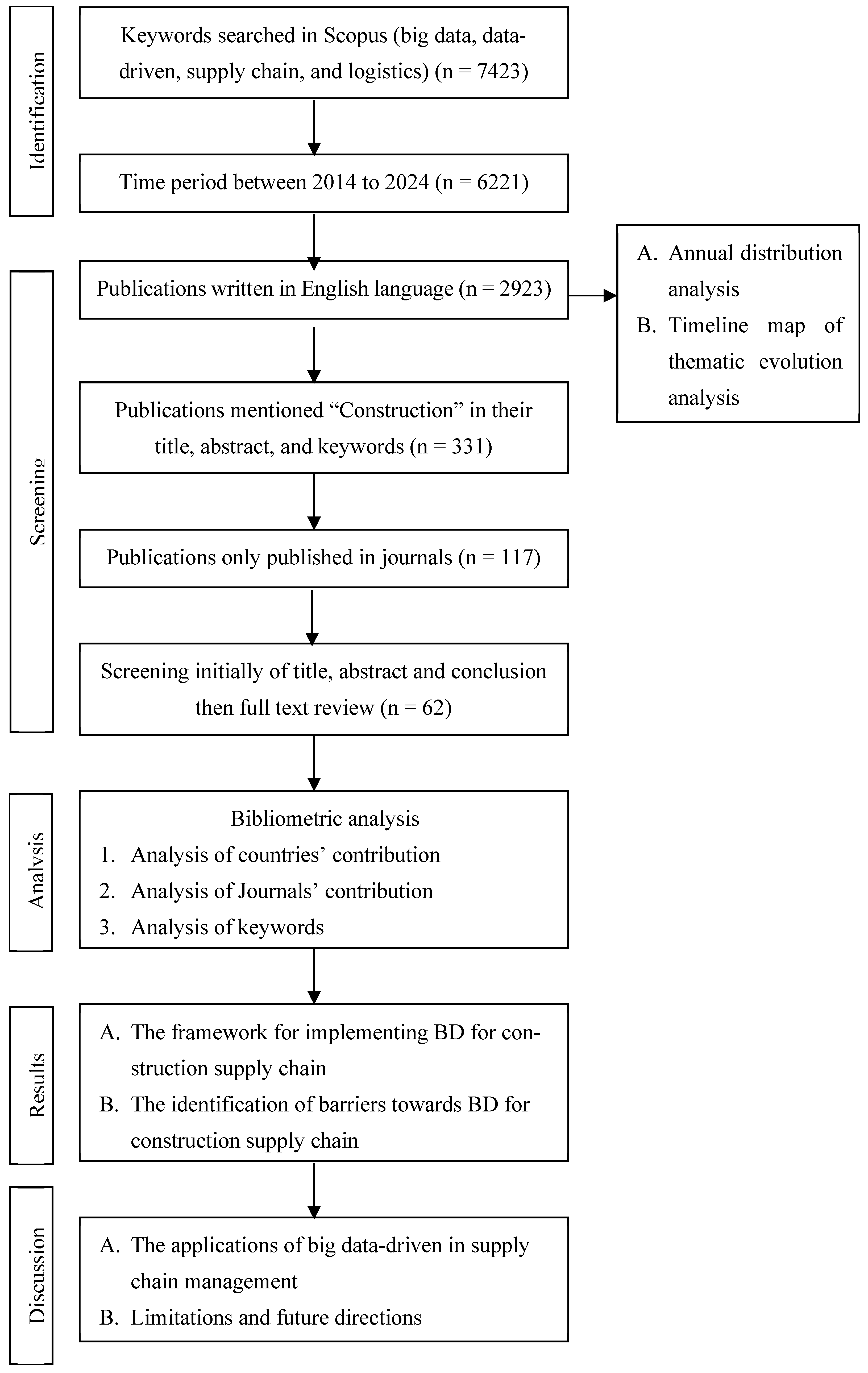

2. Research Methods

2.1. Review Methodology

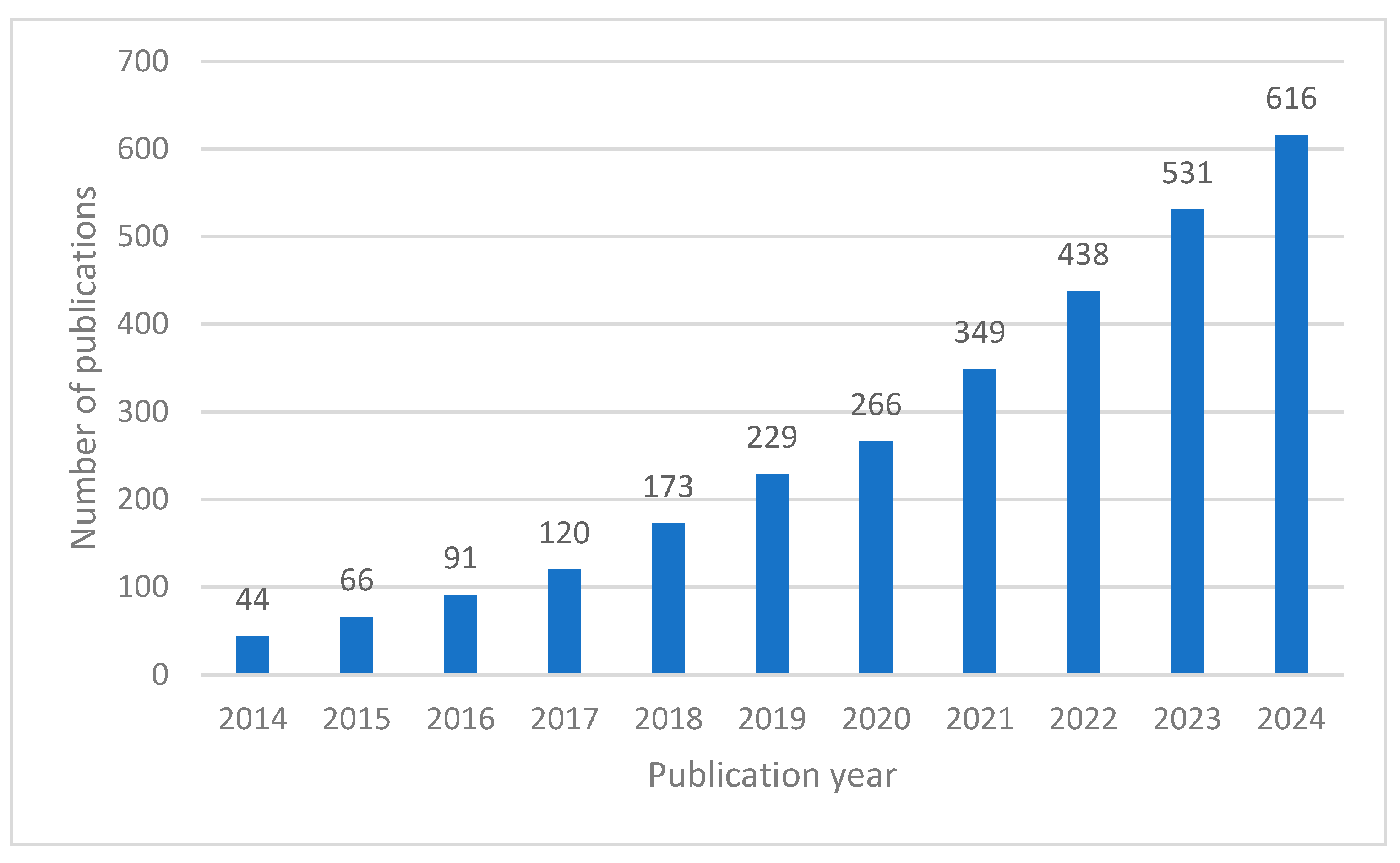

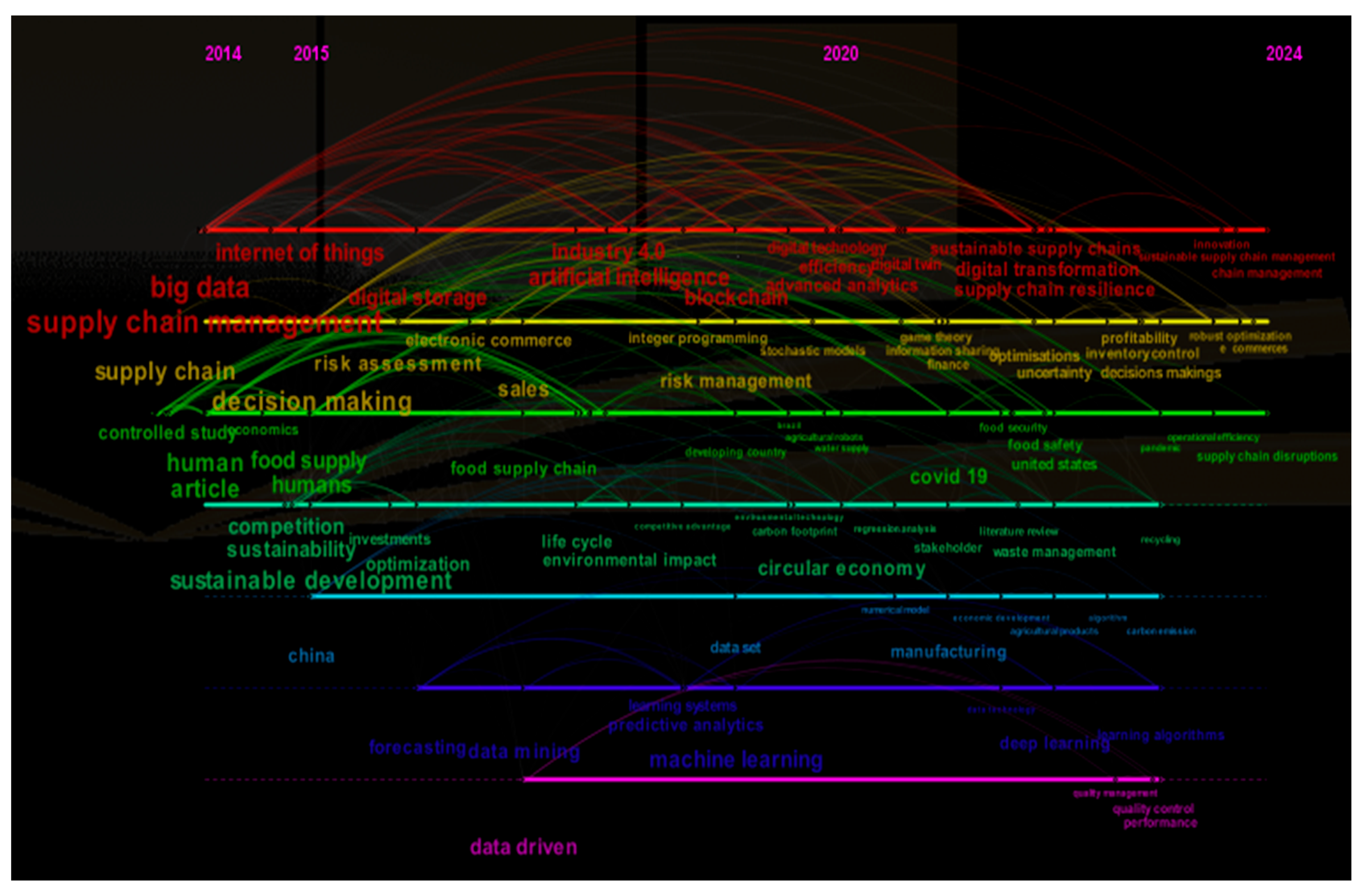

2.2. Trends and Thematic Evolution in Big Data-Driven Supply Chain Research

2.3. A Review Database Bibliometric Analysis

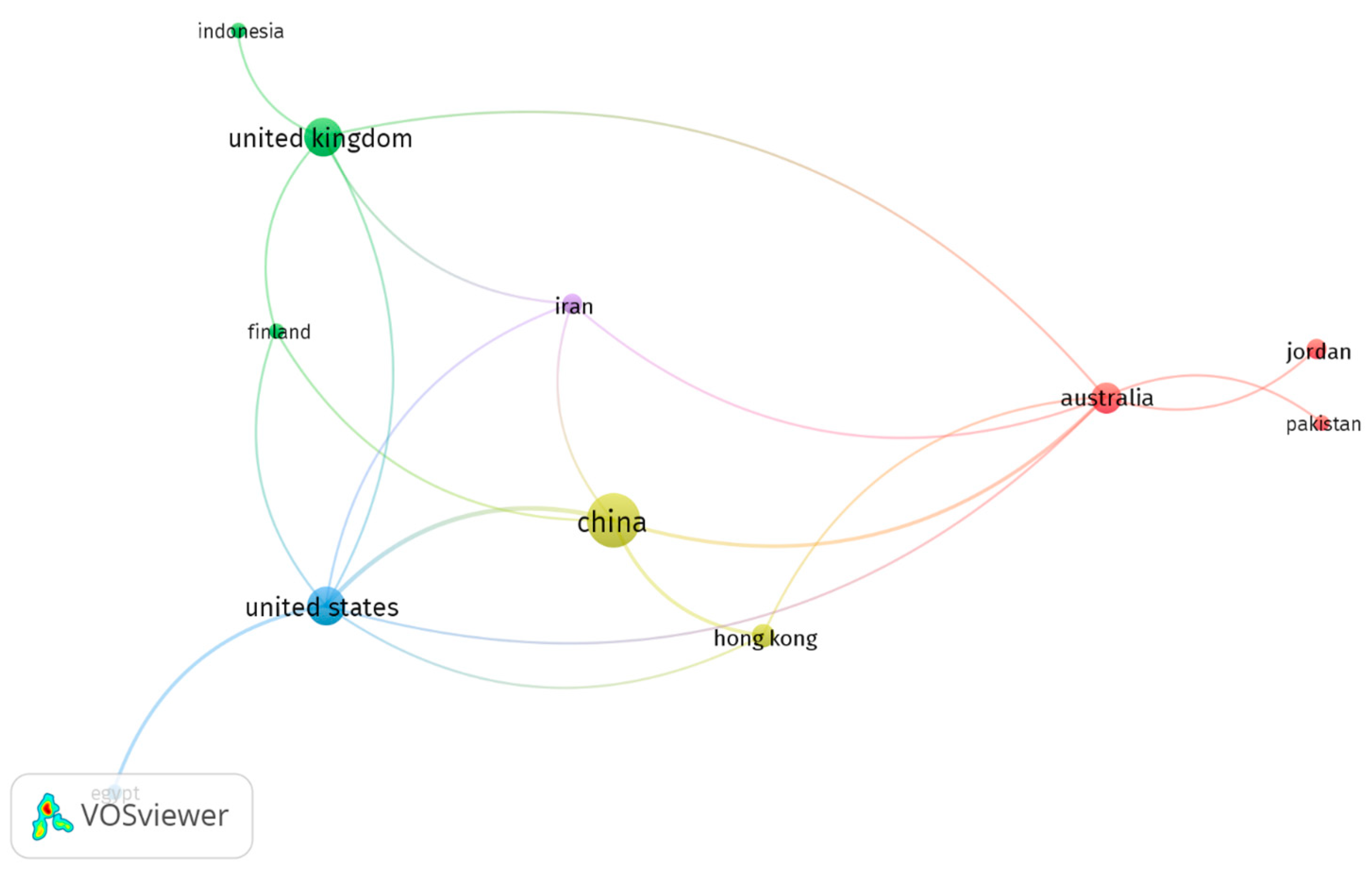

2.3.1. Analysis of Countries’ Contribution

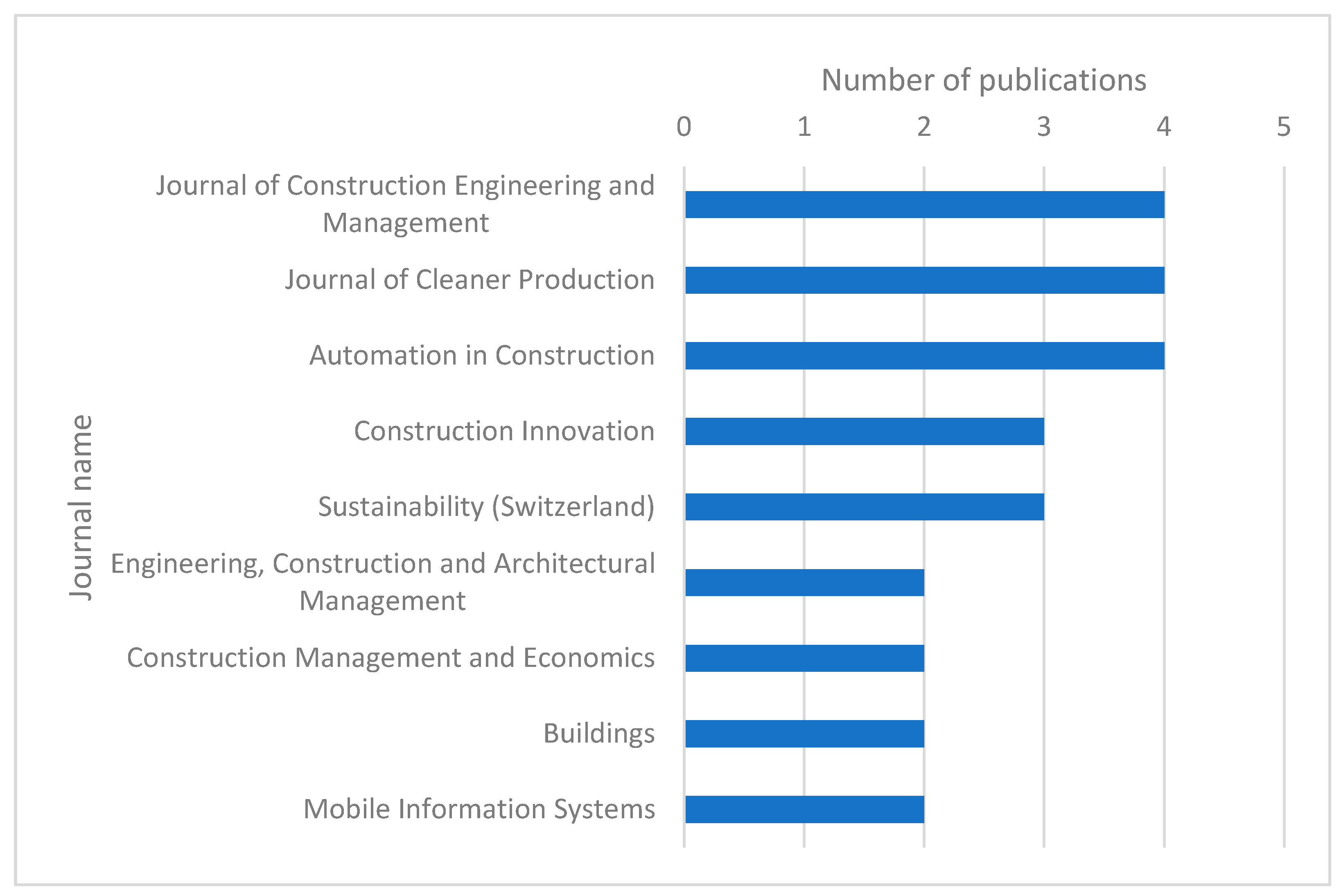

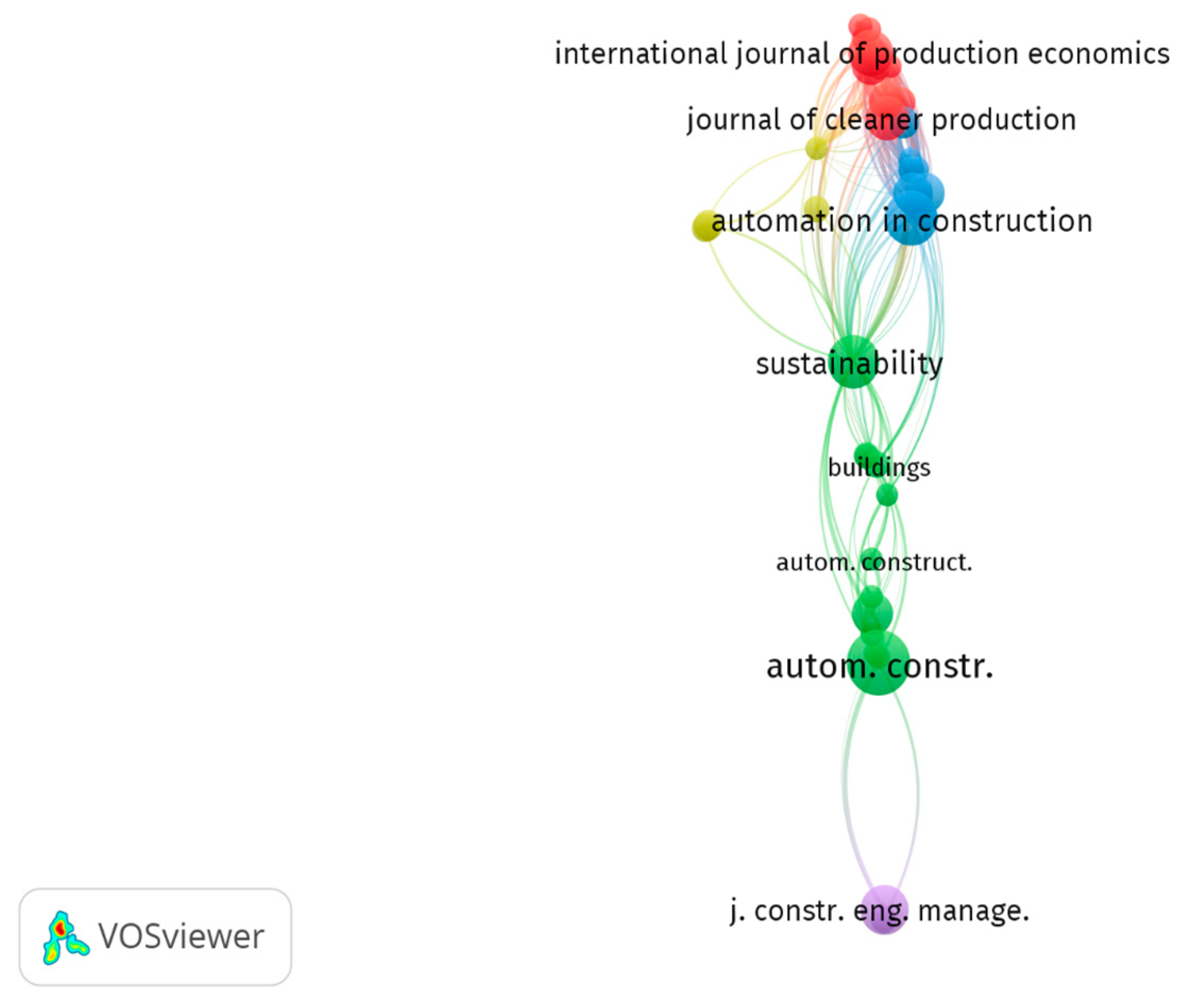

2.3.2. Analysis of Journals’ Contribution

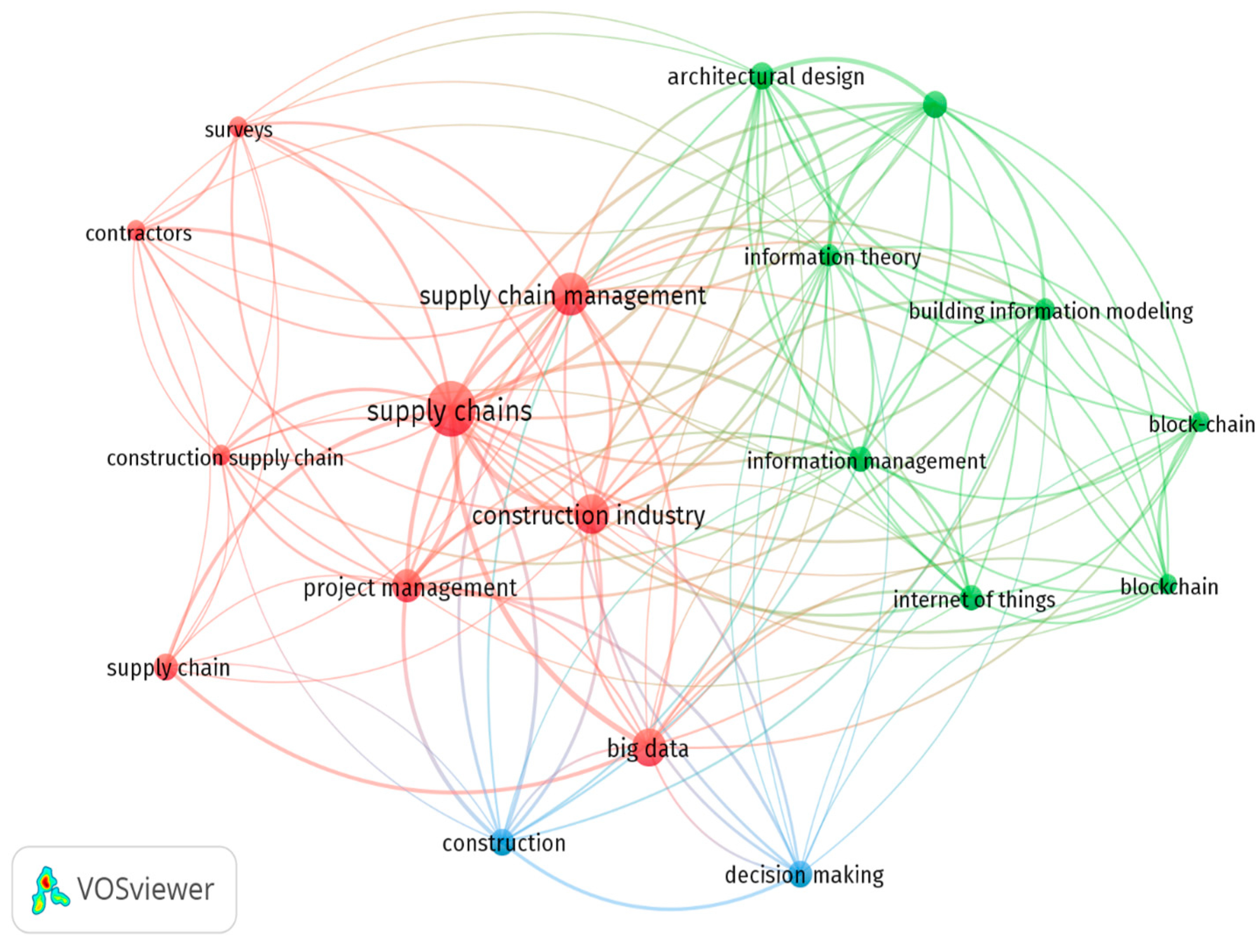

2.3.3. Analysis of Keywords

3. Results

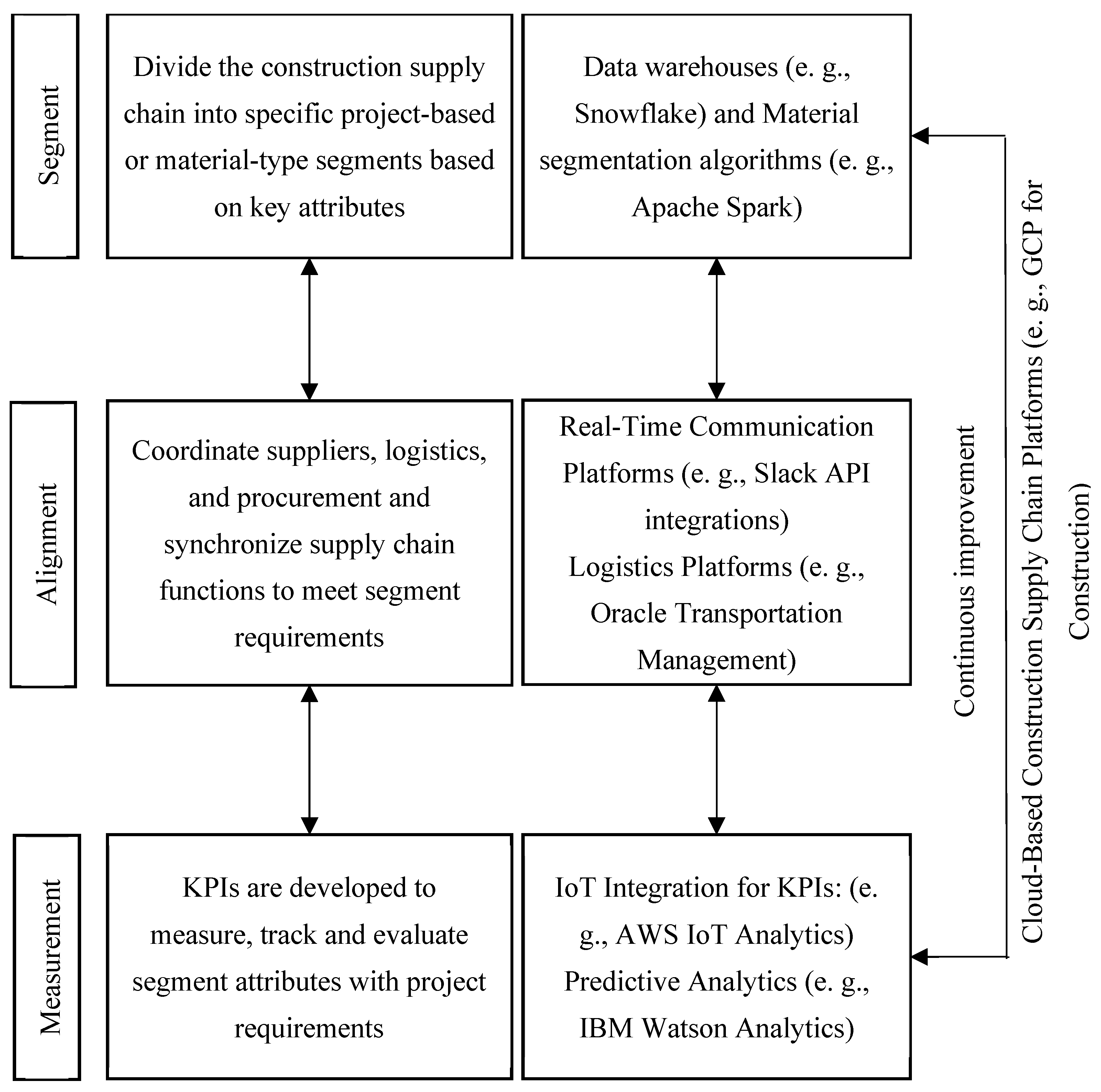

3.1. The Framework for Implementing BD for Construction Supply Chain

3.2. Barriers Towards BD for Construction Supply Chain

3.2.1. Data-Related Barriers

3.2.2. Technology-Related Barriers

3.2.3. Organizational and Human Resource Barriers

3.2.4. Regulatory-Related Barriers

3.2.5. Economic-Related Barriers

4. The Applications of Big Data-Driven in Supply Chain Management

4.1. Risk Management and Resilience

4.2. Supplier Management

4.3. Operations Optimization

4.4. Sustainability

4.5. Logistics and Transportation

5. Research Gaps and Future Directions

5.1. Research Gaps

5.1.1. Data-Related Limitations

5.1.2. Technology-Related Limitations

5.1.3. Organizational and Human-Related Limitations

5.1.4. Regulatory-Related Limitations

5.1.5. Economic-Related Limitations

5.2. Potential Research Directions

5.2.1. Data Security, Privacy, and Quality

5.2.2. Scalable Infrastructure and Tools for CSCM

5.2.3. Advancing Performance Measurement Systems

5.2.4. Organizational Transformation and Skill Development

5.2.5. Government Policies and Regulatory Frameworks

5.2.6. Economic Feasibility

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| BD | Big data |

| BDA | Big data analysis |

| BDAC | Big data analysis capabilities |

| BDD | Big data-driven |

| BI | Business intelligence |

| BIM | Building information modeling |

| CSCM | Construction supply chain management |

| CSCMP | Supply chain management professionals |

| DQAC | Data quality assessing and controlling |

| EIDP | Enterprise integrated data platform |

| GI | Green innovation |

| GSCI | Green supply chain integration |

| GSCM | Green supply chain management |

| HDFS | Hadoop distributed file system |

| IoT | Internet of Things |

| IPD | Integrated project delivery |

| IPFS | Interplanetary file system |

| IT | Information technology |

| KPIS | Key performance indices |

| PRISMA | Preferred reporting items for systematic reviews and meta-analyses |

| RFID | Radio-frequency identification |

| SCA | Supply chain analytics |

| SCM | Supply chain management |

| SMES | Small- and medium-sized enterprises |

References

- Expert Market Research. Expert Market Research China Logistics Market Report and Forecast 2024–2032sa.Pdf; Expert Market Research: Sheridan, WY, USA, 2023. [Google Scholar]

- Kambatla, K.; Kollias, G.; Kumar, V.; Grama, A. Trends in Big Data Analytics. J. Parallel Distrib. Comput. 2014, 74, 2561–2573. [Google Scholar] [CrossRef]

- Ngo, J.; Hwang, B.; Zhang, C. Factor-Based Big Data and Predictive Analytics Capability Assessment Tool for the Construction Industry. Autom. Constr. 2020, 110, 103042. [Google Scholar] [CrossRef]

- Fosso, S.; Gunasekaran, A.; Akter, S.; Ren, S.J.; Dubey, R.; Childe, S.J. Big Data Analytics and Fi Rm Performance: Effects of Dynamic Capabilities ☆. J. Bus. Res. 2017, 70, 356–365. [Google Scholar] [CrossRef]

- Yu, T.; Ph, D.; Liang, X.; Ph, D.; Wang, Y.; Ph, D. Factors Affecting the Utilization of Big Data in Construction Projects. J. Constr. Eng. Manag. 2020, 146, 1–14. [Google Scholar] [CrossRef]

- Hu, H.A.N.; Wen, Y.; Member, S.; Chua, T. Toward Scalable Systems for Big Data Analytics: A Technology Tutorial. IEEE Access 2014, 2, 652–687. [Google Scholar] [CrossRef]

- Ikegwu, A.C.; Nweke, H.F.; Anikwe, C.V.; Alo, U.R.; Okonkwo, O.R. Big Data Analytics for Data-Driven Industry: A Review of Data Sources, Tools, Challenges, Solutions, and Research Directions. Cluster Comput. 2022, 25, 3343–3387. [Google Scholar] [CrossRef]

- Nguyen, T.; Duong, Q.H.; Van Nguyen, T.; Zhu, Y.; Zhou, L. Knowledge Mapping of Digital Twin and Physical Internet in Supply Chain Management: A Systematic Literature Review. Int. J. Prod. Econ. 2022, 244, 108381. [Google Scholar] [CrossRef]

- Jeble, S.; Dubey, R.; Childe, S.J.; Papadopoulos, T.; Roubaud, D.; Prakash, A. Impact of Big Data and Predictive Analytics Capability on Supply Chain Sustainability. Int. J. Logist. Manag. 2017, 29, 513–538. [Google Scholar] [CrossRef]

- Waller, M.A.; Fawcett, S.E. Data Science, Predictive Analytics, and Big Data: A Revolution That Will Transform Supply Chain Design and Management. J. Bus. Logist. 2013, 34, 77–84. [Google Scholar] [CrossRef]

- Patrucco, A.S.; Marzi, G.; Trabucchi, D. The Role of Absorptive Capacity and Big Data Analytics in Strategic Purchasing and Supply Chain Management Decisions. Technovation 2023, 126, 102814. [Google Scholar] [CrossRef]

- Brinch, M.; Stentoft, J.; Jensen, J.K.; Rajkumar, C. Practitioners Understanding of Big Data and Its Applications in Supply Chain Management. Int. J. Logist. Manag. 2018, 29, 555–574. [Google Scholar] [CrossRef]

- Moktadir, A.; Mithun, S.; Kumar, S.; Shukla, N. Barriers to Big Data Analytics in Manufacturing Supply Chains: A Case Study from Bangladesh. Comput. Ind. Eng. 2019, 128, 1063–1075. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Newman, S.T.; Huang, G.Q.; Lan, S. Big Data for Supply Chain Management in the Service and Manufacturing Sectors: Challenges, Opportunities, and Future Perspectives. Comput. Ind. Eng. 2016, 101, 572–591. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.; Brennan, S.E.; et al. The Prisma 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Med. Flum. 2021, 57, 444–465. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Pandey, N.; Gupta, P. Forty Years of the International Journal of Information Management: A Bibliometric Analysis. Int. J. Inf. Manage 2021, 57, 102307. [Google Scholar] [CrossRef]

- Tang, M.; Liao, H. From Conventional Group Decision Making to Large-Scale Group Decision Making: What Are the Challenges and How to Meet Them in Big Data Era? A State-of-the-Art Survey ✩. Omega 2021, 100, 102141. [Google Scholar] [CrossRef]

- Ma, W.; Yuan, H.; Hao, J.L. A Bibliometric Visual Analysis of the System Dynamics Approach for Construction and Demolition Waste Management. Clean. Waste Syst. 2022, 1, 100004. [Google Scholar] [CrossRef]

- Ahmad, T.; Abdelfadeel, I.; Zayed, T. Urban Climate A Review of Climatic Impacts on Water Main Deterioration. Urban. Clim. 2023, 49, 101552. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with Digital Twin Information Systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Ruan, J.; Wang, Y.; Tung, F.; Chan, S.; Hu, X.; Zhao, M.; Zhu, F.; Shi, B.; Shi, Y.; Lin, F. A Life Cycle Framework of Green IoT-Based Agriculture and Its Finance, Operation, and Management Issues. IEEE Commun. Mag. 2019, 57, 90–96. [Google Scholar] [CrossRef]

- Giesekam, J.; Barrett, J.R.; Taylor, P. Construction Sector Views on Low Carbon Building Materials. Build. Res. Inf. 2016, 44, 423–444. [Google Scholar] [CrossRef]

- Li, X.; Lu, W.; Xue, F.; Wu, L.; Zhao, R.; Lou, J.; Xu, J. Blockchain-Enabled IoT-BIM Platform for Supply Chain Management in Modular Construction. J. Constr. Eng. Manag. 2022, 148. [Google Scholar] [CrossRef]

- You, Z.; Wu, C. A Framework for Data-Driven Informatization of the Construction Company. Adv. Eng. Inform. 2019, 39, 269–277. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Zhou, W. RFID Enabled Knowledge-Based Precast Construction Supply Chain. Comput. Civ. Infrastruct. Eng. 2017, 32, 499–514. [Google Scholar] [CrossRef]

- Xiang, Z.; Xu, M. Dynamic Cooperation Strategies of the Closed-Loop Supply Chain Involving the Internet Service Platform. J. Clean. Prod. 2019, 220, 1180–1193. [Google Scholar] [CrossRef]

- Chen, Q.; Adey, B.T.; Haas, C.; Hall, D.M. Using Look-Ahead Plans to Improve Material Flow Processes on Construction Projects When Using BIM and RFID Technologies. Constr. Innov. 2020, 20, 471–508. [Google Scholar] [CrossRef]

- Said, H. Prefabrication Best Practices and Improvement Opportunities for Electrical Construction. J. Constr. Eng. Manag. 2015, 141, 1–14. [Google Scholar] [CrossRef]

- Ahmed, V.; Tezel, A.; Aziz, Z.; Sibley, M. The Future of Big Data in Facilities Management: Opportunities and Challenges. Facilities 2020, 35, 725–745. [Google Scholar] [CrossRef]

- Jahin, A.; Shovon, S.H.; Shin, J.; Ridoy, I.A.; Mridha, M.F. Big Data—Supply Chain Management Framework for Forecasting: Data Preprocessing and Machine Learning Techniques. Arch. Comput. Methods Eng. 2024, 31, 3619–3645. [Google Scholar] [CrossRef]

- Margaritis, I.; Madas, M.; Vlachopoulou, M. Big Data Applications in Food Supply Chain Management: A Conceptual Framework. Sustainability 2022, 14, 4035. [Google Scholar] [CrossRef]

- Brinch, M. Understanding the Value of Big Data in Supply Chain Management and Its Business Processes Towards a Conceptual Framework. Int. J. Oper. Prod. Manag. 2018, 38, 1589–1614. [Google Scholar] [CrossRef]

- Sanders, N.R. How to Use Big Data to Drive Your Supply Chain. Calif. Manag. Rev. 2016, 58, 26–48. [Google Scholar] [CrossRef]

- Arunachalam, D.; Kumar, N.; Kawalek, J.P. Understanding Big Data Analytics Capabilities in Supply Chain Management: Unravelling the Issues, Challenges and Implications for Practice. Transp. Res. Part. E 2018, 114, 416–436. [Google Scholar] [CrossRef]

- Alharthi, A.; Krotov, V.; Bowman, M. Addressing Barriers to Big Data. Bus. Horiz. 2020, 60, 285–292. [Google Scholar] [CrossRef]

- Sivarajah, U.; Kamal, M.M.; Irani, Z.; Weerakkody, V. Critical Analysis of Big Data Challenges and Analytical Methods. J. Bus. Res. 2017, 70, 263–286. [Google Scholar] [CrossRef]

- Dehkhodaei, A.; Amiri, B.; Farsijani, H.; Raad, A. Barriers to Big Data Analytics (BDA) Implementation in Manufacturing Supply Chains. J. Ofmanagement Anal. 2023, 10, 191–222. [Google Scholar] [CrossRef]

- Ogbuke, N.J.; Yusuf, Y.Y.; Dharma, K.; Mercangoz, B.A. Big Data Supply Chain Analytics: Ethical, Privacy and Security Challenges Posed to Business, Industries and Society. Prod. Plan. Control 2020, 33, 123–137. [Google Scholar] [CrossRef]

- Ding, S.; Hu, H.; Xu, F.; Chai, Z.; Wang, W. Blockchain-Based Security-Minded Information-Sharing in Precast Construction Supply Chain Management with Scalability, Efficiency and Privacy Improvements. Autom. Constr. 2024, 168, 105698. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Iakovou, E.; Vlachos, D. Data-Driven Secure, Resilient and Sustainable Supply Chains: Gaps, Opportunities, and a New Generalised Data Sharing and Data Monetisation Framework. Int. J. Prod. Res. 2022, 60, 4397–4417. [Google Scholar] [CrossRef]

- Manupati, V.K.; Schoenherr, T.; Ramkumar, M.; Wagner, S.M.; Pabba, K.; Singh, R.I.R.; Schoenherr, T.; Ramkumar, M.; Wagner, S.M. A Blockchain-Based Approach for a Multi-Echelon Sustainable Supply Chain. Int. J. Prod. Res. 2020, 58, 2222–2241. [Google Scholar] [CrossRef]

- Aghamohammadzadeh, E.; Valilai, O.F. A Novel Cloud Manufacturing Service Composition Platform Enabled by Blockchain Technology. Int. J. Prod. Res. ISSN 2020, 58, 5280–5298. [Google Scholar] [CrossRef]

- Pan, X.; Zhong, B.; Sheng, D.; Yuan, X.; Wang, Y. Blockchain and Deep Learning Technologies for Construction Equipment Security Information Management. Autom. Constr. 2022, 136, 104186. [Google Scholar] [CrossRef]

- Gopal, P.R.C.; Rana, N.P.; Krishna, T.V.; Ramkumar, M. Impact of Big Data Analytics on Supply Chain Performance: An Analysis of Influencing Factors. Ann. Oper. Res. 2024, 333, 769–797. [Google Scholar] [CrossRef]

- Fernando, Y.; Chidambaram, R.R.M.; Wahyuni-td, I.S. The Impact of Big Data Analytics and Data Security Practices on Service Supply Chain Performance. Benchmarking Int. J. 2018, 25, 4009–4034. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A. Big Data-Driven Supply Chain Performance Measurement System: A Review and Framework for Implementation. Int. J. Prod. Res. 2019, 58, 65–86. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Fosso, S.; Childe, S.J.; Hazen, B.; Akter, S. Big Data and Predictive Analytics for Supply Chain and Organizational Performance. J. Bus. Res. 2017, 70, 308–317. [Google Scholar] [CrossRef]

- Rehman, M.; Chang, V.; Batool, A.; Wah, T. Big Data Reduction Framework for Value Creation in Sustainable Enterprises. Int. J. Inf. Manage 2016, 36, 917–928. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, W.; Zhong, R.Y. Blockchain-Enabled Cyber-Physical System for Construction Site Management: A Pilot Implementation. Adv. Eng. Inform. 2023, 57, 102102. [Google Scholar] [CrossRef]

- Yousif, O.S.; Zakaria, R.B.; Aminudin, E.; Yahya, K.; Yahya, M.A.; Wahi, N.; Shamsuddin, S.M. Review of Big Data Integration in Construction Industry Digitalization. Front. Built Environ. 2021, 7, 770496. [Google Scholar] [CrossRef]

- Gil, D.; Johnsson, M.; Mora, H.; SzymaNski, J. Review of the Complexity of Managing Big Data of the Internet of Things. Complexity 2019, 2019, 4592902. [Google Scholar] [CrossRef]

- Marzouk, M.; Enaba, M. Analyzing Project Data in BIM with Descriptive Analytics to Improve Project Performance. Built Environ. Proj. Asset Manag. 2019, 9, 476–488. [Google Scholar] [CrossRef]

- Vieira, A.A.C.; Dias, L.M.S.; Santos, M.Y.; Pereira, G.A.B.; Oliveira, J.A. Supply Chain Data Integration: A Literature Review. J. Ind. Inf. Integr. 2020, 19, 100161. [Google Scholar] [CrossRef]

- Borkowski, A.S. Low-Cost Internet of Things Solution for Building Information Modeling Level 3B—Monitoring, Analysis and Management. J. Sens. Actuator Networks 2024, 13, 19. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-Based Framework for Improving Supply Chain Traceability and Information Sharing in Precast Construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Lee, D.; Wen, L.; Choi, J.O.; Lee, S. Sensor-Integrated Hybrid Blockchain System for Supply Chain Coordination in Volumetric Modular Construction. J. Constr. Eng. Manag. 2023, 149, 1–13. [Google Scholar] [CrossRef]

- Elghaish, F.; Abrishami, S.; Hosseini, M.R. Integrated Project Delivery with Blockchain: An Automated Financial System. Autom. Constr. 2020, 114, 103182. [Google Scholar] [CrossRef]

- Cai, H.; Xu, B.; Jiang, L.; Vasilakos, A.V. IoT-Based Big Data Storage Systems in Cloud Computing: Perspectives and Challenges. IEEE Internet Things J. 2017, 4, 75–87. [Google Scholar] [CrossRef]

- Abdullah, N.; Ismail, S.A.; Sophiayati, S.; Sam, S.M. Data Quality in Big Data: A Review. Int. J. Adv. Soft Comput. Its Appl. 2015, 7, 17–27. [Google Scholar]

- Hazen, B.T.; Boone, C.A.; Ezell, J.D.; Jones-farmer, L.A. Data Quality for Data Science, Predictive Analytics, and Big Data in Supply Chain Management: An Introduction to the Problem and Suggestions for Research and Applications. Intern. J. Prod. Econ. 2014, 154, 72–80. [Google Scholar] [CrossRef]

- He, X.; Liu, R.; Anumba, C.J. Theoretical Architecture for Data-Quality-Aware Analytical Applications in the Construction Firms. Constr. Res. Congr. 2022, 3, 335–343. [Google Scholar]

- Chen, H.; Chang, K.; Lin, T. A Cloud-Based System Framework for Performing Online Viewing, Storage, and Analysis on Big Data of Massive BIMs. Autom. Constr. 2016, 71, 34–48. [Google Scholar] [CrossRef]

- Dong, B.; Zheng, Q.; Tian, F.; Chao, K.; Ma, R.; Anane, R. An Optimized Approach for Storing and Accessing Small Files on Cloud Storage. J. Netw. Comput. Appl. 2012, 35, 1847–1862. [Google Scholar] [CrossRef]

- Hijazi, A.A.; Perera, S.; Calheiros, R.N.; Alashwal, A. A Data Model for Integrating BIM and Blockchain to Enable a Single Source of Truth for the Construction Supply Chain Data Delivery. Eng. Constr. Archit. Manag. 2023, 30, 4645–4664. [Google Scholar] [CrossRef]

- Azeroual, O. Renaud Fabre Processing Big Data with Apache Hadoop in the Current Challenging Era of COVID-19. Big Data Cogn. Comput. 2021, 5, 12. [Google Scholar] [CrossRef]

- Salloum, S.; Dautov, R.; Chen, X.; Xiaogang, P.; Huang, J.Z. Big Data Analytics on Apache Spark. Int. J. Data Sci. Anal. 2016, 1, 145–164. [Google Scholar] [CrossRef]

- Li, F.; Laili, Y.; Chen, X.; Lou, Y.; Wang, C.; Yang, H.; Gao, X.; Han, H. Towards Big Data Driven Construction Industry. J. Ind. Inf. Integr. 2023, 35, 100483. [Google Scholar] [CrossRef]

- Neely, A.; Gregory, M.; Platts, K. Performance Measurement System Design A Literature Review and Research Agenda. Int. J. Oper. Prod. Manag. 1995, 15, 80–116. [Google Scholar] [CrossRef]

- Stefanovic, N. Collaborative Predictive Business Intelligence Model for Spare Parts Inventory Replenishment. Comput. Sci. Inf. Syst. 2015, 12, 911–930. [Google Scholar] [CrossRef]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.T.; Papadopoulos, T. Big Data Analytics in Logistics and Supply Chain Management: Certain Investigations for Research and Applications. Intern. J. Prod. Econ. 2016, 176, 98–110. [Google Scholar] [CrossRef]

- Chalmeta, R.; Barqueros-muñoz, J.-E. Using Big Data for Sustainability in Supply Chain Management. Sustainability 2021, 13, 7004. [Google Scholar] [CrossRef]

- Wang, H.; Xu, Z.; Fujita, H.; Liu, S. Towards Felicitous Decision Making: An Overview on Challenges and Trends of Big Data. Inf. Sci. 2016, 367–368, 747–765. [Google Scholar] [CrossRef]

- Mohamed, A.; Najafabadi, M.; Wah, Y.; Zaman, E.; Maskat, R. The State of the Art and Taxonomy of Big Data Analytics: View from New Big Data Framework. Artif. Intell. Rev. 2020, 53, 989–1037. [Google Scholar] [CrossRef]

- Prasad, B.R.; Agarwal, S. Comparative Study of Big Data Computing and Storage Tools: A Review. Int. J. Database Theory Appl. 2016, 9, 45–66. [Google Scholar] [CrossRef]

- Ayodele, T.O.; Kajimo-Shakantu, K. Challenges and Drivers to Data Sharing among Stakeholders in the South African Construction Industry. J. Eng. Des. Technol. 2022, 20, 1698–1715. [Google Scholar] [CrossRef]

- Long, Q. Knowle Dge-Base d Systems Data-Driven Decision Making for Supply Chain Networks with Agent-Based Computational Experiment. Knowl.-Based Syst. 2018, 141, 55–66. [Google Scholar] [CrossRef]

- Hedgebeth, D. Data-Driven Decision Making for the Enterprise: An Overview of Business Intelligence Applications. J. Inf. Knowl. Manag. Syst. 2007, 37, 414–420. [Google Scholar] [CrossRef]

- Long, Q. A Flow-Based Three-Dimensional Collaborative Decision-Making Model for Supply-Chain Networks. Knowl.-Based Syst. J. 2016, 97, 101–110. [Google Scholar] [CrossRef]

- Oncioiu, I.; Bunget, O.C.; Türkes, M.C.; Sorinel Căpus, N.; Topor, D.I.; Tamas, A.S.; Rakos, I.-S.; Rakoș, I.-S.; Hint, M.Ș. The Impact of Big Data Analytics on Company Performance in Supply Chain Management. Sustainability 2019, 11, 4864. [Google Scholar] [CrossRef]

- Hannah, D.; Patrick, I. The Impact of Big Data on Companies and a Lack of Skills as the Origin of the Challenges They Are Facing. Bachelor’s Thesis, Jönköping University, Jönköping, Sweden, 2018. [Google Scholar]

- Kusi-sarpong, S.; Juliet, I.; Gupta, H.; Kunc, M. Risks Associated with the Implementation of Big Data Analytics in Sustainable Supply Chains. Omega 2021, 105, 102502. [Google Scholar] [CrossRef]

- Shukla, M.; Mattar, L. Next Generation Smart Sustainable Auditing Systems Using Big Data Analytics: Understanding the Interaction of Critical Barriers. Comput. Ind. Eng. 2019, 128, 1015–1026. [Google Scholar] [CrossRef]

- Liu, H.; Lu, F.; Shi, B.; Hu, Y.; Li, M. Big Data and Supply Chain Resilience: Role of Decision-Making Technology. Manag. Decis. 2023, 61, 2792–2808. [Google Scholar] [CrossRef]

- Otto, B. Organizing Data Governance: Findings from the Telecommunications Industry and Consequences for Large Service Providers. Commun. Assoc. Inf. Syst. 2011, 29, 45–66. [Google Scholar] [CrossRef]

- Meredith, R.; Remington, S.; Donnell, P.O.; Sharma, N. Organisational Transformation through Business Intelligence: Theory, the Vendor Perspective and a Research Agenda. J. Decis. Syst. 2012, 21, 187–201. [Google Scholar] [CrossRef]

- Esfahbodi, A.; Zhang, Y.; Watson, G.; Zhang, T. Governance Pressures and Performance Outcomes of Sustainable Supply Chain Management e An Empirical Analysis of UK Manufacturing Industry. J. Clean. Prod. 2017, 155, 66–78. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain Technology and Its Relationships to Sustainable Supply Chain Management. Int. J. Prod. Res. 2018, 57, 2117–2135. [Google Scholar] [CrossRef]

- Hee, T.; Ho, J.; Kim, K. A Study on the Establishment of Policies for the Activation of a Big Data Industry and Prioritization of Policies: Lessons from Korea. Technol. Forecast. Soc. Chang. 2015, 96, 144–152. [Google Scholar] [CrossRef]

- Rahimian, F.P.; Reyes-veras, P.F.; Kingdom, U.; Renukappa, S.; Kingdom, U.; Suresh, S.; Kingdom, U. Challenges Faced by The Adoption of Big Data in the Dominican Republic Construction Industry: An Empirical Study. J. Inf. Technol. Constr. 2021, 26, 812–831. [Google Scholar] [CrossRef]

- Lai, Y.; Sun, H.; Ren, J. Understanding the Determinants of Big Data Analytics (BDA) Adoption in Logistics and Supply Chain Management An Empirical Investigation. Int. J. Logist. Manag. 2017, 29, 676–703. [Google Scholar] [CrossRef]

- Zhu, K.; Kraemer, K.L.; Xu, S. The Process of Innovation Assimilation by Firms in Different Countries: A Technology Diffusion Perspective on E-Business. Manag. Sci. Publ. 2006, 52, iv-1646. [Google Scholar] [CrossRef]

- Park, J.; Kim, Y.B. Factors Activating Big Data Adoption by Korean Firms. J. Comput. Inf. Syst. 2021, 61, 285–293. [Google Scholar] [CrossRef]

- Wang, Q.; Tan, Z.; De, G.; Pu, L.; Wu, J. Research on Promotion Incentive Policy and Mechanism Simulation Model of Energy Storage Technology. Energy Sci. Eng. 2019, 7, 3147–3159. [Google Scholar] [CrossRef]

- Alfaro, L.A.; Le, T.M.H.; Choi, H.R.; Cho, M.J. Deployment Model of Big Data for Port Logistics. Information 2015, 18, 7–16. [Google Scholar]

- Richey, R., Jr.; Morgan, T.R.; Lindsey-hall, K.; Adams, F.G. A Global Exploration of Big Data in the Supply Chain. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 710–739. [Google Scholar] [CrossRef]

- Atuahene, B.T.; Kanjanabootra, S.; Gajendran, T. Mapping the Barriers of Big Data Process in Construction: The Perspective of Construction Professionals. Buildings 2023, 13, 1963. [Google Scholar] [CrossRef]

- Kache, F.; Seuring, S. Challenges and Opportunities of Digital Information at the Intersection of Big Data Analytics and Supply Chain Management. Int. J. Oper. Prod. Manag. 2015, 37, 10–36. [Google Scholar] [CrossRef]

- Bello, S.A.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Manuel, J.; Delgado, D.; Akanbi, L.A.; Ajayi, A.O.; Owolabi, H.A. Cloud Computing in Construction Industry: Use Cases, Benefits and Challenges. Autom. Constr. 2021, 122, 103441. [Google Scholar] [CrossRef]

- Du, J.; Sugumaran, V.; Gao, B. RFID and Multi-Agent Based Architecture for Information Sharing in Prefabricated Component Supply Chain. IEEE Access 2017, 5, 4132–4139. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Deng, X.; Ahmed, S.; Jingfeng, J. Large-Scale Multiple Criteria Decision-Making with Missing Values: Project Selection through TOPSIS-OPA. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 9341–9362. [Google Scholar] [CrossRef]

- Morabito, V. Big Data Driven Business Models; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 9783319106649. [Google Scholar]

- Dutta, D.; Bose, I. Managing a Big Data Project: The Case of Ramco Cements Limited. Intern. J. Prod. Econ. 2015, 165, 293–306. [Google Scholar] [CrossRef]

- Hindle, G.; Kunc, M.; Mortensen, M.; Oztekin, A.; Vidgen, R. Business Analytics: Defining the Field and Identifying a Research Agenda. Eur. J. Oper. Res. 2020, 281, 483–490. [Google Scholar] [CrossRef]

- Baghalzadeh, M.; Moehler, R.C.; Fang, Y.; Aboutorab, H.; Hijazi, A.A. Construction Supply Chain Risk Management. Autom. Constr. 2024, 162, 105396. [Google Scholar] [CrossRef]

- Maklan, S. Supply Chain Resilience in the Global Financial Crisis: An Empirical Study. Supply Chain. Manag. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Wu, K.; Liao, C.; Tseng, M.; Lim, M.K.; Hu, J.; Tan, K. Toward Sustainability: Using Big Data to Explore the Decisive Attributes of Supply Chain Risks and Uncertainties. J. Clean. Prod. 2017, 142, 663–676. [Google Scholar] [CrossRef]

- Kara, M.E.; Ümit, S.; Fırat, O.; Ghadge, A. A Data Mining-Based Framework for Supply Chain Risk Management. Comput. Ind. Eng. 2020, 139, 105570. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S. Building Supply Chain Risk Resilience Role of Big Data Analytics in Supply Chain. Benchmarking Int. J. 2019, 26, 2318–2342. [Google Scholar] [CrossRef]

- Gupta, S.; Bag, S.; Modgil, S.; Beatriz, A.; De Sousa, L.; Kumar, A. Examining the Influence of Big Data Analytics and Additive Manufacturing on Supply Chain Risk Control and Resilience: An Empirical Study. Comput. Ind. Eng. 2022, 172, 108629. [Google Scholar] [CrossRef]

- Bag, S.; Sabbir, M.; Srivastava, G.; Chan, H.; Bryde, D.J. The Role of Big Data and Predictive Analytics in Developing a Resilient Supply Chain Network in the South African Mining Industry against Extreme Weather Events. Int. J. Prod. Econ. 2022, 251, 108541. [Google Scholar] [CrossRef]

- Bahrami, M.; Shokouhyar, S. The Role of Big Data Analytics Capabilities in Bolstering Supply Chain Resilience and Firm Performance: A Dynamic Capability View. Inf. Technol. People 2022, 35, 1621–1651. [Google Scholar] [CrossRef]

- Chen, C.; Xu, C. A Negotiation Optimization Strategy of Collaborative Procurement with Supply Chain Based on Multi-Agent System. Math. Probl. Eng. 2018, 2018, 4653648. [Google Scholar] [CrossRef]

- Rozados, I.V.; Tjahjono, B. Big Data Analytics in Supply Chain Management: Trends and Related Research. In Proceedings of the 6th International Conference on Operations and Supply Chain Management, Bali, Indonesia, 10–13 December 2014. [Google Scholar]

- Cheng, Y.; Peng, J.; Gu, X.; Zhang, X.; Liu, W.; Zhou, Z.; Yang, Y.; Huang, Z. An Intelligent Supplier Evaluation Model Based on Data-Driven Support Vector Regression in Global Supply Chain. Comput. Ind. Eng. 2020, 139, 105834. [Google Scholar] [CrossRef]

- Zekhnini, K.; Chaouni, A.; Anass, B. A Multi-Agent Based Big Data Analytics System for Viable Supplier Selection. J. Intell. Manuf. 2024, 35, 3753–3773. [Google Scholar] [CrossRef]

- Noorizade, A. Supplier Evaluation and Development in Construction: Data-Driven Analyses. Ph.D. Thesis, Aalto University, Espoo, Finland, 2021. [Google Scholar]

- Ali, A.M.; Kassam, A.E.H. Supplier Selection Enhanced by Big Data Analytics Using Deep Learning. AIP Conf. Proc. 2024, 3232, 020038. [Google Scholar]

- Teng, Y.; Wang, J.; Wang, R. Supplier Evaluation of Smart Grid Material Suppliers Based on Big Data Environment and AHP. In Proceedings of the 3rd International Conference on Artificial Intelligence and Advanced Manufacture, Manchester, UK, 23–25 October 2021; pp. 628–634. [Google Scholar]

- Kilimci, Z.H.; Akyuz, A.O.; Uysal, M.; Akyokus, S.; Uysal, M.O.; Bulbul, B.A.; Ekmis, M.A. An Improved Demand Forecasting Model Using Deep Learning Approach and Proposed Decision Integration Strategy for Supply Chain. Complexity 2019, 2019, 9067367. [Google Scholar] [CrossRef]

- Chong, E.; Han, C.; Park, F.C. Deep Learning Networks for Stock Market Analysis and Prediction: Methodology, Data Representations, and Case Studies. Expert Syst. Appl. 2017, 83, 187–205. [Google Scholar] [CrossRef]

- Chase, C. Using Big Data to Enhance Demand-Driven Forecasting and Planning. J. Bus. Forecast. 2013, 32, 27–32. [Google Scholar]

- Feng, Q.; Shanthikumar, J.G. How Research in Production and Operations Management May Evolve in the Era of Big Data. Prod. Oper. Manag. 2017, 38, 42–49. [Google Scholar] [CrossRef]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.T. Distribution Network Design with Big Data: Model and Analysis. Ann. Oper. Res. 2018, 270, 539–551. [Google Scholar] [CrossRef]

- Feizabadi, J. Machine Learning Demand Forecasting and Supply Chain Performance. Int. J. Logist. Res. Appl. 2022, 25, 119–142. [Google Scholar] [CrossRef]

- Hasim, S.; Fauzi, M.A.; Yusof, Z.; Endut, I.R.; Ridzuan, A.R.M. The Material Supply Chain Management in a Construction Project: A Current Scenario in Procurement Process. AIP Conf. Proc. 2018, 2020, 020049. [Google Scholar]

- Martínez, L.R.; Rios, R.A.O.; Prieto, M.D. New Trends in the Use of Artificial Intelligence for the Industry 4.0; IntechOpen: London, UK, 2020; ISBN 9781838801410. [Google Scholar]

- Tan, Y.; Gu, L.; Xu, S.; Li, M. Supply Chain Inventory Management from the Perspective of “Cloud Supply Chain”— A Data Driven Approach. Mathematics 2024, 12, 573. [Google Scholar] [CrossRef]

- Wang, C.; Wang, F.; He, S. Conceptualization on the Cost Management Model of Enterprise Supply Chain Under the Background of Big Data. In Proceedings of the 3rd International Conference on Computers in Management and Business, Tokyo, Japan, 31–January–2 February 2020; pp. 19–24. [Google Scholar]

- Mandičák, T.; Mésároš, P.; Kanáliková, A.; Špak, M. Supply Chain Management and Big Data Concept Effects on Economic Sustainability of Building Design and Project Planning. Appl. Sci. 2021, 11, 11512. [Google Scholar] [CrossRef]

- Zhang, W.; Kang, K.; Zhong, R.Y. A Cost Evaluation Model for IoT- Enabled Prefabricated Construction Supply Chain Management. Ind. Manag. Data Syst. 2021, 121, 2738–2759. [Google Scholar] [CrossRef]

- Li, X. Optimization of Logistics Flow Management through Big Data Analytics for Sustainable Development and Environmental Cycles. Soft Comput. 2024, 28, 2701–2717. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Q.; Zhang, W. Corporate Social Responsibility, Green Supply Chain Management and Firm Performance: The Moderating Role of Big-Data Analytics Capability. Res. Transp. Bus. Manag. 2020, 37, 100557. [Google Scholar] [CrossRef]

- Badi, S.; Murtagh, N. Green Supply Chain Management in Construction: A Systematic Literature Review and Future Research Agenda. J. Clean. Prod. 2025, 223, 312–322. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of Construction and Demolition Waste Management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Sakao, T.; Huisingh, D. A Framework for Big Data Driven Product Lifecycle Management. J. Clean. Prod. 2017, 159, 229–240. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, Y.; Zhang, N.; Huang, T. An Optimization Model for Green Supply Chain Management by Using a Big Data Analytic Approach. J. Clean. Prod. 2017, 142, 1085–1097. [Google Scholar] [CrossRef]

- Alkhatib, A.W. Fostering Green Innovation: The Roles of Big Data Analytics Capabilities and Green Supply Chain Integration. Eur. J. Innov. Manag. 2023, 27, 2818–2840. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-wamba, S. The Role of Big Data in Explaining Disaster Resilience in Supply Chains for Sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef]

- Khedr, A.M.; Rani, S.S. Enhancing Supply Chain Management with Deep Learning and Machine Learning Techniques: A Review. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100379. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, E.W.; Chang, M.; Lin, Y. Pragmatic Real-Time Logistics Management with Traffic IoT Infrastructure: Big Data Predictive Analytics of Freight Travel Time for Logistics 4.0. Int. J. Prod. Econ. 2021, 238, 108157. [Google Scholar] [CrossRef]

- Peng, J.; Chen, L.; Zhang, B. Transportation Planning for Sustainable Supply Chain Network Using Big Data Technology. Inf. Sci. 2022, 609, 781–798. [Google Scholar] [CrossRef]

- Liu, C. The Application of Big Data Analysis in Logistics Supply Chain Optimisation. Int. J. Inf. Commun. Technol. 2024, 25, 104–116. [Google Scholar] [CrossRef]

- Li, W.; Liang, S.; Jiang, Y.; Pan, Q. Road Condition Prediction and Logistics Distribution Path Optimization Algorithm Based on Traffic Big Data. J. Algorithm. Comput. Technol. 2019, 13, 1–11. [Google Scholar] [CrossRef]

| Ref. | Authors | Journal | Year | Citations |

|---|---|---|---|---|

| [20] | Rafael Sacks, Ioannis Brilakis, Ergo Pikas, Haiyan Sally Xie, and Mark Girolami | Data-Centric Engineering | 2020 | 340 |

| [21] | Junhu Ruan, Yuxuan Wang, Felix Tung Sun Chan, Xiangpei Hu, Minjuan Zhao, Fangwei Zhu, Baofeng Shi, Yan Shi, and Fan Lin | IEEE Communications Magazine | 2019 | 163 |

| [22] | Jannik Giesekam, John R. Barrett, and Peter Taylor | Building Research and Information | 2016 | 159 |

| [23] | Xiao Li, Weisheng Lu, Fan Xue, Liupengfei Wu, Rui Zhao, Jinfeng Lou, and Jinying Xu | Journal of Construction Engineering and Management | 2022 | 142 |

| [24] | Zhijia You and Chen Wu | Advanced Engineering Informatics | 2019 | 77 |

| [25] | Zhaojing Wang, Hao Hu, and Wei Zhou | Computer-Aided Civil and Infrastructure Engineering | 2017 | 71 |

| [26] | Zehua Xiang and Minli Xu | Journal of Cleaner Production | 2019 | 70 |

| [27] | Qian Chen, Bryan T. Adey, Carl Haas, and Daniel M. Hall | Construction Innovation | 2020 | 69 |

| [28] | Hisham Said | Journal of Construction Engineering and Management | 2015 | 53 |

| [29] | Vian Ahmed, Algan Tezel, Zeeshan Aziz, and Magda Sibley | Facilities | 2020 | 51 |

| Barriers Category | Barriers |

|---|---|

| Data barriers | 1. Data security and privacy; |

| 2. Performance and scalability; | |

| 3. Complexity of data integration; | |

| 4. Data collection and sharing; | |

| 5. Data quality; | |

| Technology barriers | 6. Lack of infrastructural for storing and transferring big data; |

| 7. Lack of availability of specific BDD tools; | |

| 8. Lack of performance measurements for evaluating BDD in companies; | |

| Organizational and human barriers | 9. Lack of planning to develop strategies towards using big data-driven; |

| 10. Time constraints; | |

| 11. No policy to share data among organizations; | |

| 12. Weakness of data-driven decision-making in organizations; | |

| 13. Lack of training facilities; | |

| 14. Lack of skilled personnel; | |

| 15. Weak support of managers in implementing new technologies; | |

| Regulatory barriers | 16. Weakness of governance policies in support of BD development; |

| 17. Weakness of government policies for new Technology Adoption; | |

| 18. Weak laws in the areas of privacy, data security and intellectual property; | |

| Economic barriers | 19. High cost of investment; |

| 20. Lack of sufficient knowledge about the economic benefits of big data-driven; | |

| 21. Weak compliance of business models with the subject of data-driven. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elkliny, A.; Mahmoudi, A.; Deng, X. Big Data-Driven Implementation in International Construction Supply Chain Management: Framework Development, Future Directions, and Barriers. Buildings 2025, 15, 2167. https://doi.org/10.3390/buildings15132167

Elkliny A, Mahmoudi A, Deng X. Big Data-Driven Implementation in International Construction Supply Chain Management: Framework Development, Future Directions, and Barriers. Buildings. 2025; 15(13):2167. https://doi.org/10.3390/buildings15132167

Chicago/Turabian StyleElkliny, Ali, Amin Mahmoudi, and Xiaopeng Deng. 2025. "Big Data-Driven Implementation in International Construction Supply Chain Management: Framework Development, Future Directions, and Barriers" Buildings 15, no. 13: 2167. https://doi.org/10.3390/buildings15132167

APA StyleElkliny, A., Mahmoudi, A., & Deng, X. (2025). Big Data-Driven Implementation in International Construction Supply Chain Management: Framework Development, Future Directions, and Barriers. Buildings, 15(13), 2167. https://doi.org/10.3390/buildings15132167