Performance of Concrete Incorporating Waste Glass Cullet and Snail Shell Powder: Workability and Strength Characteristics

Abstract

1. Introduction

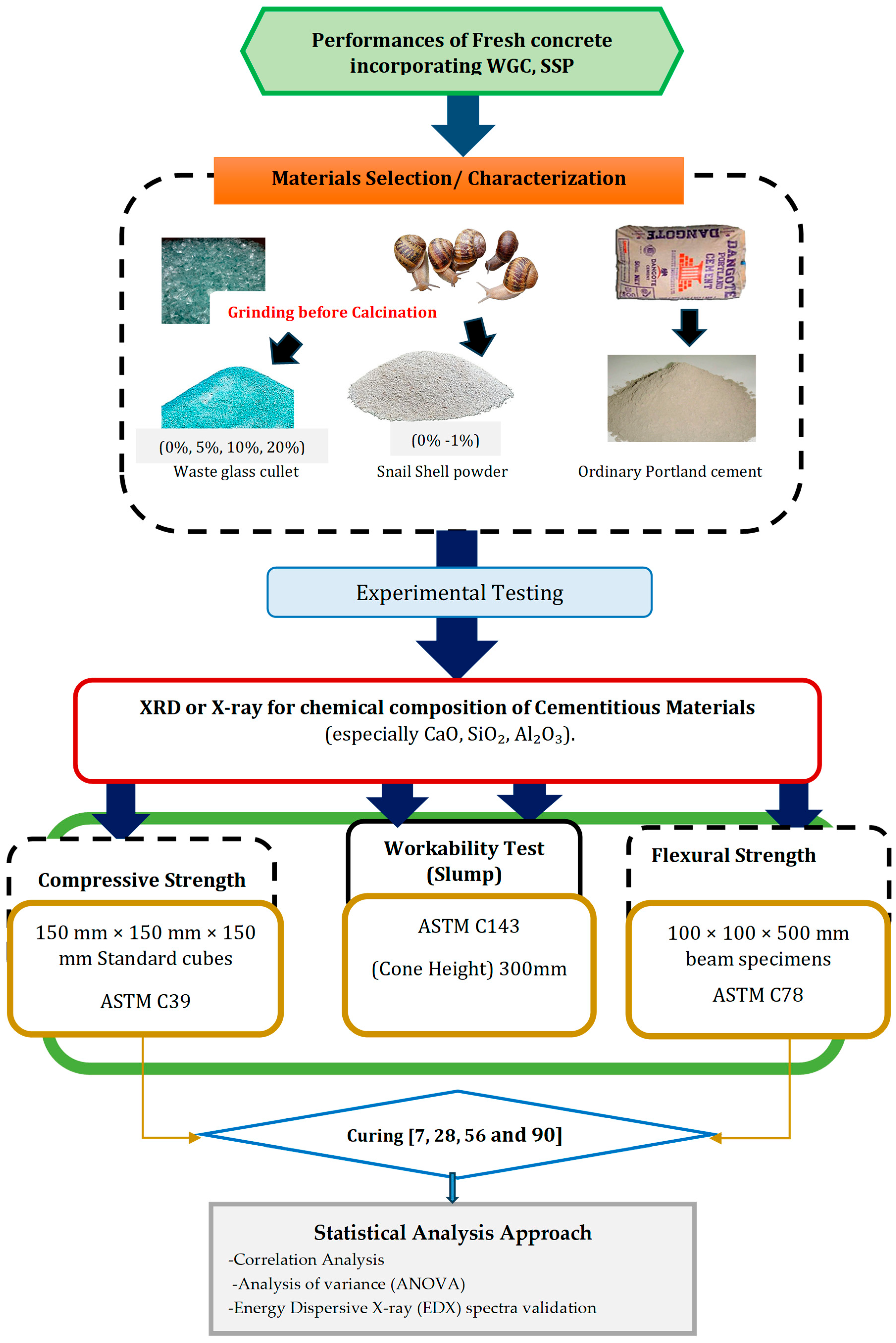

2. Materials and Methods

2.1. Material Properties and Chemical Composition

2.1.1. Ordinary Portland Cement (OPC)

2.1.2. Waste Glass Cullet (WGC)

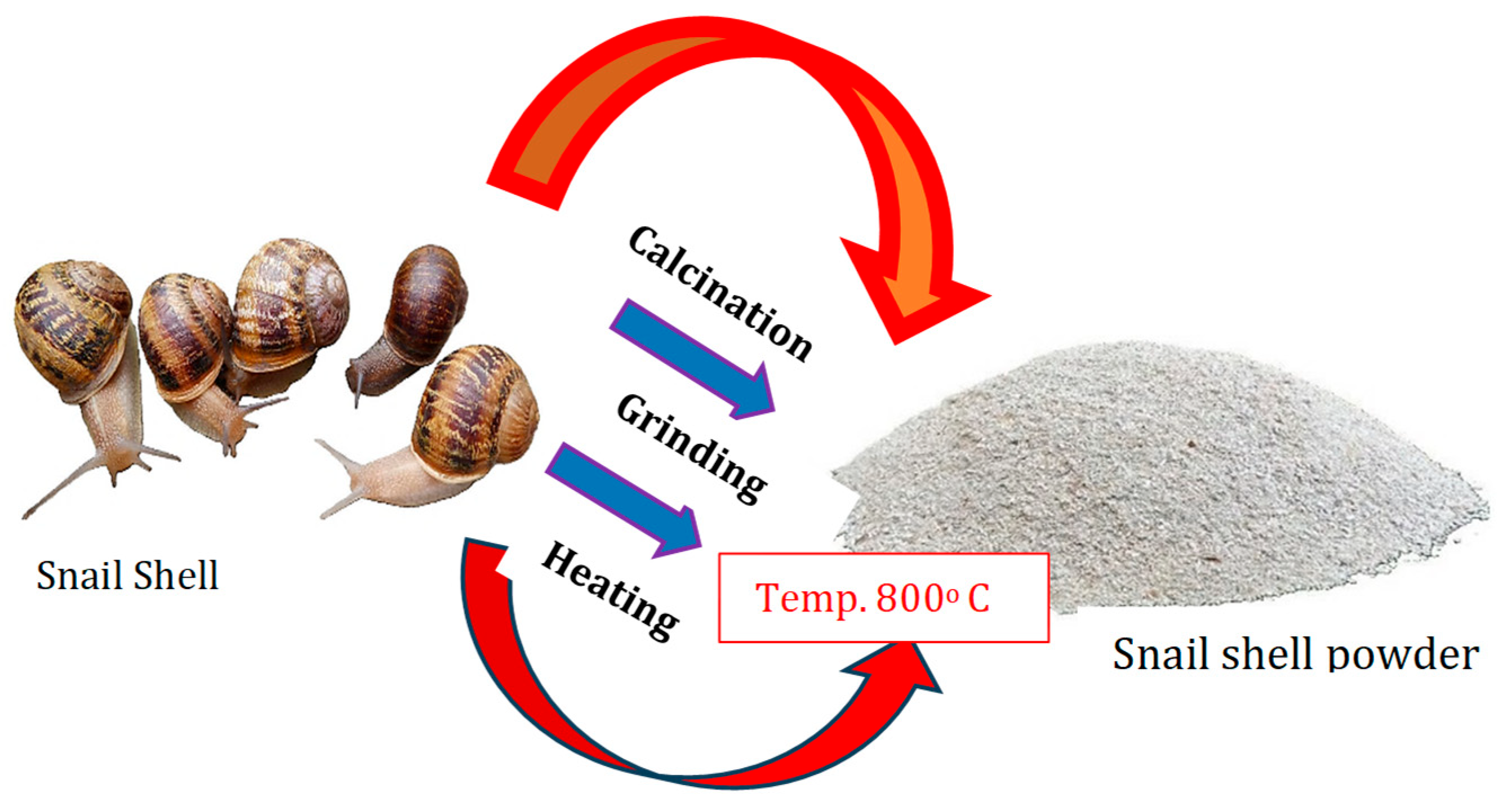

2.1.3. Snail Shell Powder (SSP)

2.2. Properties of Aggregates

2.3. Materials Mix Proportion

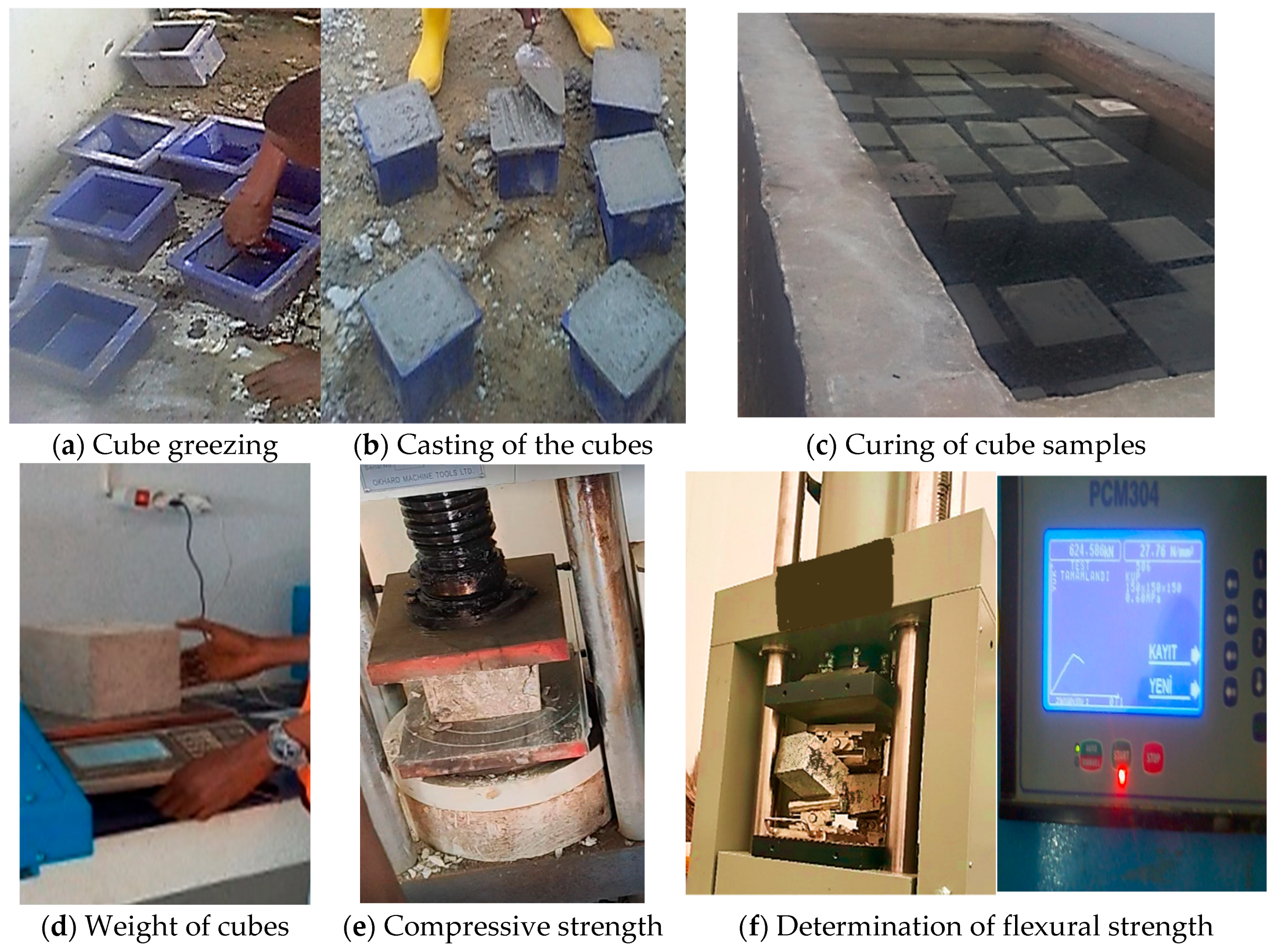

2.4. Testing Methods and Procedures

2.4.1. Chemical Composition

2.4.2. Compressive and Flexural Strength Testing

2.4.3. Slump Testing

3. Results and Discussion

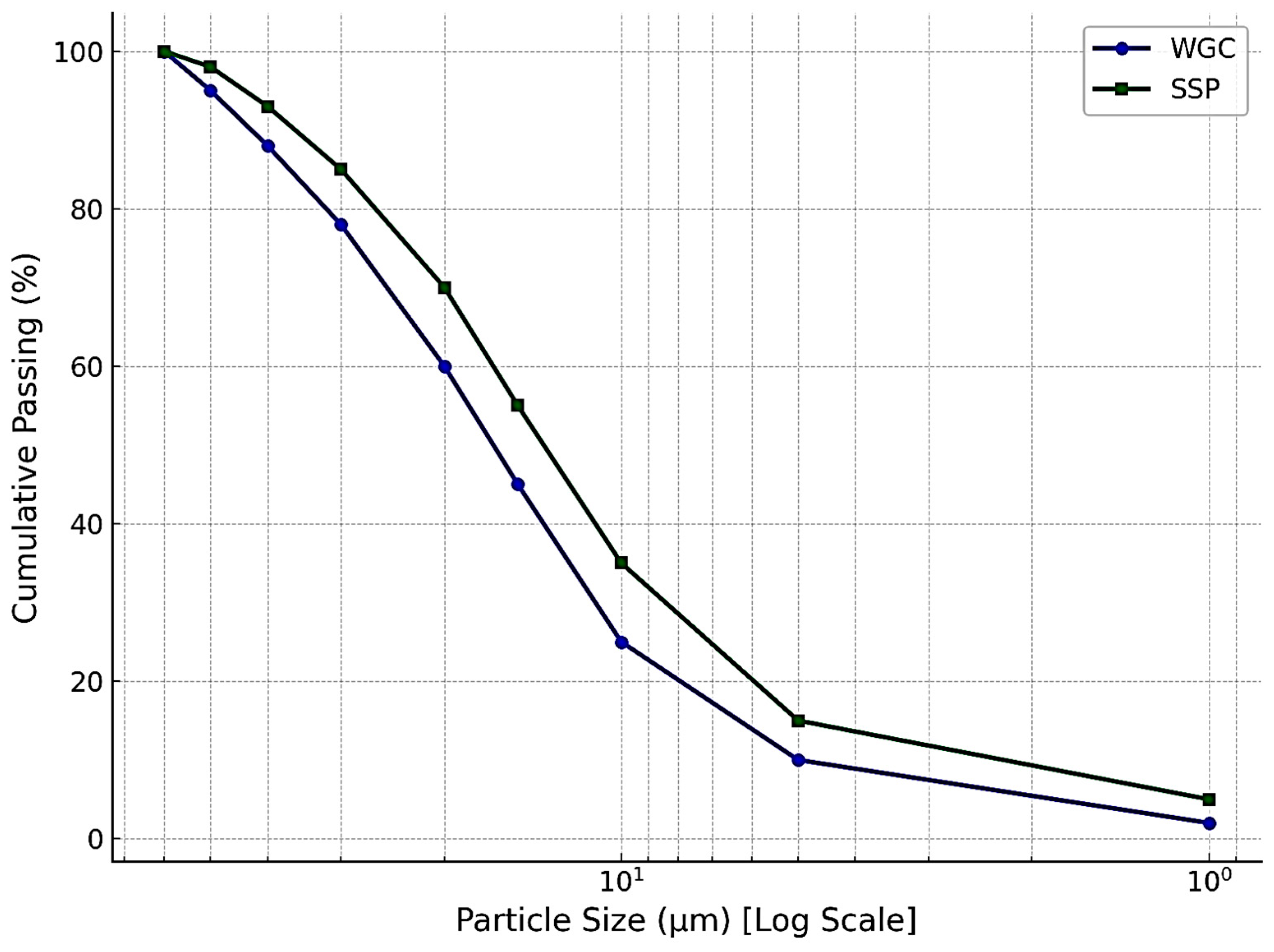

3.1. The Particle Size Distribution of WGC and SSP

3.2. Workability of Fresh Concrete Mixtures

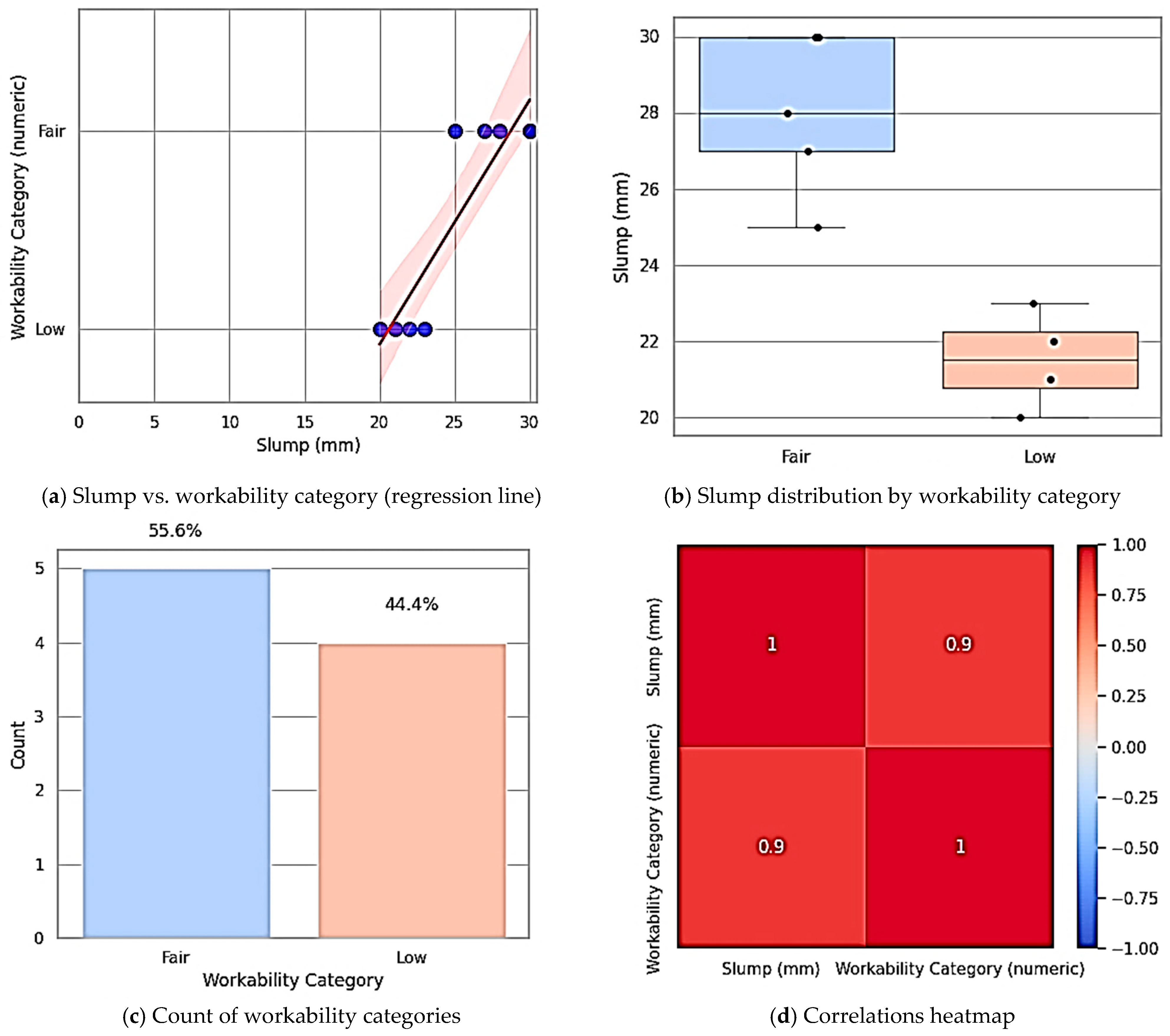

3.3. Statistical Analysis of Slump-Influencing Variables

3.4. Analysis of Variance (ANOVA)

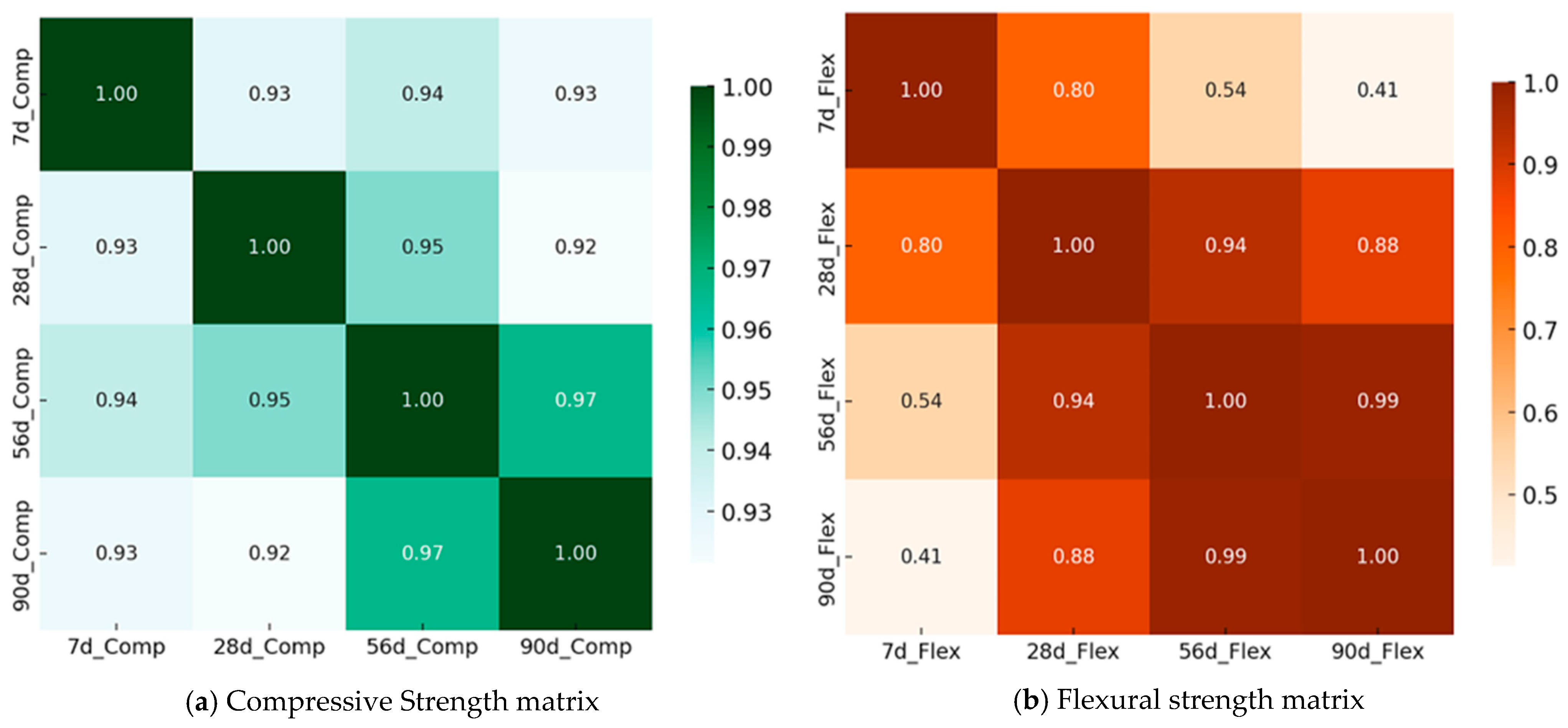

3.5. Correlation Analysis of Strength Properties

3.5.1. Compressive Strength Correlation

3.5.2. Flexural Strength Correlations

3.5.3. Slump (Workability) Correlations

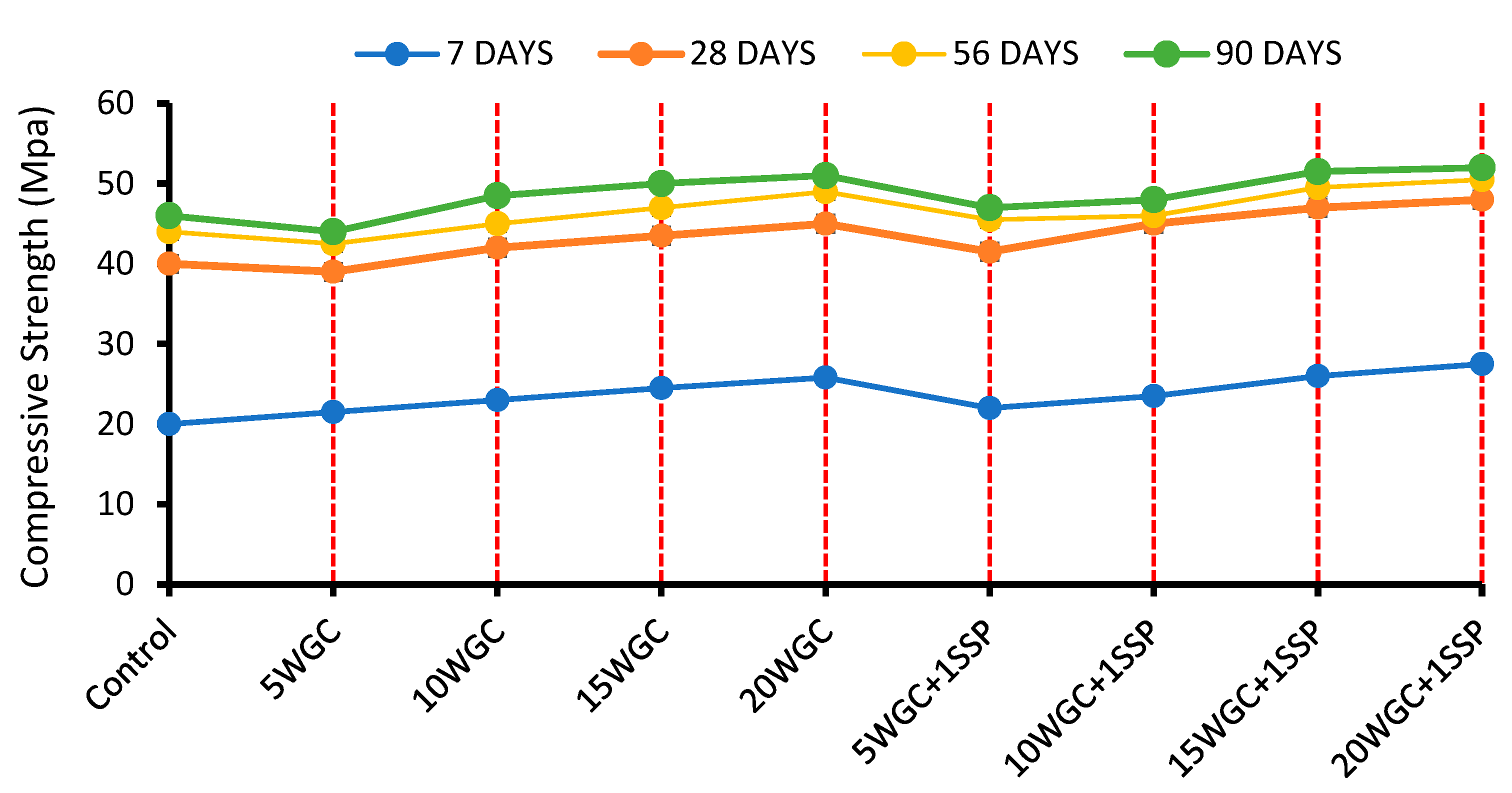

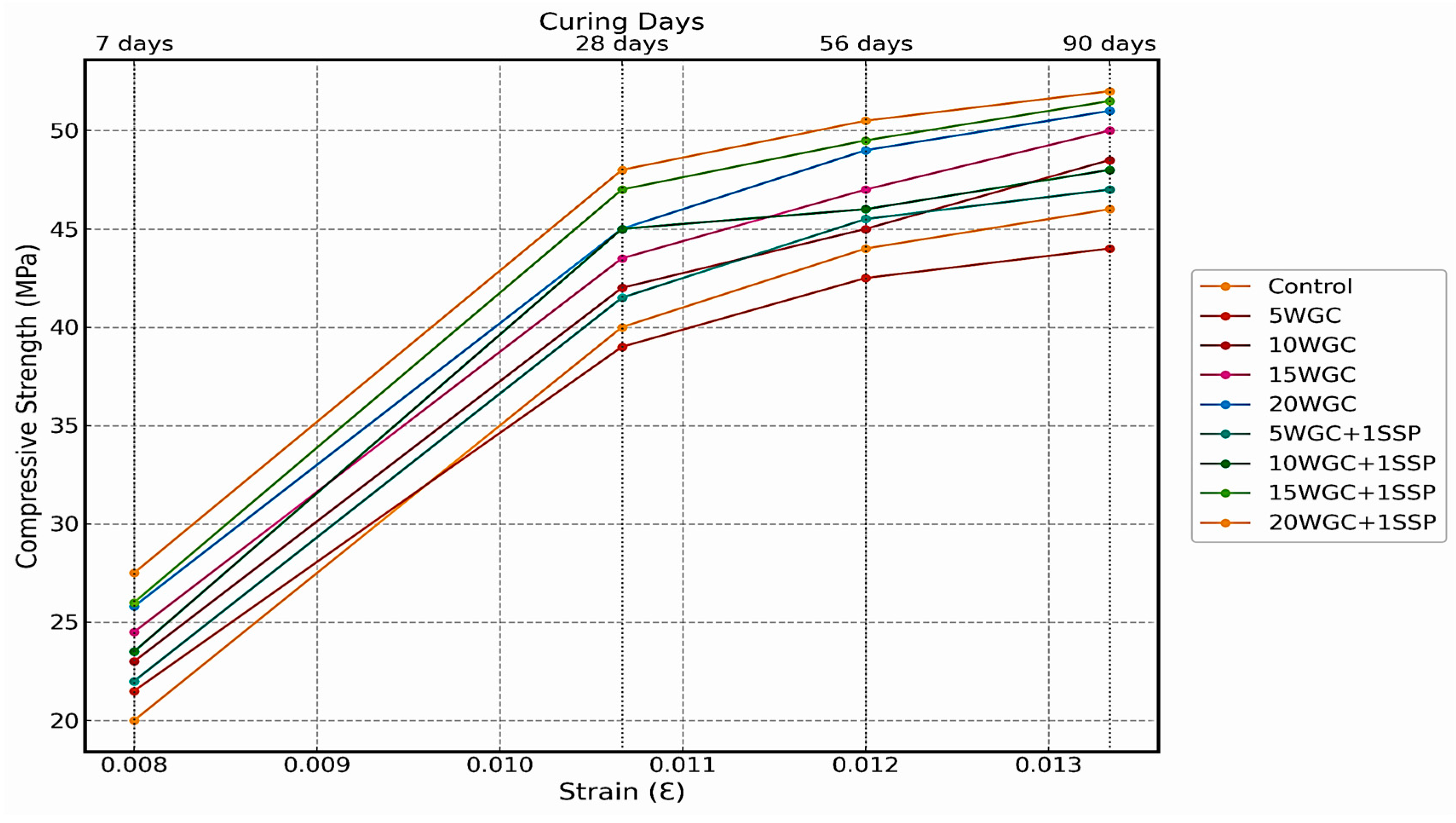

3.6. Compressive Strength Development

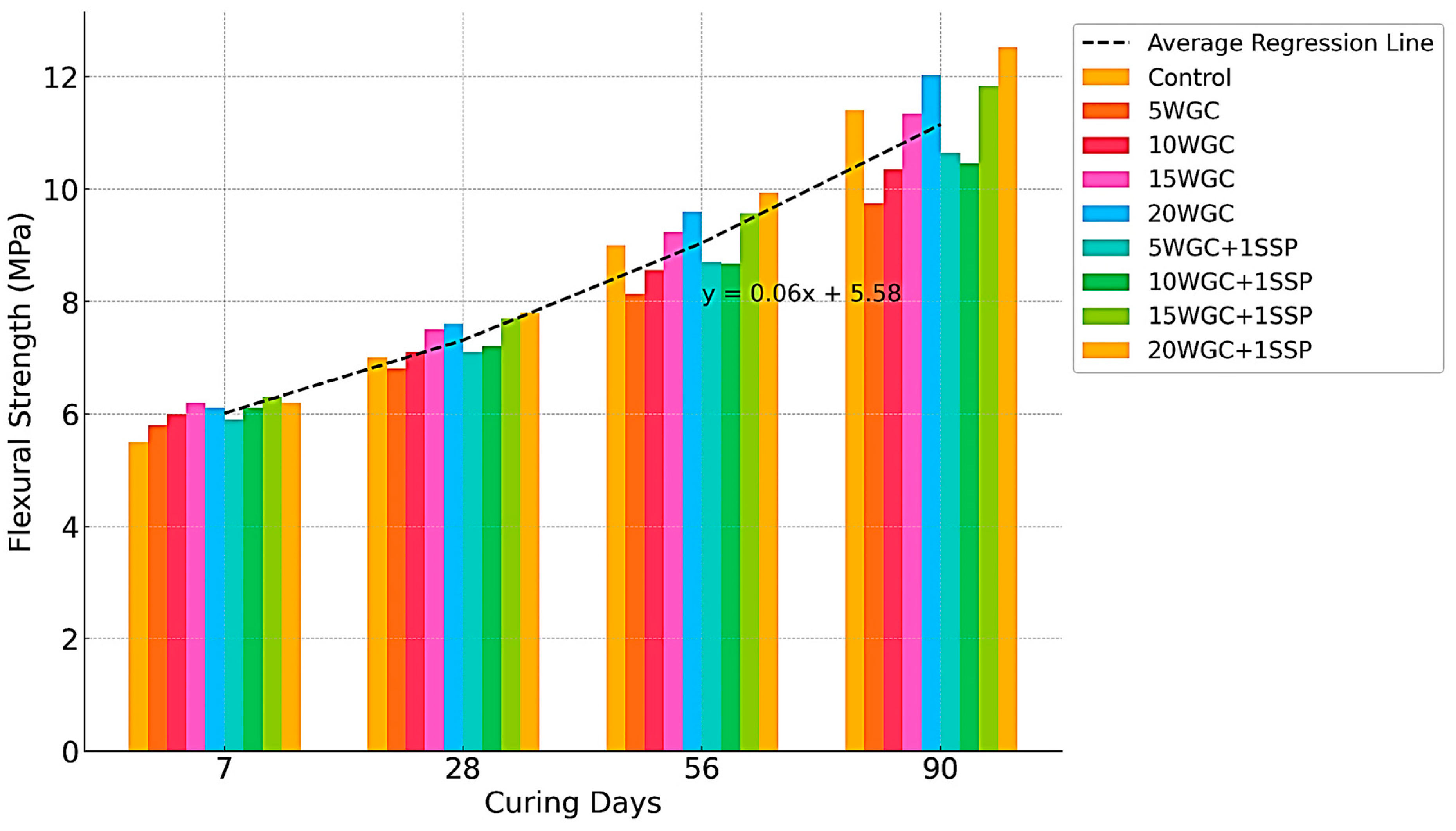

3.7. Flexural Strength Performance

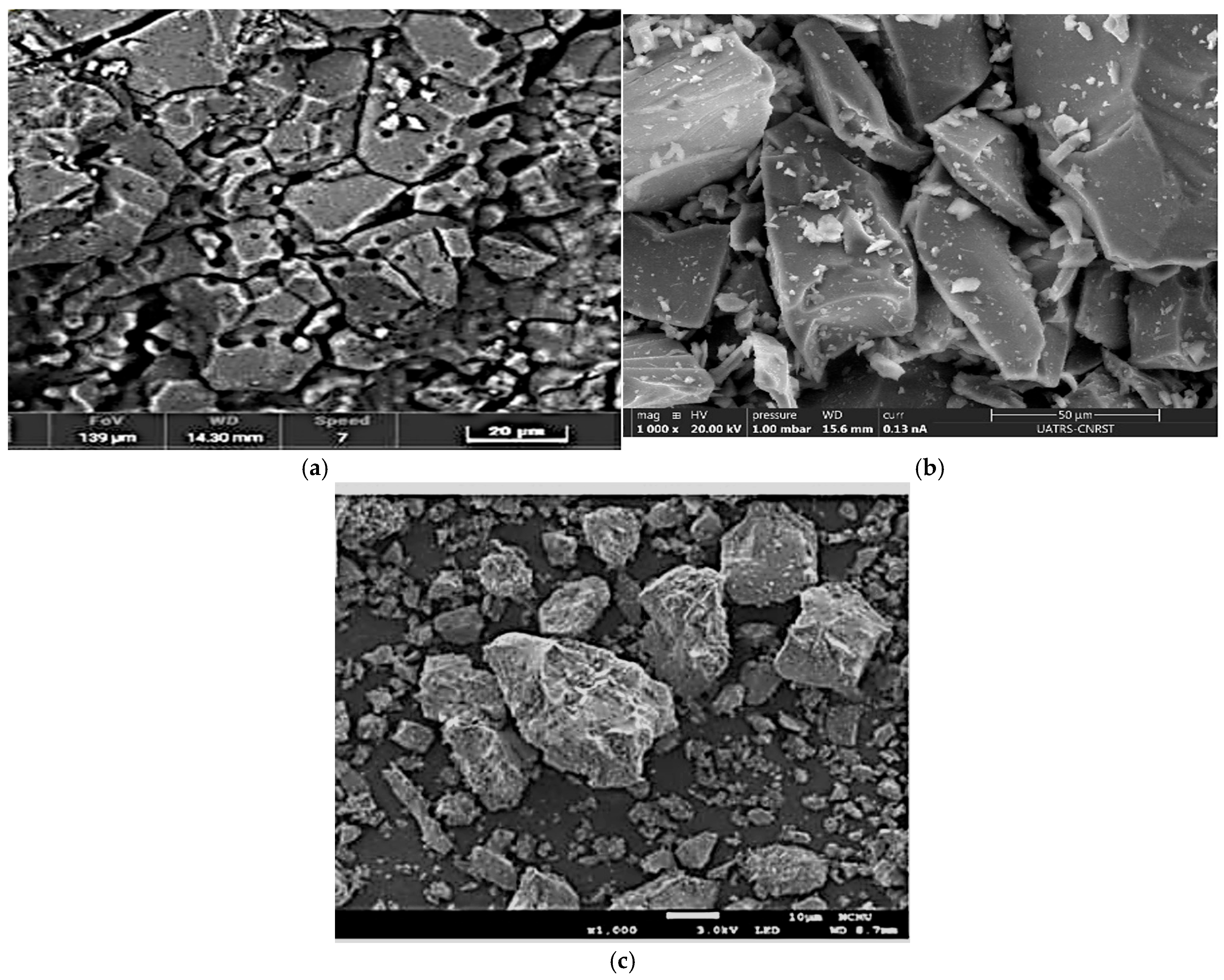

3.8. Scanning Electron Microscopy (SEM)

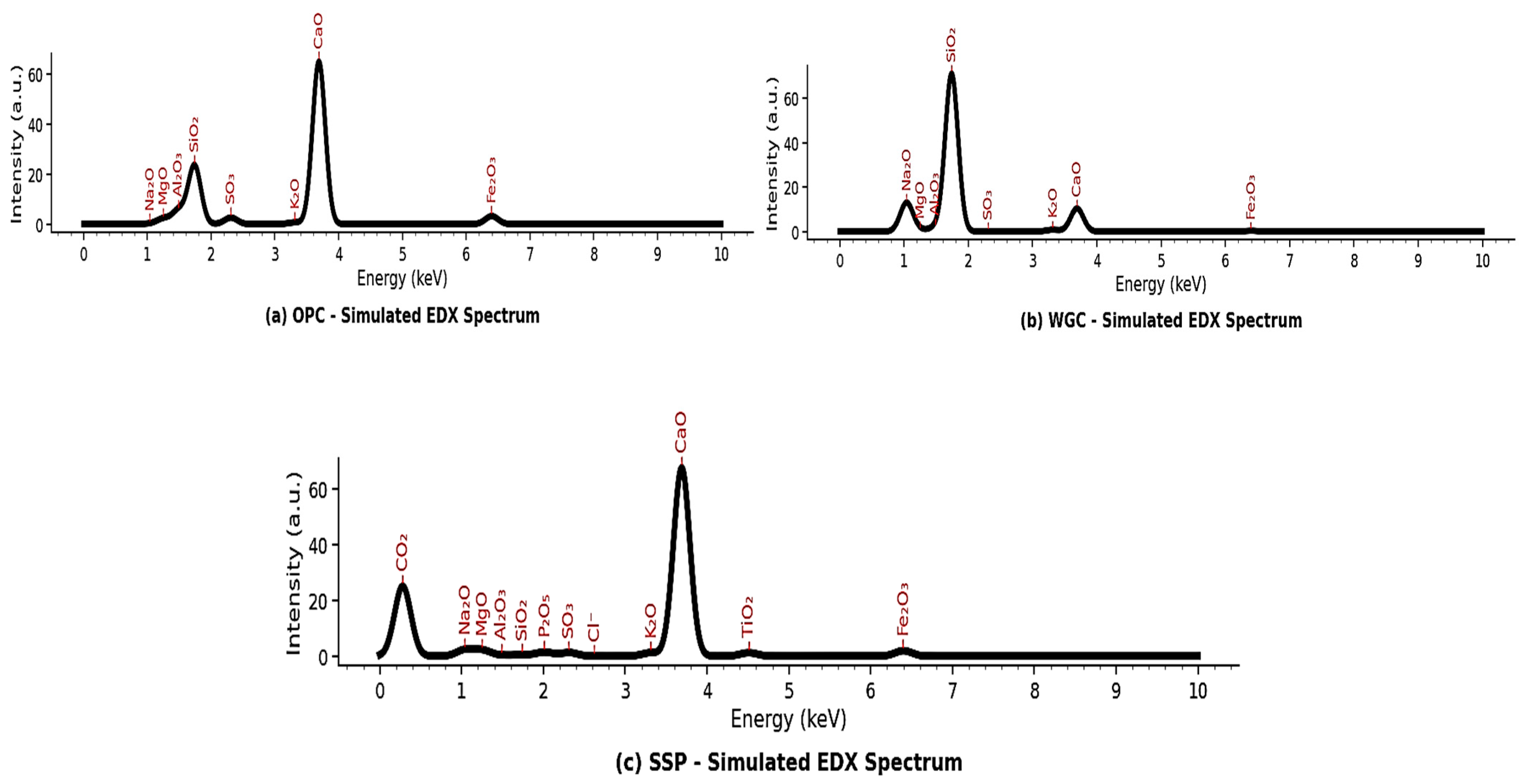

3.9. Energy Dispersive X-Ray (EDX) Spectra on Cementitious Materials

4. Conclusions

- Workability: Increased WGC content reduced slump values due to the angular shape and poor water absorption of glass particles. However, adding 1% SSP marginally improved slump, acting as a microfiller and improving paste flowability.

- Compressive Strength: Strength increased with higher WGC levels. The highest 28-day strength (48.0 MPa) was recorded in the mix containing 20% WGC + 1% SSP, compared to 40.0 MPa in the control. At 90 days, the strength reached 52.0 MPa.

- Flexural Strength: Similarly, flexural strength increased from 7.0 MPa (control) to 7.8 MPa in the optimized WGC/SSP mix, demonstrating improved tensile resistance and microstructural integrity.

- Statistical analysis confirmed significant relationships: a strong negative correlation between WGC content and slump (r = –0.97) and strong positive correlations between WGC/SSP addition and strength parameters.

- Microstructural and chemical analyses (SEM/EDX) confirmed that WGC contributes to pozzolanic silica, while SSP enhances calcium content and matrix compaction, leading to improved long-term strength.

- Rigid pavements and road slabs, where high compressive and flexural strength are critical.

- Load-bearing infrastructure, including beams, columns, and industrial flooring.

- Sustainable construction projects, particularly those targeting reduced cement usage and circular economy practices.

- Developing regions where waste glass and shell waste are locally available and processing capacity is limited.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| OPC | Ordinary Portland Cement |

| WGC | Waste Glass Cullet |

| SSP | Snail Shell Powder |

| MPa | Megapascal (Unit of Pressure/Strength) |

| ANOVA | Analysis of Variance |

| SD | Standard Deviation |

| IQR | Interquartile Range |

| C–S–H | Calcium Silicate Hydrate |

References

- Al-Kheetan, M.J.; Al-Tarawneh, M.; Ghaffar, S.H.; Chougan, M.; Jweihan, Y.S.; Rahman, M.M. Resistance of Hydrophobic Concrete with Different Moisture Contents to Advanced Freeze–Thaw Cycles. Struct. Concr. 2021, 22, E1050–E1061. [Google Scholar] [CrossRef]

- Eziefula, U.G.; Ezeh, J.C.; Eziefula, B.I. Properties of Seashell Aggregate Concrete: A Review. Constr. Build. Mater. 2018, 192, 287–300. [Google Scholar] [CrossRef]

- Hossain, M.S.; Panov, V.; Choi, S.; kim, J.B.; Yun, K.K. Durability Performance of Cement Mortar Incorporating Water-Repellent Admixtures. Constr. Build. Mater. 2024, 440, 137262. [Google Scholar] [CrossRef]

- Naik, T.R. Sustainability of Concrete Construction. Pract. Period. Struct. Des. Constr. 2008, 13, 98–103. [Google Scholar] [CrossRef]

- Meraz, M.M.; Mim, N.J.; Mehedi, M.T.; Bhattacharya, B.; Aftab, M.R.; Billah, M.M.; Meraz, M.M. Self-Healing Concrete: Fabrication, Advancement, and Effectiveness for Long-Term Integrity of Concrete Infrastructures. Alex. Eng. J. 2023, 73, 665–694. [Google Scholar] [CrossRef]

- Santhosh, M.M. Concrete as A Structural Material: Strength and Versatility. Int. J. Eng. Res. Mech. Civ. Eng. 2023, 9. [Google Scholar]

- Gagg, C.R. Cement and Concrete as an Engineering Material: An Historic Appraisal and Case Study Analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Firoozi, A.A.; Oyejobi, D.O.; Avudaiappan, S.; Flores, E.S. Emerging Trends in Sustainable Building Materials: Technological Innovations, Enhanced Performance, and Future Directions. Results Eng. 2024, 24, 103521. [Google Scholar] [CrossRef]

- Jiang, B. Beautimeter: Harnessing GPT for Assessing Architectural and Urban Beauty Based on the 15 Properties of Living Structure. AI 2025, 6, 74. [Google Scholar] [CrossRef]

- Imoh, U.U.; Apata, A.C.; Esther, O.F.; Etuke, J.O. A Comparative Study of the Effect of Lime and Cement Kiln Dust in the Stabilization of Laterite Soil. FUW Trends Sci. Technol. J. 2023, 8, 231–237. [Google Scholar]

- Dawodu, P.O.; Akindele, A.; Imoh, U. Recycling of Waste Plastic for the Production of Road Interlocking Paving Stone in Nigeria. J. Eng. Res. Rep. 2022, 23, 296–301. [Google Scholar] [CrossRef]

- Dawodu, P.O.; Apata, A.C.; Imoh, U.U.; Akintunde, F. Comparative Study of Cement Replacement with Waste Plastic in Interlocking Paving Stone for Highway Construction in Nigeria. J. Eng. Res. Rep. 2023, 24, 20–29. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary Cementitious Materials Origin from Agricultural Wastes—A Review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Meyer, C. The Greening of the Concrete Industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Shafaie, V.; Movahedi Rad, M. Dem-Driven Investigation and AutoML-Enhanced Prediction of Macroscopic Behavior in Cementitious Composites with Variable Frictional Parameters. Mater. Des. 2025, 254, 114069. [Google Scholar] [CrossRef]

- Shafaie, V.; Movahedi Rad, M. Multi-Objective Genetic Algorithm Calibration of Colored Self-Compacting Concrete Using DEM: An Integrated Parallel Approach. Sci. Rep. 2024, 14, 4126. [Google Scholar] [CrossRef] [PubMed]

- Ghodousian, O.; Reyes, G.; Shafaie, V.; and Ghodousian, A. Interfacial Bond Strength of Coloured SCC Repair Layers: An Experimental and Optimisation Study. J. Struct. Integr. Maint. 2023, 8, 140–149. [Google Scholar] [CrossRef]

- Shafaie, V.; Ghodousian, O.; Ghodousian, A.; Homayounfar, M.; Movahedi Rad, M. Slant Shear Tests and Fuzzy Logic Integration for Evaluating Shear Bond Strength in SCC and FRSCC Repair Applications. Case Stud. Constr. Mater. 2025, 22, e04176. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z. Oil-Palm by-Products as Lightweight Aggregate in Concrete Mixture: A Review. J. Clean. Prod. 2016, 126, 56–73. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.B.; Alengaram, U.J. Oil Palm Shell Lightweight Concrete Containing High Volume Ground Granulated Blast Furnace Slag. Constr. Build. Mater. 2013, 40, 231–238. [Google Scholar] [CrossRef]

- Ghodousian, O.; Behdad, K.; Shafaie, V.; Ghodousian, A.; Mehdikhani, H. Predicting 28-Day Compressive Strength of Pozzolanic Concrete by Generalized Nearest Neighborhood Clustering Using Modified Pso Algorithm. Malays. Constr. Res. J. 2021, 33, 61–72. [Google Scholar]

- Shafaie, V.; Ghodousian, O.; Ghodousian, A.; Cucuzza, R.; Movahedi Rad, M. Integrating Push-out Test Validation and Fuzzy Logic for Bond Strength Study of Fiber-Reinforced Self-Compacting Concrete. Constr. Build. Mater. 2024, 425, 136062. [Google Scholar] [CrossRef]

- Marey, H.; Kozma, G.; Szabó, G. Green Concrete Materials Selection for Achieving Circular Economy in Residential Buildings Using System Dynamics. Clean. Mater. 2024, 11, 100221. [Google Scholar] [CrossRef]

- Shafaie, V.; Ghodousian, O.; Herczeg, G.; Rad, M.M. Fuzzy Logic and Push-Out Test Innovations for Fiber-Reinforced Self-Compacting Concrete Assessment. In Proceedings of the Fib Symposium, Christchurch, New Zealand, 11–13 November 2024; pp. 855–862. [Google Scholar]

- Villagrán-Zaccardi, Y.A.; Marsh, A.T.M.; Sosa, M.E.; Zega, C.J.; De Belie, N.; Bernal, S.A. Complete Re-Utilization of Waste Concretes–Valorisation Pathways and Research Needs. Resour. Conserv. Recycl. 2022, 177, 105955. [Google Scholar] [CrossRef]

- Dige, G.; Zoboli, R.; Bahn-Walkowiak, B.; Bleischwitz, R. Effectiveness of Environmental Taxes and Charges for Managing Sand, Gravel and Rock Extraction in Selected EU Countries; European Environment Agency: Copenhagen, Denmark, 2008. [Google Scholar]

- Cucuzza, R.; Rad, M.M.; Domaneschi, M.; Marano, G.C. Sustainable and Cost-Effective Optimal Design of Steel Structures by Minimizing Cutting Trim Losses. Autom. Constr. 2024, 167, 105724. [Google Scholar] [CrossRef]

- Xiong, L.; Li, S.; Jiang, K.; He, J.; Kong, F. Development and Assessment of Sustainable Steel-Concrete Composite Beams with Novel Demountable Shear Connections. Soil Dyn. Earthq. Eng. 2024, 180, 108606. [Google Scholar] [CrossRef]

- Németh, P.; Torma, A.; Lukács, E.; Filep, B. Sustainability Opportunities and Barriers at Universities, Development of a Sustainable University Environment. Chem. Eng. Trans. 2023, 107, 505–510. [Google Scholar] [CrossRef]

- Dorahaki, S.; MollahassaniPour, M.; Rashidinejad, M.; Muyeen, S.M.; Siano, P.; Shafie-Khah, M. A Robust Optimization Approach for Enabling Flexibility, Self-Sufficiency, and Environmental Sustainability in a Local Multi-Carrier Energy Community. Appl. Energy 2025, 392, 125997. [Google Scholar] [CrossRef]

- Tahir, F.; Alzahrani, S.; Noori, Y.; Al-Ghamdi, S.G. Environmental Impacts and the Future Prospects of Waste Utilization in the Concrete Production. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Tran, C.N.N.; Illankoon, I.M.C.S.; Tam, V.W.Y. Decoding Concrete’s Environmental Impact: A Path Toward Sustainable Construction. Buildings 2025, 15, 442. [Google Scholar] [CrossRef]

- De Luca, A.; Chen, L.; Gharehbaghi, K. Sustainable Utilization of Recycled Aggregates: Robust Construction and Demolition Waste Reduction Strategies. Int. J. Build. Pathol. Adapt. 2021, 39, 666–682. [Google Scholar] [CrossRef]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in Building and Construction within the Framework of Circular Cities and European New Green Deal. The Contribution of Concrete Recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

- Ghodousian, O.; Ghodousian, A.; Shafaie, V.; Hajiloo, S.; Movahedi Rad, M. Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble. Buildings 2023, 13, 1229. [Google Scholar] [CrossRef]

- Shafaie, V.; Ghodousian, O.; Ghodousian, A.; Gorji, M.; Mehdikhani, H.; Movahedi Rad, M. Shear Bond Strength in Stone-Clad Façades: Effect of Polypropylene Fibers, Curing, and Mechanical Anchorage. Polymers 2024, 16, 2975. [Google Scholar] [CrossRef] [PubMed]

- Ismail, L.; Abdel Razik, M.; Ateya, E.S.; Said, A. Optimizing Sustainable Concrete Mixes with Recycled Aggregate and Portland Slag Cement for Reducing Environmental Impact. Discov. Mater. 2024, 4, 68. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising Cement and Concrete Production: Strategies, Challenges and Pathways for Sustainable Development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Abera, Y.A. Sustainable Building Materials: A Comprehensive Study on Eco-Friendly Alternatives for Construction. Compos. Adv. Mater. 2024, 33. [Google Scholar] [CrossRef]

- Costa, F.N.; Ribeiro, D.V. Reduction in CO2 Emissions during Production of Cement, with Partial Replacement of Traditional Raw Materials by Civil Construction Waste (CCW). J. Clean. Prod. 2020, 276, 123302. [Google Scholar] [CrossRef]

- Harrison, E.; Berenjian, A.; Seifan, M. Recycling of Waste Glass as Aggregate in Cement-Based Materials. Environ. Sci. Ecotechnology 2020, 4, 100064. [Google Scholar] [CrossRef]

- Mohanty, A.; Biswal, D.R.; Pradhan, S.K.; Mohanty, M. Impact of Nanomaterials on the Mechanical Strength and Durability of Pavement Quality Concrete: A Comprehensive Review. Eng 2025, 6, 66. [Google Scholar] [CrossRef]

- Adepitan, O.L.; Alabi, O.O.; Gbadeyan, O.J.; Deenadayalu, N.; Jayeola, A.T. Investigation into the Development and Utilization of Snail Shell Biomaterials: A Systematic Review. Discov. Mater. 2025, 5, 47. [Google Scholar] [CrossRef]

- Potortì, A.G.; Messina, L.; Licata, P.; Gugliandolo, E.; Santini, A.; Di Bella, G. Snail Shell Waste Threat to Sustainability and Circular Economy: Novel Application in Food Industries. Sustainability 2024, 16, 706. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolini, L. Comparison of Ground Waste Glass with Other Supplementary Cementitious Materials. Cem. Concr. Compos. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Siddika, A.; Hajimohammadi, A.; Ferdous, W.; Sahajwalla, V. Roles of Waste Glass and the Effect of Process Parameters on the Properties of Sustainable Cement and Geopolymer Concrete—A State-of-the-Art Review. Polymers 2021, 13, 3935. [Google Scholar] [CrossRef]

- Metwally, I.M. Investigations on the Performance of Concrete Made with Blended Finely Milled Waste Glass. Adv. Struct. Eng. 2007, 10, 47–53. [Google Scholar] [CrossRef]

- Torres-Agredo, J.; Torres-Castellanos, N.; Mejía-de-Gutiérrez, R. Permeation Properties of Concrete Added with a Petrochemical Industry Waste. Ing. Investig. 2017, 37, 23–29. [Google Scholar] [CrossRef]

- Zhan, J.; Lu, J.; Wang, D. Review of Shell Waste Reutilization to Promote Sustainable Shellfish Aquaculture. Rev. Aquac. 2022, 14, 477–488. [Google Scholar] [CrossRef]

- da Silva, A.L.; Kohlman Rabbani, E.R.; Shakouri, M. Seashell Powder as a Sustainable Alternative in Cement-Based Materials: A Systematic Literature Review. Sustainability 2025, 17, 592. [Google Scholar] [CrossRef]

- Suseela, A.; Asadi, S.S. Experimental Investigation of Snail Shell-Based Cement Mortar: Mechanical Strength, Durability and Microstructure. U.Porto J. Eng. 2023, 9, 51–70. [Google Scholar] [CrossRef]

- ASTM C33; Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C150; Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C39; Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C78; Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2022.

- Hover, K. Graphical Approach to Mixture Proportioning by ACI 211.1-91. Concr. Int. 1995, 17, 49–53. [Google Scholar]

- ASTM C143; Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- Wright, J.R.; Cartwright, C.; Fura, D.; Rajabipour, F. Fresh and Hardened Properties of Concrete Incorporating Recycled Glass as 100% Sand Replacement. J. Mater. Civ. Eng. 2014, 26, 04014073. [Google Scholar] [CrossRef]

| Oxide | Typical Percentage (%) | ||

|---|---|---|---|

| OPC (%) | WGC (%) | SSP (%) | |

| Calcium Oxide (CaO) | 64.80 | 10.40 | 67.50 |

| Silicon Dioxide (SiO2) | 23.40 | 71.00 | 0.50 |

| Aluminum Oxide (Al2O3) | 5.50 | 1.85 | 0.32 |

| Iron Oxide (Fe2O3) | 3.20 | 0.40 | 1.95 |

| Magnesium Oxide (MgO) | 2.20 | 0.62 | 2.12 |

| Sodium Oxide (Na2O) | 0.20 | 13.00 | 2.27 |

| Potassium Oxide (K2O) | 0.70 | 0.85 | 1.24 |

| Sulfate (SO3) | 2.62 | 0.21 | 1.30 |

| Phosphorus Pentoxide (P2O5) | – | – | 1.45 |

| Titanium Dioxide (TiO2) | – | – | 1.22 |

| Carbon Dioxide (CO2) | – | – | 25.00 |

| Chloride (Cl−) | – | – | 0.02 |

| Loss on Ignition (LOI) | 2.02 | 0.48 | 14.50 |

| Property | Fine Aggregate | Coarse Aggregate |

|---|---|---|

| Specific Gravity | 2.62 | 2.70 |

| Bulk Density (kg/m3) | 1590 | 1540 |

| Water Absorption (%) | 1.05 | 0.76 |

| Fineness Modulus | 2.85 | 6.50 |

| Maximum Particle Size (mm) | 4.75 | 19.0 |

| Aggregate Crushing Value (%) | – | 23.5 |

| Aggregate Impact Value (%) | – | 18.4 |

| Mix.NO. | Mix ID | OPC (kg/m3) | WGC * | SSP ** | Fine Agg. (kg/m3) | Coarse Agg. (kg/m3) | Water (kg/m3) | w/cm *** | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (%) | (kg/m3) | (%) | (kg/m3) | |||||||

| 1. | Control | 400 | 0 | 0 | 0 | 0 | 650 | 1200 | 200 | 0.50 |

| 2. | 5WGC | 380 | 5 | 20 | 0 | 0 | 650 | 1200 | 200 | 0.50 |

| 3. | 10WGC | 360 | 10 | 40 | 0 | 0 | 650 | 1200 | 200 | 0.50 |

| 4. | 15WGC | 340 | 15 | 60 | 0 | 0 | 650 | 1200 | 200 | 0.50 |

| 5. | 20WGC | 320 | 20 | 80 | 0 | 0 | 650 | 1200 | 200 | 0.50 |

| 6. | 5WGC+1SSP | 376 | 5 | 20 | 1 | 4 | 650 | 1200 | 200 | 0.50 |

| 7. | 10WGC+1SSP | 356 | 10 | 40 | 1 | 4 | 650 | 1200 | 200 | 0.50 |

| 8. | 15WGC+1SSP | 336 | 15 | 60 | 1 | 4 | 650 | 1200 | 200 | 0.50 |

| 9. | 20WGC+1SSP | 316 | 20 | 80 | 1 | 4 | 650 | 1200 | 200 | 0.50 |

| Mix ID | Slump (mm) |

|---|---|

| Control | 30 |

| 5WGC | 28 |

| 10WGC | 25 |

| 15WGC | 22 |

| 20WGC | 20 |

| 5WGC+1SSP | 30 |

| 10WGC+1SSP | 27 |

| 15WGC+1SSP | 23 |

| 20WGC+1SSP | 21 |

| Statistic | Waste Glass Culet | Snail Shell Powder | Slump |

|---|---|---|---|

| Count (samples) | 9 | 9 | 9 |

| Mean value | 11.11 | 0.44 | 25.11 |

| Std dev. | 6.97 | 0.53 | 3.82 |

| Minimum value (%) | 0 | 0 | 20 |

| 25% | 5 | 0 | 22 |

| 50% | 10 | 0 | 25 |

| 75% | 15 | 1 | 28 |

| Maximum value (%) | 20 | 1 | 30 |

| Days | Strain (ε) | Control | 5WGC | 10WGC | 15WGC | 20WGC | 5WGC+1SSP | 10WGC+1SSP | 15WGC+1SSP | 20WGC+1SSP |

|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 0.008000 | 20.00 | 21.50 | 23.00 | 24.50 | 25.80 | 22.00 | 23.50 | 26.00 | 27.50 |

| 28 | 0.010667 | 40.00 | 39.00 | 42.00 | 43.50 | 45.00 | 41.50 | 45.00 | 47.00 | 48.00 |

| 56 | 0.012000 | 44.00 | 42.50 | 45.00 | 47.00 | 49.00 | 45.50 | 46.00 | 49.50 | 50.50 |

| 90 | 0.013333 | 46.00 | 44.00 | 48.50 | 50.00 | 51.00 | 47.00 | 48.00 | 51.50 | 52.00 |

| Days | Control | 5WGC | W10GC | 15WGC | 20WGC | 5WGC+1SSP | 10WGC+1SSP | 15WGC+1SSP | 20WGC+1SSP |

|---|---|---|---|---|---|---|---|---|---|

| 7 | 5.50 | 5.80 | 6.00 | 6.20 | 6.10 | 5.90 | 6.10 | 6.30 | 6.20 |

| 28 | 7.00 | 6.80 | 7.10 | 7.50 | 7.60 | 7.10 | 7.20 | 7.70 | 7.80 |

| 56 | 9.00 | 8.13 | 8.56 | 9.23 | 9.60 | 8.70 | 8.67 | 9.57 | 9.93 |

| 90 | 11.40 | 9.75 | 10.35 | 11.34 | 12.03 | 10.64 | 10.45 | 11.83 | 12.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imoh, U.U.; Apata, A.C.; Movahedi Rad, M. Performance of Concrete Incorporating Waste Glass Cullet and Snail Shell Powder: Workability and Strength Characteristics. Buildings 2025, 15, 2161. https://doi.org/10.3390/buildings15132161

Imoh UU, Apata AC, Movahedi Rad M. Performance of Concrete Incorporating Waste Glass Cullet and Snail Shell Powder: Workability and Strength Characteristics. Buildings. 2025; 15(13):2161. https://doi.org/10.3390/buildings15132161

Chicago/Turabian StyleImoh, Udeme Udo, Akindele Christopher Apata, and Majid Movahedi Rad. 2025. "Performance of Concrete Incorporating Waste Glass Cullet and Snail Shell Powder: Workability and Strength Characteristics" Buildings 15, no. 13: 2161. https://doi.org/10.3390/buildings15132161

APA StyleImoh, U. U., Apata, A. C., & Movahedi Rad, M. (2025). Performance of Concrete Incorporating Waste Glass Cullet and Snail Shell Powder: Workability and Strength Characteristics. Buildings, 15(13), 2161. https://doi.org/10.3390/buildings15132161