Research on Fracture Energy Prediction and Size Effect of Concrete Based on Deep Learning with SHAP Interpretability Method

Abstract

1. Introduction

2. Fundamental Principle

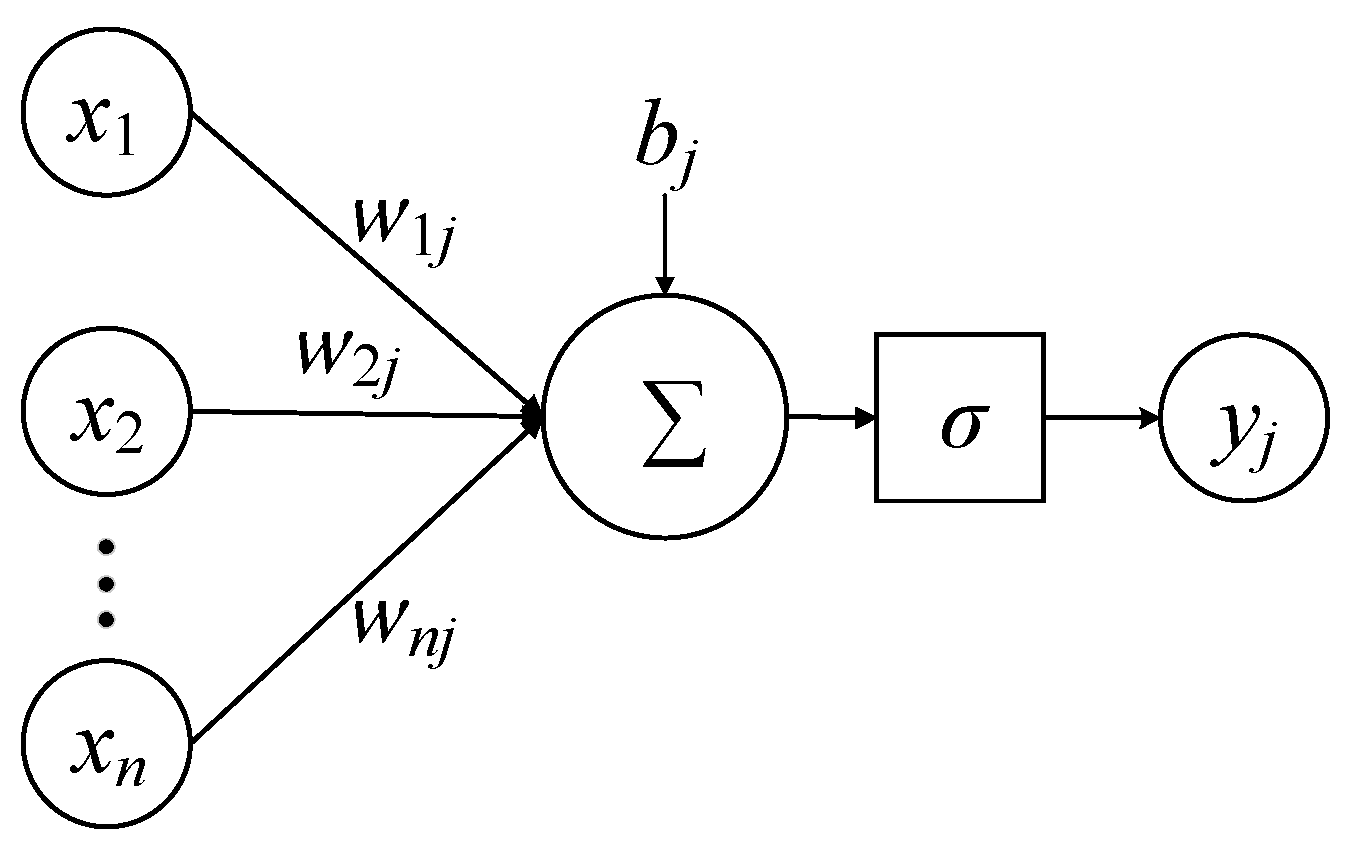

2.1. Deep Learning

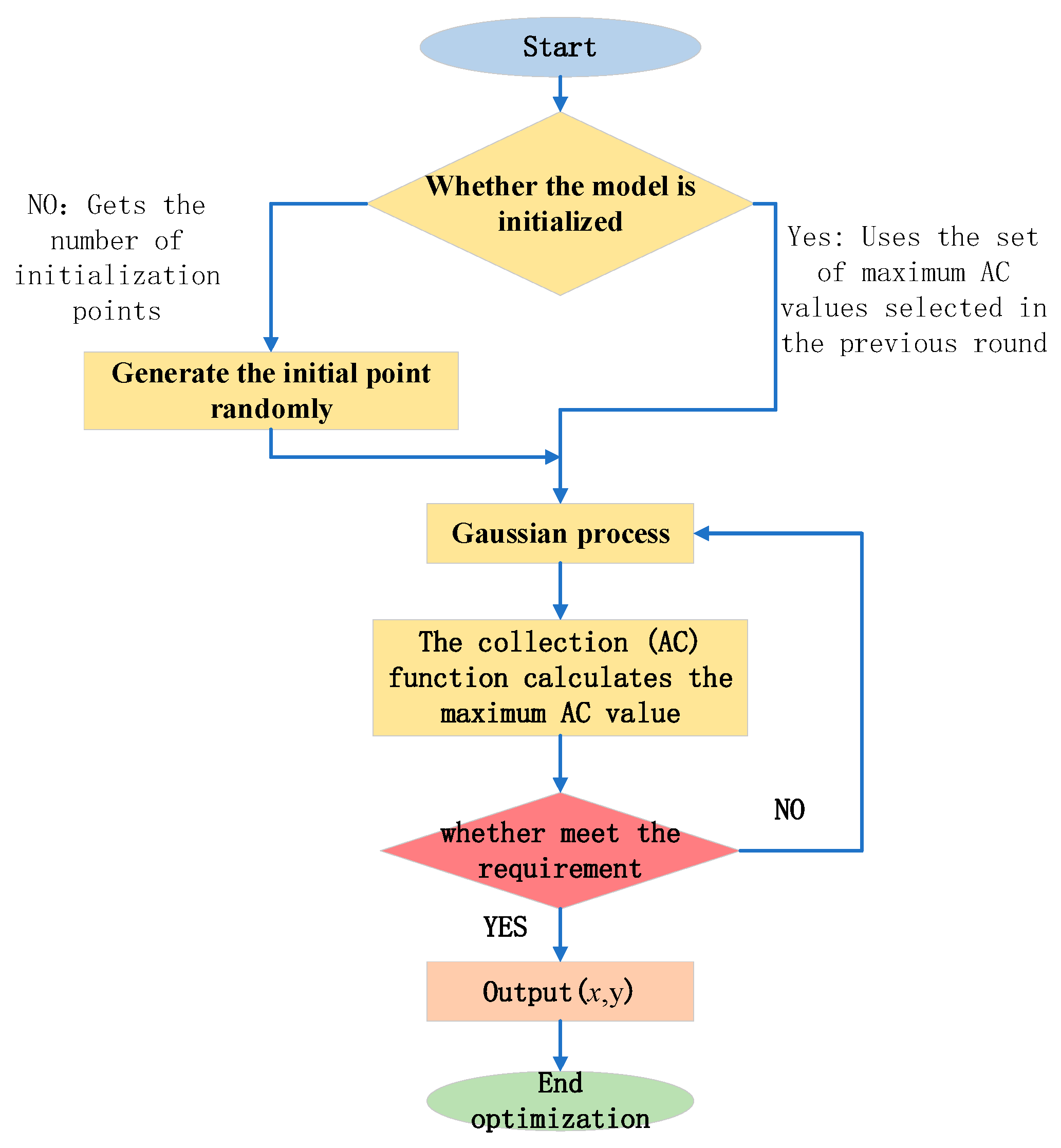

2.2. Bayesian Optimization Algorithm

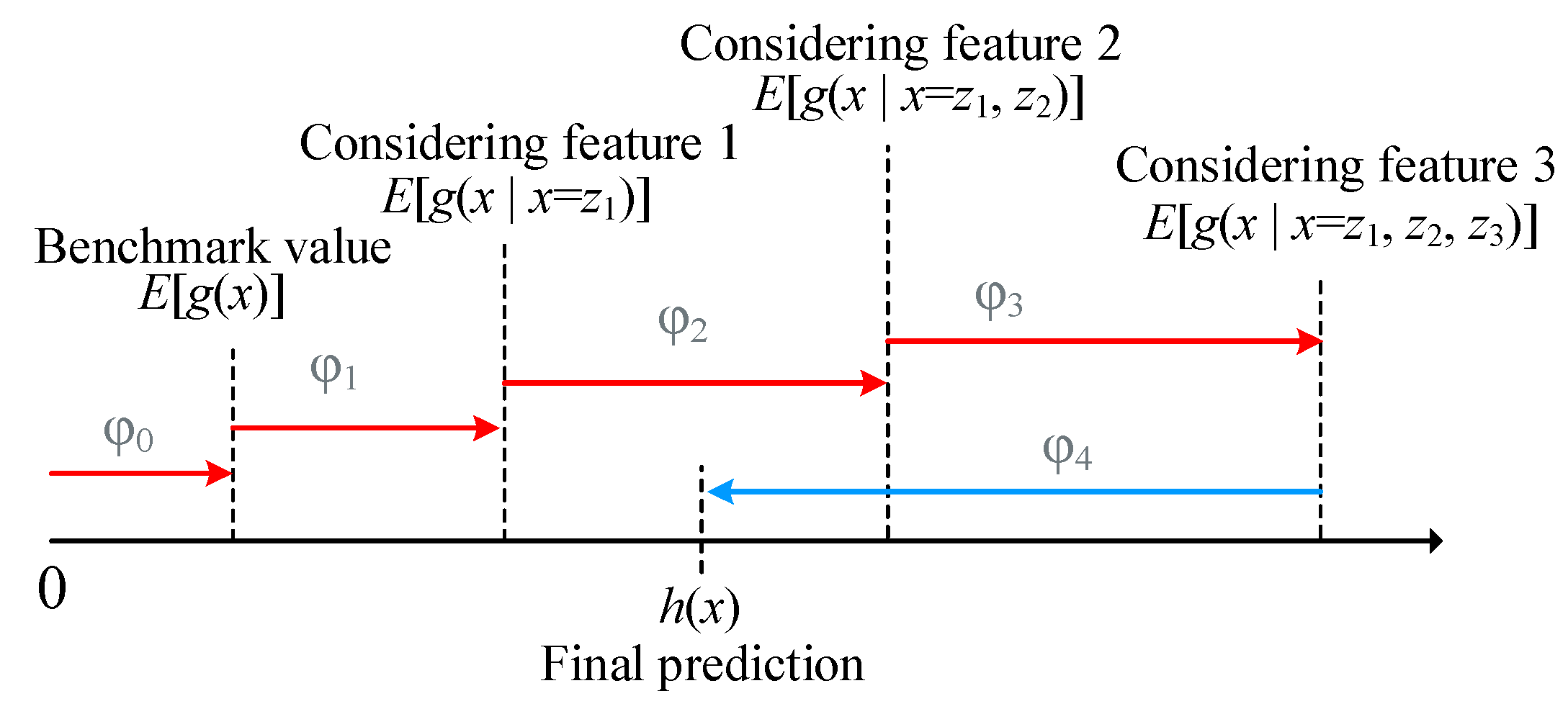

2.3. SHAP Interpretability Method

3. Model Construction

3.1. Database Creation and Data Pre-Processing

3.2. Model Parameter Setting

4. Model Prediction Results and Comparison

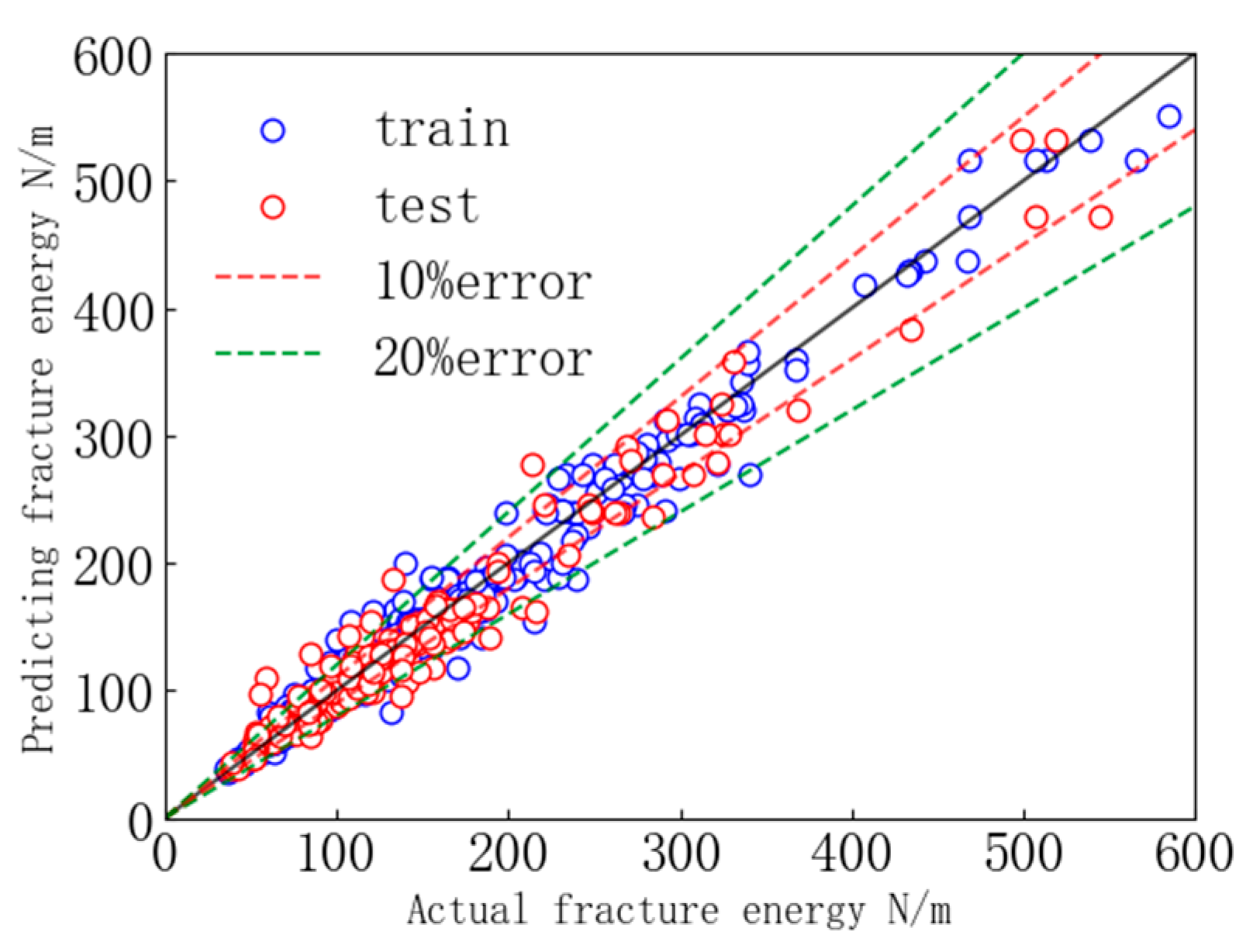

4.1. Model Prediction Results

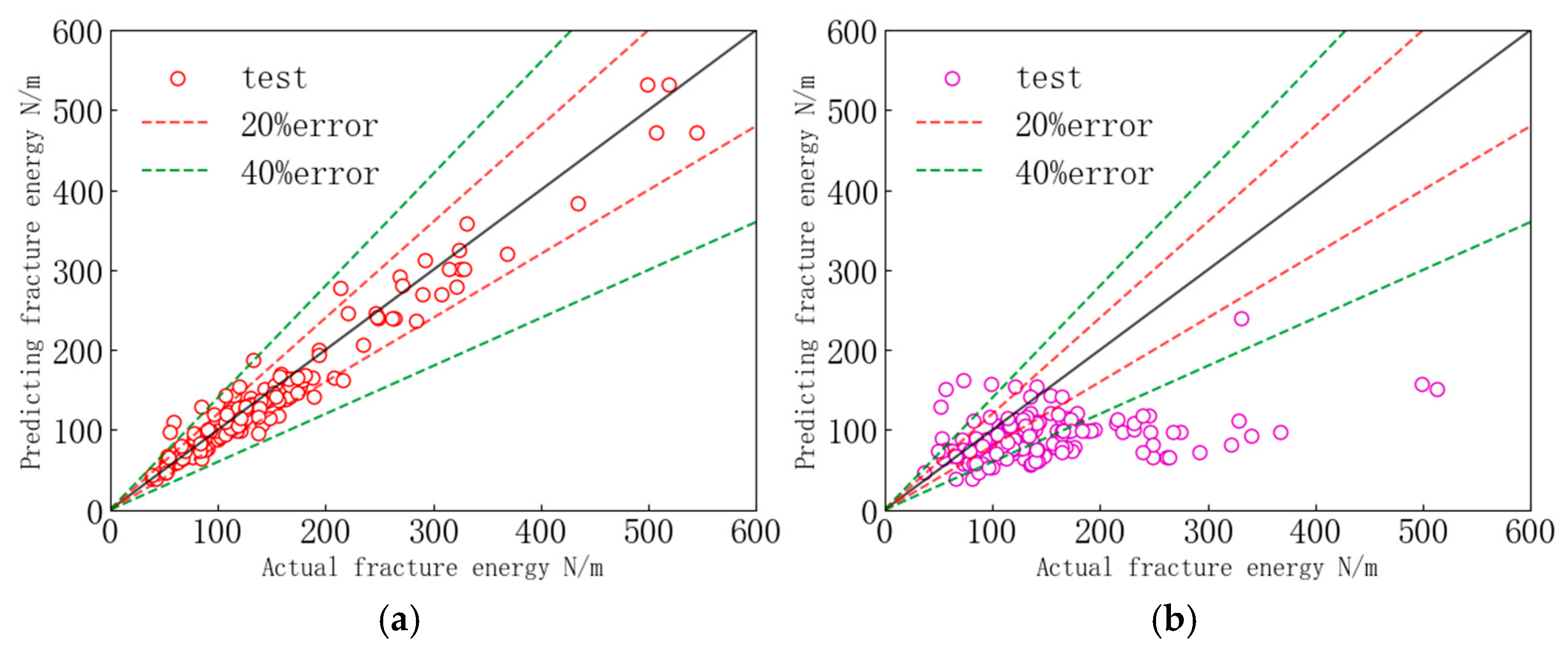

4.2. Model Comparison

5. Interpretability Analysis

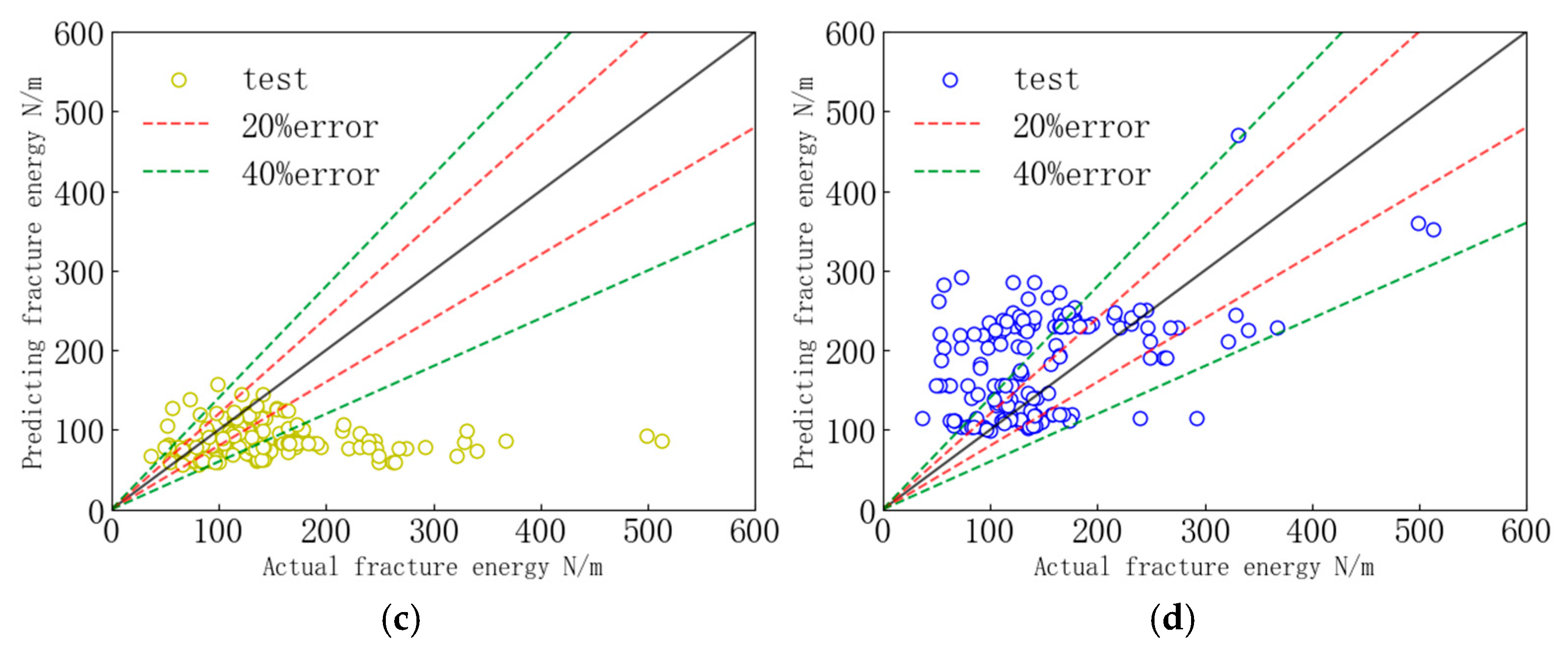

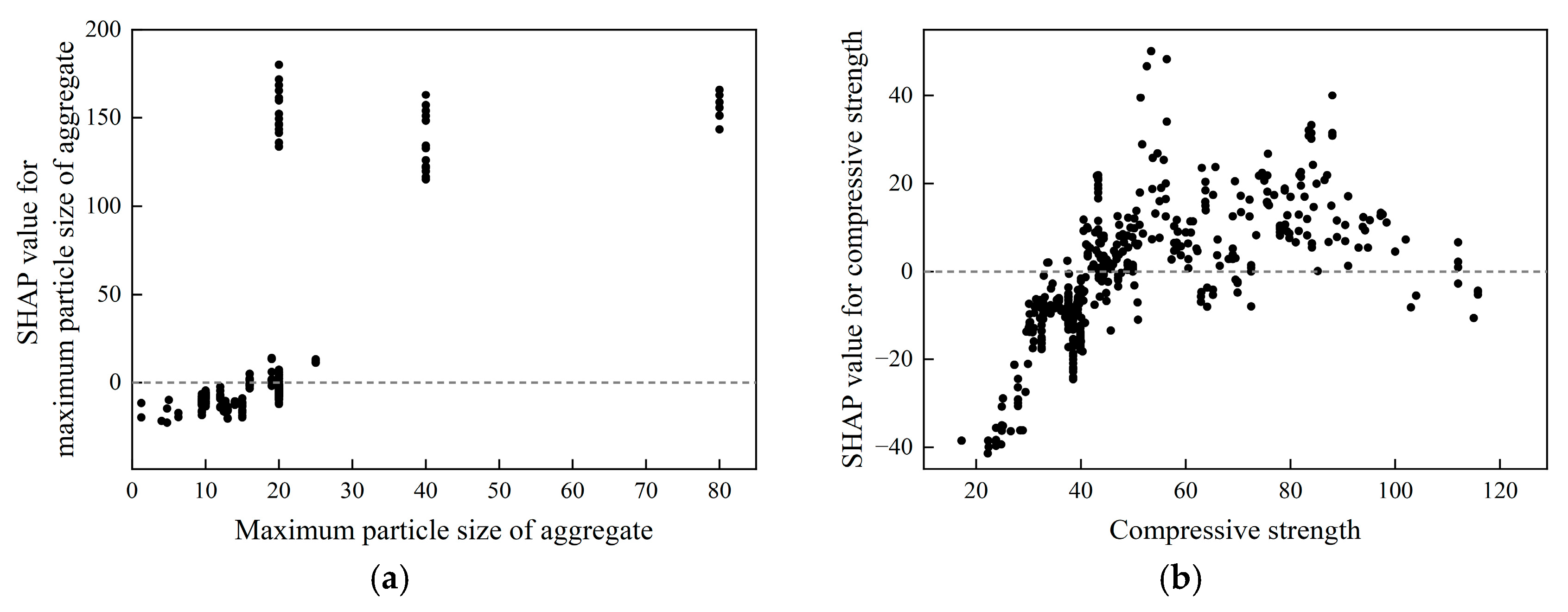

5.1. Global Interpretative Analysis

5.2. Analysis of the Effect of Material Properties on Fracture Energy

5.3. Size Effect Analysis of Fracture Energy

6. Conclusions

- Development and optimization of DNN model for predicting concrete fracture energy: Firstly, a fracture energy test database was established, followed by the construction of a DNN model based on deep learning for predicting concrete fracture energy. Subsequently, the Bayesian optimization algorithm was employed to obtain an optimal prediction model and accurately predict the fracture energy. The results demonstrate that the predicted values of DNN are in good agreement with the experimental data, with R2 being 0.953 and MAPE being 9.5% on the test set. Moreover, the DNN model exhibits superior accuracy and stability compared to existing regression models, expanding its applicability range, which proves that the model in this paper can be used as an effective model to determine the fracture energy of concrete.

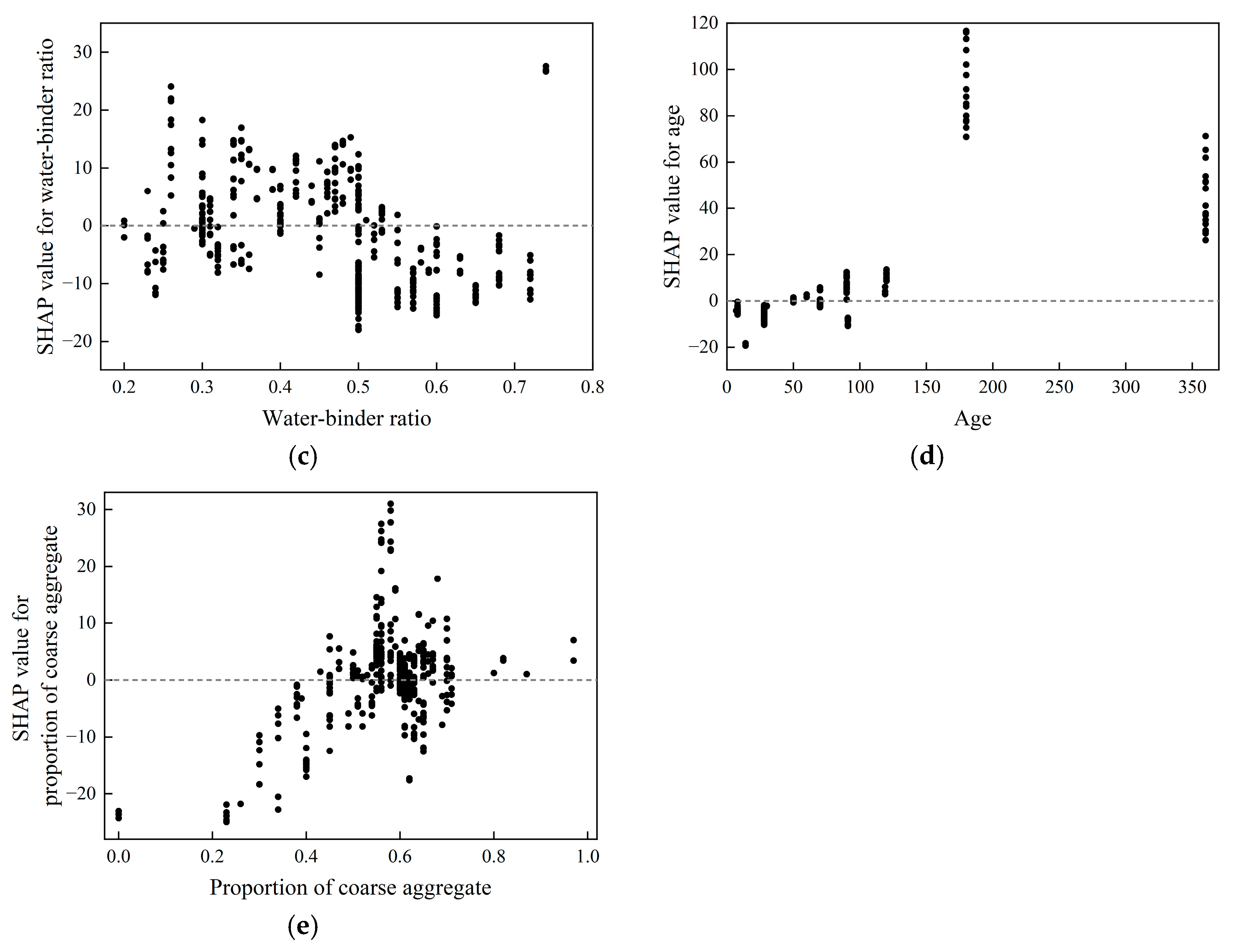

- Feature importance analysis based on SHAP: The significance of each characteristic parameter and how each feature parameter impacts the size of fracture energy are detailedly analyzed by visualizing the SHAP value of the features. The analysis reveals that the fracture energy exhibits an increasing trend with the enlargement of aggregate particle size and tends to stabilize once the particle size exceeds 20 mm; the fracture energy initially rises and then declines as compressive strength increases; a higher water–binder ratio leads to a reduction in fracture energy; the fracture energy demonstrates an initial increase followed by a decrease with an increase in coarse aggregate proportion, reaching its maximum when the proportion is approximately 0.6; and as age progresses, the fracture energy shows a trend of initial increase followed by a decrease.

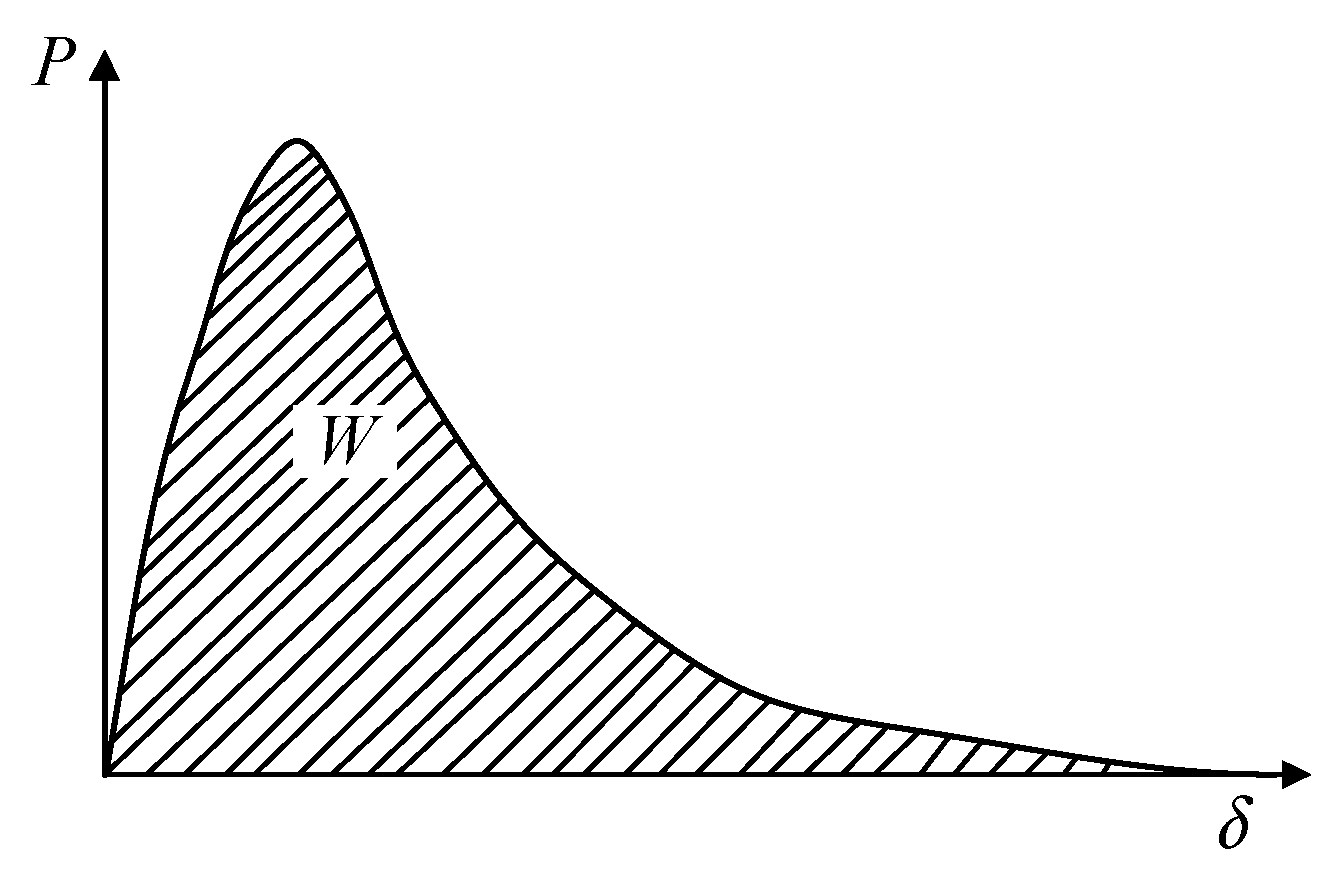

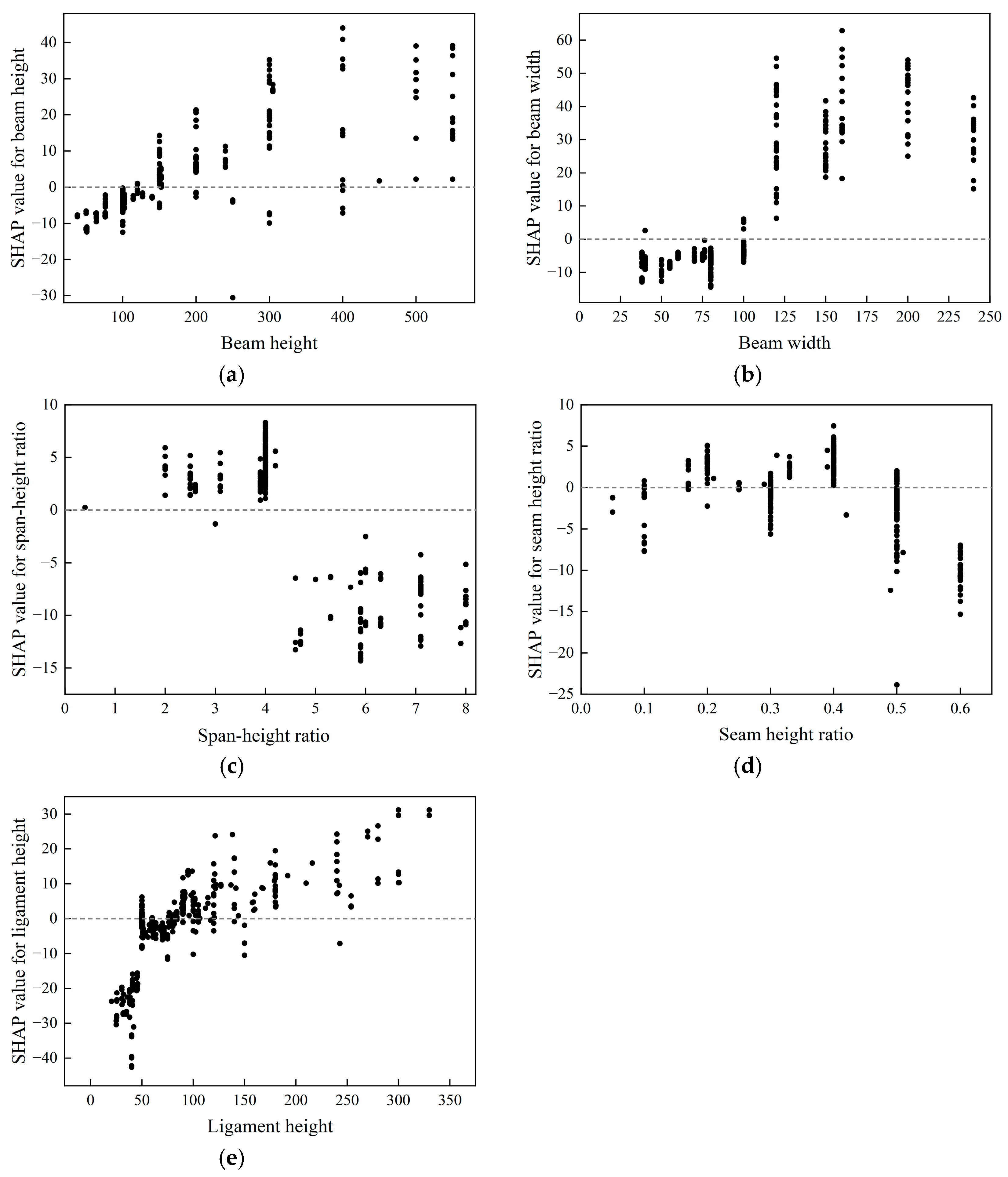

- Size effect analysis of fracture energy based on feature parameter dependence: The size effect of fracture energy in concrete is analyzed in depth by means of a SHAP dependency graph generated by visualization of geometric parameters. The analysis reveals that the fracture energy exhibits an increasing trend with the specimen height, while a decrease in fracture energy is observed when the specimen height exceeds 400 mm, indicating a size effect within a specific range of specimen height; an increase in specimen width leads to an increase in fracture energy, but the increase in width does not cause the size effect after the width exceeds 150 mm; as the span–height ratio increases, there is a decrease in fracture energy, but the size effect becomes more pronounced when the span–height ratio exceeds 4; the fracture energy initially rises and then declines with an increase in seam height ratio until it reaches its maximum at approximately 0.4; there exists a positive correlation between fracture energy and ligament height with the evident size effect.

- Concrete, as a typical multiphase composite material, exhibits complex mechanical behavior due to its heterogeneous composition. This study examined the influence of multiple feature parameters on concrete fracture energy; however, the synergistic effects among features have not yet been quantified. A deeper analysis of feature interrelationships may facilitate the development of more comprehensive predictive models.

- The study was constrained by the number of input features and the size of the dataset. Future work incorporating more extensive and diverse datasets, along with a broader range of concrete parameters, may lead to the construction of a more robust and inclusive prediction model.

- Given the diversity of current deep learning architectures, integrating more advanced and powerful models may improve both prediction accuracy and interpretability, thus providing more reliable guidance for engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hadjari, M.; Marouf, H.; Dahou, Z.; Maherzi, W. Investigation of the Mechanical and Fracture Properties of Recycled Aggregate Concrete. Buildings 2025, 15, 1155. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Davoodi, M.R.; Fallahnejad, H.; Rahimi, S.; Farahbod, F. Influence of mineral powder content on the fracture behaviors and ductility of selfcompacting concrete. J. Mater. Civ. Eng. 2015, 28, 4015147. [Google Scholar] [CrossRef]

- Beygi, M.H.; Kazemi, M.T.; Amiri, J.V.; Nikbin, I.M.; Rabbanifar, S.; Rahmani, E. Evaluation of the effect of maximum aggregate size on fracture behavior of self compacting concrete. Constr. Build. Mater. 2014, 55, 202–211. [Google Scholar] [CrossRef]

- RILEM. Draft recommendation TC50-FCM:Determinationof fracture energy of mortar and concrete by means of three-Point bend tests on notched beams. Mater. Struct. 1985, 18, 285–290. [Google Scholar]

- DL/T 5332−2005; Code for Fracture Test of Hydraulic Concrete of National Development and Reform Commission of the People’s Republic of China. China Electric Power Press: Beijing, China, 2006.

- Dong, L.; Liu, J.; Xiu, L.D.; Jing, B.L. A theoretical method to determine the tortuous crack length and the mechanical parameters of concrete in direct tension-A particle size effect analysis. Eng. Fract. Mech. 2018, 197, 128–150. [Google Scholar]

- Hu, S.; Fan, B. Study on the bilinear softening mode and fracture parameters of concrete in low temperature environments. Eng. Fract. Mech. 2019, 211, 1–16. [Google Scholar] [CrossRef]

- Rong, H.; Dong, W.; Zhang, X.; Zhang, B. Size effect on fracture properties of concrete after sustained loading. Mater. Struct. 2019, 52, 16. [Google Scholar] [CrossRef]

- Bakour, A.; Ftima, M.B. Investigation of fracture properties and size effects of mass concrete using wedge splitting tests on large specimens. Eng. Fract. Mech. 2022, 259, 108144. [Google Scholar] [CrossRef]

- Sun, L.; Du, C.; Ghaemian, M.; Zhao, W. Determination of the fracture parameters of concrete with improved wedge-splitting testing. Eng. Fract. Mech. 2022, 276, 108911. [Google Scholar] [CrossRef]

- Lei, Y.; Jin, L.; Du, X. Experimental investigation of size effects on BFRP-RC beams under combined bend-ing-shear-torsion loading. Eng. Struct. 2025, 336, 120457. [Google Scholar] [CrossRef]

- Jia, P.; Wu, H.; Ma, L. Size effect for dynamic flexural responses of RC beams under low-velocity impact. Eng. Struct. 2025, 338, 120598. [Google Scholar] [CrossRef]

- Zhao, Z.; Kwon, S.H.; Shah, S.P. Effect of specimen size on fracture energy and softening curve of concrete: Part I. Experiments and fracture energy, Cem. Concr. Res. 2008, 38, 1049–1060. [Google Scholar] [CrossRef]

- Zong, Y. Experimental Study on Wedge Splitting Tensile Fracture of Fully-Graded Concrete. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2018. [Google Scholar]

- Carloni, C.; Santandrea, M.; Baietti, G. Influence of the Width of the Specimen on the Fracture Response of Concrete Notched Beams. Eng. Fract. Mech. 2019, 216, 7–10. [Google Scholar] [CrossRef]

- Duan, K.; Hu, X.Z.; Wittmann, F.H. Thickness Effect on Fracture Energy of Cementitious Materials. Cem. Concr. Res. 2003, 33, 499–507. [Google Scholar] [CrossRef]

- Elices, M.; Rocco, C. Effect of aggregate size on the fracture and mechanical properties of a simple concrete. Eng. Fract. Mech. 2008, 75, 3839–3851. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Becq-Giraudon, E. Statistical prediction of fracture parameters of concrete and implications for choice of testing standard. Cem. Concr. Res. 2002, 32, 529–556. [Google Scholar] [CrossRef]

- Hu, S.W.; Mi, Z.X.; Lu, J.; Fan, X.-Q. A study on energy dissipation of fracture process zone in concrete. J. Hydraul. Eng. 2012, 43, 145–152. [Google Scholar]

- Yin, Y.; Qiao, Y.; Hu, S. Determining concrete fracture parameters using three-point bending beams with various specimen spans. Theor. Appl. Fract. Mech. 2020, 107, 102465. [Google Scholar] [CrossRef]

- Xie, J.; Liu, Y.; Yan, M.-L.; Yan, J.-B. Mode Ⅰ fracture behaviors of concrete at low temperatures. Constr. Build. Mater. 2022, 323, 126612. [Google Scholar] [CrossRef]

- Silva, W.R.L.D.; Lucena, D.S.D. Concrete Cracks Detection Based on Deep Learning Image Classification. Proceedings 2018, 2, 489. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Zhou, S.; Yu, Y.; Cheng, H.; Wu, X. Compressive strength prediction of recycled concrete based on deep learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Zhou, S.; Sheng, W.; Wang, Z.; Yao, W.; Huang, H.; Wei, Y.; Li, R. Quick image analysis of concrete pore structure based on deep learning. Constr. Build. Mater. 2019, 208, 144–157. [Google Scholar] [CrossRef]

- Latif, S.D. Concrete compressive strength prediction modeling utilizing deep learning long short-term memory algorithm for a sustainable environment. Environ. Sci. Pollut. Res. 2021, 28, 30294–30302. [Google Scholar] [CrossRef] [PubMed]

- Ince, R. Prediction of fracture parameters of concrete by Artificial Neural Networks. Eng. Fract. Mech. 2004, 71, 2143–2159. [Google Scholar] [CrossRef]

- Yan, Y.; Ren, Q.; Xia, N.; Shen, L.; Gu, J. Artificial neural network approach to predict the fracture parameters of the size effect model for concrete. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1347–1358. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Rahimi, S.; Allahyari, H. A new empirical formula for prediction of fracture energy of concrete based on the artificial neural network. Eng. Fract. Mech. 2017, 186, 466–482. [Google Scholar] [CrossRef]

- An, P.; Cao, D.P.; Zhao, B.Y.; Yang, X.L.; Zhang, M. Reservoir physical parameters prediction based on LSTM recurrent neural network. Prog. Geophys. 2019, 34, 1849–1858. [Google Scholar]

- Tian, R.; Meng, H.; Chen, S.; Wang, C.; Zhang, F. Prediction of intensity classification of rockburst based on deep neural network. J. China Coal Soc. 2020, 45, 191–201. [Google Scholar]

- Bergstra, J.; Bardenet, R.; Bengio, Y.; Kégl, B. Algorithms for hyper-parameter optimization. In Proceedings of the 24th International Conference on Neural Information Processing Systems, Vancouver, BC, USA, 6–9 December 2010; Curran Associates Inc.: Red Hook, NY, USA, 2011; pp. 2546–2554. [Google Scholar]

- Bergstra, J.; Bengio, Y. Random search for hyper-parameter optimization. J. Mach. Learn. Res. 2012, 13, 281–305. [Google Scholar]

- Snoek, J.; Larochelle, H.; Adams, R.P. Practical Bayesian optimization of machine learning algorithms. In Proceedings of the 25th International Conference on Neural Information Processing Systems, Lake Tahoe, NV, USA, 3–6 December 2012; ACM: New York, NY, USA, 2012; Volume 2, pp. 2951–2959. [Google Scholar]

- Friedman, J.H. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Apley, D.W.; Zhu, J. Visualizing the Effects of Predictor Variables in Black Box Supervised Learning Models. arXiv 2016, arXiv:1612.08468. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.I. A unified approach to interpreting model predictions. Adv. Neural Inf. Process. Syst. 2017, 30, 4765–4774. [Google Scholar]

- Bažant, Z.P.; Kazemi, M.T. Size dependence of concrete fracture energy determined by RILEM work-of-fracture method. Int. J. Fract. 1991, 51, 121–138. [Google Scholar] [CrossRef]

- Hu, X.Z. An asymptotic approach to size effect on fracture toughness and fracture energy of composites. Eng. Fract. Mech. 2002, 69, 555–564. [Google Scholar] [CrossRef]

- Vishalakshi, K.P.; Revathi, V.; Sivamurthy Reddy, S. Effect of type of coarse aggregate on the strength properties and fracture energy of normal and high strength concrete. Eng. Fract. Mech. 2018, 194, 52–60. [Google Scholar] [CrossRef]

- Duan, K.; Hu, X.Z.; Wittmann, F.H. Size effect on specific fracture energy of concrete. Eng. Fract. Mech. 2007, 74, 87–96. [Google Scholar] [CrossRef]

- Guan, J.F.; Hu, X.Z.; Li, Q.B. In-depth analysis of notched 3-p-b concrete fracture. Eng. Fract. Mech. 2016, 165, 57–71. [Google Scholar] [CrossRef]

- Comite Euro-lnternational Du Beton. CEB-FIP Model Code 1990; Thomas Telford Publishing: London, UK, 1993. [Google Scholar]

- Japan Society of Civil Engineers. Standard Specifications for Concrete Structures 2007 “Design”; Japan Society of Civil Engineers: Tokyo, Japan, 2010. [Google Scholar]

- Mazloom, M.; Salehi, H. The relationship between fracture toughness and compressive strength of self-compacting lightweight concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 062007. [Google Scholar] [CrossRef]

- Xu, S.L.; Zhao, G.F.; Liu, Y.; Ye, L.D. The three-point bending beam method is used to study the fracture energy of concrete and the influence of specimen size. J. Dalian Univ. Technol. 1991, 79–86. [Google Scholar]

| Parameter | Unit | Average | Standard Deviation | Minimum | Maximum |

|---|---|---|---|---|---|

| Beam spacing | mm | 647 | 323 | 95 | 2200 |

| Beam height | mm | 142 | 75.5 | 38.1 | 550 |

| Beam width | mm | 91.1 | 34.4 | 38.1 | 240 |

| Initial notch length | mm | 53.7 | 31.8 | 5 | 220 |

| Ligament height | - | 88.5 | 9.89 | 20.4 | 330 |

| Seam height ratio | - | 0.39 | 0.12 | 0.05 | 0.6 |

| Span–height ratio | - | 4.73 | 1.56 | 0.4 | 8 |

| Water–binder ratio | - | 0.47 | 0.14 | 0.2 | 0.74 |

| Percentage of coarse aggregates | - | 0.59 | 0.1 | 0 | 0.97 |

| Maximum aggregate diameter | mm | 17 | 9 | 1.25 | 80 |

| Age | d | 52 | 58 | 7 | 365 |

| Concrete compressive strength | MPa | 48.43 | 17.24 | 17.2 | 115.8 |

| Fracture energy | N/m | 146.55 | 82.77 | 35.35 | 584.7 |

| Parameter | Optimization Scope | Final Value |

|---|---|---|

| Number of hidden layers | 1~10 | 6 |

| Number of neurons | 1~200 | 12, 42, 65, 37, 18, 1 |

| Activation function | Relu, tanh, Lrelu | relu |

| Rate of learning | 1, 0.01, 0.001, 0.0001 | 0.001 |

| Optimizer | - | Adam |

| Regularization | - | dropout |

| Epochs | - | 1500 |

| Batch_size | 1~50 | 16 |

| Model | Evaluation Indicators | ||

|---|---|---|---|

| RMSE (N/m) | MAPE (%) | MAE (N/m) | |

| DNN | 20.45 | 9.5 | 14.62 |

| Bažant | 97.47 | 37.71 | 65.38 |

| CEB-90 | 88.65 | 37.48 | 62.07 |

| JSCE | 82.66 | 60.48 | 66.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhang, W.; Lin, J.; Guo, S. Research on Fracture Energy Prediction and Size Effect of Concrete Based on Deep Learning with SHAP Interpretability Method. Buildings 2025, 15, 2149. https://doi.org/10.3390/buildings15132149

Wang H, Zhang W, Lin J, Guo S. Research on Fracture Energy Prediction and Size Effect of Concrete Based on Deep Learning with SHAP Interpretability Method. Buildings. 2025; 15(13):2149. https://doi.org/10.3390/buildings15132149

Chicago/Turabian StyleWang, Huiming, Weiqi Zhang, Jie Lin, and Shengpin Guo. 2025. "Research on Fracture Energy Prediction and Size Effect of Concrete Based on Deep Learning with SHAP Interpretability Method" Buildings 15, no. 13: 2149. https://doi.org/10.3390/buildings15132149

APA StyleWang, H., Zhang, W., Lin, J., & Guo, S. (2025). Research on Fracture Energy Prediction and Size Effect of Concrete Based on Deep Learning with SHAP Interpretability Method. Buildings, 15(13), 2149. https://doi.org/10.3390/buildings15132149