Life Cycle Assessment with Carbon Footprint Analysis in Glulam Buildings: A Review

Abstract

1. Introduction

2. Life Cycle Assessment

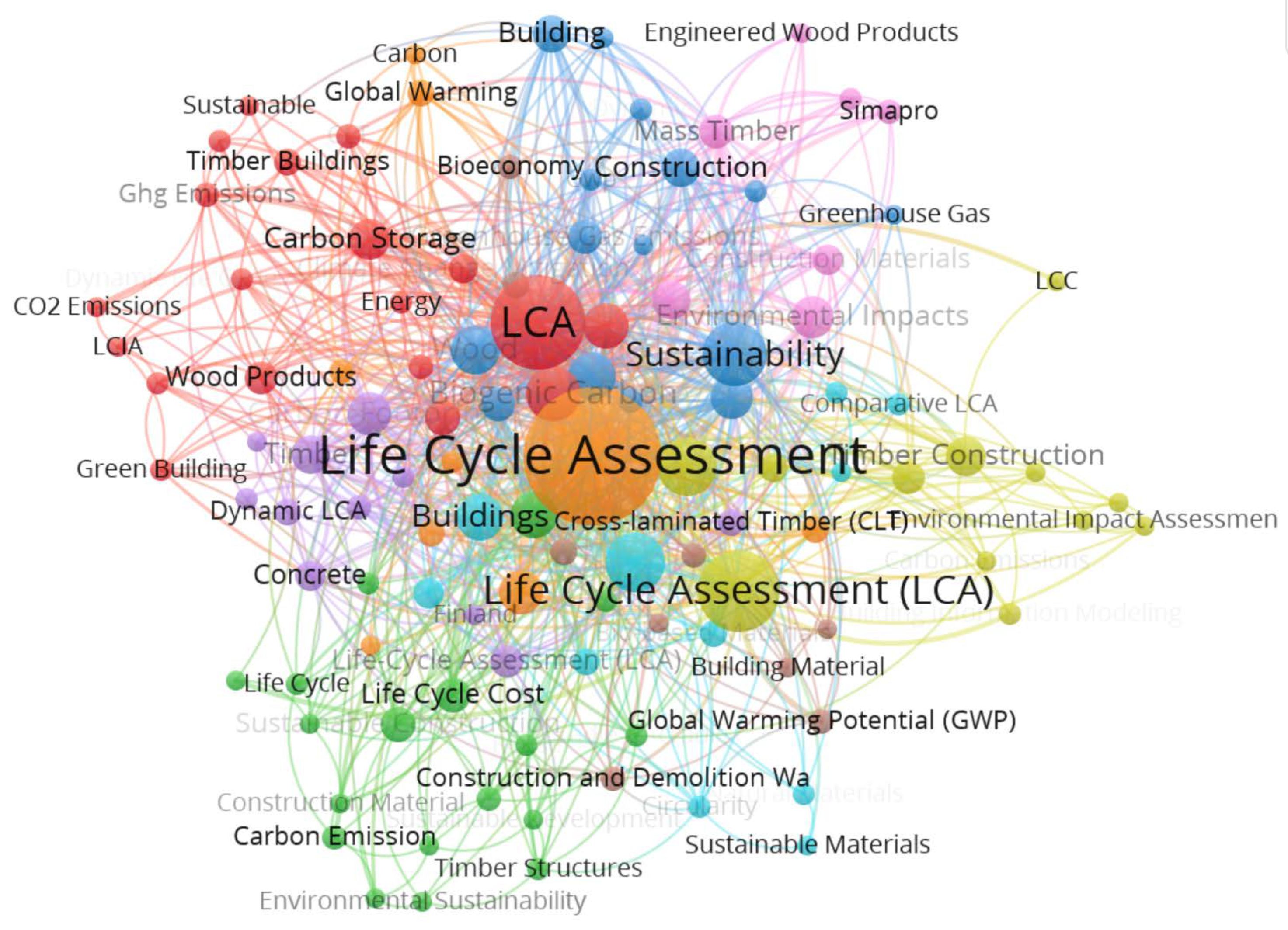

- Keywords such as Buildings, Wood buildings, and Residential buildings indicate that the research spans a range of building types, from general construction to specific wooden and residential structures. The term Building materials appears 21 times, with particular focus on wood-based materials like Timber structures, GLT, CLT, and Mass timber. This reflects growing interest in their characteristics, applications, and environmental impacts within sustainable construction.

- Related terms such as Building design, Building envelope, and Building information modeling suggest a broader research scope, encompassing not just materials but also design strategies, enclosure systems, and digital tools that enhance building performance and sustainability.

- Carbon-related keywords, including Embodied carbon, Biogenic carbon, Carbon footprint, and Carbon storage, appear frequently, signaling a strong focus on measuring carbon emissions, content, and storage in wooden buildings. These metrics are critical in assessing sustainability, especially in the context of climate change.

- Energy-related terms such as Embodied energy, Energy consumption, Energy efficiency, and Primary energy reveal a significant emphasis on energy use and efficiency throughout a building’s life cycle. This aligns with the Sustainable Development Goals to reduce energy demand and improve utilization.

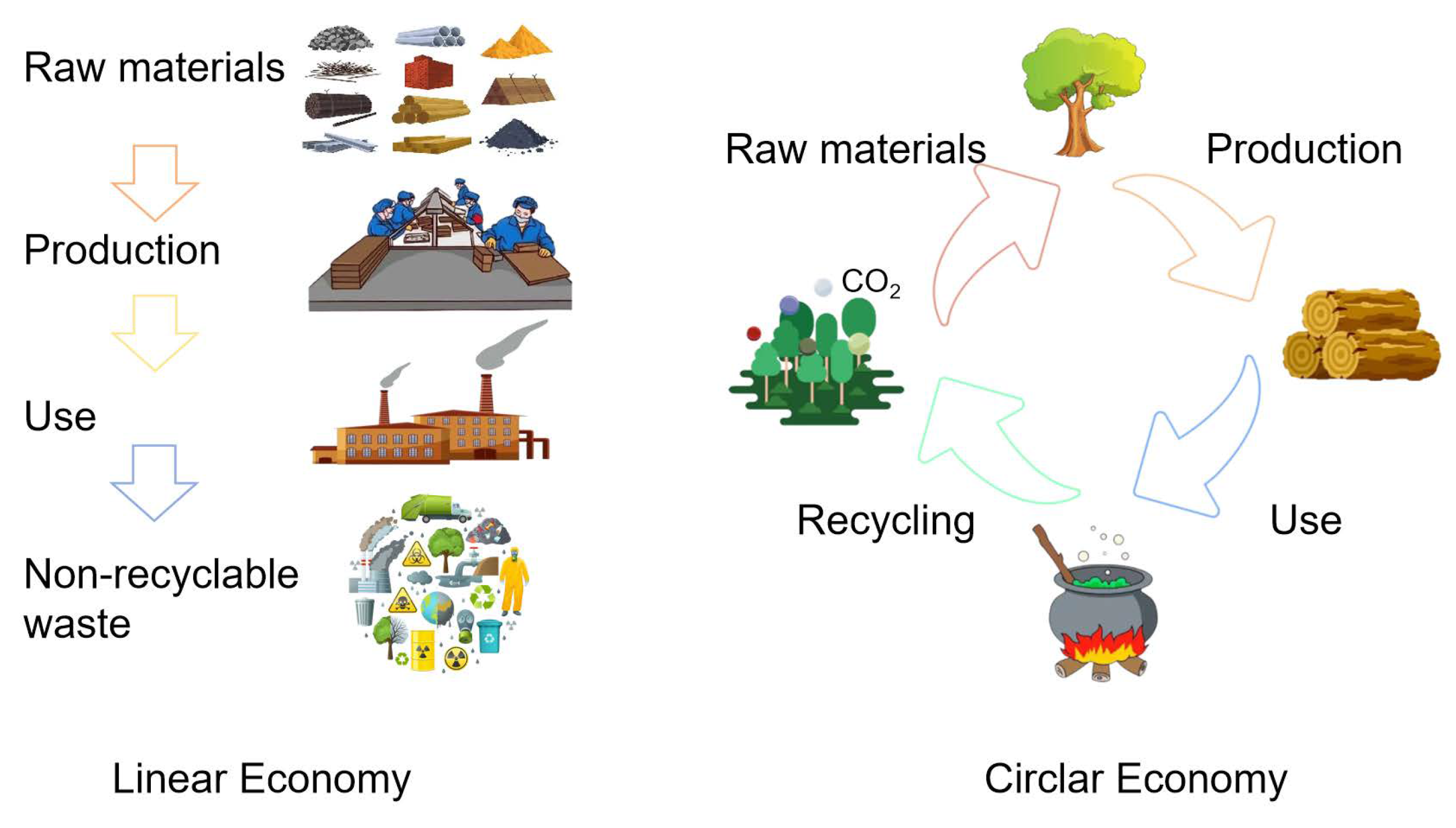

- Terms like Circular economy, Recycling, Reuse, Circularity, and End-of-life underscore the importance of circular design principles. The research highlights strategies for managing materials at the end of their life cycle and creating systems that minimize resource waste and environmental impact.

3. Multi-Aspect Impacts

3.1. Environmental Aspect

3.2. Economic Aspect

3.3. Social Aspect

4. Carbon Footprint Analysis

4.1. Raw Material Processing Stage

4.2. Transport and Construction Stage

4.3. Service Life Stage

4.4. End-of-Life Stage

5. Results and Discussion

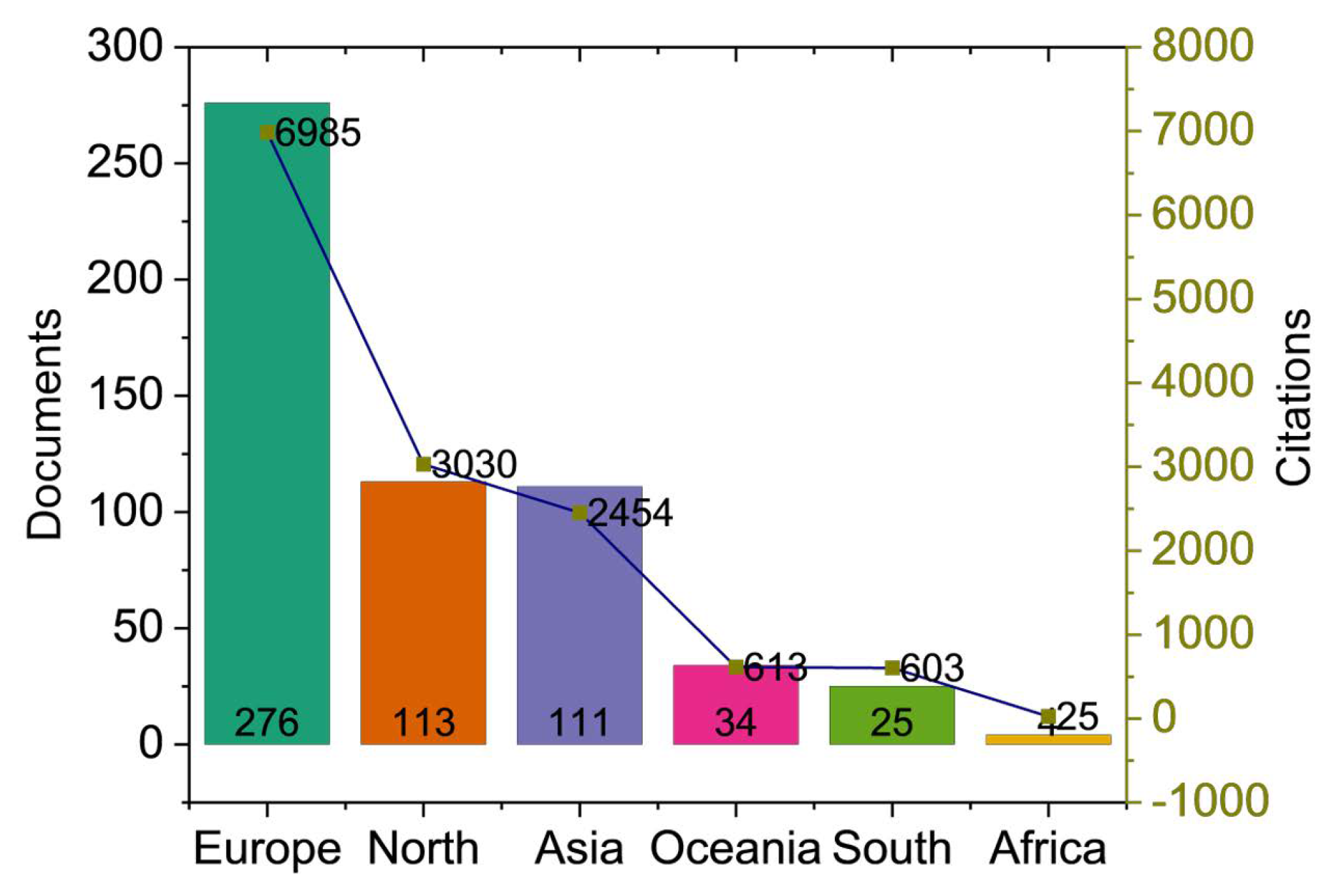

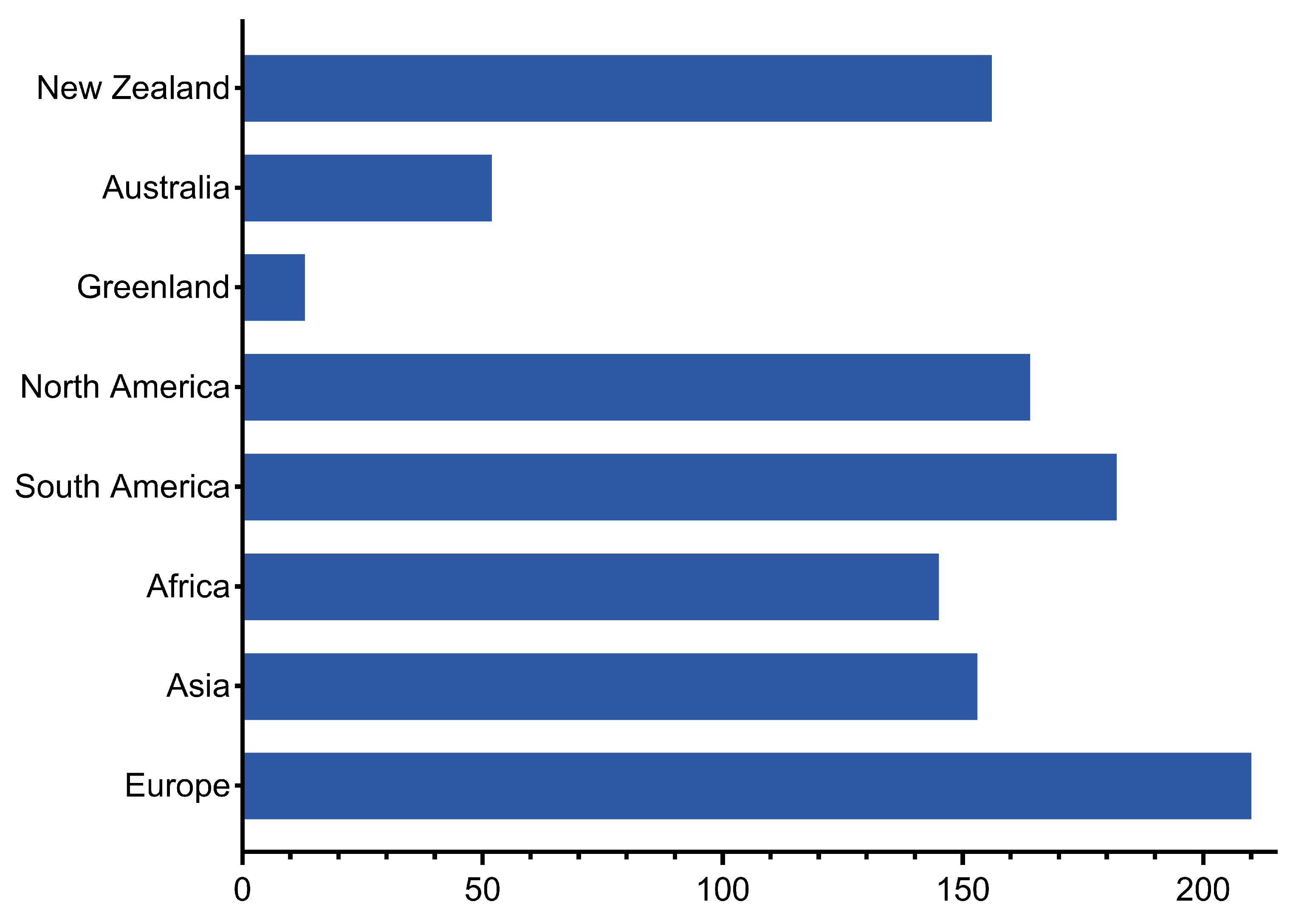

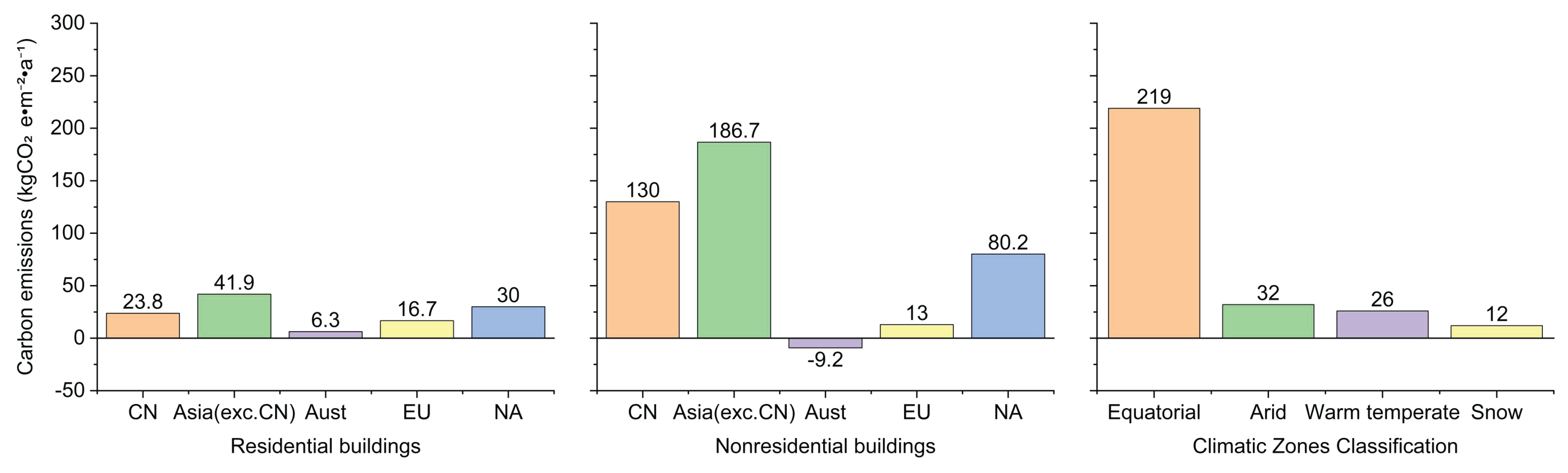

- Regional Carbon Footprint Disparities: European and North American studies consistently reported lower cradle-to-gate and cradle-to-grave carbon footprints for glulam production, typically 28–70% lower than those of conventional concrete and steel structures. These outcomes were largely attributed to advanced forest certification schemes (e.g., PEFC, FSC), widespread use of renewable energy in production (e.g., biomass boilers, hydropower), and optimized logistic networks [65,67,78]. For instance, German and Swedish glulam production systems recorded embodied carbon intensities as low as 110–160 kgCO2e/m2. Conversely, studies from parts of Asia, Sub-Saharan Africa, and Latin America highlighted significant emission burdens due to unsustainable logging practices, reliance on coal and diesel-based electricity, and lack of infrastructure for energy-efficient manufacturing. Notably, Southeast Asia’s tropical hardwood glulam products showed embodied emissions up to 340 kgCO2e/m2 (despite high-carbon-storage potential), mainly due to illegal logging, inefficient processing, and long transportation distances [70,71].

- Life Cycle Performance: Comparative LCAs demonstrated that glulam buildings outperformed reinforced concrete and steel alternatives across 11 to 18 environmental impact categories, including global warming potential (GWP), acidification, eutrophication, smog formation, and fossil fuel depletion [3,88]. Glulam’s inherent carbon storage capacity contributed to offsets ranging from 30% to 47% of total life cycle emissions, depending on regional forest growth rates, product longevity, and structural mass per square meter. Moreover, integration of low-carbon energy systems (e.g., district heating, heat pumps, photovoltaic arrays) during the operational phase reduced GWP by 9% to 67%, particularly in cold-climate applications where heating energy dominates [91,93]. For example, a Swedish study showed net-negative GWP when glulam structures were paired with biomass-based integrated gasification combined cycle (BIGCC) systems.

- Circular Economy Benefits: End-of-life (EOL) strategies emerged as a key differentiator in sustainability outcomes. Recycling and reuse of glulam components reduced EOL emissions by 12% to 29% compared to conventional demolition and landfilling pathways [99,100]. Europe led in circularity, with Sweden reporting up to 90% recovery rates of glulam beams during demolition [109]. Prefabrication techniques, including cross-laminated and hybrid glulam systems, reduced on-site construction time by up to 48% and overall project costs by 10–15%, particularly in Central and Eastern European countries like Slovakia [80,81]. These strategies also minimized embodied construction emissions, often overlooked in conventional LCA models.

- Social and Economic Impacts: Glulam construction was associated with multiple co-benefits beyond environmental metrics. In the European Union, the mass timber sector supports over 1 million jobs, particularly in rural and forestry-dependent regions, contributing to regional economic resilience [90]. Studies in Japan, Austria, and Canada linked glulam interiors with improved indoor environmental quality (IEQ), including increased thermal comfort and reduced stress levels—up to a 15% decrease in occupant-reported stress compared to concrete interiors [94]. Furthermore, glulam’s relatively low weight reduced foundation loads and site impacts, expanding feasibility in both urban infill and remote locations.

6. Conclusions

- Advance bio-based adhesives: Current limitations in the scalability, performance, and cost-efficiency of bio-adhesives impede their adoption. Targeted R&D in lignin-, tannin-, or protein-based alternatives should be prioritized to reduce the fossil-derived chemical content in glulam.

- Develop region-specific LCAs:There is an urgent need for geographically contextualized LCA models that account for local climate, forestry practices, and construction typologies, particularly in underrepresented regions like Africa and South America.

- Enhance end-of-life data and predictive modeling: Many glulam buildings have yet to reach their end-of-life stage. Longitudinal studies and scenario-based modeling should be implemented to improve accuracy in LCA projections and support circular economy planning.

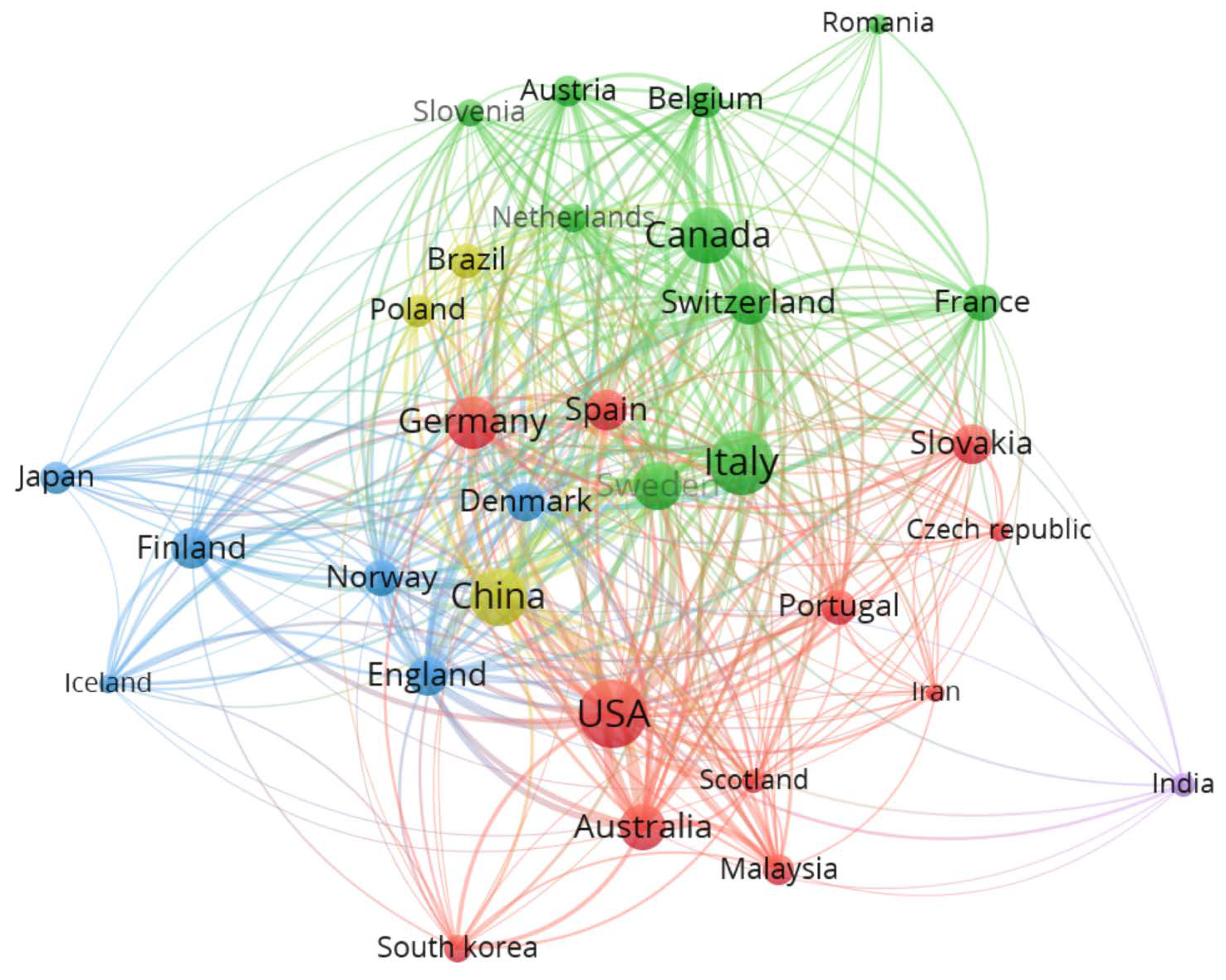

- Foster international collaboration and knowledge transfer: Partnerships such as the In Future Wood Project illustrate the importance of cross-border collaboration. Future efforts should expand shared databases, standardize life cycle inventory (LCI) formats, and facilitate policy learning between regions.

- Promote circular policy frameworks: Policymakers should incentivize material reuse, integrate cradle-to-cradle certification systems, and support demolition planning for material recovery. Financial tools such as green public procurement and carbon pricing should reward projects that demonstrate high material efficiency and low carbon intensity.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Alliance for Buildings and Construction. Global Status Report for Buildings and Construction. 2020. Available online: https://www.iea.org/reports/global-energy-review-2021 (accessed on 10 June 2025).

- Horowitz, C.A. Paris Agreement. Int. Leg. Mater. 2016, 55, 740–755. [Google Scholar] [CrossRef]

- Puettmann, M.; Pierobon, F.; Ganguly, I.; Gu, H.; Chen, C.; Liang, S.; Jones, S.; Maples, I.; Wishnie, M. Comparative LCAs of conventional and mass timber buildings in regions with potential for mass timber penetration. Sustainability 2021, 13, 13987. [Google Scholar] [CrossRef]

- Duan, Z.; Huang, Q.; Zhang, Q. Life cycle assessment of mass timber construction: A review. Build. Environ. 2022, 221, 109320. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Himes, A.; Busby, G. Wood buildings as a climate solution. Dev. Built Environ. 2020, 4, 100030. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, L.; Shi, Y.; Zhao, D.; Chen, T. Optimizing the Performance of Window Frames: A Comprehensive Review of Materials in China. Appl. Sci. 2024, 14, 6091. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Schau, E.M.; Niemelä, E.P.; Burnard, M.D. Comparing the environmental impacts of wooden buildings in Spain, Slovenia, and Germany. J. Clean. Prod. 2021, 329, 129587. [Google Scholar] [CrossRef]

- Shi, L.; Qi, X.; Yang, Z.; Tao, L.; Li, Y.; Qiu, J.; Jiang, X. Comparative study of greenhouse gas emission calculations and the environmental impact in the life cycle assessment of buildings in China, Finland, and the United States. J. Build. Eng. 2023, 70, 106396. [Google Scholar] [CrossRef]

- ISO 14040; 2006 Environmental Management-Life Cycle Assessment-Principles and Framework, second ed. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 10 June 2025).

- European Committee for Standardization. Sustainability of Construction Works-Assessment of Environmental Performance of Buildings Calculation Method. 2011. Available online: https://standards.globalspec.com/std/1406797.html (accessed on 10 June 2025).

- Concu, G. Sustainability of the timber supply chain on the island of Sardinia. In Proceedings of the Computational Science and Its Applications–ICCSA 2020: 20th International Conference, Cagliari, Italy, 1–4 July 2020; Proceedings, Part VII 20. Springer: Berlin/Heidelberg, Germany, 2020; pp. 353–367. [Google Scholar]

- Anex, R.; Lifset, R. Life cycle assessment: Different models for different purposes. J. Ind. Ecol. 2014, 18, 321–323. [Google Scholar] [CrossRef]

- Nobanee, H.; Al Hamadi, F.Y.; Abdulaziz, F.A.; Abukarsh, L.S.; Alqahtani, A.F.; AlSubaey, S.K.; Alqahtani, S.M.; Almansoori, H.A. A bibliometric analysis of sustainability and risk management. Sustainability 2021, 13, 3277. [Google Scholar] [CrossRef]

- Andersen, J.H.; Rasmussen, N.L.; Ryberg, M.W. Comparative life cycle assessment of cross laminated timber building and concrete building with special focus on biogenic carbon. Energy Build. 2022, 254, 111604. [Google Scholar] [CrossRef]

- Rinne, R.; Ilgın, H.E.; Karjalainen, M. Comparative study on life-cycle assessment and carbon footprint of hybrid, concrete and timber apartment buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S.S. COMPARATIVE LIFE-CYCLE ASSESSMENT OF A MASS TIMBER BUILDING AND CONCRETE ALTERNATIVE. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; Moya, L. Comparative BIM-based Life Cycle Assessment of Uruguayan timber and concrete-masonry single-family houses in design stage. J. Clean. Prod. 2020, 277, 121958. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W.; Yeoh, D. Recommending a new building structure to alleviate environmental impact in tropical climates: Increasing the use of wood in construction. Int. J. Life Cycle Assess. 2022, 27, 885–901. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, H.; Sun, C.; Chang, W.S. Assessing cross laminated timber (CLT) as an alternative material for mid-rise residential buildings in cold regions in China – A life-cycle assessment approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef]

- Nakano, K.; Karube, M.; Hattori, N. Environmental impacts of building construction using cross-laminated timber panel construction method: A case of the research building in Kyushu, Japan. Sustainability 2020, 12, 2220. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative life-cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the Athena impact estimator for buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Corradini, G.; Pierobon, F.; Zanetti, M. Product environmental footprint of a cross-laminated timber system: A case study in Italy. Int. J. Life Cycle Assess. 2019, 24, 975–988. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Y.; Meng, Y.; Huang, H.; Sun, C.; Shao, Y. A comparison of the energy saving and carbon reduction performance between reinforced concrete and cross-laminated timber structures in residential buildings in the severe cold region of China. Sustainability 2017, 9, 1426. [Google Scholar] [CrossRef]

- Jolly, R.; Fairweather, H.; Rayburg, S.; Rodwell, J. Life Cycle Assessment and Cost Analysis of Mid-Rise Mass Timber vs. Concrete Buildings in Australia. Sustainability 2024, 16, 6465. [Google Scholar] [CrossRef]

- Felmer, G.; Morales-Vera, R.; Astroza, R.; González, I.; Puettmann, M.; Wishnie, M. A lifecycle assessment of a low-energy mass-timber building and mainstream concrete alternative in central Chile. Sustainability 2022, 14, 1249. [Google Scholar] [CrossRef]

- Hafner, A.; Özdemir, Ö. Comparative LCA study of wood and mineral non-residential buildings in Germany and related substitution potential. Eur. J. Wood Wood Prod. 2023, 81, 251–266. [Google Scholar] [CrossRef]

- Dodoo, A.; Nguyen, T.; Dorn, M.; Olsson, A.; Bader, T.K. Exploring the synergy between structural engineering design solutions and life cycle carbon footprint of cross-laminated timber in multi-storey buildings. Wood Mater. Sci. Eng. 2022, 17, 30–42. [Google Scholar] [CrossRef]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, R.; Yao, L.; Ren, H.; Xu, J. Innovation analysis of carbon emissions from the production of glued laminated timber in China based on real-time monitoring data. J. Clean. Prod. 2024, 469, 143174. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, Y.; Feng, W.; Zhang, Y.; Zhao, G.X. How to minimise the carbon emission of steel building products from a cradle-to-site perspective: A systematic review of recent global research. J. Clean. Prod. 2022, 368, 133156. [Google Scholar] [CrossRef]

- Missiatto Gavioli, L.; Lopes Silva, D.A.; Bueno, C.; Rossignolo, J.A. Life cycle assessment as a circular economy strategy to select eco-efficient raw materials for particleboard production. Resour. Conserv. Recycl. 2025, 212, 107921. [Google Scholar] [CrossRef]

- ISO 20152-1:2010; Timber Structures–Bond Performance of Adhesives. International Organization for Standardization: Geneva, Switzerland, 2010. Available online: https://www.iso.org/standard/39252.html (accessed on 10 June 2025).

- Kumar, C.; Leggate, W. An overview of bio-adhesives for engineered wood products. Int. J. Adhes. Adhes. 2022, 118, 103187. [Google Scholar] [CrossRef]

- Allan, K.; Phillips, A.R. Comparative cradle-to-grave life cycle assessment of low and mid-rise mass timber buildings with equivalent structural steel alternatives. Sustainability 2021, 13, 3401. [Google Scholar] [CrossRef]

- Hafner, A.; Rueter, S. Method for assessing the national implications of environmental impacts from timber buildings—An exemplary study for residential buildings in Germany. Wood Fiber Sci. 2018, 50, 139–154. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, X.; Diao, J.; Chen, H.; Lin, S.; Zhu, Z.; Jiang, X.; Zhu, H. Exploring plausible contributions of end-use harvested wood products to store atmospheric carbon in China. Biomass Bioenergy 2023, 177, 106934. [Google Scholar] [CrossRef]

- Kayo, C.; Dente, S.M.; Aoki-Suzuki, C.; Tanaka, D.; Murakami, S.; Hashimoto, S. Environmental impact assessment of wood use in Japan through 2050 using material flow analysis and life cycle assessment. J. Ind. Ecol. 2019, 23, 635–648. [Google Scholar] [CrossRef]

- Shin, B.; Kim, S. Advancing the circular economy and environmental sustainability with timber hybrid construction in South Korean public building. Build. Environ. 2024, 257, 111543. [Google Scholar] [CrossRef]

- Risse, M.; Weber-Blaschke, G.; Richter, K. Eco-efficiency analysis of recycling recovered solid wood from construction into laminated timber products. Sci. Total Environ. 2019, 661, 107–119. [Google Scholar] [CrossRef] [PubMed]

- Švajlenka, J.; Kozlovská, M.; Spišáková, M. The benefits of modern method of construction based on wood in the context of sustainability. Int. J. Environ. Sci. Technol. 2017, 14, 1591–1602. [Google Scholar] [CrossRef]

- Sikkema, R.; Styles, D.; Jonsson, R.; Tobin, B.; Byrne, K.A. A market inventory of construction wood for residential building in Europe – in the light of the Green Deal and new circular economy ambitions. Sustain. Cities Soc. 2023, 90, 104370. [Google Scholar] [CrossRef]

- Goldaraz-Salamero, N.; Sierra-Perez, J.; Negro, F.; Zanuttini, R.; Blanc, S.; Brun, F. Integrated sustainability assessment of wood building products: The case of larch and chestnut cascading systems in Northern Italy. Sci. Total Environ. 2024, 951, 175601. [Google Scholar] [CrossRef]

- Svortevik, V.J.; Engevik, M.B.; Kraniotis, D. Use of cross laminated timber (CLT) in industrial buildings in Nordic climate—A case study. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012082. [Google Scholar] [CrossRef]

- Greene, J.M.; Hosanna, H.R.; Willson, B.; Quinn, J.C. Whole life embodied emissions and net-zero emissions potential for a mid-rise office building constructed with mass timber. Sustain. Mater. Technol. 2023, 35, e00528. [Google Scholar] [CrossRef]

- Cattarinussi, L.; Hofstetter, K.; Ryffel, R.; Zumstein, K.; Ioannidou, D.; Klippel, M. Life cycle assessment of a post-tensioned timber frame in comparison to a reinforced concrete frame for tall buildings. In Proceedings of the Sustainable Built Environment (SBE) Regional Conference (SBE 16), Zurich, Switzerland, 15–17 June 2016; vdf Hochschulverlag AG an der ETH Zürich: Zurich, Switzerland, 2016; pp. 656–661. [Google Scholar] [CrossRef]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; Da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete. Resour. Conserv. Recycl. 2021, 166, 105346. [Google Scholar] [CrossRef]

- Jayalath, A.; Navaratnam, S.; Ngo, T.; Mendis, P.; Hewson, N.; Aye, L. Life cycle performance of Cross Laminated Timber mid-rise residential buildings in Australia. Energy Build. 2020, 223, 110091. [Google Scholar] [CrossRef]

- Crafford, P.L.; Wessels, C.B.; Blumentritt, M. Sustainability and wood constructions: A review of green building rating systems and life-cycle assessment methods from a South African and developing world perspective. Adv. Build. Energy Res. 2021, 15, 67–86. [Google Scholar] [CrossRef]

- Larasatie, P.; Guerrero, J.E.; Conroy, K.; Hall, T.E.; Hansen, E.; Needham, M.D. What does the public believe about tall wood buildings? An exploratory study in the US Pacific Northwest. J. For. 2018, 116, 429–436. [Google Scholar] [CrossRef]

- Petruch, M.; Walcher, D. Timber for future? Attitudes towards timber construction by young millennials in Austria-Marketing implications from a representative study. J. Clean. Prod. 2021, 294, 126324. [Google Scholar] [CrossRef]

- Aguilar, F.X.; Roos, A.; Haapala, A.; Lähtinen, K.; Kniivilä, M.; Hoen, H.F. Dweller Preferences for Wood as a Load-Bearing Material in Residential Buildings. J. For. Econ. 2023, 38, 77–111. [Google Scholar] [CrossRef]

- Šujanová, P.; Rychtáriková, M.; Sotto Mayor, T.; Hyder, A. A healthy, energy-efficient and comfortable indoor environment, a review. Energies 2019, 12, 1414. [Google Scholar] [CrossRef]

- Ridoutt, B.; Ball, R.; Killerby, S. First impressions of organizations and the qualities connoted by wood in interior design. For. Prod. J. 2002, 52, 30–36. [Google Scholar]

- Cronhjort, Y. Project Wood2New. In Proceedings of the Fremtiden bygges i Tre-Seminar, Wood2New, Bergen, Norway, 23 June 2015. [Google Scholar] [CrossRef]

- Hiroyasu, S.; Yoshihiro, Y. Challenges in High-rise Wooden Structures and the Seismic Design in Japan. Int. J. High-Rise Build. 2022, 11, 171–180. [Google Scholar]

- Kosonen, A.; Keskisaari, A. Zero-energy log house–Future concept for an energy efficient building in the Nordic conditions. Energy Build. 2020, 228, 110449. [Google Scholar] [CrossRef]

- Vehola, A.; Hurmekoski, E.; Lähtinen, K.; Ruokamo, E.; Roos, A.; Toivonen, R.; Toppinen, A. Citizen beliefs concerning wood as a construction material under extreme weather events. Can. J. For. Res. 2022, 52, 1266–1279. [Google Scholar] [CrossRef]

- Van den Auwelant, E.; Nimmegeers, P.; Van Passel, S. Life cycle assessment and circular practices in the woodworking sector: A systematic review. Clean Technol. Environ. Policy 2025, 27, 1673–1692. [Google Scholar] [CrossRef]

- Amoruso, F.M.; Schuetze, T. Life cycle assessment and costing of carbon neutral hybrid-timber building renovation systems: Three applications in the Republic of Korea. Build. Environ. 2022, 222, 109395. [Google Scholar] [CrossRef]

- Viljanen, A.; Lähtinen, K.; Kanninen, V.; Toppinen, A. A tale of five cities: The role of municipalities in the market diffusion of wooden residential multistory construction and retrofits. For. Policy Econ. 2023, 153, 102991. [Google Scholar] [CrossRef]

- Bertolini Cestari, C.; Marzi, T. Conservation of historic timber roof structures of Italian architectural heritage: Diagnosis, assessment, and intervention. Int. J. Archit. Herit. 2018, 12, 632–665. [Google Scholar] [CrossRef]

- Noon, M.L.; Goldstein, A.; Ledezma, J.C.; Roehrdanz, P.R.; Cook-Patton, S.C.; Spawn-Lee, S.A.; Wright, T.M.; Gonzalez-Roglich, M.; Hole, D.G.; Rockström, J.; et al. Mapping the irrecoverable carbon in Earth’s ecosystems. Nat. Sustain. 2022, 5, 37–46. [Google Scholar] [CrossRef]

- Martinho, V.J.P.D.; Ferreira, A.J.D. Forest resources management and sustainability: The specific case of european union countries. Sustainability 2020, 13, 58. [Google Scholar] [CrossRef]

- Cosola, G.; Grigolato, S.; Ackerman, P.; Monterotti, S.; Cavalli, R. Carbon footprint of forest operations under different management regimes. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2016, 37, 201–217. [Google Scholar]

- Jensen, A.V.; Craig, N. Wood in Construction-25 Cases of Nordic Good Practice; Nordic Council of Ministers: Copenhagen, Denmark, 2019.

- Natural Resources Canada. The State of Canada’s Forests: Annual Report 2020; Natural Resources Canada: Ottawa, ON, Canada, 2020.

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. For. Int. J. For. Res. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Araya, R.; Guillaumet, A.; do Valle, Â.; Duque, M.d.P.; Gonzalez, G.; Cabrero, J.M.; De León, E.; Castro, F.; Gutierrez, C.; Negrão, J.; et al. Development of sustainable timber construction in Ibero-America: State of the art in the region and identification of current international gaps in the construction industry. Sustainability 2022, 14, 1170. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.; Long, H.; de Jong, W.; Youn, Y.C. Economic globalization, trade and forest transition-the case of nine Asian countries. For. Policy Econ. 2017, 76, 7–13. [Google Scholar] [CrossRef]

- Navaratnam, S.; Christopher, P.B.; Ngo, T.; Le, T.V. Bending and shear performance of Australian Radiata pine cross-laminated timber. Constr. Build. Mater. 2020, 232, 117215. [Google Scholar] [CrossRef]

- Dani, A.A.; Roy, K.; Masood, R.; Fang, Z.; Lim, J.B. A comparative study on the life cycle assessment of New Zealand residential buildings. Buildings 2022, 12, 50. [Google Scholar] [CrossRef]

- Sander-Titgemeyer, A.; Risse, M.; Weber-Blaschke, G. Applying an iterative prospective LCA approach to emerging wood-based technologies: Three German case studies. Int. J. Life Cycle Assess. 2023, 28, 495–515. [Google Scholar] [CrossRef]

- Tan, X.; Lin, S.; Liu, Y.L.; Xie, B.C. Has the inter-regional transmission grid promoted clean power development? A quantitative assessment on China’s electricity sector. J. Clean. Prod. 2020, 269, 122370. [Google Scholar] [CrossRef]

- Atnoorkar, S.; Ghatpande, O.A.; Haile, S.L.; Goetsch, H.E.; Harris, C.B. Carbon intensity of mass timber materials: Impacts of sourcing and transportation. Front. Built Environ. 2024, 9, 1321340. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Jones, S.; Maples, I.; Gong, Y.; Ganguly, I. Comparative life cycle assessment of mass timber and concrete residential buildings: A case study in China. Sustainability 2021, 14, 144. [Google Scholar] [CrossRef]

- Pei-Ning, T.; Bao-Hua, M.; Rui-Yong, T.; Hao-Xiang, Z.; Qi, Z. Analysis of carbon emission level and intensity of China’s transportation industry and different transportation modes. Adv. Clim. Change Res. 2023, 19, 347. [Google Scholar]

- Li, L.; Chen, K. Quantitative assessment of carbon dioxide emissions in construction projects: A case study in Shenzhen. J. Clean. Prod. 2017, 141, 394–408. [Google Scholar] [CrossRef]

- David, M.N.; Miguel, R.S.; Ignacio, P.Z. Timber structures designed for disassembly: A cornerstone for sustainability in 21st century construction. J. Build. Eng. 2024, 96, 110619. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Khan, M.; Dani, A.A.; Lim, J.B.; Roy, K. Appraising the Feasibility of 3D Printing Construction in New Zealand Housing. Buildings 2024, 14, 1084. [Google Scholar] [CrossRef]

- Cuéllar-Franca, R.M.; Azapagic, A. Environmental impacts of the UK residential sector: Life cycle assessment of houses. Build. Environ. 2012, 54, 86–99. [Google Scholar] [CrossRef]

- Van Ooteghem, K.; Xu, L. The life-cycle assessment of a single-storey retail building in Canada. Build. Environ. 2012, 49, 212–226. [Google Scholar] [CrossRef]

- Jing, R.; Wang, M.; Zhang, R.; Li, N.; Zhao, Y. A study on energy performance of 30 commercial office buildings in Hong Kong. Energy Build. 2017, 144, 117–128. [Google Scholar] [CrossRef]

- Ni, S.; Zhu, N.; Hou, Y.; Zhang, Z. Research on indoor thermal comfort and energy consumption of zero energy wooden structure buildings in severe cold zone. J. Build. Eng. 2023, 67, 105965. [Google Scholar] [CrossRef]

- Morelli, M.; Rønby, L.; Mikkelsen, S.E.; Minzari, M.G.; Kildemoes, T.; Tommerup, H.M. Energy retrofitting of a typical old Danish multi-family building to a “nearly-zero” energy building based on experiences from a test apartment. Energy Build. 2012, 54, 395–406. [Google Scholar] [CrossRef]

- Pittau, F.; Giacomel, D.; Iannaccone, G.; Malighetti, L. Environmental consequences of refurbishment versus demolition and reconstruction: A comparative life cycle assessment of an Italian case study. J. Green Build. 2020, 15, 155–172. [Google Scholar] [CrossRef]

- Lolli, N.; Fufa, S.M.; Kjendseth Wiik, M. An assessment of greenhouse gas emissions from CLT and glulam in two residential nearly zero energy buildings. Wood Mater. Sci. Eng. 2019, 14, 342–354. [Google Scholar] [CrossRef]

- Strang, M. Moisture Safety for Energy-Efficient CLT Envelopes: Pathways to Net-Zero Operational Energy for Engineered Wood Multi-Storey Buildings in Australian Tropical and Subtropical Climates. Ph.D. Thesis, School of Architecture, Design and Planning, The University of Queensland, Brisbane, Australia, 2023. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Analysis of embodied carbon in the building life cycle considering the temporal perspectives of emissions: A case study in China. Energy Build. 2017, 155, 404–413. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Operational energy in the life cycle of residential dwellings: The experience of Spain and Colombia. Appl. Energy 2010, 87, 673–680. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life cycle primary energy analysis of residential buildings. Energy Build. 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Korsavi, S.S.; Jones, R.V.; Bilverstone, P.A.; Fuertes, A. A longitudinal assessment of the energy and carbon performance of a Passivhaus university building in the UK. J. Build. Eng. 2021, 44, 103353. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Aranda Usón, A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Passarelli, R. The Environmental Impact of Reused CLT Panels: Study of a Single-Storey Commercial Building In Japan. In Proceedings of the 2018 World Conference on Timber Engineering, Seoul, Republic of Korea, 20–23 August 2018. [Google Scholar]

- Grann, B. A Comparative Life Cycle Assessment of Two Multistory Residential Buildings: Cross-Laminated Timber vs. Concrete Slab and Column with Light Gauge Steel Walls; Technical Report; FPInnovations: Vancouver, BC, Canada, 2013; pp. 1–121. [Google Scholar]

- Hafner, A.; Ott, S.; Winter, S. Recycling and end-of-life scenarios for timber structures. In Materials and Joints in Timber Structures: Recent Developments of Technology; Springer: Dordrecht, The Netherlands, 2014; pp. 89–98. [Google Scholar]

- Darby, H.; Elmualim, A.; Kelly, F. A Case Study to Investigate the Life Cycle Carbon Emissions and Carbon Storage Capacity of a Cross Laminated Timber, Multi-Storey Residential Building; Fraunhofer IRB Verlag: Stuttgart, Germany, 2013; pp. 10–12. [Google Scholar]

- Liang, S.; Gu, H.; Bergman, R. Environmental life-cycle assessment and life-cycle cost analysis of a high-rise mass timber building: A case study in Pacific Northwestern United States. Sustainability 2021, 13, 7831. [Google Scholar] [CrossRef]

- Vishnu, T.; Singh, K.L. A study on the suitability of solid waste materials in pavement construction: A review. Int. J. Pavement Res. Technol. 2021, 14, 625–637. [Google Scholar] [CrossRef]

- Head, M.; Magnan, M.; Kurz, W.A.; Levasseur, A.; Beauregard, R.; Margni, M. Temporally-differentiated biogenic carbon accounting of wood building product life cycles. SN Appl. Sci. 2021, 3, 62. [Google Scholar] [CrossRef]

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 2016, 125, 219–226. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- EN 14081-1:2019; Timber Structures–Strength Graded Structural Timber—Part 1: General Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Ridley-Ellis, D.; Stapel, P.; Baño, V. Strength grading of sawn timber in Europe: An explanation for engineers and researchers. Eur. J. Wood Wood Prod. 2016, 74, 291–306. [Google Scholar] [CrossRef]

- Husgafvel, R.; Linkosalmi, L.; Hughes, M.; Kanerva, J.; Dahl, O. Forest sector circular economy development in Finland: A regional study on sustainability driven competitive advantage and an assessment of the potential for cascading recovered solid wood. J. Clean. Prod. 2018, 181, 483–497. [Google Scholar] [CrossRef]

- Wang, J.; Teng, Y.; Chen, Z.; Bai, J.; Niu, Y.; Duan, H. Assessment of carbon emissions of building interior decoration and renovation waste disposal in the fast-growing Greater Bay Area, China. Sci. Total Environ. 2021, 798, 149158. [Google Scholar] [CrossRef] [PubMed]

- Harte, A.M.; Chúláin, C.U.; Nasiri, B.; Hughes, M.; Llana, D.F.; Íñiguez-González, G.; de Arana-Fernández, M.; Shotton, E.; Walsh, S.J.; Ridley-Ellis, D.; et al. Recovered Timber in Europe: Sources, Classification, Existing and Potential Reuse and Recycling; National University of Ireland Galway: Galway, Ireland, 2020. [Google Scholar]

- Sandberg, K.; Sandin, Y.; Harte, A.; Shotton, E.; Hughes, M.; Ridley-Ellis, D.; Turk, G.; Iniguez-Gonalez, G.; Risse, M.; Cristescu, C. Summary Report InFutUReWood–Innovative Design for the Future–Use and Reuse of Wood (Building) Components; European Forest Institute: Joensuu, Finland, 2022. [Google Scholar] [CrossRef]

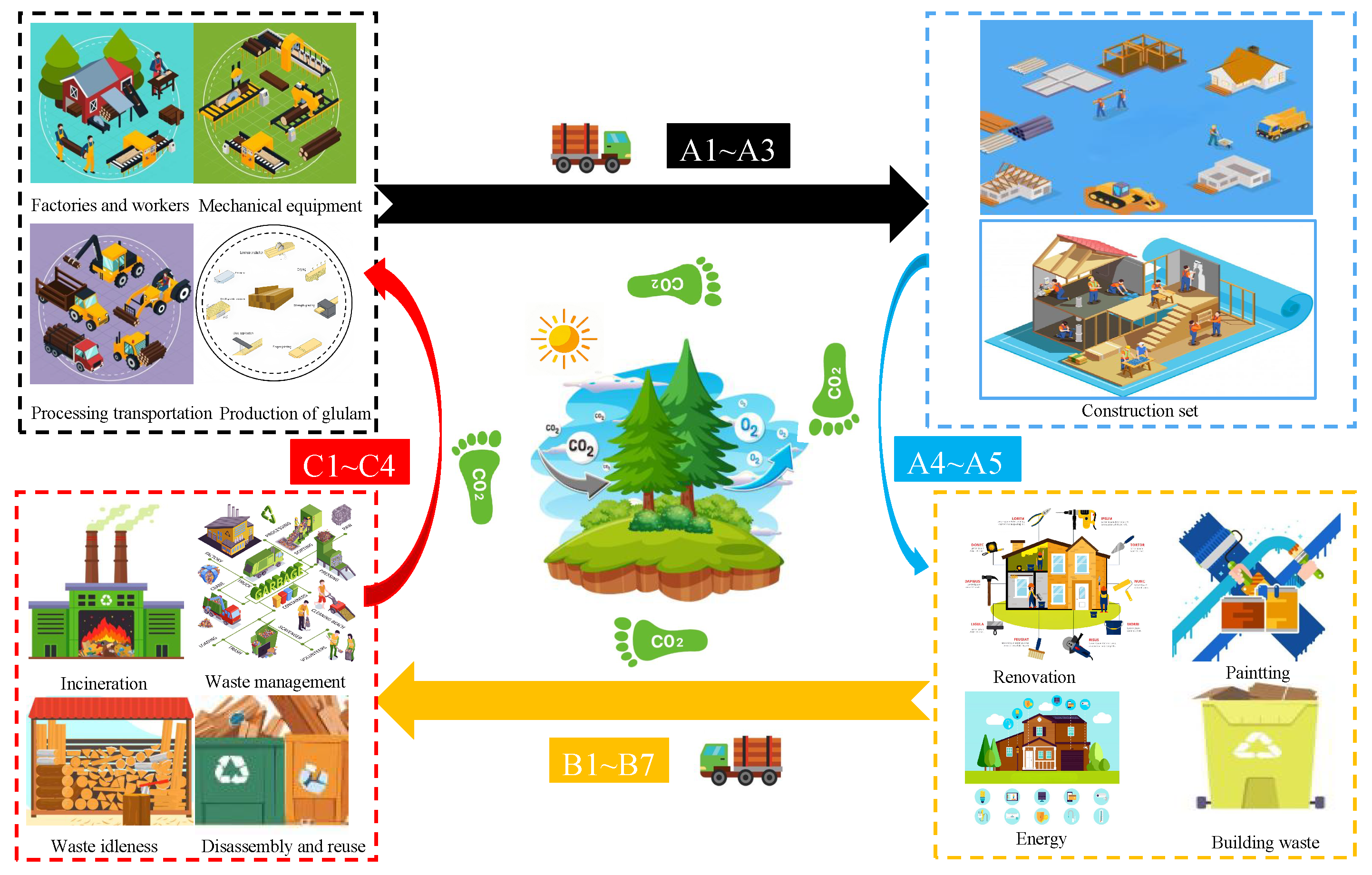

| Module | Phase | Stage | Processes |

|---|---|---|---|

| A1–3 | Production | A1 | Raw Material |

| A2 | Transport | ||

| A3 | Manufacturing in Factory | ||

| A4–5 | Construction | A4 | Transport |

| A5 | Installation and Erected Process | ||

| B1–7 | Service Life | B1 | Use |

| B2 | Maintenance | ||

| B3 | Repair | ||

| B4 | Replacement | ||

| B5 | Refurbishment | ||

| B6 | Operation Energy | ||

| B7 | Use Operation Water Use | ||

| C1–4 | End-of-Life | C1 | Demolition |

| C2 | Transport | ||

| C3 | Waste Idleness | ||

| C4 | Waste Management | ||

| D | Potential Benefits and Loads | D1 | Other Environmental Impacts |

| Keywords | Occurrences | Total Link Strength |

|---|---|---|

| Life Cycle Assessment (LCA) | 359 | 522 |

| Life cycle cost | 17 | 24 |

| Dynamic LCA | 12 | 23 |

| Simapro | 6 | 13 |

| Comparative LCA | 5 | 9 |

| Cradle-to-cradle | 5 | 15 |

| Wood | 37 | 84 |

| Wood buildings | 27 | 47 |

| CLT | 33 | 77 |

| Mass timber | 11 | 33 |

| Wood products | 10 | 20 |

| Bio-based materials | 7 | 14 |

| Natural materials | 5 | 5 |

| Environmental product declaration | 7 | 13 |

| Material substitution | 6 | 14 |

| Timber structures | 5 | 9 |

| Concrete | 9 | 22 |

| Buildings | 48 | 105 |

| Building materials | 21 | 48 |

| Green building | 5 | 11 |

| Built environment | 5 | 13 |

| Residential building | 11 | 21 |

| Building information modeling | 5 | 7 |

| Building design | 8 | 24 |

| Building envelope | 7 | 12 |

| Embodied carbon | 32 | 76 |

| Biogenic carbon | 28 | 78 |

| Carbon footprint | 19 | 37 |

| Carbon storage | 23 | 53 |

| Carbon emission | 11 | 16 |

| Sustainability | 38 | 80 |

| Sustainable construction | 12 | 15 |

| Sustainability assessment | 6 | 15 |

| Environmental impact | 50 | 96 |

| Industrial ecology | 6 | 15 |

| Global warming | 35 | 85 |

| Climate change | 20 | 53 |

| Greenhouse gas emissions | 22 | 51 |

| Climate change mitigation | 8 | 19 |

| Embodied energy | 19 | 38 |

| Energy consumption | 11 | 21 |

| Energy efficiency | 9 | 19 |

| Primary energy | 7 | 16 |

| Energy | 5 | 8 |

| Land use | 7 | 15 |

| Circular economy | 21 | 39 |

| Bioeconomy | 6 | 8 |

| Construction and demolition waste | 6 | 12 |

| Recycling | 6 | 10 |

| Circularity | 5 | 13 |

| Reuse | 5 | 12 |

| End-of-life | 5 | 8 |

| Transport | 5 | 9 |

| Allocation | 5 | 13 |

| Ref. | Location | Building Profile | Contrasting Material | Key Findings |

|---|---|---|---|---|

| [16] | Finland | Five-story apartment, 7250 m2, CLT, 50-year lifespan | Wood concrete | 28% lower emissions (A1–A3), 55% lower emissions (A4), highest CO2eq 44,627 kg, most advantageous timber, 47% in the eutrophication impact category |

| [17] | USA | Twelve-story mixed-use apartment/office, 8360 m2, 1782 m3 CLT, 557 m3 glulam | Concrete and rebar | 18%, 1%, and 47% reduction in the impact categories of global warming, ozone depletion, and eutrophication, respectively (A1–A5) |

| [18] | Uruguay | One-floor single-family house, 63 m2, CLT, 60-year lifespan | Concrete masonry structure | Glulam had low median values in impact categories such as GWP, AP, FWE, HT, and ODP, but was higher in use phase (B2–B4) |

| [19] | Malaysia | One-floor residential, 142.88 m2, CLT beams, steel-plate walls/roofs, 50-year lifespan | Light steel frame, concrete, brick | Lower emissions in all environmental categories, namely, GWP, HT, FDP, OLD, TA |

| [20] | China | Seven-story CLT structure, 2799.3 m2, 50-year lifespan | Concrete | 30% reduction in energy use, 40% reduction in CO2 emissions |

| [21] | Japan | Two-floor research building, 1424.23 m2, CLT | Concrete foundation | CLT 17% of total impact, stored carbon 32% of emissions, biomass-derived electricity was also reduced on acidification by 5%, and photochemical oxidation was reduced by 7% |

| [22] | USA | Twelve-story mixed-use, 8360 m2, glulam columns/beams, CLT floors/walls, 60-year lifespan | Concrete and rebar | 70% lower emissions than RC (excluding B6) |

| [15] | Norway | Eight-story CLT study, 3973 m2 heated, 695 m2 basement, 100-year lifespan | Five-story concrete, 2449 m2 heated | Among the 18 environmental impact indicator categories, CLT buildings scored the lowest in 11 impact categories, especially with a CLT of 49.7% lower for GWP |

| [23] | Italy | 1 m2 CLT external wall, primary school classroom, 50-year lifespan | \ | for 14 impact categories, the use phase has the highest environmental impact, in particular, ozone depletion, freshwater cutrophication, and ecotoxicity for aquatic freshwater, followed by the production, end-of-life, raw material acquisition, and construction phases |

| [24] | China | 4–17 stories, 4900–26,500 m2, 50-year lifespan | RC | 13% lower GWP than RC (excluding B3–B5) |

| [25] | Australia | 10 stories, no basement, 1558 m2, 75-year lifespan | RC | 40% reduction in GHG emissions, FW about 20 times lower, and PENRT reaching a negative value |

| [26] | Chile | Five-story midrise social housing, CLT, 1405 m2 | Concrete (same design) | 42% lower embodied emissions, biogenic carbon storage 447 tons CO2eq/m2 |

| [27] | Germany | 2–4-story office/admin buildings, 292–5445 m2, agricultural buildings 906–2555 m2, 50-year lifespan | Steel, concrete, brick | Office/admin emissions reduced by 6–48%, agricultural by 5–37%, non-agricultural by 14–44% |

| [28] | Sweden | Eight-story, 3374 m2, CLT, 50-year lifespan | \ | 203.4 kg CO2eq/m2 (material production), reduction up to 43% with engineering solutions |

| Region | Research Focus | Findings |

|---|---|---|

| China [38] | Carbon transfer from forests through industrial processing to end-use wood products | Annual net carbon sink of 14.9 Tg C per year, cumulative absorption of 893 Tg C, with 76% stored in furniture products. The carbon pool of HWPs could absorb up to 2979 ± 806 Tg C. |

| Japan [39] | Environmental impact and emission reductions of wood consumption from 1970–2013 using LCA | Increased wood use for construction, furniture, and energy production could reduce environmental impacts by CNY 357 billion in 2050. |

| South Korea [40] | Material circularity and environmental impact of timber hybrid public building | Environmental impact reductions of −13.5%, −11.5%, and −5.0% based on different structural applications. BCI improved from 0.26 to 0.31, 0.29, and 0.25. |

| Malaysia [19] | Application potential of wood in local construction | Using wood in steel and concrete construction could save 36–45% in production, labor, transportation, and machinery costs. |

| Germany [41] | Recycling technology for recovered solid wood into GLT products | Recycling into GLT resulted in 29% lower environmental impact and 32% lower costs than incineration. |

| Slovakia [42] | Benefits of prefabricated panel wood construction (PWC) | Construction time 48% shorter, cost 15% lower, and transportation cost 57% lower than brick and stone buildings. |

| European Countries [43] | Assessment of construction wood use intensity | Cyprus and Malta had the least use (0.01 ratio), Estonia and Romania had the highest (0.32 ratio). |

| Italy [44] | Environmental and market performance of wood supply chains | OSB manufacturing is a better alternative for energy use of wood chips; recycling provided better end-of-life treatment. |

| Norway [45] | Feasibility and sustainability of CLT in industrial buildings | CLT elements could achieve 3.3% total energy cost savings. |

| USA [46] | Comparison of steel frame and wood alternative for a four-story office building | 75% of CLT and 95% of glulam could be reused; remaining converted to particleboard. |

| Canada [47] | Feasibility of converting construction and demolition wood waste into biofuels | Biofuel production was economically feasible when considering GHG emission reductions. |

| Brazil [48] | Circular economy strategy using recycled wood chips | Recycling wood waste into bio-concrete provided a carbon sink and contributed to low-carbon construction. |

| Australia [49] | Comparison of GHG emissions and life cycle cost of CLT vs. reinforced concrete buildings | CLT buildings had lower initial costs (8–10% savings), 30% less construction time, and lower labor, demolition, and recycling costs. However, maintenance was 13–16% more expensive than RC. |

| South Africa [50] | Log resource availability and global warming impact of wood-based residential buildings | High self-sufficiency in forestry products; valuable sawn timber market; provided sustainable forest management practices. |

| Community Well-Being | Cultural Significance | Workforce and Job Creation | Equity and Accessibility |

|---|---|---|---|

| Contributions of glulam buildings to community health and safety, improvement in living conditions | role of glulam in preserving architectural heritage and supporting culturally appropriate designs | opportunities in forestry, manufacturing, and construction sectors tied to glulam supply chains | addressing housing affordability, inclusive design for vulnerable populations, and fair labor practices |

| Thermal Comfort | Visual Comfort | Acoustic Comfort | Indoor Air Quality | |

|---|---|---|---|---|

| Parameter | PMV/PPD or operative temperature; Humidity; Air velocity; Vertical air temperature differences; Radiant temperature asymmetry; Surface temperature of the floor | Requirements for lighting and day lighting provision; View out; Exposure to sunlight; Illuminance; Luminance; Light uniformity; Glare; Color (color rendering, light source color) | Sound level difference; Sound insulation; Sound absorption; Noise level(s) Frequency | Pollutant concentrations (such as VOCs, CO2), ventilation parameters, airflow patterns and pressure relationships |

| Human Physiology | Skin heat receptors; Core body temperature regulation system | Visual system | Auditory system | Respiratory and inhalation systems, olfactory systems |

| Influence Factors | Mild temperature; Humidity regulation | The fit of biophilic design | Sound absorption characteristics | Woody aroma, antibacterial performance, and low-carbon environmental sustainability |

| Mode of Transport | Turnover | Carbon Emission Factor |

|---|---|---|

| Aviation | 1293.25 t·km | 899.48 g/(t·km) |

| Road Freight | 59,636.39 t·km | 97.60 g/(t·km) |

| Railway | 41,539.10 t·km | 11.3 g/(t·km) |

| Water Transport | 104,003.15 t·km | 8.65 g/(t·km) |

| Phase | Reuse | Recycling | Incineration | Incineration (with Energy Recovery) | Landfill |

|---|---|---|---|---|---|

| Up to construction | −1100 | −1100 | −1100 | −1100 | −1100 |

| Demolition | 22 | 22 | 22 | 22 | 22 |

| Transport | 12 | 12 | 12 | 12 | 12 |

| Re-manufacture | - | 10 | - | - | - |

| Re-transport | - | 12 | - | - | - |

| Re-construction | 45 | 45 | - | - | - |

| Combustion | - | - | 1192 | 1192 | - |

| Energy recovered | - | - | - | −628 | - |

| Emissions from landfill | - | - | - | - | 1013 |

| Total | −1021 | −99 | 126 | −502 | −53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Yao, L.; Gong, Y.; Wang, Z. Life Cycle Assessment with Carbon Footprint Analysis in Glulam Buildings: A Review. Buildings 2025, 15, 2127. https://doi.org/10.3390/buildings15122127

Liu R, Yao L, Gong Y, Wang Z. Life Cycle Assessment with Carbon Footprint Analysis in Glulam Buildings: A Review. Buildings. 2025; 15(12):2127. https://doi.org/10.3390/buildings15122127

Chicago/Turabian StyleLiu, Ruijing, Lihong Yao, Yingchun Gong, and Zhen Wang. 2025. "Life Cycle Assessment with Carbon Footprint Analysis in Glulam Buildings: A Review" Buildings 15, no. 12: 2127. https://doi.org/10.3390/buildings15122127

APA StyleLiu, R., Yao, L., Gong, Y., & Wang, Z. (2025). Life Cycle Assessment with Carbon Footprint Analysis in Glulam Buildings: A Review. Buildings, 15(12), 2127. https://doi.org/10.3390/buildings15122127