1. Introduction

In the thermal balance of a building enclosure, windows emerge as a crucial source of net heat loss. Over extended periods, heat losses due to the temperature difference between the indoor and outdoor environments tend to exceed solar heat gains [

1]. This phenomenon is particularly significant in regions with high humidity and pronounced seasonal temperature variations, where inefficient windows can substantially increase heating and cooling demands [

2].

Among the components of a window, the frame plays a crucial role in determining its overall thermal performance. Window frames generally exhibit higher thermal transmittance than other building envelope elements, significantly influencing the total energy efficiency of the enclosure. The most used frame materials include high-conductivity options such as aluminum, which, despite its structural advantages, facilitates considerable heat transfer. In contrast, low-conductivity materials like wood and polyvinyl chloride (PVC) offer improved thermal insulation, reducing energy losses and the risk of condensation-related issues [

3].

Beyond material selection, the design and construction of the frame are critical factors influencing a window’s thermal behavior. Features such as frame geometry, thermal breaks, and insulating materials can significantly impact the window system’s overall thermal transmittance coefficient (U-value). In the context of sustainable building design, optimizing the thermal properties of window frames is crucial. This aligns with the Level(s) framework [

4,

5,

6], a comprehensive tool that promotes using energy-efficient and durable building components to enhance indoor comfort and minimize environmental impact. The Level (s) framework is particularly significant as it provides a structured approach to assessing building sustainability across six macro-objectives, several of which are directly relevant to window frame performance [

7].

A common issue related to poor thermal performance in windows is condensation, frequently observed as water droplets forming on glass and frame surfaces, especially during winter mornings. This occurs because air contains a variable amount of water vapor, but each temperature limits the absolute humidity it can retain. When this limit is exceeded, the excess vapor condenses into liquid water [

8]. This phenomenon is particularly critical in humid environments, where condensation can significantly affect indoor air quality and material durability. Condensation manifests in two primary ways: surface condensation—occurs on interior surfaces such as walls or windows when warm, moisture-laden indoor air contacts a colder surface. Interstitial condensation—develops within structural elements when moisture penetrates and condenses inside materials, potentially leading to long-term degradation such as mold growth, material weakening, and structural damage.

Given the cumulative adverse effects of surface condensation, identifying window frame materials and designs that minimize condensation risk is crucial for improving energy efficiency and indoor environmental quality, two core objectives of Level(s). Level(s) provides a structured approach to assessing building sustainability across six macro-objectives, several of which are directly relevant to window frame performance [

9]. The effect of heat transfer through windows is aligned with Indicator 1.1—Use stage energy performance by Level(s).

Surface condensation during winter or in colder periods not only leads to excessive moisture and mold growth but also accelerates the deterioration of construction materials, posing health risks to occupants [

10]. In, mold and fungal growth on window frames can contribute to poor indoor air quality, a factor addressed by Level(s) under its Indicator 4.1—Indoor air quality, which evaluates pollutants such as mold and excessive humidity that affect building occupants’ health [

11].

Additionally, condensation can damage frame materials. Wooden frames exposed to prolonged moisture may swell, deform, or rot. In aluminum frames, condensation can accumulate along thermal bridges, leading to corrosion and structural weakening. Furthermore, condensation can compromise the sealing between the frame and the glass or between the frame and the wall, resulting in water infiltration, paint deterioration, and interior and exterior finishes [

12]. This aligns with Indicator 2.3: Design for adaptability and renovation, and Level(s) Indicator 1.2: Life cycle global warming potential (GWP). All these indicators, in one form or another and to varying degrees, are addressed in several studies on the hygrothermal and energy performance of windows, which will be discussed in the following paragraphs.

Several studies have modeled the thermal behavior of windows using various analytical tools and methodologies. For instance, Hernández Martínez et al. [

13] investigated the thermal impact of windows in buildings, utilizing simulation tools such as TRNSYS and RESFEN to determine which window types and orientations most effectively reduce cooling loads. Another study, conducted in the climate of Rasht City, Iran, demonstrated how simulations can guide the selection of more energy-efficient window solutions based on building orientation [

14]. Similarly, Bienvenido-Huertas et al. [

15] applied ISO 13,788 calculations to assess surface condensation risks in social housing across different climate zones in Spain. The study analyzed potential corrosion, mold formation, and condensation risks in current and future climate scenarios (projected for 2050). Environmental conditions, including internal operative temperature and humidity, were simulated using DesignBuilder, while internal surface temperatures of façades were modeled with HTflux. This research underscored the importance of considering future climate conditions when designing condensation-resistant buildings.

Moreover, recent advancements in computational modeling have led to the development of hybrid simulation approaches. For instance, integrating computational fluid dynamics (CFD) with dynamic energy modeling tools such as EnergyPlus or IES-VE enables more detailed analyses of airflow, heat transfer, and moisture movement within buildings. This integrated methodology supports architects and engineers in making data-driven decisions regarding material selection and fenestration system design [

16].

An additional emerging trend is the application of adaptive smart glazing, which dynamically adjusts its properties in response to external climatic conditions. Recent studies by Wu et al. [

17] have investigated the potential of electrochromic and thermochromic windows across various climates, demonstrating substantial energy savings and improvements in indoor environmental quality. These technologies present a promising strategy for reducing heating and cooling loads while enhancing occupant comfort.

Furthermore, the research conducted by Serrano-Jiménez et al. [

18] contributes to the advancement of energy rehabilitation strategies through the design, methodology, and in situ application of an innovative solution involving the injection of polyurethane foam insulation into the profiles of existing aluminum window frames. This approach offers valuable insights into energy efficiency and ensures improved indoor environmental conditions through a rapid, non-destructive, and cost-effective intervention. The proposed strategy has been experimentally validated in social housing, with a monitoring campaign carried out under summer conditions, enabling the evaluation of thermal performance before and after the insulation injection treatment.

The issue of surface condensation is more critical under cold and humid climatic conditions. In a study on residential houses in Changsha, China, the authors directly assessed how construction parameters and occupant habits influence condensation on the interior surfaces of the building envelope. They concluded that using windows with superior thermal insulation properties and window-to-wall ratio is essential to minimize the risk of condensation [

19,

20].

The study by You et al., 2017 [

21] investigated condensation on interior surfaces caused by the infiltration of warm, humid air, highlighting its negative impact on indoor environmental quality and building lifespan. The research identified joints between doors and windows on the windward side as typical locations where condensation often occurs. It was also determined that interior surface condensation can develop when outdoor relative humidity exceeds 64% [

21].

Meanwhile, the studies of Nguyen et al. specifically focus on surface condensation on glazed areas (windows) in buildings. They developed an innovative full-scale experimental methodology using image processing techniques to quantify the condensation rate and observe the droplet growth mechanism [

22,

23].

Overall, the above studies collectively emphasize the importance of a holistic approach to window design, incorporating climate-responsive strategies, advanced simulation tools, and innovative materials to optimize energy efficiency and thermal performance in buildings.

The geographical focus of the present study is southern Chile, specifically the city of Valdivia, which features a temperate oceanic climate with an average annual temperature of 11.7 °C and approximately 1700 mm of precipitation. These conditions promote a high relative humidity environment throughout the year [

24].

According to Chilean standards proposed, NTM 011/2:2014 [

25] and the Sustainable Building Standards for Housing in Chile [

26] (effective since 2018), the maximum allowable thermal transmittance (U-value) for windows in southern regions ranges from 2.4 to 3.0 W/m

2K. However, since these regulations are not mandatory, studies on energy efficiency in Chilean buildings report window U-values ranging from 3.60 to 5.80 W/m

2K [

27,

28]. This national regulatory framework allows the use of windows with high U-values, which hypothetically increases the risk of surface condensation on both frames and glazing. This phenomenon is directly related to energy efficiency and indoor air quality. Consequently, the present study proposes a modification to wooden window frames by adopting the geometry of existing aluminum frames, with the aim of analyzing the hygrothermal behavior of this adaptation. The significance of this approach lies in the potential to replace installed aluminum frames with thermally improved wooden alternatives.

Therefore, the main objective of this research is to theoretically assess the hygrothermal performance of standard aluminum window frames and modified wooden frames using HTflux software under the climatic conditions of Valdivia (humid temperate oceanic climate) during the year 2023. The study seeks to identify the risk of surface condensation on window frames and evaluate the technical feasibility of the proposed modification. This research and its objectives are aligned with multiple Level(s) indicators and the principles of sustainable construction. This study offers recommendations for selecting window frames that balance energy efficiency and condensation resistance, particularly in humid climates like Valdivia. The potential benefits of this research are significant and can lead to more sustainable and comfortable building designs [

29].

Additionally, the present research is closely aligned with several Sustainable Development Goals (SDGs) [

30], as it seeks to enhance the energy efficiency and indoor environmental quality of buildings by optimizing window frame design and material selection. By addressing the thermal transmittance of window frames and mitigating issues such as condensation, the study directly supports SDG 7 (Affordable and Clean Energy) by reducing energy demand. It also contributes to SDG 13 (Climate Action) by significantly reducing greenhouse gas emissions, offering hope for a positive impact on climate change. Moreover, by improving the durability and performance of building components, the research contributes to SDG 11 (Sustainable Cities and Communities).

2. Materials and Methods

The following methodology was implemented to evaluate the thermal behavior of aluminum and wooden window frames under the hygrothermal conditions of Valdivia, in alignment with the indicators of the Level(s) framework, to address the previously stated objective. The methodology is divided into six phases.

2.1. Definition of the Case Study

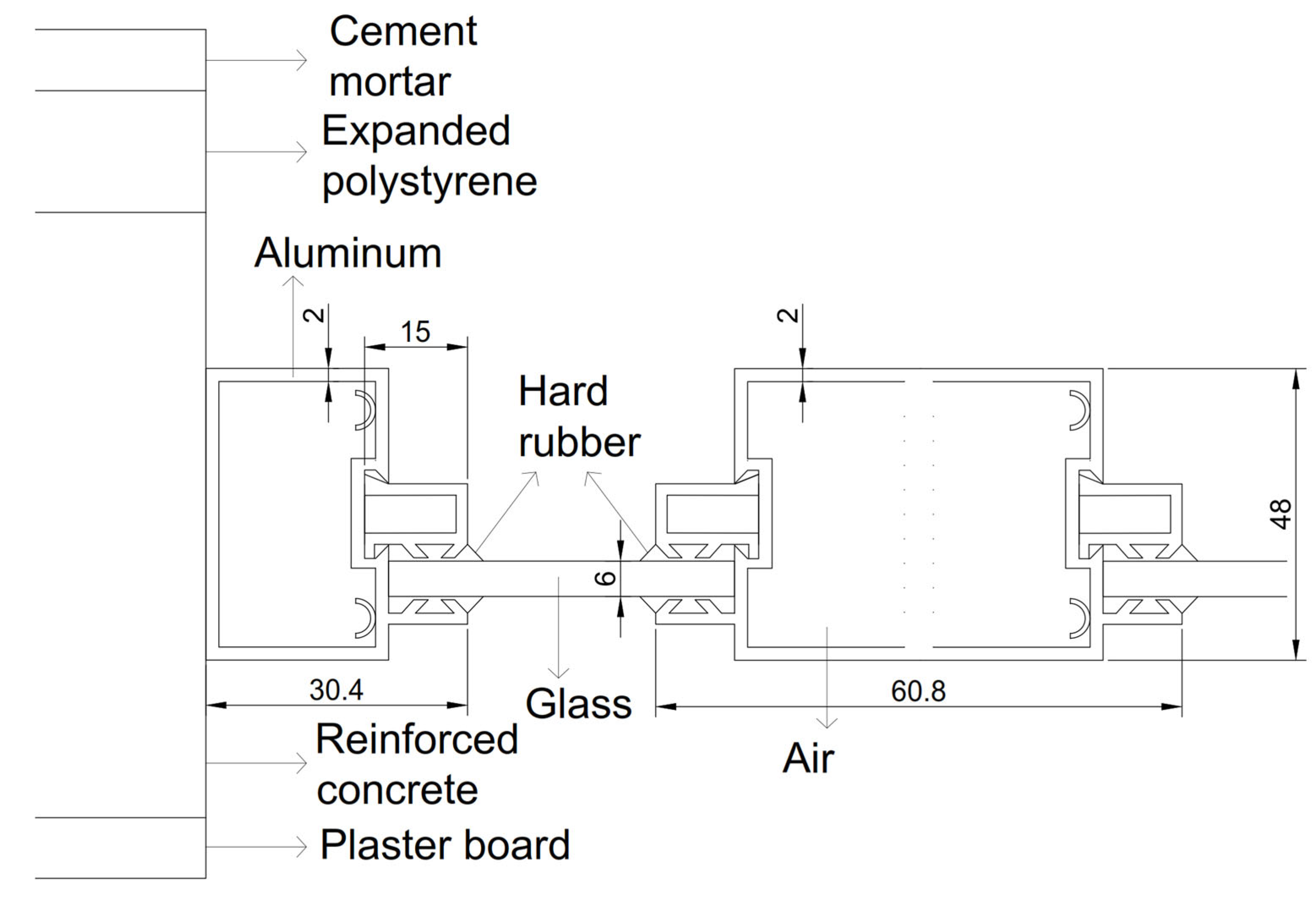

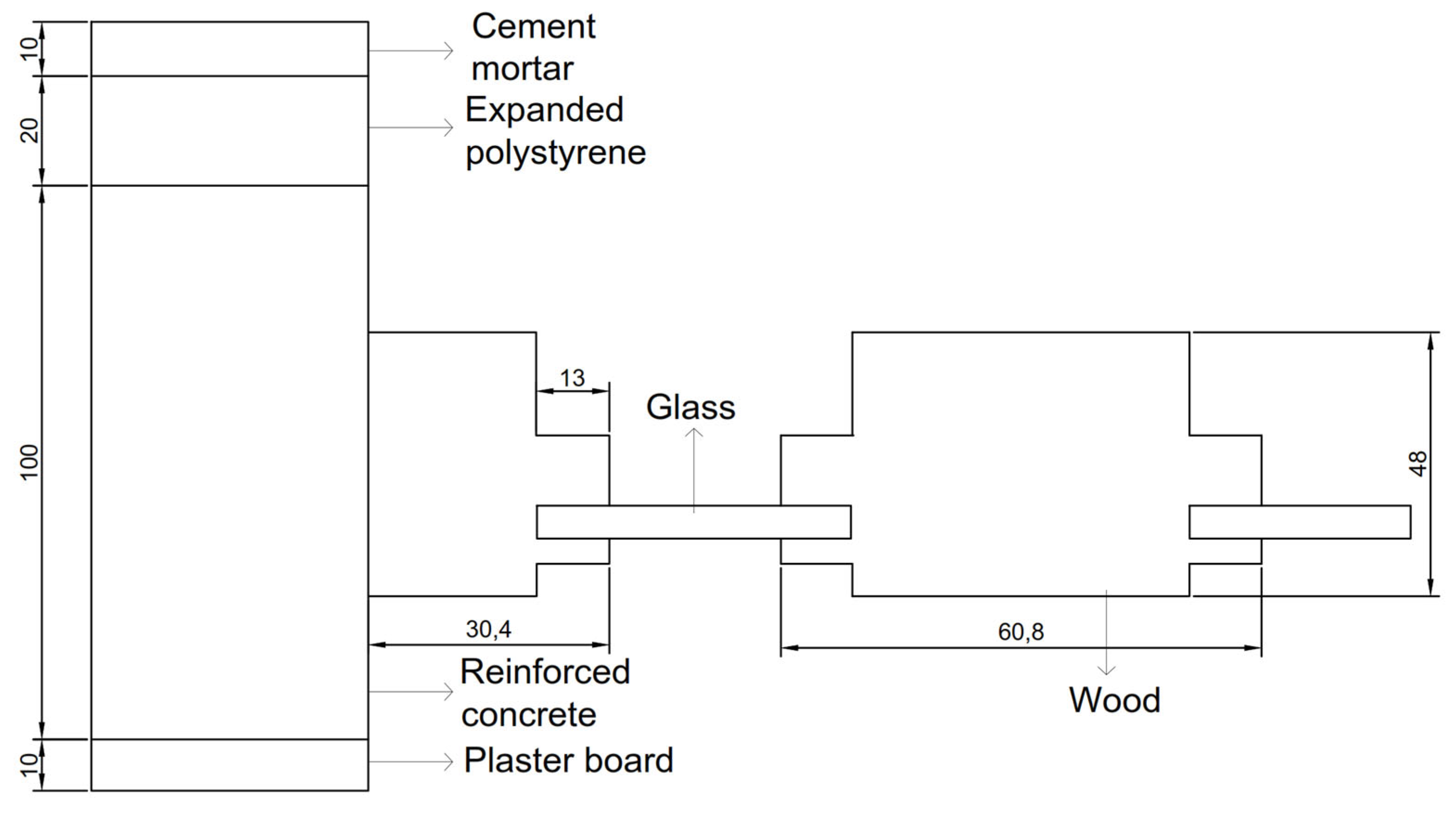

Phase 1 of the methodology focused on defining the parameters and creating the necessary models for thermal analysis. In this phase, window frames made of different materials (aluminum and wood) with identical dimensions were selected. The selection of identical dimensions was associated with the practical need to implement wooden frames as replacements for existing aluminum frames in the city’s housing stock. Another reason for maintaining the same dimensions was the need to optimize the carbon footprint of the materials used in window production. The construction details and dimensions of each frame are indicated in

Figure 1 and

Figure 2.

Both window models are fixed, without movable sashes, and are installed in a 100 mm thick reinforced concrete wall. The wall is insulated with 20 mm thick expanded polystyrene adhered to its surface. The exterior cladding consists of 10 mm thick cement mortar, while the interior of the wall is covered with 10 mm gypsum board.

The glass thickness in the aluminum windows does not significantly impact thermal insulation, although it is relevant for wind and impact resistance. For this study, a 6 mm thick glass pane was selected, representing a standard value within the typical range of 4 mm to 12 mm [

12]. The aluminum profiles used in this study have a thickness of 2 mm, which is a typical value within the 1.5 mm to 2 mm range [

12]. In this phase, a consistent model for both window types was established, which was crucial for conducting a precise and comparable analysis in the subsequent stages of the study.

2.2. Selection of Materials and Thermal Properties

The selection of wooden frames for this study was based on their ecological properties, while aluminum frames were included due to the need for their replacement in the existing housing stock of the city of Valdivia.

Wood, a traditional choice in window construction, is valued for its aesthetic and insulating properties. Its thermal characteristics offer significant advantages that can enhance the energy efficiency of buildings. For the frame model, poplar wood (

Populus spp.) was used, with a thermal conductivity of 0.091 W/mK, approximately 230 times lower than aluminum. Wooden frames typically have a lifespan of about 30 years, provided they are properly maintained through sanding, painting, and periodic adjustments [

31].

Aluminum, by contrast, is a material known for its resistance to stress and corrosion, offering a much longer lifespan than wood. Additionally, it does not swell or crack, making it ideal for supporting large glass panels. Aluminum frames also have the advantage of being less sensitive to extreme weather conditions and are non-flammable, which can extend their lifespan up to 60 years [

32].

The distribution of the materials in the window frames and wall is shown in the models of

Figure 1 and

Figure 2.

Table 1 presents the materials used in the simulation and their thermal characteristics—thermal conductivity and specific heat.

Regarding thermal conductivity, various data sources were used. For aluminum, glass, concrete plaster, and expanded polystyrene, the values were taken from the Chilean standard NCh853 [

33]. In contrast, the properties of hard rubber, reinforced concrete, and cement mortar were obtained from the

Manual of Sustainable Building Standards for Housing in Chile (ECS) [

26]. Information on specific heat was also extracted from this same manual.

To simulate the window frame, a commonly used wood in the national market—poplar—was selected. Its thermal properties were taken from the Chilean standard NCh853 [

33].

Another relevant aspect of the simulation was the exclusion of solar radiation and wind speed effects. This is because the simulation was based on the minimum daily temperature, which typically occurs in the early morning before sunrise. Therefore, the influence of solar radiation can be reasonably disregarded. Thermal resistance values of exterior and interior air were used according to ISO 6946 for vertical building components: 0.04 m2·K/W for the exterior and 0.13 m2·K/W for the interior.

An additional requirement for the simulation was the definition of internal and external conditions, specifically temperature and relative humidity values, which were input into the program.

2.3. Definition of Internal Conditions

In the next step, the internal building conditions in Valdivia were defined. The ECS was used to determine the interior temperature, as it provides information on the monthly minimum and maximum comfort temperatures for different regions of Chile. Accordingly, the data for the city of Valdivia were used, calculating the monthly average interior comfort temperature by averaging the maximum and minimum values. This average was considered the standard interior temperature for the year 2023 in this study. The monthly average interior comfort temperatures are presented in

Table 2.

Regarding the indoor relative humidity values used, it is important to note that several studies have shown that optimal indoor humidity levels should range between 40% and 60% in order to avoid the negative effects of excessive or insufficient humidity in the environment [

34].

Five indoor relative humidity levels were defined to simulate the hydrothermal behavior of the frames. These values—40%, 50%, 60%, 70%, and 80%—were selected based on their relevance to the optimal indoor humidity range and their potential to induce adverse effects on the frames.

2.4. External Conditions Definition

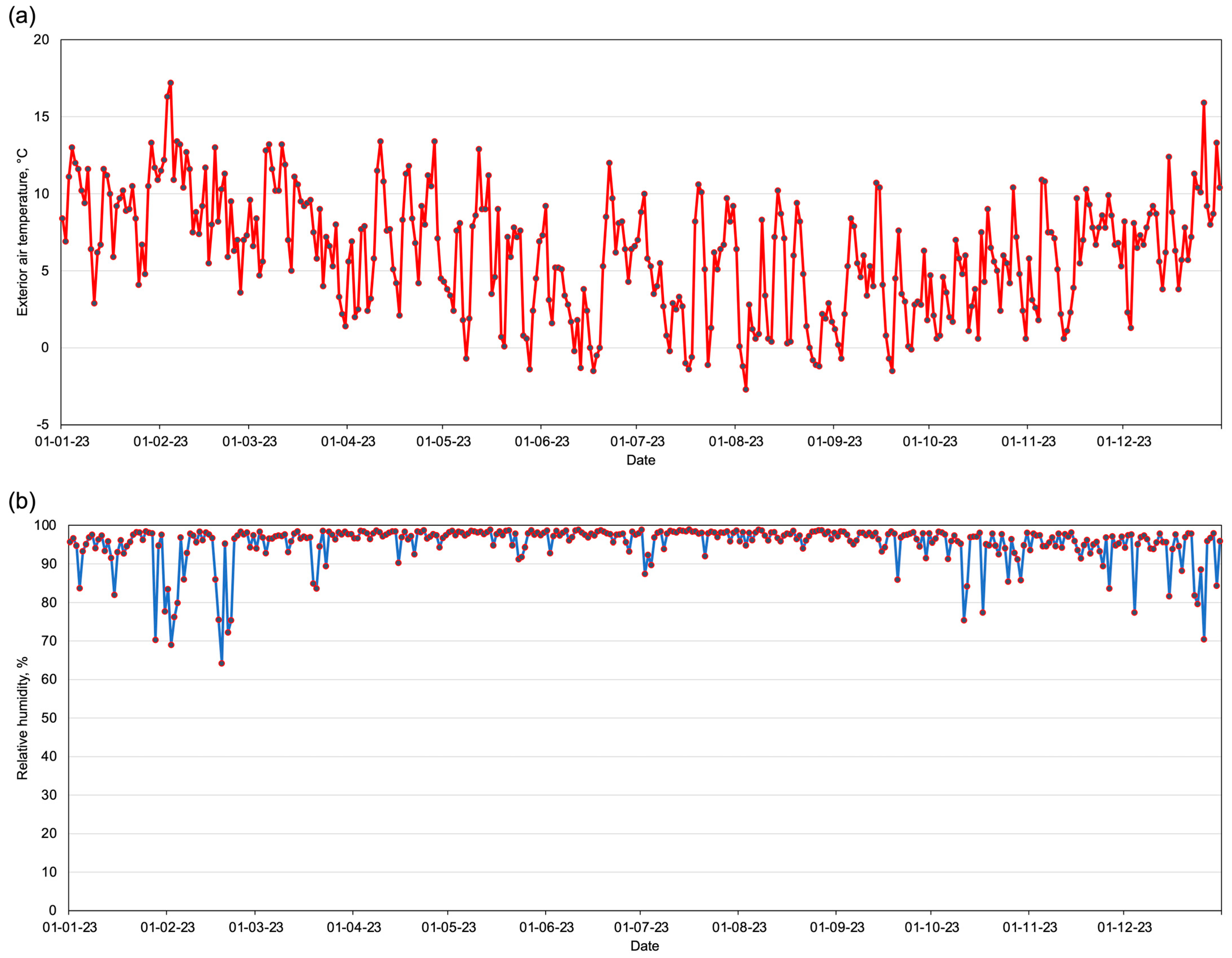

For the analysis and use of data on external meteorological conditions in the city, the period from 1 January 2023 to 31 December 2023, was selected. Hourly temperature and relative humidity data were obtained from the Chilean Agrometeorological Service website for the Austral meteorological station located in the city of Valdivia [

35]. Since the purpose of this study is to observe the presence of surface condensation for each frame type, data corresponding to the daily minimum temperature were used. The hour of the day when the minimum temperature is recorded typically coincides with the maximum relative humidity [

26]. Thus, 365 data points were collected for maximum relative humidity and 365 for minimum temperature (

Figure 3), providing an adequate dataset for this study. In general, the daily minimum temperature occurs in the early morning hours before sunrise; however, in rare cases, it can also occur at other times of the day, such as during the advection of cold air masses. The average minimum daily temperature for February was 9.9 °C, while in August it was 2.9 °C. The average daily maximum relative humidity was 89.6% in February and 97.3% in August (

Figure 3b).

This phase is essential for establishing the basis for the subsequent thermal analysis.

2.5. Thermal Simulation

At this stage, the spatial distribution of temperature in window frames for each hour of the day with the minimum temperature was simulated using HTflux software (version 1.10), considering both internal (temperature and humidity) and external (temperature and humidity) conditions. The analysis began with the development of a cross-sectional model of the aluminum and wooden window frames using AutoCAD 2025. A horizontal section (B-B) (

Figure 4) of a fixed window was used to simulate the frames, providing a representative geometric configuration for subsequent thermal modeling.

Once the AutoCAD file (illustrated in

Figure 1 and

Figure 2) was prepared, it was imported into HTflux. Within the software, the wall and frame structures were delineated using the “polygon” command, and materials were defined by inputting the thermal conductivity and specific heat values, as specified in

Table 1.

HTflux, validated according to EN ISO 10077-2:2007 and EN ISO 10211-2:2012 [

36], employs the Glaser method to simulate heat and water vapor transport in two-dimensional geometries [

37]. HTflux has been used in several previous studies. For example, in one study involving walls with different material configurations, a comparison of simulated heat transfer was made and validated using MATLAB and HTflux, revealing an error margin of around 5% for this parameter [

38]. A similar 5% error in thermal transmittance values was reported by authors of another study [

39]. In research on thermal transmittance and linear thermal transmittance of thermal bridges between floors and walls, an average error of 4.5% was reported when compared with the THERM software [

40].

Moreover, HTflux has been widely used in various studies, such as investigations of thermal bridges [

37], thermally activated building systems (TABS) [

41,

42], and thermal resistance of basement walls [

43]. Based on these references in the scientific literature, this tool was chosen for use in the present study.

This software has its limitations—for instance, it does not account for variations in the thermal resistance of the outside air due to changes in wind speed or the orientation of the surface relative to the wind vector. Additionally, it does not consider the effect of solar radiation. However, this limitation is not particularly relevant for the present study, as the simulations were conducted for scenarios involving minimum daytime temperatures, during which solar radiation is either absent or minimal.

After defining the internal and external boundary conditions and incorporating the physical characteristics and dimensions of the frames, the simulation was carried out.

A total of 365 models were generated for the aluminum frame and 365 for the wooden frame, resulting in 730 daily simulations under varying meteorological conditions. The software output includes surface temperature data (internal and external) for each model, and heat flow is computed across all materials.

2.6. Analysis of Condensation Formation

In this stage, the results of the temperature distribution for both types of frames were analyzed using HTflux models. The minimum interior surface temperature was determined for each day of the study period. These temperatures were then compared with the dew point temperature under indoor conditions and for various relative humidity levels, calculated using the Magnus equations.

The dew point temperature (i.e., the condensation formation temperature) was calculated using the following equations [

44]:

where

is the dew point temperature (°C); T is the temperature (°C); RH is the relative humidity (%).

The parameter

in Equation (1) is computed as:

where

= 17.625 y

= 243.04—Magnus coefficients.

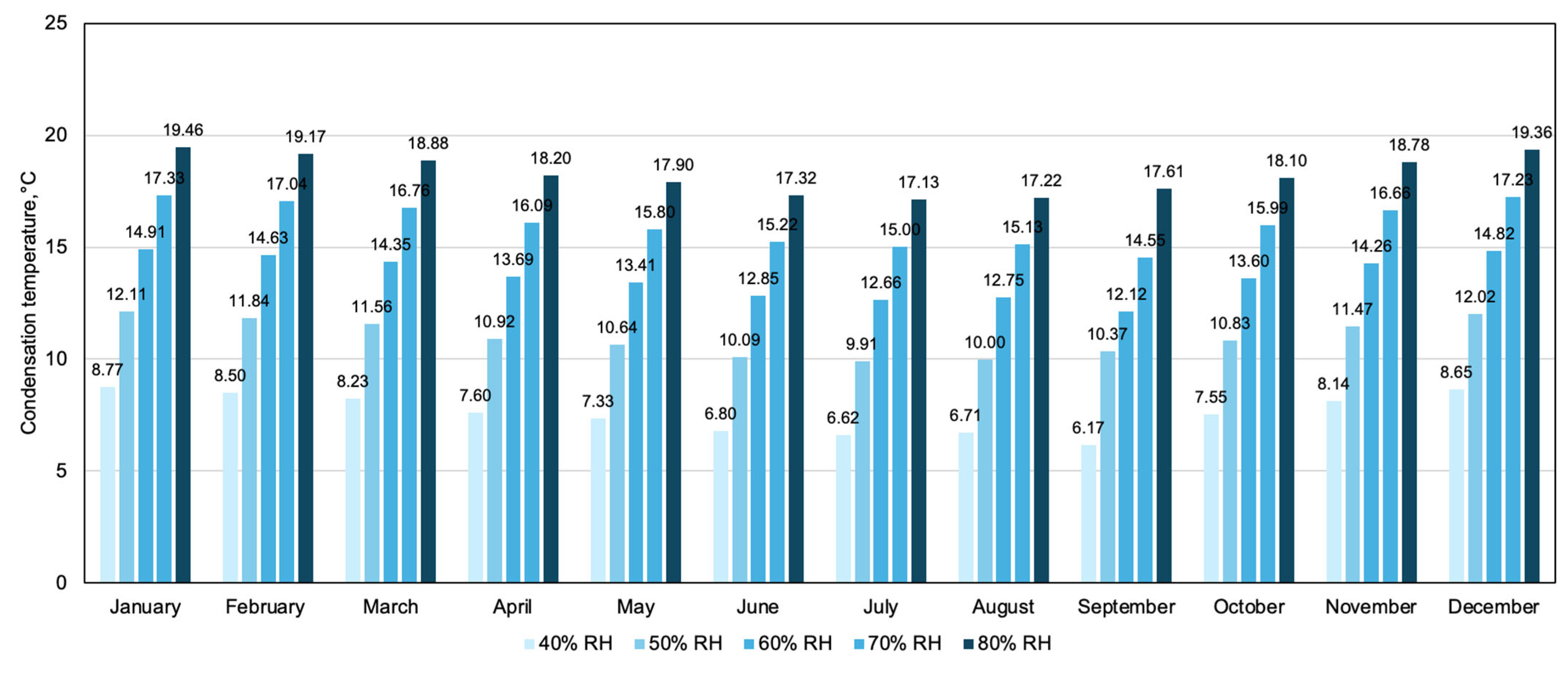

The condensation formation temperature was computed for five levels of indoor relative humidity, representing a typical range of indoor conditions. These levels were based on the monthly average indoor comfort temperature (see

Table 2). The resulting dew point temperatures for each humidity level are presented in

Figure 5, which shows the surface condensation formation temperatures corresponding to each level of indoor humidity.

In the next stage, the simulated minimum interior surface temperatures for each frame were compared to the corresponding dew point temperatures. If the simulated surface temperature exceeded the dew point temperature, condensation was theoretically unlikely to occur on that day. Conversely, if the surface temperature dropped below the dew point, condensation was expected to form.

Finally, the results were analyzed, and the impact of indoor humidity on air quality and the risk of mold formation was discussed, following the Level(s) 3.2 indicator. Additionally, the consequences of surface condensation on window component durability were considered. Based on these findings, recommendations were developed for the design of window frames suitable for the humid climate of Valdivia, prioritizing energy efficiency, indoor air quality, and sustainability.

3. Results and Discussion

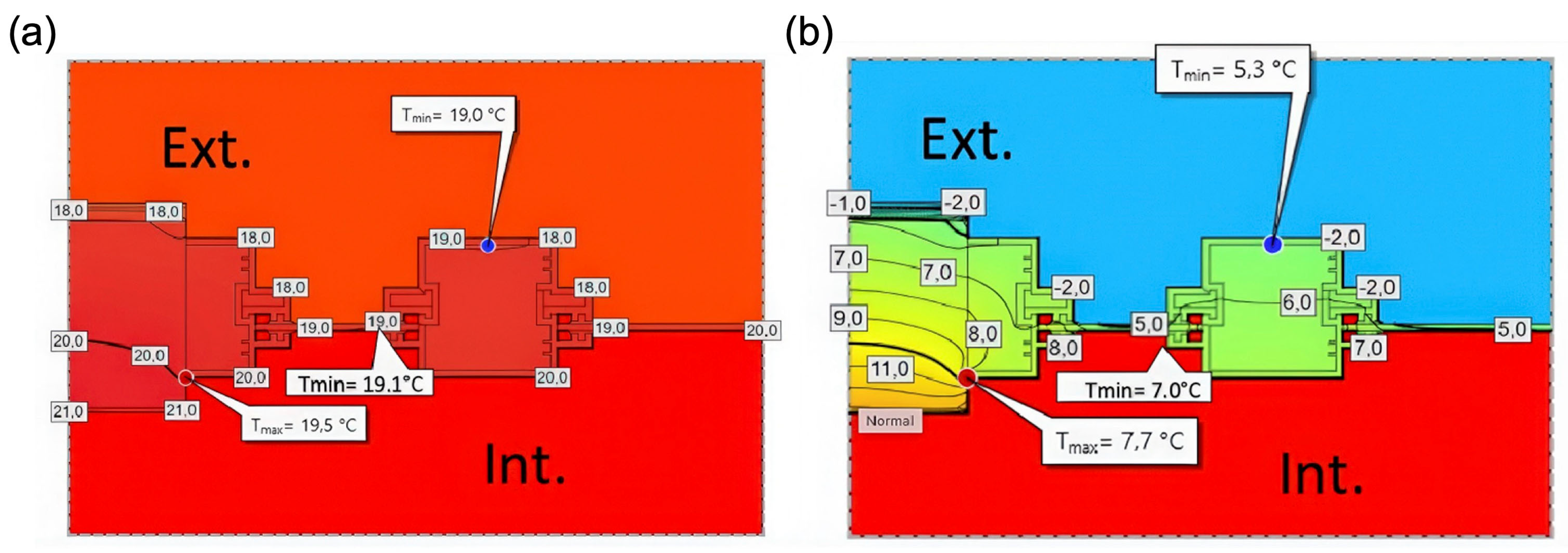

Graphical outputs obtained from HTflux include key thermal performance indicators such as surface temperature.

Figure 6 illustrates an example of temperature distribution in aluminum frames for two representative days: February 4th and August 4th. HTflux provides comprehensive results that support a detailed thermal analysis of window frames. The minimum interior surface temperature was extracted to evaluate the potential risk of condensation formation. On February 4th, the minimum value was 19.1 °C; on August 4th, it was 7.0 °C. These values were compared with those presented in

Figure 5, which shows the condensation formation temperatures under different interior relative humidity levels, to determine whether surface condensation would occur.

For instance, on August 4th, the minimum interior surface temperature on the frame was 7.0 °C (

Figure 6b), with an exterior air temperature of −2.7 °C, an interior air temperature of 20.8 °C (

Table 2), and a condensation temperature of 6.71 °C at 40% relative humidity (

Figure 5). Under these conditions, no surface condensation was observed, as the surface temperature exceeded the dew point.

This analysis was conducted for all 365 days of the year for both frame types, considering five different relative humidity levels. The results obtained in this example are consistent with findings from other studies on aluminum frames. For example, Zozulak et al. (2023) simulated aluminum-framed windows under conditions of −3.5 °C outdoor air temperature, 20 °C indoor temperature, and 50% relative humidity, and reported a minimum interior surface temperature of 6.0 °C, indicating potential condensation risk [

45].

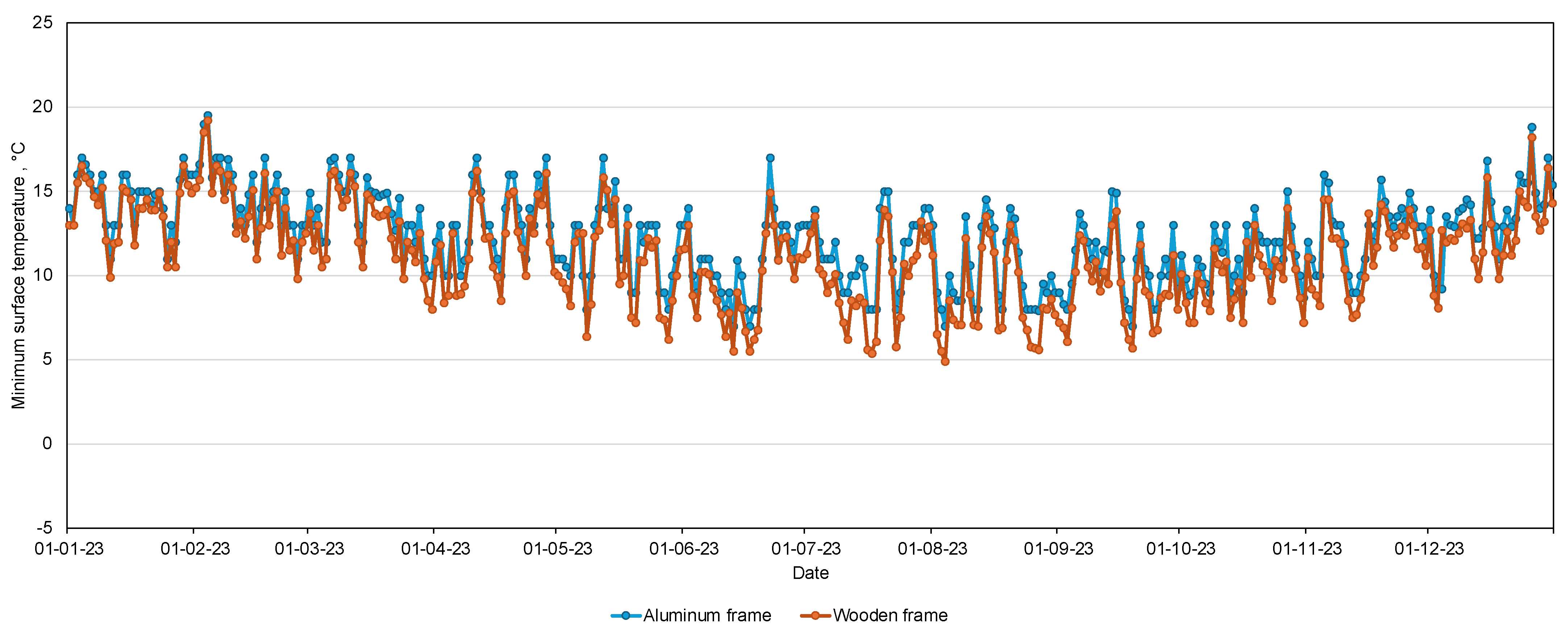

The interior surface temperature data for both frames over the course of the year were plotted to produce

Figure 7. These graphs visually represent the thermal performance of each frame. In general, the wooden frame exhibited slightly lower minimum surface temperatures than the aluminum frame. On average, the daily minimum surface temperature of the wooden frame was 1.20 °C lower than that of the aluminum frame (

Table 3). This behavior—possibly attributed to greater structural heterogeneity—may suggest a higher likelihood of surface condensation in wooden frames.

Additionally,

Table 3 presents the average difference between interior air temperature and minimum interior surface temperature for each type of frame. For the wooden frame, this difference averaged 12.2 °C during August, while the smallest difference for both frame types was observed in February. These results are logical since the minimum external temperatures correspond to the maximum difference between the internal air temperature and the surface temperature of the window frames.

Surface condensation formation on window frames is strongly influenced by indoor relative humidity, as different humidity levels result in varying dew point temperatures (

Figure 5). For aluminum frames,

Table 4 presents the monthly average difference between the dew point temperature and the minimum interior surface temperature of the frame. With an indoor relative humidity of 40%, the dew point temperature is, on average, 4.79 °C higher than the frame’s minimum surface temperature, indicating that under these conditions, surface condensation does not occur. This is corroborated in

Table 5, which shows that during the study year, no condensation risk was observed on the aluminum frame, provided that indoor humidity was adequately controlled.

However, at an indoor relative humidity level of 80%, the minimum surface temperature of the frame is, on average, 6.05 °C lower than the dew point temperature (

Table 4). This results in the occurrence of surface condensation almost daily (364 days per year) on aluminum frames (

Table 5). It is important to note that a greater temperature difference between the surface and the dew point leads to a higher amount of condensed water [

46,

47,

48], which can negatively affect indoor air quality by promoting the growth of mold and fungi. Therefore, controlling indoor relative humidity is a crucial strategy to prevent surface condensation on window frames and their associated negative impacts.

In comparison with the aluminum frame, the wooden frame exhibited slightly lower thermal performance. For example, under indoor relative humidity conditions of 40%, the dew point temperature was, on average, 3.59 °C higher than the frame’s minimum surface temperature, thus bringing the surface temperature closer to the dew point (

Table 6). As a result, a total of 30 potential days with surface condensation on the wooden frame were identified (

Table 7), in contrast to the aluminum frame, which showed no days with condensation risk throughout the study period.

For indoor relative humidity conditions of 80%, the wooden frame—like the aluminum frame—showed a potential risk of surface condensation formation for 364 days per year (

Table 7). However, the average annual difference between the dew point temperature and the minimum surface temperature increased to 7.25 °C, indicating a potentially greater amount of surface condensation on the wooden frame compared to the aluminium one. This phenomenon may intensify material degradation and shorten the service life of both the wooden frame and the window overall. The quantitative relationship between the temperature difference and condensation severity is fundamental. When the difference between the minimum surface temperature and the dew point is greater (i.e., the surface is significantly colder than the dew point), more condensation occurs. This increased accumulation of water creates a more favourable environment for mold and fungal growth.

Numerous studies have shown that most organisms responsible for wood degradation require a moisture content above the fiber saturation point (FSP), generally between 27% and 30%. However, once fungi colonize the substrate, they can continue to grow even at moisture levels as low as 20%. Consequently, wooden window frames require specific chemical treatments for protection, which in turn increases the environmental impact of producing these frames [

48,

49].

In this study, wooden frames showed inferior hygrothermal performance compared to aluminum frames. This is mainly attributed to the smaller dimensions of the wooden frames used for comparison (30.4 mm width and 48 mm depth), which are smaller than standard [

50,

51] industry dimensions (45–65 mm width and 70–90 mm depth). This suggests that although wood has excellent insulating properties, its thermal performance greatly depends on adequate geometry and sufficient material thickness to create an effective thermal break.

Other limitations of the present study include the fact that the simulation was carried out for a specific year. Different results may be observed if other years are simulated, although the overall trend should remain. Also, wind speed variation was not considered, which could affect outcomes. Only two frame models were analyzed, highlighting the need to further expand this research through in-situ measurements for validation.

Aluminum frames, despite their high thermal conductivity, can achieve good thermal performance through multi-chamber construction and the use of thermal breaks [

45]. Moreover, slimmer aluminum profiles can improve thermal efficiency by increasing the glass-to-frame ratio [

52], as glass is a better insulator than metal.

The effectiveness of a material’s inherent thermal properties (e.g., the low conductivity of wood) depends on its geometric configuration within the building component. Furthermore, the optimal material-geometry combination is climate-dependent. A slim wooden frame, while potentially suitable in a dry climate, can create thermal bridging issues in a humid and cold climate like that of Valdivia. Conversely, aluminum—despite its high conductivity—can be designed with thermal breaks and slim profiles to perform effectively, especially when indoor humidity is controlled.

It can be concluded that wooden frame design must balance several key aspects:

- (i)

Energy efficiency;

- (ii)

Design and material use optimization during production;

- (iii)

Hygrothermal performance and local climatic response.

This last aspect can be understood as: some frame geometries that perform poorly in one climate may perform well in another. If the results of the present study are integrated with the Level(s) framework, more critical factors for sustainable window frame design can be defined:

- (iv)

Environmental impact throughout the life cycle (LCA): According to Level(s), environmental impacts must be assessed based on energy efficiency and full product lifecycle—from raw material extraction to disposal. In this regard, aluminum frame production is significantly more energy-intensive than wood [

53].

- (v)

Frame durability is also essential when assessing sustainability. Wooden frames may have shorter service lives without proper maintenance due to their vulnerability to moisture, increasing the frequency of replacements and, thus, environmental impact. Aluminum frames, by contrast, are more resistant and require less maintenance, potentially resulting in lower long-term environmental impact [

54].

- (vi)

Indoor air quality: The risk of condensation on wooden frames could affect indoor air quality by creating conditions conducive to mould and bacteria. Level(s) highlights the importance of maintaining good indoor air quality. Condensation analysis is thus essential for identifying moisture sources and their effects on occupant health. For example, it has been shown that the presence of condensation on window panes in Swedish homes can increase the risk of mite allergen formation in indoor air by 18–45% [

10].

- (vii)

Social and health aspects: Occupant health and comfort are core principles within Level(s). A healthy building minimizes the risk of respiratory diseases and ensures thermal comfort. The condensation analysis in wooden frames suggests that, without proper humidity control, their use could compromise occupant health.

Integrating Level(s) principles into window frame assessments offers a more holistic perspective on sustainability. Based on this approach, material selection should consider energy efficiency, durability, lifecycle environmental impact, indoor air quality, and user well-being.

4. Design Recommendations

In the present study, an attempt was made to optimize wooden frame geometry using aluminum frame dimensions under climatic conditions of high humidity and low temperatures; however, the results were not favorable. One of the most significant findings of this study is the direct correlation between indoor relative humidity and the persistence of condensation on window surfaces, particularly during periods of high-temperature gradients. Therefore, only by controlling indoor relative humidity is it possible to implement such a geometric modification effectively.

HTflux proves to be a valuable diagnostic and predictive tool. Although not specifically designed for microbiological assessments, it allows researchers to simulate and quantify conditions conducive to biological growth—such as thermal bridges, dew point intersections, and long-term moisture accumulation. The ability to identify zones with high condensation frequency and duration provides a strong foundation for future research on integrated models linking hygrothermal behavior with microbial proliferation and health risk. Developing such models would be particularly relevant under the Level(s) framework, which includes indicators related to indoor environmental quality and occupant health.

For sustainable window design, it is essential to consider the recommendations of the Level(s) framework, which addresses key indicators such as energy efficiency, material durability, environmental impact, and indoor environmental quality. At the same time, it is recommended to incorporate thermal simulation tools like HTflux, which has proven capable of delivering reliable results while offering an intuitive and user-friendly interface for a wide range of users.

Early integration between architectural design and hygrothermal simulation provides significant benefits not only for manufacturers—by optimizing product design—but also for the environment and end-users by improving indoor comfort and reducing the risk of pathologies such as condensation. Another critical aspect is the geometric optimization of the window frames. This study aimed to identify a solution that allows replacing aluminum frames with more sustainable alternatives without requiring changes to other building components, thereby facilitating implementation in existing buildings.

In addition, the scientific literature suggests complementary strategies:

(i) Hybrid systems—using wooden frames on the interior with aluminum cladding on the exterior combines low environmental impact with high durability [

52];

(ii) Integrated envelope solutions—frame selection should be considered alongside glazing type (double or triple), use of inert gases, and thermal insulation of walls and roofs to maximize the overall energy performance [

50].

A general recommendation for the building use phase is the control of indoor humidity. The implementation of mechanical ventilation systems, the use of dehumidifiers, and occupant education are all essential. In many cases, effective humidity management can have a greater impact than the choice of frame material itself.

Finally, the present study highlights the need for further research that integrates thermal simulations, microbial risk predictions, and occupant comfort perception, thereby promoting a holistic approach. The systematic adoption of the Level(s) framework will support more sustainable design decisions, balancing durability, energy efficiency, and occupant well-being.

5. Conclusions

This study presented an attempt to optimize the design of wooden window frame geometry, considering various aspects of sustainable development and addressing the practical need to replace aluminum frames in the housing stock of the city of Valdivia.

The design validation was carried out through the simulation of the hygrothermal behavior of the modified wooden window frames using the HTflux software, considering the city’s climatic conditions throughout the calendar year. The HTflux program produced consistent and logical results, demonstrating good compatibility for solving practical design challenges.

Reducing the size of the wooden frames to replicate the geometry of aluminum frames and minimize environmental impact resulted in an average decrease of 1.2 °C in the interior surface temperature over the analyzed year. Consequently, this led to an increased risk of surface condensation. Under typical indoor comfort humidity levels (40–60%), the number of days with potential condensation on the wooden frame increased by an average of 52 days compared to the aluminum frame over the same period. These results indicate that the proposed modification of the wooden frame design is not adequate from a hygrothermal perspective without implementing control measures for indoor air humidity.

Based on the results obtained and the literature review, recommendations were provided for window frame design in humid climate zones. These are directly linked to several key indicators within the Level(s) framework for sustainable building construction.

Furthermore, a novel methodology is proposed for verifying the hygrothermal performance of window frames based on an annual analysis that highlights the need to optimize window design according to specific local climates. This approach may generate interest for future research under different climatic conditions and involving various types of window systems worldwide.