Abstract

This study provides a bibliometric analysis of life cycle assessments (LCAs) to explore the sustainability potential of mass timber buildings, focusing on glulam. The analysis highlights regional differences in carbon footprint performance within the ISO 14040 and EN 15978 frameworks. LCA results from representative countries across six continents show that wood buildings, compared to traditional materials, have a reduced carbon footprint. The geographical distribution of forest resources significantly influences the carbon footprint of glulam production. Europe and North America demonstrate optimal performance metrics (e.g., carbon sequestration), attributable to advanced technology and investment in long-term sustainable forest management. Our review research shows the lowest glulam carbon footprints (28–70% lower than traditional materials) due to clean energy and sustainable practices. In contrast, Asia and Africa exhibit systemic deficits, driven by resource scarcity, climatic stressors, and land-use pressures. South America and Oceania display transitional dynamics, with heterogeneous outcomes influenced by localized deforestation trends and conservation efficacy. Glulam buildings outperformed concrete and steel across 11–18 environmental categories, with carbon storage offsetting 30–47% of emissions and energy mixes cutting operational impacts by up to 67%. Circular strategies like recycling and prefabrication reduced end-of-life emissions by 12–29% and cut construction time and costs. Social benefits included job creation (e.g., 1 million in the EU) and improved well-being in wooden interiors. To further reduce carbon footprint disparities, this study emphasizes sustainable forest management, longer building lifespans, optimized energy mixes, shorter transport distances, advanced production technologies, and improved recycling systems. Additionally, the circular economy and social benefits of glulam buildings, such as reduced construction costs, value recovery, and job creation, are highlighted. In the future, prioritizing equitable partnerships and enhancing international exchanges of technical expertise will facilitate the adoption of sustainable practices in glulam buildings and advance decarbonization goals in the global building sector.

1. Introduction

The construction industry plays a pivotal role in global economic development, yet it remains one of the most significant drivers of environmental degradation. Responsible for approximately 40% of global CO2 emissions and 35% of total energy consumption, the sector’s heavy reliance on carbon-intensive materials, such as concrete and steel, poses a critical challenge to climate sustainability [1]. As urbanization accelerates and infrastructure demands grow, the imperative for sustainable construction practices becomes increasingly urgent. Achieving the climate objectives outlined in the Paris Agreement—specifically, a 50% reduction in global carbon emissions from 1990 levels by 2050—necessitates a radical transformation within the sector. With a remaining global carbon budget of roughly 88 billion tons between 2015 and 2100 [2,3], the construction industry must rapidly pivot toward low-carbon materials, circular economy principles, and energy-efficient building strategies to align with planetary boundaries and foster long-term resilience.

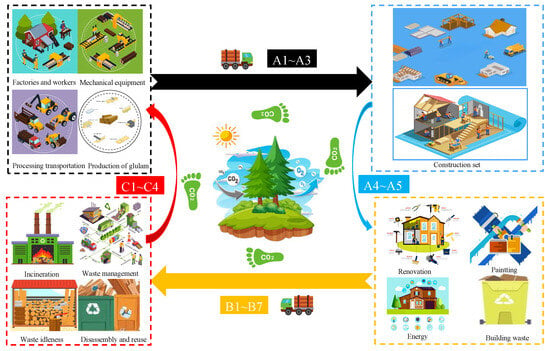

One promising solution is mass timber, particularly glued laminated timber (glulam) and cross-laminated timber (CLT). Glulam is typically based on solid wood, which has inherent advantages in the ecological cycle. Figure 1 systematically illustrates the environmental impact processes of glued laminated timber buildings throughout their entire life cycle (A1–C4), encompassing raw material production (A1–A3), transportation and construction (A4–A5), operational maintenance (B1–B7), and end-of-life treatment (C1–C4). Through carbon sequestration by renewable timber, low-carbon manufacturing and construction practices, enhanced thermal performance reducing operational energy consumption, as well as waste recycling and biomass energy recovery reflect the sustainable potential of glulam buildings in carbon emission reduction, energy efficiency, and resource circularity [4]. By comparing the greenhouse gas (GHG) emissions of building life cycles in China, Finland, and the United States, the analysis found that regional differences in energy structure, material production, and building type significantly affected the carbon footprint of buildings. Finland and the United States had advantages in energy structure, environmental protection, and the application of wooden structures. As a result, their building carbon footprint is lower than China’s. Puettmann et al. [3] compared the global warming potential (GWP) of CLT buildings in three different regions of the United States, namely the Pacific Northwest, the Northeast, and the Southeast. The CLT buildings in the Pacific Northwest had the highest GHG emissions per unit of floor area.

Figure 1.

Life cycle carbon footprint of glulam buildings [5].

Recent LCA studies have highlighted the sustainability performance of glulam buildings, demonstrating their ability to reduce carbon emissions during production, construction, operation, and end-of-life phases [6,7]. For example, Quintana-Gallardo et al. [8] used LCA to compare the environmental impact of wooden single-family model houses in different regions of Spain (Madrid, Valencia), Slovenia (Ljubljana, Portoroz), and Germany (Munich), where regional differences in the electricity mix also affected carbon emissions. Munich and Ljubljana had similar energy consumption, but carbon emissions varied depending on the electricity mix. Outside of Munich, the construction phase still accounted for more than 10% of carbon emissions. These regional disparities meant that the carbon footprint of glulam buildings was different in life cycle stages and difficult to compare, thus hindering the sustainable development of glulam buildings. However, the environmental impact of glulam structures varies significantly across regions due to differences in energy grids, manufacturing practices, and building designs [8,9]. These regional disparities pose challenges for establishing a unified framework for assessing the sustainability of glulam.

This systematic review evaluates the environmental performance of glulam buildings through a critical analysis of life cycle assessment (LCA) studies published over the past decade. Following international standards such as ISO 14040 and EN 15978 [10,11], this study specifically addresses three key research questions: (1) What is the sustainability potential of glulam buildings? (2) What is the carbon footprint profile of glulam across its entire life cycle? (3) How do regional factors influence sustainability outcomes?

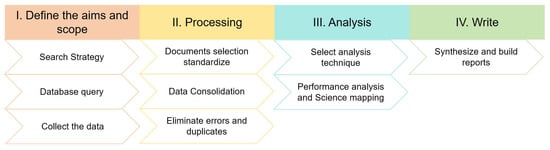

This paper aims to address critical research gaps in the field, provide evidence-based policy and operational recommendations, promote sustainable construction practices, and advance decarbonization in the building sector. Figure 2 presents a four-stage workflow for conducting a bibliometric analysis. This study used the Web Of Science Database, and the initial search yielded 673 publications, including journal articles, conference proceedings, and books. These publications had been rigorously screened to include only peer-reviewed literature from 2014 to 2024 that complied with ISO 14040/EN 15978 standards after removing duplicates and irrelevant studies (e.g., non-glulam building applications), as well as consolidating synonyms. Following this, the Visualization of Similarities Viewer (VOS-viewer) generated keyword co-occurrence networks and regional collaboration mapping to identify research hotspots through publication metrics, citation analysis, and keyword clustering, ultimately analyzing global research trends in the life cycle assessment (LCA) of glulam buildings, with particular emphasis on carbon footprint characteristics. The methodology used for this study followed that of previous research [5].

Figure 2.

Bibliometric analysis process.

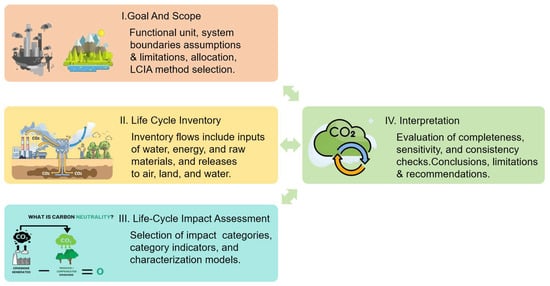

2. Life Cycle Assessment

In principle, the sustainability of a building is evaluated by quantifying the economic, social, and environmental impacts associated with it through its entire life cycle [12]. LCA is an established tool that is used for measuring the environmental impacts associated with all stages of a glulam building’s life cycle. The International Organization for Standardization (ISO 14040) defines the standard LCA framework, which consists of four main stages [10] as shown in Figure 3, as follows: the life cycle of a building starts with the extraction, production, and transportation of raw materials and extends to construction, operation, and maintenance, up until demolition and waste management at the end of its service life [13]. In the context of buildings, the European Standard EN 15978 divides the life cycle into four distinct phases [11].

Figure 3.

LCA framework as per ISO 14040 [10].

Table 1 summarizes these phases: material production and construction (Modules A1–5), service life (Modules B1–7), end-of-life (Modules C1–4), and potential benefits and loads beyond the system boundary (Module D), where additional environmental impacts may occur.

Table 1.

Life cycle stages and processes.

An increasingly popular tool for bibliometric analysis is the VOS-viewer. It efficiently visualizes similarity networks, clustering, and mapping of research data, supporting applications such as keyword co-occurrence analysis, co-citation analysis, co-authorship analyses, bibliographic coupling analyses, and others [14]. As already mentioned, data were extracted from Web Of Science, considering glulam and CLT as wood-based materials used in the construction sector, keywords such as Wood/Timber, Building/Construction, and LCA were used in the initial search. The search results were sorted by relevance, and finally, a total of 563 references were obtained. We imported the references in a .csv (Microsoft Excel) file format using the bibliometric tool VOS-viewer for the analysis of research trends, keyword co-occurrence maps, author affiliations, and LCA research results by region.

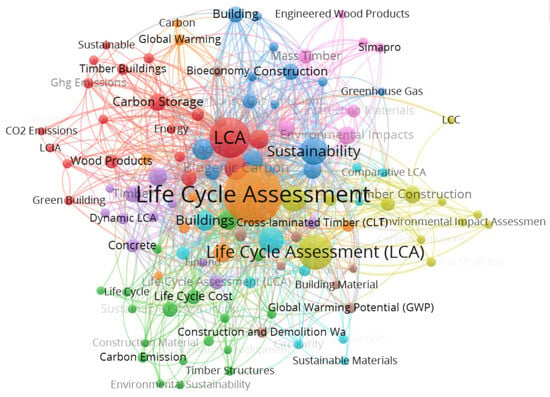

Keywords are an essential component of any research article; they convey the basic information about the content and direction of the literature. According to the preferred settings of the VOS-viewer, the keyword occurrences were filtered more than 5 times to highlight the importance of the research, as shown in Figure 4, and the initial search of author keywords resulted in 82 terms. Concerning the general practices and literature conventions in the field of LCA research. Synonyms for terms like Wood and Timber, Building and Construction, LCA and CLT were categorized and merged. Finally, 54 research keywords were identified, as shown in Table 2. As a core term related to environment and sustainability, LCA appeared 359 times with a total link strength of 522, making it an extremely critical concept. Meanwhile, Simapro, a world-leading LCA software tool, appeared six times with a total strength of 13. Sustainability appeared 38 times with a total strength of 80 and served as a crucial link connecting various specific LCA research directions. Environmental impact appeared 50 times with a strength of 96, highlighting the focus on the impacts of various activities and materials on the environment. Combined with methods like LCA, it provided a basis for sustainable development decision-making. Global warming, Climate change, and Greenhouse gas emissions appeared 35 times, 20 times, and 22 times, respectively, reflecting the research community’s strong focus on global climate issues. Related studies often revolved around how to mitigate climate change and its associated impacts through various means.

Figure 4.

Co-occurrence network map of the keywords from 2014 to 2024.

Table 2.

Keyword analysis.

- Keywords such as Buildings, Wood buildings, and Residential buildings indicate that the research spans a range of building types, from general construction to specific wooden and residential structures. The term Building materials appears 21 times, with particular focus on wood-based materials like Timber structures, GLT, CLT, and Mass timber. This reflects growing interest in their characteristics, applications, and environmental impacts within sustainable construction.

- Related terms such as Building design, Building envelope, and Building information modeling suggest a broader research scope, encompassing not just materials but also design strategies, enclosure systems, and digital tools that enhance building performance and sustainability.

- Carbon-related keywords, including Embodied carbon, Biogenic carbon, Carbon footprint, and Carbon storage, appear frequently, signaling a strong focus on measuring carbon emissions, content, and storage in wooden buildings. These metrics are critical in assessing sustainability, especially in the context of climate change.

- Energy-related terms such as Embodied energy, Energy consumption, Energy efficiency, and Primary energy reveal a significant emphasis on energy use and efficiency throughout a building’s life cycle. This aligns with the Sustainable Development Goals to reduce energy demand and improve utilization.

- Terms like Circular economy, Recycling, Reuse, Circularity, and End-of-life underscore the importance of circular design principles. The research highlights strategies for managing materials at the end of their life cycle and creating systems that minimize resource waste and environmental impact.

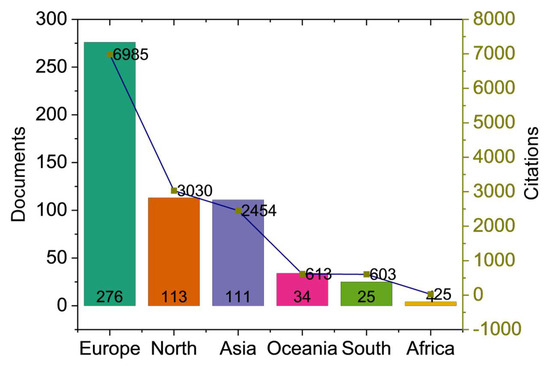

We selected studies that covered a wide range of locations globally, involving 63 countries. As shown in Figure 5, the bar and line chart illustrates the number of publications (bars, left y-axis) and citations (line, right y-axis) related to research on a specific topic across six global regions: Europe, North America, Asia, Oceania, South America, and Africa. The international distribution included 14 countries in Asia with 111 publications and 2454 citations; 35 countries in Europe with 276 publications and 6985 citations; 2 countries in Africa with 4 publications and 25 citations; 3 countries in North America with 113 publications and 3030 citations; 7 countries in South America with 25 publications and 603 citations; and 2 countries in Oceania with 34 publications and 613 citations. The geographical attribution analysis of publications is based on “countries of authorship” to reflect the main contributing regions of the research.

Figure 5.

Number of documents (i.e., publications) and citations between 2014 and 2024.

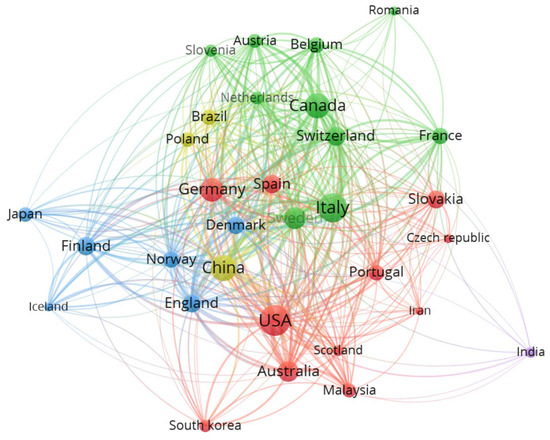

In Figure 6, different colors represent the clusters, with node size indicating the contribution level of research and the thickness of the connecting lines showing the relationships between them. Europe has the highest number of citations and publications, indicating that European research outcomes are widely recognized and influential internationally. The dense connections among European countries, such as Germany, Belgium, Italy, and Switzerland, positioned Europe at the network’s core. This reflected strong regional synergy in scientific collaboration. Europe also served as a key partner in many research projects. North America also had high citation and publication numbers driven by the influence of research from the United States and Canada. Asia had a considerable citation and publication number, demonstrating the growing impact of its research outputs. Oceania, South America, and Africa had relatively lower citation and publication numbers. Countries such as China, Japan, and Australia showed connections to multiple countries, including Canada, Australia, and the United Kingdom, indicating their active roles in international scientific collaboration. Chile’s connections with countries like China and the United States highlighted cross-regional research cooperation. Such collaborations facilitated the exchange of knowledge and technology and fostered innovation.

Figure 6.

Network of countries involved in the topic during 2014–2024.

3. Multi-Aspect Impacts

In this section, we will review the environmental, economic, and social impacts.

3.1. Environmental Aspect

Life cycle assessment (LCA) aims to quantify environmental impacts, minimize resource consumption, and reduce pollution. Table 3 shows the environmental impacts during the building life cycle of representative countries from six continents that use locally produced glulam in buildings, and carbon emissions were compared using the conversion factor of emissions per m2. The studies followed EN 15978:2011 life cycle assessment stages and corresponding modules. The buildings ranged from low to high rises, with floor areas ranging from 63 to 13,488 m2. Building types include residential apartments, commercial, and mixed-use. The samples included four buildings from Europe, three from North America, four from Asia, two from South America, and one building from Oceania. Data from Africa were not available at the time of study. Overall, the results of LCA studies indicated that, compared to traditional construction solutions, the impact on most environmental categories is reduced when using wood material, but we cannot conclude if it has the best environmental performance because the impact categories where the traditional construction has the lowest impact scores might be the most important. Furthermore, the environmental impact of glulam is mainly in the reduction in GHG emissions, which is in line with previous studies [15]. The quality of data used in the LCA studies conducted on glulam buildings has been an ongoing challenge. This is perhaps unsurprising as glulam buildings are constructed using relatively new materials produced by a limited number of manufacturers. Moreover, existing glulam buildings have not yet reached the end of their service lives, which thus leads to approximations or significant limitations while assessing the life cycle carbon footprint of these buildings.

Table 3.

Life cycle stages of glulam buildings.

During the raw material processing stage, the primary material for glulam is wood. Wood absorbs carbon dioxide during its growth, contributing to mitigating climate change [29]. The energy required for glulam production is primarily used in processes such as cutting, drying, and gluing. A significant portion of this energy can be supplied by electricity or biomass [30]. Compared to the high-temperature calcination in concrete production and the complex smelting processes in steel production, the carbon emissions from glulam production are significantly reduced [31,32]. However, while high-performance adhesives ensure the strength and durability of glulam, the production of adhesives itself also generates carbon emissions. Missiatto Gavioli et al. [33] found that the use of bio-based adhesives in production process produced significantly lower carbon emissions than traditional petroleum-based adhesives, but still faces significant technical and cost limitations in development. For instance, bio-based adhesives (e.g., soy protein) can achieve 70–85% of the dry strength of traditional phenolic resin (PF), but their wet strength drops significantly (only 40–50%). Under hygrothermal cycling tests, the adhesive layer exhibits strength degradation, making it difficult to comply with the ISO 20152-1:2010 standard [34]. Due to higher extraction costs of raw materials (e.g., tannins and high-purity proteins) and increased production expenses from modification processes (e.g., enzymatic treatment and nanofiller incorporation), certain bio-adhesives (e.g., starch- or lignin-based formulations) require adjustments to hot-pressing parameters and extended curing times, which negatively impact production efficiency [35]. Currently, bio-based adhesives have only achieved commercial viability in limited non-structural applications. Large-scale implementation will require breakthroughs in reducing raw material production costs and demonstrating long-term durability performance.

During the transportation and construction stage, the high strength-to-weight ratio of glulam could reduce energy consumption. Transportation distance has a significant impact on the building’s environmental footprint. The study [22] found that when CLT was sourced from Europe, the global warming potential of timber buildings was higher than that of concrete buildings. During the construction process, a study by Jolly et al. [25] indicated that concrete building materials, being heavier than glulam, resulted in higher CO2 emissions from crane operations. The prefabrication and modular assembly of glulam reduce the time required in temporary facilities on-site, thereby lowering energy consumption and associated emissions. Dodoo et al. [28] reduced the number of connectors by optimizing the connection system, improving assembly efficiency, and consequently, reducing the material production carbon footprint of CLT components by 1.1%.

During the service life stage, glulam buildings exhibit excellent thermal insulation properties, which help reduce the heating and cooling demands during operation, thereby lowering energy consumption and GHG emissions, especially in colder regions [20]. Felmer et al. found that the greenhouse gas emissions during the operation phase of passive CLT building designs are lower than those of traditional concrete buildings [26]. However, buildings in the operation phase may experience increased environmental impact due to maintenance requirements, such as the extensive use of paints in wood maintenance. This introduces challenges in predicting the end-of-life outcomes and results beyond the system boundaries [18,36]. The release of biogenic carbon at the end of a glulam building’s life increases the environmental impact [21]. However, extending the building’s lifespan could help achieve long-term carbon reduction benefits. At the end of their lifespan, the wooden components of a building could be dismantled and recycled. The research of [37] pointed out that reusing or recycling wood at the end of a building’s life can further improve its life cycle performance and reduce the demand for new timber extraction.

3.2. Economic Aspect

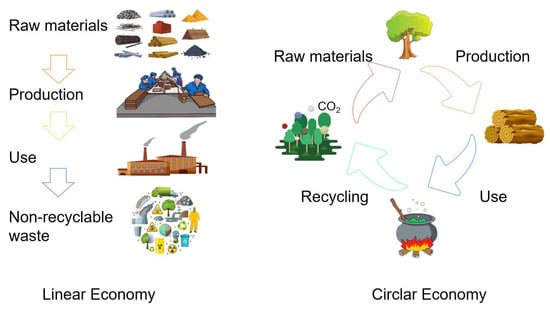

The economic benefits of glulam are mainly reflected in the circular economy. As shown in Figure 7, the circular economy starts from the awareness of resource limitations, unlike the traditional linear economic model, which is based on the cradle-to-cradle concept [12]. This involves production, distribution, and operation, followed by the recycling and reuse of raw materials, with the entire process being sustainable and interconnected. This approach reduces or eliminates waste and maximizes the value of resource usage. Table 4 shows the circular economy performance of glulam buildings in different regions.

Figure 7.

Linear economy vs. circular economy (adapted from [12]).

Table 4.

Study on circular economy performance of glulam buildings in different countries.

In the raw material processing stage, a study from China showed that between 1961 and 2020, the carbon sink of end-user furniture products produced 14.9 Tg C per year, accumulating to a total of 893 Tg C with 76% stored in the furniture products themselves [38]. Another study from Japan predicted that by 2050, the increased use of wood in construction, structures, furniture materials, and energy production could reduce costs by CNY 357 billion through carbon storage, material substitution, and fuel substitution [39]. This highlighted the value of carbon storage. Furthermore, in South Africa, which has a high self-sufficiency rate in forestry products, sustainable management ensured the supply of forest resources [50]. A study from Slovakia analyzed prefabricated timber frame buildings during the transportation and construction stage. It was found that, compared to brick and stone buildings, construction time was reduced by 48%, construction cost was lowered by 15%, and transportation cost was lowered by 57%. Noise, dust, and waste emissions were also reduced [42]. Another study from Malaysia showed that the use of wood in steel–concrete buildings could save costs by 36–45% [19].

In the service life stage, glulam buildings play a significant role in energy conservation and emission reduction, particularly in cold-climate regions. For example, Svortevik et al. [45] studied the use of CLT in industrial buildings for Nordic climates and found a potential 3.3% in total energy savings. In Australia, glulam residential projects proved that their excellent insulation properties could reduce energy consumption during service. Compared to conventional brick–concrete houses, winter heating costs and summer cooling costs were reduced by approximately 25%. Although maintenance costs are 13–16% higher than reinforced concrete buildings, the overall long-term operational cost advantage was evident [49]. At the end of its lifespan, wood has a higher building circularity indicator (BCI) compared to steel–concrete structures [40]. A study in the United States compared traditional steel-frame structures and large-scale wood alternatives for a four-story office building. It was pointed out that 75% of CLT and 95% of glulam could be directly reused at the end of their life, with the remainder converted to particleboard [46]. Goldaraz-Salamero et al. [44] explored the environmental and market performance of two timber supply chains in northern Italy. It was found that oriented strand board (OSB) is the most valuable alternative produced by recycling wood. Another study from Canada explored the economic feasibility of converting wood waste into biofuels [47]. Furthermore, new recycling technologies in Germany have transformed recycled solid wood into glulam products, reducing environmental impact by 29% and costs by 32% compared to incineration-based wood recycling. This demonstrated both environmental and economic benefits [41]. A study in Brazil highlighted the potential for converting recycled wood chips into bio-concrete to act as a carbon sink [48]. In summary, the diverse experiments from different countries in all life cycle phases of glulam buildings have accumulated valuable experience, contributing to the development of a circular economy.

3.3. Social Aspect

Social sustainability can be interpreted as the protection and enhancement of human–social capital, which is the guarantee of well-being (safety, health, education, etc.) equally distributed among the population [12]. Table 5 summarizes indicators of social sustainability in glulam construction.

Table 5.

Social sustainability metrics in glulam buildings.

Community well-being is commonly evaluated through a combination of subjective surveys and objective quantitative measures. The study on building preference reported attributes of wood products that were particularly appreciated [51,52,53]. The criteria include a set of measurable physical parameters, called indoor environmental factors, evaluating thermal comfort, visual comfort, indoor air quality, and acoustical quality. The criteria corresponding to the connection with human physiology were described [54], as shown in Table 6. In this regard, it is noteworthy that several studies have explored the connection between the use of wood and the physical and mental well-being of occupants. Wood in buildings reminds occupants of contact with nature. For example, wooden interiors in offices conveyed a sense of innovation, vitality, and comfort, which could enhance employee well-being and boost productivity. Visible wood grain reduces stress hormone secretion by 15% [55]. Another study suggested that the use of wood material in hospitals had a positive impact on patient healing, reducing hospital stays [56]. In earthquake-prone countries like Japan or cold Nordic regions, the use of glulam in buildings significantly enhanced residential safety and comfort [57,58,59]. Additionally, in remote forested areas like Sardinia and parts of South Africa, the supply chain of timber products had created employment opportunities and stimulated the local economy [12,50]. In the EU, the timber industry contributed significantly to their GDP. Gross capital reached EUR 122 billion and added value reached EUR 31.2 billion while providing employment to over 1 million people in 184,000 companies, from which most are small or medium-sized enterprises (SMEs) [60]. Glulam also presented a viable alternative to construction and renovations, particularly for the revamping of old buildings and the restoration of historic buildings. This included preserving cultural heritage by adding new floors to revamp old residential buildings in urban areas [61,62,63].

Table 6.

The criteria in terms of measurable physical parameters, related to human physiology.

4. Carbon Footprint Analysis

Many countries worldwide are actively addressing the climate crisis and broader environmental issues. Glulam buildings contribute to these efforts by offering a sustainable construction option that supports carbon reduction goals. However, their environmental impact can vary by region due to different materials, construction practices, and energy sources.

4.1. Raw Material Processing Stage

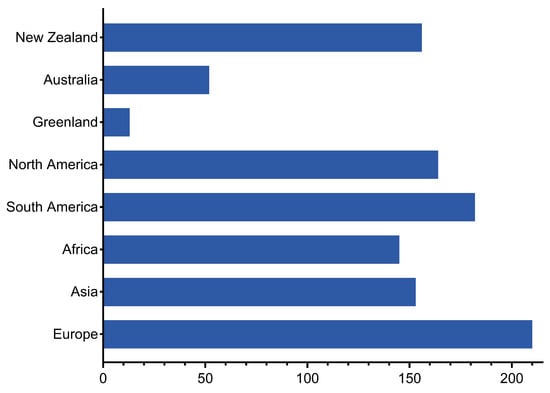

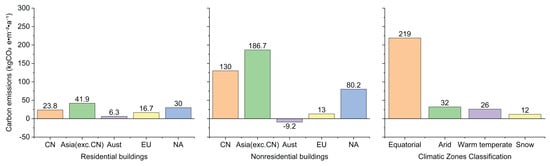

Glulam is primarily manufactured from solid wood. Its production involves pre-treatment processes such as cutting, grading, and drying, followed by pressure bonding with high-performance adhesives. This stage mainly includes logging and transporting raw materials to processing facilities. As illustrated in Figure 8, the geographical distribution of forest resources significantly influences the carbon footprint of glulam production [64]. This is critical not only for offsetting emissions generated during harvesting and processing but also for enhancing the material’s carbon storage potential.

Figure 8.

Carbon footprint characteristics of different regions.

Europe has a well-developed forest management system that promotes sustainability through forest certification, carbon trading mechanisms, and policy-driven initiatives. Nordic countries such as Sweden and Finland are at the forefront of glulam construction, pioneering its use as a means of enhancing carbon sequestration [65,66,67]. North America’s carbon storage potential is strongly linked to its extensive forest resources, with Canada alone accounting for 347 million hectares, approximately 9% of the world’s total forest area. Canada has long been a leading producer of harvested wood products (HWP). Through the implementation of sustainable harvesting and renewal strategies, carbon emissions associated with timber harvesting can be significantly reduced [68]. Chen et al. [69] investigated forest carbon stocks under a baseline harvesting scenario across four forest management units. Their study found that carbon stocks initially declined from 1.359 megatons of carbon (MtCO2e) to 1.353 MtCO2e over 20 years, but subsequently rose to 1.426 MtCO2e after 80 years, where they stabilized. These findings suggest that, in the long term, sustainable forest harvesting for wood production offers greater benefits for greenhouse gas mitigation compared to forest conservation alone.

Tropical rainforest ecosystems in South America and South Africa possess exceptionally high-carbon-storage capacity. Glulam processing facilities in these regions are often strategically located near forest resources, enabling the sourcing of timber within short transport distances, thereby reducing carbon emissions associated with transportation. Strict protection of tropical rainforests helps minimize disturbance to natural ecosystems and extends the duration of carbon sequestration [50,70]. Asia’s carbon storage capacity varies significantly due to differences in forest types and regional distribution. High-carbon-storage areas are primarily concentrated in East Asia, such as the coniferous forests of Northeast China and the Russian Far East, and in Southeast Asia, including the tropical rainforests of Indonesia and Malaysia. Although Southeast Asia’s rainforests possess high-carbon-storage potential, they face challenges from illegal logging, which results in carbon removal from the system through wood products, but eventual end-of-life decomposition releases carbon back into the atmosphere, compromising long-term climate mitigation benefits. Consequently, sustainable forest management must integrate both responsible harvesting practices and extended carbon storage in durable products. Through the utilization of plantation forests, carbon sequestration can be achieved in the short to medium term; however, this approach must be carefully balanced with the preservation of natural forests to ensure long-term climate mitigation benefits [71]. In recent years, China has actively promoted glulam construction technologies by using fast-growing wood, which not only reduces carbon emissions associated with traditional building materials but also contributes to sustainable forest management. In Oceania, forest resources are relatively concentrated. Australia and New Zealand have established large-scale plantations of fast-growing species such as Radiata pine, providing a steady supply of raw materials for glulam production [72,73]. Moreover, the adoption of advanced production and processing technologies in these countries enhances wood utilization efficiency and reduces emissions caused by outdated equipment and energy waste. For example, glulam plants in Germany have begun incorporating clean energy technologies, such as biomass and solar power, into their production processes to further reduce their carbon footprint [74]. In contrast, many countries in Asia and Africa continue to rely heavily on coal and oil due to slower progress in energy transition [75].

4.2. Transport and Construction Stage

The transportation and construction phase encompasses the delivery of finished glulam products to construction sites, the installation of components, and the operation of related machinery and equipment. Transportation distance, shaped by the geographical distribution of material suppliers, plays a significant role in the overall carbon footprint. Atnoorkar et al. [76] examined four transportation scenarios ranging from 1029 to 6953 km in the United States and found that longer distances could contribute up to 923 MJ/m2 (20%) of energy consumption in glulam buildings. When higher-density wood species were used, this contribution rose to 1246 MJ/m2 (24%), largely due to increased fossil fuel use. Similarly, Chen et al. [77] revealed that transporting glulam from Southeastern China to a construction site over 2000 km away resulted in a global warming potential (GWP) of 252–270 kgCO2/m2, which exceeded that of equivalent reinforced concrete (RC) buildings (245 kgCO2/m2) when road transport was used. Table 7 illustrates the carbon emission factors of various transportation modes. Aviation has the highest emissions at nearly 900 g/(t·km), approximately 9 times that of road transport, 79 times that of rail, and 104 times that of water transport. Road transport, the second most carbon-intensive mode, emits roughly 9 times more than rail and 12 times more than water, making it a key target for transport-related carbon reduction strategies [78]. Calculating carbon emissions from on-site construction, referred to as Embodied Construction Emission Assessment (ECEA), is complex. It includes direct energy use, emissions from machinery and equipment, indirect emissions from transporting construction tools, and the carbon impact of off-site personnel activities [79]. However, the adoption of advanced prefabrication and assembly technologies in some developed countries has helped mitigate these emissions. Techniques such as intelligent prefabrication and 3D printing can reduce on-site construction time, minimize machinery use, and enhance overall efficiency [80,81,82].

Table 7.

Transport modes, turnover, and carbon emission factors.

4.3. Service Life Stage

The service life stage encompasses the building’s energy consumption and maintenance activities, both of which are significantly influenced by regional climatic conditions. As illustrated in Figure 9, heating and cooling systems represent the dominant sources of energy use, contributing approximately 80% to 90% of carbon emissions during the operational phase [83,84,85].

Figure 9.

Effects of different climate characteristics on the carbon footprint of buildings.

Carbon emissions tend to be higher in equatorial regions and across parts of Asia, particularly in non-residential buildings. In contrast, residential buildings in China exhibit lower emissions compared to other Asian countries. Regions such as Australia, the European Union, and snow-covered areas demonstrate better performance in carbon reduction, often due to climate-adapted building strategies and cleaner energy sources. Numerous studies conducted in countries including China [86], Denmark [87], Italy [88], Sweden [89], the United States [3], and Australia [90] have affirmed the carbon reduction benefits of glulam, particularly in low-energy buildings. These benefits are most evident in colder climates, where heating systems account for a significant portion of operational emissions. The energy mix plays a critical role in shaping a building’s carbon footprint. Zhang et al. compared several heating systems for high-rise residential buildings in cold regions of China, revealing a progressive decrease in emissions from coal-fired boilers to solar-assisted heat pumps [91]. Similarly, studies in Spain and Colombia found that replacing high-carbon electricity with low-carbon alternatives reduced building energy consumption by 9% to 67% [92]. Optimizing the energy mix has proven to be a key strategy for carbon reduction. In Sweden, research by Växjö et al. demonstrated that wooden buildings utilizing district heating in combination with biomass-based integrated gasification combined cycle (BIGCC) systems, or heat pumps paired with BIGCC, could achieve net-negative carbon emissions [93]. Likewise, a study by Korsavi et al. on a UK campus building showed that integrating photovoltaic systems reduced energy consumption by 30% [94].

However, operational emissions are not limited to energy use; buildings also undergo maintenance and replacement over time. Glulam buildings, particularly in high-humidity tropical and oceanic climates, are susceptible to wood decay, mold, and related deterioration [7]. Regular inspections and proactive maintenance can help minimize the long-term carbon footprint associated with these issues. Most LCA studies assume a service life of 50 to 60 years for glulam structures, which aligns with the commonly accepted structural lifespan of 40 to 75 years [95]. To improve the accuracy of carbon footprint assessments related to maintenance and repair, the development of robust service life prediction models for glulam buildings is urgently needed.

4.4. End-of-Life Stage

The end-of-life phase of glulam buildings encompasses activities such as demolition, waste transportation, and final disposal. Timber structures, in particular, offer significant carbon reduction potential through the recycling and reuse of materials, as well as energy recovery processes. Three primary end-of-life scenarios are typically considered for glulam buildings: (a) partial or complete reuse; (b) incineration, with or without energy recovery; and (c) landfilling [96,97,98]. These scenarios can occur in combination, each contributing to the overall carbon footprint based on their respective proportions. In this context, Darby et al. conducted a comparative assessment of glulam buildings under different end-of-life pathways, taking into account biogenic carbon dynamics [99]. Their findings, summarized in Table 8, show that reuse and recycling offer the most environmentally advantageous outcomes. For example, Liang et al. reported that recycling mass timber at the end of its life provides a carbon offset of 364 kg CO2eq/m2, reducing greenhouse gas emissions by an additional 12% compared to reinforced concrete (RC) structures [100]. Beyond reducing global warming potential, such strategies promote a circular economy and support cradle-to-cradle approaches in construction. This not only enhances material efficiency but also contributes to long-term sustainability by extending the functional life of building components and reducing environmental burdens.

Table 8.

Phase-wise environmental impact values for different waste management strategies.

Studies conducted across various countries yield similar findings, as summarized in Table 3. However, the dominant approach to managing discarded wood components is their recycling into biofuel to replace fossil fuels, followed by landfilling. Improper incineration of wood, however, releases substantial greenhouse gases and harmful substances [101]. Head et al. highlighted that landfilling not only occupies land resources but also leads to methane emissions as wood decomposes anaerobically over time [102]. The effectiveness of reuse or recycling largely depends on the upstream production processes, construction methods, and the management of waste wood [25,103,104]. Current wood strength grading standards, such as EN 14081-1:2019, require detailed information on the wood species, growth region, and prior grading [105]. These requirements are often difficult to meet for recycled glulam, which impedes the realization of its full potential for reuse [106]. While wood recycling is practiced in demolition projects in Finland, a significant portion is shredded for biomass energy to offset demolition costs [107]. Wang et al. [108] found that 95% of renovation waste in nine cities across China is disposed of via landfilling. Similarly, in Brazil, over 10 million tons of wood waste are generated annually, with 63% being incinerated [48].

Despite these practices, the reuse of glulam remains underdeveloped, and its end-of-life management predominantly involves incineration or landfilling. In regions with more advanced glulam use, such as Sweden, recycling systems have been established. Harte et al. found that 90% of glulam beams were recycled during building demolitions in Sweden [109]. To promote the reuse and recycling of glulam, the In Future Wood Project was established, led by Sandberg et al. [110] and involving 22 partners from seven countries, including Finland and Germany. The project developed new design methods, assessed the performance of recycled wood products, and identified factors influencing demolition practices. Key recommendations included the preparation of demolition plans by designers, financial incentives from governments to encourage wood reuse, and the adoption of common standards and regulations. Furthermore, graded utilization of wood and the establishment of an integrated policy framework were recommended to support sustainable wood recycling and reuse practices.

5. Results and Discussion

This systematic review synthesized findings from 563 peer-reviewed studies published between 2014 and 2024 to comprehensively assess the sustainability performance of glulam (glued laminated timber) buildings using life cycle assessment (LCA) methodologies. The analysis covered diverse geographic contexts, material flows, and building typologies, with particular attention to regional carbon dynamics, life cycle emissions, circular economy integration, and socioeconomic implications.

- Regional Carbon Footprint Disparities: European and North American studies consistently reported lower cradle-to-gate and cradle-to-grave carbon footprints for glulam production, typically 28–70% lower than those of conventional concrete and steel structures. These outcomes were largely attributed to advanced forest certification schemes (e.g., PEFC, FSC), widespread use of renewable energy in production (e.g., biomass boilers, hydropower), and optimized logistic networks [65,67,78]. For instance, German and Swedish glulam production systems recorded embodied carbon intensities as low as 110–160 kgCO2e/m2. Conversely, studies from parts of Asia, Sub-Saharan Africa, and Latin America highlighted significant emission burdens due to unsustainable logging practices, reliance on coal and diesel-based electricity, and lack of infrastructure for energy-efficient manufacturing. Notably, Southeast Asia’s tropical hardwood glulam products showed embodied emissions up to 340 kgCO2e/m2 (despite high-carbon-storage potential), mainly due to illegal logging, inefficient processing, and long transportation distances [70,71].

- Life Cycle Performance: Comparative LCAs demonstrated that glulam buildings outperformed reinforced concrete and steel alternatives across 11 to 18 environmental impact categories, including global warming potential (GWP), acidification, eutrophication, smog formation, and fossil fuel depletion [3,88]. Glulam’s inherent carbon storage capacity contributed to offsets ranging from 30% to 47% of total life cycle emissions, depending on regional forest growth rates, product longevity, and structural mass per square meter. Moreover, integration of low-carbon energy systems (e.g., district heating, heat pumps, photovoltaic arrays) during the operational phase reduced GWP by 9% to 67%, particularly in cold-climate applications where heating energy dominates [91,93]. For example, a Swedish study showed net-negative GWP when glulam structures were paired with biomass-based integrated gasification combined cycle (BIGCC) systems.

- Circular Economy Benefits: End-of-life (EOL) strategies emerged as a key differentiator in sustainability outcomes. Recycling and reuse of glulam components reduced EOL emissions by 12% to 29% compared to conventional demolition and landfilling pathways [99,100]. Europe led in circularity, with Sweden reporting up to 90% recovery rates of glulam beams during demolition [109]. Prefabrication techniques, including cross-laminated and hybrid glulam systems, reduced on-site construction time by up to 48% and overall project costs by 10–15%, particularly in Central and Eastern European countries like Slovakia [80,81]. These strategies also minimized embodied construction emissions, often overlooked in conventional LCA models.

- Social and Economic Impacts: Glulam construction was associated with multiple co-benefits beyond environmental metrics. In the European Union, the mass timber sector supports over 1 million jobs, particularly in rural and forestry-dependent regions, contributing to regional economic resilience [90]. Studies in Japan, Austria, and Canada linked glulam interiors with improved indoor environmental quality (IEQ), including increased thermal comfort and reduced stress levels—up to a 15% decrease in occupant-reported stress compared to concrete interiors [94]. Furthermore, glulam’s relatively low weight reduced foundation loads and site impacts, expanding feasibility in both urban infill and remote locations.

These findings not only corroborate earlier assessments of glulam’s carbon sequestration and life cycle benefits, but also underscore persistent regional disparities. For example, while European case studies confirmed the long-term advantages of sustainably managed forests and integrated carbon accounting, tropical regions such as Indonesia and Brazil face leakage from illegal logging and post-harvest losses, which diminish net carbon storage gains over time [50]. Discrepancies also arose in operational phase evaluations: cold-climate buildings reported efficiency gains from high-performance envelope and HVAC integration, whereas in tropical zones, moisture resistance, termite control, and maintenance frequency were the dominant factors influencing long-term performance and emissions [7].

A notable gap identified across the reviewed literature is the limited availability of end-of-life data for glulam structures. Most of the current LCA studies rely on modeled assumptions, as relatively few glulam buildings constructed in the last two decades have reached their demolition phase. This calls for the development of dynamic predictive models and long-term monitoring systems to better estimate disposal pathways and material recovery rates [110]. Additionally, while the adoption of bio-based adhesives (e.g., lignin-phenol, soy protein) has been explored as a promising alternative to formaldehyde-based resins, scalability remains a challenge. Only 4% of studies reported successful industrial-scale substitution due to unresolved trade-offs between cost, mechanical performance, and durability under varying climate conditions [8]. This contrasts with more optimistic projections from early research and underscores the need for further innovation in sustainable bonding agents.

6. Conclusions

This review addressed three primary research objectives concerning the sustainability performance of glulam buildings across different life cycle stages and geographic contexts. Drawing from 563 peer-reviewed studies published between 2014 and 2024, our synthesis offers nuanced insights into the environmental, technical, and policy dimensions that influence glulam’s viability as a sustainable building material. Regarding the sustainability potential of glulam buildings, evidence overwhelmingly supports their effectiveness in reducing greenhouse gas (GHG) emissions throughout the entire life cycle. Emission reductions ranged from 28% to 70% compared to conventional materials such as reinforced concrete and steel. This is primarily attributed to glulam’s inherent carbon storage capacity, lower embodied energy, superior thermal insulation properties, and compatibility with energy-efficient building systems. Additional sustainability benefits were observed in construction speed and material circularity. Prefabricated glulam systems not only shortened construction timelines but also minimized on-site waste and energy use, reinforcing glulam’s alignment with low-impact construction practices. The carbon footprint profile of glulam buildings revealed substantial regional variability influenced by several interdependent factors. Forest management practices, the carbon intensity of regional energy grids, and the mode of material transport were among the most significant contributors to emission differences. Transportation emerged as a non-negligible component of embodied emissions, with aviation and road transport accounting for up to 24% of total GHGs in some cases. In contrast, waterborne shipping and localized production, especially in regions where forestry and manufacturing are co-located, significantly reduced transportation emissions. The use of prefabricated modules further amplified carbon savings by decreasing construction-related emissions and enabling better logistics. On the regional influences on glulam deployment, we identified major disparities driven by policy maturity, technological infrastructure, and forest governance. Europe and North America consistently demonstrated strong performance across all sustainability indicators, largely due to well-established regulatory frameworks (e.g., EPDs, timber traceability laws), financial incentives for green buildings, and access to certified forests. Meanwhile, regions such as Southeast Asia, Sub-Saharan Africa, and parts of Latin America face persistent barriers, including illegal logging, lack of investment in clean energy, and weak end-of-life wood management. The review underscores the importance of equitable international partnerships, harmonized grading and reuse standards (e.g., adaptations of EN 14081-1:2019), and capacity-building initiatives to address these structural gaps.

Based on these findings, we have several future research directions and policy recommendations, as follows:

- Advance bio-based adhesives: Current limitations in the scalability, performance, and cost-efficiency of bio-adhesives impede their adoption. Targeted R&D in lignin-, tannin-, or protein-based alternatives should be prioritized to reduce the fossil-derived chemical content in glulam.

- Develop region-specific LCAs:There is an urgent need for geographically contextualized LCA models that account for local climate, forestry practices, and construction typologies, particularly in underrepresented regions like Africa and South America.

- Enhance end-of-life data and predictive modeling: Many glulam buildings have yet to reach their end-of-life stage. Longitudinal studies and scenario-based modeling should be implemented to improve accuracy in LCA projections and support circular economy planning.

- Foster international collaboration and knowledge transfer: Partnerships such as the In Future Wood Project illustrate the importance of cross-border collaboration. Future efforts should expand shared databases, standardize life cycle inventory (LCI) formats, and facilitate policy learning between regions.

- Promote circular policy frameworks: Policymakers should incentivize material reuse, integrate cradle-to-cradle certification systems, and support demolition planning for material recovery. Financial tools such as green public procurement and carbon pricing should reward projects that demonstrate high material efficiency and low carbon intensity.

Author Contributions

R.L.: Conceptualization, Methodology, Formal analysis, and Writing—original draft. Z.W.: Data Curation, Investigation, and Visualization. L.Y.: Supervision, Project administration, Funding acquisition, and Resources. Y.G.: Review and Editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 32360356.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The completion of the paper is thanks to the National Natural Science Foundation of China (32360356) and Inner Mongolia grassland talent team, innovative talent team (Tc2019071720712).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Global Alliance for Buildings and Construction. Global Status Report for Buildings and Construction. 2020. Available online: https://www.iea.org/reports/global-energy-review-2021 (accessed on 10 June 2025).

- Horowitz, C.A. Paris Agreement. Int. Leg. Mater. 2016, 55, 740–755. [Google Scholar] [CrossRef]

- Puettmann, M.; Pierobon, F.; Ganguly, I.; Gu, H.; Chen, C.; Liang, S.; Jones, S.; Maples, I.; Wishnie, M. Comparative LCAs of conventional and mass timber buildings in regions with potential for mass timber penetration. Sustainability 2021, 13, 13987. [Google Scholar] [CrossRef]

- Duan, Z.; Huang, Q.; Zhang, Q. Life cycle assessment of mass timber construction: A review. Build. Environ. 2022, 221, 109320. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Himes, A.; Busby, G. Wood buildings as a climate solution. Dev. Built Environ. 2020, 4, 100030. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, L.; Shi, Y.; Zhao, D.; Chen, T. Optimizing the Performance of Window Frames: A Comprehensive Review of Materials in China. Appl. Sci. 2024, 14, 6091. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Schau, E.M.; Niemelä, E.P.; Burnard, M.D. Comparing the environmental impacts of wooden buildings in Spain, Slovenia, and Germany. J. Clean. Prod. 2021, 329, 129587. [Google Scholar] [CrossRef]

- Shi, L.; Qi, X.; Yang, Z.; Tao, L.; Li, Y.; Qiu, J.; Jiang, X. Comparative study of greenhouse gas emission calculations and the environmental impact in the life cycle assessment of buildings in China, Finland, and the United States. J. Build. Eng. 2023, 70, 106396. [Google Scholar] [CrossRef]

- ISO 14040; 2006 Environmental Management-Life Cycle Assessment-Principles and Framework, second ed. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 10 June 2025).

- European Committee for Standardization. Sustainability of Construction Works-Assessment of Environmental Performance of Buildings Calculation Method. 2011. Available online: https://standards.globalspec.com/std/1406797.html (accessed on 10 June 2025).

- Concu, G. Sustainability of the timber supply chain on the island of Sardinia. In Proceedings of the Computational Science and Its Applications–ICCSA 2020: 20th International Conference, Cagliari, Italy, 1–4 July 2020; Proceedings, Part VII 20. Springer: Berlin/Heidelberg, Germany, 2020; pp. 353–367. [Google Scholar]

- Anex, R.; Lifset, R. Life cycle assessment: Different models for different purposes. J. Ind. Ecol. 2014, 18, 321–323. [Google Scholar] [CrossRef]

- Nobanee, H.; Al Hamadi, F.Y.; Abdulaziz, F.A.; Abukarsh, L.S.; Alqahtani, A.F.; AlSubaey, S.K.; Alqahtani, S.M.; Almansoori, H.A. A bibliometric analysis of sustainability and risk management. Sustainability 2021, 13, 3277. [Google Scholar] [CrossRef]

- Andersen, J.H.; Rasmussen, N.L.; Ryberg, M.W. Comparative life cycle assessment of cross laminated timber building and concrete building with special focus on biogenic carbon. Energy Build. 2022, 254, 111604. [Google Scholar] [CrossRef]

- Rinne, R.; Ilgın, H.E.; Karjalainen, M. Comparative study on life-cycle assessment and carbon footprint of hybrid, concrete and timber apartment buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S.S. COMPARATIVE LIFE-CYCLE ASSESSMENT OF A MASS TIMBER BUILDING AND CONCRETE ALTERNATIVE. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; Moya, L. Comparative BIM-based Life Cycle Assessment of Uruguayan timber and concrete-masonry single-family houses in design stage. J. Clean. Prod. 2020, 277, 121958. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W.; Yeoh, D. Recommending a new building structure to alleviate environmental impact in tropical climates: Increasing the use of wood in construction. Int. J. Life Cycle Assess. 2022, 27, 885–901. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, H.; Sun, C.; Chang, W.S. Assessing cross laminated timber (CLT) as an alternative material for mid-rise residential buildings in cold regions in China – A life-cycle assessment approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef]

- Nakano, K.; Karube, M.; Hattori, N. Environmental impacts of building construction using cross-laminated timber panel construction method: A case of the research building in Kyushu, Japan. Sustainability 2020, 12, 2220. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative life-cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the Athena impact estimator for buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Corradini, G.; Pierobon, F.; Zanetti, M. Product environmental footprint of a cross-laminated timber system: A case study in Italy. Int. J. Life Cycle Assess. 2019, 24, 975–988. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Y.; Meng, Y.; Huang, H.; Sun, C.; Shao, Y. A comparison of the energy saving and carbon reduction performance between reinforced concrete and cross-laminated timber structures in residential buildings in the severe cold region of China. Sustainability 2017, 9, 1426. [Google Scholar] [CrossRef]

- Jolly, R.; Fairweather, H.; Rayburg, S.; Rodwell, J. Life Cycle Assessment and Cost Analysis of Mid-Rise Mass Timber vs. Concrete Buildings in Australia. Sustainability 2024, 16, 6465. [Google Scholar] [CrossRef]

- Felmer, G.; Morales-Vera, R.; Astroza, R.; González, I.; Puettmann, M.; Wishnie, M. A lifecycle assessment of a low-energy mass-timber building and mainstream concrete alternative in central Chile. Sustainability 2022, 14, 1249. [Google Scholar] [CrossRef]

- Hafner, A.; Özdemir, Ö. Comparative LCA study of wood and mineral non-residential buildings in Germany and related substitution potential. Eur. J. Wood Wood Prod. 2023, 81, 251–266. [Google Scholar] [CrossRef]

- Dodoo, A.; Nguyen, T.; Dorn, M.; Olsson, A.; Bader, T.K. Exploring the synergy between structural engineering design solutions and life cycle carbon footprint of cross-laminated timber in multi-storey buildings. Wood Mater. Sci. Eng. 2022, 17, 30–42. [Google Scholar] [CrossRef]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, R.; Yao, L.; Ren, H.; Xu, J. Innovation analysis of carbon emissions from the production of glued laminated timber in China based on real-time monitoring data. J. Clean. Prod. 2024, 469, 143174. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, Y.; Feng, W.; Zhang, Y.; Zhao, G.X. How to minimise the carbon emission of steel building products from a cradle-to-site perspective: A systematic review of recent global research. J. Clean. Prod. 2022, 368, 133156. [Google Scholar] [CrossRef]

- Missiatto Gavioli, L.; Lopes Silva, D.A.; Bueno, C.; Rossignolo, J.A. Life cycle assessment as a circular economy strategy to select eco-efficient raw materials for particleboard production. Resour. Conserv. Recycl. 2025, 212, 107921. [Google Scholar] [CrossRef]

- ISO 20152-1:2010; Timber Structures–Bond Performance of Adhesives. International Organization for Standardization: Geneva, Switzerland, 2010. Available online: https://www.iso.org/standard/39252.html (accessed on 10 June 2025).

- Kumar, C.; Leggate, W. An overview of bio-adhesives for engineered wood products. Int. J. Adhes. Adhes. 2022, 118, 103187. [Google Scholar] [CrossRef]

- Allan, K.; Phillips, A.R. Comparative cradle-to-grave life cycle assessment of low and mid-rise mass timber buildings with equivalent structural steel alternatives. Sustainability 2021, 13, 3401. [Google Scholar] [CrossRef]

- Hafner, A.; Rueter, S. Method for assessing the national implications of environmental impacts from timber buildings—An exemplary study for residential buildings in Germany. Wood Fiber Sci. 2018, 50, 139–154. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, X.; Diao, J.; Chen, H.; Lin, S.; Zhu, Z.; Jiang, X.; Zhu, H. Exploring plausible contributions of end-use harvested wood products to store atmospheric carbon in China. Biomass Bioenergy 2023, 177, 106934. [Google Scholar] [CrossRef]

- Kayo, C.; Dente, S.M.; Aoki-Suzuki, C.; Tanaka, D.; Murakami, S.; Hashimoto, S. Environmental impact assessment of wood use in Japan through 2050 using material flow analysis and life cycle assessment. J. Ind. Ecol. 2019, 23, 635–648. [Google Scholar] [CrossRef]

- Shin, B.; Kim, S. Advancing the circular economy and environmental sustainability with timber hybrid construction in South Korean public building. Build. Environ. 2024, 257, 111543. [Google Scholar] [CrossRef]

- Risse, M.; Weber-Blaschke, G.; Richter, K. Eco-efficiency analysis of recycling recovered solid wood from construction into laminated timber products. Sci. Total Environ. 2019, 661, 107–119. [Google Scholar] [CrossRef] [PubMed]

- Švajlenka, J.; Kozlovská, M.; Spišáková, M. The benefits of modern method of construction based on wood in the context of sustainability. Int. J. Environ. Sci. Technol. 2017, 14, 1591–1602. [Google Scholar] [CrossRef]

- Sikkema, R.; Styles, D.; Jonsson, R.; Tobin, B.; Byrne, K.A. A market inventory of construction wood for residential building in Europe – in the light of the Green Deal and new circular economy ambitions. Sustain. Cities Soc. 2023, 90, 104370. [Google Scholar] [CrossRef]

- Goldaraz-Salamero, N.; Sierra-Perez, J.; Negro, F.; Zanuttini, R.; Blanc, S.; Brun, F. Integrated sustainability assessment of wood building products: The case of larch and chestnut cascading systems in Northern Italy. Sci. Total Environ. 2024, 951, 175601. [Google Scholar] [CrossRef]

- Svortevik, V.J.; Engevik, M.B.; Kraniotis, D. Use of cross laminated timber (CLT) in industrial buildings in Nordic climate—A case study. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012082. [Google Scholar] [CrossRef]

- Greene, J.M.; Hosanna, H.R.; Willson, B.; Quinn, J.C. Whole life embodied emissions and net-zero emissions potential for a mid-rise office building constructed with mass timber. Sustain. Mater. Technol. 2023, 35, e00528. [Google Scholar] [CrossRef]

- Cattarinussi, L.; Hofstetter, K.; Ryffel, R.; Zumstein, K.; Ioannidou, D.; Klippel, M. Life cycle assessment of a post-tensioned timber frame in comparison to a reinforced concrete frame for tall buildings. In Proceedings of the Sustainable Built Environment (SBE) Regional Conference (SBE 16), Zurich, Switzerland, 15–17 June 2016; vdf Hochschulverlag AG an der ETH Zürich: Zurich, Switzerland, 2016; pp. 656–661. [Google Scholar] [CrossRef]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; Da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete. Resour. Conserv. Recycl. 2021, 166, 105346. [Google Scholar] [CrossRef]

- Jayalath, A.; Navaratnam, S.; Ngo, T.; Mendis, P.; Hewson, N.; Aye, L. Life cycle performance of Cross Laminated Timber mid-rise residential buildings in Australia. Energy Build. 2020, 223, 110091. [Google Scholar] [CrossRef]

- Crafford, P.L.; Wessels, C.B.; Blumentritt, M. Sustainability and wood constructions: A review of green building rating systems and life-cycle assessment methods from a South African and developing world perspective. Adv. Build. Energy Res. 2021, 15, 67–86. [Google Scholar] [CrossRef]

- Larasatie, P.; Guerrero, J.E.; Conroy, K.; Hall, T.E.; Hansen, E.; Needham, M.D. What does the public believe about tall wood buildings? An exploratory study in the US Pacific Northwest. J. For. 2018, 116, 429–436. [Google Scholar] [CrossRef]

- Petruch, M.; Walcher, D. Timber for future? Attitudes towards timber construction by young millennials in Austria-Marketing implications from a representative study. J. Clean. Prod. 2021, 294, 126324. [Google Scholar] [CrossRef]

- Aguilar, F.X.; Roos, A.; Haapala, A.; Lähtinen, K.; Kniivilä, M.; Hoen, H.F. Dweller Preferences for Wood as a Load-Bearing Material in Residential Buildings. J. For. Econ. 2023, 38, 77–111. [Google Scholar] [CrossRef]

- Šujanová, P.; Rychtáriková, M.; Sotto Mayor, T.; Hyder, A. A healthy, energy-efficient and comfortable indoor environment, a review. Energies 2019, 12, 1414. [Google Scholar] [CrossRef]

- Ridoutt, B.; Ball, R.; Killerby, S. First impressions of organizations and the qualities connoted by wood in interior design. For. Prod. J. 2002, 52, 30–36. [Google Scholar]

- Cronhjort, Y. Project Wood2New. In Proceedings of the Fremtiden bygges i Tre-Seminar, Wood2New, Bergen, Norway, 23 June 2015. [Google Scholar] [CrossRef]

- Hiroyasu, S.; Yoshihiro, Y. Challenges in High-rise Wooden Structures and the Seismic Design in Japan. Int. J. High-Rise Build. 2022, 11, 171–180. [Google Scholar]

- Kosonen, A.; Keskisaari, A. Zero-energy log house–Future concept for an energy efficient building in the Nordic conditions. Energy Build. 2020, 228, 110449. [Google Scholar] [CrossRef]

- Vehola, A.; Hurmekoski, E.; Lähtinen, K.; Ruokamo, E.; Roos, A.; Toivonen, R.; Toppinen, A. Citizen beliefs concerning wood as a construction material under extreme weather events. Can. J. For. Res. 2022, 52, 1266–1279. [Google Scholar] [CrossRef]

- Van den Auwelant, E.; Nimmegeers, P.; Van Passel, S. Life cycle assessment and circular practices in the woodworking sector: A systematic review. Clean Technol. Environ. Policy 2025, 27, 1673–1692. [Google Scholar] [CrossRef]

- Amoruso, F.M.; Schuetze, T. Life cycle assessment and costing of carbon neutral hybrid-timber building renovation systems: Three applications in the Republic of Korea. Build. Environ. 2022, 222, 109395. [Google Scholar] [CrossRef]

- Viljanen, A.; Lähtinen, K.; Kanninen, V.; Toppinen, A. A tale of five cities: The role of municipalities in the market diffusion of wooden residential multistory construction and retrofits. For. Policy Econ. 2023, 153, 102991. [Google Scholar] [CrossRef]

- Bertolini Cestari, C.; Marzi, T. Conservation of historic timber roof structures of Italian architectural heritage: Diagnosis, assessment, and intervention. Int. J. Archit. Herit. 2018, 12, 632–665. [Google Scholar] [CrossRef]

- Noon, M.L.; Goldstein, A.; Ledezma, J.C.; Roehrdanz, P.R.; Cook-Patton, S.C.; Spawn-Lee, S.A.; Wright, T.M.; Gonzalez-Roglich, M.; Hole, D.G.; Rockström, J.; et al. Mapping the irrecoverable carbon in Earth’s ecosystems. Nat. Sustain. 2022, 5, 37–46. [Google Scholar] [CrossRef]

- Martinho, V.J.P.D.; Ferreira, A.J.D. Forest resources management and sustainability: The specific case of european union countries. Sustainability 2020, 13, 58. [Google Scholar] [CrossRef]

- Cosola, G.; Grigolato, S.; Ackerman, P.; Monterotti, S.; Cavalli, R. Carbon footprint of forest operations under different management regimes. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2016, 37, 201–217. [Google Scholar]

- Jensen, A.V.; Craig, N. Wood in Construction-25 Cases of Nordic Good Practice; Nordic Council of Ministers: Copenhagen, Denmark, 2019.

- Natural Resources Canada. The State of Canada’s Forests: Annual Report 2020; Natural Resources Canada: Ottawa, ON, Canada, 2020.

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. For. Int. J. For. Res. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Araya, R.; Guillaumet, A.; do Valle, Â.; Duque, M.d.P.; Gonzalez, G.; Cabrero, J.M.; De León, E.; Castro, F.; Gutierrez, C.; Negrão, J.; et al. Development of sustainable timber construction in Ibero-America: State of the art in the region and identification of current international gaps in the construction industry. Sustainability 2022, 14, 1170. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.; Long, H.; de Jong, W.; Youn, Y.C. Economic globalization, trade and forest transition-the case of nine Asian countries. For. Policy Econ. 2017, 76, 7–13. [Google Scholar] [CrossRef]

- Navaratnam, S.; Christopher, P.B.; Ngo, T.; Le, T.V. Bending and shear performance of Australian Radiata pine cross-laminated timber. Constr. Build. Mater. 2020, 232, 117215. [Google Scholar] [CrossRef]

- Dani, A.A.; Roy, K.; Masood, R.; Fang, Z.; Lim, J.B. A comparative study on the life cycle assessment of New Zealand residential buildings. Buildings 2022, 12, 50. [Google Scholar] [CrossRef]

- Sander-Titgemeyer, A.; Risse, M.; Weber-Blaschke, G. Applying an iterative prospective LCA approach to emerging wood-based technologies: Three German case studies. Int. J. Life Cycle Assess. 2023, 28, 495–515. [Google Scholar] [CrossRef]

- Tan, X.; Lin, S.; Liu, Y.L.; Xie, B.C. Has the inter-regional transmission grid promoted clean power development? A quantitative assessment on China’s electricity sector. J. Clean. Prod. 2020, 269, 122370. [Google Scholar] [CrossRef]

- Atnoorkar, S.; Ghatpande, O.A.; Haile, S.L.; Goetsch, H.E.; Harris, C.B. Carbon intensity of mass timber materials: Impacts of sourcing and transportation. Front. Built Environ. 2024, 9, 1321340. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Jones, S.; Maples, I.; Gong, Y.; Ganguly, I. Comparative life cycle assessment of mass timber and concrete residential buildings: A case study in China. Sustainability 2021, 14, 144. [Google Scholar] [CrossRef]

- Pei-Ning, T.; Bao-Hua, M.; Rui-Yong, T.; Hao-Xiang, Z.; Qi, Z. Analysis of carbon emission level and intensity of China’s transportation industry and different transportation modes. Adv. Clim. Change Res. 2023, 19, 347. [Google Scholar]

- Li, L.; Chen, K. Quantitative assessment of carbon dioxide emissions in construction projects: A case study in Shenzhen. J. Clean. Prod. 2017, 141, 394–408. [Google Scholar] [CrossRef]

- David, M.N.; Miguel, R.S.; Ignacio, P.Z. Timber structures designed for disassembly: A cornerstone for sustainability in 21st century construction. J. Build. Eng. 2024, 96, 110619. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Khan, M.; Dani, A.A.; Lim, J.B.; Roy, K. Appraising the Feasibility of 3D Printing Construction in New Zealand Housing. Buildings 2024, 14, 1084. [Google Scholar] [CrossRef]

- Cuéllar-Franca, R.M.; Azapagic, A. Environmental impacts of the UK residential sector: Life cycle assessment of houses. Build. Environ. 2012, 54, 86–99. [Google Scholar] [CrossRef]

- Van Ooteghem, K.; Xu, L. The life-cycle assessment of a single-storey retail building in Canada. Build. Environ. 2012, 49, 212–226. [Google Scholar] [CrossRef]

- Jing, R.; Wang, M.; Zhang, R.; Li, N.; Zhao, Y. A study on energy performance of 30 commercial office buildings in Hong Kong. Energy Build. 2017, 144, 117–128. [Google Scholar] [CrossRef]

- Ni, S.; Zhu, N.; Hou, Y.; Zhang, Z. Research on indoor thermal comfort and energy consumption of zero energy wooden structure buildings in severe cold zone. J. Build. Eng. 2023, 67, 105965. [Google Scholar] [CrossRef]

- Morelli, M.; Rønby, L.; Mikkelsen, S.E.; Minzari, M.G.; Kildemoes, T.; Tommerup, H.M. Energy retrofitting of a typical old Danish multi-family building to a “nearly-zero” energy building based on experiences from a test apartment. Energy Build. 2012, 54, 395–406. [Google Scholar] [CrossRef]

- Pittau, F.; Giacomel, D.; Iannaccone, G.; Malighetti, L. Environmental consequences of refurbishment versus demolition and reconstruction: A comparative life cycle assessment of an Italian case study. J. Green Build. 2020, 15, 155–172. [Google Scholar] [CrossRef]

- Lolli, N.; Fufa, S.M.; Kjendseth Wiik, M. An assessment of greenhouse gas emissions from CLT and glulam in two residential nearly zero energy buildings. Wood Mater. Sci. Eng. 2019, 14, 342–354. [Google Scholar] [CrossRef]

- Strang, M. Moisture Safety for Energy-Efficient CLT Envelopes: Pathways to Net-Zero Operational Energy for Engineered Wood Multi-Storey Buildings in Australian Tropical and Subtropical Climates. Ph.D. Thesis, School of Architecture, Design and Planning, The University of Queensland, Brisbane, Australia, 2023. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Analysis of embodied carbon in the building life cycle considering the temporal perspectives of emissions: A case study in China. Energy Build. 2017, 155, 404–413. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Operational energy in the life cycle of residential dwellings: The experience of Spain and Colombia. Appl. Energy 2010, 87, 673–680. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life cycle primary energy analysis of residential buildings. Energy Build. 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Korsavi, S.S.; Jones, R.V.; Bilverstone, P.A.; Fuertes, A. A longitudinal assessment of the energy and carbon performance of a Passivhaus university building in the UK. J. Build. Eng. 2021, 44, 103353. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Aranda Usón, A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Passarelli, R. The Environmental Impact of Reused CLT Panels: Study of a Single-Storey Commercial Building In Japan. In Proceedings of the 2018 World Conference on Timber Engineering, Seoul, Republic of Korea, 20–23 August 2018. [Google Scholar]

- Grann, B. A Comparative Life Cycle Assessment of Two Multistory Residential Buildings: Cross-Laminated Timber vs. Concrete Slab and Column with Light Gauge Steel Walls; Technical Report; FPInnovations: Vancouver, BC, Canada, 2013; pp. 1–121. [Google Scholar]

- Hafner, A.; Ott, S.; Winter, S. Recycling and end-of-life scenarios for timber structures. In Materials and Joints in Timber Structures: Recent Developments of Technology; Springer: Dordrecht, The Netherlands, 2014; pp. 89–98. [Google Scholar]

- Darby, H.; Elmualim, A.; Kelly, F. A Case Study to Investigate the Life Cycle Carbon Emissions and Carbon Storage Capacity of a Cross Laminated Timber, Multi-Storey Residential Building; Fraunhofer IRB Verlag: Stuttgart, Germany, 2013; pp. 10–12. [Google Scholar]

- Liang, S.; Gu, H.; Bergman, R. Environmental life-cycle assessment and life-cycle cost analysis of a high-rise mass timber building: A case study in Pacific Northwestern United States. Sustainability 2021, 13, 7831. [Google Scholar] [CrossRef]

- Vishnu, T.; Singh, K.L. A study on the suitability of solid waste materials in pavement construction: A review. Int. J. Pavement Res. Technol. 2021, 14, 625–637. [Google Scholar] [CrossRef]

- Head, M.; Magnan, M.; Kurz, W.A.; Levasseur, A.; Beauregard, R.; Margni, M. Temporally-differentiated biogenic carbon accounting of wood building product life cycles. SN Appl. Sci. 2021, 3, 62. [Google Scholar] [CrossRef]

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 2016, 125, 219–226. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- EN 14081-1:2019; Timber Structures–Strength Graded Structural Timber—Part 1: General Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Ridley-Ellis, D.; Stapel, P.; Baño, V. Strength grading of sawn timber in Europe: An explanation for engineers and researchers. Eur. J. Wood Wood Prod. 2016, 74, 291–306. [Google Scholar] [CrossRef]