The Effects of BIM Maturity Levels on Modularization and Standardization in the Construction Industry: A Systematic Literature Review and Case Studies

Abstract

:1. Introduction

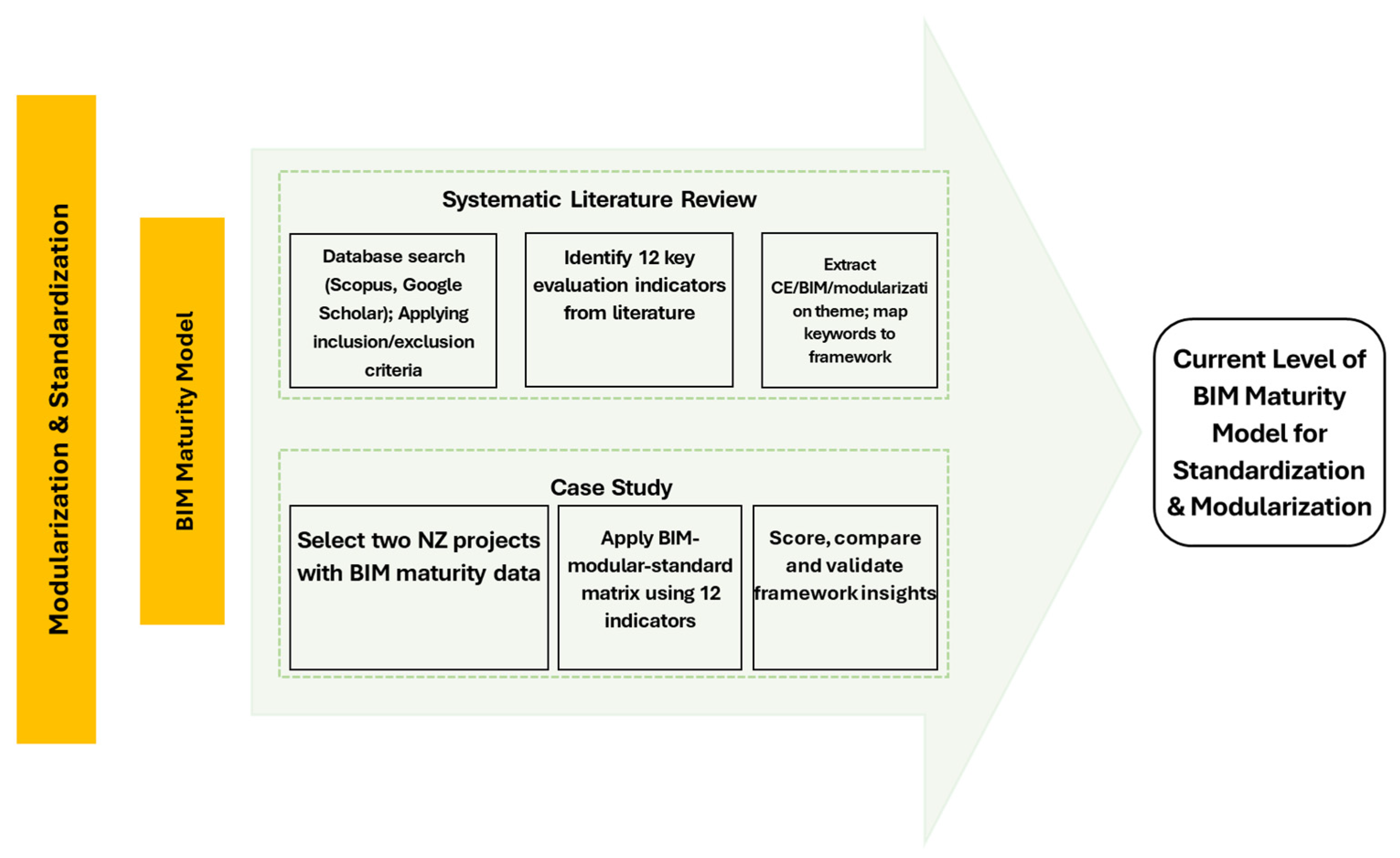

2. Background

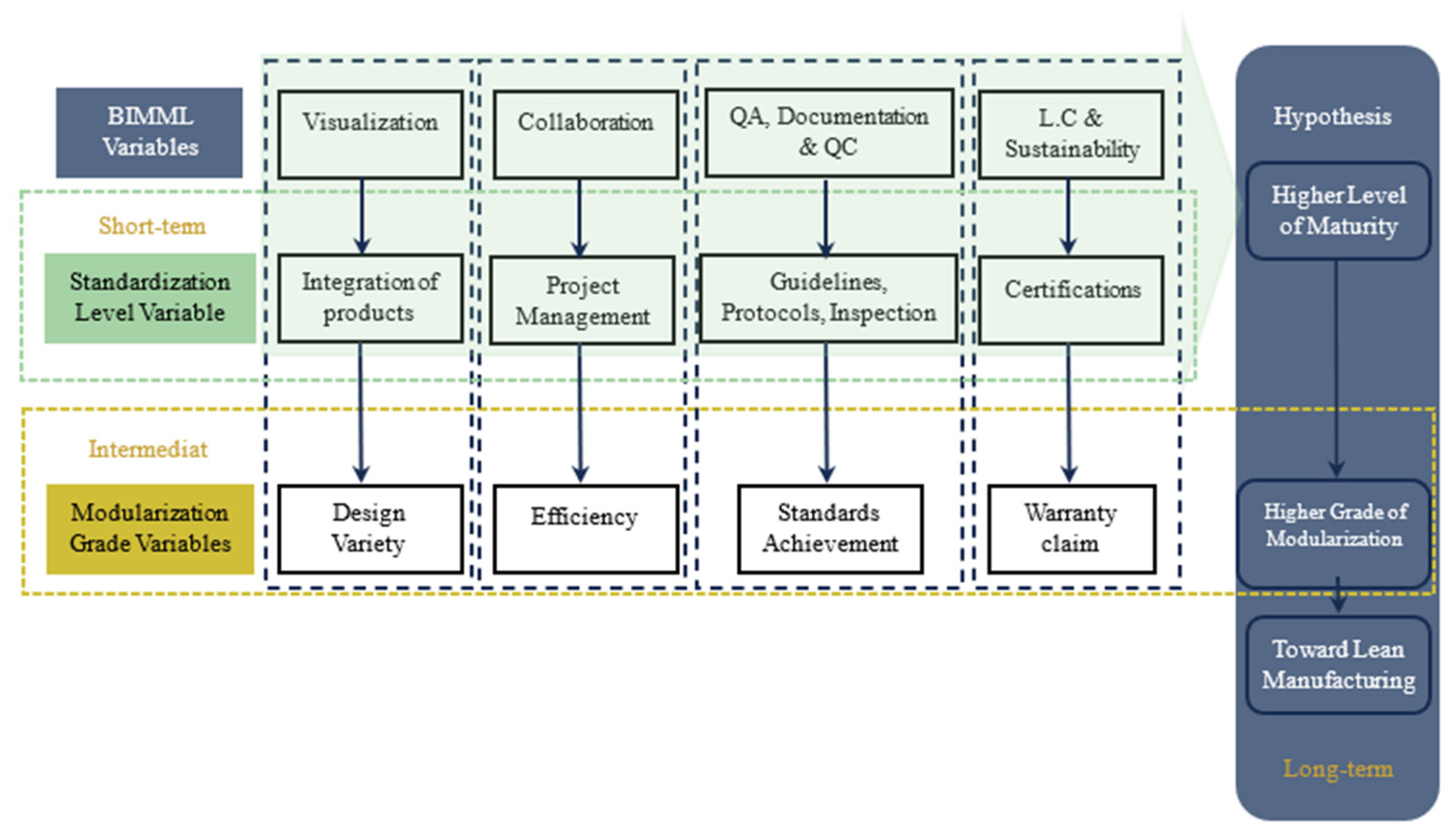

2.1. Modularization and Standardization in Construction

2.2. BIM and Its Maturity Levels

2.3. Global Practices and Policy Support

2.4. The Knowledge Gap in the New Zealand Context

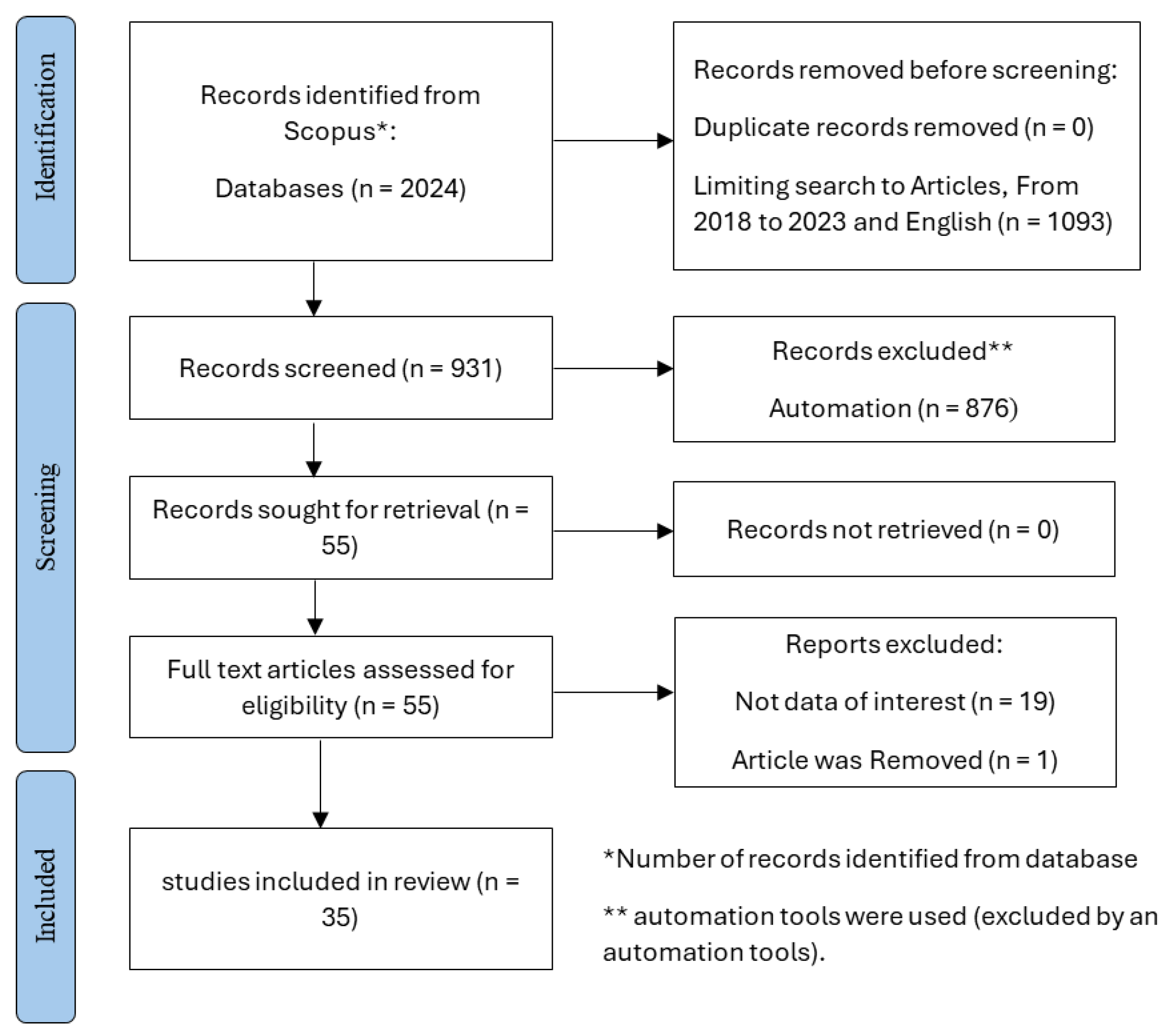

3. Methodology

4. Systematic Literature Review and Conceptual Framework

- Keywords: “BIM”, “Modularization”, “Standardization”, “Prefabrication”, and “Off-site Construction (OSC)”;

- Timeframe: 2018–2023;

- Language: English.

- Peer-reviewed journal articles;

- Explicit discussion of BIM in relation to modularization and/or standardization;

- Clear research design (quantitative, qualitative, or mixed methods);

- Relevance to the construction industry, particularly digital workflows or prefabrication;

- Full-text availability.

- Conference papers, editorials, and grey literature;

- Non-construction-related studies;

- Studies focusing on ICT without relevance to BIM/modularization integration;

- Articles lacking methodological transparency or practical relevance.

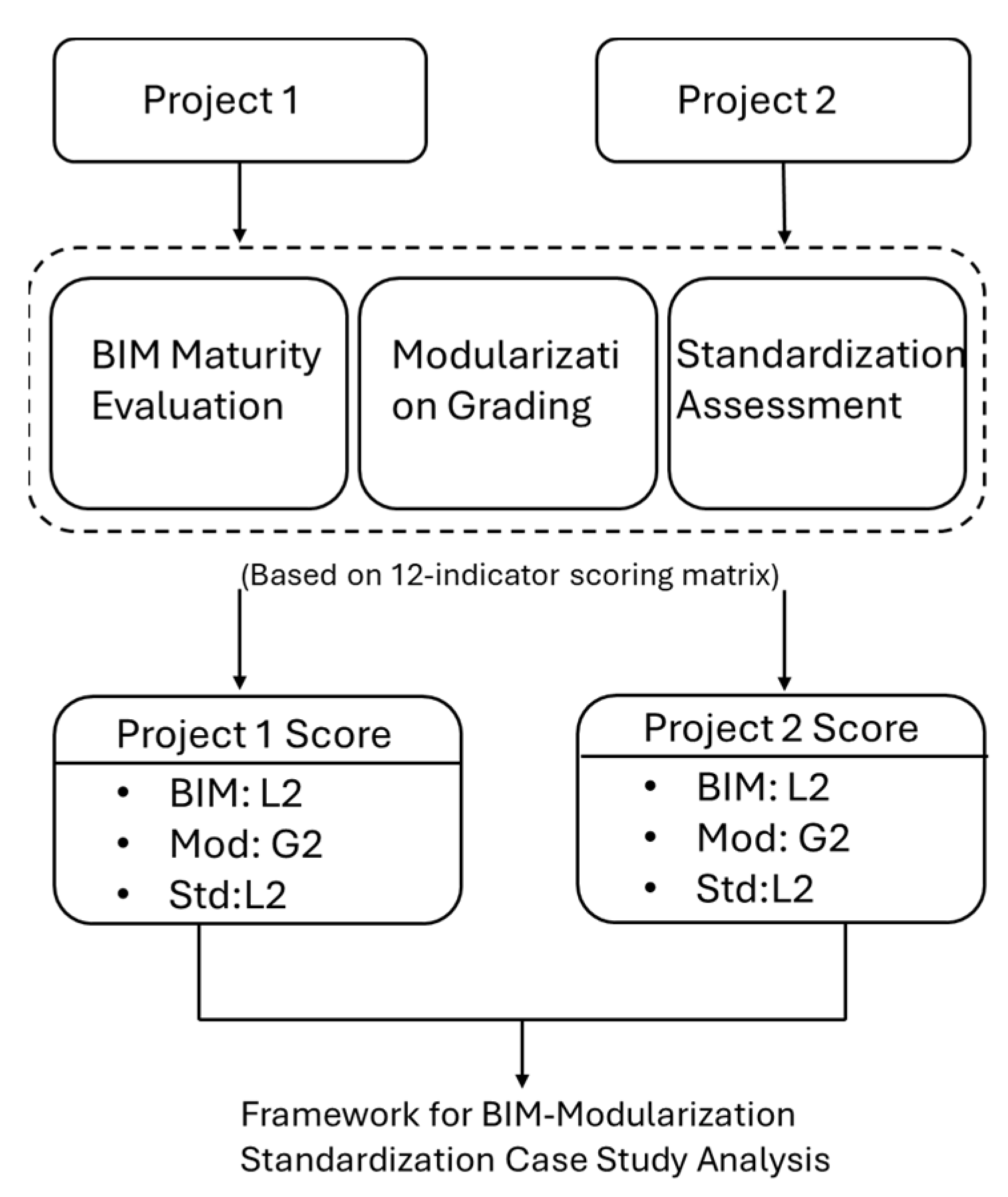

5. Case Study Analysis and Discussion

5.1. First Case Study

5.2. Second Case Study

5.3. BIM Maturity as a Driver of Modularization and Standardization

5.4. Key Enablers Supporting BIM-Driven Modularization

5.5. Strategic Role of Digital Integration in Construction Outcomes

6. Practical Implications and Study Limitations

7. Conclusions

Future Research Directions

- Applying the framework to projects with a broader range of BIM maturity levels.

- Validating the model through primary data collection and cross-regional case studies.

- Exploring the influence of organizational, economic, and policy factors on BIM adoption and modular standardization.

- Developing unified standards for measuring BIM maturity in relation to modular construction.

- Investigating barriers to achieving higher BIM maturity in real-world projects.

- Extending the framework through additional case studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- O’Connor, J.T.; O’Brien, W.J.; Choi, J.O. Critical Success Factors and Enablers for Optimum and Maximum Industrial Modularization. J. Constr. Eng. Manag. 2014, 140, 04014012. [Google Scholar] [CrossRef]

- Shafiee, S.; Piroozfar, P.; Hvam, L.; Farr, E.R.; Huang, G.Q.; Pan, W.; Kudsk, A.; Rasmussen, J.B.; Korell, M. Modularisation strategies in the AEC industry: A comparative analysis. Archit. Eng. Des. Manag. 2020, 16, 270–292. [Google Scholar] [CrossRef]

- Choi, J.O.; Shrestha, B.K.; Kwak, Y.H.; Shane, J.S. Innovative technologies and management approaches for facility design standardization and modularization of capital projects. J. Manag. Eng. 2020, 36, 04020042. [Google Scholar] [CrossRef]

- Wu, C.; Xu, B.; Mao, C.; Li, X. Overview of BIM maturity measurement tools. ITcon 2017, 22, 34–62. [Google Scholar]

- Fixson, S.K. Modularity and Commonality Research: Past Developments and Future Opportunities. Concurr. Eng. 2007, 15, 85–111. [Google Scholar] [CrossRef]

- Likita, A.J.; Jelodar, M.B.; Vishnupriya, V.; Rotimi, J.O.B.; Vilasini, N. Lean and BIM Implementation Barriers in New Zealand Construction Practice. Buildings 2022, 12, 1645. [Google Scholar] [CrossRef]

- Babaeian Jelodar, M.; Yiu, K.T.W.; Wilkinson, S. A Multi-Objective Decision Support System for Selecting Dispute Resolution Methods in the Construction Industry. J. Comput. Civ. Eng. 2014, 2014, 1642–1649. [Google Scholar] [CrossRef]

- Gao, Y.; Xiaoyu, L.; Shuibo, Z.; Jinyue, Z.; Guo, Q. BIM application and collaboration in construction projects: A perspective of the Chinese construction market. Constr. Manag. Econ. 2022, 40, 429–441. [Google Scholar] [CrossRef]

- Gong, C.; Xu, H.; Xiong, F.; Zuo, J.; Dong, N. Factors impacting BIM application in prefabricated buildings in China with DEMATEL-ISM. Constr. Innov. 2023, 23, 19–37. [Google Scholar] [CrossRef]

- Hwang, B.-G.; Shan, M.; Looi, K.-Y. Knowledge-based decision support system for prefabricated prefinished volumetric construction. Autom. Constr. 2018, 94, 168–178. [Google Scholar] [CrossRef]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Ghaffarianhoseini, A.; Tookey, J. Developing a framework for building information modelling (BIM) adoption in New Zealand. Built Environ. Proj. Asset Manag. 2024, 14, 490–506. [Google Scholar] [CrossRef]

- Darlow, G.; Rotimi, J.O.B.; Shahzad, W.M. Automation in New Zealand’s offsite construction (OSC): A status update. Built Environ. Proj. Asset Manag. 2022, 12, 38–52. [Google Scholar] [CrossRef]

- Babaeian Jelodar, M.; Wilkinson, S.; Kalatehjari, R.; Zou, Y. Designing for construction procurement: An integrated Decision Support System for Building Information Modelling. Built Environ. Proj. Asset Manag. 2022, 12, 111–127. [Google Scholar] [CrossRef]

- Tang, X.; Chong, H.-Y.; Zhang, W. Relationship between BIM Implementation and Performance of OSM Projects. J. Manag. Eng. 2019, 35, 04019019. [Google Scholar] [CrossRef]

- Pham, T.; Skelton, L.; Samarasinghe, D. A study of the implementation of BIM in the AEC industry in New Zealand. In Proceedings of the 54th International Conference of the Architectural Science Association (ANZAScA) 2020, Auckland, New Zealand, 26–27 November 2020. [Google Scholar]

- Tookey, J. Prefabricated Construction in New Zealand: Current Status and Underlying Trends. Available online: https://www.offsitenz.com/education-skills-attitudes-survey-2021 (accessed on 17 March 2025).

- Rehman, S.U.; Kim, I.; Choi, J. Data-driven integration framework for four-dimensional building information modeling simulation in modular construction: A case study approach. J. Comput. Des. Eng. 2023, 10, 2288–2311. [Google Scholar] [CrossRef]

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction: From Projects to Products; McKinsey Co.: Capital Projects & Infrastructure: New York, NY, USA, 2019; Volume 1, pp. 1–34. [Google Scholar]

- Diekmann, J.; Kluck, M.; Meyer, W.; O’Brien, W.J.; O’Connor, J.T. Industrial Modularization: Five Solution Elements; Construction Industry Institute: Austin, TX, USA, 2013. [Google Scholar]

- Evans, E. Component Standardization: A Code of Sustainability. In Proceedings of the Wellington Faculty of Engineering Ethics and Sustainability Symposium, Wellington, New Zealand, 7 July 2022. [Google Scholar]

- Poster, D.L.; Fasolka, M.J.; Cavanagh, R.R.; Beary, E.S. Measurements, standards, and data in support of the sustainable use of materials. MRS Bull. 2012, 37, 348–355. [Google Scholar] [CrossRef]

- Babaeian Jelodar, M.; Shu, F. Innovative Use of Low-Cost Digitisation for Smart Information Systems in Construction Projects. Buildings 2021, 11, 270. [Google Scholar] [CrossRef]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of Lean and Building Information Modeling in Construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef]

- Alshorafa, R.; Ergen, E. Determining the level of development for BIM implementation in large-scale projects. Eng. Constr. Archit. Manag. 2021, 28, 397–423. [Google Scholar] [CrossRef]

- Cavka, H.B.; Staub-French, S.; Poirier, E.A. Developing owner information requirements for BIM-enabled project delivery and asset management. Autom. Constr. 2017, 83, 169–183. [Google Scholar] [CrossRef]

- Ahmad Latiffi, A.; Brahim, J.; Mohd, S.; Fathi, M. Building Information Modeling (BIM): Exploring Level of Development (LOD) in Construction Projects. Appl. Mech. Mater. 2015, 773–774, 933–937. [Google Scholar] [CrossRef]

- Protocol, A.B.T. Practical Implementation of BIM for the UK Architectural. Available online: https://aecuk.files.wordpress.com/2015/06/aecukbimtechnologyprotocol-v2-1-1-201506022.pdf (accessed on 17 March 2025).

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Mousavi, Y.; Gharineiat, Z.; Karimi, A.A.; McDougall, K.; Rossi, A.; Gonizzi Barsanti, S. Digital Twin Technology in Built Environment: A Review of Applications, Capabilities and Challenges. Smart Cities 2024, 7, 2594–2615. [Google Scholar] [CrossRef]

- Smits, W.; Marc, v.B.; Hartmann, T. Yield-to-BIM: Impacts of BIM maturity on project performance. Build. Res. Inf. 2017, 45, 336–346. [Google Scholar] [CrossRef]

- Thai, H.-T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Kordestani Ghalehnoei, N.; Babaeian Jelodar, M.; Paes, D.; Sutrisna, M. Exploring Off-site Construction and Building Information Modelling Integration Challenges; Enhancing Capabilities within New Zealand Construction Sector. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 042008. [Google Scholar] [CrossRef]

- Sutrisna, M. Research Methodology in Doctoral Research: Understanding the Meaning of Conducting Qualitative Research, Working Paper. In Proceedings of the Association of Researchers in Construction Management (ARCOM) Doctoral Workshop, Liverpool, UK, 12 May 2009; pp. 48–57. [Google Scholar]

- Thomas, J.; Harden, A. Methods for the thematic synthesis of qualitative research in systematic reviews. BMC Med. Res. Methodol. 2008, 8, 45. [Google Scholar] [CrossRef] [PubMed]

- Gough, D. Qualitative and mixed methods in systematic reviews. Syst. Rev. 2015, 4, 181. [Google Scholar] [CrossRef] [PubMed]

- Stake, R. Case Study Research; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; SAGE: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar] [CrossRef]

- Cavalieri, M.; Rossana, C.; Guccio, C. Tales on the dark side of the transport infrastructure provision: A systematic literature review of the determinants of cost overruns. Transp. Rev. 2019, 39, 774–794. [Google Scholar] [CrossRef]

- David Moher, A.L.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. J. Integr. Med. 2009, 7, 889–896. (In Chinese) [Google Scholar] [CrossRef]

- Likita, A.J.; Jelodar, M.B.; Vishnupriya, V.; Rotimi, J.O.B. Lean and BIM integration benefits construction management practices in New Zealand. Constr. Innov. 2024, 24, 106–133. [Google Scholar] [CrossRef]

- Snyder, C. A case study of a case study: Analysis of a robust qualitative research methodology. Qual. Rep. 2012, 17, 26. [Google Scholar] [CrossRef]

- Johansson, R. On Case Study Methodology. Open House Int. 2007, 32, 48–54. [Google Scholar] [CrossRef]

- Innella, F.; Arashpour, M.; Bai, Y. Lean Methodologies and Techniques for Modular Construction: Chronological and Critical Review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Shahzad, W.M.; Rajakannu, G.; Kordestani Ghalenoei, N. Potential of Modular Offsite Construction for Emergency Situations: A New Zealand Study. Buildings 2022, 12, 1970. [Google Scholar] [CrossRef]

- Fan, S.-L.; Chi, H.-L.; Pan, P.-Q. Rule checking Interface development between building information model and end user. Autom. Constr. 2019, 105, 102842. [Google Scholar] [CrossRef]

- Wang, S.; Sinha, R. Life Cycle Assessment of Different Prefabricated Rates for Building Construction. Buildings 2021, 11, 552. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, W. Facility layout design for modular construction manufacturing: A comparison based on simulation and optimization. Autom. Constr. 2023, 147, 104713. [Google Scholar] [CrossRef]

- Barkokebas, B.; Khalife, S.; Al-Hussein, M.; Hamzeh, F. A BIM-lean framework for digitalisation of premanufacturing phases in offsite construction. Eng. Constr. Archit. Manag. 2021, 28, 2155–2175. [Google Scholar] [CrossRef]

- Zou, Y.; Wu, Y.; Guo, B.H.W.; Papadonikolaki, E.; Dimyadi, J.; Hung, S.N. Investigating the New Zealand Off-Site Manufacturing Industry’s Readiness for Automated Compliance Checking. J. Constr. Eng. Manag. 2022, 148, 05022013. [Google Scholar] [CrossRef]

- Almashaqbeh, M.; El-Rayes, K. Minimizing transportation cost of prefabricated modules in modular construction projects. Eng. Constr. Archit. Manag. 2022, 29, 3847–3867. [Google Scholar] [CrossRef]

- Cho, K.; Ahn, S.; Park, K.; Kim, T.W. Schedule Delay Leading Indicators in Precast Concrete Construction Projects: Qualitative Comparative Analysis of Korean Cases. J. Manag. Eng. 2021, 37, 04021024. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Wong, B.C.L.; Chan, C.M.; Cheng, J.C.P.; Gan, V.J.L. BIM-BVBS integration with openBIM standards for automatic prefabrication of steel reinforcement. Autom. Constr. 2021, 125, 103654. [Google Scholar] [CrossRef]

- Yilmaz, G.; Akcamete, A.; Demirors, O. BIM-CAREM: Assessing the BIM capabilities of design, construction and facilities management processes in the construction industry. Comput. Ind. 2023, 147, 103861. [Google Scholar] [CrossRef]

- Siebelink, S.; Voordijk, H.; Endedijk, M.; Adriaanse, A. Understanding barriers to BIM implementation: Their impact across organizational levels in relation to BIM maturity. Front. Eng. Manag. 2021, 8, 236–257. [Google Scholar] [CrossRef]

- Matthews, J.; Love, P.E.D.; Joshua, M.; Christopher, S.; Ramanayaka, C. Building information modelling in construction: Insights from collaboration and change management perspectives. Prod. Plan. Control 2018, 29, 202–216. [Google Scholar] [CrossRef]

- Chan, D.W.M.; Olawumi, T.O.; Ho, A.M.L. Perceived benefits of and barriers to Building Information Modelling (BIM) implementation in construction: The case of Hong Kong. J. Build. Eng. 2019, 25, 100764. [Google Scholar] [CrossRef]

- Pan, Y.; Mario, C. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch. Comput. Methods Eng. 2023, 22, 1081–1110. [Google Scholar] [CrossRef]

- Ramaji, I.J.; Memari, A.M.; Messner, J.I. Product-Oriented Information Delivery Framework for Multistory Modular Building Projects. J. Comput. Civ. Eng. 2017, 31, 04017001. [Google Scholar] [CrossRef]

| BIM Maturity Levels | Modularization Grades | Standardization Levels |

|---|---|---|

| Level 1: partial collaboration | Grade 1: Panelized Modular | Level 1: Basic Standardization |

| Level 2: full collaboration | Grade 2: Sectional Modular | Level 2: Adequate Standardization |

| Level 3: full integration | Grade 3: Volumetric Modular | Level 3: Advanced Standardization |

| Asp. | BIM Maturity | Standardization | Modularization |

|---|---|---|---|

| 1 | Design in CAD | Adherence to design guidelines | Adherence to reg. |

| 2 | Manufacturing and fabrication processes embodied in drawings | Standardized fabrication processes | Percentage of production capacity utilization |

| 3 | On-site logistics and assembly catalogues | Implementation of standardized logistics planning | Cost reduction in modular manufacturing |

| 4 | 3D modelling and visualization | Utilization of 3D modelling | Diversity of standardized design model usage |

| 5 | Automation and AI utilization | AI-driven process optimization | Modular installation time reduction |

| 6 | Stakeholder collaboration | Collaboration via BIM platforms | Modular manufacturing cost reduction |

| 7 | Information exchange and data Management | Cloud-based data management | Documentation regulation |

| 8 | Quality assurance processes | Adherence to standards and building codes | Reduction in safety incidents |

| 9 | Regulatory compliance and Standards | BIM-based quality control implementation | Warranty claims received |

| 10 | Lean construction principles | Adoption of lean construction practices | Inventory turnover rate |

| 11 | Supply chain and material tracking | Integration of BIM and supply chains | Modular manufacturing cost reduction |

| 12 | Energy efficiency and sustainability | BIM tools for energy analysis and optimization | Focus on sustainability (life cycle) design |

| Levels | Rates in Different Levels | Levels Weight | Weighted Rate | WΣ | Total WΣ of the 12 Aspects | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.25 | 0 | 0 | 1 | 1.25 | 0 | 0 | 1.25 | 15 | ||

| 2 | 2.5 | 1.25 | 0 | 1 | 2 | 2.5 | 2.5 | 0 | 5 | 60 | |

| 3 | 1.25 | 3.75 | 1.25 | 1 | 2 | 3 | 1.25 | 7.5 | 3.75 | 13 | 155 |

| 3.75 | 2.5 | 1.25 | 1 | 2 | 3 | 3.75 | 5 | 3.75 | 13 | ||

| Asp. | Maturity Level 1 | Maturity Level 2 | Maturity Level 3 | Basic Standardization | Adequate Standardization | Advanced Standardization | Grade 1 | Grade 2 | Grade 3 | WΣ BIM | WΣ St. and Mod. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4.7 | 3.7 | 3.0 | 3.0 | - | 12.2 | 3.0 | ||||

| 2 | 3.7 | 2.9 | 2.0 | 2.0 | 3.0 | 9.6 | 5.0 | ||||

| 3 | 4.3 | 3.5 | 2.6 | 2.0 | 3.0 | 11.3 | 7.9 | ||||

| 4 | 5.0 | 4.0 | 3.0 | 2.0 | 2.0 | 4.0 | 13.0 | 8.5 | |||

| 5 | 4.0 | 2.0 | - | 2.0 | 4.0 | 10.0 | 5.0 | ||||

| 6 | 4.7 | 3.7 | 4.0 | 4.0 | 3.0 | - | 15.9 | 11.5 | |||

| 7 | 5.0 | 4.0 | 4.0 | 3.0 | 3.5 | 17.0 | 10.8 | ||||

| 8 | 4.0 | 3.2 | 3.0 | 3.0 | 3.5 | 13.6 | 9.8 | ||||

| 9 | 4.0 | 2.0 | 3.0 | 3.0 | - | 10.0 | 3.0 | ||||

| 10 | 4.3 | 3.5 | 4.0 | 3.0 | - | 14.7 | 7.5 | ||||

| 11 | 1.7 | 1.3 | 3.7 | 3.0 | 4.0 | 5.7 | 11.2 | ||||

| 12 | 4.3 | 3.5 | 1.7 | 2.0 | 4.0 | 14.7 | 7.5 | ||||

| Total Weighted Sum | 147.6 | 90.6 | |||||||||

| Asp. | Maturity Level 1 | Maturity Level 2 | Maturity Level 3 | Basic Standardization | Adequate Standardization | Advanced Standardization | Grade 1 | Grade 2 | Grade 3 | WΣ BIM | WΣ St. and Mod. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3.3 | 2.7 | 4.0 | 3.0 | 2.5 | 8.7 | 6.5 | ||||

| 2 | 2.7 | 2.1 | 3.0 | 2.0 | 3.0 | 7.0 | 5.5 | ||||

| 3 | 4.0 | 3.2 | 1.0 | 1.0 | 2.0 | 3.0 | 10.4 | 6.0 | |||

| 4 | 3.0 | 2.4 | 4.0 | 2.0 | 2.0 | 4.0 | 7.8 | 9.0 | |||

| 5 | 3.7 | 2.9 | 1.0 | 2.0 | 4.0 | 12.5 | 5.5 | ||||

| 6 | 4.7 | 3.7 | 1.0 | 3.0 | 3.0 | 3.0 | 15.9 | 9.5 | |||

| 7 | 4.3 | 3.5 | 1.0 | 3.0 | 3.0 | 3.0 | 14.7 | 9.5 | |||

| 8 | 3.7 | 2.9 | 1.0 | 3.0 | 3.0 | 2.0 | 12.5 | 8.8 | |||

| 9 | 3.0 | 2.4 | 2.0 | 3.0 | 10.2 | 2.5 | |||||

| 10 | 4.0 | 3.2 | 1.0 | 3.0 | 3.0 | 2.0 | 13.6 | 9.5 | |||

| 11 | 4.0 | 3.2 | 1.0 | 3.0 | 3.0 | 3.0 | 13.6 | 9.5 | |||

| 12 | 3.3 | 2.7 | 1.0 | 1.3 | 2.0 | 2.0 | 11.3 | 5.5 | |||

| Total Weighted Sum | 138.1 | 87.2 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bayzidi, E.; Kordestani Ghalenoei, N.; Babaeian Jelodar, M. The Effects of BIM Maturity Levels on Modularization and Standardization in the Construction Industry: A Systematic Literature Review and Case Studies. Buildings 2025, 15, 2124. https://doi.org/10.3390/buildings15122124

Bayzidi E, Kordestani Ghalenoei N, Babaeian Jelodar M. The Effects of BIM Maturity Levels on Modularization and Standardization in the Construction Industry: A Systematic Literature Review and Case Studies. Buildings. 2025; 15(12):2124. https://doi.org/10.3390/buildings15122124

Chicago/Turabian StyleBayzidi, Elham, Nazanin Kordestani Ghalenoei, and Mostafa Babaeian Jelodar. 2025. "The Effects of BIM Maturity Levels on Modularization and Standardization in the Construction Industry: A Systematic Literature Review and Case Studies" Buildings 15, no. 12: 2124. https://doi.org/10.3390/buildings15122124

APA StyleBayzidi, E., Kordestani Ghalenoei, N., & Babaeian Jelodar, M. (2025). The Effects of BIM Maturity Levels on Modularization and Standardization in the Construction Industry: A Systematic Literature Review and Case Studies. Buildings, 15(12), 2124. https://doi.org/10.3390/buildings15122124